- Pump Maintenance Malysh

- The principle of operation and advantages of the submersible pump "Brook". Do-it-yourself repair instructions

- Technical characteristics of the pump "Brook"

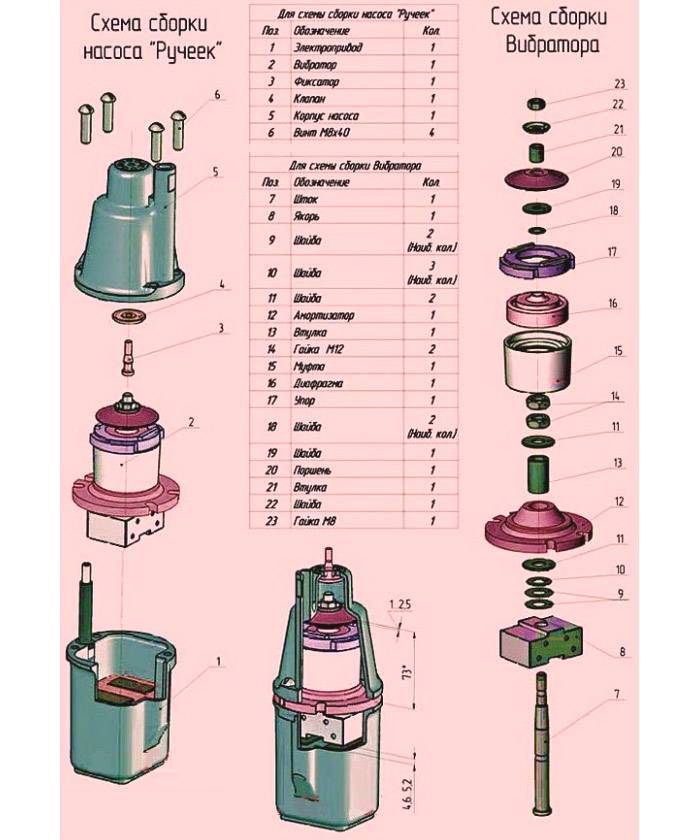

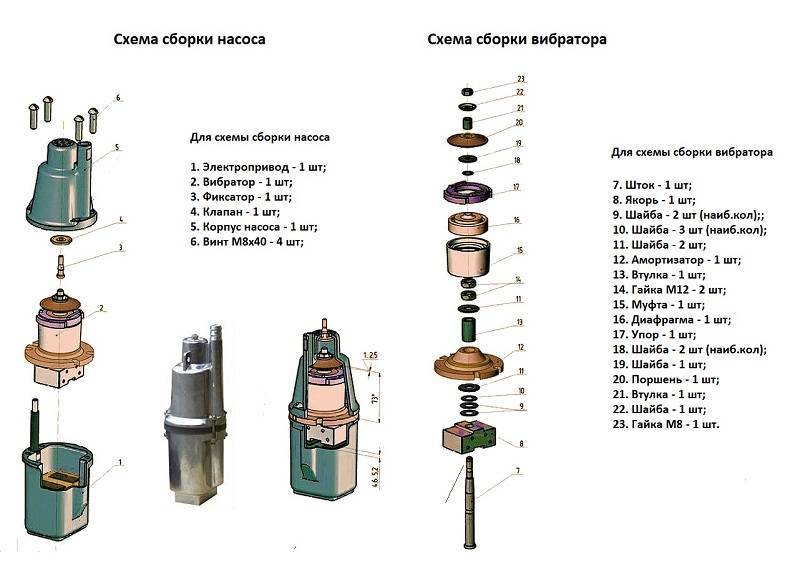

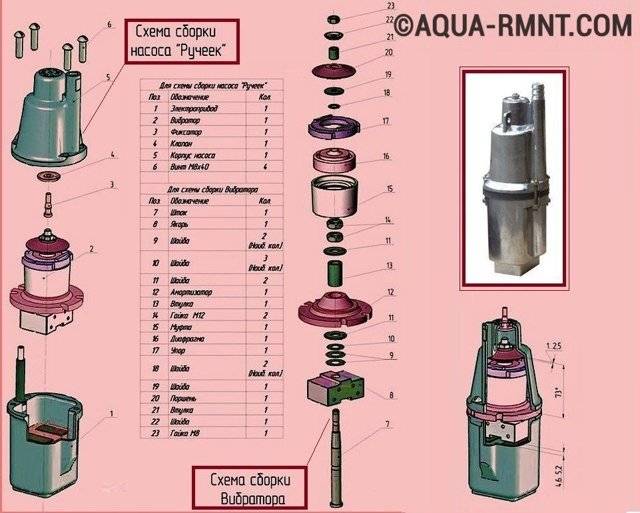

- Brook pump device

- Principle of operation

- Submersible vibration pump - principle of operation

- Advantages of vibration pumps

- 2 How to repair the Brook pump?

