- General installation tips and helpful video

- Plumbing in private homes

- Which pipes are suitable

- HDPE products

- PVC materials

- Polypropylene Products

- Summer water supply in the country: features of arrangement

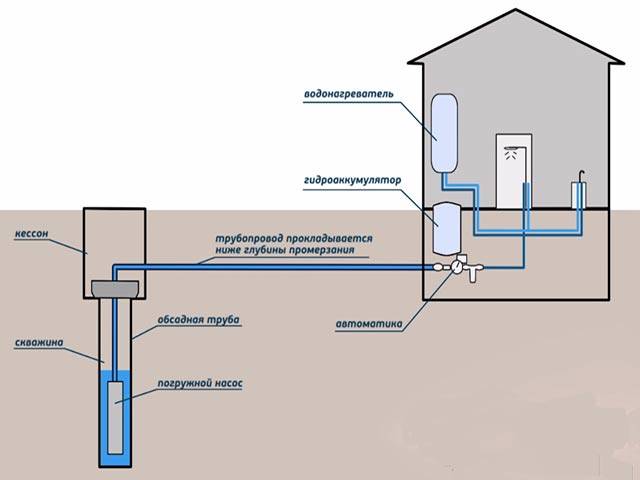

- Water for autonomous water supply

- thermal insulation

- How to raise water from a well: choose the right pump

- water intake

- Centralized water supply

- Well

- Well

- Sources of water supply

- Centralized water supply

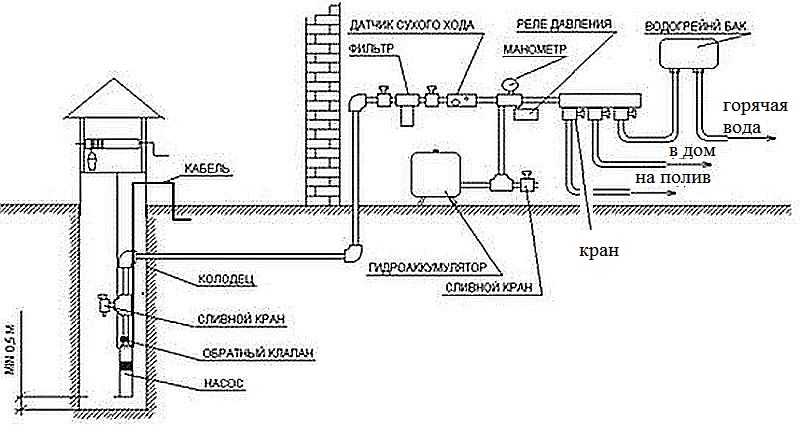

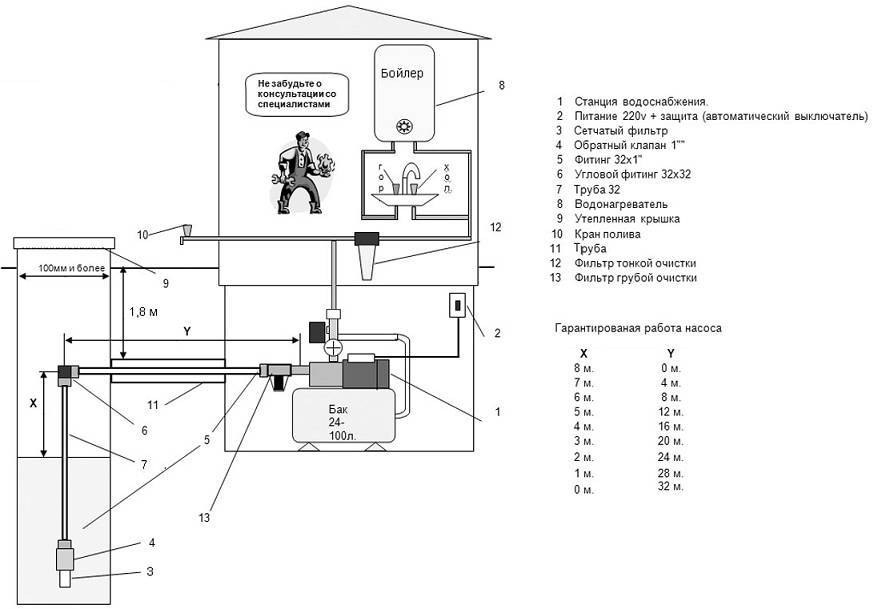

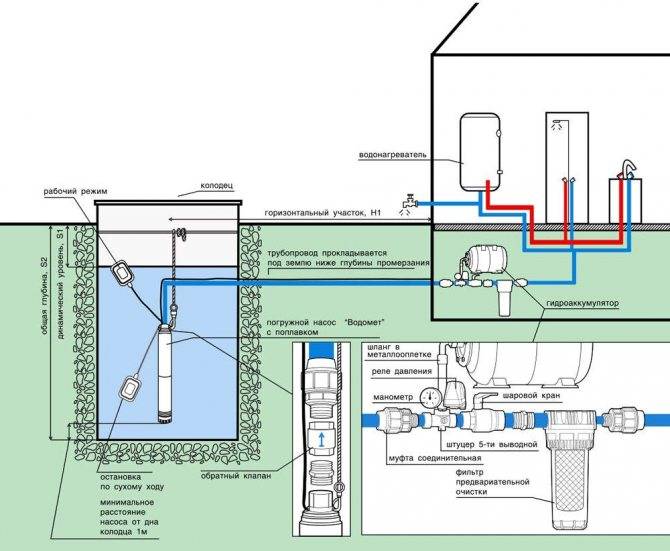

- Plumbing from a well

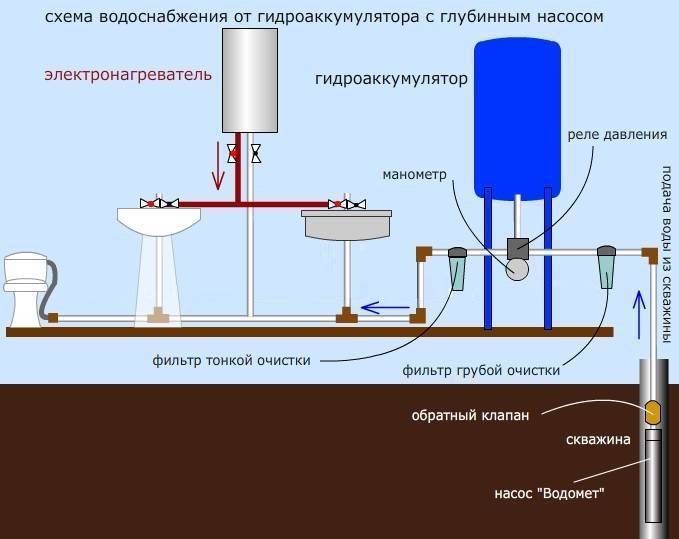

- Water supply from a well

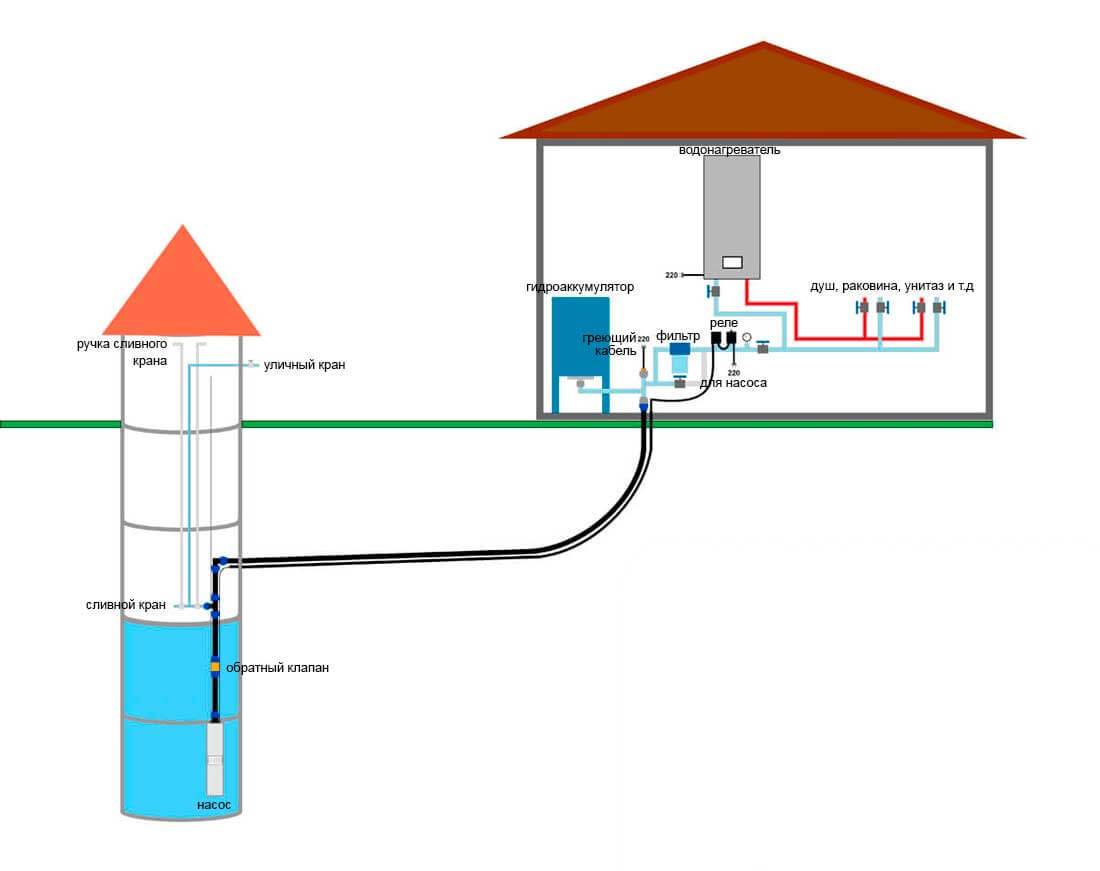

- Insulation of the well and pipeline, backfilling

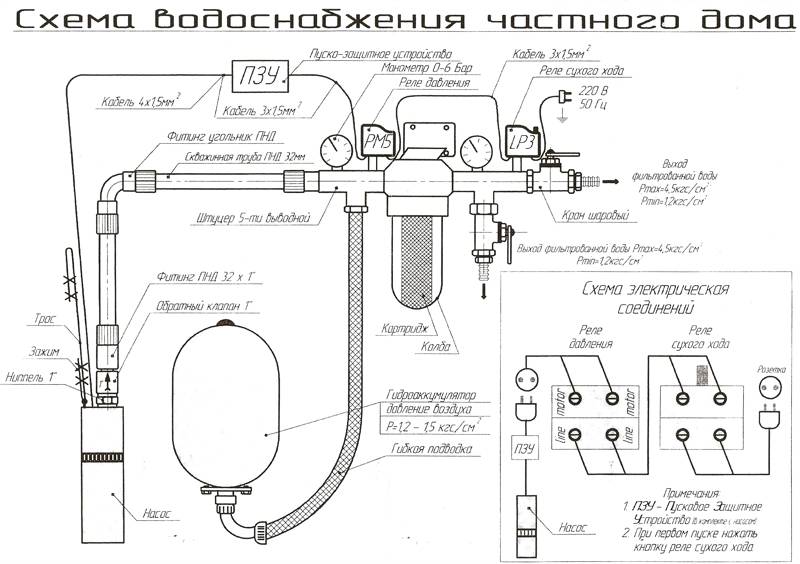

- Installation of water supply from HDPE

- Pipes made of HDPE, there are several types

- Internal wiring and installation

- Parallel mounting

- Mounting in series

- Device

General installation tips and helpful video

The water supply system of a private house is quite complex, and must be carried out in accordance with the requirements of SNiPs and sanitary standards. Therefore, before proceeding with the installation of an intra-house water supply system with your own hands, you should carefully read all the recommendations and draw up a detailed plan. If you are not sure of your own knowledge, then it makes sense to seek the advice of specialists.

In general, it is quite possible to create a water supply system for a private house with your own hands.In this way, it is possible to save significant financial resources that would otherwise have to be paid to plumbers.

Helpful2Useless

Plumbing in private homes

- Prepared pipes are laid in the house, starting from water consumers.

- The pipes are connected to the consuming point with an adapter so that a tap can be installed to shut off the water.

- Pipes are laid to the collector. It is advisable not to pass pipes through walls, as well as partitions, and if this has to be done, enclose them in glasses.

For easier repairs, place pipes 20-25 mm from wall surfaces. When installing drain taps, create a slight slope in their direction. Pipes are attached to the walls with special clips, installing them on straight sections every 1.5-2 meters, as well as in all corner joints. Fittings, as well as tees, are used to combine pipes at angles.

When connecting pipes to the collector, shut-off valves are always installed (it is needed for repairs and the possibility of turning off water consumption).

