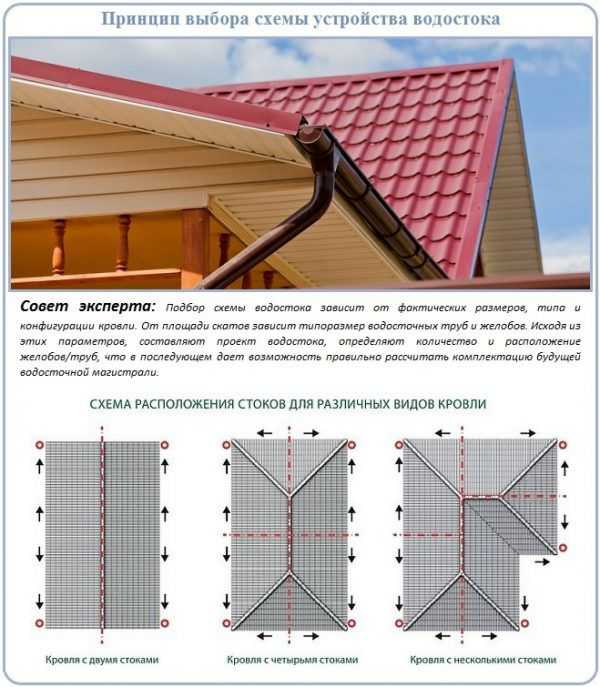

- Gutter: dimensions and role of the slope

- Plastic system for building roof

- Rafters with struts

- Materials for the device of an external drain

- Gutter system material

- Plastic

- Metal coated

- Other options

- Some features of operation

- Device

- gravity flow

- Siphon

- Technical requirements

- Design

- Metal gutters

- Plastic gutters

- Stage VI. Installation of horizontal gutter elements

- Features of mounting holders

- What is a flat roof?

- Useful video on the topic

- The choice of material of manufacture: what gutters to install

Gutter: dimensions and role of the slope

Actually, there are not so many classifications that separate different types of this element. Most often, the inlet channels are distinguished depending on the material of manufacture.

Thus, we should talk about:

- metal. As in any other situation, the main reason for preferring metal is rigidity and reliability. Due to the individual properties of the guides can last 30-40 years. Resistant to mechanical stress;

- plastic. In this case, there are advantages - lightness and immunity to corrosion.But on the other hand, their disadvantages are due to low strength and poor sound insulation;

- concrete. They were developed during the construction of high-rise buildings and the installation of a sidewalk drainage system. Due to the significant weight in the "home" construction is not used. In addition, the stone is not such an effective rival to water loads in the long run.

NOTE!

The choice in favor of metal gutters should be based on the provision of load on the structure of the roof and foundation. The steel will add serious stress to the outer edges of the walls and truss system.

Another characteristic by which modern drains are usually distinguished is the section. On this basis, the channels are divided into rectangular, square and round. Visually, all this can be understood immediately, hence the names in the classification.

As for the features and feasibility of using one or another type, rectangular drainage systems are used in regions where there is a large amount of precipitation. At low humidity parameters, square gutters are fixed, and round gutters are generally considered to be universal.

Gutter slope

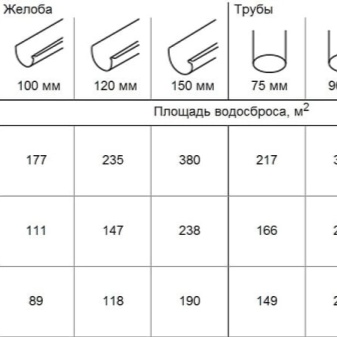

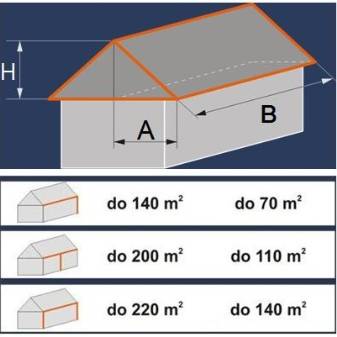

The length of the gutter is equal to that of the eaves of the house. Their number is determined for each slope separately. As for the width of the channels, this value depends on the area of \u200b\u200bthe roof. Below are the proportions using the example of the Profil gutter system instructions.

On the left is the roof area, on the right is the width of the drainage pipe:

- one riser at the edge: up to 70 sq. m - 90 mm, 70-140 sq. m - 130 mm;

- one riser in the center: up to 110 sq. m - 90 mm, 110-200 sq. m - 130 mm;

- two risers at the edges: up to 140 sq. m - 90 mm, 140-220 sq. m - 130 mm

In addition to the dimensions of the structure, pay attention to the slope

CAREFULLY!

CAREFULLY!

The slope of the depression is very important, because if the position is too flat, part of the liquid will not be transported to the composite pipe, and if the slope is large, the water flow will not be commensurate with the capabilities of the funnels. The slope of the gutter is 3-5 mm per linear meter.

Plastic system for building roof

Plastic roof drainage is not uncommon due to its diverse configuration and wide color palette. Faultless service for 30 years is possible with proper operation. The elements of the plastic system are connected using a special adhesive or rubber o-rings.

The advantages of a plastic drainage system from the roof of a house are light weight, neat appearance, reasonable price and easy installation.

Of the shortcomings, fragility at low temperatures and the possibility of damage during snow melting in winter deserve special attention.