- 2.1 There were extraneous noises and sounds

- 2.2 The pump is buzzing and pumping poorly

- 2.3 Pump leak

- 2.4 Faults related to power supply and pressure

- The design and principle of operation of the pump "baby"

- Advantages and disadvantages

- Features of repair work

- We disassemble the pump

- We replace membranes

- We change the winding

- Repairing the surface of an electric magnet

- Specifications and working principle

- The device of the pump Brook and the principle of its operation

- Specifications

- "Stream" vibration type

- Device

- Principle of operation

- We connect the relay to the water line

- The procedure for connecting the pressure switch to the water line for dummies (specialists can not read)

- Vibration pump for domestic water supply fontanel - Well

- How does this pump work?

- Why choose this particular device?

Pump Maintenance Malysh

In order for the pump to serve for a long time and properly, it is necessary to observe the operating and storage conditions recommended by the manufacturer. In this case, the manufacturer guarantees its normal operation for two years. The pump does not require complex maintenance and care, and simple rules will not be difficult to follow.

After the first installation of the device in the well, you need to let it work for one to two hours, and then take it out and carefully inspect the body and components for faults. If everything is normal, then the vibration pump can be replaced and used further, leaving it immersed in water for a long time.

Periodically, at least once every three months, and if possible, then every hundred hours of operation, it is also necessary to inspect the unit. If at the same time traces of friction are found on the body, it means that it was installed incorrectly and, during operation, came into contact with the walls of the water intake.

To avoid this, it is necessary to set it evenly and put an additional rubber ring on the body.

If the inlet holes become clogged, they must be carefully cleaned without damaging the rubber valve. For cleaning, it is best to use a tool with a blunt end.

If the pump is not used in winter, it must be pulled out of the well, washed and dried well. During storage, the unit should be placed away from heaters and protected from direct sunlight.

The principle of operation and advantages of the submersible pump "Brook". Do-it-yourself repair instructions

The Rucheek pump was developed in Soviet times more than forty years ago. It was made at the Mogilev OAO Olsa in Belarus.This device competed with any models of this class. This was due to simple reasons:

- Its size and shape of the cylinder are convenient for use in places unsuitable for other devices, such as a well, the bottom of a deep well, flooded garages and basements, the shore of a reservoir;

- Easy to use: does not require filling with water before operation, does not need lubrication of the mechanism;

- Long service life associated with high quality indicators, long-term developments in process technology;

- Good water pressure;

- The minimum power consumption is about 225 watts per hour.

It was invented for use in summer cottages and today it has a very wide distribution. The pump is of good quality, relatively inexpensive, and its power is quite enough to serve a small family and a plot of six to twelve acres.

Breakdowns are rare, repair work is not difficult, spare parts are readily available and not expensive. On average, the pump can last from five to eight years.

The submersible vibration pump is designed to draw water from a well shaft more than one hundred millimeters wide and up to forty meters deep. The pump weighs about four kilograms.

The "Pen" pump involves taking water from above, which of course is a plus from the ingress of various contaminants into the device.

Technical characteristics of the pump "Brook"

The pump has a small power consumption of two hundred twenty to three hundred watts. This is comparable to an aquarium pump filter for three hundred to five hundred liters. If necessary, it can be easily powered by a battery or generator. The pump is powered from a household network. For wells up to forty meters deep, the capacity will be up to 40 liters per hour.If the fence is superficial and the depth of the fence is not more than one and a half meters, the fence capacity will be up to one and a half cubic meters per hour. A working time of up to twelve hours is provided and often used.

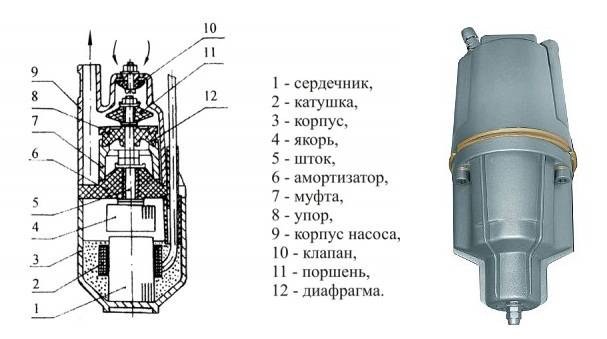

Brook pump device

Attaching the pump is not always necessary. In a vertical position, it weighs on a cable.