Which pipes are suitable

Even 20 years ago, steel pipes were indispensable. Today they are almost never used: too expensive and impractical. Iron pipes rust very badly. Therefore, they came up with an alternative - plastic pipes. But plastic is different. Consider products from it.

HDPE products

The most popular material for pipes is low-density polyethylene. Their advantage is that they do not require additional installation. Fittings for HDPE assembly are threaded and twisted by hand.

The advantages of the material are as follows:

- The term of use is 50 years.

- Do not give in to corrosion and do not rot.

- If water freezes in them, the pipes will not burst; when thawed, they will return to their previous position.

- Smooth inner surface. This is necessary so that less pressure is lost during transportation and deposits do not accumulate on the walls.

- Convenient assembly.

HDPE, of course, has several disadvantages:

- Poor heat tolerance (except for XLPE pipes).

- Low strength - you can not walk on them.

HDPE pipes are welded with an “iron” - a special apparatus, you can still connect them using fittings. Tees, adapters, pieces of pipes are connected using threaded connections. Such a connection may seem fragile, but it is not.

Pipes differ in working pressure:

- L - light, up to 2.5 atm.

- SL - medium - light, withstand up to 4 atm.

- Medium - C, up to 8 atm.

- Heavy - T, from 10 atm and above.

For the installation of water pipes, classes SL and C are used. Pipe diameters are 32, 40 and 50 mm. Pipes also differ in density: 63, 80 and 100 PE.

PVC materials

Another type of pipe used for water supply is polyvinyl chloride. They are cheaper than HDPE pipes, they are connected by welding with glue. The seam at the same time withstands 12−15 atm. The service life is the same as that of HDPE.

Characteristics that the material has:

- It is used at temperatures from -15 degrees to +45.

- Does not tolerate freezing well.

- Moderately sensitive to ultraviolet light.

PVC pipes have several very important advantages:

- Easy pipe installation, flexibility.

- Smooth inner surface.

- Not affected by corrosion.

- Low flammability.

Like any material, PVC pipes have their drawbacks:

- Upper limit +45 degrees.

- It is difficult to dispose of, as it is harmful.

- Not strong.

Cracks and scratches greatly reduce the strength of PVC pipes, threaded connections are impractical. If piping around the site is a simple matter, then equipment piping is a difficult task. Due to this disadvantage, the use of material for external water pipes is limited, therefore, such pipes are used more often for internal wiring, where the risk of damaging the pipes is minimal.

Polypropylene Products

Another material that can be used as pipes is polypropylene. It also belongs to the category of plastic. Pipes are connected using couplings and soldering - there are special soldering irons that heat plastic on two elements, then connect them. It turns out a monolithic structure. You don’t even have to buy a soldering iron, you can rent it at a store that sells pipes and fittings for them.

The disadvantage of polypropylene pipes is one - expensive fittings.

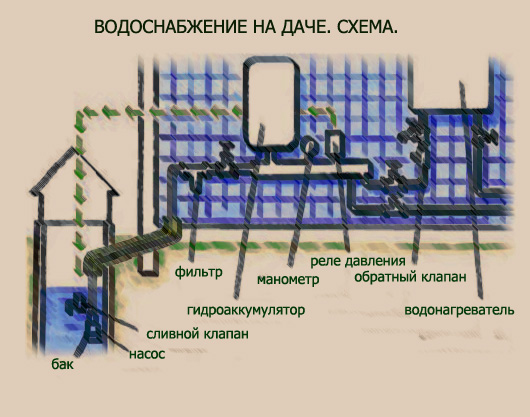

Summer water supply in the country: features of arrangement

Unlike the winter water supply, the summer system has significant differences regarding not only its installation, but also the presence of additional branches, for example, for watering plants, arranging a shower, etc.

The main differences of summer water supply are as follows:

- Deep ditches are not required for laying the pipeline. Sufficient depth will be 70-80 cm.

- A significant advantage is that the summer system does not need insulation.

- The permanent system must be equipped with a drain for waste water.

- Pipes in simpler systems are connected to each other in series, in more complex systems a manifold is used to connect them.

- Unlike a permanent water supply system that requires equipment with a pumping station, a heating system and a storage tank, a surface pump is enough to operate a temporary water supply.

- Summer collapsible water supply is best suited for regions with a warm period of about 3 months. For areas with a more severe climate, it is better to equip a stationary system well prepared for various conditions.

Water for autonomous water supply

First of all, it is worth figuring out what kind of water is suitable for an autonomous water supply device.

If you imagine everything is simple and accessible, then there are three types of groundwater.

- Verkhovodka. What has managed to seep into the soil, but has not yet become a stable aquifer. Worst quality water. It is easy to recognize it - the level of perched water varies greatly depending on the season. Not suitable for drinking water supply.

- Ground water. More stable aquifers. The depth of occurrence is from several meters from the surface to several tens. It is they who are mainly used for autonomous water supply.

- Artesian water. The deepest and oldest water carriers. The depth of occurrence can exceed a hundred meters. Water is most often suitable for drinking purposes, but it can be excessively hard, saturated with various minerals.

Water extracted from an autonomous source must undergo a cycle of comprehensive studies at the SES or another organization accredited for water analysis.

Based on the results of the analyzes performed, conclusions are drawn about the possibility of its use as drinking or technical.

A scheme that simulates a hydrogeological section without observing the scale, demonstrates the principle of occurrence and distribution of groundwater

The organization that conducted the water analysis can recommend the optimal treatment scheme if the technical option can acquire a drinking category after filtration.

thermal insulation

The performance of thermal insulation works does not take much time and does not require special skills and abilities.

Before applying the heat-insulating material, it is necessary to equip a trench - pour sand or gravel to the bottom.

The insulation procedure depends on what type of insulation you have chosen. One of the simplest ways of insulation is glass wool or mineral wool. Water pipes are wrapped with glass wool and secured with bundles or special tape. A waterproofing layer of roofing material is laid on top.

Styrofoam or basalt wool insulation is made like a shell, so they are simply overlapped over the pipe and fixed with glue or tape. Next is the laying of the protective layer. Corners and joints are equipped with shaped shells

It is important to choose the right diameter of the shell so that it fits snugly around the pipe.

Such a pipe heating system can be equipped with temperature sensors and fully automated. Indicators for the automatic system can be set depending on the climatic conditions of the area, the depth of the pipes and the characteristics of the soil.

