- Safety requirements when preparing the pump for start-up

- Pump problems and how to fix them

- Types of circulation pumps and their device

- Wet Rotor Pumps

- Pumps with a "dry" rotor

- 1 Regular maintenance

- How does the circulation mechanism work?

- Design features of a pump for heating a private house

- wet rotor

- Dry Rotor

- Elementary safety rules

- Major malfunctions and their own repair

- The pump is buzzing and pumping poorly: how to repair?

- Why there is no buzz and rotation

- Switching on is accompanied by loud noise

- Insufficient pressure

- Stop after start

- How to disassemble the device

- Possible causes of problems

- Rules for the operation of centrifugal pumps

- Malfunctions of centrifugal pumps and their elimination

Safety requirements when preparing the pump for start-up

Before starting the pump

do the following: delete

all foreign objects from the pump,

check for damaged parts

pump, are there any loose bolts in

pump piping, check the presence and

quality of oil in lubricators, serviceability

lubrication systems, as well as lubricate

moving parts at their joints,

check the installation of guards on

clutches and their fastening.

Check the condition of the seals

skew grundbuksa and is it enough

seals are stuffed and tight, check

presence, serviceability and inclusion

pressure gauge at the pump outlet, at the intake

and discharge pipelines, make sure

in the presence of grounding of the pump and electric motor,

check the rotation of the rotor by hand (with

the rotor should rotate easily,

without seizures). Check Direction

motor rotation at

disconnected coupling (direction

rotation should be clockwise,

when viewed from the motor side)

check the flow of sealant and

coolant on the end

seals and bearings by pressing

start and stop buttons on the remote control

control, close the valve on

discharge pipeline and open

in the intake pipeline. Produce

priming the pump with product, air from

bleed the pump through the drain line.

In winter, with long stops

pumps must be run in

operation after heating the manifold with steam

or hot water and test pumping

liquids through pipes. It is forbidden to warm up

manifold open source of fire.

Pump problems and how to fix them

Any repair work can be carried out if the equipment is disconnected from the network. It is also necessary to pre-drain the site.

Consider what are the problems of the circulation pump:

- If you turn on the pump, but the shaft does not start to rotate, noise is heard. Why does noise appear and the shaft does not rotate? If you did not turn on the pump for a long time, then the shaft could oxidize. It is necessary to check its correctness. If the pump is blocked, it must be disconnected from the mains. Next, you need to drain the water and unscrew all the screws that connect the housing and the electric motor. The impeller can then be turned by hand and the motor removed.Pumps with low power have special notches. With their help, you can unlock the shaft. It is enough just to turn the serif with a screwdriver.

- Electricity problems. Often the pump is connected inconsistently with the voltage indicated in the technical data sheet of the equipment. It is necessary to check whether the voltage in your house matches the recommended one. And also it will not be superfluous to check the terminal box and all connections in it. You should also check the phases.

- The wheel is blocked due to a foreign object. In this case, you need to get the engine, as indicated in the first paragraph. In order to prevent various objects from falling into the wheels, you can install a special strainer in front of the circulation pump.

- If the pump turned on as usual, and then turned off. In this case, deposits may be the cause. They are formed between the stator and the rotor. To fix the problem, it is necessary to remove the engine and clean the stator jacket from scale.

- The pump does not turn on and does not hum. There may also be no voltage. There can be two reasons: the motor winding burned out or the fuse was damaged. First of all, you need to replace the fuse, but if after replacing it the pump does not start working, then the problem lies in the winding.

- The circulation pump vibrates during operation. Often this is due to bearing wear. In this case, the operation of the pump is accompanied by noise. To fix the problem, the bearing must be replaced.

- There is a loud noise when the pump is turned on. With such a problem, you need to release the air, and then install the air vent at the highest point of the piping.

- If the motor protection trips after starting the circulation pump? In this case, it is necessary to look for the cause in the electrical part of the engine.

- Often there is such a problem as improper water supply, as well as its pressure. In the technical passport of the equipment, the same values \u200b\u200bare indicated, and during operation, the pressure and flow differ significantly. This problem happens in three-phase pumps due to incorrect connection.

- You need to check the terminal box. Also check fuse contacts for dirt. It will not be superfluous to check the resistance of the phases to ground.