The pump has a practical metal housing and is very durable. To prevent collision with the walls of the well shaft, a rubberized cushioning ring is put on it.

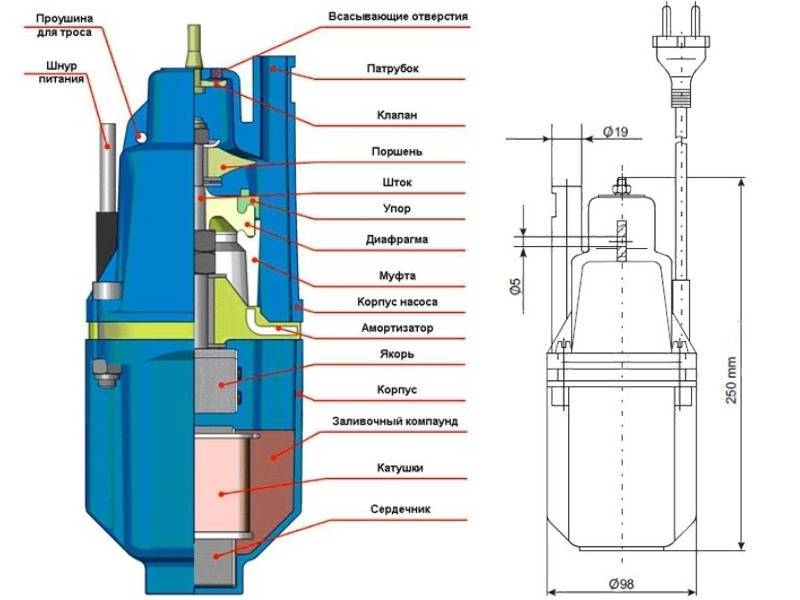

Principle of operation

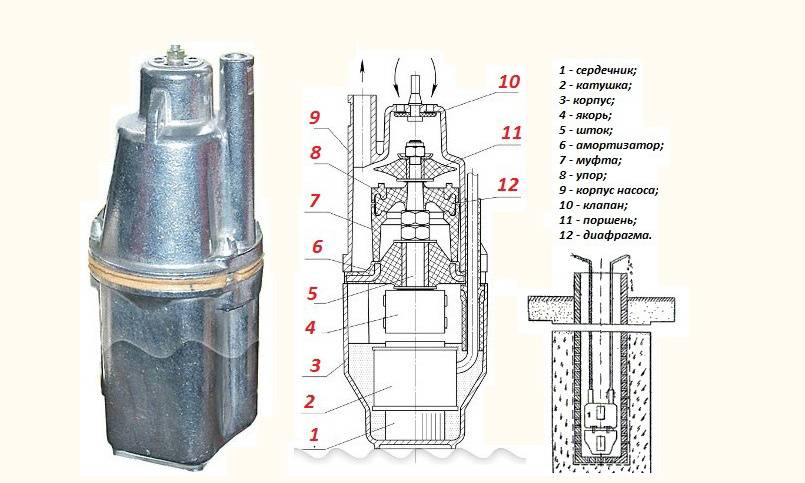

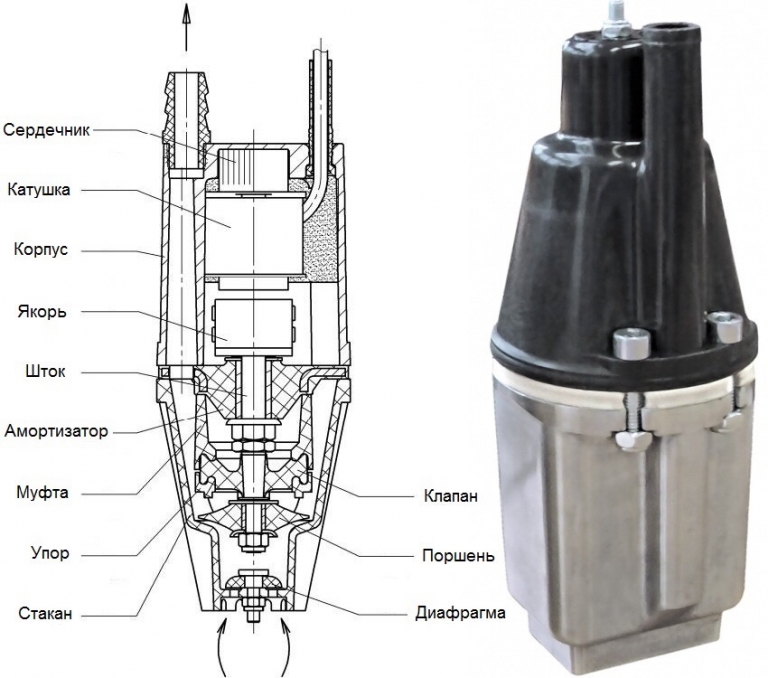

The principle of operation of the pump is based on the vibrational movements of the armature with the membrane, produced by the action of a magnetic coil. Electromagnetic voltage creates magnetic fields that cause a change in the internal pressure of the pump. The pressure oscillation of the diaphragm causes the water to rise.

