- Cleaning and disinfection with autonomous water supply

- Standard arrangement of the water supply system

- The right choice of location

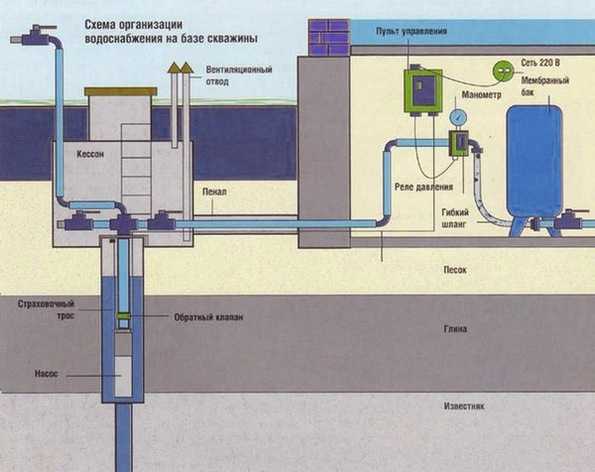

- Generic Schema Definition

- Layout and location of equipment

- Pipe laying features

- Do-it-yourself arrangement of a well around a well

- Device

- Segment Importance

- Selection and installation of equipment for the supply of water

- Surface pump for shallow well

- Deep well submersible pump

- Pipeline laying

- Seasonal plumbing options

- summer construction

- winter construction

- Equipment connection sequence

- Installation of equipment

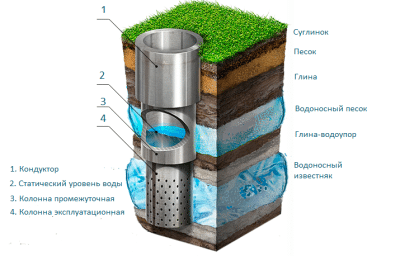

- Artesian well: device diagram

- Equipment selection

- Caisson or adapter

- Pump units

- Accumulator and relay

- Well cap

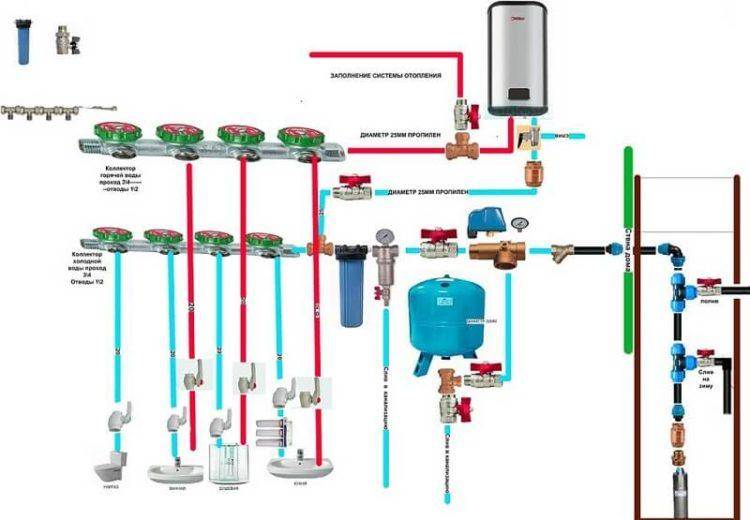

- Installation of plumbing in the house

- Video: how to work with plastic pipes.

Cleaning and disinfection with autonomous water supply

Be sure to install a coarse filter, 500 - 300 microns. Behind it is a fine filter. There are mechanical and membrane type filters with a filtration value of only 0.8 microns. These filters will remove all the suspension. However, salts, microorganisms and bacteria will remain.

For disinfection, you can purchase installations with various principles of action: ozone, ultraviolet, ultrasonic, electric discharge and others. Some of them are able to purify and from various metals and their salts.

For disinfection, you can purchase installations with various principles of action: ozone, ultraviolet, ultrasonic, electric discharge and others. Some of them are able to purify and from various metals and their salts.

For purification from salts and metals, water treatment equipment is installed, operating on the principle of osmosis, ozonation, ion-exchange resins, activated carbon sorption filters and others.

It should be noted that the cost of such equipment is very high. It must be selected taking into account the chemical analysis of the composition of water from this area. The units themselves require regular maintenance and periodic replacement of consumables.

Standard arrangement of the water supply system

Laying the water supply system of a private house from a well has its own characteristics. Let's take a closer look at the steps of this process.

The right choice of location

First of all, it is necessary to determine the place of drilling. Based on financial costs, it should be as close as possible to the point of consumption.

Well location:

- no closer than 5 meters from capital buildings;

- at the maximum distance from the cesspool and septic tank, the minimum distance is 20 meters;

- the location should be convenient for drilling and maintenance.

With the right choice of location, the water from the well to the house will meet the requirements of drinking water supply.

