- What kinds exist?

- Why is it needed?

- Water pump: an overview of the varieties of hydraulic devices

- Varieties of low voltage small water pumps

- Characteristics of circulating water pumps 12 Volt

- Division according to the method of creating a vacuum chamber

- Centrifugal type devices

- Vibratory electromagnetic pumps

- Vortex pump models

- The best submersible pumps for a well

- Pedrollo NKM 2/2 GE - pump for wells with moderate energy consumption

- Water cannon PROF 55/50 A DF - for pumping contaminated water

- Karcher SP1 Dirt is a silent model with low power consumption

- Grundfos SB 3-35 M - powerful pump with low starting current

- Possible malfunctions of the cooling system pump

- Vortex

- Centrifugal

- DIY option

- Technical equipment to increase the water pressure in the apartment

- Key pump selection parameters

- Video - Options for solving the problem of low pressure in the tap

- Conclusions and useful video on the topic

What kinds exist?

All hydraulic pumps are divided into 2 large groups according to the area of \u200b\u200buse, that is, household appliances needed in everyday life and industrial units used in special services (Ministry of Emergency Situations, fire departments).

There are several types of high-pressure devices for water, which are divided into groups according to the following principles of operation:

- Manual or continuous pumps - the device is started and switched off as needed by manual control. Such a unit operates around the clock, constantly pumping water.

- Automatic pumps - have a special sensor that reacts to the flow of water, that is, the device turns on automatically when using water and turns it off when the tap is closed. This type of unit is more comfortable and economical to operate.

The introduction of additional units in the design of pumps allows to increase their performance. Such devices are relatively simple in design and have a low cost.

These include:

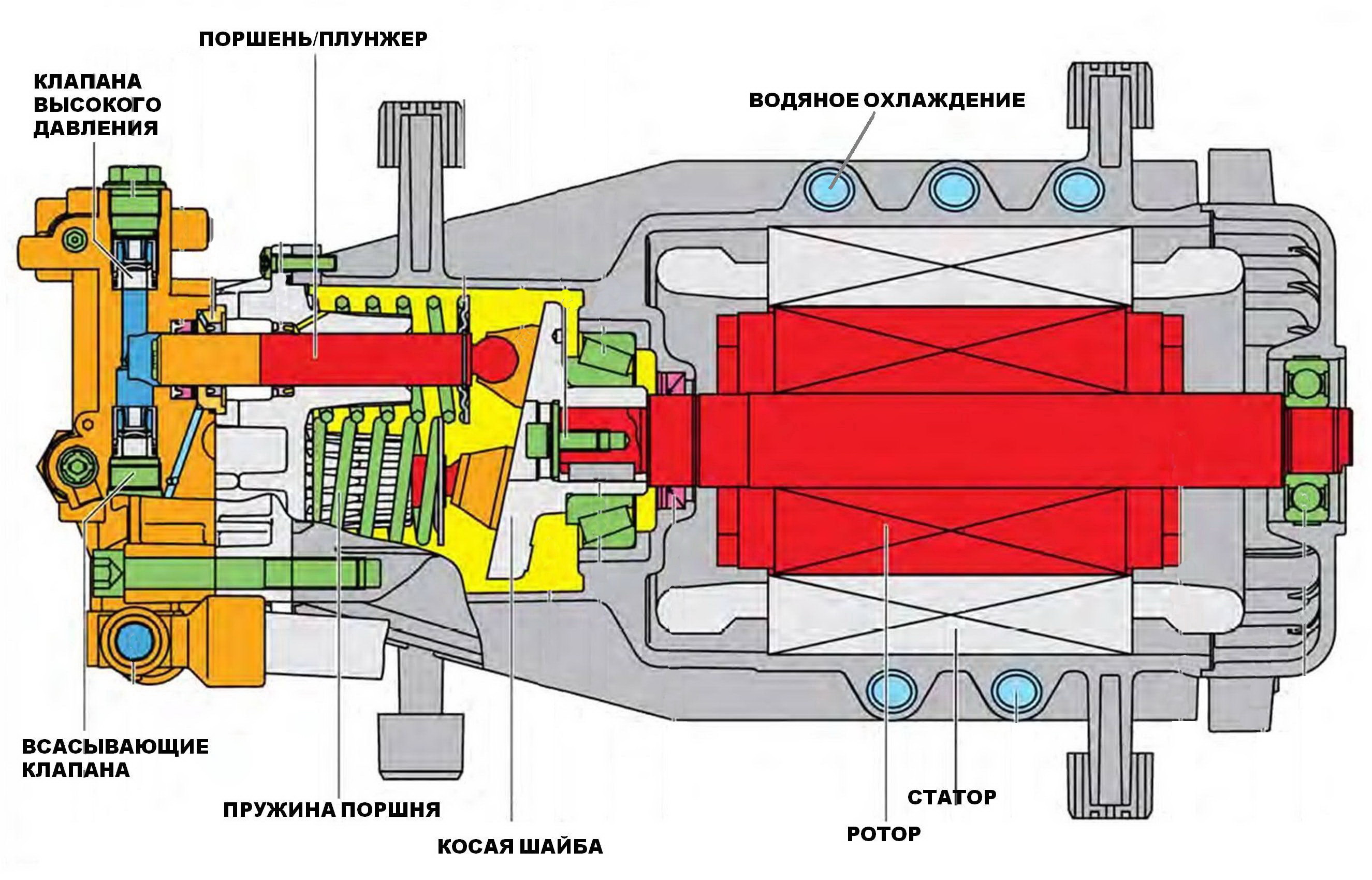

- A plunger hydraulic pump is a positive displacement mechanical device in which the plunger is a piston that reciprocates.

