- Operation and possible breakdowns

- Dzhileks pumps for pumping water from a well

- Most popular

- How to choose a Gilex pump

- 2 The most common malfunctions and their repair

- What to look for when choosing a pump?

- Features of the device of this pump

- Belamos well pump

- Borehole pumps "Vodomet": an overview of the typical design

- Conclusion

Operation and possible breakdowns

Since pumping equipment is completely submerged in water, it works in extreme conditions. Despite constant improvement, the pump can fail. The most common causes of breakdowns can be such phenomena:

- If the installation and use of the unit was carried out without following the recommendations and instructions of the manufacturer, then there is a high probability of a breakdown.

- Voltage fluctuations in the network can lead to the failure of pumping equipment.

- If the unit is constantly pumping very dirty water with a high content of sand particles, this will accelerate its wear and failure.

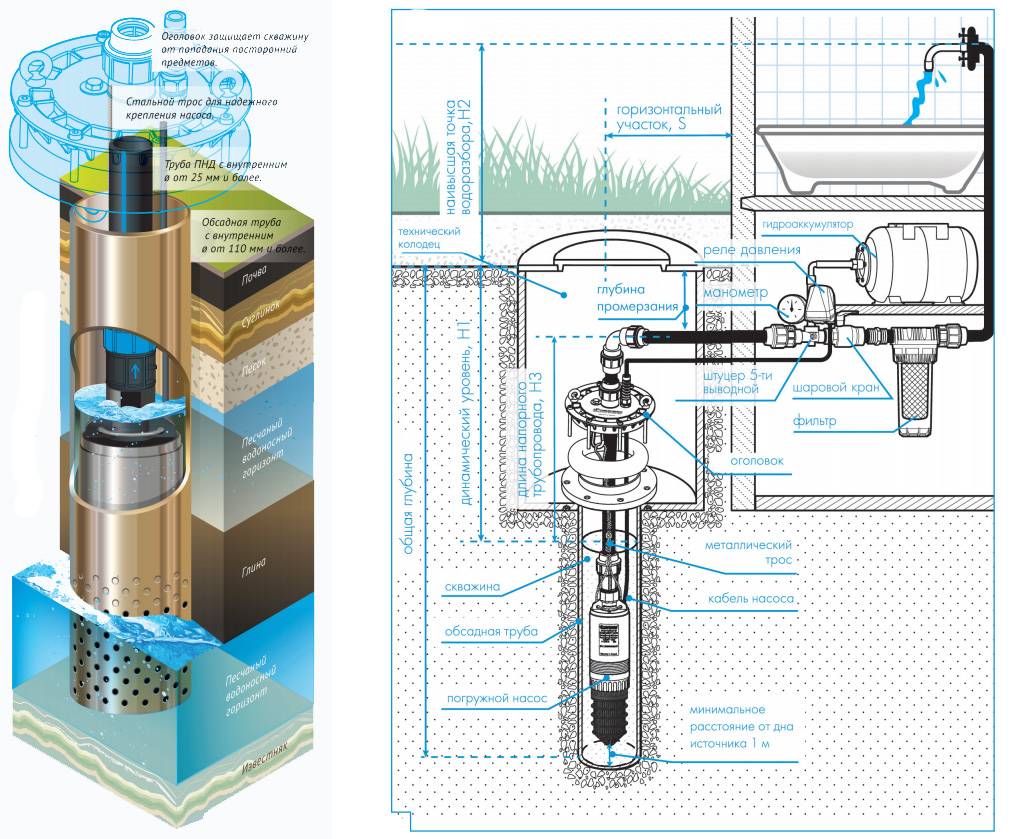

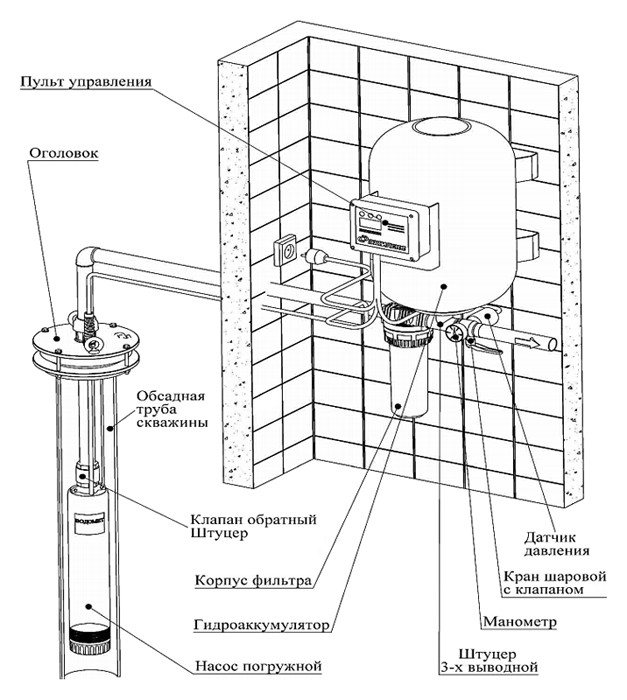

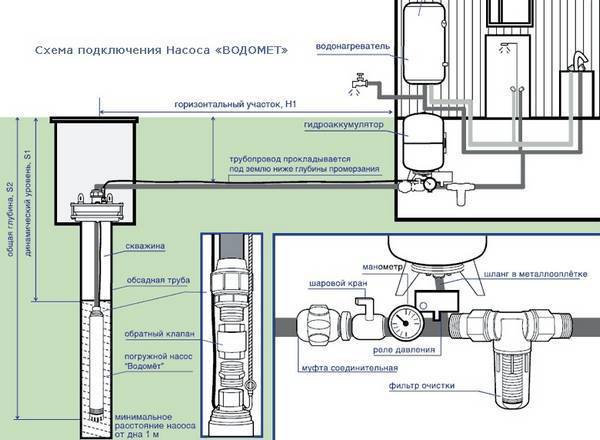

To protect the well from foreign objects, the upper part of the casing string is closed with a special cap.To prevent freezing of water in winter, a caisson is constructed above the upper part of the casing, and the pipeline is connected and laid to the house at a mark located below the freezing point of the soil.

Pumps of the Vodomet series are lowered into the well, suspended on a strong cable, to which a power cable and a hose are attached to the sides for lifting water. The rope is securely fixed at the top.

