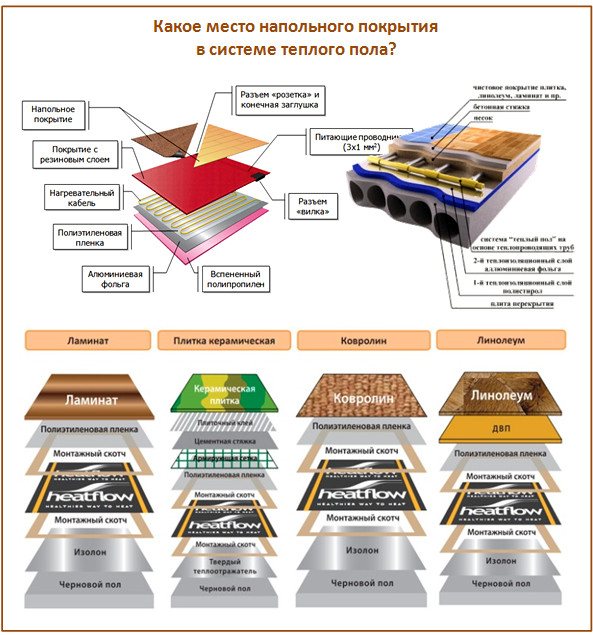

- Linoleum marking

- Features of the underfloor heating system on a wooden base under linoleum

- Laying technology

- Features of laying linoleum

- Is it possible to use plywood sheets on underfloor heating Benefits of plywood floors

- What types of plywood are used for heated floors?

- Advantages of plywood floors

- Electric floor heating device

- Safety Precautions and Usage Tips

- The choice of linoleum

- Floor preparation, calculation of materials and components

- Characteristics of the laminate as a condition for choosing a warm floor under it