An increase in the volume of the chamber leads to a discharge and absorption of water.

With the reverse action of the plunger, the area decreases, and water is pushed out under pressure. The hydraulic pump of this type is characterized by simplicity of design and reliability.

- High pressure centrifugal devices - the principle of operation of this type of pump is based on the centrifugal force that is created inside the casing, which has a spiral shape. A wheel with radial curved blades is rigidly fixed inside it. Water, getting into the center of the wheel, is thrown by centrifugal force to its periphery, followed by its expulsion and increased pressure through the pressure pipe.

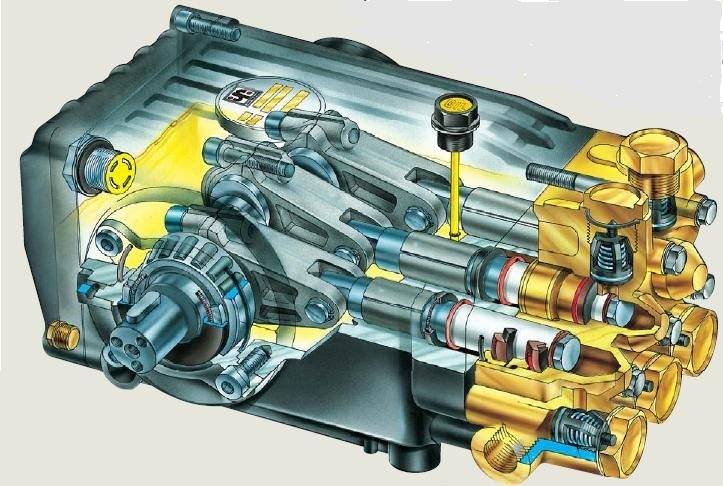

- Piston hydraulic pumps - this type of unit consists of a cylinder and a piston, which are the main working parts. The piston makes reciprocating movements inside the cylinder, in which the useful volume filled with water either increases or decreases.

The release of water into the injection system of the pipeline is accompanied by an increase in pressure due to its displacement from the cylinder by a working piston.

- Circulation pumps are devices designed for installation in a closed heating system. They move water in the pipeline and maintain it at a certain temperature.

This type of pump does not make up for the loss of water and does not replenish it in the system. This is done with a special pump. The principle of operation of the unit is based on the creation of a continuous circulation of water in the network with pressure parameters of the same nature. These pumps operate continuously. They are compact and quiet.

Simplicity in the constructive solution of these types of devices, reliability and high efficiency, make these pumps in demand in various fields of economic activity.

Why is it needed?

In private houses that do not have a connection to the centralized DHW and central heating networks, autonomous heating and hot water supply systems are used.

In private houses that do not have a connection to the centralized DHW and central heating networks, autonomous heating and hot water supply systems are used.

To organize the correct mode of supplying hot water or heating, heated H2O starts in a circle. For this, a special hot water pump is used, designed to pump liquid under certain conditions.

It is called circulating (or recirculating), since it is needed precisely for the non-stop movement of water (or coolant).

Standard DHW supply schemes have a dead-end structure. The outlet from the riser passes to the last consumption device, where it ends. If the water is not turned on for a long time, it cools down in the pipes.

The operation of heating systems is also based on the circulation of a heated coolant (water).There are systems whose functioning occurs due to natural circulation. However, they are ineffective due to the low speed of movement.

Installing a circulation pump allows you to increase the speed, which significantly improves the heating mode and gives considerable savings. When the coolant passes through the system at a high speed, it cools less. This reduces fuel consumption and reduces the load on the heating boiler.

Water pump: an overview of the varieties of hydraulic devices

A water pump is a hydraulic device that sucks, pumps and moves fluid from one point to another. In one of the articles we talked about garden pumps. In this article, we will talk about the types of pumps for pumping water according to the principle of operation.

Garden pump: the heart of an artificial water source (read more)

This happens according to the principle of transferring kinetic or potential energy to the medium. Water units are presented in several varieties and differ in design, power, performance, efficiency, head and pressure.

Pumps for pumping water differ among themselves in power, design and performance.

Pumps for pumping water differ among themselves in power, design and performance.

Varieties of low voltage small water pumps

Low-voltage pumps can be divided into several types: circulation, vacuum, diaphragm and pump pumps. The last group includes submersible, surface and hand pumps for pumping water. They are used for pumping liquid from basements, cellars, cleaning wells and wells, removing contaminated liquid from cesspools.

