- 1 Characteristics of polypropylene products

- Distribution of polypropylene pipes

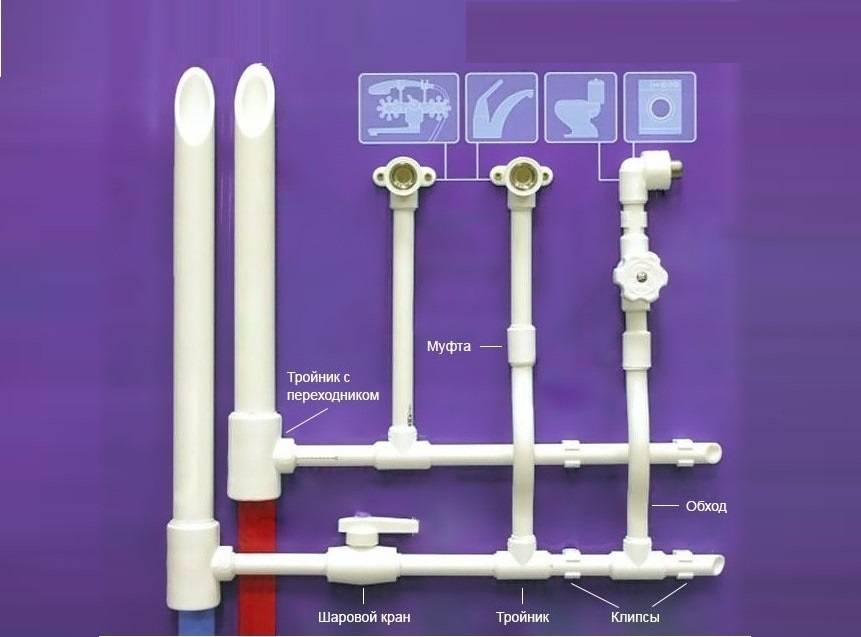

- We consider fittings

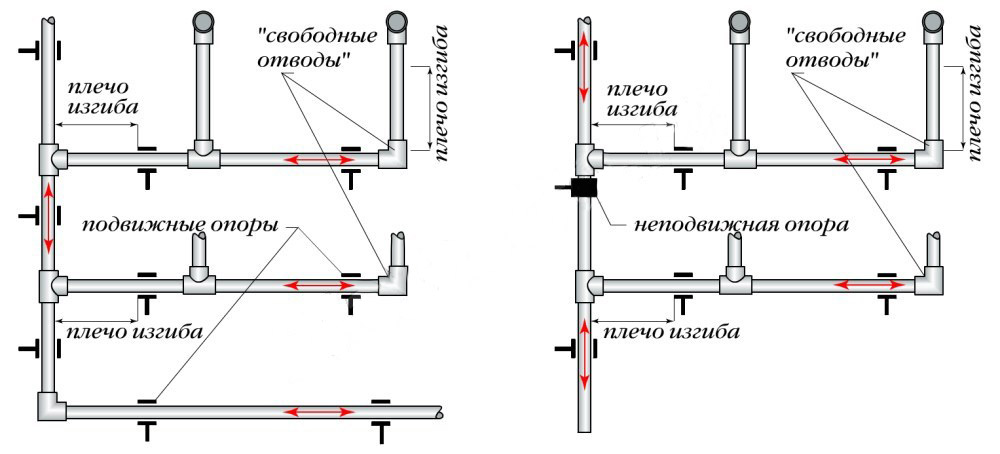

- Laying methods

- The nuances of soldering

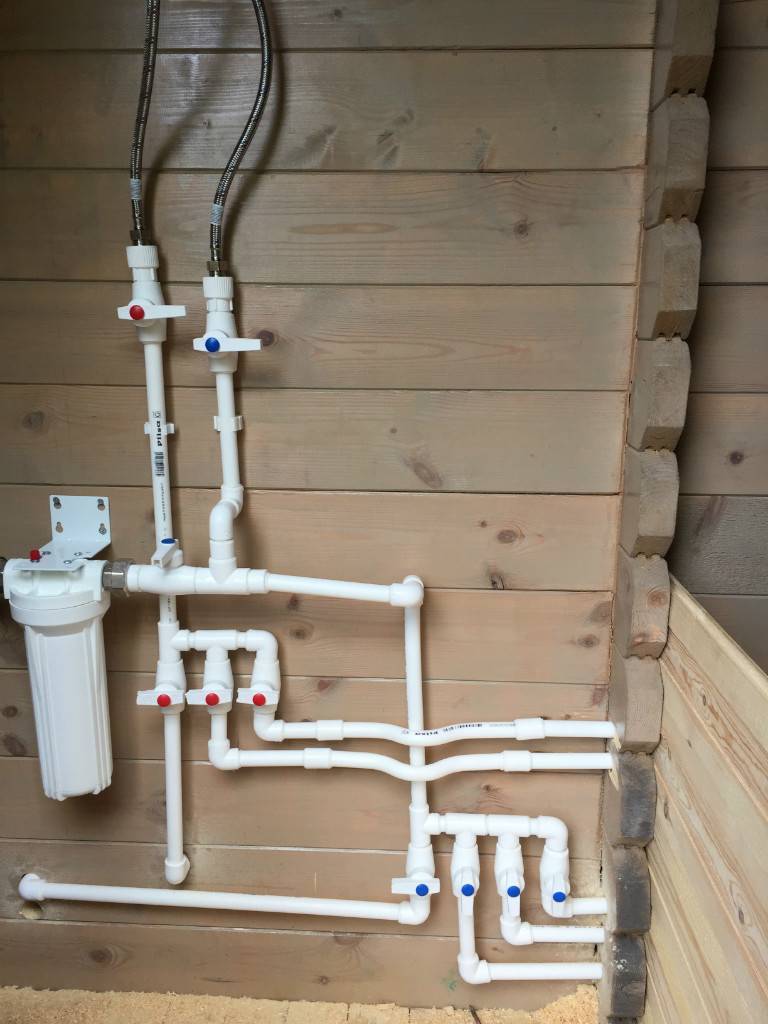

- Installation of serial wiring

