- How to choose the right pump for your home

- What to give preference

- Choice by purpose

- Types and action of high pressure pumps

- Dry rotor units

- Glandless devices

- Hand pump

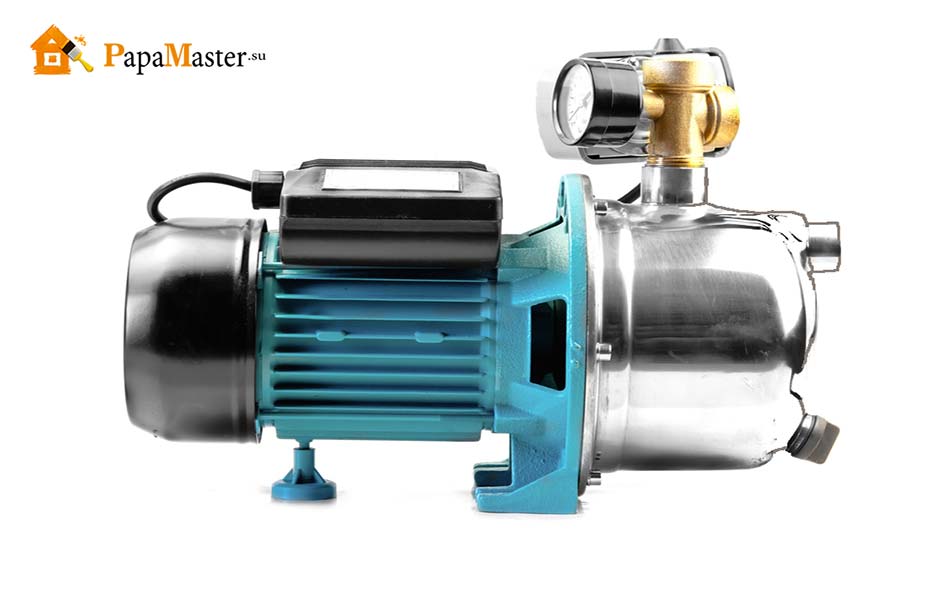

- Types of self-priming pumps

- The device and principle of operation of a centrifugal pump

- Working principle of self-priming peripheral pump

- Features of submersible pumps for pumping water

- What kinds exist?

- DIY option

- Classification depending on the purpose of use

- Water pump design

- Frame

- Axle, bearings, oil seal

- Video: Pump Selection. LUZAR pump.

- Pulley, impeller

- vortex pumps

How to choose the right pump for your home

What other difference can be noted for self-priming pumps of different types?

- Centrifugal units are superior to vortex ones in size and weight. At the same time, they work much quieter and can pump water with fairly large foreign inclusions through themselves without fear of breakage. For example, fecal and drainage pumps have just such a structure. Vortex units are quite sensitive, so filtering units that purify water must be placed in front of them.

- Centrifugal pumps are considered more reliable equipment. Their service life with regular maintenance can be 20 years or more.In repair, they are also quite simple - there are a lot of parts for sale, if you wish, you can do everything yourself if you have at least basic knowledge of the structure of electric motors.

- We have already written about the consumption of electricity and efficiency, we will not repeat ourselves.

Before buying, be sure to ask for a product passport and familiarize yourself with its performance characteristics. We are interested in the following:

- First of all, we look at performance and power. This parameter must be compared with the distance of the well from the house, the depth from which the unit raises water, the volume of the entire water supply system and the maximum possible volume of water flow at any given moment. Before going to the store, you need to make the appropriate calculations so that you don’t have to guess whether it’s enough or not. The methodology for carrying out such calculations is not complicated, it is easy to find it on the net. You can also use convenient online calculators in which you just need to drive in all the necessary data.

- The minimum pressure that must be in the system is 0.3 bar. It must be constant, otherwise household appliances connected to the water supply may simply fail.

- It is also worth correlating the capabilities of your pump with the diameter of the well casing and its maximum performance. Such information is best obtained from specialists who performed drilling in your area.

What to give preference

There is no single universal advice for choosing a self-priming type pump. Recommendations can be summarized in the following nuances:

Centrifugal devices have large dimensions and are characterized by almost silent operation. Their disadvantages include low productivity and the ability to work with a depth of no more than 8-10 meters.It is a good choice for installation in the home and connection to a shallow well, and as a seasonal option for watering beds with water drawn from a river or lake.

For medium depth wells, a peripheral pump is the best choice.

It is more powerful, works with a depth of up to 15, and with the existing ejector, up to 30 meters. Such a pump can be installed inside the well by immersing it in water (special submersible models). We add that you need to think about choosing a pump already at the stage of drilling a well.

Choice by purpose

The choice of model depends on the scope of use, here are a few options for using water pumping equipment:

- With insufficient water pressure in the system, it is worth buying a high-pressure water pump to increase it.

- A fecal type of pump is used to service sewers or pump out waters with a high level of pollution. More convenient models with an automatic switching system

- If you need to drain a pool, cellar or well, purchase a semi-submersible drainage model (the pump is partially under water), or a submersible pump with a float shut-off mechanism

- It is easy to get water for irrigation of the site or personal needs using a submersible pump, provided that the depth does not exceed 5 meters. For a depth of 5-10 meters, choose a model with an ejector, and more than 10 meters, it is better to buy a submersible pump

Submersible pumps, although equipped with protection against idle operation, require installation without contact with the bottom of the reservoir and with a water level above 1 meter. Such conditions are associated with changes in the seasonal water level in a well or well and the need for additional cooling of the mechanism.