12 Volt water pumps can be used for autonomous water supply systems.Manual units are driven by certain physical efforts that a person must make.

Vacuum pumps 12 Volt are used for pumping water from ground tanks and underground sources. They are distinguished by high performance, low noise and vibration levels, low power consumption, and the ability to operate in a wide temperature range.

Low-voltage small water pumps are divided into circulation, diaphragm, vacuum and pump pumps.

Diaphragm pumps are used to draw water from a well, pump it from one container to another, drain artificial reservoirs and wash equipment. The principle of operation of such units is based on a change in the total volume of the working fluid. The membrane used as the main working element draws in water and pushes it out through the inlet pipes.

Characteristics of circulating water pumps 12 Volt

12 Volt circulation pumps are centrifugal-type units that are used in the arrangement of heating and hot water supply systems. The main task of such devices is to maintain the necessary pressure in the event of a failure of the main pump or in the absence of a power supply network.

Circulation pumps are presented in two varieties - with a dry or wet rotor. In the latter type of unit, the rotor is located in the liquid. The contacts are hidden in a special stainless steel compartment. Such a pump has small dimensions, is characterized by long-term trouble-free operation, low noise level and ease of use. The main disadvantage is the low efficiency, which can be as low as 50%.

Mini water pumps with a dry rotor, in which it is separated by ceramic or metal sealing rings, are characterized by higher efficiency. It can only pump clean water, otherwise the tightness of the pairing of the rings may be broken. Such pumps are horizontal, vertical and block.

12 Volt circulation water pumps are centrifugal type devices that are used in the arrangement of hot water supply and heating systems

A special category is high-pressure equipment that operates on a voltage of 12 volts. It can be safely used to supply water to the heating system.

Division according to the method of creating a vacuum chamber

The mechanism of operation of this type of device is based on the displacement reaction. The pumping process is carried out under the action of changing the dimensions of the working chamber. The magnitude of the resulting vacuum directly depends on the degree of tightness of the working chamber.

The vacuum level can be adjusted. Due to this, the pressure in certain places of the system can increase, or, on the contrary, decrease.

Vacuum pumps in most configurations are in the form of a cylinder, inside of which a shaft or impeller equipped with an impeller is built.

The shaft is the leading working tool of the mechanism. The impeller equipped with blades performs rotational movements. Under the action of the blades moving in a circle, the liquid in the working chamber is captured. As it rotates, centrifugal force is generated. It also leads to the formation of a liquid ring. The empty space formed inside the ring is a vacuum.

Depending on the methods by which a vacuum chamber is created, high-pressure pumps for water are centrifugal, vibratory and vortex.

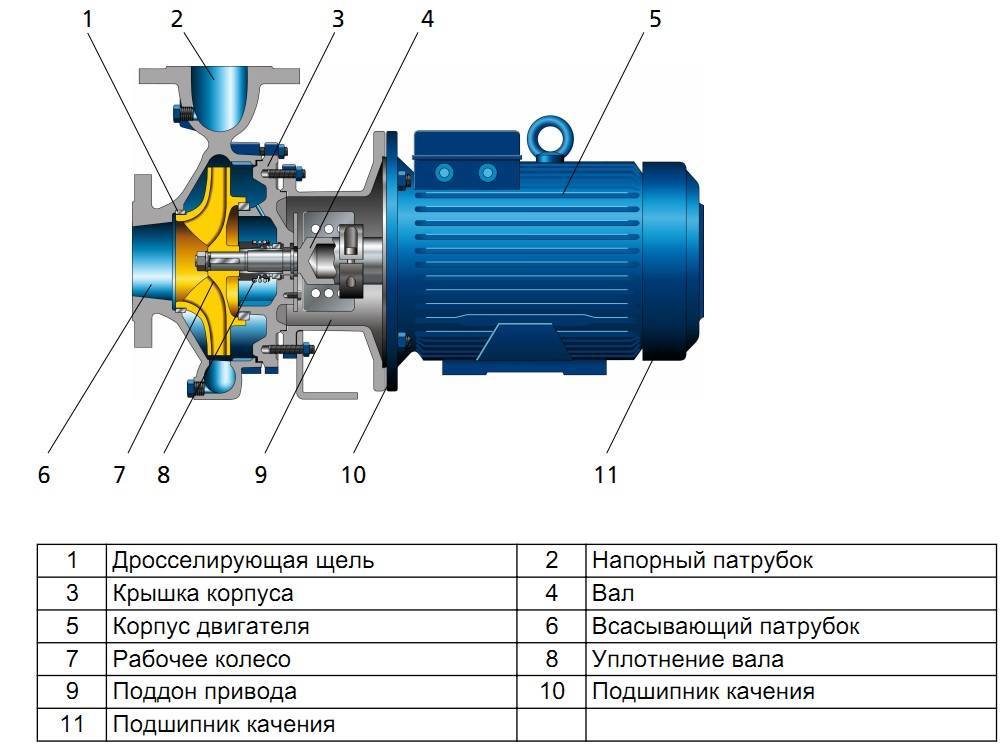

Centrifugal type devices

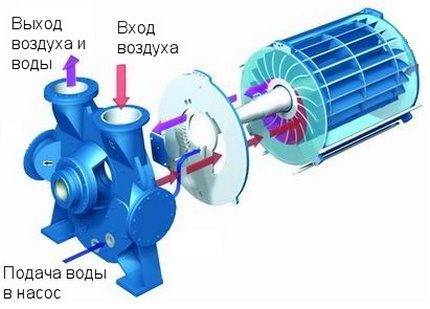

Centrifugal pumps are the most common type of pumping devices capable of providing high pressure in the system. They pump water by rotating the impeller fixed inside the spiral housing. The impeller consists of two fastened disks, between which the blades are fixed in the direction opposite to the flow of the incoming liquid.