- Drafting a project

- Installation work on laying pipes made of polypropylene

- Marking the pipe and fitting

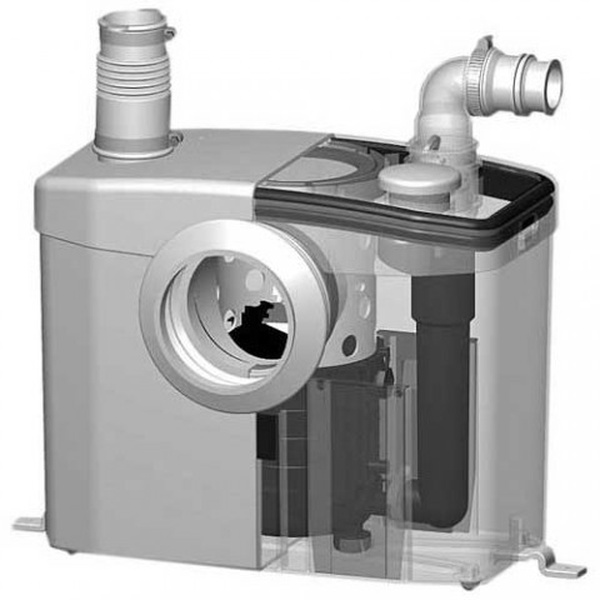

- Design features of a water supply system made of polypropylene pipes

- Do-it-yourself polypropylene plumbing

- Contact welding (soldering)