To perform several tasks, one- and two-stage models, or several in combination, are suitable.

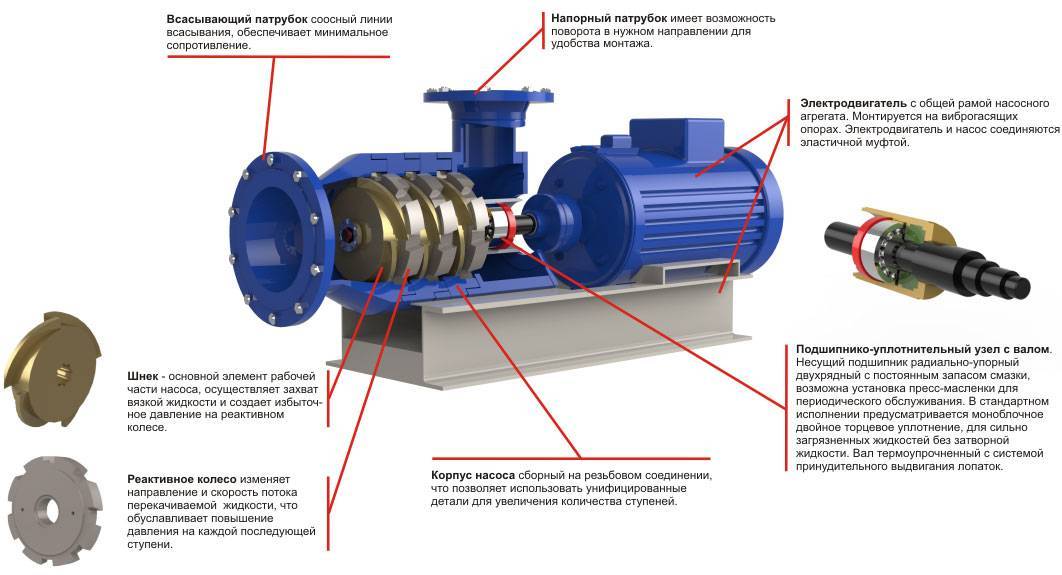

Types and action of high pressure pumps

Before deciding to install a stimulation pumping device, the condition of the pipeline should be assessed. It is possible that the pressure deficit is due to pipes clogged with sediment. If you can get out of a predicament only by installing the device, then you should familiarize yourself with their technical specifics in more detail.