Pipes can be insulated using heat-protective sprays or paints. Technically, insulation in this way is in many ways superior to the use of glass wool and polystyrene. Its advantages are the lowest thermal conductivity, uniform coating without gaps, durability, safety.This material is sprayed directly onto the pipe in an even layer and allowed to dry.

It is known that if water is under a certain pressure, it will not freeze. To maintain the desired pressure level, a receiver crashes into the pipe. A prerequisite for pressurizing is the presence of a check valve, as well as a closed tap. For the time of absence in the country in the winter, it is enough to set the pressure at 3-5 atmospheres. Before starting the plumbing system, it will be necessary to release the pressure.

Thermal insulation of pipes will eliminate such a phenomenon as the accumulation of condensate on pipes with cold water in the event that the installation of an air conditioner with humidity control in the house is not provided.

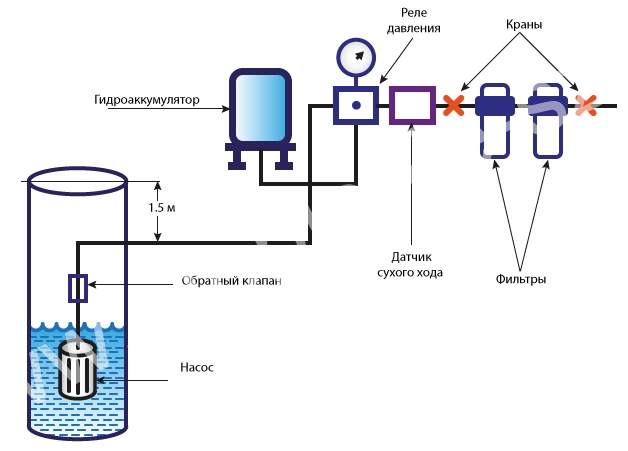

How to raise water from a well: choose the right pump

Water supply for the plumbing system from a well or well will have to be implemented using a pump. This is one of the main tasks in planning the water supply of a summer residence. The choice of pump depends on several parameters:

- expected volume of consumption;

- well depth;

- productivity of the well itself;

- water pressure;

- well diameter;

- available budget.

Some of the parameters are determined approximately with a rough estimate. To avoid mistakes, it is better to consult with an experienced master. There are two types of pumps: submersible and surface.

The surface option is used if you want to pump water from a well. It is placed on the surface or inside the well, but afloat. The maximum depth for the surface version of the pump is 8 m. If your well is deeper or it is generally a deep well, then this type of pump will not work.

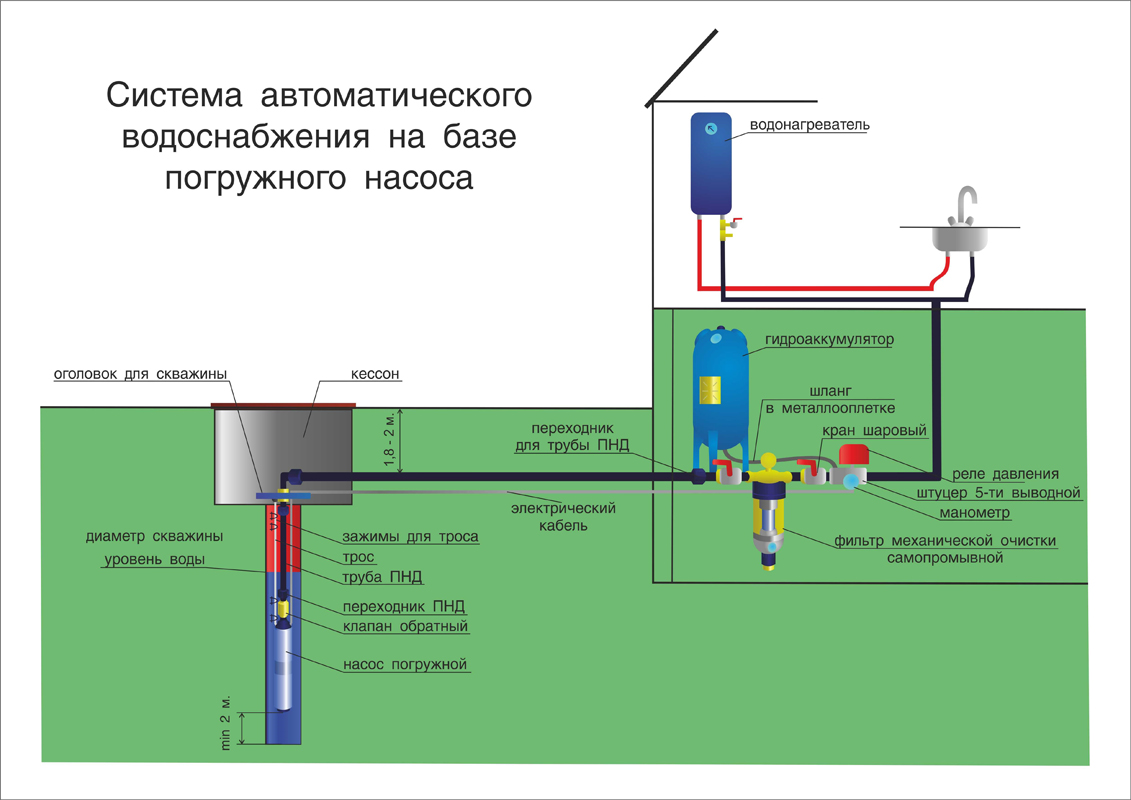

To pump water from deep sources, you should purchase submersible pumps that are not afraid of water ingress. Their advantages also include low energy consumption with a high level of performance and silent operation. There are 2 types of submersible pumps, depending on the type of action, they are centrifugal and vibration.

Vibrating aggregates in their structure have a finely porous membrane. The liquid is pumped due to the occurrence of a pressure difference from the deformation of the membrane. Such a pump requires careful maintenance, as the membrane can become dirty and fail. And replacing or repairing such a breakdown will be expensive.

Centrifugal pumps pump liquid through the operation of the blades. Under the action of the centrifugal force resulting from the rotation of the blades, the water moves through the pipeline. These models are very popular due to their high performance, reliability and reasonable price.