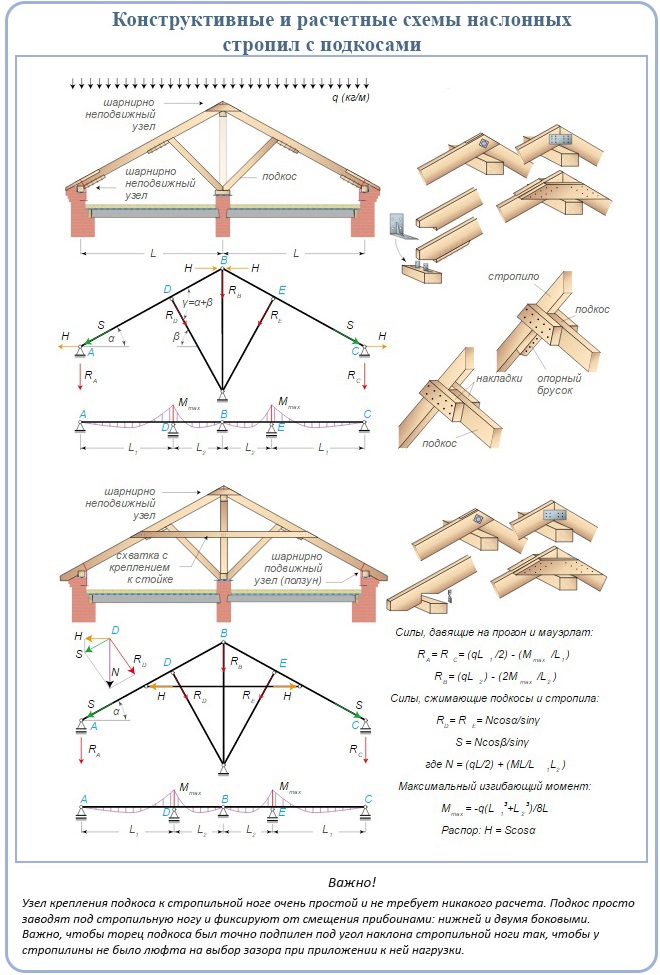

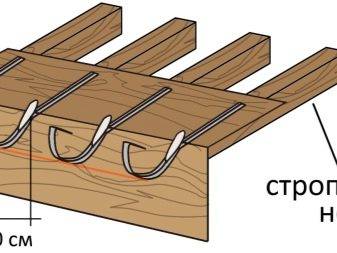

Rafters with struts

Such systems can be arranged both according to spacer and non-spacer schemes. Their difference from the options already considered is the presence of a third supporting part under the rafter leg - a strut (rafter leg).

The brace changes the system. The rafter from a single-span beam turns into a two-span continuous one. This allows you to increase the overlapped span, up to 14 m. And also - to reduce the cross section of the rafters.

The brace is connected to the rafter in such a way as to prevent its displacement. This is done as follows: the brace is brought under the rafter and fixed with wooden plates on the sides and bottom.

Materials for the device of an external drain

As such for drains are used:

- Cink Steel.

- Copper.

- PVC.

The first is most often used in apartment buildings. This is an inexpensive option, and also of no value to thieves. The advantage of such systems was the fact that they began to be produced in different colors; this is achieved either by applying a polymer coating or painting.

The first is most often used in apartment buildings. This is an inexpensive option, and also of no value to thieves. The advantage of such systems was the fact that they began to be produced in different colors; this is achieved either by applying a polymer coating or painting.

Copper has recently become widespread both in private houses and in restoration work: sometimes this material matches the color of the roof of an old building. The only disadvantage of copper is its high cost.

Plastic weirs can even be made from sewer pipes, although specialized products are also available. They are cheap, easy to assemble and easily replaced with similar ones in case of failure, because they weigh a little.

Gutter system material

More recently, the main raw material from which gutters were made was metal, more precisely, galvanized sheet. Even earlier, gutters were made from ordinary steel sheet, which was painted. The latter gradually went out of circulation. Galvanization is still used today, because the material has a presentable appearance, copes well with natural loads and has good technical characteristics.

Gutter system made of galvanized sheet

Gutter system made of galvanized sheet

Scientific and technological progress does not stand still, and today the question of what to make a drain from means the possibility of choosing from several materials. To pure galvanization, galvanized metal coated with a polymer composition and purely plastic are added. Consider their pros and cons.

Plastic

A big plus of plastic is that the material does not corrode when it comes into contact with water. Hence the long service life.For other benefits plastic drainage system relate:

- the ability to operate under almost any temperature conditions;

- one hundred percent inertness to ultraviolet;

- presentable appearance, indicated by huge possibilities in terms of color design;

- lightness of construction.

plastic drainage system

plastic drainage system

The only thing that plastic products are afraid of is shock loads, under the influence of which they crack and become unusable.

About plastic brackets. It will not be possible to bend them, to give the necessary shape to the mount. In this regard, metal ones are better, they are easier to customize. Therefore, when installing plastic brackets, it is necessary to accurately install them on the frontal board, taking into account the landing site and the height of the roof overhang. True, today manufacturers offer adjustable products in which you can change the angle of inclination using a swivel. A good option, which proved that in the category of plastic brackets it is the most convenient.

Metal coated

According to their characteristics, in terms of service life, the products will not yield to plastic ones. But there is one serious drawback - the polymer layer itself. It is not strong enough and can be easily scratched or peeled off with little force using a sharp tool.

Therefore, it is important not to spoil the protective polymer coating during the installation of the gutter on the roof.

Metal gutter systems with polymer coating

Metal gutter systems with polymer coating

There is no protective layer even on a meager area, you get a defect through which water begins to penetrate to the metal sheet.The consequence is metal corrosion, reduced service life.

Other options

It should be noted that on the market you can find exclusive water drainage systems made of copper or aluminum alloys, titanium and zinc. Firstly, the products are marked by long-term operation of the structure and increased reliability. Secondly, a design approach to solving the problem of decorating the facade of a house. But exclusive gutters are not cheap, so they are rarely purchased by the general mass of consumers.

Some features of operation

Clogging is the most common problem in drains. To avoid it, outdoor systems need an annual inspection and, if necessary, manual cleaning. For an internal drain, it is better to leave revision tees with plugs.

Clogging is the most common problem in drains. To avoid it, outdoor systems need an annual inspection and, if necessary, manual cleaning. For an internal drain, it is better to leave revision tees with plugs.

The destruction of funnels by ice is a problem for outdoor systems. Sometimes, because of this, it is necessary to change the funnel, and even parts of the gutter adjacent to it. A modern means of combating frost is the installation of heating cables powered by the network and located in the gutters. Even special fasteners for such cables are sold.

It is desirable to place the internal drain pipe in a sleeve made of extruded polystyrene foam or polyethylene foam. You can also use cotton wool, but the latter also requires foil strapping. The fact is that cold water flowing through the pipe can cause condensation to form on nearby walls and mold growth. Waterproof insulation solves this problem.