Centrifugal stations are equipped with hydraulic tanks that provide a supply of water in case of shortages and pressure drops, and automatic control devices.

In the process of rotation, a centrifugal force is formed, which stimulates the displacement of water flows from the center of the chamber, throwing it to distant areas. Due to this, the pressure level in the center of the rotating impeller decreases, and water begins to flow into the inside of the casing.

Centrifugal devices in most versions are equipped with hydraulic accumulators. They are connected to pressure pipelines by means of branch pipes of different diameters.

If the volume of the hydraulic tank of the pumping station is not enough, it can be used as a unit that supplies water to the storage tank

Centrifugal-type equipment is capable of providing uninterrupted water supply at high pressure. The only operating condition is that when starting the unit, it is necessary to fill the case with water. The centrifugal variety has limitations: they cannot pump water from a depth of more than 8 m, but they are quite suitable as an addition to a pressure boosting system of several pumps and accumulators.

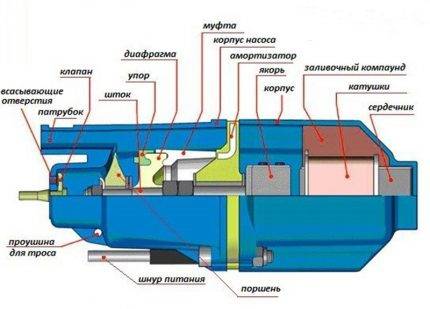

Vibratory electromagnetic pumps

The principle of operation of vibration pumps is based on the ability of a magnet to alternately attract and then release the armature-piston tandem due to the action of alternating current. Changing the polarity of the armature makes alternating movements. Within one second, the position of the anchor can change several dozen times.

Due to the absence of rotating parts in electromagnetic vibration-type devices, they are considered the most reliable and durable.

As a result of vibrational vibrations, water is first sucked into the working chamber, and then pushed out through the valve into the pressure pipe. The vibration unit can work in pairs with a centrifugal colleague or pump a supply of water into a storage tank.

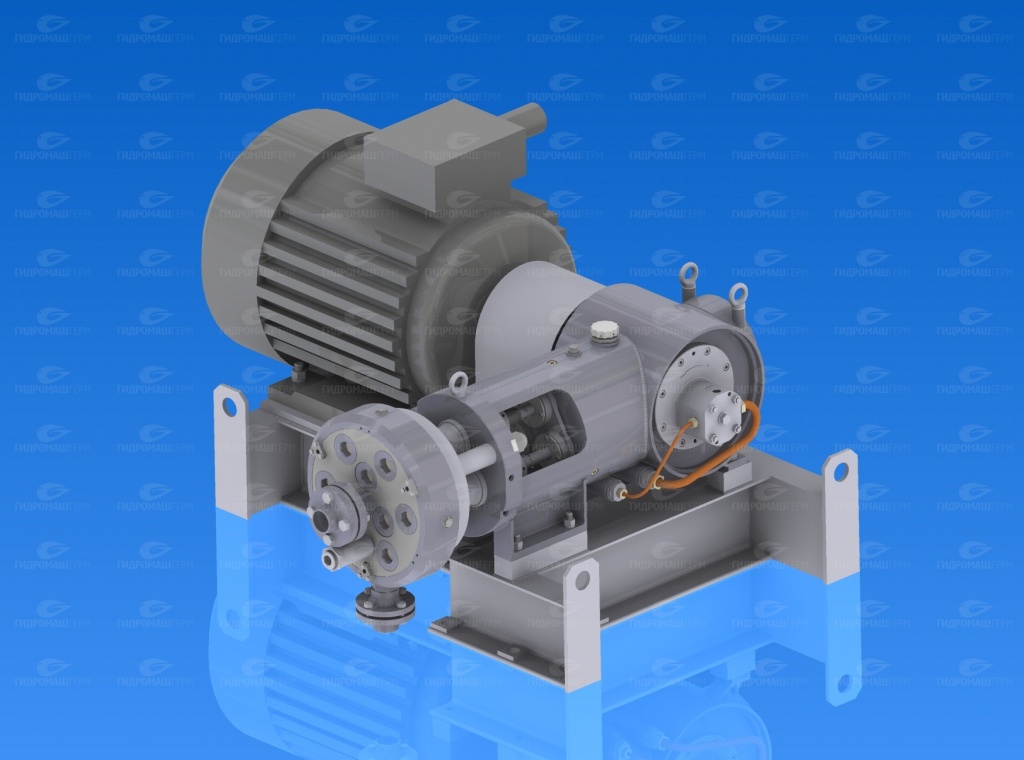

Vortex pump models

In the body cavity of such units there is a flat disk equipped with radially fixed blades. The rotation of the wheel with peripheral blades creates a vacuum.

