- Properties of copper pipes

- Non-metallic pipes

- Polypropylene

- Polyethylene

- metal-plastic

- PVC

- Product types

- Installation steps

- Copper pipe marking

- Pipe selection based on operating conditions

- Applications of copper pipelines

- Extracts from standards and requirements EN1057 for copper drinking piping.

- How to choose copper pipes for heating?

- Main technical characteristics of copper pipes

- How to choose the right copper pipes?

- We carry out installation of copper pipes for heating systems

- Pipeline development

- Varieties of copper pipes

- Scope and limitations of use

- Specifications of steel water pipes

- Light pipes

- Ordinary pipes

- reinforced pipes

- Threaded pipes

- Methods for the production of copper pipe products

- Types of pipes

Properties of copper pipes

When arranging a water supply system, the optimal cross-section of pipes is always taken into account, which determines the throughput of a particular product. If the pipeline is installed from pipes with a small cross section, after a while the plumbing equipment may break down, because the pressure in the network is too high. On the contrary, pipes that are too thick will entail additional costs due to their high cost, while their installation is completely unjustified.

The sizes of a copper water pipe can be found in the copper pipe size table, which lists all types of pipe products manufactured by manufacturers.

Non-metallic pipes

The main factor contributing to the widespread use of non-metallic water pipes is their durability and low cost. Scale and rust do not form on the inner walls of plastic products.

Their service life can exceed half a century, and installation and repair are much cheaper than metal counterparts. Moreover, maintenance or replacement of plastic plumbing does not require welding, which means that any homeowner will be able to do it, with some experience and tools.

Polypropylene

This type of product is characterized by increased strength and durability. Polypropylene pipes used for hot water supply will surely last 25 years or more, and for cold water - over 50. The material is very light, which has a positive effect on ease of installation and transportation.

This type of product is characterized by increased strength and durability. Polypropylene pipes used for hot water supply will surely last 25 years or more, and for cold water - over 50. The material is very light, which has a positive effect on ease of installation and transportation.

An important positive property is the invariability of the characteristics of polypropylene, even with a sharp fluctuation in temperature and freezing of water.

When installing a polypropylene water pipe, fittings are used at bending points. Due to the increased rigidity of the material, bending it in the usual way is unacceptable.

Polyethylene

Plumbing from this material is highly reliable, due to the ability to withstand pressure up to 16 atmospheres. Despite many positive aspects, polyethylene products are not widely used.

The temperature range in which they can be operated is from -40 C to +40 C.Given the low heat resistance, coupled with a fairly large rate of linear expansion, such a plumbing may not always be a suitable option for a home.

The undeniable advantages of a polyethylene plumbing unit include:

- increased strength;

- resistance to low temperatures;

- inertness to many chemicals present in water;

- fittings used for installation do not interfere with the patency.

metal-plastic

The product has a multi-layer construction, in which the outer and inner layers are made of plastic, and in the middle - of metal. This results in increased strength at low weight.

The elasticity inherent in metal-plastic pipes allows them to be given various shapes. The positive properties include excellent thermal conductivity of the product, easy and convenient installation.

Vulnerabilities in the metal-plastic water supply - connections

When carrying out work, you need to pay increased attention to the quality of the installation of fittings. The fact is that with sudden changes in temperature, aluminum shrinks faster than plastic and high pressure in the system can lead to an emergency.

PVC

Polyvinyl chloride pipes are in many ways superior to plastic counterparts in terms of strength and resistance to aggressive chemicals, and the allowable pressure in such a water supply system can reach 46 atmospheres.

Polyvinyl chloride pipes are in many ways superior to plastic counterparts in terms of strength and resistance to aggressive chemicals, and the allowable pressure in such a water supply system can reach 46 atmospheres.

Resistance to high temperatures allows the use of PVC plumbing for hot water. It confidently withstands temperatures up to 90 degrees Celsius.

Installation does not cause any particular difficulties and you can do all the work with PVC plumbing yourself without welding.In the process, only couplings and angles are needed, which makes installation cheaper compared to analogues for which you need to purchase fittings.

Product types

When installing a plumbing system from 32 mm HDPE pipes, you will need connecting elements for various purposes and configurations. Any pipeline never consists of one straight section.