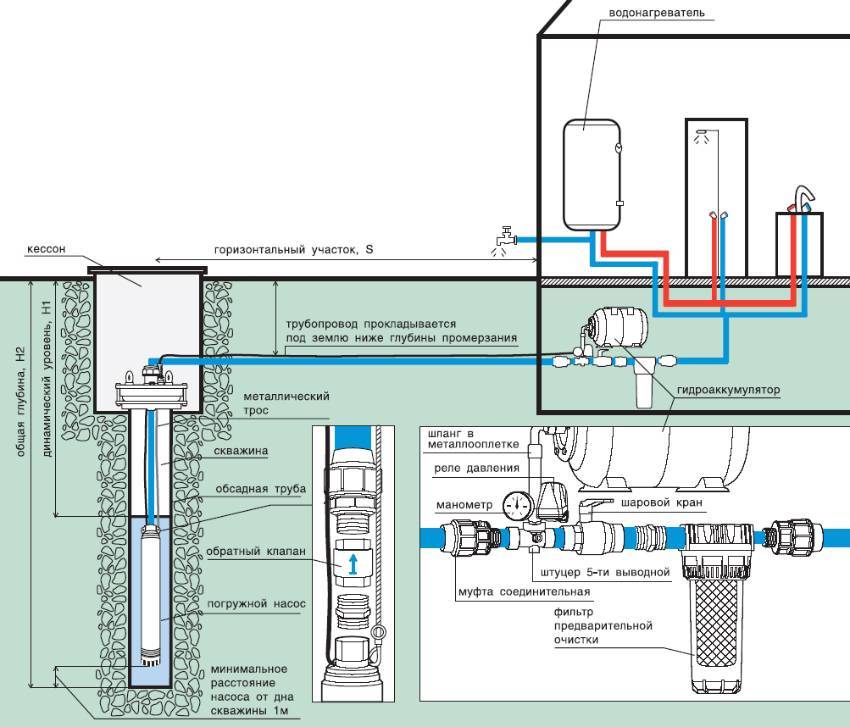

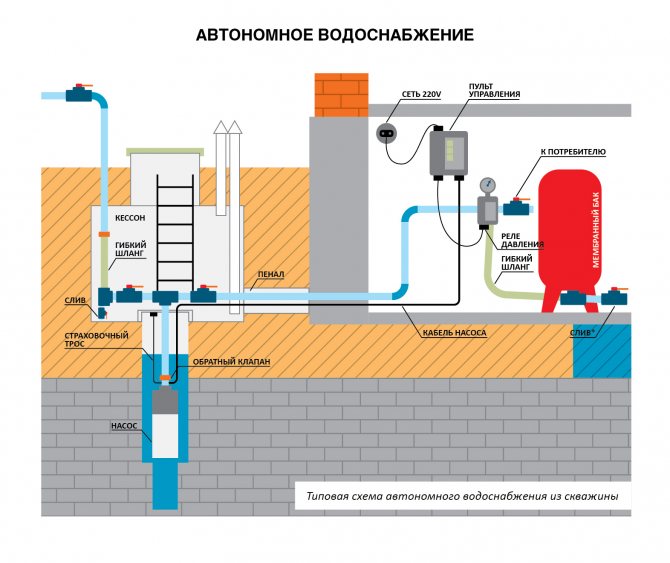

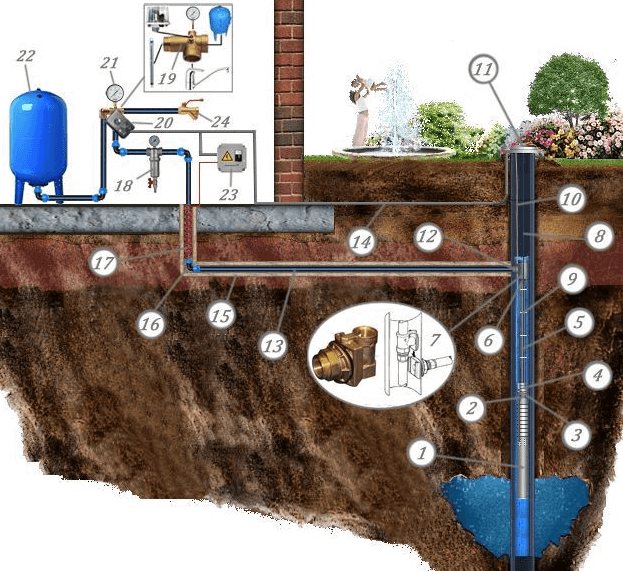

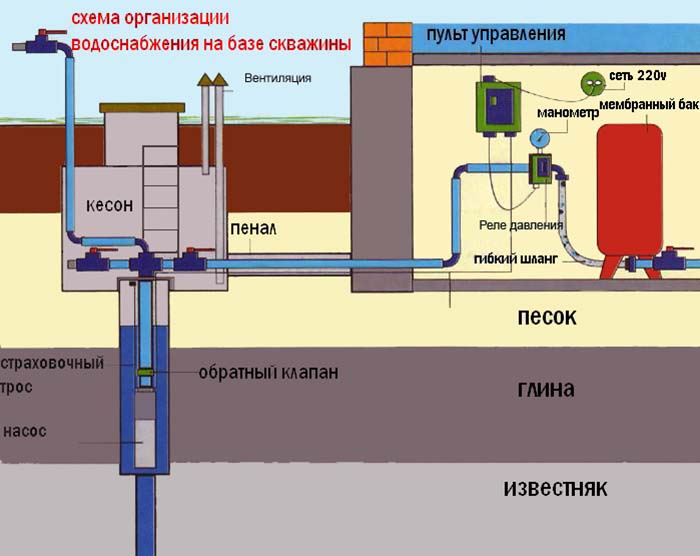

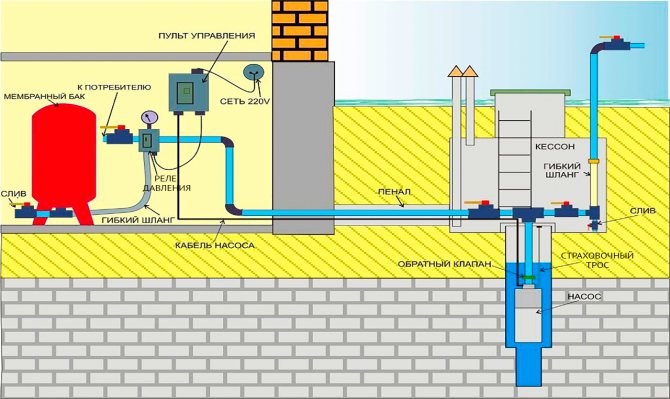

Generic Schema Definition

The water supply of a private house from a well with a hydraulic accumulator has its own characteristics.

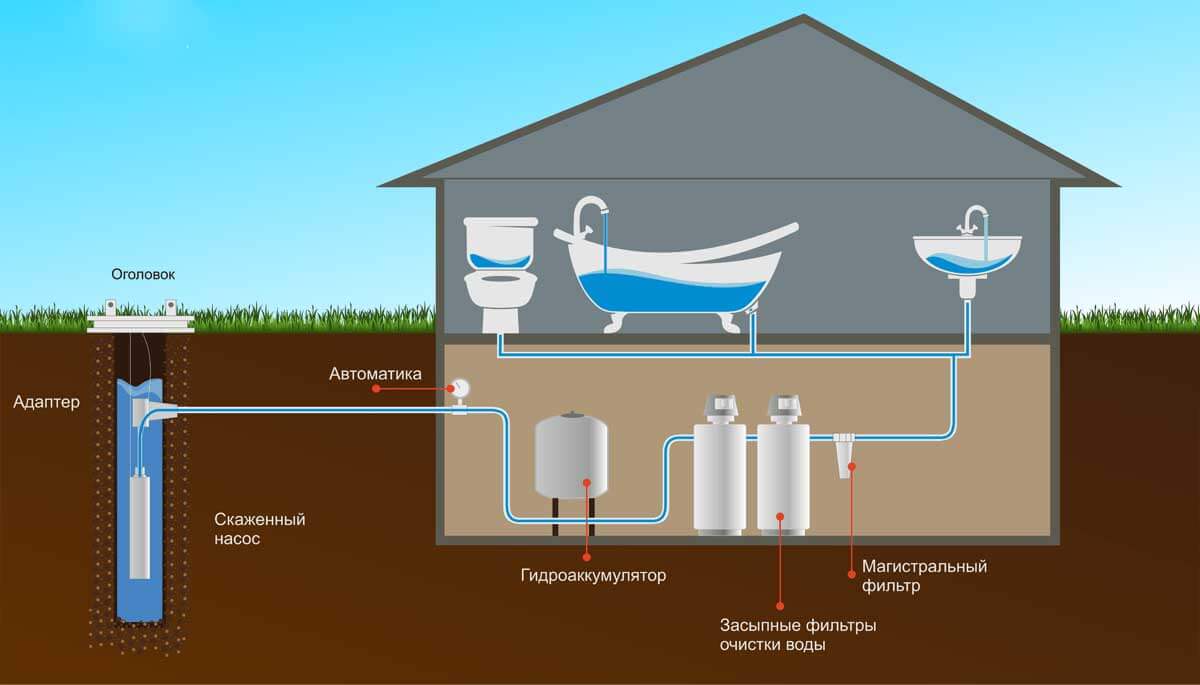

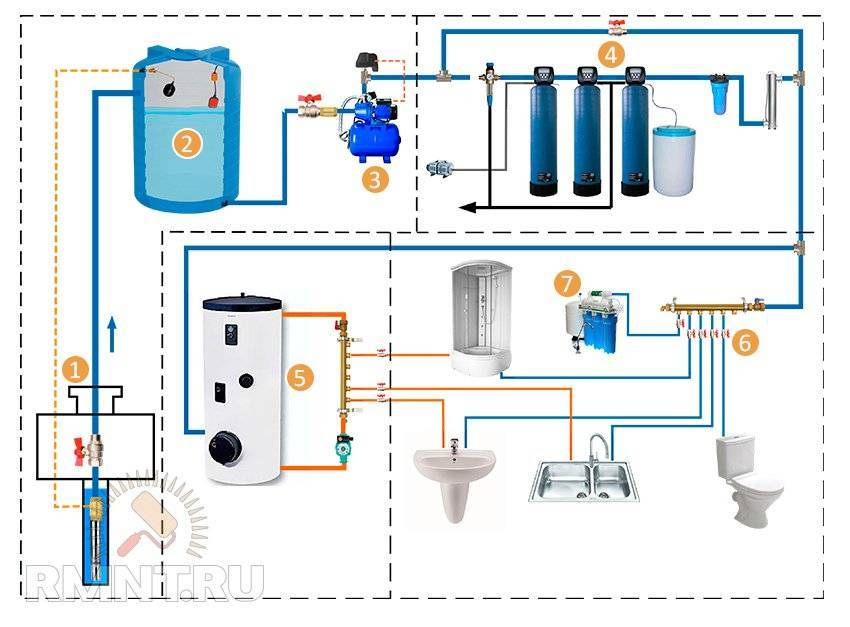

Let us consider in more detail the elements used and the scheme of their connection:

- The main element that creates the movement of water to the surface is the pump. It can be surface and located indoors, or submersible and be in the water.The first option is used with a small lifting depth of up to 8 meters. The second type of pump is more popular and is used for depths of 100 meters or more.

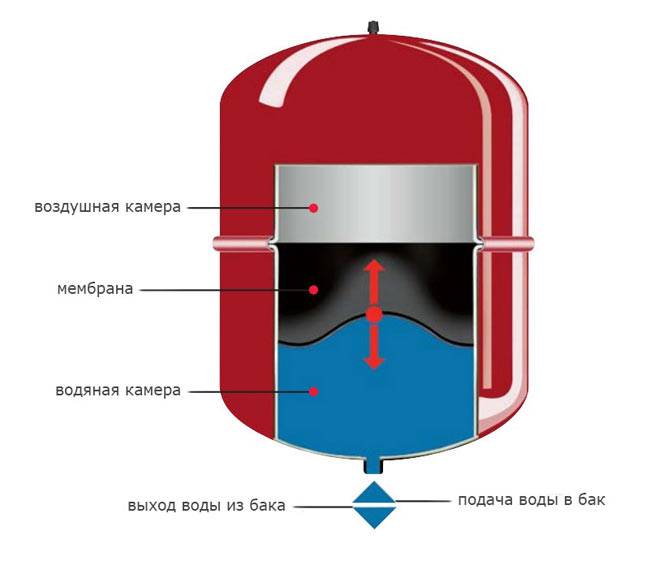

- Installation of a hydraulic accumulator, which is a tank made of a rigid case, in which there is a rubber container for filling with air. The constant pressure in the system depends on this element.

- Automation is responsible for the smooth operation of the system and independently turns on and off the pump if necessary. The pump power and the volume of the storage tank are calculated with a margin, depending on all points of water consumption.

- Coarse filters are located at the water intake site, which cut off large fragments from their entry into the water supply system. Next, a fine filter is installed in front of the pump, which is selected depending on the composition of the water.

Layout and location of equipment

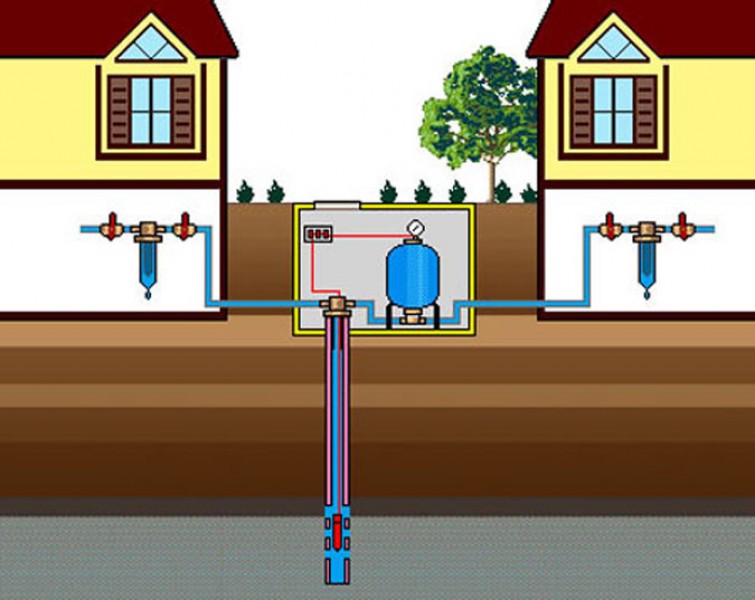

An important point remains the correct location of the equipment used in the water supply from the well. The most acceptable option is the arrangement of a caisson well, which is located above the well and allows you to provide comfortable conditions for the operation of the equipment used.