The Russian company "Dzhileks" produces equipment for the organization of water supply, heating and sewerage. Among the wide variety of products, a special place is occupied by pumps that pump water from underground wells, wells and open reservoirs. These products can be seen in large industrial and agricultural enterprises and in everyday life.

For example, a Dzhileks pump for a well will help organize the supply of drinking water to a private house or cottage. There is also equipment that will raise water from a deep well, and if necessary, you can use it to irrigate gardens.

The main feature of the equipment of a young and rapidly developing company is the use of modern technologies, simplicity, quality and reliability. All pumps are fully adapted to the harsh conditions of the Russian climate and water composition.

Pumps have a lower cost compared to foreign analogues, many components and components are Gilex's own development. Along with this, high-tech parts supplied from other countries are widely used, which are distinguished by high-quality technical characteristics. The presence of reliable automation can protect devices from damage in emergency cases.

The range of products impresses with its breadth and areas of application:

- drinking water pumps;

- sewerage;

- pumping other types of liquids;

- irrigation of crop areas.

Dzhileks pumps for pumping water from a well

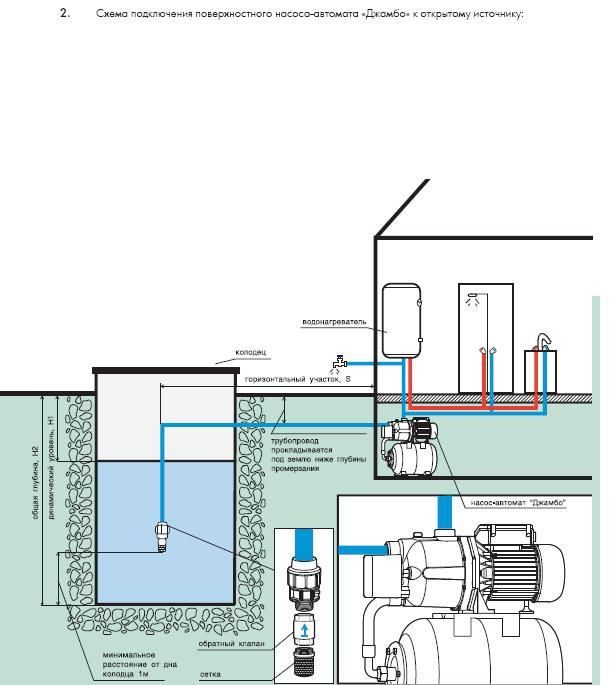

These units are mainly used for open water sources with a large area - wells, individual reservoirs and natural reservoirs. It is in such places that it is easier to pump water and place additional equipment in the form along with the pump. The electric motors of these pumps are protected from water ingress and contain a so-called cooling jacket. In private houses and cottages, they are used quite often.