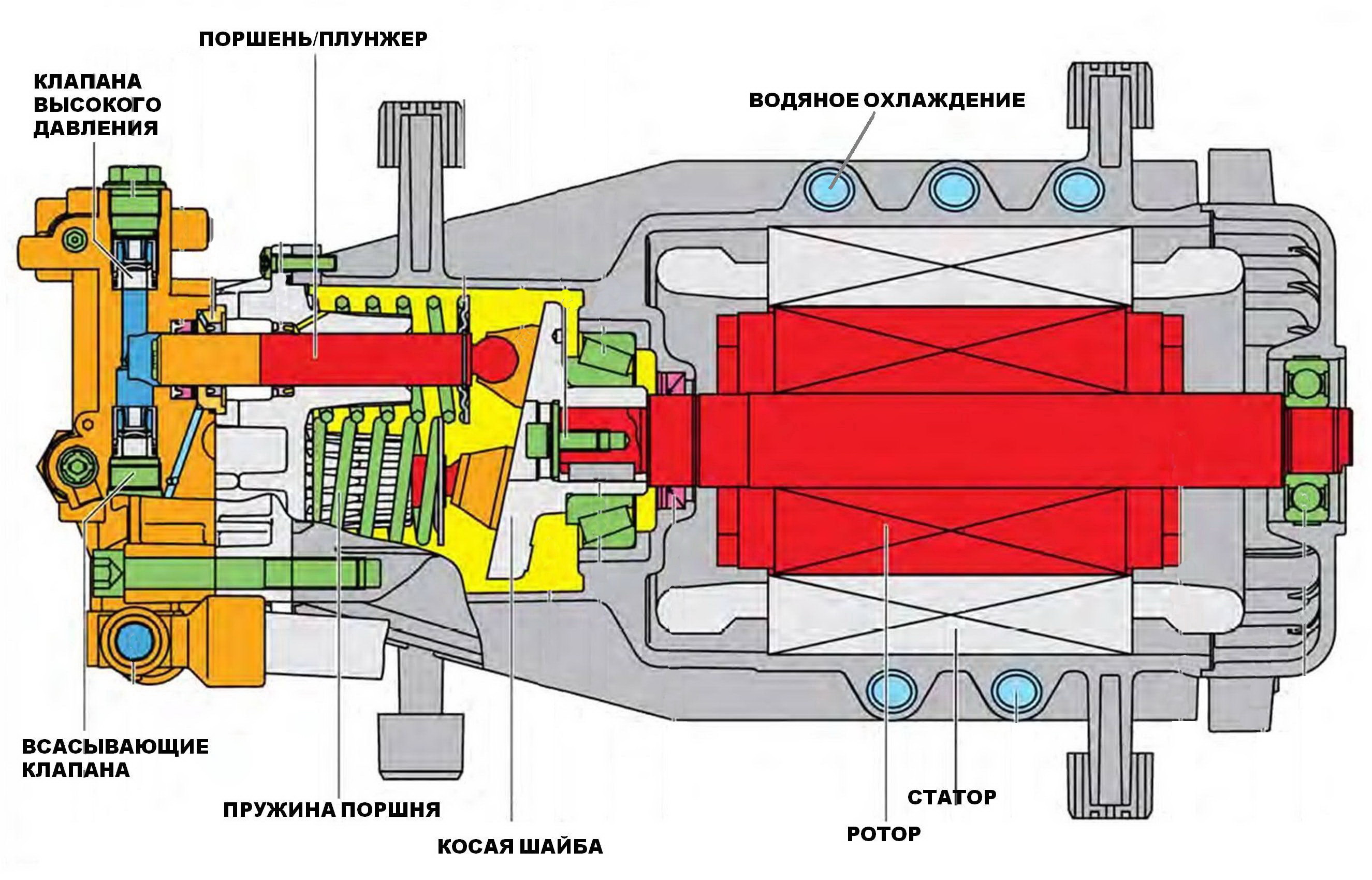

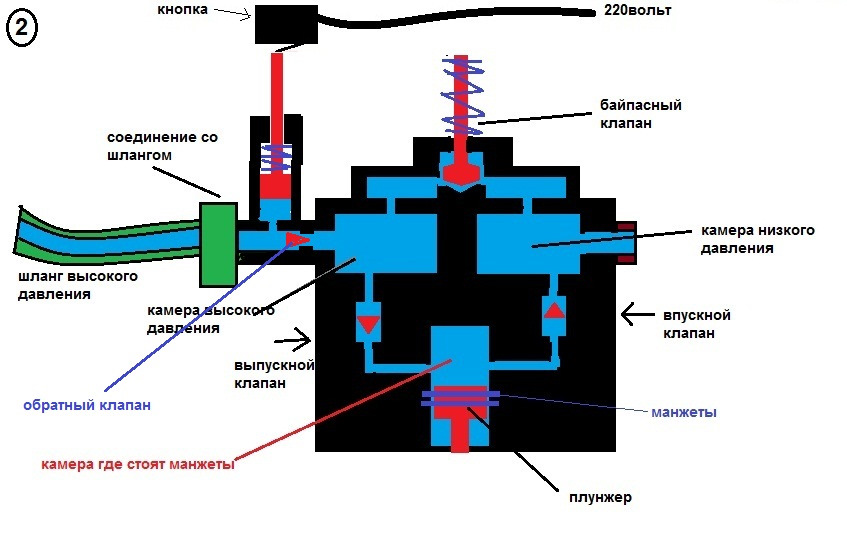

The principle of operation of high-pressure pumps, regardless of the version of the working body and the type of design, is the same. During the operation of the working unit, the device creates a vacuum space inside the cavity, due to which water is absorbed.

By creating a vacuum space, water is “drawn” from the source into the chamber, and then, under the action of high pressure, is pushed through the outlet pipe

On sale are models of a universal type, suitable for water of any temperature, and those that can only be used in a cold or only in a hot environment.

Depending on the method of cooling the running motor, the units are of two types: dry and wet rotor.