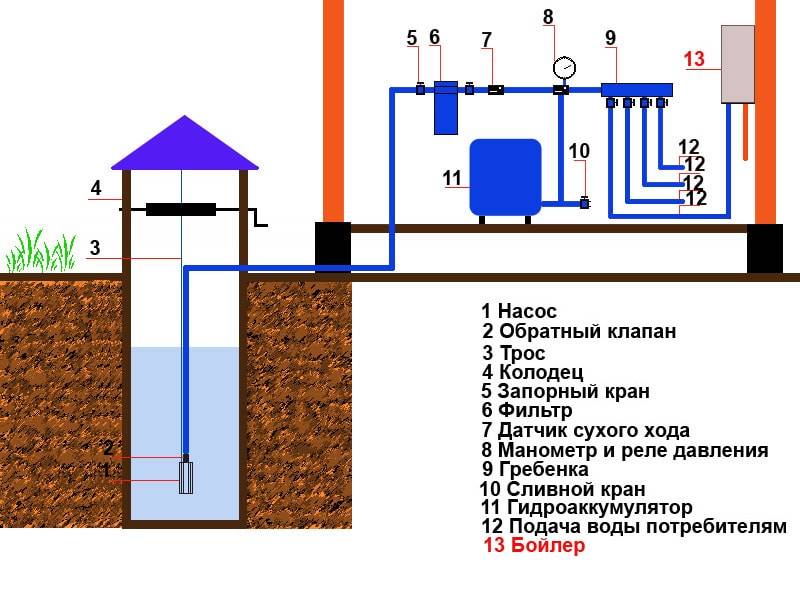

water intake

One of the most important issues that needs to be resolved before doing the plumbing in the country with your own hands is where the water will flow into the system. There are three standard water intake options - centralized water supply, a well, a well, each of them has its own nuances, advantages and disadvantages.

Centralized water supply

But in this case you yourself will have to install the wiring only at home. You don’t have to worry about pipe repairs, pressure drops, a global water purification system - home filters are enough. But, again, the owner will have to pay for water consumption and discharge according to the meters.

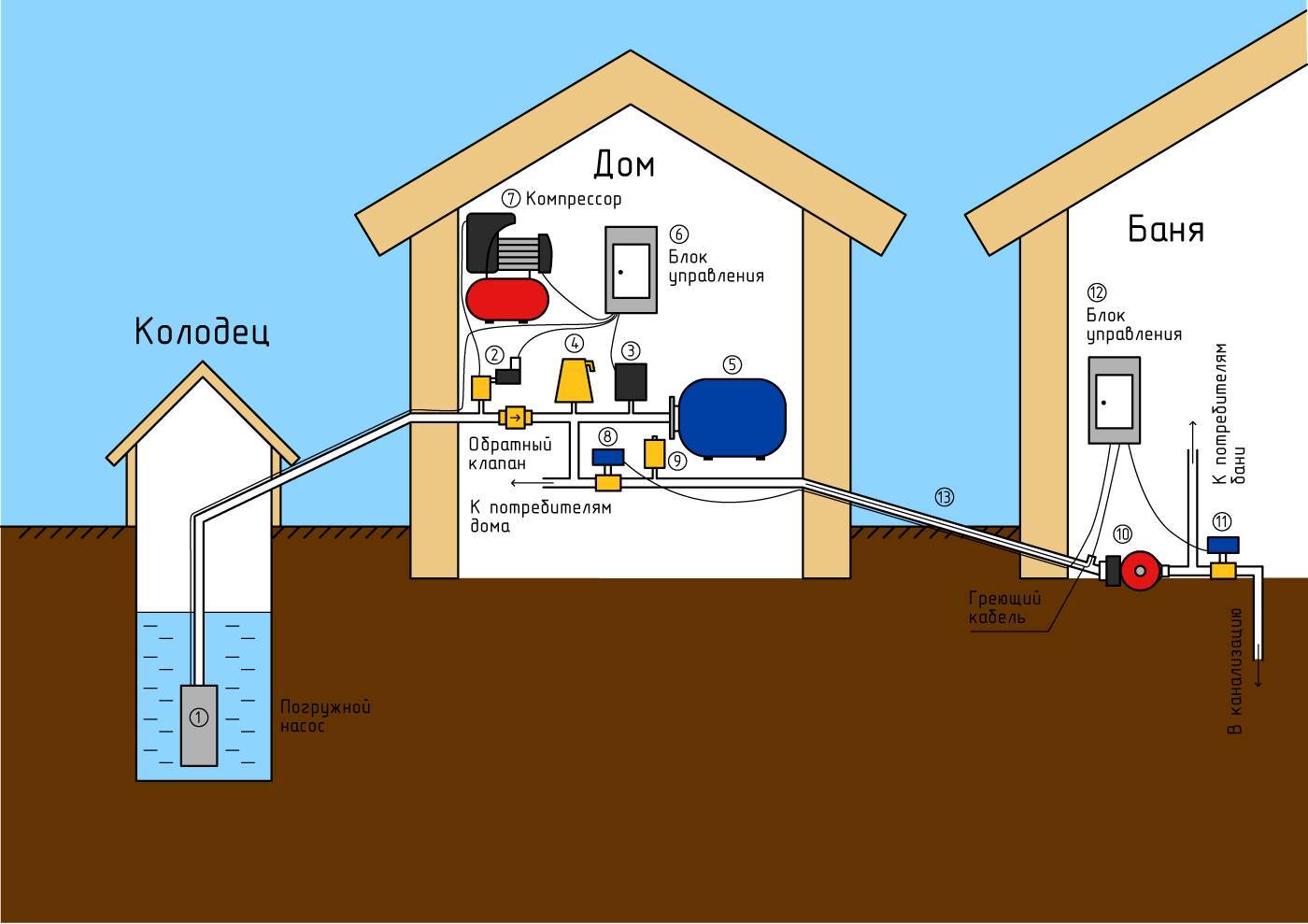

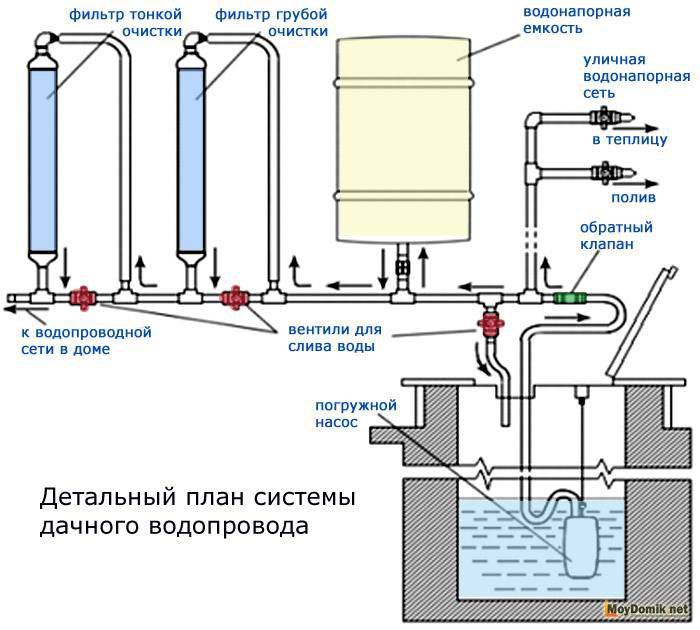

Well

Do-it-yourself plumbing in a country house from a well is perhaps the simplest arrangement scheme.There are wells in many areas, and if not, then digging and installing it is not a problem, moreover, it will not require large financial and time costs. Usually this option is suitable in areas where the depth of groundwater does not exceed ten meters.