The membrane sucks water through the check valve into the mechanism and pushes it out through the outer fitting. Water is distributed to users through a hose attached to a fitting. Due to the minimalist design, the vibrating mechanism can be cleaned from clogging by unscrewing four screws.

Submersible vibration pump - principle of operation

Uninterrupted long-term operation is ensured by the fact that there are no rubbing and rotating parts. The Brook pump has restrictions in the field of domestic use. It is not used for industrial purposes, as it has little power. In the farm, devices with more power and a storage tank are used.

"Trickle" is convenient for use in a well with low power.Where, when the well is empty, a powerful pump goes to idle or turns off, then the Brook, when the thermal protection is activated, continues pumping the well at a speed of five to seven liters per minute. Often after the work of the Brook, an increase in well capacity by fifty percent is observed.

Applicable:

- for the delivery of water from a well for consumption;

- for the delivery of water for irrigation;

- for filling the heating system;

- when pumping out a pool or reservoir.

"Trickle" is used to clean wells clogged with silt. Also, the pump can be used to pump out drainage water. It is mainly used, of course, for pumping drinking water, but due to various situations that arise in summer cottages, it can be used as a drainage device. Even a special device is commercially available that protects the pump when working with contaminated water.

This is interesting: Do-it-yourself balcony on the roof of the house: we understand in detail

Advantages of vibration pumps

The positive aspects of submersible pumps are:

- Reliability. The design does not contain bearings and high mobility parts, so it does not need lubrication and maintenance.

- Unpretentiousness. This type of pump is adapted to work at any temperature conditions, as well as in alkaline and salt water.

You can also note the ease of repair and long service life. But these advantages depend on many parameters and are not a feature exclusively of vibration pumps.

Simple mechanism provides high reliability and unpretentiousness to working conditions

2 How to repair the Brook pump?

Repair of the vibration unit begins with the extraction from the well.Immerse an unstable pump in a container of water. Connect to the network, checking the voltage. If it corresponds to 200 V, turn off the pump, drain the water from it and blow out the outlet with your mouth. Start disassembling.

Before this, it is recommended to mark on the joined elements with a pencil or felt-tip pen, which will ensure the correct assembly and its efficiency. However, remember that if the warranty period of the device has not expired, it is forbidden to open the case yourself. In this case, be sure to contact the service center. Disassembly is carried out using a vice. They compress the ledges on the body, located near the screws. To loosen the screws, as well as to tighten, it is necessary gradually.

It will not be superfluous during the first disassembly to replace the screws with similar ones with a head for a convenient hexagon. These actions will further facilitate the assembly and disassembly of the device. To understand what we are dealing with, we propose to consider the most common causes of malfunctions.

2.1 There were extraneous noises and sounds

The pump makes a characteristic sound, similar to ringing. After disassembly, perform a thorough visual inspection. If, during the inspection, an armature imprint and a black spot are found on the surface of the electromagnet, this indicates that the armature hits the surface of the magnet. This malfunction negatively affects the vibrator and leads to the burning of the winding.

Pump disassembly and necessary tools

It is necessary to measure the distance from the filling cap to the surface of the magnet.The height of the pour should be 3.9 cm, but the value on the caliper is 4.9 cm, since the thickness of the bar located on the surface of the pour is 1 cm.

Then the vibrator is disassembled, the adjusting washer is replaced in accordance with the filling height norm. For example, if it is 2.85 cm, then a 1.05 cm washer is required. A large sleeve is inserted into the shock absorber, and a small one into the piston. After the pump is twisted, the screws are locked by punching.

Make sure that there is no distortion, screw the screws evenly and tightly, not too tight, so as not to reduce the gap between the armature and the magnet. Using measuring instruments, check the parameters of the pump. In the absence of knocking, lifting height of at least 40 m - you managed to repair your unit successfully.