- Rules for the installation of polypropylene pipes

- Connection principle

- Internal or external laying

- Features of the assortment of polypropylene pipes

- PP pipe manufacturers

- System planning

1 Characteristics of polypropylene products

Previously, wiring was carried out with metal pipes, but today more and more propylene pipes are being chosen. Their popularity is no coincidence, the advantages include:

- high resistance to long-term effects of various kinds;

- durability, which guarantees trouble-free operation for 50 years, which is several times more than that of steel products;

- good tightness of connections;

- high sound insulation, since the material of manufacture completely absorbs the noise of water moving through the pipes;

- environmental safety of polypropylene, which allows it to be used for laying drinking water supply;

- light weight facilitates installation work;

- low hydraulic resistance;

- a wide range of accessories.

There are several disadvantages of using polypropylene.

Firstly, these are high rates of thermal expansion with low thermal stability, therefore, when laying heating in a private house, special attention is paid to the characteristics of the pipes. But for a water supply network in which there are no elevated temperatures, this is not an obstacle.

Another problem is the need to use specialized equipment: a soldering iron, with which the parts are heated and connected to each other, cutting shears, with the help of which the elements are prepared according to the given dimensions.

Products are issued one-, multilayer. The first - for laying a pipeline for cold water. Reinforced, the structure of which consists of several layers of polypropylene and reinforcing material, are relevant for the arrangement of hot water and heating systems.

Define the scope of the product can be marking:

- PN10. Designed for cold water. Operating temperature up to +20º.

- PN16. Can be used to supply cold, hot water. Maximum heating up to +60º.

- PN20. Temperature load no more than +80º.

- PN25. Reinforced with aluminum foil, therefore, they withstand high pressure at rates up to + 95º.

You also need to pay attention to the inner, outer diameter in inches or in the usual millimeters. Based on the indicated diameter values, the nozzles are selected, which will be used for soldering pipeline parts

| Outer diameter (mm) | Wall thickness PN10 (mm) | Thickness walls PN16 (mm) | Thickness walls PN20 (mm) | Thickness walls PN25 (mm) |

| 16 | — | — | 2. 7 | — |

| 20 | 1. 9 | 2. 8 | 3. 4 | 3. 4 |

| 25 | 2. 3 | 3. 5 | 4. 2 | 4. 2 |

| 32 | 3. 0 | 4. 4 | 5. 4 | 3. 0 |

| 40 | 3. 7 | 5. 5 | 6. 7 | 3. 7 |

| 50 | 4. 6 | 6. 9 | 8. 4 | 4. 6 |

| 63 | 5. 8 | 8. 4 | 10. 5 | 5. 8 |

| 75 | 6. 9 | 10. 3 | 12. 5 | 6. 9 |

| 90 | 8. 2 | 12. 3 | 15. 0 | — |

| 110 | 10. 0 | 15. 1 | 18. 4 | — |

Distribution of polypropylene pipes

Polypropylene pipes are used for mounting a comb of cold or hot water, heating. The choice of diameter in each case is individual - it depends on the volume of liquid that needs to be pumped per unit of time, the required speed of its movement (the formula in the photo).

The formula for calculating the diameter of polypropylene

Calculation of pipe diameters for heating systems is a separate issue (the diameter must be determined after each branch), for water pipes everything is easier. In apartments and houses, pipes with a diameter of 16 mm to 30 mm are used for these purposes, with the most popular ones being 20 mm and 25 mm.

We consider fittings

After determining the diameter, the total length of the pipeline is considered, depending on its structure, fittings are purchased in addition. With the length of the pipes, everything is relatively simple - measure the length, add about 20% for the error and possible marriages in the work. A piping diagram is required to determine which fittings are needed. Draw it, indicating all the taps and devices to which you want to connect.

An example of the layout of polypropylene pipes in the bathroom

To connect to many devices, a transition to metal is required. There are also such polypropylene fittings. They have a brass thread on one side, and a regular solder fitting on the other. Immediately you need to look at the diameter of the pipe of the connected device and the type of thread that should be on the fitting (internal or external). In order not to be mistaken, it is better to write everything down on the diagram - above the branch where this fitting will be installed.