- Advantages of water heated floors under linoleum

- How to lay the heating cable correctly

- Installation of ceramic tiles

- Method 1. Mounting on an old wooden floor

- Materials and tools

- Floor preparation and priming

- Marking and cutting

- plywood laying

- Types of underfloor heating

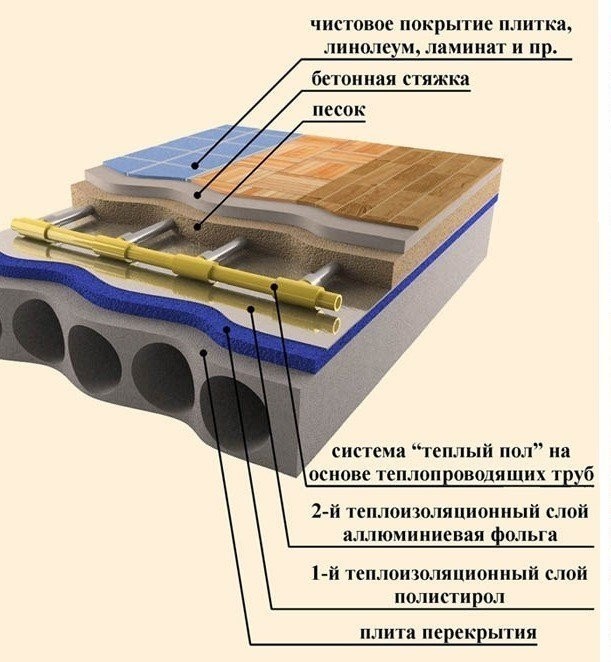

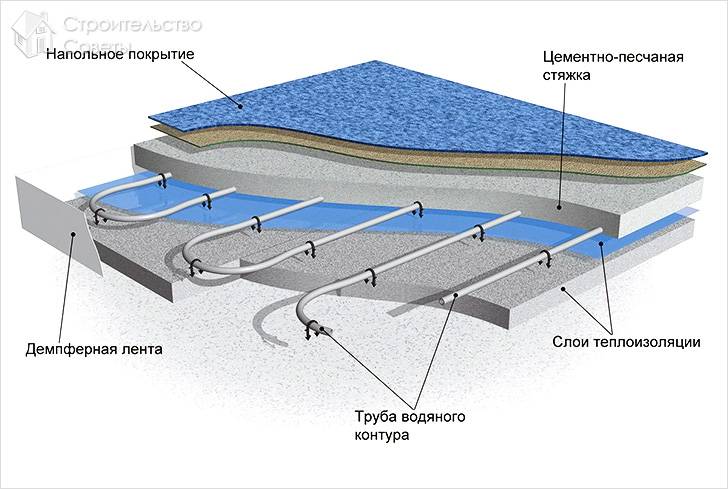

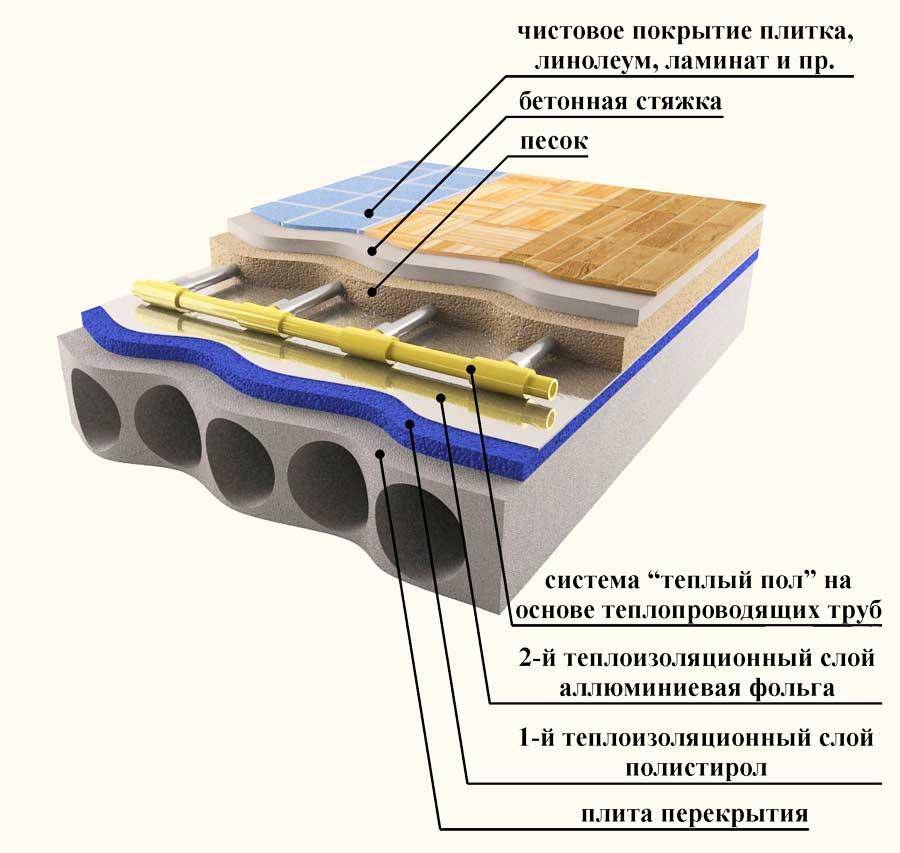

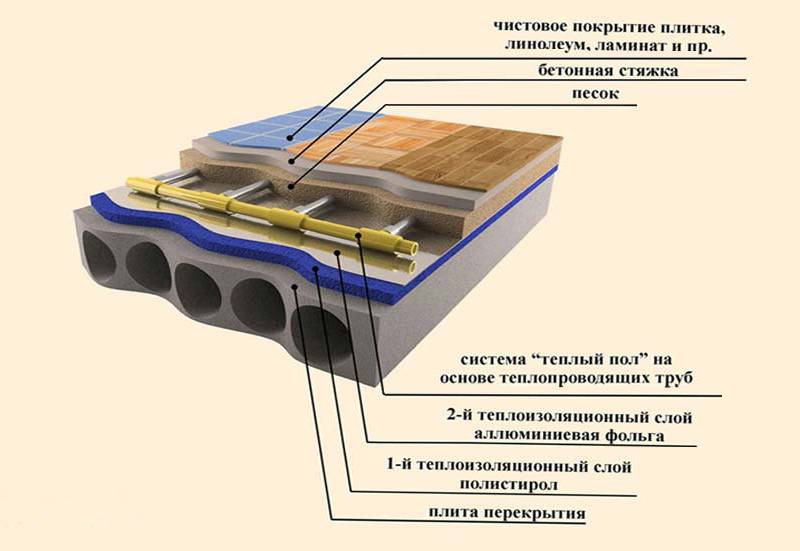

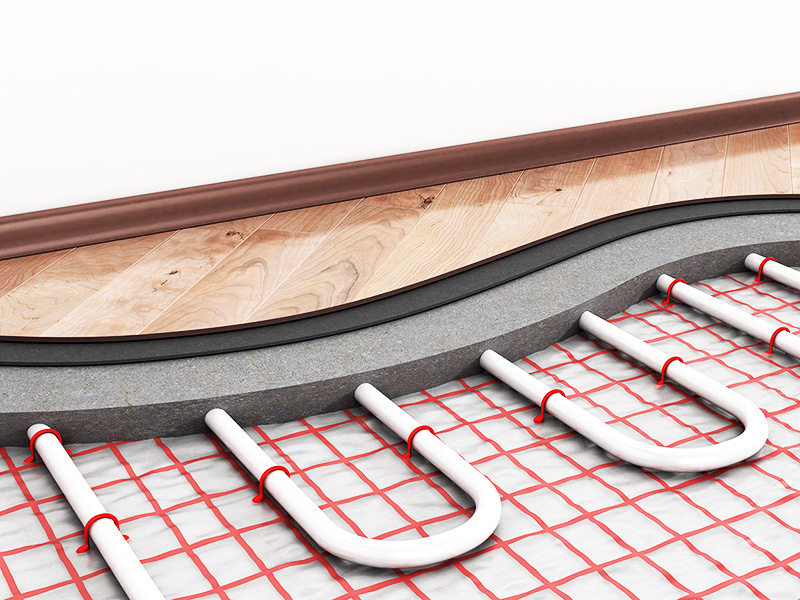

- Water heated floor

- Heating cables

- infrared floor

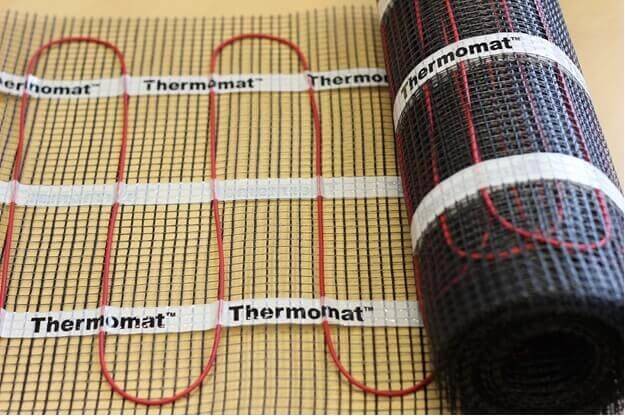

- Cable thermomats

- Technical features of underfloor heating

Linoleum marking

Significant assistance in choosing a linoleum coating can be provided by him.

a marking that is encrypted with a set of alphanumeric characters or

special signs. The main ones are presented in the table.

Linoleum marking

First digit in material class

indicates the type of room in which it is planned to be used: "2" - in

their houses, apartments; "3" - for premises in which the permeability of personnel and

customers are rated as medium and high; "4" - production and

special rooms.

The second digit characterizes the load the material can withstand.

and has 4 gradations. Degree

load that corresponds to each step is presented in column 3

tables.

You can also find out about the compatibility of the coating with a warm floor by

stylized symbols.

Permissive marking

Permissive marking

Linoleum of some manufacturers

may have extended labeling indicating specific properties

material:

- antistatic;

- flame retardant qualities;

- increased degree of protection against scratches;

- compliance with the global eco-label GEN "Leaf of Life".

Domestic PVC linoleums have additional articles,

denoting the underlying material:

- woven - T;

- non-woven - NT;

- artificial leather - RK.

One-color and multi-color graphic printing on the cover

marked accordingly - OP and MP.

Features of the underfloor heating system on a wooden base under linoleum

