- Disadvantages of the Vibratory Pump "Brook"

- 1 Device design

- 1.1 How it works

- Principle of operation and technical characteristics

- Installation in a well or well

- Connecting hoses and pipes

- Preparation and descent

- Installation in a shallow well

- Installation in a river, pond, lake (horizontal)

- Brief overview of popular models ↑

- Troubleshooting

- No water flow or low pressure

- Cable charring occurs

- The pump generates very little pressure.

- Strong pump vibration heard

- Specifications

Disadvantages of the Vibratory Pump "Brook"

One of the disadvantages of the Brook vibration pump is a loud sound during operation. If you use it only for watering, you can put up with it. But if you use the pump to operate a fountain, overflow or circulate water in the pool, then the hum of the pump will interfere and annoy. For these purposes, it is better to use pumps of a different type.

With the help of "Stream 1" you can download only part of the water above the suction hole. It will not be possible to completely pump out water from the tank.

Adapters and quick-release fasteners are not provided for connecting the hose. The hose connector has a round section (some models have notches), so the hose often disconnects due to vibrations.You have to crimp it with a knitting wire or a clamp. Disconnecting the hose is then problematic.

The pump device does not provide for automatic shutdown. The user himself has to monitor the water level. "Brook" is cooled by the water in which it is located. If the pump runs idle, it quickly heats up and fails.

Float device for automatic shutdown can be purchased separately. Many owners make their own.

Of course, it will not be possible to solve all problems with its help. To pump water and other liquids in large volumes, you will need a more powerful pump.

The water supply of a country house and the provision of high-quality irrigation of the area adjacent to it is a topic that excites any person who spends part of his life outside the city. For this purpose, various devices and devices are used, including the Rucheek submersible pump, known since Soviet times, whose technical characteristics are quite consistent with many modern and "advanced" analogues.

With its low power, averaging 225-300 W, and the minimum price (1300-2100 rubles, depending on the model), the Brook water pump is quite capable of providing water to a small family of 2-3 people, as well as watering a summer cottage with an area of 6 -12 acres.

The vibration pump can also be used for purposes such as:

Pumping water from pools, basements and various containers.

Most often, the problem of flooding of premises located on the lower tiers of residential buildings and utility structures occurs during the spring flood, when groundwater rises especially high.Since they practically do not have solid impurities in their composition, they can be pumped out using a submersible vibration pump Brook.

The filter for the pump Brook is a special device that has the shape of a cap, which is worn on the receiving part of the pump. This procedure is best done after the pump has warmed up.

Filling the heating system before starting it.

This manipulation is carried out in the absence of the possibility of connecting to a centralized heating system at this stage of construction. The process itself looks like this:

- Water is delivered to the house in a barrel, into which a hose from the pump is inserted.

- The second hose connects to the radiator drain cock.

— The tap opens at the same time as the pump starts.

- The system is filled using a pressure gauge until the pressure in it reaches the desired level.