Further, according to the scheme, the number of "T" and "G" figurative compounds is considered. For them, tees and corners are bought. There are also crosses, but they are rarely used. Corners, by the way, are not only at 90 °. There are 45°, 120°.Do not forget about couplings - these are fittings for joining two pipe sections. Do not forget that polypropylene pipes are completely inelastic and do not bend, so each turn is done using fittings.

When you purchase materials, agree with the seller on the possibility of replacing or returning part of the fittings. Problems usually do not arise, since even professionals cannot always immediately determine exactly the required assortment. In addition, during the installation process, sometimes it is necessary to change the structure of the pipeline, which means that the set of fittings changes.

Compensator for hot water supply and heating from polypropylene pipes

Polypropylene has a fairly significant coefficient of thermal expansion. If a polypropylene hot water supply or heating system is being installed, it is required to make a compensator, with which the lengthening or shortening of the pipeline will be leveled. This can be a factory-made compensator loop, or a compensator assembled according to the scheme from finigs and pieces of pipes (pictured above).

Laying methods

There are two ways to install polypropylene pipes - open (along the wall) and closed - in strobes in the wall or in the screed. On the wall or in the strobe, pipes made of polypropylene are mounted on clip holders. They are single - for laying one pipe, there are double - when two branches run in parallel. They are fastened at a distance of 50-70 cm. The pipe is simply inserted into the clip and held due to the force of elasticity.

Fastening polypropylene pipes to walls

When laying in a screed, if it is a warm floor, the pipes are attached to the reinforcing mesh, no other additional fastening is required. If the connection to the radiators is monolithic, the pipes can not be fixed.They are rigid, they do not change their position even when filled with coolant.

The option of hidden and external wiring in one pipeline (behind the bathroom, the wiring was made open - less work)

The nuances of soldering

The process of welding polypropylene pipes, as you have seen, does not leave much work, but there are a lot of subtleties. For example, it is not clear how, when joining pipes, to adjust the sections so that the pipes are exactly the length that is required.

Another point of welding polypropylene pipes is soldering in hard-to-reach places. It is not always possible to put a pipe and a fitting on the soldering iron on both sides. For example, soldering in the corner. Soldering iron, you have to put it in a corner, on one side the nozzle rests directly against the wall, you can’t pull the fitting on it. In this case, a second set of nozzles of the same diameter is installed and the fitting is heated on it.

How to solder polypropylene pipes in a hard-to-reach place:

How to switch from iron pipe to polypropylene:

Installation of serial wiring

Serial wiring consists in laying the main line, to which household nodes are connected using tees. The disadvantage of the scheme is to reduce the pressure while turning on several consumers at the same time. The wiring is mounted open or hidden behind false panels.

Do-it-yourself installation of polypropylene pipes includes the following operations:

Drafting a project

The number of points of sanitary equipment (bath, toilet, bidet, washbasin) and household appliances (washing machine, dishwasher, boiler) connected to the water supply is counted. The volume of constant consumption is calculated and the diameter of the main pipe is determined. The width of the connection tees will be 2-4 mm less.

Installation work on laying pipes made of polypropylene

The laying of the water line begins with the places where consumers will be connected. In these places, threaded adapters and ball valves are mounted to disconnect plumbing from the general system in case of repair work.

Depending on the type of wiring, pipes are pulled from consumers to the collector or the next consumer. When performing installation work, the distance between the pipe and the wall must exceed 2 cm. The clamp screwing step is 1-1.5 m (in addition, the clamps are attached to each corner and turns).

Particular attention is paid to laying the pipeline through walls and partitions. The pipe must be placed in a special glass, which acts as a protective barrier against mechanical stress. It is recommended that a minimum number of pipes pass through the wall (preferably one)

If there are drain taps, the pipes are installed with a slight slope towards them.