It has turns, branches, branches, muffled ends.

Brass fittings for HDPE pipes 32 mm (as well as for lines of other diameters), the following types are used:

- bends - these elements are designed to change the direction of the pipeline at an angle from 45 to 120º;

- tees - allow you to create a separate branch on the main line at an angle of 90 degrees;

- cross - connects four segments in two mutually perpendicular directions;

- coupling - connects two pipe segments of the same diameter, which are laid in one straight line;

- adapter sleeve - allows you to reliably connect two sections with different diameters lying on the same straight line;

Brass fittings of different types (tees, bends, straight lines)

- plugs (caps, plugs) - allow hermetically sealing the free end of the pipe;

- fitting - a connecting element for connecting to the main pipeline (water source) or the container in which it is located;

- nipple - a specialized tube with an external thread at both ends, which allows you to make a connection with a pipe or fitting.

The system, consisting of 32 mm HDPE pipes, can be mounted using polyethylene fittings. And many builders do just that, arguing such actions with the low cost of materials. But for HDPE pipes 32 mm, it is preferable to use connectors that are made of brass.

One of the reasons why it is worth paying a little more is the strength characteristics of the materials and the possibility of repeated use.

Brass fittings can provide a hermetic connection of HDPE pipes with a diameter of 32 mm and a wall thickness of 2.4 mm, with a guaranteed absence of leaks.

This is due to the fact that the compression ring (it is also made of brass) has a kind of thread on the inner surface, which, when the nut is tightened, is pressed into the polyethylene structure. Thus, when the pipe is stretched (deformed) under external physical impact, the connection will not be broken.

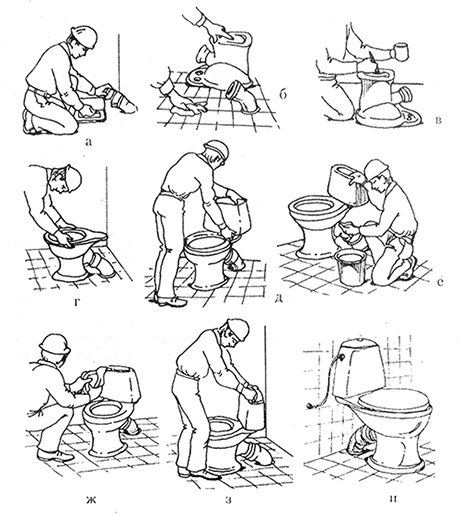

Installation steps

Before proceeding with the process of assembling the pipeline, you must do the following:

- Cut HDPE pipes 32 into sections according to the required length in separate sections.

- Prepare brass fittings of the required type (configuration) for connecting individual segments.

- Check compliance with the general plan by laying out the individual elements of the pipeline in the required sequence at the place of its passage.

After making sure that everything is in place, you can start assembling. The principle of connecting pipes with a brass fitting is the same for all its configurations:

Step-by-step installation of brass fittings on HDPE pipe

- it is necessary to clean the ends of the pipes after they have been cut with a pipe cutter or a metal hacksaw;

- apply a mark that shows that the pipe has entered the fitting as far as it will go;

- lubricate the end of the pipe for easier entry into the fitting;

- unscrew the union nut of the fitting by 3-4 turns;

- insert the pipe (according to the label);

- tighten the nut.

The sequence of application of parts when installing a brass fitting

In order to be sure of the future tightness of the connection during the installation of each individual element of the pipeline, experts recommend unscrewing the union nut completely. This is due to the fact that, after almost complete disassembly of the connecting node, it will be possible to verify two important circumstances:

- all internal parts of the fitting are in place and in working order (the rubber ring requires special attention);

- during the subsequent final assembly, it is possible to visually check the correct position of all rings (crimp, inner, rubber).