Rationality is as follows:

- the equipment is located in close proximity to the water intake, which contributes to the maximum efficiency of its use;

- soundproofing materials are used in the well to ensure the noiselessness of the pump;

- the equipment is located in one place and protected from mechanical damage;

- high-quality thermal insulation allows uninterrupted use of water supply throughout the year.

Of course, this equipment can be placed in the bathroom or in another room, but the presence of a caisson is certainly a big advantage.

Pipe laying features

The most suitable are low-density polyethylene pipes. They are distinguished by their durability and unpretentiousness, as well as their ease of construction and ease of installation:

it is possible to lay them directly into the ground, but it is recommended to dig a trench to a depth that excludes freezing; a technical pipe is installed in it, in which the pipeline itself is located; it is important to use heat-insulating materials, it is desirable to have a heating cable; in inaccessible places, unnecessary connections should be avoided, which is facilitated by the HDPE pipe. Indoors, the pipeline can be constructed from other materials: copper and steel

Indoors, the pipeline can be constructed from other materials: copper and steel.

Do-it-yourself arrangement of a well around a well

The well is located 3 meters from the house, it was decided to dig 1m³ of earth around the pipe, after spending 3-4 hours dodging around the pipe, I dug a hole 1x1x1 meters hole. I installed the formwork and backfilled with rubble, I unscrewed an additional 1 meter of pipe prepared in advance. I poured it with concrete to the top of the earth, I used cement grade 500, as I had already burned myself with 400 when pouring the ceiling. The walls came out 4-5 cm thick.

A week later, I dismantled the formwork, drilled a hole in the concrete with a crown, put a 50 mm sewer pipe into this hole from the house into the well, put a SIP wire (for reliability) and a ¾ HDPE pipe into the pipe. Then he filled the sewer cover with concrete.

Device

Not all pipes on the building materials market are suitable for creating an autonomous water supply system. Therefore, when choosing them, first of all, you need to look at the markings. Water pipes have approximately the following designations - PPR-All-PN20, where

- "PPR" is an abbreviation, an abbreviated name for the material of the product, in the example it is polypropylene.

- "All" - an inner aluminum layer that protects the pipe structure from deformation.

- "PN20" is the wall thickness, it determines the maximum working pressure of the system, measured in MPa.

The choice of pipe diameter is based not so much on the diameter of the threaded inlet on the pump and the automated pressure control system, but on the expected volume of water consumption. For small private houses and cottages, pipes 25 mm in diameter are used as standard.

When selecting a pump, the following points should be considered:

If water from a well is used, a vibration unit cannot be used, it will damage the casing and filter element. Only a centrifugal pump is suitable.

The quality of the water from the well must meet the requirements of the pump. With a well “on the sand”, grains of sand will come across in the water, which will quickly lead to a breakdown of the unit

In this case, it is important to choose the right filter.

Dry run automatic. When choosing a pump, if the choice fell on a model without built-in protection against "dry running", you must additionally purchase automation for the appropriate purpose

Otherwise, in the absence of water that performs a cooling function for the motor, the pump will overheat and become unusable.

The next step is drilling a well.Due to the complexity and high labor intensity, this stage is best performed with the help of a specialized team with the necessary drilling equipment. Depending on the depth of water and the specifics of the soil, various types of drilling are used:

- auger;

- rotary;

- core.

The well is drilled until the aquifer is reached. Further, the process continues until a water-resistant rock is found. After that, a casing pipe with a filter at the end is inserted into the opening. It should be made of stainless steel and have a small cell. The cavity between the pipe and the bottom of the well is filled with fine gravel. The next step is to flush the well. Most often, this procedure is performed using a hand pump or submersible, lowered into the casing. Without this, the action of clean water can not be expected.

The caisson serves as protection for both the well and the equipment lowered into it. The life of the water supply system, as well as the convenience in servicing units immersed in the well, directly depend on its presence.

The caisson, depending on the material used, may be as follows:

- metal;

- cast from concrete;

- lined with concrete rings with a diameter of at least 1 meter;

- finished plastic.

The cast caisson has the most optimal qualities, the creation of which can take into account all the existing specifics of the well. Plastic caisson has low strength and needs to be reinforced. The metal look is subject to corrosion processes. Concrete rings are not very spacious and maintenance or repair work in such a caisson is very difficult. The depth of this structure is determined by the level of soil freezing in winter and the type of pumping equipment used.

For clarity, consider an example. If the depth of soil freezing is 1.2 meters, then the depth of the pipelines leading to the house is approximately 1.5 meters. Given that the location of the well head relative to the bottom of the caisson is from 20 to 30 cm, it is necessary to pour concrete about 100 mm thick with about 200 mm crushed stone. Thus, we can calculate the depth of the pit for the caisson: 1.5 + 0.3 + 0.3 = 2.1 meters. If a pumping station or automation is used, the caisson cannot be less than 2.4 meters deep. When arranging it, it is worth remembering that the upper part of the caisson should rise above ground level by at least 0.3 meters. In addition, a natural ventilation system is needed to prevent the accumulation of condensate in summer and frost in winter.

Segment Importance

The constant availability of water in a private house or in the country is a very important component for a comfortable stay for all residents. Water is essential for many things. This is not only cooking and bath procedures, but also watering the garden, washing and cleaning, all kinds of technical work in the house and on the site.

The convenience lies in the fact that all communications are reliably protected from mechanical and other influences due to their location underground, but at the same time they have easy access for repair or partial replacement.

In this article we will tell you in detail how to equip the water supply on the site as simply and efficiently as possible.

Selection and installation of equipment for the supply of water

Equipment for individual water supply consists of the following elements:

- Pump, it can be submersible or located on the surface.

- Automation that controls the operation of the pump and protects it from overloads.

- Hydraulic accumulator, open or closed (membrane tank). The latter is preferable, it provides stable pressure in the water supply.

An open water storage tank has to be installed at the top of the water supply, in the attic or under the ceiling of the upper floor. The closed container has no restrictions on the place of installation.

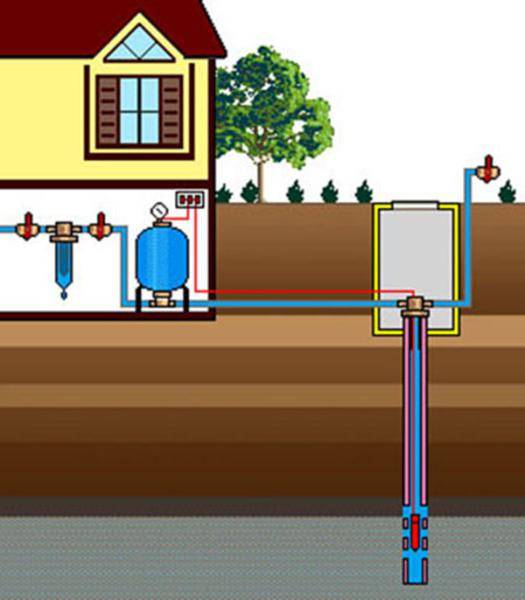

The main elements of the water supply equipment of a private house from a well: a pump, a hydraulic accumulator, automation

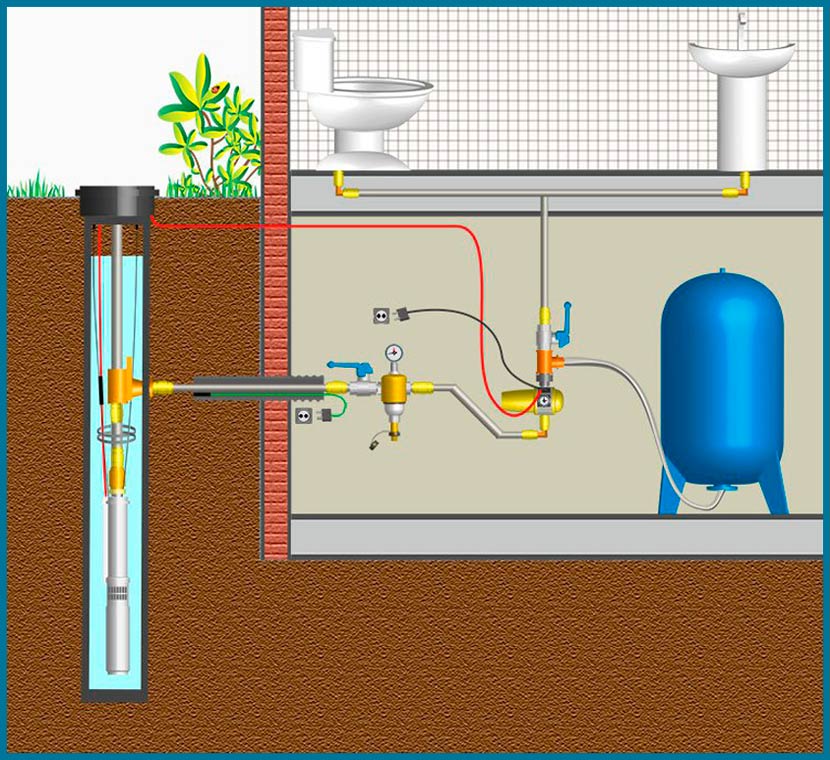

The nature of the well arrangement is largely determined by the type and location of the water supply equipment. Consider the main options for completing the source with equipment.