Types of circulation pumps and their device

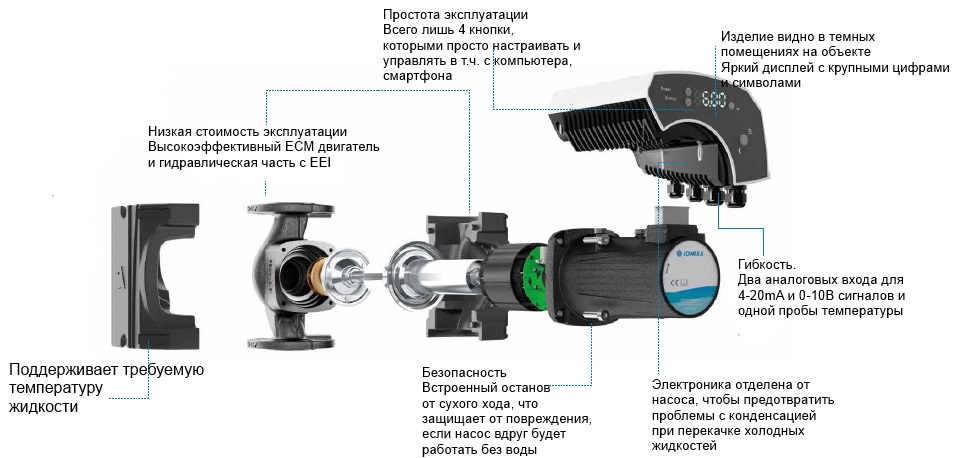

The body of any circulation pump for heating is made of stainless metal or alloy. The body can be steel, cast iron, aluminum, brass or bronze. Inside the housing there is a steel or ceramic rotor, on the shaft of which a paddle wheel-impeller is mounted. The equipment is powered by a single-phase or three-phase electric motor. Depending on whether the rotor is in contact with water or not, pumps are usually divided into "wet" and "dry".

Wet Rotor Pumps

A “wet” circulation pump is characterized by the fact that its impeller with a rotor interacts with a coolant (hot water). At the same time, water lubricates and cools the moving parts of the device. The rotor and stator of this type of circulation pump separate the walls of the metal cup. As a result, such a constructive solution provides a hermetic arrangement of the stator of the electric motor under voltage.

Wet-type pumping equipment can be operated for a long time without any maintenance.Repair of these products, as well as setting up, is not particularly difficult. The devices are compact, lightweight, energy-efficient, silent, which allows them to be mounted directly in the house. In construction wet circulation pumps the rotor provides for the presence of threaded or flanged connections that facilitate the installation of products in the home heating system.

It looks like a model of a circulation pump for a water heating system of a private house or cottage. The pump rotor is in contact with the coolant

The pump is installed in the heating system in such a way that the axis of its shaft must be located in a strictly horizontal plane. It is this arrangement that will allow the coolant to continuously wash the bearings, while ensuring their lubrication. If this requirement is ignored, a pump failure is likely due to increased wear of moving parts due to a lack of lubricant.

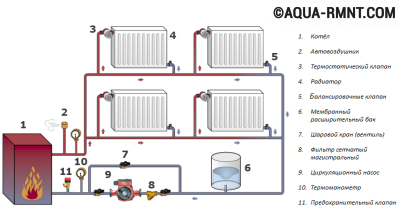

One of the possible schemes for connecting a "wet" type circulation pump to the heating system of a country house with forced circulation of the coolant

The main disadvantage of "wet" pumps lies in the low efficiency value, which is only 50%. This fact must be taken into account when choosing, since this equipment makes sense to install only in water heating systems with a short pipeline length. Such models are recommended to be used to ensure forced circulation of the coolant in the heating system of a small private house.

Pumps with a "dry" rotor

The design of the "dry" circulation pump is designed in such a way that the rotor of the device does not come into contact with the water circulating through the pipes.The working part and the electric motor of this type of pump are hermetically separated from each other by special seals. There are three subspecies of dry rotor circulation pumps:

- block;

- vertical;

- horizontal (console).

Pumping equipment of this type is characterized by high efficiency, reaching 80%, as well as an increased noise level.

Therefore, the installation of a "dry" type circulation pump is recommended to be carried out in a separate utility room, while paying special attention to its sound insulation.

1 Regular maintenance

The pump, like other equipment, needs maintenance. To prevent breakdowns, you must follow these recommendations:

In the summer, when the device is not working, it must be turned on at least once a month for 15 minutes. But at the same time, the device should not run dry: if the pipes are currently empty, they simply pump water from one container to another by connecting the unit to them with hoses

This procedure will prevent oxidation of the shaft surface and prolong bearing life.