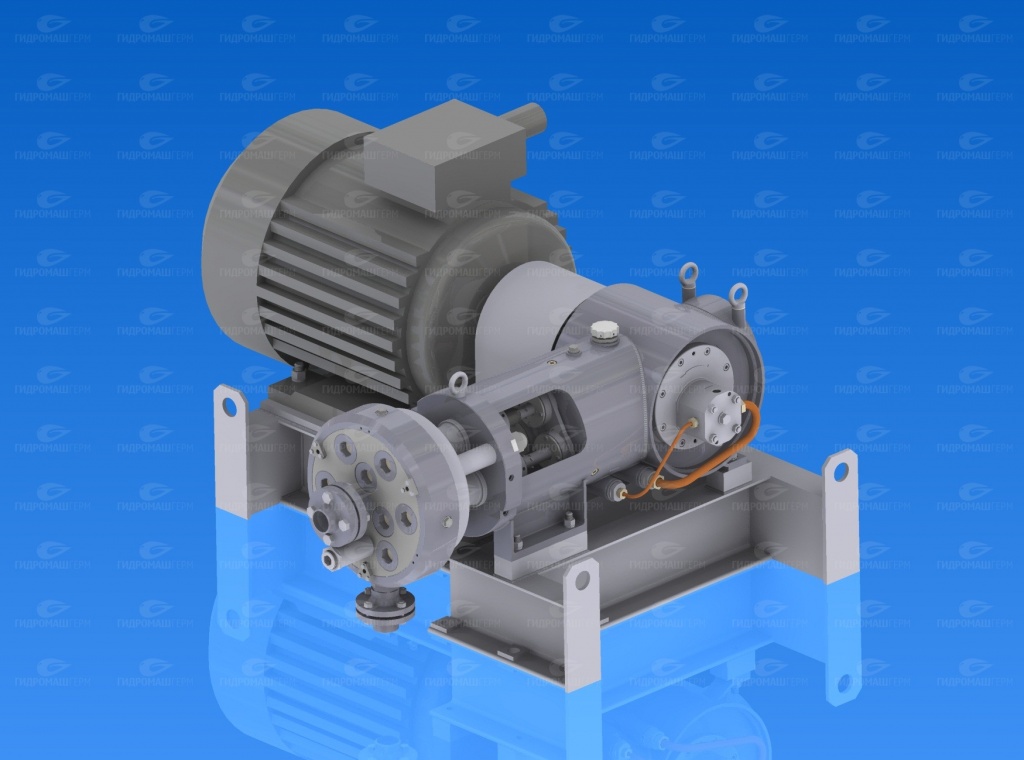

Dry rotor units

Modifications with a dry rotor are difficult to confuse with wet counterparts. They have an asymmetric shape with a clear preponderance towards the power part of the device. The fact is that its engine is equipped with an vane cooling device, tk. is not washed in the process of work with water.

Due to the asymmetric shape and the displacement of the axis towards the motor, “dry” models are equipped with console devices for additional fixation on the wall.

Pumping devices equipped with a dry rotor are famous for their high level of performance and are used when it is necessary to supply large areas with water

Due to the fact that the engine in such models is separated from the hydraulic part at the end of the axle by a stuffing box seal, they serve much longer “wet”. True, the seal, like the rolling bearing, tends to wear out and needs to be replaced periodically.

For this reason, units equipped with a dry rotor require more frequent maintenance and regular lubrication of rubbing parts. Another disadvantage is that “dry” appliances are noisy, so the place for their installation should be carefully considered.

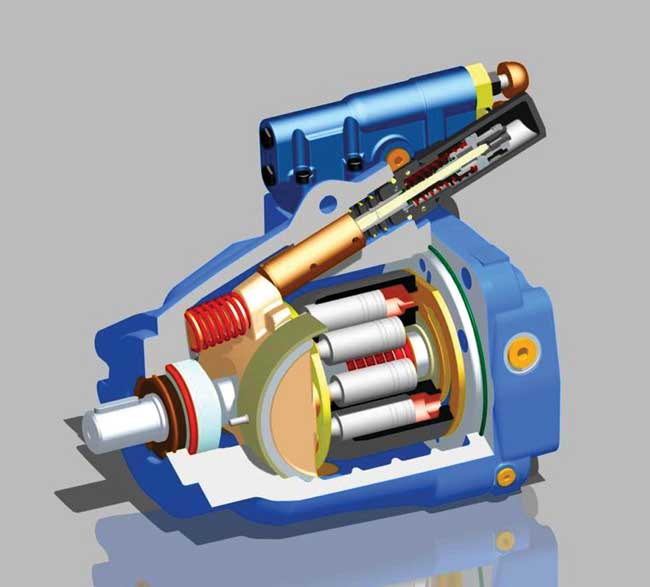

Glandless devices

Flow units require cooling due to the pumped water. In this case, the rotor of the device is placed in an aqueous medium and isolated from the stator by a waterproof damper.

Wet rotor units are characterized by a low level of generated noise interference. Glandless circulation pumps are designed for arranging heating systems, but are often used for water supply systems for heating residential premises.

Devices of this type have a modular design, due to which they can be easily disassembled into component units if it is necessary to replace an individual element.

The plain bearings used in the assembly of the structure do not require additional maintenance. However, “wet” pumps serve less and lose to “dry” units in terms of the pressure generated. There are restrictions on the direction of installation - it can only be horizontal.

A significant disadvantage of pumps of this type is the vulnerability when working with dirty water, foreign inclusions of which can disable the device.

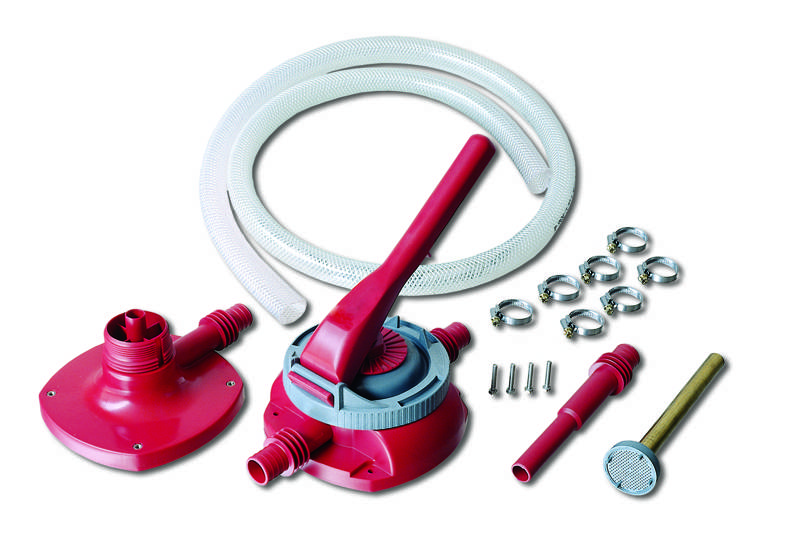

Hand pump

Manual stationary option

An excellent solution for places where there is no electricity. The pumping of water, in this case, occurs due to the movement of the piston. Most of the manual pumps are double-acting, so there is no idle mode.