Under the action of disk rotation, the liquid enters a specially equipped cavity of the body, and then, after passing through the chamber, it is pushed out

Vortex devices are famous for their high suction power. They are not afraid of the presence of air bubbles in the water. But they are vulnerable to the presence of suspended particles in the liquid and therefore have a limited scope. Since vortex devices break down quickly when pumping dirty water, they are not recommended for use in sand wells and wells.

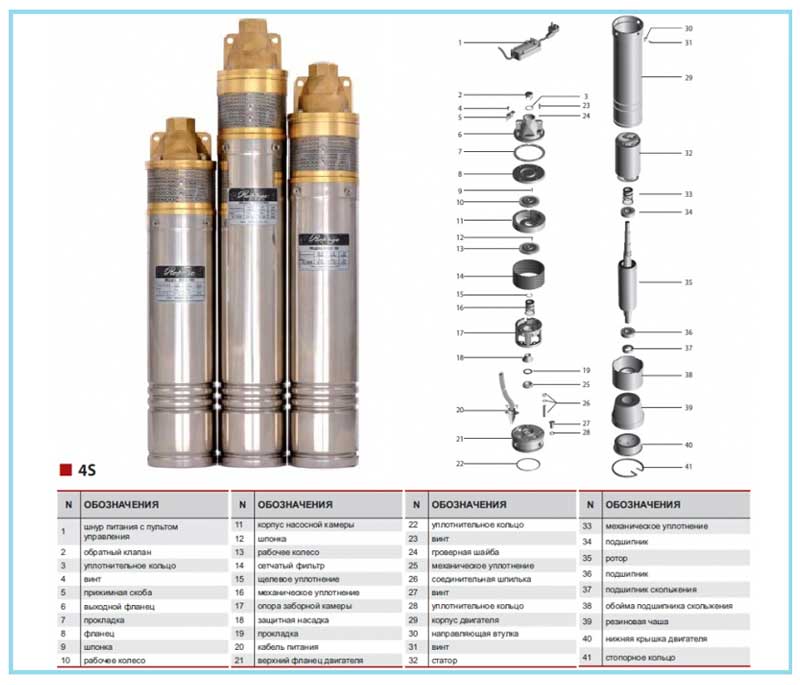

The best submersible pumps for a well

As the name suggests, these pumps are designed to be fully or partially submerged in water. Among them, well and borehole models are distinguished. Depending on the selected type, the height of the water column varies from 9 to 200 m.Submersible pumps are characterized by high (in comparison with surface models) efficiency and the presence of a sealed housing.

Usually they are equipped with a filter and automatic protection against dry running.

Experts also recommend paying attention to the presence of a float that will turn off the power to the pump when a critical water level is reached.

Pedrollo NKM 2/2 GE - pump for wells with moderate energy consumption

5.0

★★★★★editorial score

100%

buyers recommend this product

A productive and reliable pump that is able to "digest" water with minor mechanical impurities up to 150 grams / 1 m3 without harm to itself. With an immersion depth of 20 m, the unit provides up to 70 liters of water, raising it by 45 m. Also, this model can work stably in networks with a "drawdown" of voltage.

Advantages:

- Reliability.

- Excellent performance.

- Stable operation in polluted water.

- Low power consumption.

- The presence of a float switch.

Flaws:

High cost - 29 thousand.

A very good model for organizing the water supply of a private house. The main thing when using this pump is to take into account the flow rate of the well.

Water cannon PROF 55/50 A DF - for pumping contaminated water

4.9

★★★★★editorial score

97%

buyers recommend this product

See review

The novelty of this year is a submersible pump with impressive technical characteristics. When submerged to a depth of 30 m, this unit is capable of delivering up to 55 l / min. to a height of up to 50 m. Protection against dry running is provided by a float switch.

The main feature of the device is the floating design of the impeller.This technical solution makes it possible to pump water containing solids up to 2 kg/m3. The cost of the unit is 9500 rubles.

Advantages:

- Good performance and pressure.

- Existence of protection against an overheat.

- Ability to work in water with a high content of mechanical impurities.

- The presence of drainage channels to reduce the load on the engine at start.

Flaws:

Non-return valve included.

A good model for creating an automated water supply system at home. However, its construction requires equipment with additional elements and accessories (hoses, fittings, check valve, etc.) that must be purchased separately.

Karcher SP1 Dirt is a silent model with low power consumption

4.8

★★★★★editorial score

90%

buyers recommend this product

See review

A reliable submersible pump from a well-known German manufacturer is designed for a maximum performance of 5.5 m3 / h at a depth of immersion up to 7 m. The unit is equipped with a carrying handle, a patented quick connection system, has the ability to work in manual and automatic modes with float switch fixation.