During the heating season, from time to time it is necessary to pay attention to the operation of the device. Has the unit started to make noise, vibrate, or have other signs of a malfunction? Does the circulation pump get too hot? After all, the early stage of a malfunction is much easier to eliminate than a running one.

If there is a coarse filter in the heating system in front of the pump, then it is periodically checked for rust or other contaminants.

Do not forget about lubrication and check its sufficient presence in the places provided.

How does the circulation mechanism work?

At the moment the pump is turned on, the water in the heating system (in a closed circuit) is drawn into the inlet under the influence of the rotation of the wheel with blades. The water that has entered the chamber, due to the action of centrifugal force, is pressed against the walls of the working chamber and pushed out (to the outlet). Following this, the pressure in the chamber drops, which contributes to a new injection of water into the pump reservoir.

Thus, during the continuous cycle of the pump, the heating system can be in a state of constant set temperature, which significantly reduces the cost of fuel or electricity consumption for heating water.

Design features of a pump for heating a private house

In principle, a circulation pump for heating is no different from other types of water pumps.

It has two main elements: an impeller on a shaft and an electric motor that rotates this shaft. Everything is enclosed in a sealed case.

But there are two varieties of this equipment, which differ from each other in the location of the rotor. More precisely, whether the rotating part is in contact with the coolant or not. Hence the names of the models: with a wet rotor and dry. In this case, we mean the rotor of the electric motor.

wet rotor

Structurally, this type of water pump has an electric motor in which the rotor and stator (with windings) are separated by a sealed glass. The stator is located in a dry compartment, where water never penetrates, the rotor is located in the coolant. The latter cools the rotating parts of the device: the rotor, impeller and bearings. Water in this case acts for bearings, and as a lubricant.

This design makes the pumps quiet, because the coolant absorbs the vibration of the rotating parts. A serious drawback: low efficiency, not exceeding 50% of the nominal value. Therefore, pumping equipment with a wet rotor is installed on heating networks of small length. For a small private house, even 2-3 floors, this would be a good choice.

The advantages of wet rotor pumps, in addition to silent operation, include:

- small overall dimensions and weight;

- economical consumption of electric current;

- long and uninterrupted work;

- Easy to adjust rotation speed.

Photo 1. Scheme of the device of a circulation pump with a dry rotor. Arrows indicate parts of the structure.

The disadvantage is the impossibility of repair. If any part is out of order, then the old pump is dismantled, installing a new one. There is no model range in terms of design possibilities for pumps with a wet rotor. All of them are produced of the same type: vertical execution, when the electric motor is located with the shaft down. The outlet and inlet pipes are on the same horizontal axis, so the device is installed only on a horizontal section of the pipeline.

Important! When filling the heating system, the air pushed out by water penetrates into all voids, including the rotor compartment. To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover. To bleed the air plug, you must use a special bleed hole located in the upper part of the electric motor and closed with a sealed rotating cover

To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover.

Preventive measures for "wet" circulation pumps are not required. There are no rubbing parts in the design, cuffs and gaskets are installed only on fixed joints. They fail due to the fact that the material has simply grown old. The main requirement for their operation is not to leave the structure dry.

Dry Rotor

Pumps of this type do not have a separation of the rotor and stator. This is a normal standard electric motor. In the design of the pump itself, sealing rings are installed that block the access of the coolant to the compartment where the elements of the engine are located. It turns out that the impeller is mounted on the rotor shaft, but is in the compartment with water. And the entire electric motor is located in another part, separated from the first by seals.

Photo 2. A circulation pump with a dry rotor. There is a fan at the back to cool the device.

These design features have made dry rotor pumps powerful. The efficiency reaches 80%, which is quite a serious indicator for equipment of this type. Disadvantage: the noise emitted by the rotating parts of the device.

Circulation pumps are represented by two models:

- Vertical design, as in the case of a wet rotor device.

- Cantilever - this is a horizontal version of the structure, where the device rests on the paws. That is, the pump itself does not press on the pipeline with its weight, and the latter is not a support for it.Therefore, a strong and even slab (metal, concrete) must be laid under this type.