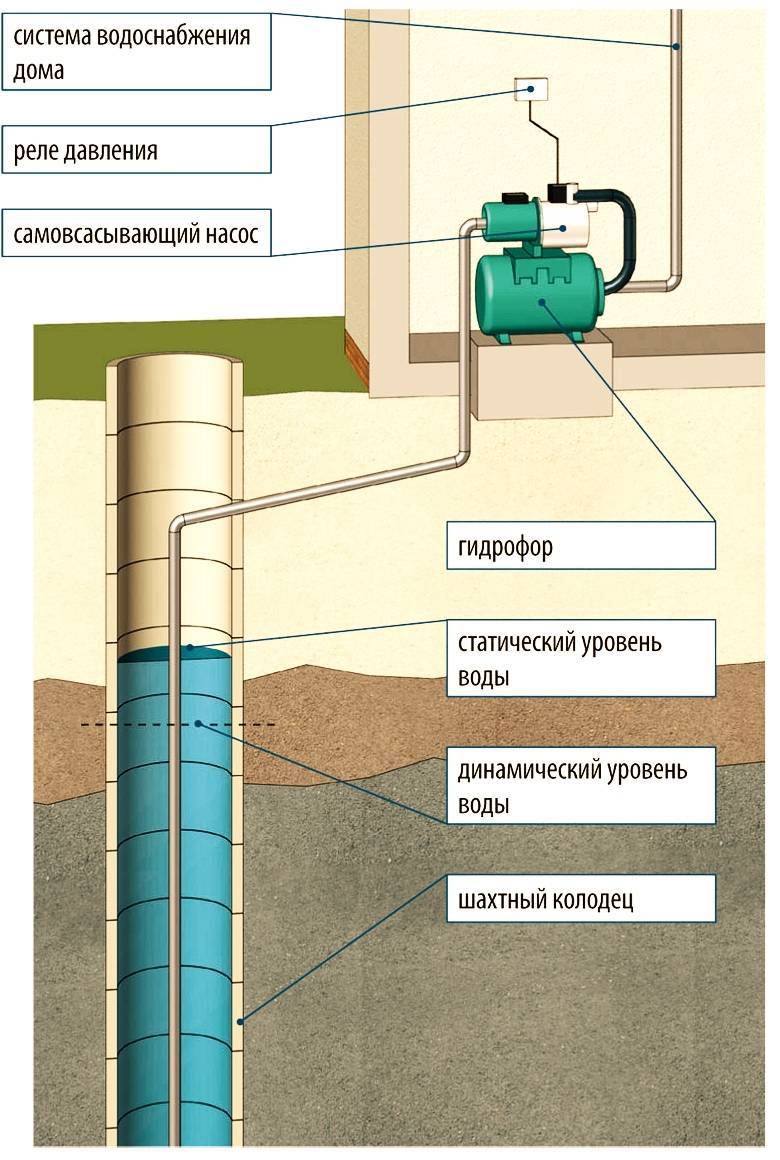

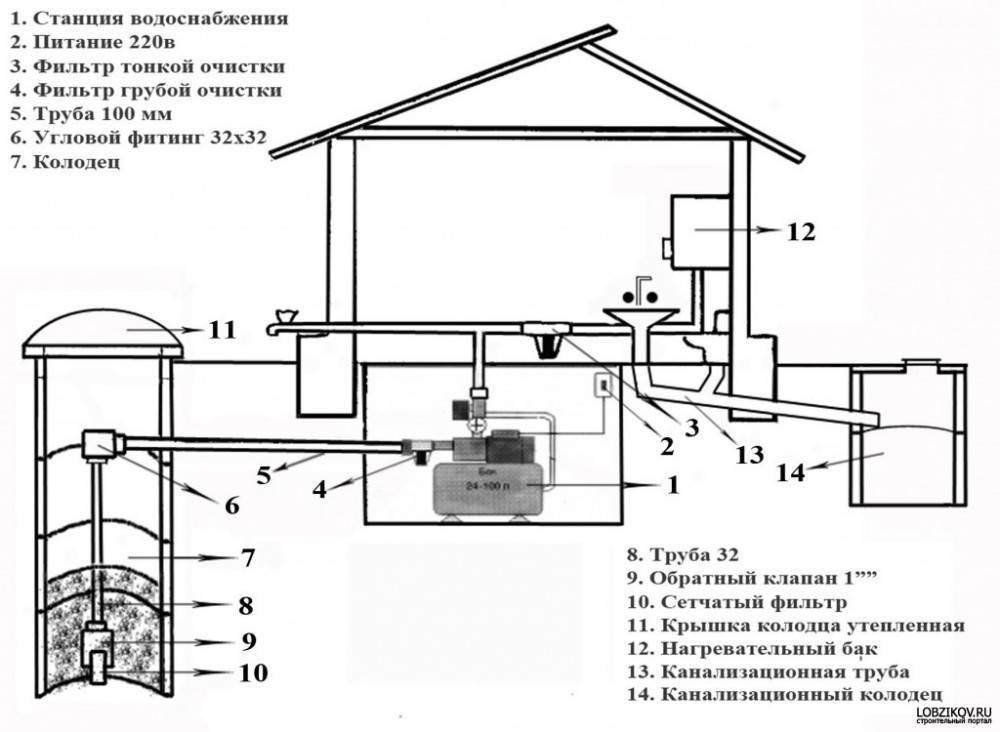

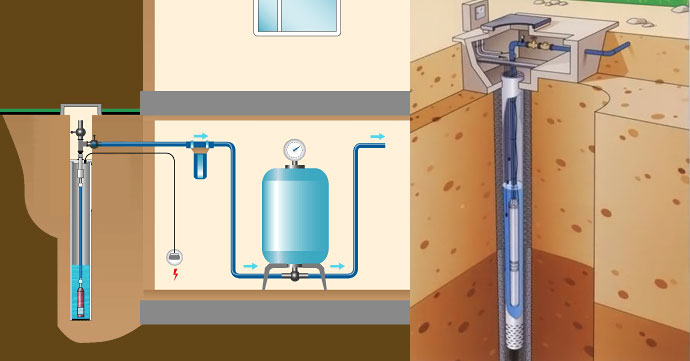

Surface pump for shallow well

A surface pump is significantly cheaper, easier to install and maintain than a submersible one. The most rational and economically justified option is a three-in-one complete pumping station, which includes a surface pump, a relatively small (20-60 l) membrane tank and all the necessary automation.

Only the suction hose is lowered into the well. Thus, the arrangement of the well and the maintenance of the pump are simplified. In addition, the hose has a small diameter, which allows it to be used in the so-called "Norton wells" (Abyssinian wells), where the submersible pump simply does not fit.

Pumping stations have only one, but a very significant drawback. A surface pump is not able to lift water from a great depth, for most models the limit is 8-10 m. This limits the scope of pumping stations to wells and shallow wells.

Due to the low lifting height, pumping stations with a top-mounted pump often have to be installed as close to the wellhead as possible.Otherwise, you will have to additionally overcome the hydraulic resistance from the water source to the place in the house where the pump is installed.

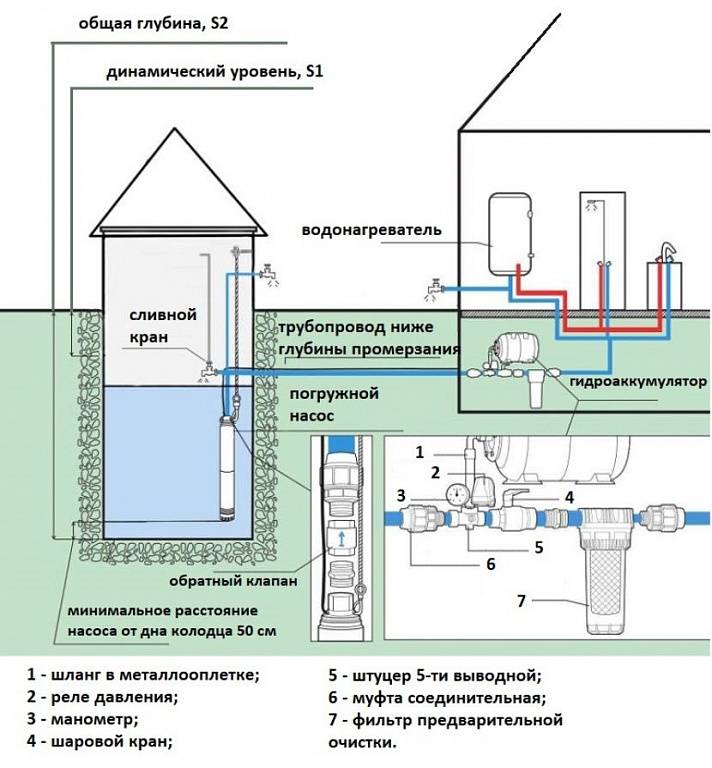

Schematic diagram of water supply based on a complete pumping station with a surface pump. It is used for shallow wells due to the low height of the water rise