The main feature of Karcher SP is the possibility of stable operation in turbid water with mechanical inclusions up to 2 cm in diameter. At the same time, the price of the device is quite low - 3300 rubles.

Advantages:

- High performance.

- No noise during operation.

- Quality build.

- "Digestion" of large mechanical inclusions.

- Extended warranty (5 years) from the manufacturer.

Flaws:

- There is no inlet filter included.

- Large outlet diameter - 1″.

The extremely low pressure of 4.5 m indicates the narrow specialization of the device.It is suitable for watering the site, draining drainage wells and pools.

Grundfos SB 3-35 M - powerful pump with low starting current

4.7

★★★★★editorial score

85%

buyers recommend this product

Structurally, this model differs from analogues in the absence of automation, due to which the manufacturer has significantly reduced its cost. The pump is equipped with a 0.8 kW motor, which provides a solid performance of 3 m3/h with a water column of 30 m.

Alas, the cheapening of the device affected its ability to work with polluted water. The device is able to "digest" no more than 50 g/m3 of mechanical impurities. The price of the unit was a little less than 16 thousand.

Advantages:

- Reliability.

- Simplicity of design.

- Good pressure and performance.

- A small load on the power grid when starting the device.

Flaws:

No dry run protection.

A very good model for a private house with increased water consumption. In case of urgent need, the problem of lack of automation is easily solved by purchasing and installing a float switch.

Possible malfunctions of the cooling system pump

A failure of the coolant pump can bring the entire system to a standstill. This can seriously affect the condition of the engine. The most common pump problems are:

- Deterioration of the seal (gland). In this case, a coolant leak occurs.

- Impeller failure. When the impeller is destroyed, the injection of liquid becomes worse (pressure drops) or stops altogether.

- Seizing of bearings. If the lubrication of the pump deteriorates, which can also be due to leakage of the coolant, the pump starts to work intermittently.

- Increased play between impeller and pump shaft.During operation, the impeller mounted on the shaft may become loose, which leads to unstable operation of the pump and other breakdowns.

- chemical corrosion. Most often, this problem affects the pump impeller and occurs if poor quality fluids are used.

- Destruction due to cavitation. Air bubbles that can occur during pump operation intensively destroy it from the inside, which leads to brittleness of parts and their corrosion.

- System pollution. Chemical deposits and just dirt that gets inside the pump, over time, form a hard coating on its parts, which makes it difficult for the impeller to rotate and the fluid to pass.

- Destruction of bearings. In this case, when the pump is running, a characteristic whistle appears. It is difficult to replace such bearings, and therefore in this case the pump is simply changed.

- Broken drive belt. If a belt of poor quality is used or if it is not replaced in time, a break or slip may occur.

If you stop for only 5-6 minutes, the engine may overheat. The action of high temperatures violates the geometry of the cylinder head and leads to damage to the crank mechanism. Do not ignore minor malfunctions of the cooling system, as in the future they can lead to serious repairs.

Vortex

In vortex submersible pumps, the intake and expulsion of water occurs with the help of one impeller with blades, which is located in the upper part of the vertically suspended housing next to the outlet pipe.To reduce hydraulic losses, the design provides for a very small distance between the side face of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to work in an environment with sand particles.

Vortex-type devices have good pressure characteristics (liquid lifting height reaches 100 m) and average pumping volumes (about 5 cubic meters / hour).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Whirlwind, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump - design and appearance

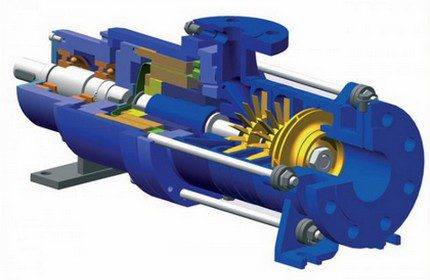

Centrifugal

Centrifugal devices have achieved such distribution due to the following properties:

- Their coefficient of performance (COP) is the highest of all analogues, in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel, and is pushed out through the side pipe. This allows you to make multi-stage centrifugal devices in which the ejected fluid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters / h.

- Centrifugal type units are less affected by fine sand particles on the working mechanism, they are widely used in sand wells, choosing a model to work with a suitable particle size indicated in the passport.

- A significant advantage of centrifugal types is the high level of automation, the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) supply their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save electricity during the operation of the electric pump (up to 50%), but also to significantly increase its service life.

If we list all manufacturers of centrifugal pumps that represent their products on the domestic market, the list will be quite voluminous, so we will limit ourselves to the world's leading manufacturers listed above. Of the domestic brands, Aquarius, Dzhileks Vodomet, Whirlwind, Belamos, Caliber, Unipump received the greatest fame.

Rice. eight Centrifugal submersible pumps - design and materials of manufacture on the example of Grundfos SBA

DIY option

You can try to make a hydraulic pumping system with your own hands. First you need to weld a metal frame. Its height is equal to human height. On the sides make holes at the same distance from each other. They will be used for metal rods that perform a stubborn role. They are mounted nodes that require great strength. A large number of holes will help to adjust the height.