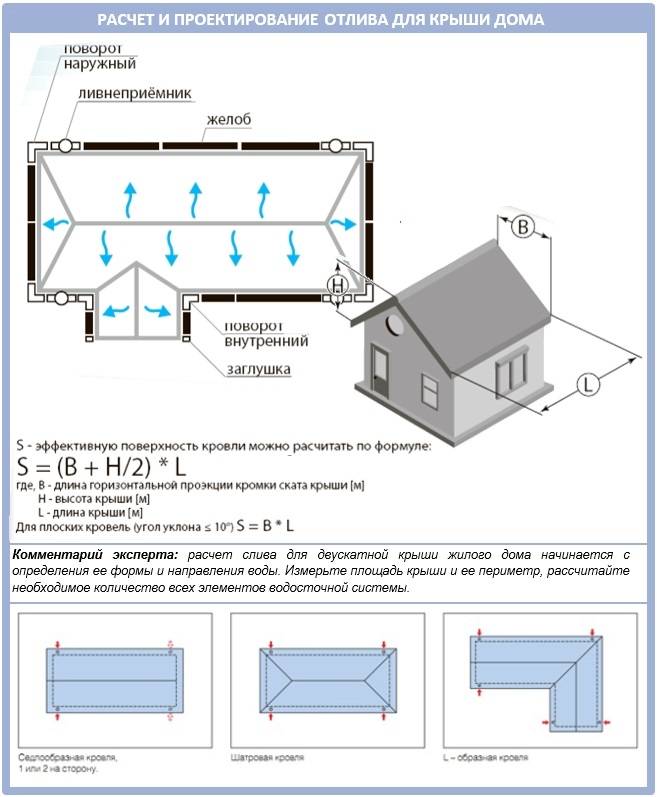

Device

Drainage facilities on flat roofs are equipped with two types:

gravity flow

They collect and freely discharge precipitation along chutes installed with a slope. However, the pipes are not completely filled with water.

Siphon

The main principle of their work is to completely fill the drainpipe with precipitation, as well as the formation of a water column that originates at the water inlet and ends near the outer outlet of the stream.

With a decrease in the level of precipitation, there is a forced suction of liquid from the receiver into the riser. This method is considered more effective than self-flowing, however, for it to work all the time, careful sealing of all joints is required due to the exact match of the diameter pipes used, as well as the use of those materials with which high-quality sealing can be achieved.

A characteristic feature of siphon structures is the presence of flow stabilizers. They help guide water and prevent air from entering the system, which is usually installed using the butt welding method.

The advantages of this design are obvious and are that:

- with light precipitation, it can work as a gravity one, and with an excess of melt or rain water, it perfectly eliminates it;

- its device requires a smaller number of water inlets and risers than for gravity, and the pipes used can be smaller in cross section, which allows decrease expenses;

- due to the rapid movement of precipitation, the system can self-clean.

On a flat roof, the main function of collecting and receiving water is assigned to the funnel. Typically, such a device consists of:

- cover covering the top of the product;

- grating that protects the drain from contamination by foreign objects and rubbish;

- rings that give the funnel tightness;

- water intake bowl, from where water is redirected to the drain;

- release - a special fitting, located horizontally or vertically.

The kit also includes a gland to help seal the outlet with a downpipe, a flange or bolt with which the water receiver is attached.