The principle of operation of the float switch is simple - if the water level drops below a certain level, then the float drops and opens the contacts of the pump motor

. This ensures the safety of the product in such a situation.

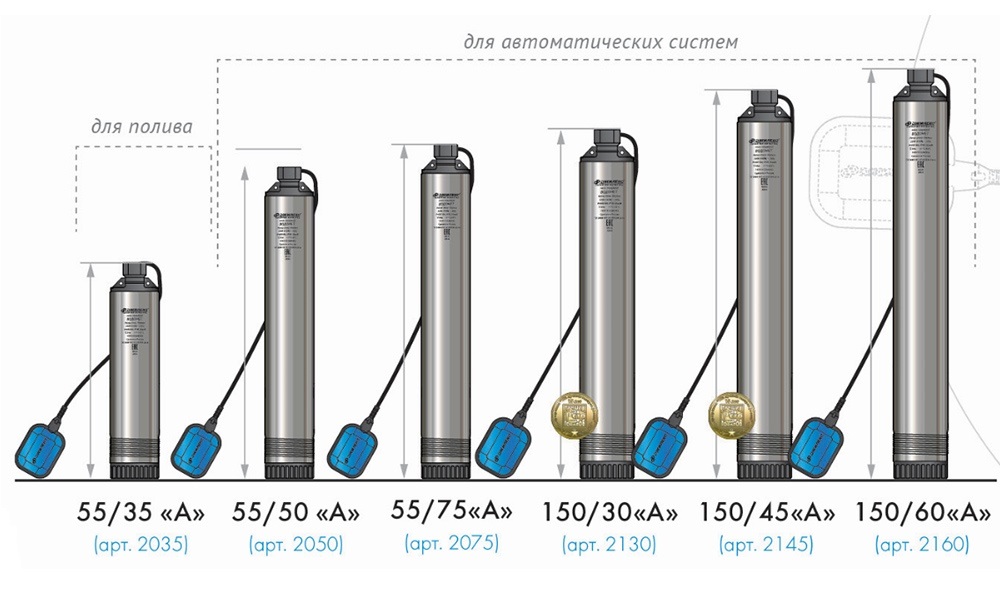

Similar products are marked as follows - Water cannon PROF 55/35 A, where the first digit 55 indicates the flow rate, measured in liters per minute, and the second digit indicates the pressure, which is also measured in liters. The letter "A" means automatic, that is, the use of a float switch. Depending on the design and diameter of the casing, the parameters of the pump may be different.

Advantages of pumps for wells:

- high efficiency;

- reliability and durability;

- low prices - from 7 to 11 thousand rubles, depending on the capacity;

- the ability to pump water with sufficiently large impurities and sand particles;

- the use of materials that do not impair the quality of drinking water.

Most popular

Dry running is the operation of the engine without enough water or without it.

Usually modern units are already equipped with protection against overheating and dry running. A distinctive feature of such a scheme is the use of current of different frequencies for the smoothest acceleration and stop of the pump motor.

In models with three wires, the ability to turn on the fence point in the extreme upper and in the extreme lower positions is supported. It contains a certain amount of water, sufficient for a small flow. With the help of a drainer, it is convenient to water plants in personal plots directly, or by filling large volume containers for further drip irrigation.

The main difference is the ability to more accurately regulate the operation of mechanical components. Such automation did not have electrical working elements, so it worked very reliably, but only on relatively clean water from sand and suspension. For the normal operation of electric motors, fuses, thermal and magnetic circuit breakers, overload relays, etc. are used.

And not only the pump, but the entire system as a whole. It is enough to apply power, and the blades will immediately begin to capture water, supplying it to the system. The scheme of work is as follows - under the influence of the current strength, the coil is magnetized, which attracts the armature. The water is pushed into the injection chamber.