2.2 The pump is buzzing and pumping poorly

The brook shakes badly and buzzes. The reason for this may be the loosening of the nuts or the wear of the valve. In the first case, disassemble the pump, tighten the nuts until they stop. The top must be fixed to avoid a similar problem in the future. If rust is found on the coupling screws during the process, use a grinder to carefully cut them, replace them with new ones with a hex head. In the second case, simply replace the valve, which is suitable for a cork from a medical bottle.

2.3 Pump leak

The case is in contact with the walls of the well, depressurization of the device is observed. As a result of impacts against the walls of the well, which are equivalent to hammer blows, the body cannot withstand overload, heats up, and the filling peels off from the magnet. If the unit has run dry, similar phenomena will be observed.It is necessary to remove the magnet, before separating the electrical part, cut shallow grooves over the entire surface with a grinder. Then it is lubricated with sealant and returned to the housing in its place. This uses a press. Wait for the sealant to dry before reassembling the pump.

2.4 Faults related to power supply and pressure

When there is insufficient intake in the vibrator, the problem should be corrected by adding washers to the vibrator. Their number is determined until the necessary water pressure is restored empirically. If the plug knocks out when connecting, check the winding in the armature. In this case, most likely, it burned down, and it needs to be updated.

Vibrating pumps are supplied complete with cable

When the cable is charred, a tester is needed to check for its serviceability. It also needs to be replaced. It should be said that not all models have such a procedure. In this case, the cable is extended by twisting.

When the rod (rocking mechanism) breaks or its destruction occurs due to mechanical influences, repair is impractical. Consider buying an analogue.

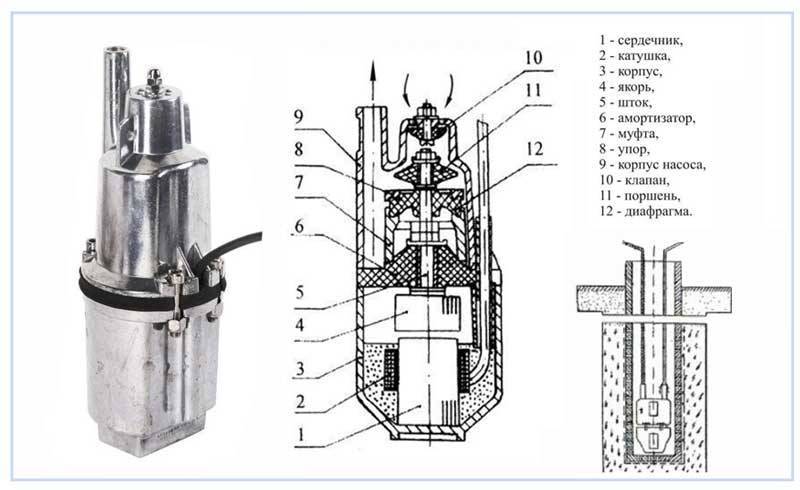

The design and principle of operation of the pump "baby"

Vibropumps are made according to individual technology and exact characteristics are used. On the basis of which, when electricity is supplied through the power cable, oscillatory movements occur, transmitted to the internal mechanism of the installation, called a float, the valve acts on the membrane, as a result of which it pumps water if the pressure is observed and the diameter of the pipeline is optimal. This is the correct principle.

We draw the user's attention to the fact that the vibration pump is very sensitive to overheating, therefore, an automatic control sensor must be installed on such structures, which monitors the presence of idling and pressure, and prevents the device from breaking. Despite the low indicator of the level of work, the “baby” installation does an excellent job with the tasks of domestic needs. According to the design features, the submersible vibration pump is usually divided into two types: a device with an upper and lower water intake

The preferred device is one that is equipped with a top water intake valve. The equipment itself is located in the lower part, due to which it is not clogged with small debris, silt and gravel

According to the design features, the submersible vibration pump is usually divided into two types: a device with an upper and lower water intake. The preferred device is one that is equipped with a top water intake valve. The equipment itself is located in the lower part, due to which it is not clogged with small debris, silt and rubble.

If your practice uses installations with a lower water intake valve, then you need to take care of the safety of the pump, equip it with an additional filter and automatic control in order to prevent overheating with your own hands if there is an increase in pressure. The diameter of the tubes at the inlet and outlet must also be observed.

Advantages and disadvantages

The most important indicator is the stable quality of pumping equipment of this brand, good performance, efficiency. In addition, domestically developed products have the following advantages:

- Simple and reliable design.

- Relative unpretentiousness in work.

- Reliability, low cost.

- High maintainability - it is possible to replace all rubber components and elements.

- Ease of operation.