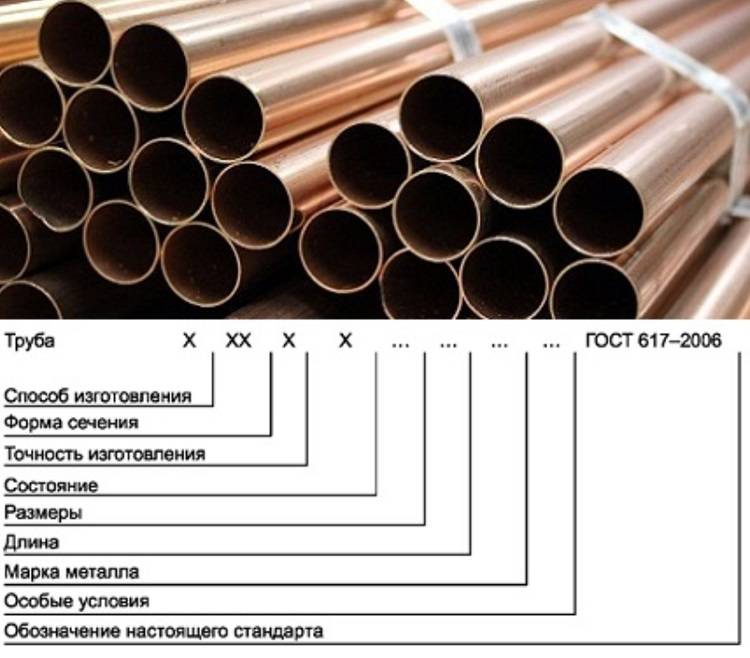

Copper pipe marking

To determine the technical characteristics of the selected pipes, it is enough to correctly read the marking, which is applied in accordance with GOST 617-19.

The label must indicate:

- the method used in the manufacture (D - drawn, G - pressed, and so on);

- section of the manufactured pipe (for example, KR - round);

- accuracy in production (N - normal, P - increased);

- type (M - soft, P - semi-hard, and so on);

- outer diameter (diameters of all pipes made from copper are indicated in mm. It is unacceptable to indicate the diameters of copper pipes in inches);

- wall thickness (in mm);

- segment length;

- the grade of copper that is used for manufacturing.

Symbols on a copper pipe

For example, DKRNM 12*1*3000 M2:

- D - drawn pipe;

- KR - has a circular cross section;

- H - has normal accuracy;

- M - soft;

- outer diameter 12 mm;

- pipe wall thickness is 1 mm;

- pipe length 300 mm;

- the pipe is made of M2 grade copper.

Pipe selection based on operating conditions

The distribution of the water supply network is designed to supply the medium to plumbing fixtures. The main parameter to consider when choosing is pressure. Depending on the material of manufacture, its value can vary from 2.5 to 16 kg / cm². For internal installation, only metal pipes can be used without restrictions. Polymeric and metal-polymer products have some restrictions not only on pressure, but also on the temperature of the transported medium.

If the installation of the system is carried out in a private house, then the owner has the right to decide for himself which pipes to choose for the water supply. Most often, polypropylene structures with threaded fittings are used. Installation of such products can be done independently.

The arrangement of an external water supply system is carried out using pipes with an external protective coating to give the material increased anti-corrosion properties. Depending on the temperature of the liquid, the material of the product is selected. To decide which polypropylene pipes are better to use - low-temperature or designed for extreme temperatures, it must be remembered that the latter have a service life that is 2 times less than that of products with a normal thermal load.

To replace carbon steel products with polymer ones, it is necessary to use a variant with a design pressure not lower than that of the previously used ones.

Applications of copper pipelines

The areas of use of copper pipes are very numerous.

Most often, such pipes are used in the following systems:

- in heating pipelines;

- in water supply systems (both hot and cold);

- in pipelines transporting gas or compressed air;

- in freon supply systems in refrigeration equipment;

- in hydraulic systems for oil supply;

- in fuel pipelines;

- in condensate removal systems;

- when connecting technological equipment;

- in air conditioning systems and others.

1/4 copper pipe is used to connect the outdoor unit of the air conditioner with the indoor

Extracts from standards and requirements EN1057 for copper drinking piping.

For a more accurate consideration of this issue, consider the norms according to SanPin (EN1057 clause 3.1) drinking water supply systems. These standards include the following requirements:

DIN 4046 standard - water for human use and satisfaction of its needs, must have all the quality features - corresponding to the current regulation, in particular, the "Ordinance for drinking water", DIN 2000 and DIN 2001 standards.