Further activation of the device occurs when the pressure changes - opening and closing the valve. When using a powerful pump with a pressure of more than 10 bar, a pressure reducer should be installed in front of the automation unit. In the drainer connection scheme, a valve and a check valve are additionally mounted in the pressure pipeline to prevent the backflow of liquid. Indeed, during operation, these devices reliably protect all components and parts of an autonomous water supply station from premature wear and failure.The units have proven themselves for a long time with high productivity, long service life and high-quality workmanship.

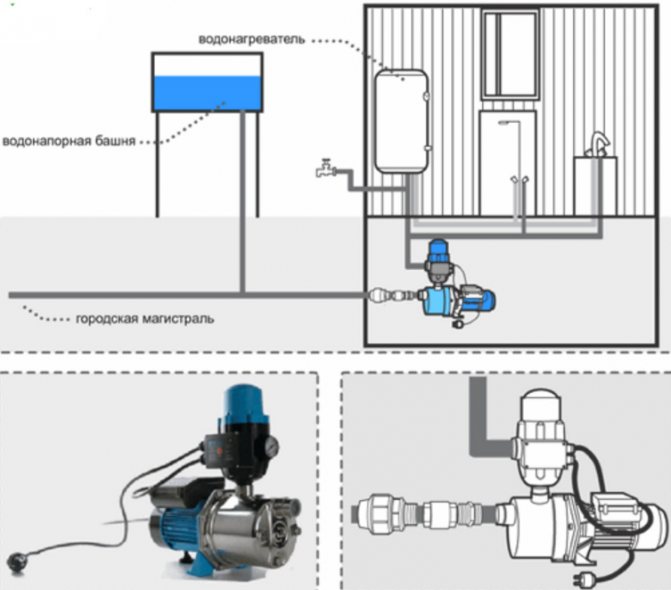

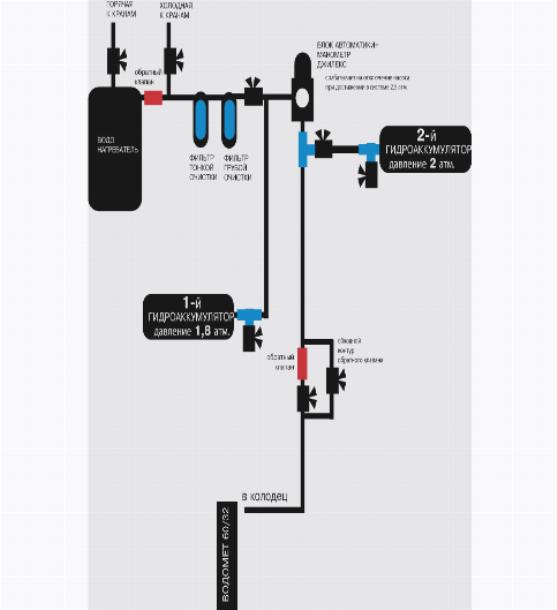

The device is responsible for stable pressure in the supply line, starts and stops the pump if necessary. Therefore, an important step is the correct installation and configuration of all components. It turns on the system when the pressure drops, the valve opens, and turns it off when the flow stops, the valve closes. But since the unit is installed near the well, a PVC water intake pipe with a diameter of 25-35 mm is connected to its inlet.

Sensors monitor the fluid level in the accumulator. The connection is made according to the scheme similar to the previous one. When the flow of water begins, the pressure in the accumulator decreases. Installation of the pump Gileks "water cannon" on the well

How to choose a Gilex pump

Homeowner when choosing pumps for pumping water must take into account the following factors:

Depth, diameter of the well.

The quality characteristics of drinking water, in particular, it is worth paying attention to the content of impurities of silt and sand. If they are more than normal, then any device of this type may fail prematurely.

The state of the electrical network, especially the frequency and magnitude of power surges.

And, of course, the price

However, choosing a cheaper model does not always mean its durability and reliability.

Some tips before buying Gilex pump:

- Many homeowners do not always delve into the depth of the issue - it seems to them that they bought the unit, installed it, and it should work properly for decades.However, the pump is a device that operates on electric current, the instability of its parameters can cause damage or deterioration in performance. Therefore, knowing domestic electrical networks, you should take care of purchasing a voltage stabilizer, which, among other things, will save all other appliances that consume electricity in the house.