- Does not require expensive maintenance.

- It can be used for pumping water from any artificial or natural reservoir, tank, well, well.

- The electrical part of vibration pumps is perfectly cooled in cold water. Since the pump is located in the upper layers of the water, it cannot become clogged with debris or silt that usually accumulates at the bottom.

- The pump kit includes a thermal protection device, so if the unit heats up to critical levels, it automatically turns off. This usually happens if the water level in the source is greatly reduced.

There are disadvantages in the devices of this brand. It:

- Insufficient performance, therefore, the Brook pump is designed for operation in wells and wells with a low water level - it can supply water for a long time, and at the same time it will not drain the hydraulic structure. Because of this, the disadvantage as such can not be considered.

- The thermoregulation sensor may not always work. This leads to overheating of the unit, which reduces its service life.

- Vibration patterns can destroy the well.

- Submersible pumps must not be used for pumping contaminated liquids and sewage.

Features of repair work

Since the cost of the pump is low, many do not even think about repairing, but simply buy a brand new device. But in fact, there is nothing difficult to repair, and it will come out much cheaper. For this reason, we do not recommend throwing away a broken pump, it is better to take it in for repair and buy another one.Thanks to this tricky move, you will get an uninterrupted supply of water. If you have a little free time and basic skills, you can handle the repair yourself.

We disassemble the pump

First you will need to remove the mounting bolts. As a rule, they sit in the case "tightly" and covered with rust. If you can’t unscrew with a screwdriver, cut off the heads with a grinder

To do this, use only small discs in diameter, so as not to damage the motor if you move carelessly. Also do not forget that the pump will need to be fixed in a vise

We replace membranes

The most common cause of failure is the failure of the membrane due to the ingress of a foreign element. There are special repair kits available for free. But if you don't have a spare valve and membrane handy, they can be easily replaced with a rubber cap from medicines. This simple action will cope with its task with a bang.

We change the winding

In this type of repair work, it will not be possible to do without engineering knowledge, so it will be better to give the device to the workshop.

Repairing the surface of an electric magnet

This type of damage is easy to replace with auto sealant. To do this, apply shallow grooves with a grinder, and apply glue on top.

Specifications and working principle

This pump belongs to the group of submersible pumps used for lifting or pumping cold fresh water from depths up to 60 m (depending on the model). With a weight of only 4 kg, it is able to pump out about 450 liters per hour.

Refers to vibration-type systems that work due to vibrations of the diaphragm, which reacts to changes in pressure inside the device. The difference in pressure is formed due to the fact that the electricity passing through the coil creates a magnetic field, and this, in turn, sets all the parts in turn in motion, thus raising the water flow upward. The brook pump device works from 220V, consuming about 270 watts per hour. depending on the power of the model.

There are no bearings and rubbing parts in the brook pump, which increases the service life of the device

Due to the absence of rotating elements and bearings, the brook water pump works for a long time and without problems, because it is friction that disables parts and requires their replacement. The water intake in the structure is located on top, which gives an additional plus in the form of cooling of the entire system. It does not experience excessive heating during operation, which means that it functions without overloads. The second plus of the upper fence is that silt is not sucked in from the bottom, and water does not become cloudy in the well.

The device of the pump Brook and the principle of its operation

Almost by design, all models do not differ from each other and are conditionally divided into vibration and vibration-immersed.

Their main elements:

- Anchor.

- An electromagnet that consists of 2 coils and a core.

Specifications

In addition to the fact that each modification has its own technical characteristics of the pump Brook, they also have common ones, which include:

- Power. Almost all devices consume 300 watts.

- For uninterrupted operation, a mains voltage of 220 V is required.

- The maximum head is up to 60 m.

- Performance.It can be different, it completely depends on the depth of the well or well. For example, for pumping water to a height of 1 m, the pump can supply 1.5 cubic meters per hour. If the water intake is carried out to a height of 40 m, the device will be able to pump only 0.43 cubic meters per hour (430 liters).

The only difference from the whole series is the pump of the Rucheek-1M brand. He has a water intake pipe located at the bottom of the case, and for all other models it is located on top. This significantly reduces the possibility of getting into the pumping chamber of large particles drawn in with water from silt or sand. And since the body during operation is constantly in the aquatic environment, overheating of the engine is completely excluded.

Reference. Pumps with water intake through the bottom of the casing are only used for pumping from clean containers where there are no deposits whatsoever.

"Stream" vibration type

When the device is turned on, an electric current excites an electromagnet, which drives the armature with a piston. The piston, in turn, causes the membrane to vibrate. This is the basis of the operation of the vibration pump.