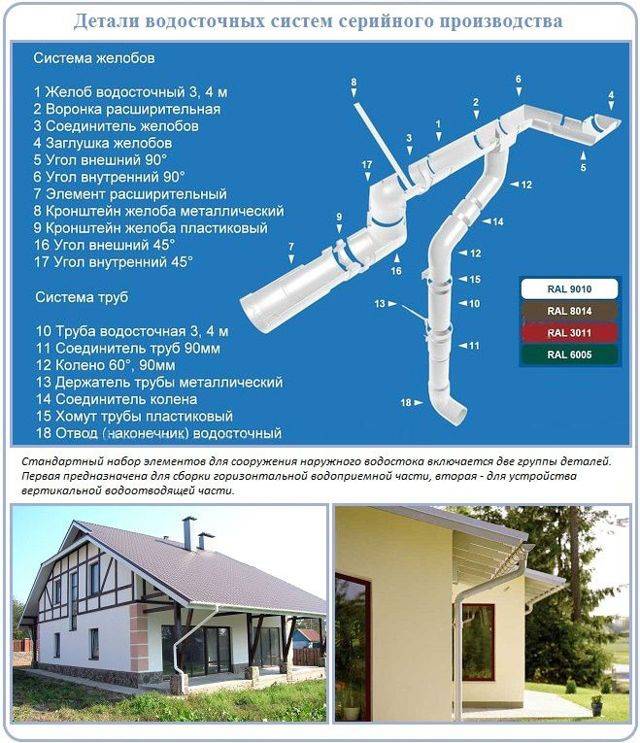

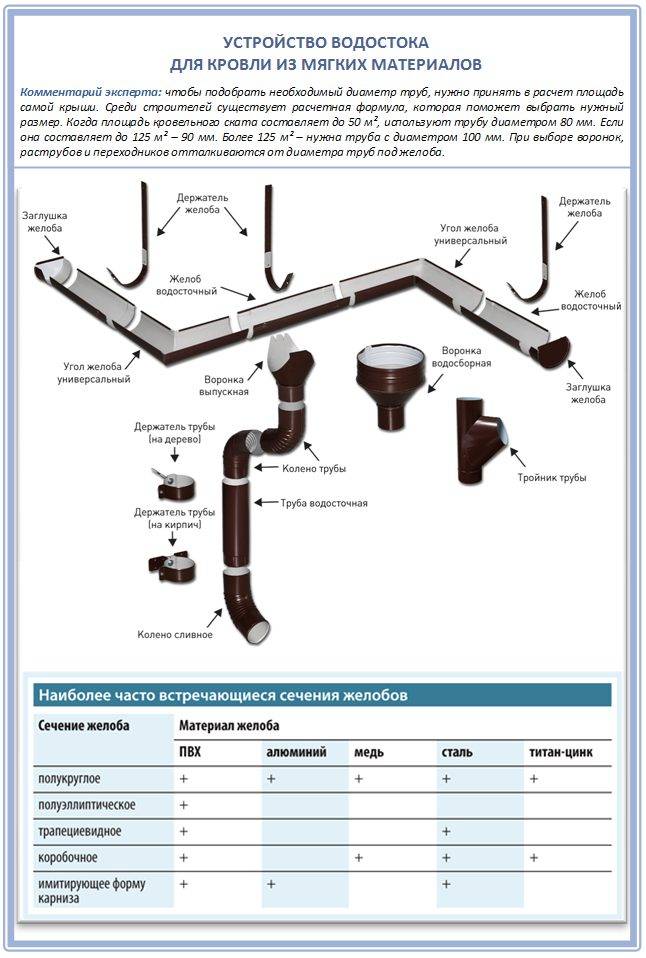

Technical requirements

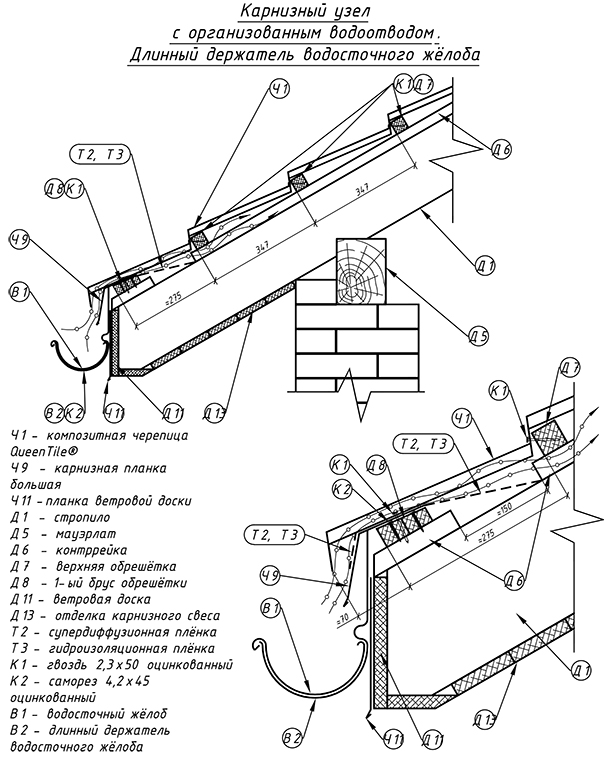

The number of brackets according to SNiP is calculated according to the standard distance between the fasteners, which should be 50-60 cm. To calculate the required number of fasteners, the total length of the system must be divided by this distance. If the building has a non-linear shape, then you can calculate the total with respect to each wall. Corner elements must be counted in pieces, since the drains located at the corners must be adhered to on both sides.

Brackets can be attached in several ways.

- To the roof truss system. This option is suitable for roofing material that has not yet been laid.

- To the wind board. This option is the only one in case the ebbs are made of plastic. With other materials, this is one of the possible options.

- To the last board of the sheathing under the roofing material, if it is solid.

This method is also suitable if the roofing material has not yet been laid. GOST suggests that the brackets should be mounted taking into account the slope of the system created. The easiest way is with metal options, since they can be bent with improvised means.

According to all the same regulatory parameters, the gutter must be placed so that the roof covering ends before reaching half of the gutter. The correct location of the gutter is 1/2-1/3, this will allow the system to capture water even during heavy rain showers.

If the region of your residence is not snowy, and the roof has a sufficient slope, you don’t have to worry too much about the location of the structure.If a low gutter does not work, then additional snow retainers can be installed. The snow will come off the roof little by little and will not harm the storm system.

In addition to fasteners, it is important to correctly calculate the number of pipes and gutters. It is also worth considering that if the diameter of the system is displayed incorrectly, then it will not be able to divert the required amount of water from the roof, or it will cope, but it will turn out to be unreasonably expensive

There are certain principles for calculation.

- For surfaces with a total area of slopes up to 50 square meters, pipes of 75 mm and gutters of 100 mm are used.

- For surfaces ranging from 50 to 10 square meters, pipes with a diameter of 87 mm and gutters of 125 mm are used.

- For roofs with a quadrature of more than 100 square meters, pipes with a diameter of 100 mm and gutters of 150 mm are relevant.