Drinking water systems are installed according to DIN 1988 (TRWI). Drinking water supply systems, according to DIN 1988, part 1, are all pipelines and / or devices that make up the system, which provide water supply to the tanks for the treatment and consumption of drinking water, included in the central and / or individual water supply systems. The regulations specify the exact distinctions.

In drinking water supply systems, it is not recommended to treat water in any form for the purpose of anti-corrosion protection.

There are many pathogenic bacteriacapable of reproducing in heated drinking water supplies. That's why pipelines must be installed in accordance with the requirements of the DVGW Worksheet W551 “Drinking water heating systems; pipelines for drinking water; technical measures to reduce the growth of the number of pathogenic bacteria”.

Mandatory regulation for drinking water pipelines AVB-Wasser V (requirements for general conditions for the supply of water) is valid for all elements of the pipeline, and therefore for the pipes themselves, they are subject to requirements for manufacturing in compliance with recognized rules and technologies. The order notes that the presence of marking with the quality mark of a recognized control service confirms the fulfillment of these requirements.

COPPER PIPES, meeting these requirements, are allowed for use in pipelines of cold and hot drinking water supply.

Copper as a material is suitable for drinking water without any restrictions if the drinking water complies with the requirements and conditions of DIN 50930

An important quantity is

the value of the pH of the water, which, according to the requirements, should be in the range of 6.5 ... 9.5. And also drinking water must be neutral to the content of free carbon dioxide, according to DIN 50930, part 5, the coefficient of content of free carbon dioxide in water Kv 8.2 should not exceed 1.00 mol / m. cube

cube

For central water supply systems, data on pH and Kv 8.2 should be provided by the water supply services, and in separate or individual systems, provided by local services.

The minimum permissible nominal inner diameter of pipes for drinking supply systems, according to DIN 1988, part 3, is DN 10 (corresponds to a copper pipe 12x1). Frequently used pipes with parameters 18x1 correspond to DN 16.

Engineers, designers and installers are strongly advised to use only pipes that have passed DVGW inspection and are marked with the DVGW quality mark (EN1057).

For the connection of copper pipelines in cold and hot drinking water systems, the rules specified in the DVGW Worksheet GW 2 and information publication 159 "Copper pipe connections" apply. The following is essential - since temperatures above 400°C are used in brazing, the formation of scale and film, unfavorable from the point of view of hygiene, on the inside of the pipeline is possible. Therefore, in copper pipes for drinking water supply with a diameter of up to 28 mm inclusive, it is allowed to make connections only by low-temperature soldering - soft soldering. And also for pipes with these diameters, annealing for bending or making a socket is not recommended. Accordingly, pipes with a diameter greater than 28 mm do not have such restrictions.

How to choose copper pipes for heating?

Example of laying copper pipes

For the organization of heating systems, galvanized, steel and copper pipes are traditionally used. In this article, we will analyze in detail the advantages and disadvantages of the latter.

Main technical characteristics of copper pipes

- Resistant to high temperatures. Copper can withstand temperatures up to 600 degrees;

- Products are not subject to corrosion;

- High price. Copper is considered one of the elite materials;

- Poor compatibility with other materials;

- Rather complicated installation, made with the help of fittings and soldering;

- Durability;

- Due to the fact that the pipe has a relatively low internal pressure, its walls can be quite thin;

- The product is excellent for organizing hidden wiring due to its resistance to corrosion;

- The operating temperature range is extremely wide: from -200 to +500 degrees;

- Installation of a heating system in an apartment building, taking into account different product configurations, is carried out quite quickly;

- The product is versatile. It can be used both in a private and in an apartment building;

How to choose the right copper pipes?

The optimal diameter of pipeline elements for heating systems is 12-15 mm. This diameter ensures good pipeline geometry. Joints are made using tees or fittings. You can connect the pipeline to the heating boiler using standard connection blocks. Both fittings, and tees, and connection blocks can be purchased at any specialized store. In order not to make a mistake with the choice, it is recommended to look at the reviews before buying.