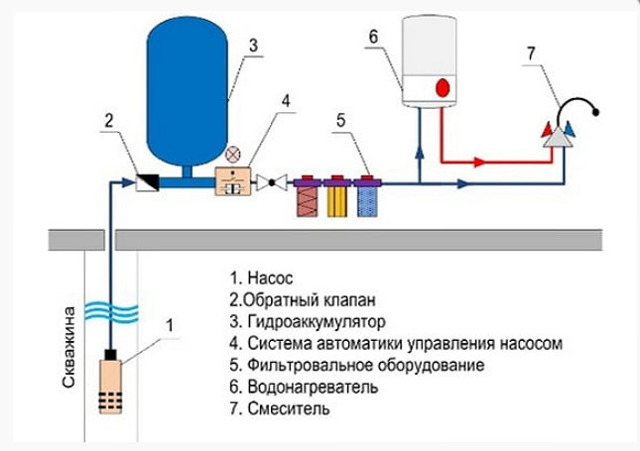

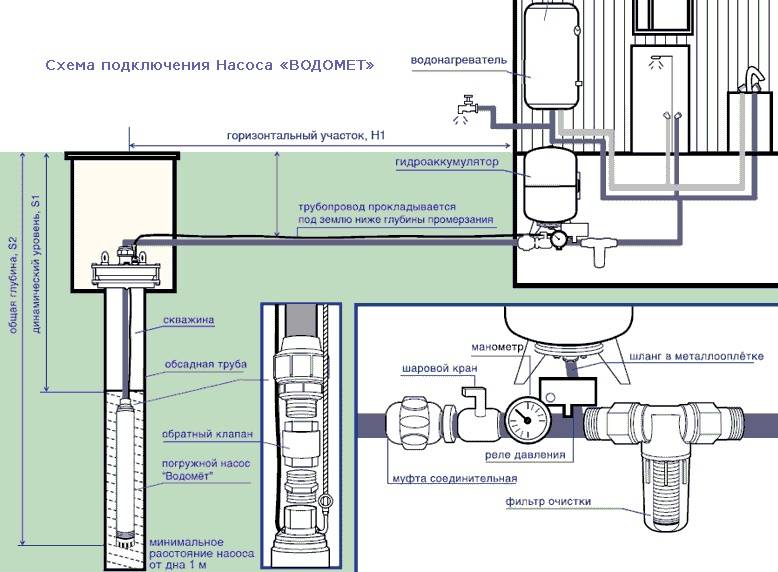

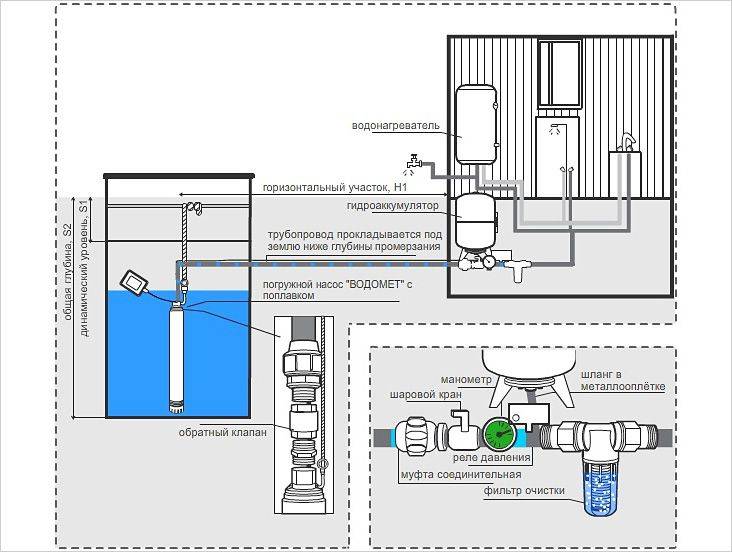

Deep well submersible pump

To lift water from wells with a depth of more than 10 m, submersible pumps have to be used. The correct choice of the pump and the determination of its suspension height in the casing is a separate and rather difficult issue.

As part of the topic of the article, we just need to understand what additional equipment the pump is equipped with, how it is mounted, connected.

As we have already mentioned, the mandatory elements of the water supply equipment of an individual house are a hydraulic accumulator and control automation. In the case of a submersible pump, the lifting height of which is several times greater than that of a surface pump, there are no restrictions on the installation location of a closed accumulator.

The membrane tank and control can be placed quite far from the wellhead, the distance to the source does not significantly affect the operation of the system. An excellent place to place equipment is a dry and clean technical room in the house, in the basement or ground floor.

Scheme of autonomous water supply based on a submersible pump. The membrane tank can be located at a fairly large distance from the well

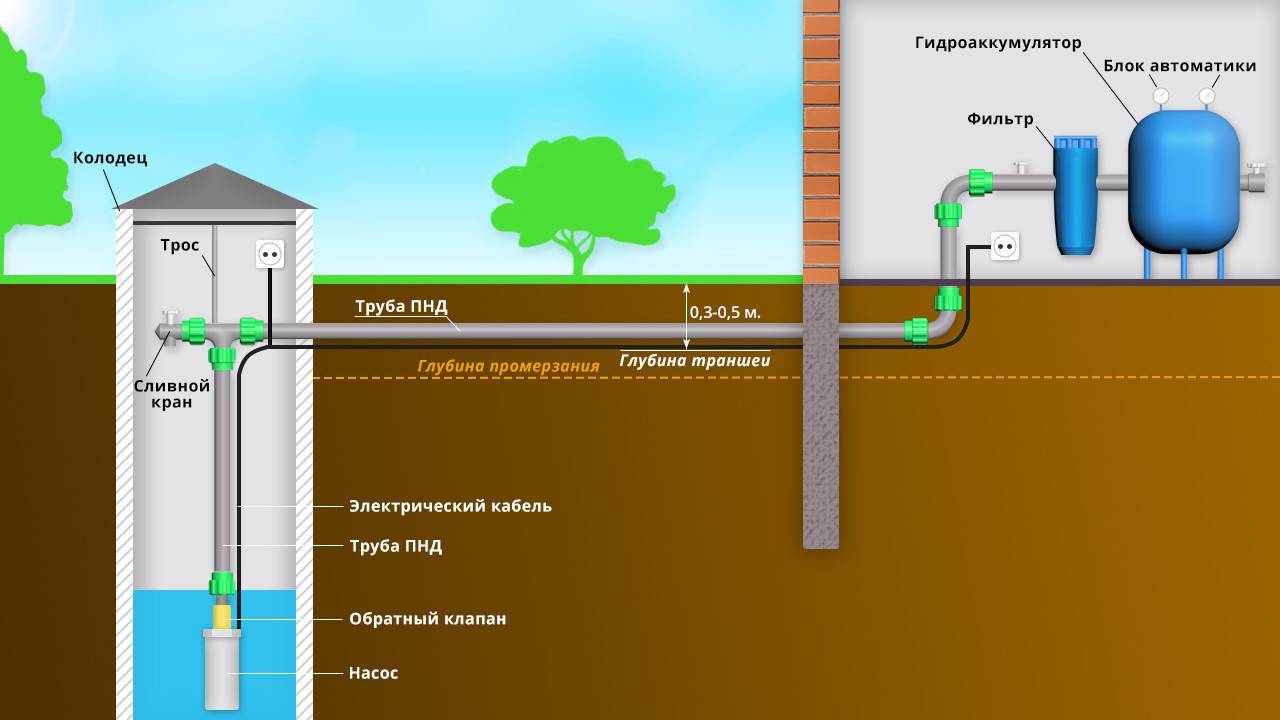

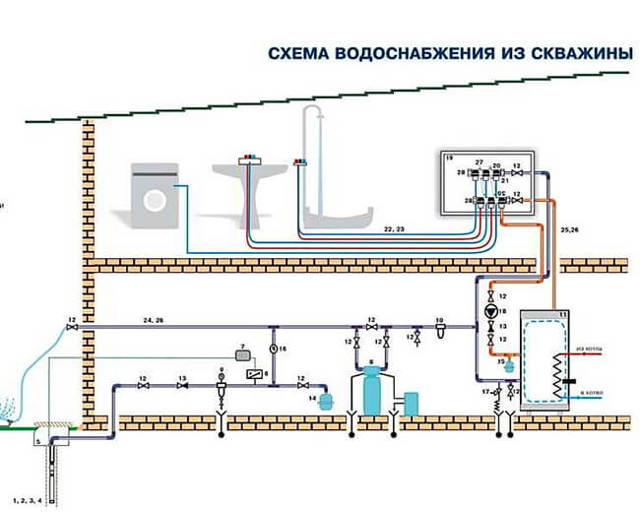

Pipeline laying

When installing water supply from a well, it is important to ensure that the pipes pass below the ground freezing level. The optimal level is determined in sanitary rules and regulations and depends on the region

Well arrangement scheme and technology her work.

To lay the pipe, a trench of optimal length should be made - from the house to the well. A pillow of sand is arranged at the bottom, a pipe with a diameter of 30 mm is laid on top.

Pipes are best to choose metal or polyethylene. Sometimes HDPE pipes are used, but they require high-quality insulation in cold climates: when the temperature drops below 0 degrees, the material becomes brittle.

However, the requirement for insulation is applicable for pipes of any type.

When laying, it is worth paying attention to the fact that the area in the lifting points can freeze through in the cold season. It is easy to fix this problem: it is enough to insulate the foundation of a residential building, wrap the pipe with a heating self-regulating cable and thermal insulation

Do not use hoses to supply water.