It is recommended that a minimum number of pipes pass through the wall (preferably one). In the presence of drain taps, the installation of pipes is carried out with a slight slope in their direction.

Each pipe branch is connected to a manifold with the obligatory installation of locking elements. After that, everything is collected in one system.

An autonomous water supply system consists of such elements;

- the starting point of the tie-in is a well, well or other source of water intake;

- water meters;

- a water line in a trench on the street (in the northern regions it is recommended to insulate it);

- pipe entrance to a private house;

- coarse filter (mounted on the inside of the house);

- additional filters in front of plumbing and household appliances (if necessary, but always in front of the washing machine and faucet in the kitchen).

To transport warm water to the kitchen, a tee is mounted after the filter, which is designed to distribute water over two branches: hot and cold. The pipe through which cold water enters is connected to "its" collector. The branch with hot water must be connected to the boiler.

Marking the pipe and fitting

Installation of PVC pipes by marks

On high-quality expensive plastic, there are always marks along the pipe and fittings to maintain the alignment of the elements. It is convenient to solder such plastic “in place”. If there are no such elements, apply them with a marker - it draws best on a polypropylene pipe.

Installation of inexpensive products (the manufacturer saves on everything - on labels too) is associated with a high risk of inaccuracies. And each error then leads to the fact that in the end it is necessary to re-solder the pipeline with your hard-working hands: cut and install a coupling-connector for lengthening.

To avoid this, beat off one axial line under the ruler. This is done simply: two pipes are laid side by side (one for soldering, the other for support) along an even profile (for example, for plasterboard).

Cutting a polypropylene pipe

The ruler is attached close to the profile and lowered onto the pipes. Along the edge of the ruler, marks are made along the area prepared for installation. Two marks around the edges are enough. If the section is long and there are no marks, then it is better to solder “in place”: install the segment in the prepared fasteners and then solder the remaining sections.

Soldering difficult areas with many turns should also be done according to the markup.Make sure there is a flat, level surface on which to check (evaluate) the alignment and squareness of the brazed pipes. For example, such a surface cannot be an old wooden or tiled floor - there are a lot of warps on them. A half-sheet of drywall, plywood is fine.

In no case do not cut all sections of the polypropylene pipe at once: even craftsmen with experience cannot afford this. Constant checking, fitting and phased welding of the pipeline is the key to success.

Design features of a water supply system made of polypropylene pipes

The water pipeline from polypropylene pipes is assembled in the form of a multi-branch structure, through which the liquid flows to the point of consumption. To create it, you will need pipes and special parts for connecting individual pieces - fittings, also made of plastic.

When choosing pipes, pay attention to the material from which they are made. The scope of products depends on the type of polypropylene

| Pipe material | Application | Advantages | Flaws |

| PP-N single layer pipe | For cold water | High strength | Low temperature resistance, high thermal expansion |

| PP-B single layer pipe | For cold and warm water | High strength and heat resistance | High thermal expansion |

| PP-R multilayer pipe | For cold and hot water | High strength and heat resistance | Very low thermal expansion |

There are several dozen types of fittings, but the most popular are:

- Couplings - cylindrical products, the diameter of which is the same and corresponds to the diameter of the connected cuts.

- Adapters - parts for connecting workpieces of different sizes.

- corners - products for changing the direction of the route.Parts are bent at an angle of 45-90 degrees. The use of corners when bending the water pipe is mandatory. It is strictly forbidden to bend the plastic after heating, because. the walls become thinner, while the pipe loses its strength.

- Crosses and tees - fittings for connecting several workpieces in one place. Available in various configurations and sizes.

In the photo, accessories for polypropylene pipes

Other components are often used in the plumbing:

- Contours - factory-bent tubes that make it easy to bypass small obstacles. They are produced in a large assortment, which allows you to choose samples that will pass at a minimum distance from the object.