As far as we know, linoleum is in most cases a synthetic material made from a number of chemicals that, when heated, can emit toxic fumes. That is why those who plan to lay linoleum often abandon the idea of installing floor heating systems. Also, the matter can be complicated by the fact that the floors in the house are wooden, and no one is going to change them for a concrete screed.

The structure of semi-commercial linoleum

However, even in such situations, it is still possible to equip the heating system.Of course, it is not so easy to install, and the same properties of linoleum often scare away apartment owners from installing underfloor heating.

But if you approach this problem with all your attention, then you can always find a way out of the situation and make warm floors. First you need to decide which heating system can be equipped in a house with a wooden base.

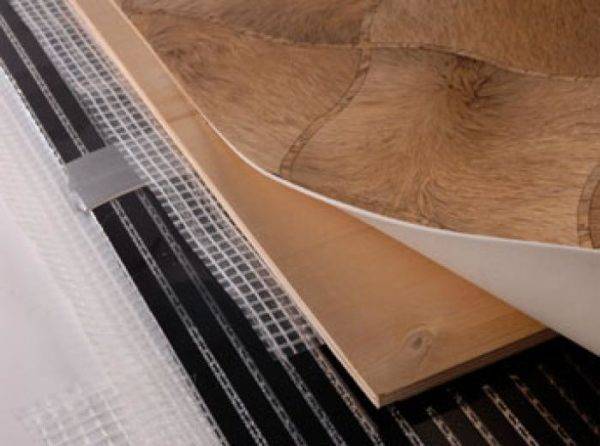

Linoleum laid on plywood base

Laying technology

In principle, everything is very simple to do and therefore, there is no need to consider each of the stages in detail. It is worth clarifying only the general order of work and in each case it may vary slightly.

- First, the foundation is prepared. The surface should not be dirty, it should not have protruding defects and depressions.

- A heat-reflecting substrate is laid on the surface. Without it, such floors are less effective.

- Mats are neatly laid out over the substrate.

- The system is connected and the first working test is made.

- A protective coating of plywood or other rigid materials is laid on top of the mounted heating circuit.

All work should take approximately half a day. This is provided that you have to work indoors and in standard sizes and everything will be done very carefully. If you have experience in installing such devices, the time can be reduced. However, do not rush too much, as inaccuracies and inaccuracy in work lead to serious errors, which in turn can lead to an inoperable state of the entire system.

Features of laying linoleum

Separate strips are laid with an overlap of 10-20 cm and secured with tape

In this case, it is necessary to move along the surface of the infrared film very carefully so as not to violate the integrity of the graphite heaters.