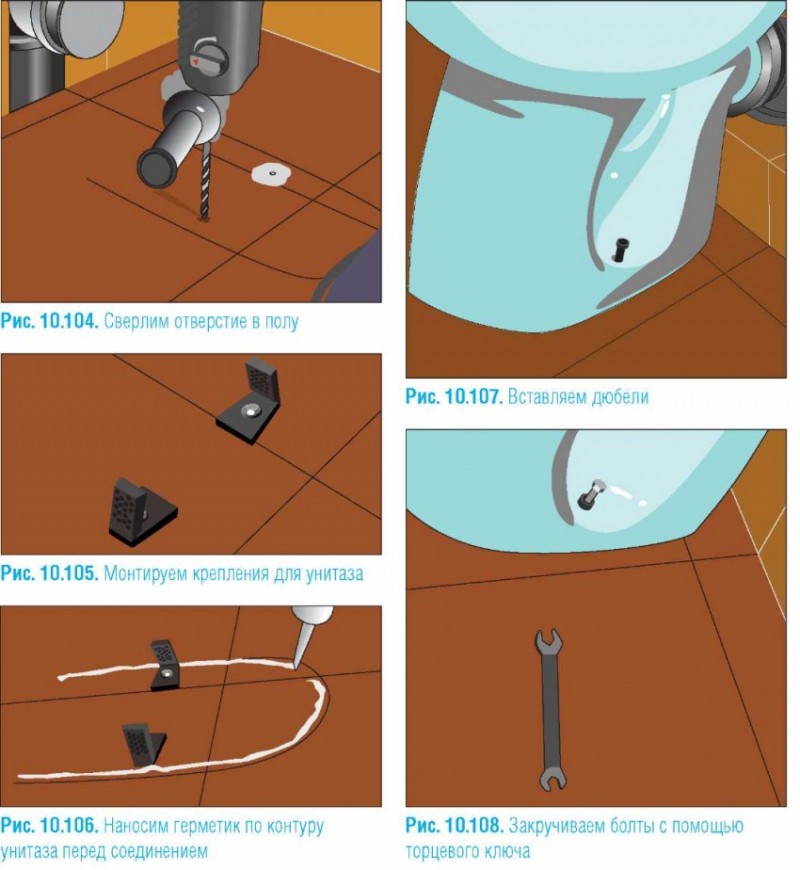

We carry out installation of copper pipes for heating systems

To get started, you need to stock up on the following tools:

- Mechanical or manual pipe cutter. It should be selected based on the technical characteristics of the pipes;

- Sander or sandpaper;

- Special gas burner or soldering iron.

Let's start installation:

It is required to draw up a plan for the heating system. On this diagram, it is necessary to indicate the places where it is planned to place the batteries;

Using a pipe cutter, pieces of the desired length are cut from the copper pipe

It is important to ensure that the ends of the products are strictly perpendicular;

The edges of the products are processed until the burrs and roughness are completely eliminated. The joint area is cleaned with a fine-grained skin;

Flux is applied to the pre-prepared end of the copper pipe

Then the product is inserted all the way into the fitting or radiator;

We apply solder intended for copper heating systems to the joint area;

Solder is applied to the joint area

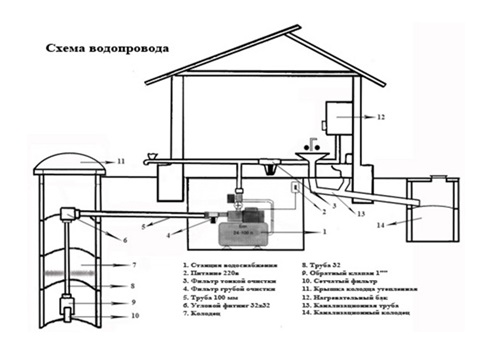

Pipeline development

Before the direct assembly of pipes and installation of the pipeline, it is necessary to develop a general scheme of the system, according to which it is possible to calculate:

- the number of required pipes of a certain diameter;

- the number of fittings that will be installed at the branching of the system, at the places where pipes are bent, at the places where plumbing equipment is connected;

- the number and installation locations of additional equipment (water heaters, pumps, mixers, taps, valves, and so on).