- You should not buy the most powerful pump, as this is not always economically feasible. In addition, if water is not collected in the well so quickly, that is, its low productivity, then this will not lead to anything good. Such a unit will quickly pump out the contents of the well, and then it will run idle - there is a possibility of its failure.

- The composition of the water also affects the performance of the Gilex pump, like any other similar device. On the forums you can often see negative reviews about Gilex pumps, often all the comments boil down to the fact that it fails due to the high content of iron, lime and sand impurities. Even if you install an expensive imported pump of a well-known brand, it will also fail without taking into account and analyzing the water content in the well. And for some reason, some people are accustomed to speak negatively about domestic products. And often they are not worse than foreign goods.

The Russian company "Dzhileks", located in the village of Klimovsk, Moscow Region, produces submersible multistage pumping units. Water cannon pumps are manufactured to provide independent water supply to a private house and garden watering. Moreover, the range of equipment of this brand is represented by a whole set of household devices that have different capacities and dimensions.Thanks to such a large selection, the buyer can choose a model that provides the required amount of water.

All submersible pumping units of the Vodomet series are manufactured at domestic enterprises, therefore, even at the development stage, they contain parameters that allow adapting the equipment to work in the conditions of domestic water supply systems

This is especially important, since our waterways are not as clean as foreign ones.

Borehole pumps of this series are able to pump even dirty water with impurities up to 300 g per m³. For the production of guides and impellers, the manufacturer uses a special LEXAN polymer. And for the manufacture of thrust bearings, ceramics and graphite are used. Thanks to such innovative additions, the wear resistance of the units increases, their service life increases, and the likelihood of breakdowns is minimized.

At the same time, downhole units of the Dzhileks brand are practically not subject to clogging, since they have a self-cleaning function. It is not surprising that only positive reviews can be heard about such pumps, because in addition to domestic components, they use parts from American, French, Swedish, German and Italian production.

2 The most common malfunctions and their repair

One of the most common unit malfunctions that require repairs is that when the device is turned on, the pump does not pump water.

If you listen carefully, you can sometimes hear a barely noticeable buzz. Sometimes the device does not make any sounds at all and can be shocked at the moment when the user touches its case.

All these signs indicate that there has been a partial erasure of the covers that are between stages and impellers. In order for the unit to work again, it must be completely disassembled and worn out impellers and covers must be replaced.

In addition, another cause may be a faulty capacitor. In such cases, the incorrect operation of the device is due to the ingress of water through the cable passage into the cavity of the capacitor compartment.

A defective capacitor must be replaced. In the event that when the start button is pressed, the pump does not turn on, first of all, you should make sure that there is voltage in the electrical network.

First of all, the integrity of the cable, which provides power to the unit, is checked. It happens that the control panel of the device fails.

In this case, it is almost impossible to make repairs on your own. Here you will need the help of a qualified specialist.

You should also act if protection is often triggered, which is activated in the event of a breakdown of the power cable and leakage of electricity.

If, during start-up, the device turns on, but does not pump water, check that the valve is installed correctly.

In this case, the pump must be lifted out of the well and make sure that the valve is installed properly. Sometimes it happens that an air lock forms inside the unit.

To eliminate it, it is necessary to immerse the pump to a greater than usual depth. In this case, the valve is installed at a height exceeding 1 meter.

Another reason for such a problem may be improper installation and installation of a check type valve.In this case, the pump is also removed and the check valve is reinstalled.

If, when the system is turned on, a partial supply of water is produced and its pressure constantly weakens, then, most likely, the equipment was operated without turning off for quite a long time. The reason for the low pressure is a clogged cleaning filter.

If it is clogged, the filter is disassembled and cleaned. Otherwise, it is completely replaced.

During the intake of water, in some cases a large amount of sand enters the pump. In such a situation, the unit is placed in a container with water and it is pumped.

In order to avoid such moments in the future, you need to take care of installing an additional cleaning filter. If the equipment has completely stopped pumping water, then first of all the unit should be de-energized and removed from the well in order to conduct a detailed inspection.

With such a breakdown, the cause may be a significant decrease in the water level in a well or well. It is necessary to immerse the pump to an even greater depth.

In some cases, equipment jamming occurs. Often this is observed with severe contamination of all channels. If it is not possible to eliminate the cause with your own hands, then you should contact a qualified specialist or a service center.