- Compensators of various typesnecessary to eliminate the effects of thermal expansion of polypropylene pipes.

- Cover caps for openingswhich are not planned to be used in the near future.

- Distribution nodes for collector piping, allowing to equalize the pressure of the liquid at different points of water intake.

- Ball Valves - are placed in front of each plumbing fixture to shut off the water.

- Mounting clamps or clips - used to fasten the line to the walls.

Do-it-yourself polypropylene plumbing

Polypropylene pipes are gradually replacing metal pipes in heating and water supply, and this is primarily due to ease of installation. Polypropylene (PP) is a material with excellent performance and qualities, which is used for both cold and hot water.

The advantages of polypropylene include:

- long service life;

- a wide range of fittings and other accessories;

- light weight;

- absence of condensate and mineral deposits during operation;

- resistance to corrosion;

- strength;

- ease of installation;

- resistance to aggressive media and high pressure.

Do-it-yourself polypropylene plumbing

The disadvantages include only the inability of most polypropylene pipes to withstand temperatures above 50-60ᵒ. There are several brands that can withstand boiling water (not for long, because already at 90ᵒС the plastic softens and loses its properties).

Important! For hot water (less than 90ᵒС), pipes marked PN25 and PN20 are used, and for cold water (less than 20ᵒС) - PN10 and PN16. Contents of step by step instructions:

Contents of step by step instructions:

Contact welding (soldering)

Since the water supply is carried out under a sufficiently high pressure, pipes and fittings must be connected as securely as possible.

1. Pipes are cut into pieces the desired length with a grinder, pipe cutter or special scissors. For stripping products with aluminum reinforcement, a special device is used - shaver.

Reinforced pipe shaver

2. In order for the segments to freely enter the fittings, they must be removed from their edges chamfer at a slight angle. In this case, its recess should have a size of up to 3 mm. For these purposes, it is used beveler.

beveler

3. Pipe ends are degreased alcohol or white spirit.

4. They are applied mark, equal to the depth of the fitting minus a couple of mm (for example, for a 25 mm pipe it will be 16 mm);

Marking

5. Fitting and pipe are placed on both sides of the nozzle soldering iron so that when heated they reach the required mark. The ends of the nozzle have a small cone, so it is necessary to put the pipe and fitting on them with little effort.

Nozzle installation

Apparatus for welding (soldering iron)

6. If the soldering iron is equipped with a temperature controller, it must be set to 260 ° C.

7. Pipe heating interval depends on its thickness. Having endured the required time (it is indicated in the instructions for the soldering iron and can be from 5 to 15 seconds), the pipes and fittings are smoothly removed from the nozzle (mandrel) and docked. It is advisable to do this in one motion, without unnecessary displacements, as quickly as possible - after all, the solidification time of polypropylene is only 30 seconds.

Important! During the heating process, in order to avoid damage to the plastic, it is not recommended to rotate the pipe and fitting. You shouldn't force it to cool down.

8. Products of large diameter are more difficult to join, so they are connected using a special device.

Advice. To get used to welding, it is better to practice a little: buy a few fittings and try to fix them in small segments.

9. Small streaks formed during welding are removed with an ordinary knife.

10. After assembling the water pipe, it is filled with water and check for tightness under pressure. At the same time, it is selected 1.5 times higher than the nominal value. You can increase the pressure using a car pump. If necessary, problematic joints are cut out and new segments are soldered into the system.

Important! System testing is allowed only 2 hours after soldering is completed.

Rules for the installation of polypropylene pipes

Before you start assembling a water pipe from polypropylene with your own hands, you need to draw up its diagram. First, measurements of the premises are made and a detailed drawing of the house (apartment) is drawn up. Then all the details of the water supply system are applied to it on a scale.

Experts recommend following these rules when installing water supply systems:

- Pipes and fittings should be purchased with a margin of 10-15%, since errors and marriage are possible during operation. The remaining material can be used for the next repair or for home creativity.