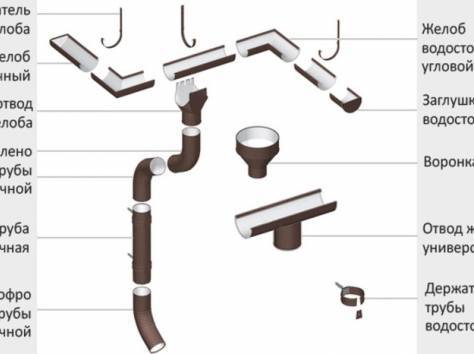

Design

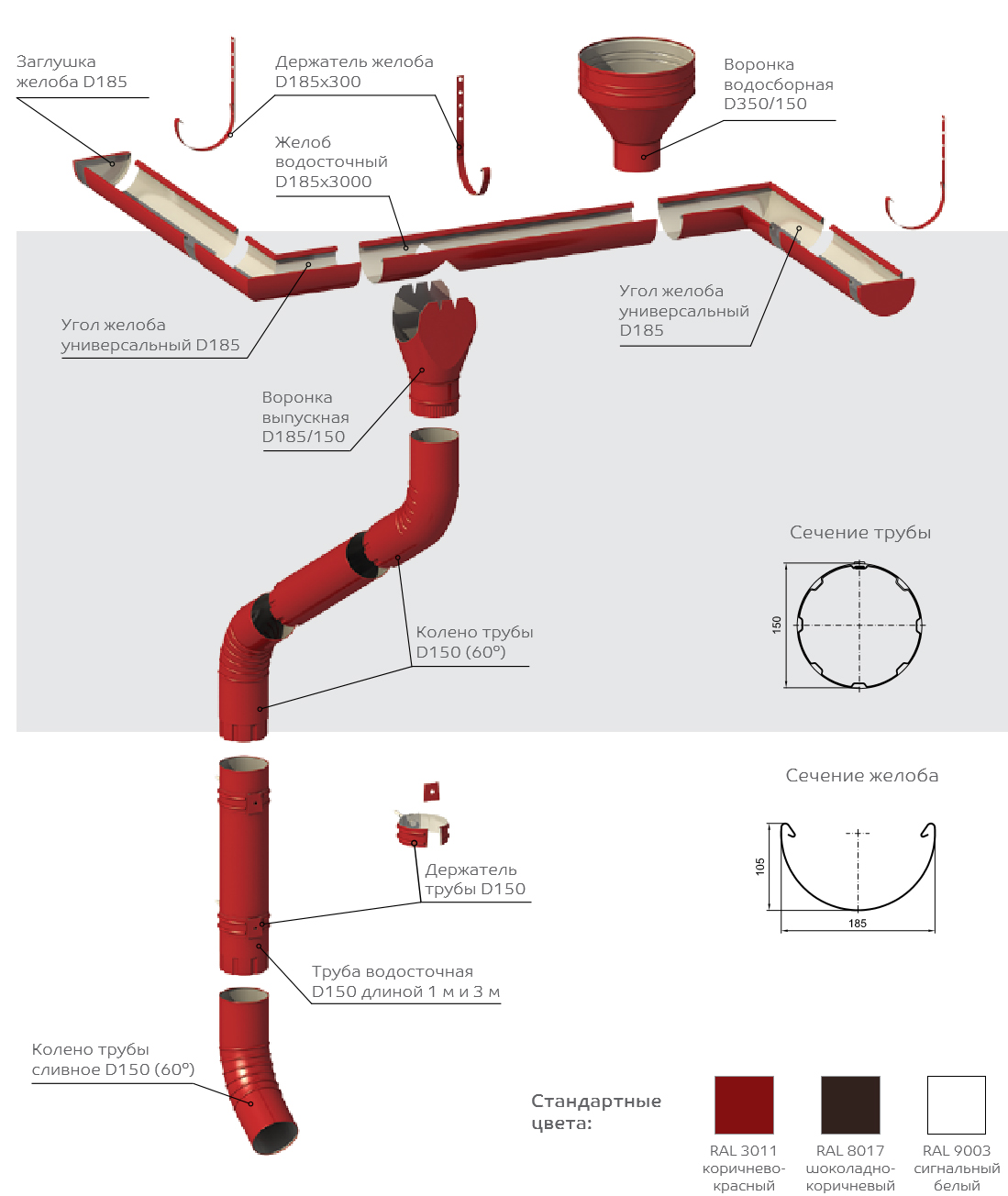

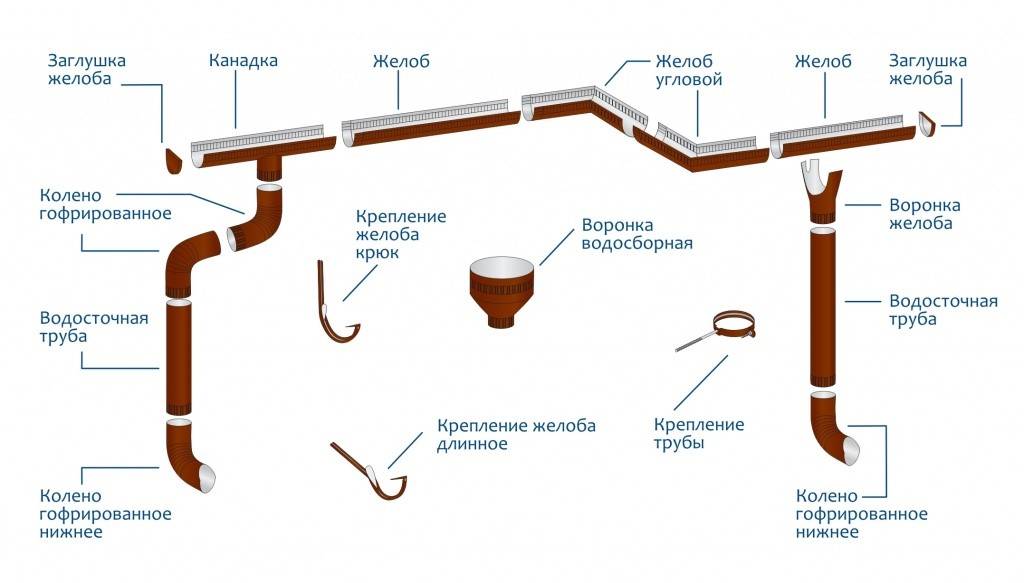

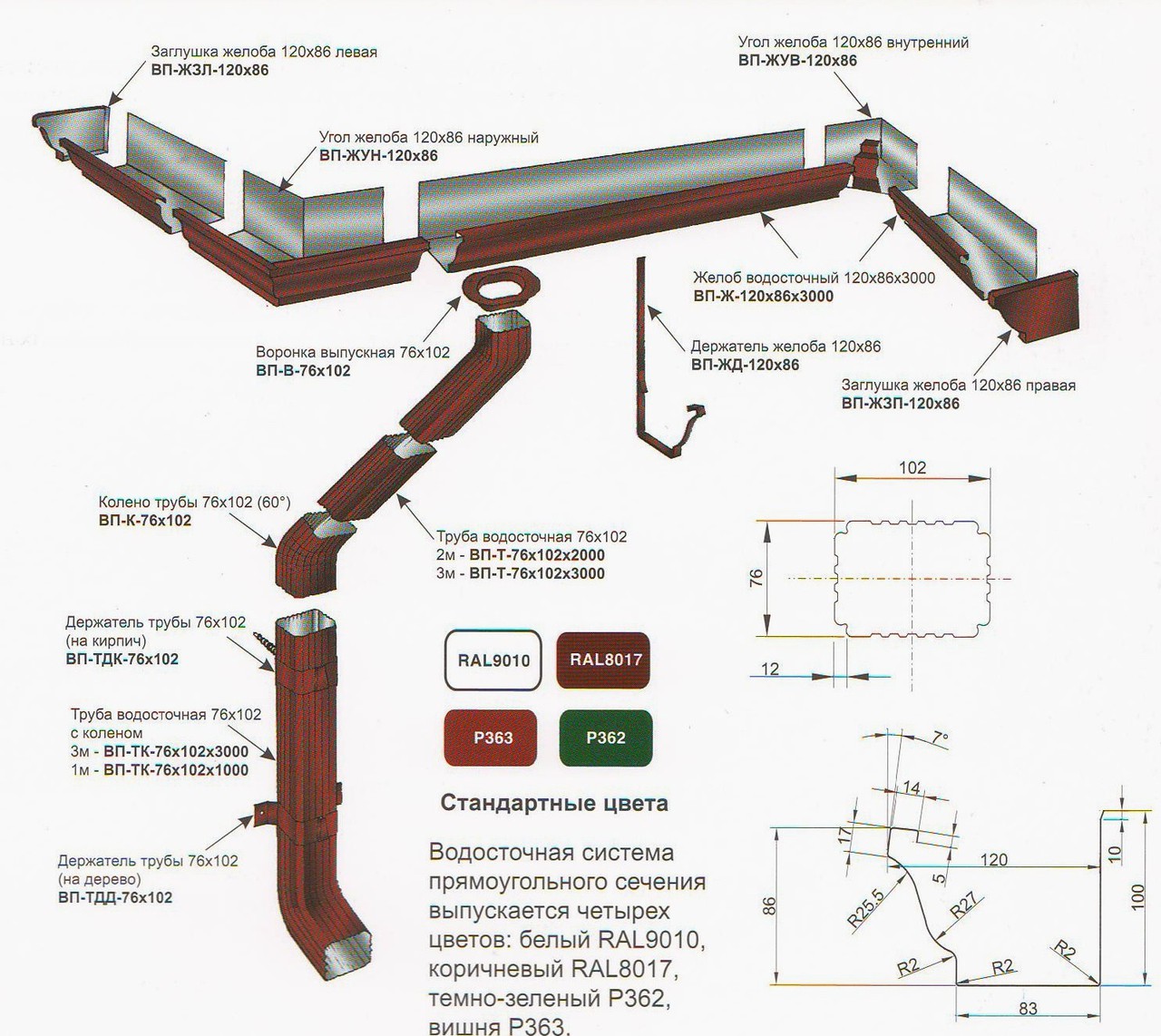

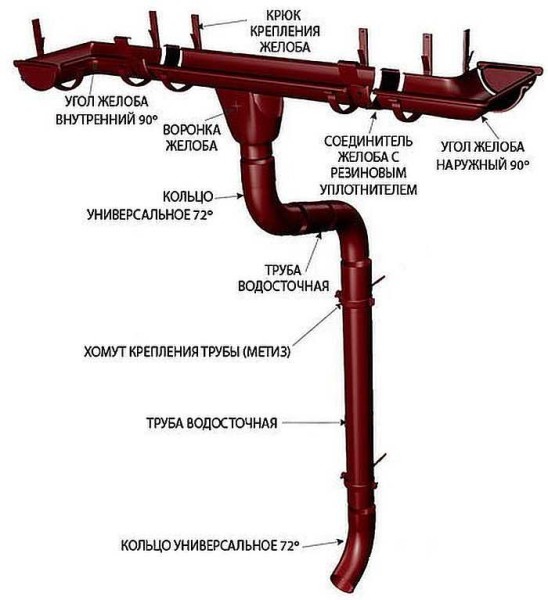

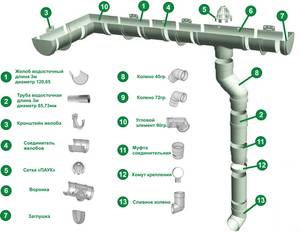

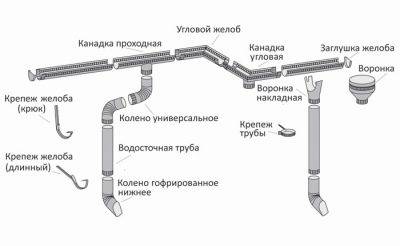

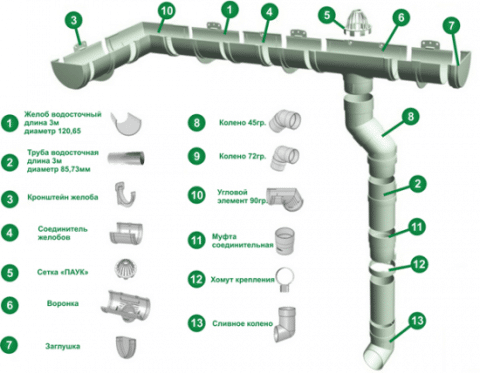

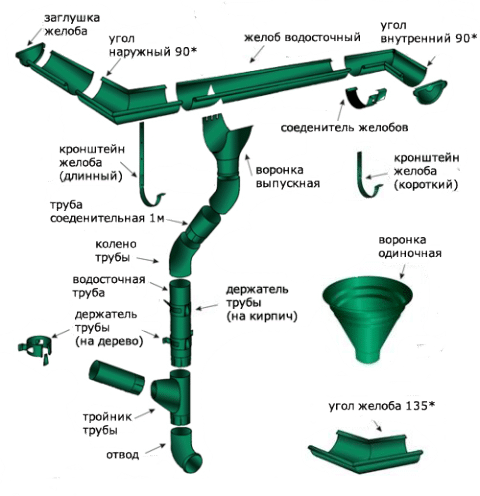

Roof gutters are devices needed to collect water from roof slopes and deliver it to storm sewers. The device of the drainage system is a collection of pipes. It includes the following elements:

The design of the external roof drainage system

- Gutters. Gutters are semicircular or rectangular halves of pipes. They are mounted around the perimeter of the building so that the liquid from the slopes does not spoil the wall decoration material, but leaves the blind area of the house in an organized manner. They are produced in different diameters to fit any area of slopes and the amount of precipitation.

- Drainage funnels. Drain funnels are devices that resemble a funnel in appearance. They are mounted on a gutter to redirect the liquid to the storm sewer.

- Water plums. Vertical pipes that are connected to a gutter through a water intake funnel are called a drain.Through them, melt and rain water enters the sewer. Usually, when developing a drainage scheme for a roof, several drains are placed in different places in the house. Gutters are located above the storm sewer grate so that the water pouring from them does not erode the soil or concrete pavement around the house.

- Brackets. Brackets are called hooks needed for fastening. With their help, plums, gutters are fixed on the walls and cornices of the building. The strength of these elements determines whether the gutter can withstand the weight of snow or collapse.