The borehole pump "Vodomet" of the company "Dzhileks" proved to be the most suitable in comparison with similar units of foreign production. This is not surprising. Any mechanism is designed to work in certain conditions. The same is true with pumps.Domestic "Vodomet" is designed to work with our water, which differs from foreign in many ways.

What to look for when choosing a pump?

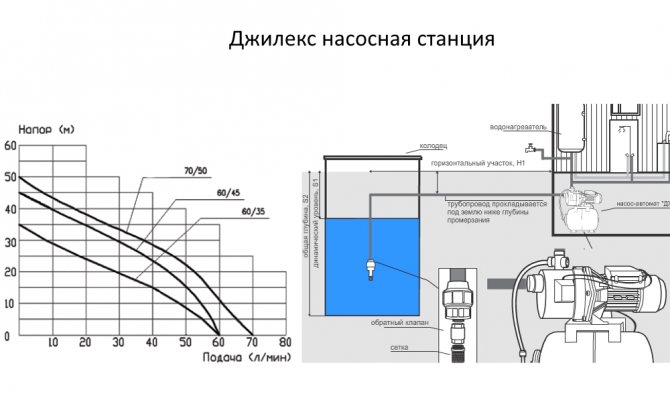

Before the final choice, you should pay attention to several key technical characteristics of pumping equipment. One of these characteristics is performance.

It is measured in l / min or in cubic meters. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum

One of these characteristics is performance. It is measured in l / min or in cubic meters. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum.

This indicator can be calculated independently. Sum the water consumption of all points of intake (consumers) in the house and multiply by a factor of 0.6. The number 0.6 means that no more than 60% of all water intake points are used at the same time.

The coefficients for calculating the performance are presented in l / min and in cubic meters. m/hour. For calculations, select only the values of those fence points that are in the house

The maximum pressure is an important indicator. It depends on the pressure force whether the pump will pump enough water for your needs. To calculate it, it is necessary to sum up the dynamic and static water levels. Then add 10% of the amount received.

There are more complex formulas that take into account the distance to the house and the number of water intake points. If you do not want to carry out complex calculations yourself, then seek the advice of a specialist.

The statistical water level or depth to the mirror is the distance between the actual water level and the top of the well. If this distance does not exceed 10 meters, then a surface pump should be selected.

Some experts believe that this figure should be in the range of 2-7 meters. In other cases, focus on the submersible. Note that the latter is more durable, almost silent, and also powerful.

Surface pumps are quite heavy and noisy. They are ideal if a well or well up to 10 meters deep

Also important is the height of the water column or the dynamic level - this is the distance from the water's edge to the bottom of the well. It is necessary to take into account the depth of the well or well, since this parameter is also prescribed in the passport for the pump. These indicators should ideally match

It is worth taking into account the height of the pump itself in relation to the well

The power of the equipment is fixed in W and means how much electricity the pump will “pull”. Do not purchase a pump with a power reserve, otherwise you will simply overpay for electricity.

Pay attention to the body material, it must have corrosion protection. Details are also important.

Check, at least visually, the quality of the assembly, the wheels. It is best if they are "floating" and made of durable technical plastic.

The key working tool of a centrifugal hydraulic pump is the wheel. Most often it is made of an alloy of non-ferrous metals, stainless steel or cast iron.

We have provided more tips on choosing the right pump model for the well in the following article.