- A sharp tool is suitable for cutting links. If pipes with internal reinforcement are used, then it is advisable to use a pipe cutter.

- After separating the links into blanks, their ends must be cleaned of dust, chips and grease. Sharp edges are recommended.

- First you need to buy a welding machine, and only then pipes with the corresponding nozzles with an inner and outer diameter.

- Before starting installation, mark the walls, floor and ceiling. After that, install the clips that will support the workpieces during the welding process.

- For pipes of different diameters, there is a warm-up time in the soldering iron. It can be obtained from the seller of the goods or read in the instructions for the unit.

- The workpieces must be inserted into the soldering iron and removed from it at the same time. Immediately after extraction, they must be docked.

- Connected parts can be adjusted horizontally. It is forbidden to twist, stick in and stick out. Such actions weaken the connection and violate the tightness.

- An indicator of high-quality welding is a side made of frozen plastic. It appears outside and inside the joint.

Connection principle

Polypropylene pipes have a lot of advantages, but one of the disadvantages is that they do not bend. Therefore, when installing a water supply system from polypropylene pipes, fittings are used for all branches and turns. These are special elements - tees, angles, adapters, couplings, etc.There are also taps, compensators, bypasses and other elements of the system, also made of polypropylene.

Polypropylene fittings

All these elements with pipes are connected by soldering. The material of both connected parts is heated until melted, then joined. As a result, the connection is monolithic, so the reliability of the polypropylene plumbing is very high.

To connect with other materials (metal), to switch to household appliances or plumbing fixtures, there are special fittings. On the one hand, they are completely polypropylene, on the other, they have a metal thread. The size of the thread and its type is selected according to the type of connected device.

Internal or external laying

One of the advantages of polypropylene plumbing is that it can be easily embedded in walls and floors. This material does not corrode, does not react with any materials, and does not conduct stray currents. In general, if the connection is made correctly, pipes can be hidden into the wall or into the floor without any problems. The whole catch is to make a quality connection.

Polypropylene plumbing can be hidden in walls or in the floor

To make sure that the assembled system does not leak, it is checked - pressure testing is carried out. There are special devices for this. They connect, pump water, increase pressure. Under this pressure, the water supply is left for several days. If no leaks were found, then at operating pressure everything will work for a long time and without problems.

Features of the assortment of polypropylene pipes

Polypropylene is a type of plastic obtained by cracking petroleum products and petroleum gases. Its basis is propylene gas. Under high pressure with the presence of a catalyst, a polymerization reaction is carried out, as a result of which polypropylene is obtained. Pipes are subsequently produced from it. For water pipes, two types of such products are produced: single and multilayer.

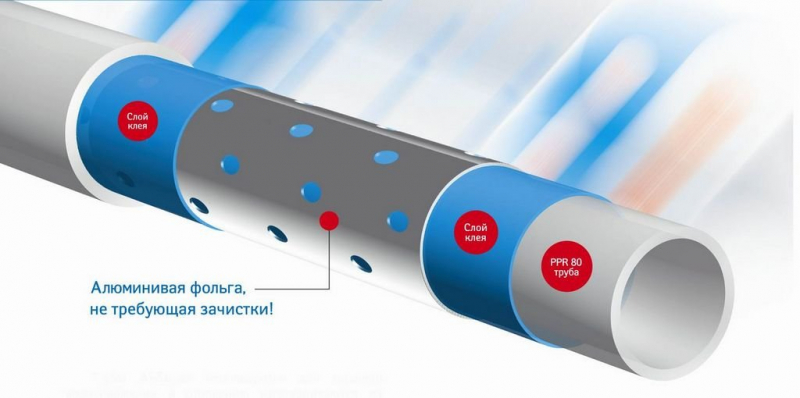

The first option is intended mainly for various types of pipelines through which cold water is transported. Multilayer or reinforced parts are used for arranging hot water mains, they are also used for installing heating systems. Their main difference is the presence of several layers of polypropylene, between which a reinforcing material is laid.