Attention! O-rings often fail, becoming thin, which creates conditions for the penetration of the coolant into the compartment where the electrical part of the electric motor is located. Therefore, once every two or three years, they carry out preventive maintenance of the device, inspecting, first of all, the seals

Elementary safety rules

Although the device of the circulation pump is quite simple, a certain qualification will be required to eliminate the breakdowns that have occurred. Therefore, it is easier to prevent a problem than to heroically fix it later. One of the signs that something is wrong with the equipment is its excessive heating during operation.

To prevent this, following the simplest rules of operation will help:

- The wiring must never come into contact with moisture.

- Particular care should be taken to check the tightness of the connection between the pumping equipment and the pipeline. If there are leaks, the gaskets should be replaced.

- It is forbidden to turn on the device without first grounding it. The heating pump device includes special terminals.

- The force of the internal pressure should not exceed the operating standards.

To figure out why the heating pump is not working, it is recommended to seek help from a professional master. You can try to fix the simplest problems yourself.

Major malfunctions and their own repair

Many pump problems are typical, and minimal knowledge is required to fix them. Repair work must be carried out with the power off.

Important! If the pump is still under warranty, try to contact specialized service centers for troubleshooting. Below are signs of the most common problems and how to fix them yourself.

Below are signs of the most common problems and how to fix them yourself.

The pump is buzzing and pumping poorly: how to repair?

If, after a long period of inactivity, a buzz is heard when the heating equipment is turned on, then the cause of the problem is the oxidation of the shaft.

To restore functionality:

- turn off the power;

- remove water from the equipment;

- dismantle the engine;

- turn the rotor in any way possible.

Sometimes a foreign object stuck inside can be the cause of the problem. To remove it after turning off the power and removing the water, remove the case fixing screws. Installing a strainer at the pump inlet will help to avoid a repeat of the emergency.

Why there is no buzz and rotation

Check the power supply, use a tester for this. Replace blown fuse. Check the correct connection of the terminals.

Switching on is accompanied by loud noise

Accumulated air in the heating system manifests itself in the form of loud noises.

Purge the air from the heating circuit.

To prevent a problem in the future, provide a special node in the pipeline.

Insufficient pressure

Several reasons can lead to this problem:

Wrong direction of rotation of the blades due to broken phasing. To correct the problem, check the phase connection and correct it.

Increased viscosity of the heat transfer fluid

To increase the pressure, pay attention to the cleanliness of the inlet filters.Check if the pipeline inlet parameters match the pump settings.

Stop after start

Make sure the phase connection is correct, the fuse contacts are clean, the clamps are clean. Eliminate any deficiencies found.

How to disassemble the device

The preparatory stage for disassembling the pump - dismantling:

- Be sure to turn off the power.

- When removing the pump from the heating circuit, use the provided heating bypass pipe.

- If a lengthy repair is expected, connect a replacement pump unit.

- You can remove the pump after unscrewing the shut-off valves.

Equipment disassembly steps:

- The pump cover is removed. If the bolts fixing it are “sticky”, then a special aerosol will help to unscrew them. You can buy it in specialized stores.

- A rotor with an impeller is taken out of the housing. To dismantle it, unscrew the fixing bolts or clamps.

- Replace the failed assembly.

Possible causes of problems

If during the next routine inspection you find that the circulation pump is working “somehow wrong”, then this is an occasion to make a deeper check using some specialized tools. The most common problems are: lack of rotation of the rotor, overheating of the pump and poor coolant current. Each of them there may be several reasons. Let's take a closer look at each possible malfunction:

- lack of rotation of the rotor when the pump is connected to the network. As a rule, this indicates some kind of failure in the delivery of power to the equipment. First of all, you need to inspect all the elements directly responsible for this function: electrical wire, device switch, etc.If you find any defect - for example, even the smallest violation of the insulation - you must immediately replace the damaged part with a new one. Until the defect is eliminated, the device cannot be used, as this is fraught with short circuits and other troubles. After checking the external components, inspect the plastic fuse. With frequent voltage drops in the mains, it begins to melt and constantly opens the circuit. If you see that it has already frankly deformed, it needs to be replaced. The next item to check is the winding of the electric motor. To do this, you need a multimeter, which measures the level of resistance. In the normal state of the winding, the indicator can vary from 10 to 15 ohms or from 35 to 40 ohms, depending on the specific rotor model. If the multimeter gives infinity or a value close to zero, then this indicates the need to replace the winding,