When the device is turned on, an electric current excites an electromagnet, which drives the armature with a piston. The piston, in turn, causes the membrane to vibrate. This is the basis of the operation of the vibration pump.

An important point - in the design of the "Brook" there are no rotating mechanisms, so the parts of the device do not wear out, except for the membrane.

Also, due to the absence of friction, there are no by-products that are often formed during this process (for example, metal dust). Due to this, the working mechanism always remains clean, which ultimately does not require repairs for a long time and increases their service life.

At the same time, the device during operation also, thanks to the water intake holes located on the case cover, does not heat up and does not suck in silt and various small debris. from the bottom of the well or wells.

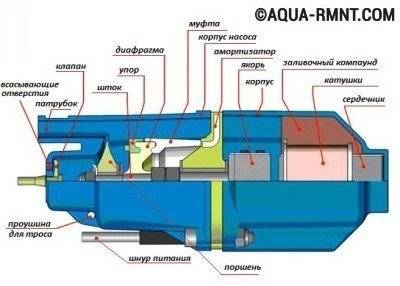

Device

The pump housing is divided into two chambers. In one chamber there is a pump drive mechanism, in the other there are nozzles with inlet and outlet valves, which are equipped with built-in shut-off valves (inlet and outlet).

The chambers are separated by a thick elastic rubber membrane. It is attached through a rubber shock absorber to the rod, which causes it to oscillate.

An electromagnetic coil is fixed in the chamber with a drive mechanism, causing oscillatory movements of the armature, which drives the membrane through the rod attached to it.

To ensure free water drain after turning off the pump, there is an additional valve. When the device is running, it closes the drain hole under the pressure of the liquid. As soon as the pump stops working, pressure in the working chamber falls and the shut-off valve releases the drain hole through which the remaining water leaves the working part of the device.

Submersible models practically do not differ from vibration models and are intended for deep work. But they are not recommended for use in open water and in wells with water supersaturated with salts.

Principle of operation

The operation of the pumping device "Stream" is based on the vibration of the membrane, due to which a constant change in pressure occurs in the passage chamber, at which a continuous flow of water is formed. All actions are performed in this way:

- When an electric current is applied around the coil winding, a magnetic field is formed that draws the piston rod into itself.

- The membrane, following the rod, bends towards the chamber in which the pump mechanism is located.Due to this, a discharged space is created in the water intake chamber, which is filled with water through the inlet valve. The outlet valve is closed at this time.

- The next cycle, which occurs after a change in the direction of the alternating current, the magnetic field around the coil disappears, the rod returns to its original position. At the same time, the inlet valve closes and the outlet valve opens, and the water is pushed out by the membrane from the intake chamber into the pipeline.

- After that, with the next cycle, the whole process starts again and so on until the device is turned off at a frequency of 100 cycles per second, which causes the equipment to vibrate.

We connect the relay to the water line

It is necessary to connect the pressure switch to water first of all, and to electricity second. Setting up the relay is the last, third stage.

Suppose everything turned out great and we found that piece of threaded pipe to which the pressure switch must be screwed. Do you know how to make reliable threaded connections? If yes, then good. If not, then you have to practice. Now there is a Tangit Unilok thread on sale. It's pretty cute and comfortable. It is more convenient than flax for sealing threaded water connections, but it is quite expensive. we will use it!

The procedure for connecting the pressure switch to the water line for dummies (specialists can not read)

So let's pray, let's get started. When sealing threads with flax or tangit, there are some tricks. Tangit is wound, which is obvious, on the thread, which is on the tube. We have this tube end, that is, the end face towards us.It turns out that we are looking directly at the end, on which we will wind whatever it is. We estimate approximately how much thread we will use. We take the tangita thread and start wrapping it. We start this process not from the end, but to the end, stepping back from the edge to the distance that will be inside the nut. In the above diagram, I indicated the approximate position from which to start with the green arrow. When winding the tangit, twist the thread clockwise (red arrow in the diagram), looking at the end of the pipe. The first loop should firmly secure the thread. so that it does not stretch and does not bloom. Then we act according to the instructions for the tangit, that is, we make sure that the thread does not lie inside the thread grooves.