Next, mount a flat surface of fiberboard. This material will reliably protect the warm floor and will become a suitable base for linoleum. This type of flooring is delivered rolled up, so it is recommended to spread it out and leave it for several days before installation.

Before laying linoleum must be decomposed on a flat surface of a warm floor, turn on the system and wait until the coating is leveled

In the case of underfloor heating, the process can be improved. Linoleum is laid on a fiberboard base without fixing, and then an infrared film is turned on. Under the influence of heat, the alignment process will be faster. In this case, the thermostat should be set to a level of 28 degrees or slightly less. For linoleum, this temperature is considered optimal.

After the coating becomes sufficiently even, it remains only to fix the linoleum on the base. This operation is performed using double-sided tape or glue.

The use of an adhesive is considered more suitable for use with underfloor heating, unless dismantling and relocation of equipment is planned. The adhesive provides a snug fit and uniform heating.

Before laying a heating element-based transformer substation, it is necessary to check whether there are possibilities for an internal power supply for additional load.

The screed allows you to get an even, solid base. A thermostat is a must. The exception is a self-regulating cable.

The device of a single-two-core heating cable for underfloor heating

What is the difference (other than structure) between these types? Two-wire: more expensive, installation - easier.One side connection. Single core has contact sleeves at both ends.

Mounting the heating wire under furniture is not recommended. Indent:

- from the outer walls - 25 cm;

- from internal wall fences - 5 - 10 cm;

- from furniture - 15 cm;

- from heating devices - 25 cm.

Before laying the conductor, it is necessary to calculate its length for each room.

Shk = (100×S) / L,

Where Shk is the wire pitch, cm; S is the estimated area, m2; L is the length of the wire, m.

When choosing the length of the conductor, it is necessary to take into account the value of its specific linear power.

For a room of 10m2 (with average standards of 200 W / m2 and 80% of the usable area), the power should be 1600 W. With a specific linear power of the wire of 10 W, its length is 160 m.

From the formula, SC = 5 cm is obtained.

This calculation is valid for TP as the main means of heating. If used as an additional one, then, depending on the purpose of the room, the percentage of heating is reduced from 100% to 30% - 70%.

The sequence of technological operations:

- Preparing the concrete base: leveling, applying waterproofing.

- Laying a heat-insulating substrate made of foil material with markings.

- Installation of a thermostat.

- Layout according to the scheme of the heating element. The temperature sensor is installed inside the corrugated tube.

- Screed filling.

To get a complete picture of the installation of a structure with a heating conductor, you can watch the video.

Before pouring the screed, you need to check the operation of the heating circuit. It is desirable to include for testing no earlier than 28 days, when the solution gains 100% strength.

Practical Tips:

- If the wire crosses the seam between the plates (deformation), then it should be laid

- with slack for the possibility of relative elongation;

- When crossing another heat source, it is necessary to make thermal insulation to protect against overheating;

- For accurate readings of the temperature sensor, it is placed closer to the surface, placing a gasket of the required thickness.

Pie cable underfloor heating

Is it possible to use plywood sheets on underfloor heating Benefits of plywood floors

Many residents of high-rise buildings and private houses experience discomfort from chilled floor coverings that are impossible to walk barefoot on. Therefore, it is quite logical to want to insulate the floors. Many people lay plywood on a warm floor, on which they subsequently lay a top coat (laminate, tile, etc.).

What types of plywood are used for heated floors?

Manufacturers produce a large number of varieties, varieties of plywood. Therefore, consumers are asking questions, is it possible to use it for laying underfloor heating, what types are used? Note that all types are suitable for use in installing a warm floor (on logs, on a wooden floor, concrete), but it is worth choosing the material individually, for each specific case.

There are five grades of material, and some of them are moisture resistant. To make plywood of the 1st grade, only birch, oak, beech veneer is used; knots cannot be found on it. Such materials are laid on the floor, but their cost is high, and the construction of the floors will be costly.

Second-rate material is more suitable for arranging a warm floor, while the quality does not suffer, and it will not hit the wallet.

Advantages of plywood floors

With the help of plywood material, a good quality intermediate base is made for floor heating.When a piece parquet, a parquet board, fastened to the rough base with self-tapping screws, is placed on the adhesive mixture for a fine finish, then the addition of plywood sheets is mandatory.

Professionals advise putting such a "pie" of the floor even when laminate, linoleum is used as a decorative coating. With such a position of materials, the role of heat and sound insulation falls on plywood.

The general advantages of plywood in arranging underfloor heating include:

- Strength characteristics,

- environmental friendliness of the material,

- Acceptable cost in terms of purchase, work,

- The range includes moisture-resistant types for use in rooms with high humidity,

- The material is easy to process and maintain.