This simple design is durable and does not require special skills in maintenance. The advantage is the cheap cost of the mini-pump. It is advisable to use it where there is no electricity connection or there is no need to pump a large volume of water.

What you should pay attention to when choosing a water pump:

One of the main parameters that you should pay attention to when buying a water pump is its performance (the volume of liquid distilled per unit of time).

The units of performance measure the power of the pump and are designated "liters per minute", in some cases "cubic meters per hour".

Water pump

To ensure the normal operation of autonomous water supply, the maximum pressure of the pump is also important. This value is equal to the height of the water level, which the device is capable of raising. Such a characteristic is necessary for the accurate calculation of a water supply, heating or sanitation project.

The consumption of resources depends on the above values. It should be calculated taking into account the number of residents, the presence of household appliances that use water, the magnitude of hydraulic water resistance and the peak height of the point of water analysis.

Types of self-priming pumps

Manufacturers produce self-priming pumps with a built-in or remote ejector. In this type of pumping equipment, the suction and rise of the liquid occurs due to its discharge.During operation, ejector installations make too much noise, so a special room is selected for their placement on the site, located at a sufficient distance from the residential building. The main advantage of self-priming pumps with an ejector is their ability to lift water from a great depth, on average about 10 meters. In this case, a supply pipe is lowered into the water intake source, and the pump itself is installed at a certain distance from it. This arrangement allows you to freely control the operation of the equipment, which affects the duration of its use.

The second type of equipment includes self-priming pumps that provide water lifting without ejectors. In models of this type of pumps, liquid suction is provided by a hydraulic device that has a special multi-stage design. Hydraulic pumps operate silently, unlike ejector models, but they are inferior to them in terms of the depth of liquid intake.

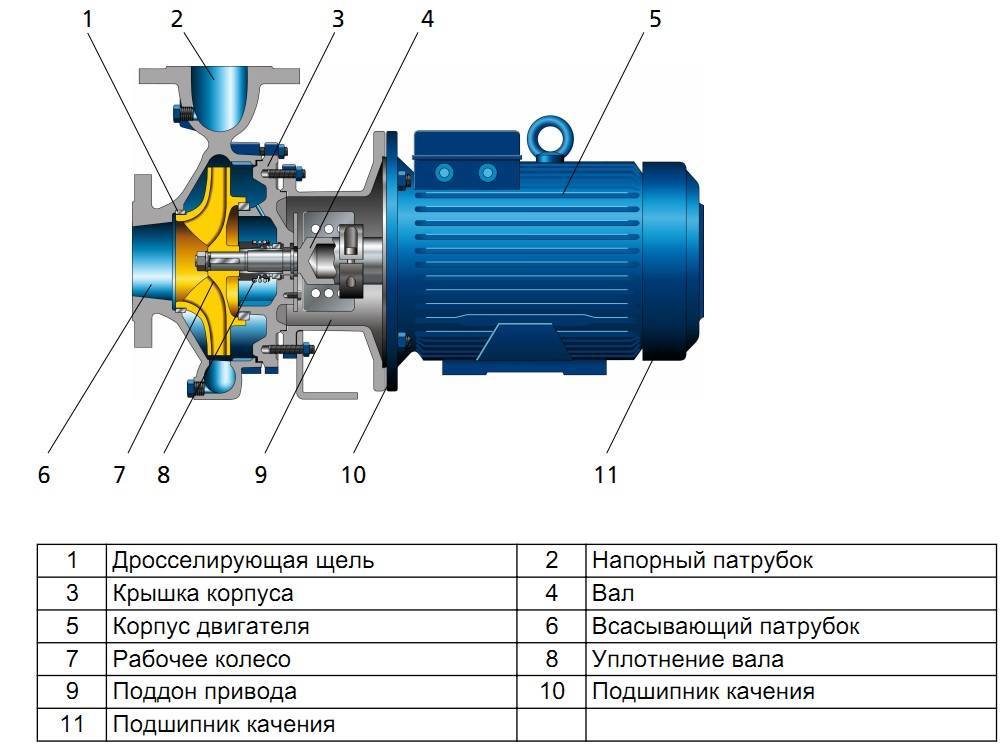

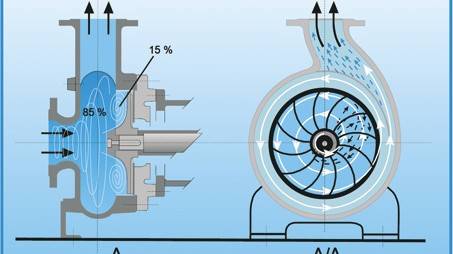

The device and principle of operation of a centrifugal pump

The figure shows the device of a self-priming centrifugal pump. In the body, which has a spiral shape, there is a rigidly fixed wheel, which consists of a pair of disks with blades inserted between them. The blades are bent in the opposite direction from the direction of rotation of the impeller. With the help of nozzles of a certain diameter, the pump is connected to the pressure and suction pipelines.

So schematically, you can imagine the device of a self-priming centrifugal pump for pumping water used in private homes and cottages

The principle of operation of centrifugal self-priming pumps is as follows:

- After the casing and the suction pipe are filled with water, the impeller starts to rotate.