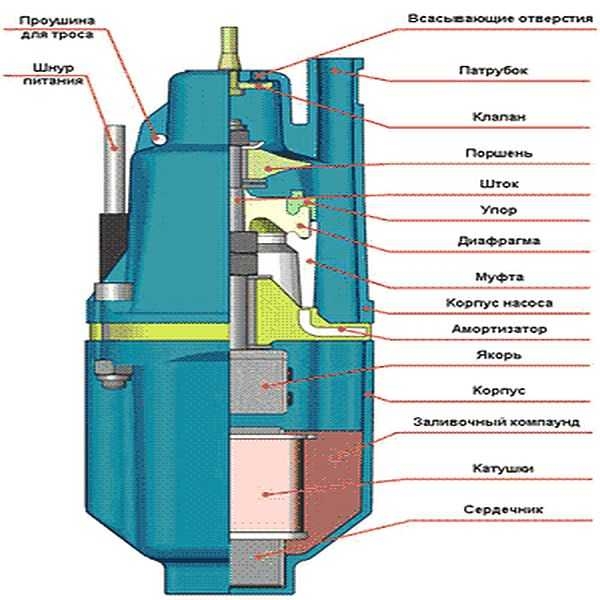

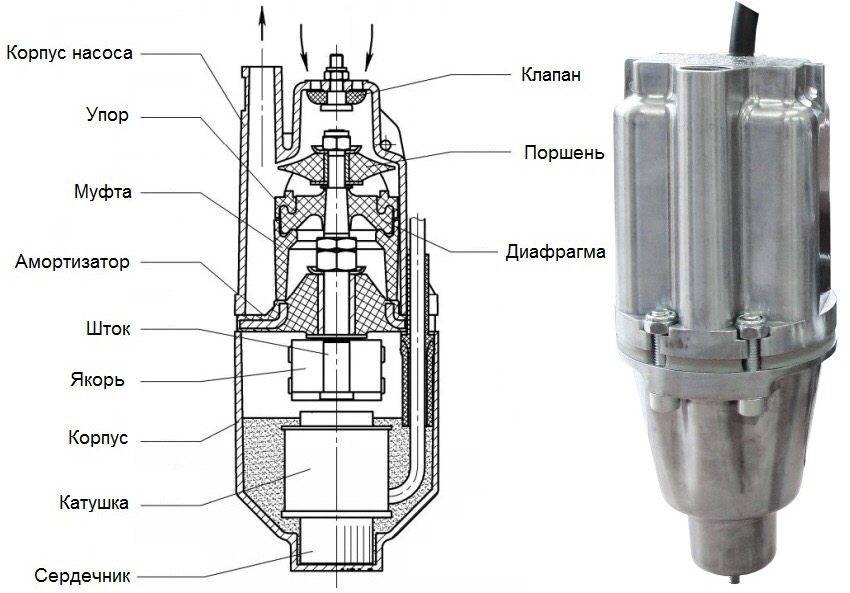

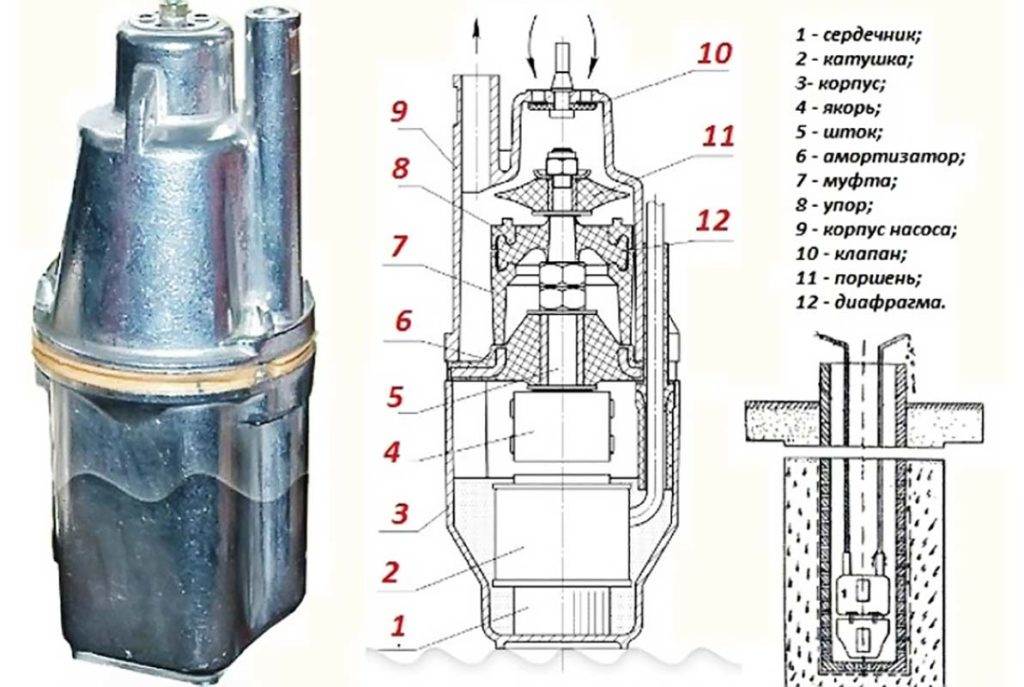

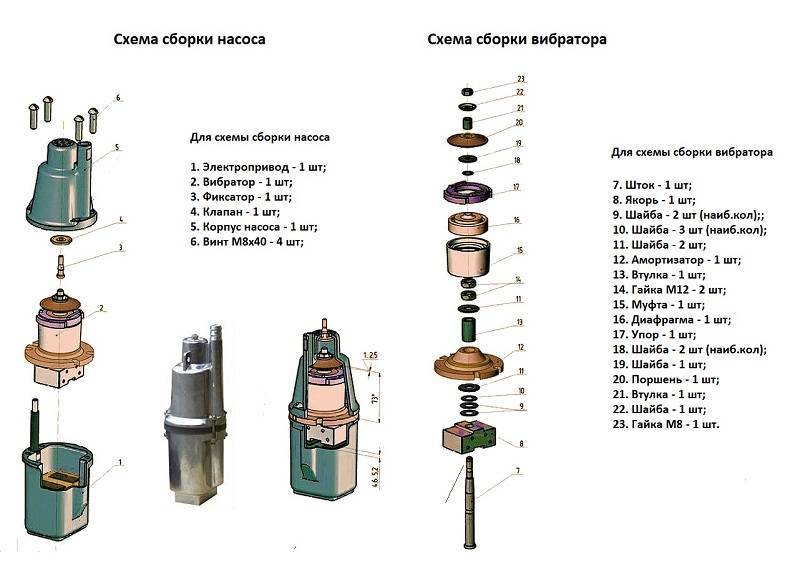

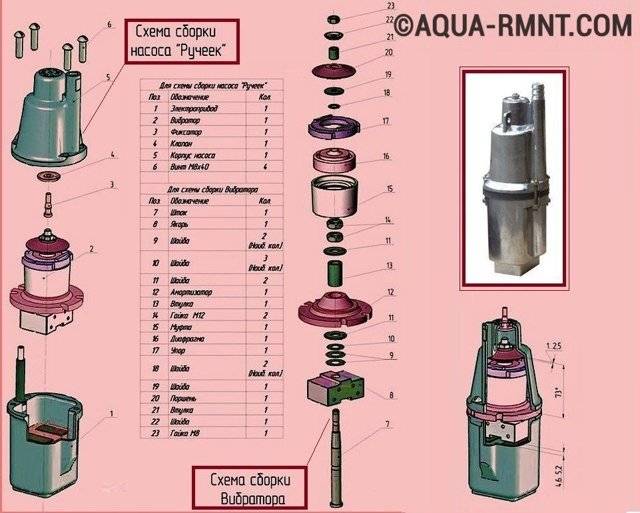

1 Device design

The device of the vibration pump baby is quite simple. It consists of three main parts:

- frame;

- electromagnet;

- anchor vibrator.

The body of the device is made of metal alloys and consists of two halves. The lower part is cylindrical. The top is made in the form of a cone.

The electromagnet of the device consists of a U-shaped metal core, on which several layers of electrically conductive winding are placed. The winding is fixed on the core with a compound (plastic resin). The same material secures the magnet inside the body of the device, isolating the coil from the metal components of the device. The composition of the compound also includes quartz-containing sand, which removes heat from the magnet, preventing it from overheating.

The anchor of the device is equipped with a special rod.With the rest of the nodes, it is attached with a spring, which ensures that the vibrator returns to the neutral position when the magnet ceases to act.

1.1

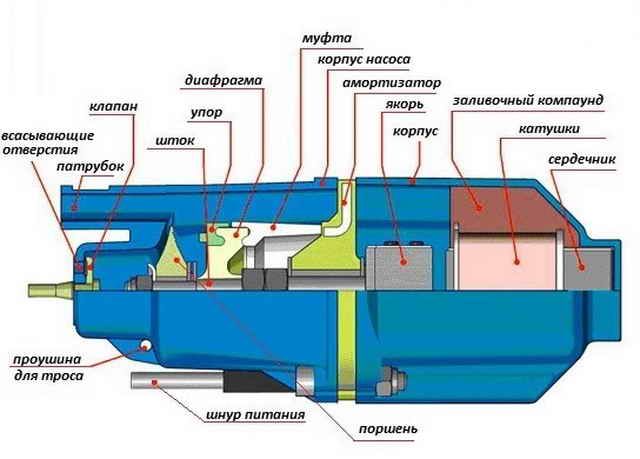

Operating principle

Proper repair of a vibration pump is impossible without a clear understanding of how the device works. The principle of operation of the pumps, the kid refers them to the inertial type of devices.

Submersible type devices are switched on only after complete immersion in the working environment. Whole algorithm device action is as follows:

- The pump is connected to the electrical network.

- After connecting, an electromagnet begins to act, which attracts the anchor. The magnet works intermittently, with a frequency of up to 50 inclusions per second. When it is turned off, the anchor returns under the force of the spring.

- When the armature is retracted by the spring, it also retracts the piston attached to it. As a result, a space is formed into which water saturated with air enters. This composition of the liquid provides greater elasticity, and hence susceptibility to vibrations.

- Under the action of the vibrator, the water begins to move. And subsequent portions of liquid from the inlet rubber valve put pressure on the previous liquid, directing the flow exclusively in the direction of the outlet pipe.