- pump overheating. This usually happens in cases where the circulation equipment, for some reason, is forced to work with an increased load. Detecting overheating is quite simple - if the pump is hotter than the pipe, then this clearly indicates a problem. In the case when this happens with newly installed equipment, it makes sense to check the correctness of the installation. Incorrect placement of the instrument may cause it to malfunction. If you find any shortcomings, then you need to re-perform the installation procedures, making the appropriate adjustments. Another common cause of overheating is clogging of structural elements with dirt. Rust and scale play a big role in this.They form in some sections of the pipeline, and then fall off piece by piece and go along with the coolant, clogging all the equipment where they fall. This is also the case with the circulation pump. The presence of foreign particles inside the structure narrows the path along which the coolant flows. Thus, the pump has to apply more force to move the liquid. Therefore, overheating occurs. The solution to the problem in this case is the cleaning of clogged elements. The third reason for overheating has already been mentioned above - it can be an insufficient amount of lubricant on the bearings located inside the pump. The fourth reason may be too low - below 220 V - the voltage in the network. You need to check this indicator with a voltmeter and, if problems are found, fix them,

- poor coolant current. This refers to situations where the fluid circulates at insufficient speed. The reason for this may be an incorrect connection if your home uses a 380 V network. Check that the electrical wire is connected to the phase correctly - it is quite possible that it needs to be connected to another. The second reason for poor current can be the same clogging of the internal structural elements, which was mentioned above. This is solved by clearing the elements.

Rules for the operation of centrifugal pumps

Due to the reliability of centrifugal devices, the need for repair and maintenance rarely arises. Breakdowns occur due to non-observance of maintenance rules. These rules include:

- the device is operated only with liquid.Dry running wears out the shaft seal;

- no machine downtime. If there is no need for the device to work, it must be started once a month. With a long idle time, the shaft is oxidized;

- the unit is used at positive temperature. Working in frost leads to freezing of the liquid and breakdown of the unit;

- operation in passport mode. Work takes place at an average flow without exceeding the maximum efficiency indicator;

- timely maintenance of oil seals. In the absence of lubrication, the shaft of the apparatus fails.

Malfunctions of centrifugal pumps and their elimination

Based on the signs of a malfunction, the cause of the breakdown is determined.

Centrifugal pump device

Symptoms and their elimination:

- After starting, the device does not supply water. The causes of failure in this case may be: incorrect start-up of the device (to eliminate it, it is necessary to restart the device after removing the air); low wheel speed (in order to eliminate the breakdown, increase the frequency); the air collector is not closed on the body of the device (it is worth closing the air collector); clogging of the intake valve (the valve is cleaned to eliminate it); weakening of the stuffing box (tighten the stuffing box to eliminate it).

- The connected device is working, the shaft does not rotate. The reasons for the breakdown are: blocking of the device due to prolonged downtime (for repair, the shaft is scrolled with a screwdriver or manually, depending on the power); foreign body entering the flow path of the centrifugal pump (after removing the snail, a foreign object is removed and a filter is installed); problematic power supply from electricity (the correct connection is checked and the match between the consumed and nameplate power is checked).

- The device does not turn on.The cause of this failure may be a fuse melting or winding burning (replacement of devices is necessary for repair).

- Noise during operation of the device. There can be several reasons for this type of breakdown: the device is filled with air (bleed air and install a vent); the liquid level is below the suction level (lower the device).

- The working device is accompanied by vibration. The reason is poor attachment of the device (attach the device), the bearing of the centrifugal pump has worn out (the bearing should be replaced).

- The bearings get hot. The reason is that the alignment of the shaft and the device is poor (make alignment).

- Increased pressure at the outlet of the device. The cause of the breakdown is a high rotational speed (reduce the rotational speed or cut and shift the working wheel).

- High power consumption. Caused due to the high density of the liquid (the engine is changing to a more powerful one); high resistance of the system (for repair it is necessary to close the valves on the pressure hose).

- Lack of machine supply. Occurs due to air entering the system through the gland (it is necessary to tighten the glands, turn off the device and increase the liquid level in the device to normal); contamination of the intake valve or suction pipe (to eliminate it, you need to disassemble the unit to clean the valve).

- High noise level when starting a centrifugal pump. The reason is the lack of lubrication (lubricate the apparatus); poor quality fasteners (tightly attach to the foundation); air entering the device (the device is turned off and filled with liquid again); low pressure (set the device operation process).

- After the start of work, motor protection is activated. The reason is electricity (the problem of resistance in the ground phase is eliminated).