If for some reason it is impossible to dig a trench on the site, then it is worth making an autonomous water supply of a private house on the surface. Then the pipe is buried a little, but it is well insulated with special material and a heating cable is launched. The cable from the pump is also laid with the pipe. The wire will fit only two-wire. The box can be installed in a residential building, in a room allocated for this.

Seasonal plumbing options

For the arrangement of local water supply systems, various options can be used. Taking into account their needs and accommodation options, the owners of suburban areas in the absence of centralized communications can independently equip their plots.

summer construction

Summer water supply schemes are represented by systems:

- collapsible;

- stationary.

Summer water connection

The collapsible design is extremely easy to install and operate.With the advent of the warm season, you can safely install the necessary set of elements on the site.

The configuration of plastic pipes and the hose is laid on top of the ground in the required directions. The design will be characterized by high reliability when using high-quality connecting adapters and valves.

The stationary structure is a conventional plumbing system laid in the ground. The depth of the bookmark may not be significant. In the necessary places, water taps are displayed. The shallow depth of occurrence will always allow reorienting such a system in the summer season.

However, it should be borne in mind that frost can damage the system. Therefore, there must necessarily be some slope of the highway to be able to free the system.

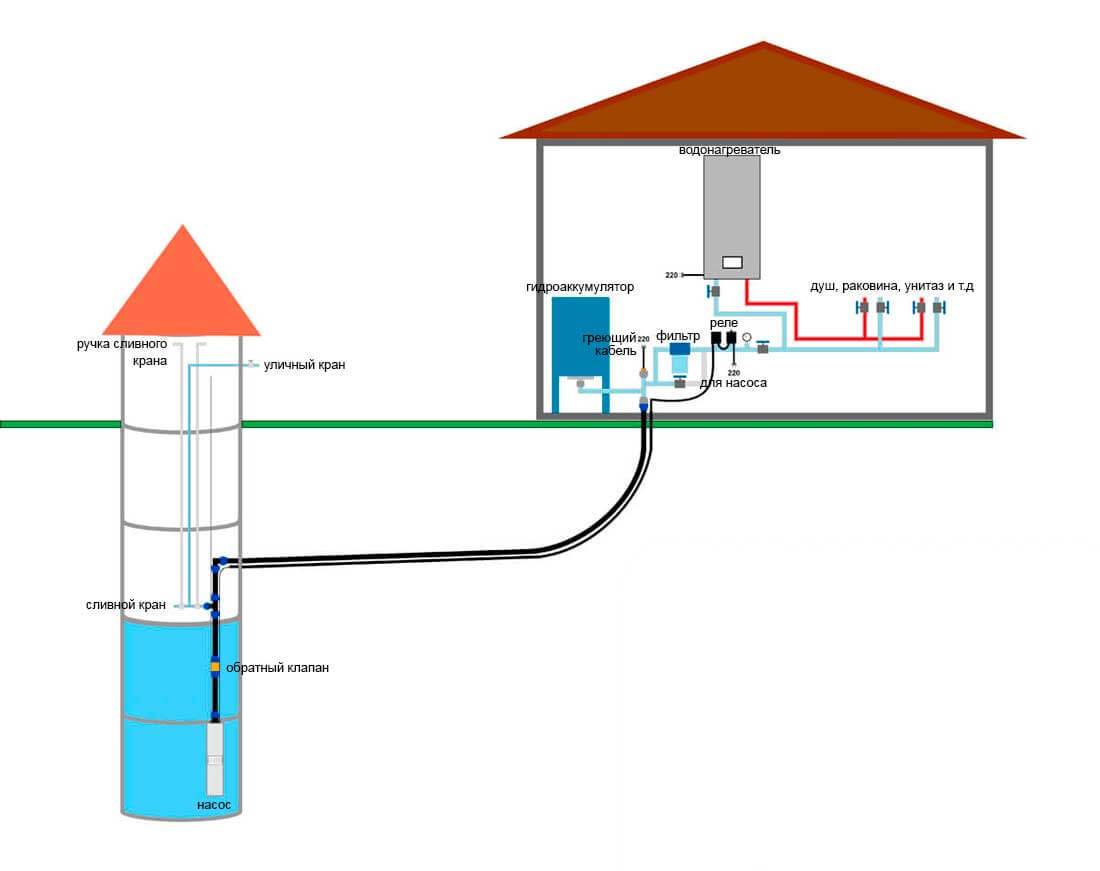

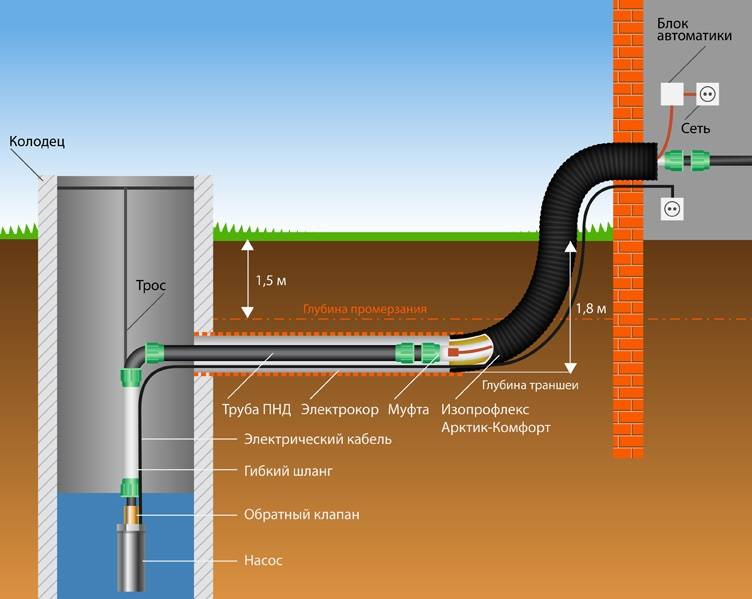

winter construction

For the efficient and reliable operation of the winter version of the water supply, its thorough insulation will be required. This guarantees its safety and functioning.

Winter plumbing heating scheme

Work begins at the point where the pump is connected. Many owners combine plumbing with a power cable in a common casing.

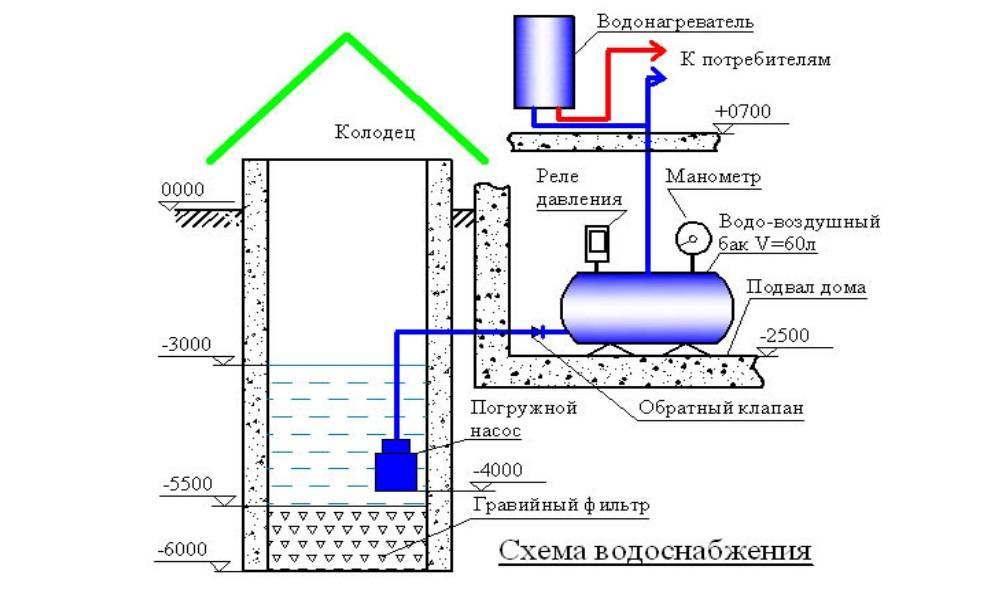

Equipment connection sequence

There are various equipment installation schemes, but they all have mandatory elements that cannot be dispensed with. In addition, the sequence of their connection is very important.

Water supply scheme from a submersible pump in a well

Below are all the required elements of the circuit and the sequence of their connection.

- Pump. Definitely with check valve. Stainless steel safety cable. The pump control unit, with relay and automation, can be installed immediately at the head of the well.

- Drainage of water from the pipeline into the well for conservation for the winter or work on the equipment. If the check valve is installed separately from the pump, then it is necessary to drain the water for the winter so that it does not interfere with the drain.

- Branch for the yard water tap and watering. It is recommended to install before the coarse filter in order to reduce the load on the filter, as well as to flush it with water from the accumulator when using an outdoor tap.

- Coarse filter 300 microns. Be sure to install between the street crane and the accumulator.

- Hydraulic accumulator. Install a faucet in front of the tank. To replace the membrane, the accumulator has to be removed and disassembled. Can be installed on the floor, but it is better to attach to the wall with the outlet down for better drainage.

- Fine filter. If, in addition to the yard tap, there are other consumers who do not need to purify the water with a fine filter, connect them to the filter.

- Pipeline to the internal water supply of the house.