Plan of the plumbing system of a country house

A well-designed scheme is the key to the successful operation of the system. Therefore, it is more expedient to develop the scheme together with qualified specialists.

Varieties of copper pipes

Copper pipes can be classified according to several criteria:

- according to the method of manufacture are divided into the following types:

Heat treated copper pipes

To increase the strength index, annealed pipes can be made with a protective sheath.

Copper pipes of various diameters

- section type. Copper pipes can be produced in round or rectangular shapes. The latter are widely used for drainage systems;

Rectangular copper pipes

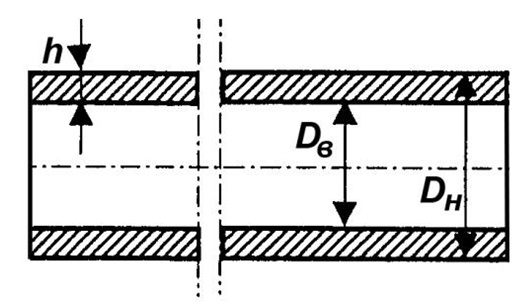

- dimensions. For various pipelines, it is necessary to correctly select not only the outer and inner diameters, but also the thickness of the pipe wall.

Pipe parameters to be considered when selecting

Scope and limitations of use

Rolled copper pipes are used in various communication systems for domestic and industrial purposes.

Water pipes. Traditionally used in the arrangement of water supply for various purposes. The characteristics of copper and an extensive range of rolled pipes allow you to equip highways of different capacities and footage.

Sanitary copper is neutral to the low concentration of chlorine contained in drinking water (the norm is not more than 0.5 mg / l). Copper piping has proven itself in storm drains and sewerage systems

Heating network. A double effect is achieved. On the one hand, the durability of operation due to corrosion resistance, on the other hand, the protection of the system from unregulated temperature fluctuations of the coolant. The use of a copper pipeline with an insulating sheath is justified in "warm floor" systems.

Gas pipeline. The convenience of rolled copper lies in the tightness of the line. When transporting gas, there is no oxidation and galvanic corrosion. The reliability of pressed joints and adhesions increases the safety of the gas pipeline in areas with seismic activity.

Fuel system. Due to the neutrality, copper fittings are used in networks for pumping fuel oil - there is no risk of ignition, the formation of a static charge.

Copper tubes are used in gas water heater heat exchangers, hydraulic and braking systems of vehicles and aircraft, refrigerator cooling circuits and climate systems

Nuances and limitations of application:

- The limiting velocity of liquid transportation in the water supply system is 2 m/s. Compliance with the recommendation will extend the life of the "plastic" line.

- Copper is a soft metal and constant contact with a medium filled with solid particles can lead to “washout” of the walls. To prevent the formation of erosion, it is desirable to provide preliminary cleaning of water from foreign suspensions. It is enough to install a coarse (mechanical) filter.

- Under favorable conditions, an oxide film appears on the inner walls of the copper main - the coating does not impair water quality and protects the metal from wear. Requirements for the formation of patina: acidity of the water flow pH - 6-9, hardness - 1.42-3.42 mg / l. With other parameters, cyclic destruction and restoration of the film occurs due to the consumption of metal.

- Do not use lead solder for the installation of drinking water supply - the metal and its compounds are toxic. The substance is able to accumulate in the body, exerting a gradual detrimental effect on various organs.

Docking of copper communications with a pipeline made of brass and plastic is acceptable. When combining copper pipes with steel and aluminum elements, the joining sequence must be followed.

Connection rule: sections of other metals should be placed in front of copper pipes in the direction of circulation of the coolant. In reverse order, electrochemical corrosion occurs

Specifications of steel water pipes

State VGP standards also apply to such technical characteristics as length and weight.

According to GOST 3262 75, the length of the finished product can vary between 4-12 m

Taking into account this parameter, this type of product is divided into 2 categories:

- measured length or a multiple of the measured length - all products in the batch have one size (a deviation of 10 cm is permissible);

- unmeasured length - in a batch there may be products of different lengths (from 2 to 12 m).

The cut of the product for plumbing should be done at a right angle. The permissible bevel of the end is called a deviation of 2 degrees.