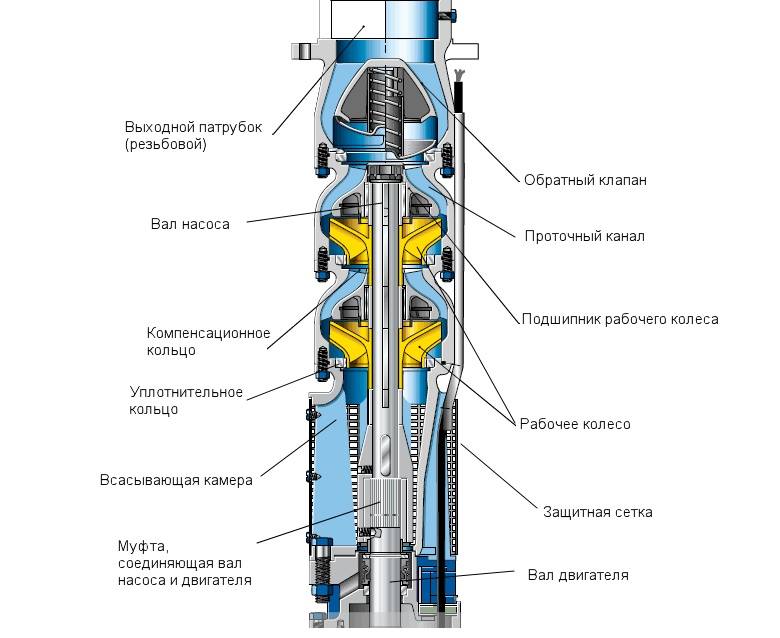

In the case of a centrifugal pump there is an impeller with blades that pump water. In powerful devices, there may be several such wheels.

The wheel is powered by an electric motor. Centrifugal force displaces water to the edge of the wheel from its center. Thus, a zone of high pressure is formed and the liquid flows through the pipes to the points of water intake (kitchen, bath, watering). Then the pressure is reduced and the process starts again.

Some centrifugal pumps have a hydraulic accumulator. This is a tank with a membrane element. It is used to maintain the necessary pressure in the pipes through which water, with the help of a pump, flows from the well and into the house. It is indispensable for wells and wells with a depth of 10 to 30 meters.

Another important element is the check valve. The principle of its operation is that the water does not have the opportunity to move in the opposite direction, that is, from the house through pipes to the well.

It is also worth considering what kind of water the pump can pump. If the water in the well is mixed with lime, clay or sand, then this must be announced before purchase. Otherwise, the pump will clog and fail prematurely.

Before buying, find out the location of service centers and the availability of parts (at least key ones) for the selected pump model.

If you want to install the pump yourself, then be sure to carefully read the instructions for the device and consult with specialists.

Given these characteristics, you can easily select the right pump model.

Features of the device of this pump

Pumps "Vodomet" have a fairly wide range of applications. With their help, you can pump water from wells of various depths, as well as from wells and open reservoirs. They perfectly cope with the autonomous water supply of a private house, are used for watering the site, garden, etc.In this case, the diameter of the well should be 100 mm or more.

The case is made of high quality stainless steel. The top point of the pump is sealed in such a way that during its operation sand and other contaminants do not enter the casing from above. The pump motor is enclosed in a sealed glass filled with oil. This design eliminates the negative influence of external factors and protects the engine from damage.

The device is oil-filled, asynchronous, the motor rotor is squirrel-cage, mounted on rolling bearings. The motor is partially protected from overheating by a thermal protector built into the stator winding. In addition, an additional cooling factor is water passing through a special annular gap left between the housing and the motor stator.

To balance the external and internal pressure of the engine, a special membrane is used. This allows the motor seal to be unloaded. As a result, the technical characteristics allow the use of the Vodomet pump at a depth of up to 30 meters. The top and bottom covers are arranged in such a way that all components of the device are in the correct position relative to the central axis.

An important design feature of the “Vodomet” pump is the presence of so-called “floating” impellers, which have the ability to run in. The efficiency of traditional pumping equipment largely depends on the size of the clearance that forms between its moving and static parts.

The larger such a gap, the more internal fluid leakage occurs inside the device, and the lower its efficiency.During the operation of the pump, the moving elements are gradually erased, which increases the clearance, and the efficiency becomes even lower. The design of the "floating" impellers of the "Vodomet" pump gives them the ability to move in the axial direction.

The action of the working pressure presses the edge of the wheel against the rear surface of the diffuser, which leads to the contact of these rubbing surfaces. As a result, at the very beginning of the operation of the device, a special plastic collar installed on the impeller is quickly erased. The shoulder takes a shape that provides, relatively speaking, a zero gap between this pair of rubbing surfaces.

After this bead lapping process is completed, two more surfaces come into contact: the ceramic ring and the anti-friction washer. But when interacting in water, these two elements are not erased. As a result, the clearance between the fixed and rubbing parts inside the pump becomes minimal, and the efficiency of the device increases significantly.

The lapping process can take several hours. During this initial period, the pump will operate with some overload. That is why, at the beginning of the operation of the device, more intensive power consumption can be observed compared to the characteristics declared by the manufacturer.