All these elements of the water supply system can be installed in the well pit. If the use of water will be in winter, then the pit must be insulated, and the soil must not freeze through the entire depth of the pit. Otherwise, the accumulator and subsequent elements (after point 5) should be in a warm room.

If you plan to install disinfection and water treatment systems, then you should decide what needs the purified water should be used for:

- for drinking and cooking;

- for the adoption of water procedures;

- for washing clothes;

- for dish washing;

- for all household needs in the house, including a bathroom.

From the decision made, further connection of equipment and plumbing in the house will be selected.In making the right decision, a laboratory analysis of the chemical composition after the fine filter and the table from section 1 of this article can help.

Important: usually in a private house, disinfection and water treatment of water from an artesian and sandy well is carried out only for drinking and cooking. From surface reservoirs, a well and a surface well, water should be purified for all needs, excluding technical purposes and a bathroom.

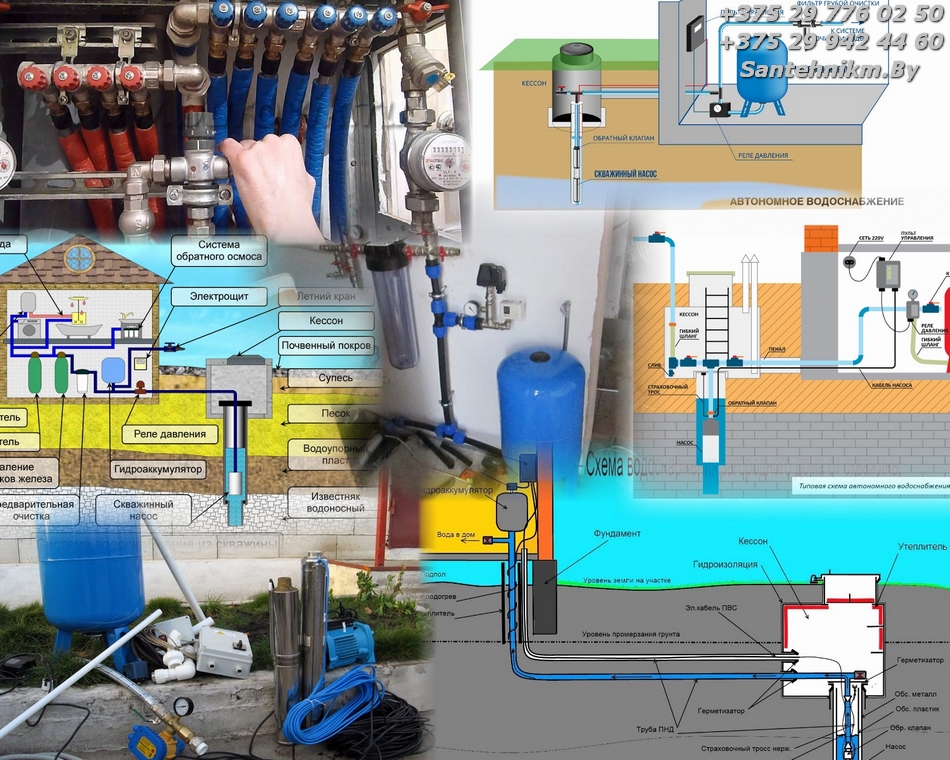

Installation of equipment

The equipment must ensure the stability of the water supply. For uninterrupted supply, there are various types of pumps, and their operation requires electrical power. The simplest option for arranging a place for well equipment is a pit. The undeniable advantage of such a site is that it can be made from improvised materials.

Due to the fact that moisture can get into the pit, experts recommend this type of platform for equipment as an adapter. Methods for arranging sites with an adapter imply that the role of the caisson is played by the casing string. It is possible to apply the method if the arrangement of the casing string is made in one container and the tightness of the pipes is ensured. For such a case, pipes are usually selected from steel. Plastic is not recommended for the adapter design, as the pump is fixed to the water pipe and not suspended from a cable.

Another option for a site for arranging equipment, the caisson mentioned above. This is a sealed container, which is considered reliable and durable. The container can be equipped ready-made or made by hand. Caissons are either plastic or steel. Plastic sealed, weigh a little, easy to install.Steel options are airtight, reliable, but need to be treated with anti-corrosion compounds, they have a higher price

The equipment is mounted after the site is mounted, while it is important to take into account some of the nuances

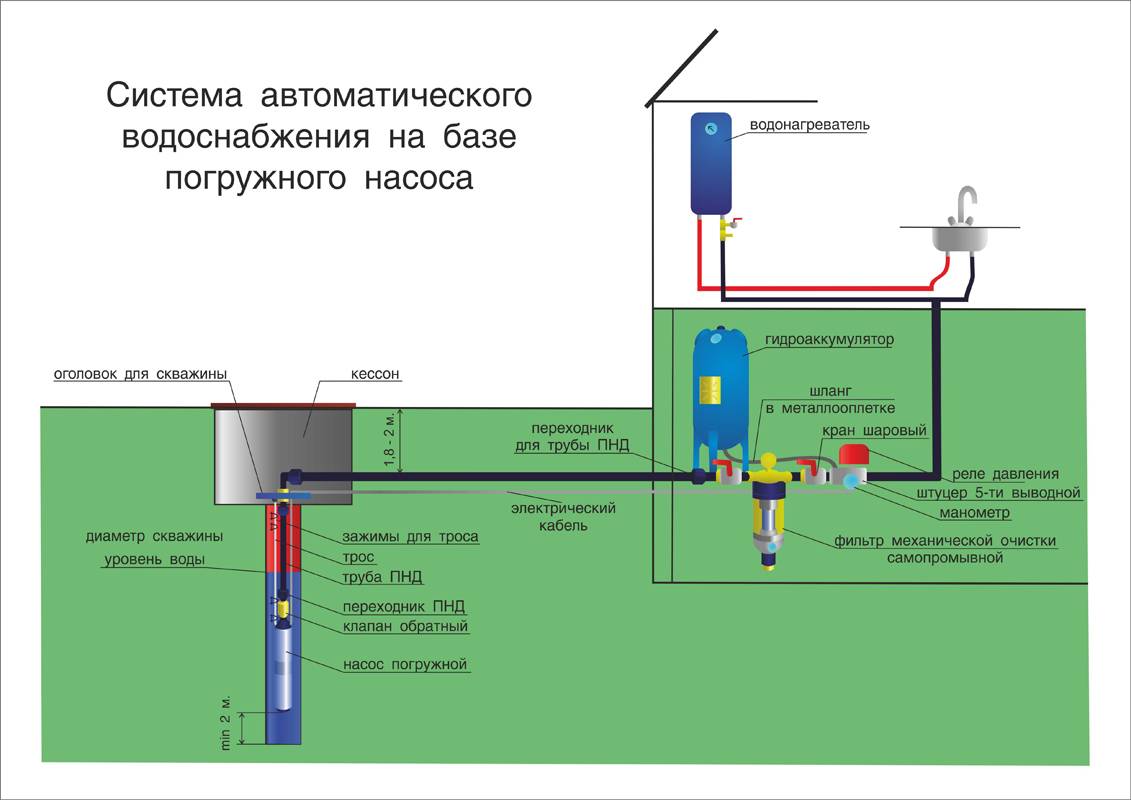

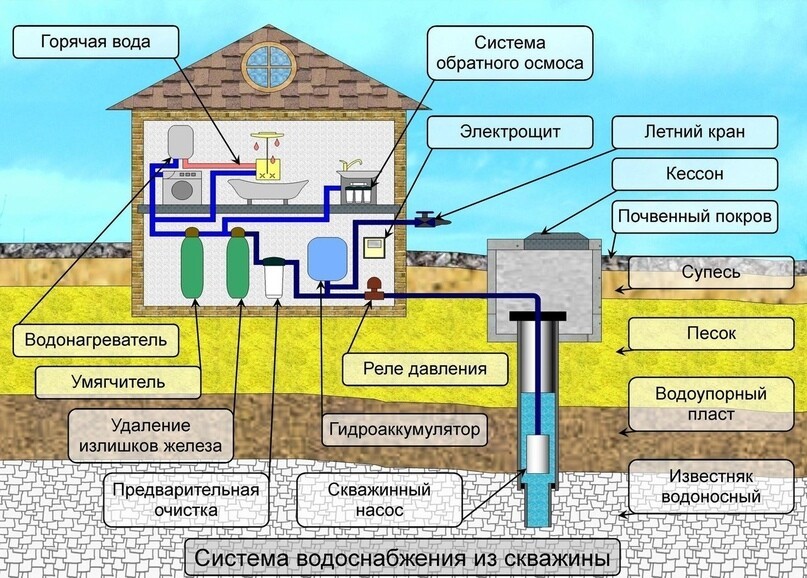

Artesian well: device diagram

There are several types of water intake designs. The most common among them:

- single-pipe;

- two-pipe;

- telescopic;

- with a conductor.

The choice of an artesian well device scheme depends on several factors:

- formation level;

- required performance;

- features of casing pipes;

- type of lifting equipment.

This is the simplest type of water intake arrangement. One pipe is installed in the drilled hole, which is used as casing and production at the same time. Its diameter is usually 133 or 159 mm.

This design can be chosen only in cases where the structure is built on limestone soil without sand and clay. In wells of this type, the water level is high enough that the pump can be installed at a depth of 2/3 of the pipe.

A single-pipe design is the most profitable, but its arrangement requires almost ideal geological conditions, which is rare.