However, care must be taken to insulate the well itself and the pump. For the first, foam, polyethylene foam and other insulating materials are used. As for the pump, to protect it in winter you will need a caisson - an external pit, warm at the same time.

For all the simplicity of the country water supply from the well, it also has disadvantages. So, the water in the well is most often polluted, so if the water is used not only for domestic, but also for drinking needs, you should take care of a high-quality filtration system. In addition, with a large flow of water, not every well will be able to cover it. For example, if daily watering of the site is required, water supply to the house, baths, washing, filling the pool.

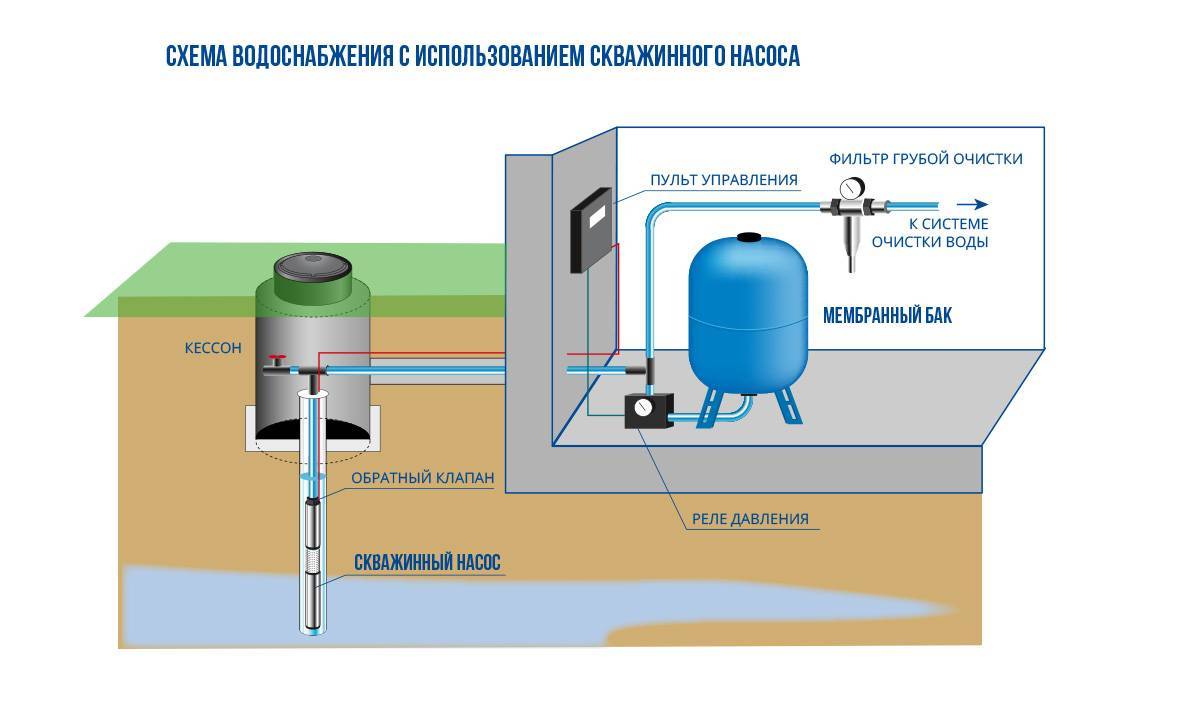

Well

Own well on the site - a great option to solve the problem with water. You can also equip the water supply in the country from the well. Thus, water is taken that lies lower than that which enters the wells. It is usually cleaner. To install a water supply system in a country house from a well, you will need a submersible pump - the equipment is more expensive and complex than surface.

A well, especially equipped without the help of specialists, can often upset with problems. You can learn more about the reasons for its failure in work here.

However, water supply from a well is for centuries.With proper operation, the design will last for many years and will provide liquid for the whole family, personal plot, outbuildings.

To protect the water in the well from freezing in winter, a coffered well made of brick, concrete or other materials is installed. You can read more about warming water sources in winter here.

Sources of water supply

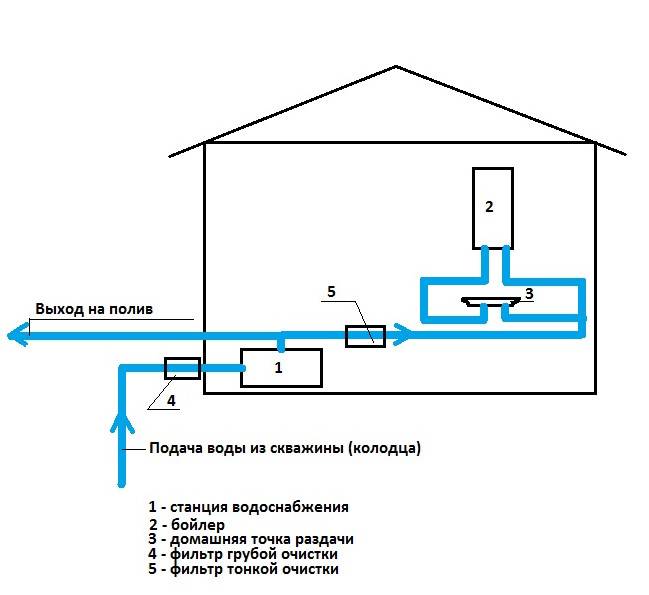

Depending on the nature of the source of water supply, the method of installing the water supply system will differ. Below we will take a closer look at the most popular options.

Centralized water supply

This option is the easiest, so even an inexperienced builder can handle it. However, it is only possible if the water pressure in the pipes is quite strong, otherwise you will need to buy a pump or consider alternative options for providing water to the house.

To create a centralized water supply, pipes and accessories for their connection - fittings are used. Laying is carried out according to a fairly simple scheme and does not require special skills from the worker. You only need to dig a trench, put pipes in it and bring them to the central highway.