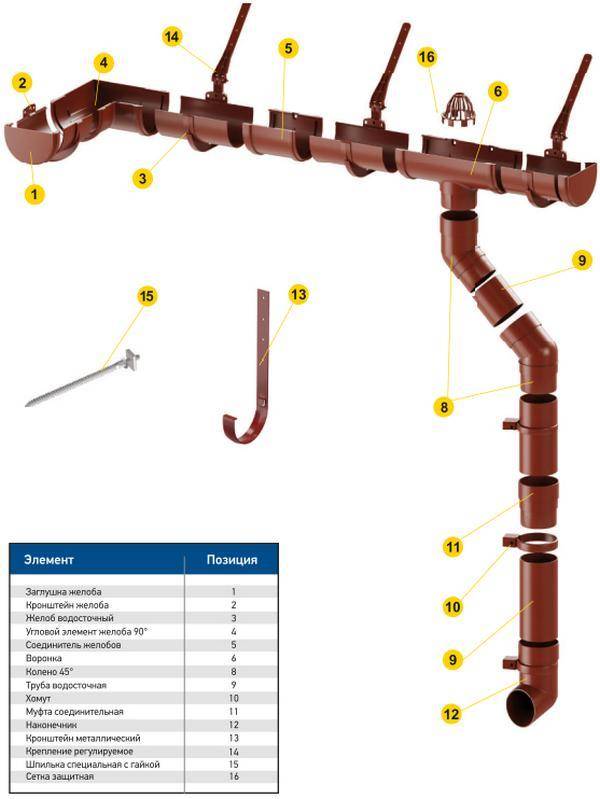

Metal gutters

Products for the equipment of an external drain from metal are very popular. They are made by pressing from zinc-alloyed steel. As a rule, they have a semicircular shape, in rare cases rectangular. Self-installation of metal gutters is so common due to the following qualities:

- High resistance to corrosion. Galvanized steel does not react, so it does not rust. Due to this, metal products for ensuring the drainage of water from the roof have a long service life.

-

Mechanical strength. The construction of gutters, funnels and drains made of metal is strong enough to withstand a significant snow load. Branches falling from trees and falling debris do not harm or damage structural elements.

- Resistant to temperature changes. The strength of steel does not decrease either in extreme heat or in frost. Even a sharp drop from positive to negative temperature does not affect its integrity.

- Fire resistance. The steel parts from which the gutter system of the house is equipped do not burn and do not support combustion, and therefore comply with strict fire safety standards.

Plastic gutters

To reduce the load on the roof truss frame, manufacturers have developed additional elements for assembling a drain made of plastic or, as it is correctly called, polyvinyl chloride. It differs from metal models:

- A light weight. Plastic drains, gutters and funnels weigh several times less than the same galvanized parts. Therefore, the installation of plastic gutters is possible even on old roofs, in which it is simply risky to increase the load on the rafters.

- Diverse color palette of elements. Even the most budget manufacturers offer their customers a choice of 6-8 colors. If we talk about expensive products, then the range of shades is not limited to a dozen items, so you can easily match the color to match the roofing material or walls of the house.

-

Complete tightness of connections. Plastic models of gutters, drains and funnels are connected into a single system more hermetically, so leaks in it occur less frequently.

- Complete selection of accessories. The range of elements for assembly is a paradise for owners of non-standard roofs, the corners of which are not 90 degrees. This diversity allows for many individual configurations.

- Affordable price. The price for plastic products, according to construction consultants, is 1.5-2 times lower than for high-quality metal products.

Stage VI. Installation of horizontal gutter elements

Modern galvanized gutters are connected with brackets, latches, locks or rubber gaskets. The easiest to install is a special snap-on design:

- Step 1. All gutters must be aligned symmetrically in the center so that the joint remains 3-4 millimeters between them.

- Step 2Now pull the front of the connector up to the gutter and snap the lock into place.

- Step 3. The next step is to lock the lock itself, for which return the latch to its original position.

- Step 4. Next, at a distance of 10-15 centimeters from the connection of the gutters, install additional hooks.

- Step 5. Now the gutter curl must be inserted into the corner curl to a depth of 2-3 cm, and then sealed.

- Step 6. Fix the connection point with two rivets and install an additional gutter connector.

- Step 7. The curl on the plugs must be wound at an angle, and turned in the opposite direction. You should feel that the plug is inserted into the gutter until it stops. For sealing and fixing, use special glue. But on the back of the gutter, the plug must be fixed with rivets.

- Step 8. Now we mount the funnel. Hook its front edge to the front edge of the chute and turn the funnel in its direction so that the fixing plate is bent inside the chute. Optionally, insert the "spider" into the funnel at this stage.

- Step 11. At the last stage, we make the transition from the funnel to the drainpipe. To do this, you need two universal elbows. Consider water drainage at the bottom.

- Step 12. Mount the gutter corner pieces according to the marks as you did with the funnel and gutter connectors.

- Step 13. Then install the plugs at the ends of the gutters so that the distance to the gable roof boards is at least 3 centimeters.

- Step 14 Start pipe installation from the funnel. If the roof extension is small, then use a coupling or coupling outlet.

- Step 15 Install the pipe bracket and leave 10mm to compensate for thermal expansion - this is a very important point.

Here is a good tutorial on this topic:

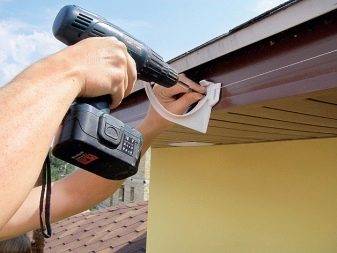

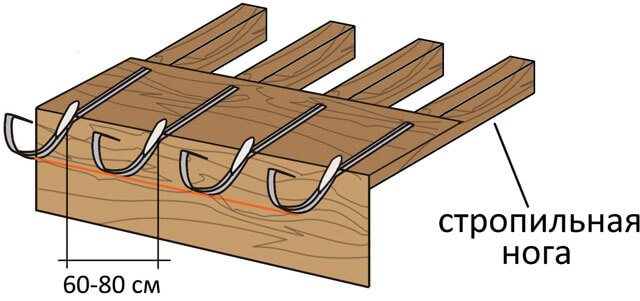

Features of mounting holders

To solve the problem of how to drain from the roof, you need to learn that each type of bracket has its own mounting method. In the first case, the hook is installed on the base of the roof, so before fixing it must be bent along the slope of the slope. The second option involves a simple mounting of the holder to the frontal board.

First of all, the brackets supporting the funnels are fixed. Then the distance between the installed elements is divided by the recommended step between the holders (for plastic elements it is 60 cm, for metal - 90 cm). To create the desired slope of the gutters, a rope is pulled between the extreme supporting elements.