For a full-fledged press pump at the top of the structure, you will need to mount a high-power hydraulic cylinder. You can take appliances from trucks and other large automotive vehicles. For small efforts, use a knot from a jack. The upper frame, which is the reference point of the hydraulic cylinder, is hung on steel springs.

High pressure pumps are quite common in the plumbing system. HPAs maintain the desired pressure in the system. The devices are compact and highly efficient.

Technical equipment to increase the water pressure in the apartment

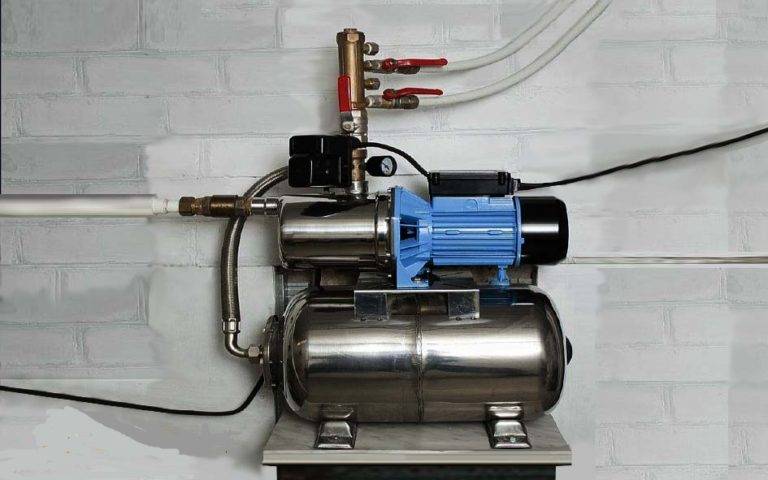

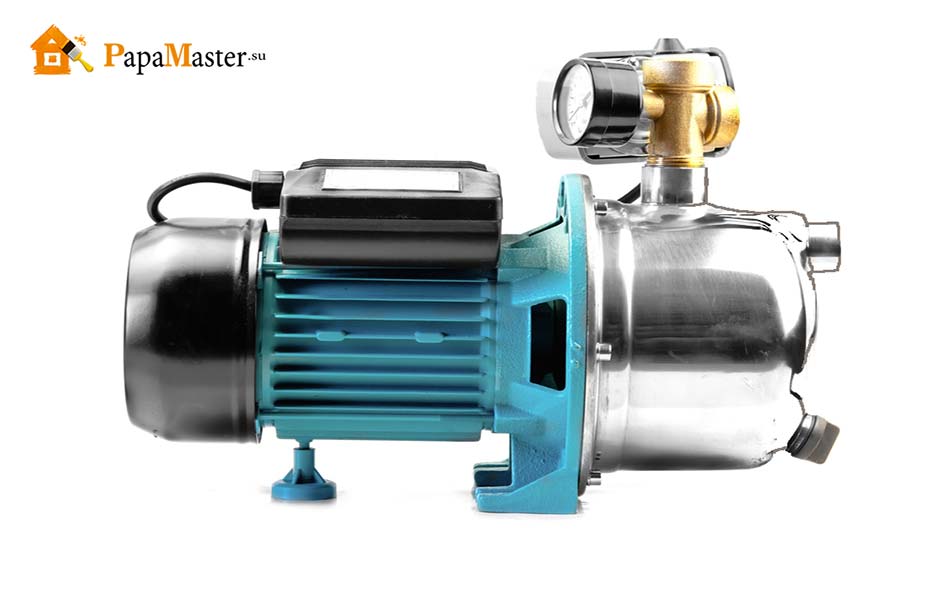

When the cause of problems with pressure is hidden outside the apartment, and contacting the management company does not work, then you can get out of the situation only by applying mechanical methods to increase pressure. You will need to install a pump with a hydraulic accumulator.

If the piping system in the apartment has no flaws, and everything is caused by weak pressure that is supplied to the house, then tie-in the pump will be the only way out of the situation. An additional argument in favor of this solution is the higher pressure on the lower floors.

Pressure Boosting Pump System

Pressure Boosting Pump System

Having a lack of water pressure in the apartment, a pump or pumping station is installed in the system immediately after the meter. They allow you to increase the pressure level of the water supplied directly to key consumers, such as a washing machine, dishwasher, bathroom, etc.