Plumbing from a well

If there is a well on your site, it would be blasphemy not to use it "to its fullest" and not to make a source of water supply. If there is no well, it is not so difficult to make it. To dig a mine, you will need a couple of assistants and a little theoretical knowledge.

The most important thing is to find out the depth of groundwater - it should be no more than 10 m. Plumbing in a country house from a well has a lot of advantages, the main of which is that you can independently repair and maintain the system without calling specialists.Plus, the maintenance and care of such a water supply system requires minimal effort and cost.

Among the shortcomings, limited water consumption can be distinguished, so if a family of 3-4 people lives in the country house, something more than an ordinary well will be required. Before starting work, you should carefully weigh all the factors and calculate how much water you will have enough on average for a comfortable stay, and whether the well can provide you with the required volume. If there is not enough water, it may make sense to deepen the mine or use another source.

In order to make a source from a well, you need to purchase a good surface pump. Deep in this case, it is irrational to use, but it will come in handy for another source - a well.

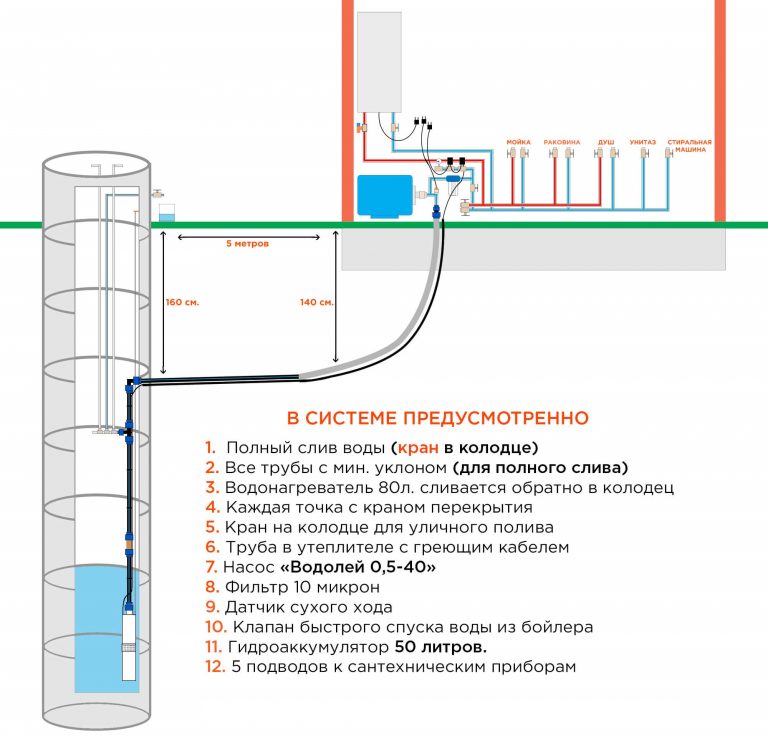

Water supply from a well

If the groundwater in your area lies at a depth of more than 10 m, it is best to drill a well, which will require some costs, since drilling services cost decent money. However, this amount will pay off in the near future, as you will use your water, clean and healthy. Thus, you will benefit not only financially, but also provide your family with a healthy drink, rich in natural trace elements.

Since drilling and maintaining a well is quite expensive, it makes sense to discuss this issue with neighbors in order to pay for work in pool for 2-3 houses. You will also need a special borehole or deep-well pump.

Insulation of the well and pipeline, backfilling

Now that the passage of the highway through the territory of the site is completed, and the end of the pipe is lowered to the water in the well, you can proceed to the insulation measures.

First, from the bottom line of freezing to the main surface of the soil, insulation material is fixed or sprayed around the walls of the well - it can be polystyrene foam, polyurethane foam (spraying), polyethylene foam. Less often - mineral wool, since it is not all right with moisture resistance. We will have to provide for waterproofing also separately for the insulation, and this is extra hassle and costs.

Insulation of the well to the level of soil freezing.

Insulation of a water pipe in a ditch using a Styrofoam panel.

- In cold regions, it is desirable to equip additional insulation by laying a layer of insulation material on top of the pipeline - this can be a 100 mm thick polystyrene foam panel. The material is inexpensive, and such a measure will protect the water supply in case of some abnormal frost.

- After carrying out the insulation, the backfilling of the previously selected soil around the well and ditch continues. For backfilling, a sand-gravel mixture is also widely used, which is recommended to pre-backfill the trench before laying the soil there.

The backfill will inevitably shrink over time, so do not rush into concreting the blind areas - it is better to do this in a few months.

Options for arranging a clay "castle" around the well.

One of the effective ways to additionally waterproof the external walls of the well is to create a clay "castle", which is able to protect the area around the walls of the mine from the effects of precipitation.

The clay gate is equipped at the stage of backfilling the sand-gravel mixture and soil into the space around the well after its waterproofing and insulation. The recommended dimensions for this compacted clay layer are well illustrated in the diagram above.

Laying a clay castle around the well.

In this case, concrete blind areas are arranged on top of the clay castle.

Installation of water supply from HDPE

Pipes made of polymeric materials today act as successful competitors to metal and asbestos-cement products, being increasingly used for laying plumbing systems. This is due to a wide range of plastic pipes made from various polymers with different technical characteristics. As a result, it is always possible to choose the starting material for the installation of the pipeline, in accordance with the operational and technical requirements for it.

One of the most common polymers used for the production of plastic pipes is HDPE - low pressure polyethylene.

The production technology of HDPE pipes is as follows:

- The polyethylene melt is squeezed out through a matrix of the required size.

- The polymerization process in this case occurs at atmospheric pressure, in contrast to high-pressure polyethylene.

- After the polyethylene blank has hardened, they are cut into segments of standard length, or rolled into coils.

- Products are marked in accordance with their technical characteristics, and the pipes are sent for sale.

Pipes made of HDPE, there are several types

- Lightweight, designed for a working pressure of not more than 2.5 atmospheres. Marked with the letter "L".

- Medium-light, marked "SL" and withstand pressure up to 4 atm.

- Medium, marking "C", working pressure up to 8 atm.

- Heavy - "T", capable of withstanding up to 10 atmospheres.

When buying, you should pay attention to the marking, choosing the material for the water supply network, depending on the expected working pressure inside the system. Do-it-yourself installation of HDPE plumbing in the country is not particularly difficult due to the manufacturability of the assembly

HDPE pipes are connected to each other with the help of special fittings and additional elements - tees, corners, etc.