The use of plywood for heated floors is not as effective due to its poor heat conductivity. Therefore, underfloor heating under thermal insulation plywood will have to be used at full capacity so that heat seeps through the wood, and this will lead to increased heating costs. And in order to maximize the effect of the warm floor, it is recommended to choose the appropriate option for laying the structure.

Installation of floor heating on a plywood basis, unlike the traditional laying technique, is done without rigid fixation. Sheets of material are attached with this method of installation with metal mounting brackets. This makes it possible for the wood veneer to expand with an increase in humidity, and eliminates the appearance of swelling and cracks.

To install intermediate plywood flooring, several methods are used:

A material 1.2 cm thick is laid on a concrete screed,

Attention! Plywood sheets are attached to concrete using dowel-nails, adhesive mortar

- On the base of wooden logs, thick sheets 2 cm thick are applied in 2 layers with spaced seams,

- On old wooden floors apply material of any thickness.

Masters do not recommend installing a warm water floor under plywood, as this is ineffective, and there is a risk of damage, leakage of coolant pipes. And if this happens, then all the wet, damaged plywood will have to be thrown away. Therefore, for such floors it is better to choose a different finish.

When installing a warm electric floor using plywood, and then laying carpet, linoleum, it is worth considering some features. For installation, it is recommended to use underfloor heating film components from one manufacturer, which prevents problems with the use of the coating.

The assembly of a warm film floor resembles a "pie":

- A heat reflector is laid on the main floor,

- Then lay a layer of thermal film,

- Lay down the plastic film

- Then a hard coating is mounted, ensuring alignment,

Attention! It is not recommended to use sheets of chipboard, fiberboard, OSB - they do not give a flat surface, they can sag

- Plywood sheets are fixed with self-tapping screws to the main coating, the joints are puttied,

- After 2 days, lay the top coat.

A person who decides to make a floor heating system should remember that it is possible to use plywood on a warm floor system. You should only strictly monitor the base before laying - it must be perfectly dry, otherwise the plywood will absorb moisture, and the structure will become unusable.

Electric floor heating device

When laying film electric heating on a concrete subfloor, it is necessary to carefully prepare the base.The screed should be completely cleaned of debris and dust and made as even as possible.

After that, a special film with heat-reflecting properties is laid. This thermal insulation is attached to the base with adhesive tape.

Next, the pre-prepared heating elements themselves are laid on top of it.

In this case, it should be ensured that the contacts of the individual strips do not come into contact with each other.

To prevent further displacement of the heating strips, they should be attached to the draft base and this can be done with adhesive tape or a stapler.

At the final stage of laying, it is necessary to carefully check the reliability of fastening of all supply wires and insulation.

After the installation of the infrared film is completed, it is necessary to install a special control relay and check the floor in operation.

Next, a polyethylene film is laid over the electric strips of the warm floor, which should completely cover the surface of the base.

Electric underfloor heating should never be filled with concrete screed.

On top of the film, it is recommended to lay sheets of plywood or chipboard, pre-treated with special protective compounds. Only after this is the laying of linoleum.

As in the case of a water floor, in order for the material substrate to take the correct shape, it is necessary to turn on the heating for two days.

Only after the linoleum substrate takes the form of a base, the material is finally fixed in place.

You can learn more about how to install an electric heated floor with your own hands by watching the video below.

Video:

Underfloor heating makes it possible to create the most optimal temperature conditions in the house. It is allowed to lay linoleum on top of it, however, for this it is necessary to take into account the specifics of this material.

In any case, subject to certain rules and technology for installing a warm floor, all the work can be done by hand in the shortest possible time.

Safety Precautions and Usage Tips

Infrared heated floors are the best option for additional heating when using linoleum as a floor covering. When carrying out installation work, do not neglect the following measures and tips:

- If the total power of the IR film laid in the room is more than 3 kW, we advise you not to be lazy and lay a separate line from the electrical panel;

- Be sure to install a residual current circuit breaker - it will protect the power grid from overloads in the event of an accident and help turn off the underfloor heating for repairs;

- Do not use old and damaged wires, carefully evaluate the quality of electrical insulation, follow safety rules when working with electrical appliances;

- Do not overheat linoleum - no matter how expensive and reliable they are, but due to overheating, it can lose its qualities. Color loss is also possible.

Using our instructions, you can quickly and effortlessly lay infrared heated floors in the rooms and lay linoleum.

The choice of linoleum

This aspect must be taken with all due attention just because linoleum, when heated, is capable of releasing toxic substances into the environment. And then you can use the floors only at your own peril and risk to health.