You need to wind quite evenly and tightly. Do not try to wrap it so that you get a whole tumor of tangit. This is where some experience is really needed. Wrapping a little is bad. Will flow. A lot - do not screw the nut, crush the thread and again it will flow. Dont be upset! Get it - good. No - practice. Suppose wrapped. We start to wind the relay

Let's spin slowly! very slowly and carefully. First, hands, but not for long. As soon as we feel resistance, we begin to work with a wrench

The first sign that everything is fine is that the nut is not screwed too easily along the tangit. The presence of the thread should be felt, but in moderation. We carefully monitor how the relay nut is screwed on. If it is wound on a tangit, then this is just fine. Unfortunately, you may find that the tangit under the nut forms loops, bunches up and comes out of the thread. This is bad.In this case, I propose to twist a little more and, if the situation with the loops worsens, then it is better to unscrew the relay and redo the entire winding. In this case, it is better to free the thread from the old thread and make everything clean

As soon as resistance is felt, we begin to work with a wrench. The first sign that everything is fine is that the nut is not screwed too easily along the tangit. The presence of the thread should be felt, but in moderation. We carefully monitor how the relay nut is screwed on. If it is wound on a tangit, then this is just fine. Unfortunately, you may find that the tangit under the nut forms loops, bunches up and comes out of the thread. This is bad. In this case, I propose to twist a little more and, if the situation with the loops worsens, then it is better to unscrew the relay and redo the entire winding. In this case, it is better to free the thread from the old thread and make everything clean.

Suppose everything worked out, there were no loops, or there was one small one that formed when we had practically wound everything up. Then we twist the relay to the end. But not too hard! We translate the spirit. There is a high probability that everything will be in order and there will be no leakage.

Vibration pump for domestic water supply fontanel - Well

"Rodnichok" is a typical representative of domestic pumping equipment. Inexpensive, easy to use and fairly reliable unit. If you follow all the requirements of the technical operating instructions, the unit is able to serve the owners for many years.

Initially, the device was designed to work near the source of water intake. Modern models do not have this disadvantage. Pumps of the brand beloved by consumers are used without problems to supply water from wells and wells.They are also used to drain basements and water garden beds.

Autonomous water supply is not a luxury at all. Not a single country cottage or country house can do without it. Different devices can be selected for arranging the system.

It is necessary to take into account many factors: the depth of the well or well, the amount of water required by the consumer, the type of soil, and much more.

Many summer residents decide to buy a spring water pump, and are satisfied with their choice.

How does this pump work?

The design of Rodnichka is very simple. There are two main elements in the body that allow the mechanism to pump water. This is a vibrator and an electromagnet. The first is an anchor with a pressed rod with a rubber spring acting as a shock absorber.

It is rigidly fixed on the shaft. The movements of the shock absorber are limited by a special sleeve. A rubber diaphragm, fixed at a certain distance from the shock absorber, guides the rod and is an additional support for it. In addition, it closes the hydraulic chamber and separates it from the electric one.

Scheme of the device of the pump Rodnichok

In the electrical compartment there is an electromagnet consisting of a winding and a U-shaped core. Two coils connected in series form a winding.

Both elements are housed in a housing and encapsulated in a compound that performs several functions: it helps remove heat from the coils, holds the parts in place and provides the necessary insulation.

In addition, the fontanel pump device involves the installation of a special valve in the housing that closes the inlet holes. If there is no pressure, water flows freely through a special gap.

When the device is turned on, the core begins to vibrate at a speed of 100 times per second

After the device is turned on, the core begins to attract the anchor. The shock absorber drops the anchor once every half cycle.

A hydraulic chamber is formed, whose volume is limited by a valve on the body and a piston. The water pumped by the pump has a certain elasticity due to the dissolved and undissolved air present in it.

Thus, when the piston moves, it expands like a spring and pushes excess fluid through the pressure pipe. The valve on the body allows water to enter and prevents it from leaking through the inlets.

Why choose this particular device?

Initially, the vibration pump "Rodnichok" was designed to supply water from wells, wells, pump out liquid from basements, drain flooded areas and aerate. Due to their design features, the first models could only work close to the power source, the latter are free from this drawback. The installation has a number of undeniable advantages:

- The maximum pressure of the device is 60 m, which makes it possible to raise water from a well or well into a two-story building.

- Rated power - 225 W, so the pump can be used in tandem with low-power generators.

- The maximum particle size that can be passed by the mechanism is 2 mm.

- The outlet pipe has the most common and popular diameter ¾ inch.

- The installation is completely safe thanks to full waterproofing and double insulation of all electrical parts.

- The maximum pump capacity - 1500 l / h makes it possible to equip several points of water intake at once.

- A non-return valve built into the system prevents fluid from draining from the mechanism.

- The device does not require additional special maintenance during the entire period of operation.

- The inlet fitting is located at the top of the mechanism, which prevents the capture of dirt and sludge from the bottom of the tank or well.