There are special requirements for galvanized products. This zinc coating shall be a continuous thickness of at least 30 µm. There may be areas on the threads and ends of the finished product that are not zinc plated. Places with a bubble coating and various inclusions (oxides, hardzinc) are strictly prohibited - such products are considered defective.

According to the wall thickness of the product are divided into 3 types:

- lungs;

- ordinary;

- reinforced.

Light pipes

A feature of light pipes is the small wall thickness. Of all the possible varieties of VGP, light types of this rolled metal product have the smallest thickness. This indicator varies from 1.8 mm to 4 mm and directly depends on the outer diameter of the product.

The weight of 1 meter in this case is also characterized by the lowest rates. Products with an outer diameter of 10.2 mm in the amount of 1 m weigh only 0.37 kg. Thin-walled products should be chosen if the object is subject to increased requirements in terms of weight. However, water supply using such rolled metal has a limited scope. The liquid pressure in such pipes should be no more than 25 kg / sq. cm. When marking products with light weight, they are designated with the letter “L”.

Ordinary pipes

Rolled metal of this type has an ordinary wall thickness. This indicator varies between 2-4.5 mm. The main influence on this characteristic is the diameter of the product.

Ordinary steel pipes are considered the most common, they should be chosen in cases where there are no special requirements for laying water pipes.

The list of advantages of this type of rolled metal should include:

- optimal weight - in comparison with thick-walled products, such products can reduce the total weight of the finished structure;

- the allowable pressure has the same indicator as for thin-walled ones (25 kg / sq.m), however, hydraulic shocks are acceptable here;

- average cost - achieved due to the weight indicator.

When marking a special designation of an ordinary pipe, there is no. The letter designation is assigned only to light and reinforced products.

reinforced pipes

Products of this type include those steel pipes that have an increased wall thickness - from 2.5 mm to 5.5 mm. The weight of such a finished structure will be very different from the weight category of a structure made of light and even ordinary products.

However, such water and gas pipeline systems also have an advantage - they are suitable for objects with high pressure (up to 32 kg / sq. cm). When marking such pipes, the designation “U” is used.

Threaded pipes

The quality of threaded steel pipes is controlled by GOST 6357 and must fully comply with accuracy class B.

To achieve high quality products, the thread must meet several important requirements:

- be clear and clean;

- the presence of burrs and flaws is not allowed;

- a small amount of blackness may be present on the threads of the thread (if the thread profile is reduced by no more than 15%);

- according to GOST, there may be broken or incomplete threads on the thread (their total length should not exceed 10% of the total);

- the gas supply pipe may have a thread, the useful length of which is reduced by 15%.

Methods for the production of copper pipe products

The sizes of copper pipes are different. When arranging domestic systems, two types of copper products are usually used:

- unannealed (more details: "Types of copper unannealed pipes, characteristics, areas of use");

- annealed.

The first type of pipe is sold in straight sections with a length of 1 to 5 meters.

In the second case, the products undergo heat treatment - they are fired, after which they become soft, and the strength characteristics decrease slightly, but the installation of copper fittings becomes easier. Annealed pipes are sold to consumers in lengths from 2 to 50 meters, packed in coils.

In addition to products with round sections, manufacturers produce rectangular products. Such pipes, due to their non-standard shape, are difficult to manufacture and therefore their cost is higher compared to conventional products.

Types of pipes

Those who want to buy copper pipes for plumbing should pay attention to their type. There are pipes:

Solid samples are made from more durable copper, it practically does not deform and is really expensive.

This option is appropriate when assembling the central channels of the water supply system, as well as in the case when it is planned to transport a medium under high pressure in the pipe.

Solid samples are made from more durable copper, it practically does not deform and is really expensive.This option is appropriate when assembling the central channels of the water supply system, as well as in the case when it is planned to transport a medium under high pressure in the pipe.

By and large, they are high-pressure pipes, as they have thickened walls and an increased strength class.

The second option is better suited for creating household water distribution. Soft copper pipes have thin walls and are easily deformed. A sample of small diameter can even be bent by yourself without using a pipe bender, which is often used by plumbers.

They are cheaper and easier to handle, but they are inferior to competitors in terms of strength characteristics.