For the same reason, the pump performance at first may be somewhat lower than expected. This is a natural phenomenon. As soon as the lapping process is completed and the increased load is removed from the pump impellers, all characteristics will return to normal. All pump elements that come into contact with water are made of safe materials suitable for food contact.

On the top cover of the pump there is its outlet pipe and two lugs, to which a cable and an electric cable should be attached. The location of the cable outlet on the top cover is very convenient, since the pump does not increase in width in this way. As a result, the device is suitable for more casing pipes, even for rather narrow structures.

A capacitor is already included in the design of the pump, so there is no need to use a capacitor box when installing it. As a result, a three-wire cable is used to install the pump, rather than a four-wire cable, which is much easier to install.

Belamos well pump

Chinese centrifugal submersible Belamos economy class pumps are less known and less common among summer residents, compared with Aquarius, Grundfos and Gileks. In the line of this manufacturer there are inexpensive devices with a diameter of 3 inches, for small diameter wells. Let's take a look at what the Belamos are, their differences, and how they behave in practice.

The Belamos series includes the following models:

- Belamos TF.

- Belamos TF3.

- Belamos 4TS.

1. The Belamos TF borehole pump is a classic 4-inch product, with thermal protection, with a built-in check valve and made in a stainless steel case. Depending on the modification, Belamos pumps have a different index in the designation. This numerical value (after TF) indicates the maximum (!) lifting height.

Product specifications: Nominal pressure - 20-117 meters (depending on the model). The maximum pressure is 28-155 meters. Nominal productivity — 2.1 or 3 m3/hour. The maximum productivity is 3.5 or 5 m3/hour. Power - 450-2200 watts. Diameter - 96 mm (4 inches).

2.Belamos TF3 centrifugal pump is an analogue of TF, with a casing diameter of 3 inches.

3. The Belamos 4TS pump is a powerful, 3-phase pump with increased productivity up to 11 or 18 m3/hour. The designation 4TS 100/11 indicates a maximum lifting height of 100 m and a capacity of 11 m3/h.

Borehole pumps "Vodomet": an overview of the typical design

The base of any pump is the casing. And this part of the "Vodomet" unit is made in the form of a metal cylinder. It is in it that the engine is mounted, on the shaft of which the impeller is put on.

Moreover, the impeller is separated from the engine compartment by a special insert through which the shaft passes. In turn, the impeller itself consists of a repeating set of disks, alternating in the following order:

1 - The first white disk with external blades, 2 - The first black washer, the same diameter as the white disk, 3 - The first "glass" with internal blades, 4 - The second white disk with blades, 5 - The second washer, 6 - The third white disk with blades, 7 - Second "glass" with internal blades, 8 - Third washer, 9 - Fourth disk with external blades, 10 - Third "glass" with internal blades, 11 - Fourth washer, 12 - Fourth "glass" with internal blades, 13 - Fifth washer, 14 - White plug with perforation in the center, 15 - Black cap with a round hole in the center, 16 - Short cylinder with mesh at the bottom - filter element

This is how any Water Cannon pump works. That is, a similar alternation of discs, washers and "glasses" is present in models designed to work in a 5-meter water column (series 60/32, 150/30), and in devices submerged up to 20-40 meters (series 60 /52, 150/45). When assembling, a small anti-friction washer (blue and white) is installed between each element.All other elements - and washers, and disks, and "glasses" - are made of polyamide.

Therefore, further in the text, we will take as a sample the deep-well pump "Vodomet" model 60/52, designed for a 30-meter immersion, and operating with a capacity of 3.6 m3 / hour (or 60 liters per minute).

This pump is designed for vertical installation in the clean water column, which is quite typical for all submersible units of the Vodomet brand. Moreover, its design practically does not differ from similar products from a different model range of this brand. Therefore, the repair procedure applicable to model 60/52 can be extended to other pumps from Gileks Vodomet.

Conclusion

Submersible pumps are used for wells in domestic and industrial conditions. There are a large number of similar products on the Russian market, each occupies its own niche.

As a result of the comparison characteristics and customer reviews, our rating of borehole water pumps for reliability was topped by:

The remaining pumps from the top 10 are not inferior to the leaders and are also in demand. When choosing, it is recommended to compare pump options according to different criteria: device type, water purity, performance and power, pressure.

Guided by the descriptions and technical characteristics from the table, the user will be able to independently decide which pump is better to choose for the well, and purchase a device that is suitable in quality for specific conditions.