For country water supply, it is recommended to use pipes made of polyethylene grade 80 or 100. They are perfect for supplying cold water, being resistant to solar ultraviolet radiation and the corrosive effects of liquids. The main water branch is usually made from a pipe with a diameter of 32-40 mm, and branches from it - from the 20-25th pipe.

This is interesting: Self-regulating heating cable for plumbing: a device and an example of pipeline insulation

Internal wiring and installation

Installation of pipes inside the house is an important and crucial stage. It is really possible to do the installation of pipes with your own hands, but only taking into account the design features of the pipe layout inside the house.

Making the right pipe layout means simplifying your life in the future. With proper wiring for any pipe, the risk of destruction is reduced, its repair is extremely rare, and the useful return is improved.

There are two main types of distribution of water supply systems in private homes. There is a breakdown:

- parallel;

- consistent.

Parallel wiring is better suited for large houses, where pipes diverge into many rooms that are far from each other. Sequential is suitable for apartment-type buildings, where bathrooms are located compactly.

Parallel mounting

The parallel pipe laying scheme provides for the installation of many branches, the diameter of which is equal to the minimum values, namely, it does not exceed the mark of 30-40 mm, except in rare cases.

The small diameter of the pipe has a positive effect on cost savings. The point here is that parallel wiring provides for the need to make many parallel water supply branches. Each branch serves its specific direction. There are one or two nodes per branch.

The branches are isolated from each other, the input is carried out in the boiler room, where they are connected to the finished collector outlet. Cranes are mounted at each outlet, allowing any pipe to be cut off from the supply.

Such a scheme allows you to make the most safe and autonomous pipeline. Each pipe operates separately, breakage in any area is easily localized.

But at the same time, a parallel wiring scheme, even taking into account the fact that the minimum diameter of the pipes is required for it, requires a significant amount of funds, because each branch needs to be laid, and this costs money.

Mounting in series

The sequential scheme takes a slightly different approach. It has one or two base pipes, the diameter of which starts from 80 mm. These pipes are a kind of clusters, they pass through all the premises with bathrooms.

At the location of the bathroom, a smaller branch is diverted from the main pipe, whose diameter is calculated depending on the water demand of a particular device.

The larger the diameter, the more water the knot will receive. A series circuit is a more traditional option. Sewerage is collected according to the same system.

The large diameter of the pipes slightly increases their cost, but this approach is still cheaper than the parallel one, since in the end you save on the length of the pipes.

Device

The water supply mechanism is one of the main components of home life. There is no point in talking about her work again. The design of the network is made in such a way that the building is fully supplied with water according to the needs of the owners.

It is necessary to organize a mechanism so that water enters the water intake points from the water meter unit. This mechanism makes it possible to significantly reduce housing costs.

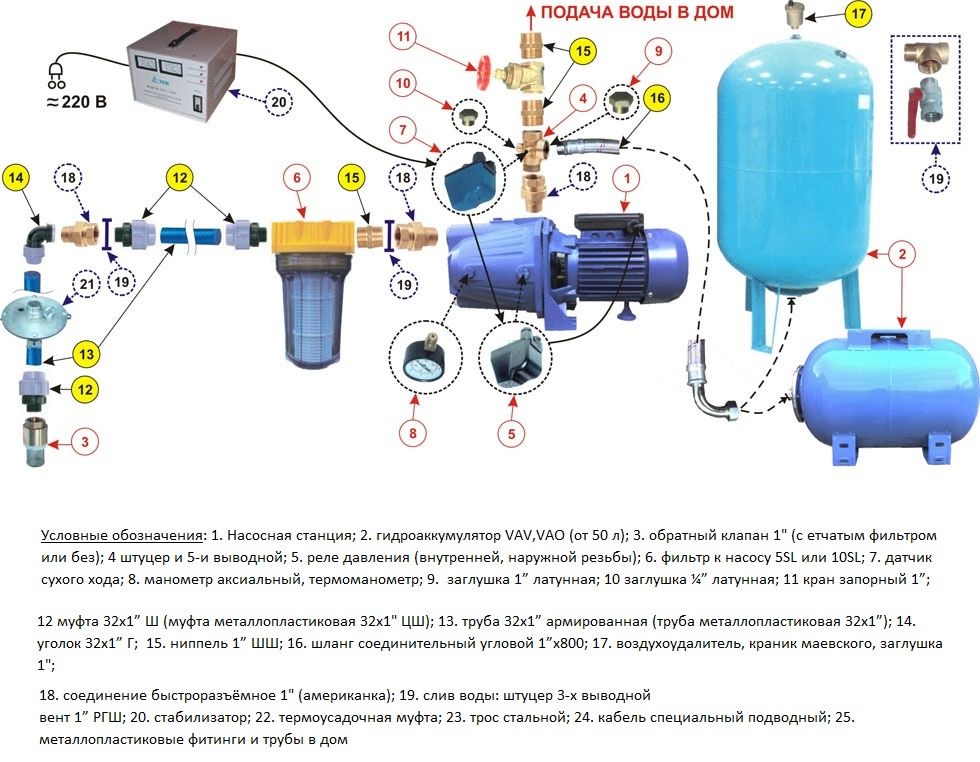

In order for such a system to function efficiently, it must be equipped with technical devices and equipment that provides not only partially, but also fully automatic operating mode. In order for the system to become such, it is necessary to install a hydraulic accumulator. It is used as a buffer tank, where a water supply is formed, or as a device that allows you to maintain a stable water pressure in the mechanism. A membrane tank will also be needed. It is usually divided into 2 compartments. One will contain water, and the other will contain air. They are separated by a rubber membrane. When the container is filled with water, the air part is compressed more and increases the pressure inside the tank.

At the moment when a water supply tap is opened somewhere, the pressure in the system begins to slowly drop. The electrical relay again responds to such a change. It reactivates the pump when the water level reaches 50 percent.The use of a hydraulic accumulator allows not only to ensure the automation of all water supply systems and create water reserves, but also significantly extend the life of pumping equipment by reducing the number of switching on and off.

It should be said that autonomous water supply mechanisms usually consist of external and internal elements. The internal part usually includes pipes laid from the source to the water intake points, plumbing equipment, fittings, an accumulation tank, a pump, and a hydraulic accumulator.

In order to select the features of the mechanism as accurately and correctly as possible, you should:

- clearly articulate the requirements for how intensive and regular water supply you need;

- understand what sources of water supply are, as well as how much this or that system will cost;

- analyze water quality;

- select equipment and calculate the approximate cost of laying engineering-type networks.