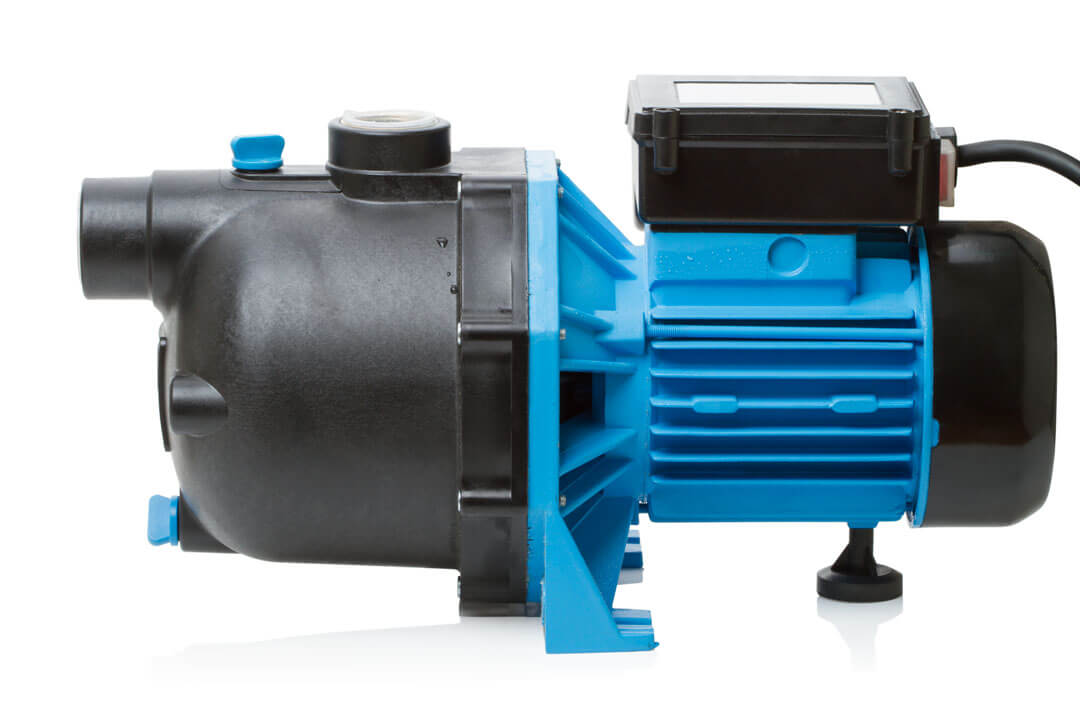

The pump for increasing the pressure directly in the apartment is small in size. Its dimensions can be no more than a liter can. In the case when there is a big problem with pressure, then a more massive pump is installed.

Powerful boost pump

Powerful boost pump

The pumping station is the same pump, but additionally equipped with a hydraulic accumulator. This tank accumulates water in itself and subsequently gives it away. This eliminates the need to constantly start the pump when opening the tap for a short time, for example, to fill the kettle. The pump and accumulator can act in one bundle. In this case, there is a platform on top of the tank to which the pump is screwed. In most cases, all equipment is bought separately, and mounted together directly in the apartment.

Pumping station for pressure increase

Pumping station for pressure increase

Key pump selection parameters

To get a sufficient level of water pressure in the apartment, without creating problems for household appliances, you need to choose the right pump

First of all, you need to pay attention to its indicators:

- minimum water flow rate to turn on;

- maximum feed;

- operating pressure;

- section of connecting elements.

The minimum water flow rate to switch on is very important. The fact is that insensitive pumps can only work if the mixer is opened at full power. Subsequently, when trying to reduce the flow, the pump stops. Ideally, the pump automatic would allow it to start at a flow of 0.12-0.3 l / min. An insensitive device will not pump up pressure when the toilet bowl is filled, since it is connected through a thin armature and filled with a small stream of water.

Video - Options for solving the problem of low pressure in the tap

The maximum flow shows how much water the pump can pump in a certain period of time. It can be determined in liters per second or minute, as well as cubic meters per hour.It is quite possible to purchase a weak pump, then the volume of pumped water will not be enough for the normal operation of all equipment and other points of consumption. To calculate the optimum performance of the pump, it is required to determine the volume of consumption of all points of water intake. To do this, the use of tabular data will help. It is necessary to sum up the indicators of all consumers, adding a power reserve of 10-30%.

Table 1. Water consumption of different points of water intake.

| Name of the water point | Average water consumption l/s |

|---|---|

| Bathroom faucet | 0,1-0,2 |

| Toilet | 0,1 |

| kitchen faucet | 0,1-0,15 |

| Dishwasher | 0,2 |

| Washing machine | 0,3 |

| Bidet | 0,08 |

The maximum pressure parameter is selected individually, based on the pressure gauge connected to the pipeline in the apartment. An indicator of 2-4 atmospheres is considered optimal. That is, you need to choose a pump that creates a pressure level that is not enough to the norm.

Compact pump to increase the pressure in the apartment

Compact pump to increase the pressure in the apartment

The final key selection criterion is the section of the connecting elements. Since the pump cuts into the pipeline, it is ideal that all fittings match the dimensions of the existing pipes. Incompatibility will require the purchase of additional adapters, which are accompanied by unnecessary costs.

Conclusions and useful video on the topic

The operation of a booster pump in an apartment of a multi-storey building is clearly shown in the following video:

Informative video on the installation of a booster pump:

Many models of booster pumps can easily be installed independently. Even a novice plumber will cope with this task without any problems. But the level of comfort with normal water pressure in the system will increase very noticeably.

Interested in information or have questions? Please leave comments on the article, post thematic photos. Perhaps you have useful information in your arsenal that you are ready to share with site visitors.