- The centrifugal force that occurs when the wheel rotates displaces water from its center and throws it to the peripheral areas.

- Due to the increased pressure created in this case, the liquid is displaced from the periphery into the pressure pipeline.

- At this time, in the center of the impeller, on the contrary, the pressure decreases, which causes the flow of liquid through the suction pipe into the pump casing.

- According to this algorithm, water is continuously supplied by a self-priming centrifugal pump.

Working principle of self-priming peripheral pump

The air, shown in yellow in the figure, is sucked into the pump housing due to the vacuum created by the rotation of the impeller (impeller). Next, the air that has entered the pump is mixed with the working fluid contained in the unit housing. In the figure, this liquid is shown in blue.

This figure shows the device and principle of operation of a vortex self-priming pump for lifting liquid to a height of no more than eight meters.

After the mixture of air and liquid enters the working chamber, these components are separated from each other, based on the difference in their densities. In this case, the separated air is removed through the supply line, and the liquid is recirculated in the working chamber. When all air is removed from the suction line, the pump fills with water and starts working in centrifugal installation mode.

Possible versions of vortex self-priming water pumps manufactured by manufacturers for domestic use by owners of private houses and country cottages

A non-return valve is installed on the suction flange, which is designed to prevent air from returning to the pipeline, as well as to ensure the constant presence of working fluid in the pump chamber. Thanks to this device and the principle of operation, vortex self-priming pumps are capable, with a filled chamber, of lifting liquid from a depth not exceeding eight meters, without installing a bottom valve.

Features of submersible pumps for pumping water

Submersible pumps 12 Volt or 220 V are installed directly in the source for fluid intake. In this case, the engine can be immersed in water or be above its surface. This type of pumping equipment is capable of pumping liquid from a considerable depth. The unit has high performance, is characterized by efficient engine cooling.

Deep well pumps and drainage and fecal devices.

Deep well pumps and drainage and fecal devices.

Submersible pumps, based on the purpose of the unit, are divided into the following groups: drainage, well, borehole and fecal.

Well pumps are used to pump water from wells and mines. They differ in significant dimensions, small depth of immersion, high power, silent operation without vibration. Units can work with a liquid that contains sand, silt or clay.

Downhole pumps are characterized by compact dimensions, elongated shape, and are installed directly in the well. Water intake can be carried out from a very great depth.Such units are characterized by high power and productivity. They can be used for clean or slightly contaminated water.

Drainage units are used for the intake of slightly polluted or dirty water from basements, pits, trenches, containing sand, clay, grass and small debris.

Fecal pumps can work with liquid containing large solid particles up to 35 mm in diameter. Please note! There are submersible drainage models equipped with knives for grinding impurities.

Fecal sewage pumps are similar to drainage pumps. Such units can work with heavily polluted waters, which contain large solid particles with a diameter of about 35 mm. Some designs are equipped with a powerful cutting mechanism made of stainless steel or cast iron for crushing large debris. These pumps are used to pump sewage and fecal water into a special septic tank.

Note! Fecal pumps are both submersible and surface type.

The fecal pump for pumping dirty water is characterized by resistance to aggressive environments. The device is additionally equipped with special floats, which, if it is necessary to stop the operation of the device, give signals.

Drainage pumps are used to draw dirty water containing clay, sand, grass and small debris.

Drainage pumps are used to draw dirty water containing clay, sand, grass and small debris.

What kinds exist?

All hydraulic pumps are divided into 2 large groups according to the area of \u200b\u200buse, that is, household appliances needed in everyday life and industrial units used in special services (Ministry of Emergency Situations, fire departments).

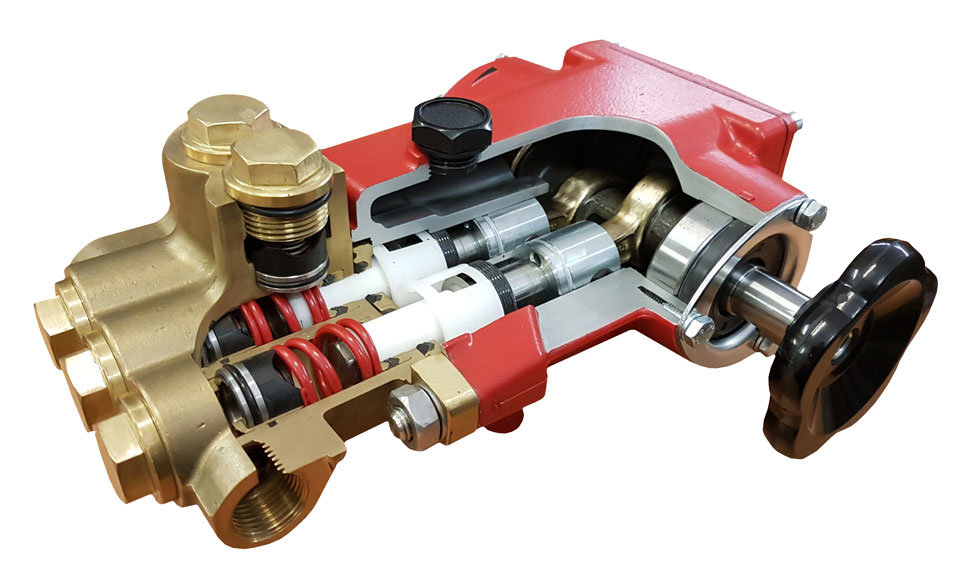

There are several types of high-pressure devices for water, which are divided into groups according to the following principles of operation:

- Manual or continuous pumps - the device is started and switched off as needed by manual control. Such a unit operates around the clock, constantly pumping water.