How to choose the right linoleum

Table. Types of linoleum.

| View | Description |

|---|---|

| PVC | This is the cheapest, and therefore the most common option. It is based on ordinary PVC, which is sensitive to heat. This material is distinguished by a wide variety of color variations, can have different thicknesses, and also have a base in the form of a warming material. Unfortunately, it is this material that, when laid on warm floors, not only begins to release toxic substances into the air, but also shrinks, and also begins to smell unpleasant. |

| Marmoleum | This is a natural type of coating, which is of high quality and high price. It is not afraid of fire, does not electrify, and when heated, almost does not emit toxic substances into the air. It contains natural dyes, wood flour and cork flour, pine resin, linseed oil. Also, it is usually based on jute fabric. Such linoleum is easy to clean, does not fade in the sun and does not lose its appearance for many years. The only thing he does not like is washing with alkaline substances. Under the action of alkali, it will begin to collapse. |

| relin | This linoleum contains bitumen, rubber, rubber. It does not tolerate heat and therefore, in general, it rarely fits in houses and apartments, more often it can be seen in a number of industrial premises. When heated, it releases substances that are quite dangerous for humans. It is strictly forbidden to use it with a floor heating system. |

| Nitrocellulose | Such material is also called colloxylin. He is not afraid of water, elastic, thin, but does not like heat. So it cannot be used with a heating system. |

| Alkyd | Also called glyptal. Synthetic material, which is based on fabric. It’s worth saying right away that he, like the previous options, does not like heating.But it can be used in combination with underfloor heating, since it does not emit an excessive amount of hazardous substances. |

The process of laying linoleum

According to the information in the table, it is possible to mount marmoleum or PVC material on wooden floors in the presence of heating systems. However, experts note that both options can be laid on water floors, but it is better to put marmoleum on film floors.

Table with a list of characteristics of linoleum

Floor preparation, calculation of materials and components

To install a warm film floor, you will need the following materials

and tools. In addition to the linoleum itself, you will need an infrared film, electrical

contacts for it, copper wire, thermostat with temperature sensor, wide

polyethylene film 2 mm thick, wide strong adhesive tape, heat reflective

underlay, thin plywood.

From the equipment: a sharp knife or large scissors, pliers,

construction stapler, Phillips screwdriver. It may be necessary and

some other accessories and equipment.

Measure the room in length and width. Count how many times the width of a roll of infrared film is laid. Multiply the length of the room by the number of stripes. Now it is worth considering each floor element, its area and configuration.

Under cabinets, sofas and other massive and constantly

objects located in one place, heating devices are not placed.

This is harmful to furniture and useless in terms of heating rooms. The best thing

draw a diagram on a piece of paper. Just in case, increase the desired length

by about 5-10%.

You also need to consider the place where the thermostat will be located. It is placed next to the outlet. Please note that the infrared floor consumes about 200 W per 1 m2. This means that a room of 16 m2 may require up to 3.2 kW. If the consumption is more than 3 kW, be sure to stretch a separate power line.

But, even if the consumption is less, it is necessary to check the wiring. It is advisable to replace the thin aluminum wire with a high-quality copper one. It may be necessary to change all the wiring in the apartment and it will be necessary to obtain consent to increase the power consumption from the mains.

It is best to connect a film underfloor heating with

installation of separate fuses on the shield. This is done before

work on the floor will begin. If the power grid refuses to increase capacity, then

you will have to abandon the film infrared floor.

In the same way, the need for underlying plywood, underlayment and film is calculated. But count on the fact that the film must be laid with an overlap - this will increase the amount by 10-15%. Elements are laid throughout the space of the room.

Characteristics of the laminate as a condition for choosing a warm floor under it

The warm floor is laid under the laminate, observing two conditions: moisture isolation and temperature control. The fibreboard of the carrier layer gives rise to mutually exclusive disadvantages of the laminate: it is afraid of both high humidity and high temperature. Both that and another breaks structure of a plate, bends it.

The temperature of the warm floor under the laminate should not be higher than 25 C. The logic is simple: at 27o the boards begin to crumble; at 26 Co, formaldehydes, toxic fumes that are harmful to health, are released from their protective film.

Which underfloor heating laminate to choose? The technical passport contains a marking that can be placed on underfloor heating. For example, a laminate labeled "Warm Wasser" ("Warm Water") is recommended for a water-heated system.

The choice of laminate for underfloor heating - Photo 02

A variety of types of laminate - Photo 03

Advantages of water heated floors under linoleum

The design of a water-based warm floor includes several layers, which are insulation, fittings, pipes, screed. If you plan to install water heating, you should take into account that the height of the room will decrease by 10-15 cm. Installing an infrared floor in the form of a thin film changes the height of the room to a minimal extent.

The choice in favor of a water-heated floor under linoleum is more often made by owners of private houses. Electric underfloor heating is installed in the apartments, and water systems are rarely used. This is due to the fact that in the latter case, the load on the central heating increases, and the piping system is not designed for this. The main advantages of using linoleum as a coating for water-based underfloor heating are the following:

- Excellent thermal insulation characteristics of the base.

- Saving materials due to the minimum thickness of the concrete screed.

- Rapid heating of floors.

- Reduced electrification of linoleum due to the absence of electromagnetic radiation.

- Safety of a water heat-insulated floor.

- The linoleum coating has optimal technical characteristics for laying on the surface of a warm floor.