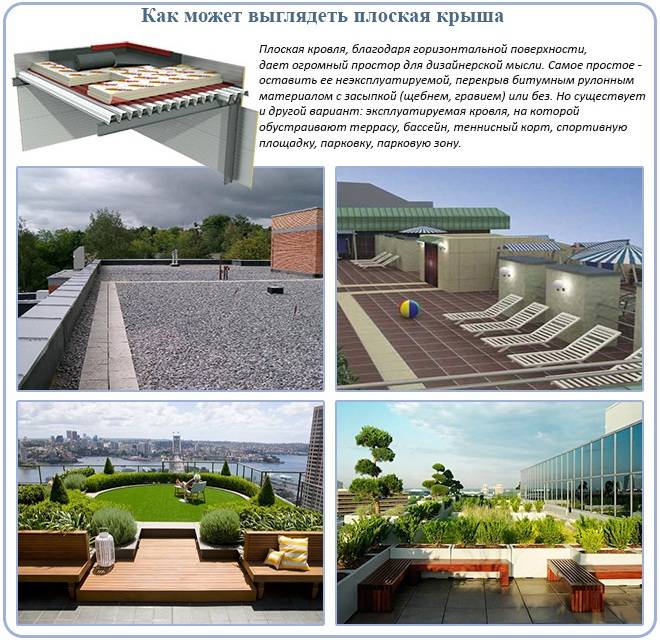

What is a flat roof?

Let's start with the basics. In fact, a flat roof only visually gives the impression of absolute horizontality. There is still a slight slope - 1-5 ° (1.7-8.7%). Visually and during operation, it is completely imperceptible, however, it allows atmospheric precipitation to flow freely to the catchment points - this is its main task.

Unlike pitched counterparts, a flat roof does not have a truss frame and, in fact, is a horizontal ceiling resting on the walls of the building. Its feature is in the reinforced layers of heat and waterproofing, which are necessary due to the communication of the roof with the environment.

The attractiveness of a flat roof for developers is justified by the following advantages:

- Reduced price. Compared to a pitched roof, a flat roof has a smaller area, and therefore the cost of materials is lower.

- Simplified installation and further maintenance. The arrangement of a flat structure is simpler than a pitched one, since it is easier to move along a horizontal plane than along an inclined one. For the same reason, various maintenance measures for the roof itself and the devices located on it (chimneys, fans, antennas, etc.) do not differ in complexity.

- The possibility of obtaining additional usable area (with an exploited roof). The surface of a flat roof can be easily used as a terrace, a walking area and even ... a garden with a real lawn.

The main element of a flat roof is a solid foundation: reinforced concrete slabs, corrugated board or a solid surface made of boards, plywood, OSB, DSP (when roofing on wooden beams). The very same roofing is made of several layers. Their number, location in the structure and materials of manufacture depend on the purpose of the roof and its type.

Types of flat roofs:

- Unexploited roof. The simplest, not carrying any additional functions, except for protecting the premises from environmental influences. It is not used for arranging places of recreational or household purposes. All that is required of it is a sufficient protective function, the ability to withstand snow and wind loads, as well as the weight of workers conducting maintenance activities. That is, during the construction of such a roof, the calculation is carried out on the fact that 1-2 people can be on it at the same time, and not constantly, but only for the period of maintenance and repair of the coating.

- Operated roof. It is equipped to perform some additional functions, except for directly roofing.For example, sports grounds, terraces, parking lots, lawns are planted and flower beds are laid out on exploited roofs.

- Inversion roof. It is characterized by an unconventional placement of layers - heat-insulating mats (EPS) are laid almost at the very top of the pie. Waterproofing is mounted under a layer of insulation. This solution helps to extend the life of the waterproofing coating, and, accordingly, the roof itself. Inverted roofs can be both operated (most often) and non-operated.

Useful video on the topic

We have selected video materials that will visually present the process of assembling and installing metal gutters.

Video with detailed animation instructions for drain installation for long hooks:

Video recommendations of professionals for installing a gutter system on short brackets:

The process of installing a drainage system with a rectangular cross section:

assembly and metal gutter installation somewhat more complicated than the same steps for installing the polymer version. Mistakes cost more. However, it is quite possible to cope with the work with your own hands, if you learn the intricacies of installation.

The choice of material of manufacture: what gutters to install

Galvanized steel products should not be considered for installation on a residential building. The low cost of materials will not make the installation cheaper: installation will take a lot of time, and it is almost impossible to hermetically assemble handicraft-made parts. Steel covered with a thin protective layer of galvanization will begin to rust in 2 to 3 years, you will have to install a new system. Modern budget drains are made:

Made of plastic - PVC.

Made of metal with polymeric protective coating.

Aesthetic appearance and reasonable price: the advantages of plastic gutters

Inexpensive plastic parts can last for decades without breaking. Components are made from polyvinyl chloride - a polymer based on acrylic resins. Gutters and pipes are ultralight in weight, easy to transport and do not require special skills during installation.

Elements of the plastic system

Plastic systems are perfect for installation on low one-story residential buildings, outbuildings, garages, country houses. Mounted on old roofs with fasteners on the wind board. Manufacturers recommend PVC for organizing a drain on the roofs of attic floors: plastic trays are almost silent, unlike metal ones.

The material is quite fragile and does not differ in strength. Subject to mechanical damage, especially at low air temperatures. Therefore, when choosing a system for installing a plastic roof drain in a region with a cold climate, it is worth considering the simultaneous installation of a heating cable. The roofing is equipped with the obligatory presence of snow retainers in order to reduce the risk of damage to the drain when snow melts.

Gutters made of metal with a polymer layer belong to the middle price category. Parts are made of steel alloy, several layers of polymer are applied on top to protect the box from water. When calculating the drainage system, the price of installation should also be taken into account: it is difficult to install metal-plastic parts on your own. The gutters are quite heavy; it is impossible to mount the trays alone at a height.

Metal-plastic drain: details

When assembling, you need a special tool and skills to work with metal: metal-plastic parts cannot be cut with a grinder or a nozzle on a drill. The polymer coating is sensitive to temperature; when overheated, it exfoliates. Also, metal-plastic products require careful handling during loading and transportation: the surface must be closed. Scratches on the polymer are conductors of water to the metal base, respectively, rust quickly forms at the points of damage.

Metal-plastic is the best choice for:

Drainage assembly for country cottages of large area and height.

Installation of trays on rafters - it is allowed to increase the interval between fasteners up to 90 cm.

Installations in difficult climatic conditions.