- Automatic pumps - have a special sensor that reacts to the flow of water, that is, the device turns on automatically when using water and turns it off when the tap is closed. This type of unit is more comfortable and economical to operate.

The introduction of additional units in the design of pumps allows to increase their performance. Such devices are relatively simple in design and have a low cost.

These include:

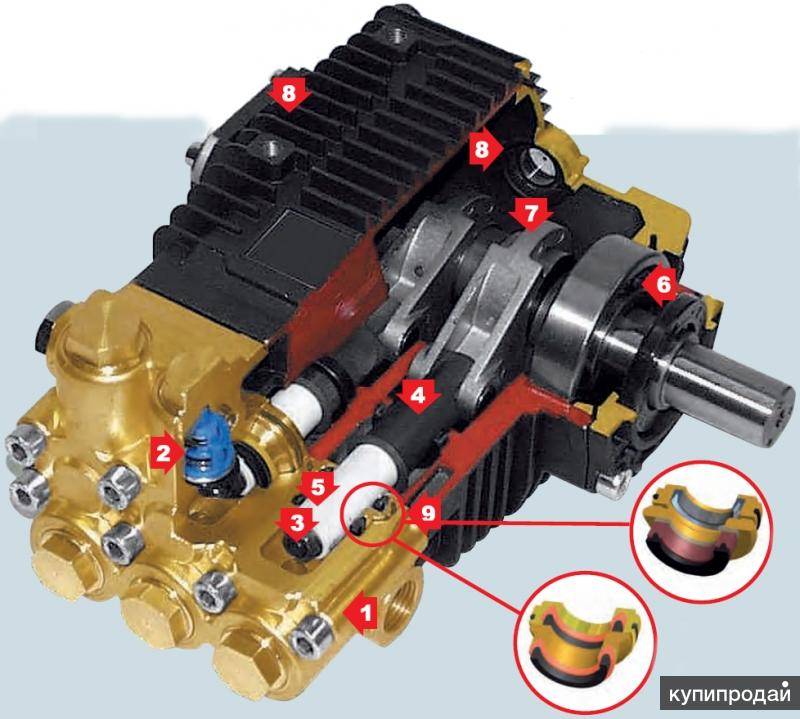

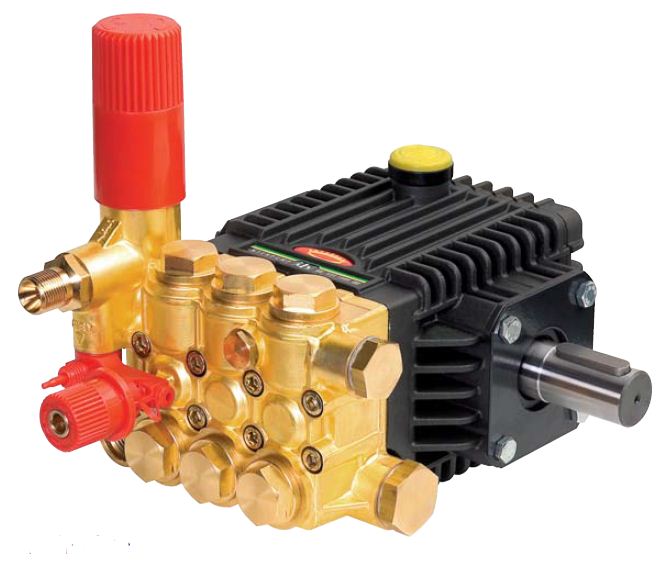

- A plunger hydraulic pump is a positive displacement mechanical device in which the plunger is a piston that reciprocates.

An increase in the volume of the chamber leads to a discharge and absorption of water.

With the reverse action of the plunger, the area decreases, and water is pushed out under pressure. The hydraulic pump of this type is characterized by simplicity of design and reliability.

- High pressure centrifugal devices - the principle of operation of this type of pump is based on the centrifugal force that is created inside the casing, which has a spiral shape. A wheel with radial curved blades is rigidly fixed inside it. Water, getting into the center of the wheel, is thrown by centrifugal force to its periphery, followed by its expulsion and increased pressure through the pressure pipe.

- Piston hydraulic pumps - this type of unit consists of a cylinder and a piston, which are the main working parts. The piston makes reciprocating movements inside the cylinder, in which the useful volume filled with water either increases or decreases.

The release of water into the injection system of the pipeline is accompanied by an increase in pressure due to its displacement from the cylinder by a working piston.

- Circulation pumps are devices designed for installation in a closed heating system. They move water in the pipeline and maintain it at a certain temperature.

This type of pump does not make up for the loss of water and does not replenish it in the system. This is done with a special pump. The principle of operation of the unit is based on the creation of a continuous circulation of water in the network with pressure parameters of the same nature. These pumps operate continuously. They are compact and quiet.