The coating provides additional waterproofing of the room, as well as the penetration of heat given off by the pipes of the system into the room.You should not choose linoleum that has a synthetic base, since it is capable of releasing substances hazardous to human health under the influence of high temperatures.

How to lay the heating cable correctly

The installation process is preceded by the stage at which the wooden or concrete floor base must be prepared:

First of all, it needs to be leveled and strengthened. If it is concrete, then you will have to fill in the screed to repair the defects and give the plane a certain evenness. The type of screed can be anything - a do-it-yourself cement-sand mortar, a dry ready-mix or polymer floors. The wooden base must be sanded, but before that, all cracks and gaps must be sealed.

Next, two layers are laid on the prepared surface:

- bottom - waterproofing

- upper - thermal insulation

Now all this is filled with a screed, which will be thicker than the screed from below.

Someone may note that such a thick cake will significantly reduce the height of the ceilings. You can’t argue with this, so sometimes they refuse the heat-insulating layer. But this results in little heat loss.

Now to the question of how to lay the heating cable:

- The best option is a snake. But keep in mind that it is necessary to avoid places where large-sized furniture and large objects will be installed. This is the first.

- Secondly, the distance from the walls to the cable should be at least 10 centimeters.

- Thirdly, the optimal distance between the turns is 25–30 centimeters.

If you take all this into account, then you can guarantee the effective distribution of heat over the entire surface.

There are several nuances that relate to the quality of the result.Since the heating cable is laid under ceramic tiles, it will be difficult to repair it if something suddenly goes wrong. Therefore, experts advise before pouring the screed to check the electric underfloor heating for proper operation. That is, a cable is laid, a temperature sensor is mounted in the floor between two turns of the cable, a thermostat is installed in the wall, and all this is connected to each other and through the thermostat to the AC mains, that is, to the outlet.

Now you need to check if all the turns are working, if they are at the same temperature, and if there are any failures. If everything suits you, then the system is disconnected from the electricity supply, and the screed is poured. What screed should be used in this case? There is no difference. The main thing is that the floor is durable, so cement-based mortar is the best option. The technology of applying the screed requires the creation of an even base, on which ceramic tiles will subsequently be laid. Therefore, you will have to try. An important point is the uniform distribution of the solution over the entire surface.

And now remember one rule - after pouring the cement mortar, you should not rush. It is necessary to wait at least two weeks for it to dry well. During this period of time, it is impossible to turn on floor heating under the tiles. The screed is still wet, so there is a high chance that the heating cable will burn out.

Installation of ceramic tiles

Underfloor heating device

So, everything is ready, and you can proceed to the final stage. Today, the construction market offers special bonding mixtures, as well as tile grouts, which are used specifically for laying tiles on a warm floor.It is rather difficult to choose from the whole variety of mixtures offered, even if the package says what this composition is intended for. Therefore, contact the manager of the hardware store and do not waste your time searching.

What is the difference between these ready-made mixtures from the rest?

- Firstly, the solution made from them is more plastic.

- Secondly, they have better characteristics, in particular, significant resistance to high temperatures.

- Thirdly, they contain a large number of various additives that improve the quality of the solution.

Method 1. Mounting on an old wooden floor

When laying plywood on a wooden floor, there are many options for fixing sheets:

- on self-tapping screws;

- on glue;

- for liquid nails.

Among the adhesive compositions, water-based glue, a two-component composition, mounting glue and bustilat are distinguished. However, self-tapping screws are preferable.

Materials and tools

For the successful installation of plywood sheets, the following tools and materials will be required:

- plywood sheets;

- jigsaw;

- level;

- roulette;

- marker;

- self-tapping screws;

- screwdriver;

- substrate;

- construction vacuum cleaner or broom.

You may also need a grinder, roller and primer, glue and sealant.

Floor preparation and priming

Installation of plywood on wooden floors is carried out only if the height difference when checking the level is no more than 1 cm. In this case, a substrate compensating for unevenness and adhesive tape will also be required, which will need to glue the joints of the strips of material.

Check the condition of the floors. Strengthen creaking and loose floorboards, replace rotten and damp ones.Do not try to restore boards with traces of mold, damage, attacked by rodents. They must be removed and the room ventilated.

Removing skirting boards, inspecting the condition of the floor

Sweep dust and dirt from the floors with a broom. If desired, go over with a wood primer twice for better adhesion of the materials. And dry the base for at least 16 hours.

Marking and cutting

Saw plywood only on a rigid base

Plywood sheets are sawn so that the number of joints is minimal, taking into account damper joints 3-4 mm between sheets and 8-10 mm between plywood and the wall. This will help to avoid swelling of the sheets, since during operation, under the influence of the microclimate and temperature fluctuations, the workpieces will increase in area by several millimeters.

Laying plywood sheets

Leave a gap between the wall and plywood

Cutting is done with an electric jigsaw, while the ends of the workpieces are carefully inspected for delaminations and polished. On large areas, for ease of installation, plywood can be cut in squares of 50x50 or 60x60 cm. This technique will help to more accurately level the surface and eliminate possible laying defects.