It can be aluminum foil, polyethylene or fiberglass. Details differ in the thickness of the reinforcing layer and the base.

In the manufacture of polypropylene pipes, the following marking of the material used in the manufacture is used:

- RR-N. Products for cold water, can be used for ventilation systems.

- RR-V. Material for the production of products with high impact resistance. Designed for arranging cold water supply and floor heating.

- PP-R. Pipes made from it can be used to equip any type of plumbing.

- PPs. It is used in the production of flame-retardant products intended for pipelines through which hazardous substances are transported.

The classification of materials used in the manufacture of pipeline products from thermoplastics for the construction of communications is given in GOST under the number 52134-2003.

Single-layer polypropylene pipes are mainly used for transporting cold water.

Marking of finished products is different. For polypropylene pipes, the following nomenclature designations are used:

- PN10. Products manufactured for the transportation of cold water with a working tº of not more than +20º C.

- PN16. Universal products that can be used for the construction of water pipes with cold and hot water. However, the temperature of the liquid should not exceed +60º C. It is rarely produced, moreover, in limited quantities.

- PN20. Pipes providing normal transportation of liquid tº + 80ºС. By analogy with the previous species, it is one of the universal ones.

- PN25. High pressure resistant parts, can be used for both plumbing and heating. The pipes are reinforced with aluminum foil and can be used to transport water up to +95ºС.

According to the marking of pipes, the pressure that PP pipes can resist when water moves through them is determined. For example, pipes PN 10 work normally at 1 MPa, PN 20 at 2 MPa, PN 25 at 2.5 MPa.

Polypropylene is sensitive to ultraviolet light, so pipes of different colors are produced. Black parts have the highest resistance to UV radiation. The production of polypropylene pipes is standardized, so they are produced in certain sizes.

Multilayer reinforced pipes can withstand higher temperatures and pressures. The reinforcing layer can be aluminum, as in the picture, or fiberglass

The first thing you need to pay attention to is the inner and outer diameters. They can be indicated both in inches and in the usual millimeters.

The diameter values determine the selection of the dimensions of the fittings that will be used to connect the pipeline parts.

The outer diameter of the products varies from 16 to 500 mm. The length of the pipes can be from 2 to 5 m, which is quite enough for arranging an intra-house water supply. Moreover, the products are easy to process.

PP pipe diameters must be taken into account when selecting fittings for pipeline assembly. It is assembled by means of detachable connections using fittings and tees (+)

PP pipe manufacturers

To install a polypropylene water supply system, it is better to use high-quality pipes from manufacturers who have already managed to positively recommend themselves. These include Ekoplast, Kalde, Rilsa, and so on. The use of low-quality products is fraught with consequences.

When heated, pipes will melt longer than expected, and their diameter may not fit the nozzle. If the end of the product enters the nozzle too freely, then a high-quality connection is unlikely to work.

To prevent this from happening, a small segment is bought and soldered to the fitting. This will allow you to draw the right conclusions regarding the purchase of PP pipes from an unknown manufacturer.

System planning

When developing a project for a heating system for a summer house or a house, they take into account the area of \u200b\u200bliving premises and the degree of wall insulation. For one square meter, the standard rate of heat is 41 kcal. The technical characteristics of the battery indicate the thermal power of one section. Based on these data, the number of radiator sections is calculated.

Additional calculations include:

- The length of the distribution of pipes with polypropylene;

- Number of turns and adapters;

- The presence of thermostats and bypasses;

- Installation of vertical and horizontal structures;

- Connection diagram to the boiler room (bottom, side, two-pipe or one-pipe version.

Important! Ignoring calculations at the initial stage can increase the cost of the project in the future. Extra sections of radiators will create discomfort in the apartment, and their insufficient number will lead to poor heating.