Simplicity in the constructive solution of these types of devices, reliability and high efficiency make these pumps in demand in various fields of economic activity.

DIY option

You can try to make a hydraulic pumping system with your own hands. First you need to weld a metal frame. Its height is equal to human height. On the sides make holes at the same distance from each other. They will be used for metal rods that perform a stubborn role. They are mounted nodes that require great strength. A large number of holes will help to adjust the height.

For a full-fledged press pump at the top of the structure, you will need to mount a high-power hydraulic cylinder. You can take appliances from trucks and other large automotive vehicles. For small efforts, use a knot from a jack. The upper frame, which is the reference point of the hydraulic cylinder, is hung on steel springs.

High pressure pumps are quite common in the plumbing system. HPAs maintain the desired pressure in the system. The devices are compact and highly efficient.

Classification depending on the purpose of use

The choice of the type of pumping equipment depending on the purpose of use can be made on the basis of the following classification:

- All submersible pumps can be divided into three groups:

- downhole type units are suitable for installation in wells;

- drainage equipment is divided, in turn, into two types: pumps that work with clean water, and devices that can be used to pump dirty water;

- well units are installed in mine wells.

- All surface pumps can be divided into the following types:

- fountain;

- sewer installations, which are divided into units for external and internal use;

- pumping stations.

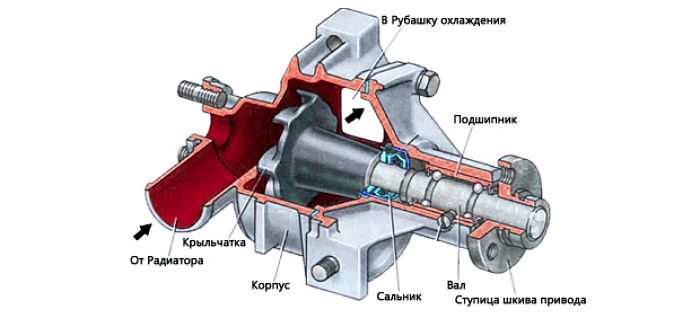

Water pump design

The appearance of water pumps can be different (the design features of power plants from different manufacturers affect), but they are all structurally the same and consist of:

- frame;

- axis;

- pulley or gear;

- impeller;

- stuffing box;

- bearings.

Frame

The housing is a load-bearing element and it contains all of the listed components, except for the impeller and pulley, which are located on the outside. The body is usually made from aluminium. Also, through it, the pump is attached to the cylinder block. To ensure tightness in the place where the housing fits to the motor, a gasket is installed between them.

To prevent antifreeze and moisture from accumulating in the area of \u200b\u200bthe bearings, a drainage hole is made in the housing.

Axle, bearings, oil seal

Inside the case there is a steel axle, mounted on two bearings, which makes it easy to rotate. The axle is usually made of steel, which ensures high strength.

The bearings are closed, that is, there is no access to them. Their lubrication is done due to the embedded lubricant, which should be enough for the entire life of the pump. But on some old trucks, there was a grease fitting in the body, so their bearings could be lubricated.

Video: Pump Selection. LUZAR pump.

To prevent contact of the working fluid with the bearings, a sealing rubber element - stuffing box is installed on the side of the impeller. Without it, antifreeze would get into the bearing area, which would lead to their rapid wear.

Pulley, impeller

The pulley or gear are the elements that receive the force from the crankshaft. The pulley is used on cars in which the timing mechanism is driven by a chain drive. Due to such a constructive solution, it was not possible to organize the transfer of force to the pump by a chain. Therefore, to ensure the rotation of the pump, a separate belt drive is used, which can additionally provide the operation of other attachments of the motor - power steering pump, compressor, etc.

In cars in which the timing drive is provided by a toothed belt, it is also used to ensure the operation of the pump. That is, with one belt, both the timing and the pump are involved in the work. And so that there are no losses due to slippage during the transmission of force, a gear wheel is used as a drive element on the pump.

The pulley or gear wheel is rigidly connected to the axle. For this, either a keyed connection or a bolted connection is used.

On the other hand, an impeller is planted on the axis - a special disk with wings applied to it in a special way. It is made more often from aluminum, although there are also impellers made of plastic. Landing it on the axle is also tough.

vortex pumps

Vortex pumps have a similar structure to centrifugal pumps, only in them water is supplied in such a way that when water enters the chamber, it moves tangentially relative to the periphery and shifts to the center of the wheel, from where, under pressure and due to the movement of the blades, it again goes to the periphery, and from there ejected through the outlet pipe. The main difference is that with one revolution of the wheel with blades (impeller), the cycle of suction and expulsion of water occurs many times.

This design allows you to increase the pressure by 7 times even with a small amount of water - this is the fundamental difference between vortex pumps and centrifugal pumps. Just like centrifugal pumps, these models do not tolerate the presence of solid inclusions in the water, and also cannot work with viscous liquids. However, they can be used to pump gasoline, various liquids containing gas or air, and aggressive substances. Minus - low efficiency.

Such pumps are used for various purposes and areas, but their installation is advisable if the amount of substance to be worked with is small, but high pressure is needed at the outlet. Compared to centrifugal models, these devices are quieter, smaller and cheaper.