The sawn sheets are numbered, and similarly to their numbers, a schematic arrangement of the blanks is drawn on a wooden base.

Leave the vent open

plywood laying

Mounting blanks has several features.

- If necessary, a substrate is placed on the old wooden coating, the strips are glued together with adhesive tape.

- Holes for self-tapping screws are drilled in advance, and then countersunk with a slightly larger diameter drill.

- Self-tapping screws are sunk into plywood sheets.

Carefully sink the hats of self-tapping screws or dowels

Upon completion of installation, you should check the quality of the coating, remembering that the ideal gap between the level and plywood is 2 mm, the maximum is 4 mm.

Types of underfloor heating

Such home comfort technology as a warm floor can be

performed in several versions. The implementation of this system in conjunction with the correct

selected coating makes it possible

pleasant tactile sensations.

Underfloor heating with linoleum trim can also effectively

supplement the heating system. This is achieved by covering with heating

elements of the entire area of the room and its optimal heating - with a higher

temperature below at the heat source (22 - 24 ° C) and slightly lower, but

quite comfortable, under the ceiling (18 - 22 ° C).

Comparison of heat transfers for different types of heating

Heat transfer technology

Underfloor heating energy can be divided into two main types:

- Water.

- Electric.

Electric heating systems and

liquid heat carrier can differ in the way the project is implemented.

Water heated floor

The standard version of the water warm flooring is performed according to the following scheme:

- laying on the base of hydro- and heat-insulating

materials; - fixing pipelines on a metal mesh;

- pouring pipes with concrete.

The thickness of the screed over pipes with a diameter of 16-18 mm, as a rule,

is at least 30 mm.

Pipe laying option for water heating

Pipe laying option for water heating

Due to the need to rotate the pipes, the laying step

is limited and must be within 22.5 - 35 cm. Base with hydraulic

heated compatible with marmoleum and PVC material.

Heating cables

Another solution for warm flooring under linoleum -

use of electric heating cable.

heating cable

heating cable

Electrical cable system using resistive

cable is equipped with a thermostat and temperature sensor.

Gaining great popularity

modern self-regulating thermal cables. The basis of such a heating cable is a heating

cross-linked polymer matrix with graphite additives. This matrix contains two

copper strands.

Heating power of the system is adjusted

by changing the resistance of the matrix depending on the temperature

heating element.

Self-regulating heating cable

Self-regulating heating cable

Coating with cable system

heating can be universal, including linoleum, compatible with

underfloor heating system.

infrared floor

At the heart of infrared

technology is based on the use of a special film.

IR technology with low intensity heat dissipation

fully compatible with the variant of the linoleum flooring device.

The infrared floor heating system is one of the most

energy saving. Compared to a heating cable, less energy is consumed per

25%.

Heating elements are sealed in polypropylene film,

supplied in rolls.

Infrared film material

Infrared film material

The strips are heated by a source of electricity transmitted

along copper-silver busbars located at the edges. Due to the applied

on the carbon paste film thermal energy in the form of infrared radiation

heats up the floor surface and is transferred to the environment.

Cable thermomats

The principle of operation of the thermostat is based on

heating resistive cables woven into dielectric fiberglass

grid. To reduce the level of electromagnetic radiation of the cable core in mats,

used for residential areas, double, shielded and protected by external

shell.

Thermomat roll

Thermomat roll

System design and operation

heating using thermomats are simple. Automatic regulation

heating temperature allows you to combine with heating mats not very

heat sensitive coatings.

Technical features of underfloor heating

According to the engineering device, these are rather complex systems with several layers. The specific list of works and materials depends on the characteristics of the base and finish coating. What should be considered during the manufacture of such a design for linoleum on a wooden floor?

-

The load-bearing capacity of a wooden floor. The structures are laid on logs, the calculation of the section of the elements of which was often done without taking into account the additional load. In new buildings, wooden floors have a sufficient margin of safety and hold heating systems without problems. Old structures are often of critical importance due to the natural wear of the elements or damage to the tree by rot. In the event of an increase in the load, the base may not withstand and sag, and the consequences of this are very unpleasant and require great effort to eliminate.

-

Lumber breathes, constantly increasing or decreasing the relative humidity, depending on the operating conditions. To increase the service life, the wooden floor must be able to get rid of excess moisture, and heating systems significantly impair the effectiveness of natural ventilation. During the construction of a warm floor, it is necessary to use a set of special construction measures to ensure optimal ventilation of wooden structures.

-

Linoleum must be laid only on flat and hard surfaces. This means that the heating systems must be closed.For these purposes, cement screeds, plywood or OSB boards are used. The specific material should be chosen after a competent analysis of the technical parameters and the actual condition of the wooden floor structures. At the same time, it is necessary to achieve cost reduction and increase the efficiency of the heating system.

Wooden floors are not considered the optimal base, but modern building materials and technologies allow us to achieve excellent results even in such adverse conditions.