A two-pipe system is equipped on limestone soils, where there are layers of clay. As a casing, a large diameter structure is installed - 159 or 133 mm. It protects the production pipe from pressure during soil movement.

The production string is a smaller section pipe - 133 or 117 mm. It is installed to the aquifer, and if the soil is unstable, then to the bottom.It can be metal or plastic. The choice of material depends on the geological conditions of the area and the personal preferences of the owner.

This artesian well device technology is used either on too dense soils, or on loose, prone to collapse. The design consists of pipes, each of which is smaller in diameter than the previous one.

The first performs the function of casing. The second one is also used as a casing and put up to a layer of limestone rock. The third is operational. It is the smallest diameter and, if the previous two are usually made of metal, then this one can be plastic. Install it to the aquifer.

This is a good option for soils with quicksand. The conductor is a separate wide pipe, the task of which is to cut off the quicksand. The pipe prevents destruction of the production string, protecting it from overpressure, and can be combined with the design of the caisson

Mounting a conductor is an expensive undertaking, and far from always there is a need for it. To determine how appropriate it is for a particular well, serious research is needed. They are carried out by professionals with special equipment.

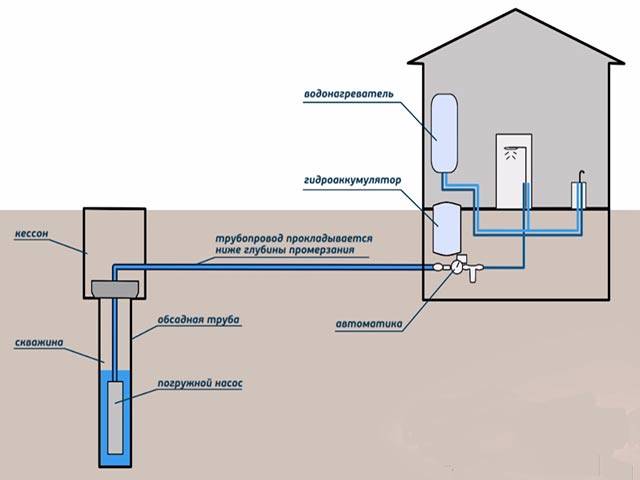

Equipment selection

The choice of equipment for arranging your future well is one of the most important stages, since the quality and duration of its work will depend on the right choice.

The most important equipment to pay attention to is: a pump, a caisson, a well head and a hydraulic accumulator

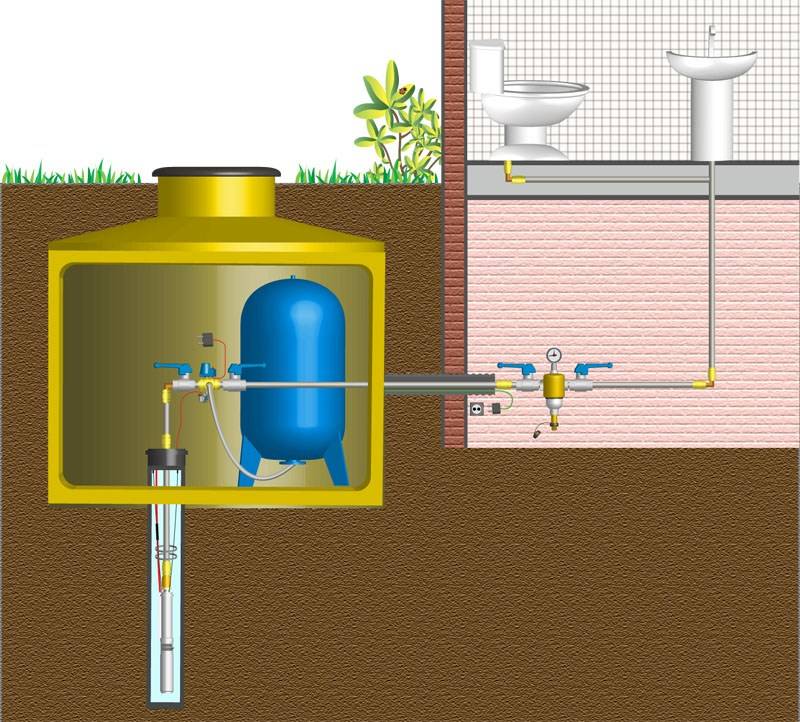

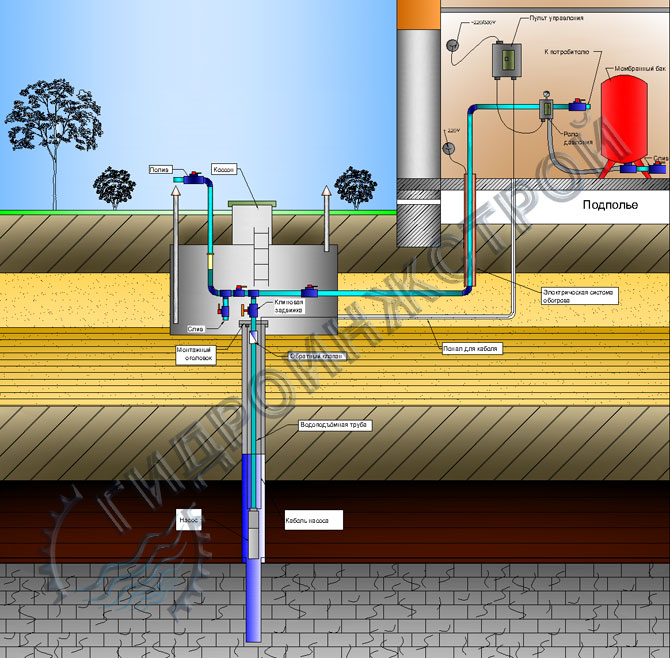

Caisson or adapter

The principle of arrangement with a caisson or adapter

The caisson can be called the main design element of the future well.Outwardly, it resembles a container similar to a barrel and is used to protect equipment from groundwater and freezing.

Inside the caisson, you can place all the necessary components for automatic water supply (pressure switch, membrane tank, pressure gauge, various water purification filters, etc.), thus freeing the house from unnecessary equipment.

The caisson is made of metal or plastic. The main condition is that it is not subject to corrosion. The dimensions of the caisson are usually: 1 meter in diameter and 2 meters in height.

In addition to the caisson, you can also use an adapter. It is cheaper and has its own characteristics. Let's consider below what to choose a caisson or adapter and what are the advantages of each.

Caisson:

- All additional equipment can be placed inside the caisson.

- Best suited for cold climates.

- Durable and reliable.

- Quick access to the pump and other equipment.

Adapter:

- To install it, you do not need to dig an additional hole.

- Fast installation.

- Economical.

The choice of caisson or adapter also follows from the type of well

For example, if you have a well in the sand, many experts advise paying attention to the adapter, since the use of a caisson is not always beneficial due to the short life of such a well

Pump units

One of the key elements of the entire system is the pump. Basically, three types can be distinguished:

- Surface pump. Suitable only if the dynamic water level in the well does not fall below 7 meters from the ground.

- Submersible vibration pump. A budget solution, it is rarely used specifically for the water supply system, as it has low productivity, and it can also destroy the walls of the well.

- Centrifugal borehole pumps. Profile equipment for water supply systems from a well.

Borehole pumps are widely represented on the market by a large variety of manufacturers, for every taste and budget. The selection of the characteristics of the pump takes place according to the parameters of the well and directly to your water and heat supply system.

Accumulator and relay

The key function of this equipment is to maintain a constant pressure in the system and to store water. The accumulator and pressure switch control the operation of the pump, when the water in the tank runs out, the pressure drops in it, which catches the relay and starts the pump, respectively, after filling the tank, the relay turns off the pump. In addition, the accumulator protects plumbing equipment from water hammer.

In appearance, the accumulator is similar to a tank made in an oval shape. Its volume, depending on the goals, can range from 10 to 1000 liters. If you have a small country house or cottage, a volume of 100 liters will be enough.

Hydraulic accumulator - accumulates, relay - controls, pressure gauge - displays

Well cap

To equip the well, a head is also installed. Its main purpose is to protect the well from the ingress of various debris and melt water into it. In other words, the cap performs the function of sealing.

headroom

Installation of plumbing in the house

If you intend to live in a country house permanently, then the next stage in the construction of a water supply system in the country with your own hands from a well or other source will be the installation of a water supply system in the room

It is important to choose the pipe material. Classic metal has given way to plastic and metal-plastic.The main reason for this is that modern materials have a number of advantages:

The main reason for this is that modern materials have a number of advantages:

- they withstand temperature extremes;

- resistant to the constant action of moisture both inside and outside (to water corrosion);

- they are not subject to air corrosion.

You need to work with pipes with the help of a special “iron” soldering iron, which can be purchased or rented at a quite affordable price.

Video: how to work with plastic pipes.

Installation of pipes is not very difficult, but requires accuracy. First you need to draw up a detailed scheme for supplying the system to supply all parts of the room - kitchen, toilet, bath, bath (if available). You can mount both on the lower path and on the upper one. This path is especially convenient if you plan to make a stretch ceiling, under which it is convenient to hide all communications.

After the installation is completed, it is imperative to install a special device that will regulate the pressure in the pipes in order to avoid gusts. This is an expansion tank. It automatically takes part of the water if there is an increase in pressure in the system, and gives it back in the event of a decrease in pressure. The principle of operation is shown in this diagram.

Typically, the tank can hold up to 100 liters of water as much as possible, and this is quite enough for an autonomous water supply. Externally, the device is mounted to the wall in the utility room.