This principle of operation provides a high pressure in the tube, which allows you to keep the pressure over a long distance.

Principle of operation and technical characteristics

A small-sized borehole submersible pump copes with the extraction of water both from the deck shafts and from an open source. Works from a household network, providing a constant inflow of water.The functionality is based on high-frequency oscillations of the working membrane, which supports pressure changes in the working chamber. The simplicity of the device ensures the reliability of the device and a significant operational resource. Subject to the conditions, Rodnichok will last more than one year.

The technical characteristics of the pump are few, but the downhole unit is used not only for pumping water for domestic needs, but also for watering the garden. The device parameters are as follows:

- Mains supply 220 V, power consumption 225 W. The downhole pump can work when the central power is turned off, connected to diesel generators or gasoline low-power devices;

- The maximum pressure of up to 60 meters is sufficient to provide a flow of two-three-story buildings;

- Productivity at shallow depth up to 1.5 m3/hour;

- It is desirable to use a water pump for pumping a clean stream, however, Rodnichok can work with water, where there are small inclusions of insoluble or fibrous particles, provided that the size is not more than 2 mm;

- Structurally, the submersible pump is equipped with an upper water intake, which eliminates the ingress of large debris, however, when processing a dirty stream (switching on after floods), conventional filtering equipment should be used, located at the bottom of the well;

- Equipped with a built-in valve does not allow water to drain back;

- Double-circuit isolation of the electrical part of the pump guarantees increased safety of the device;

- It is necessary to connect the downhole unit to a hose or pipeline with a diameter of 3/4 inch.

These specifications position the Rodnichok pump as the most affordable, convenient and acceptable equipment for extracting water from a well, well or open source.

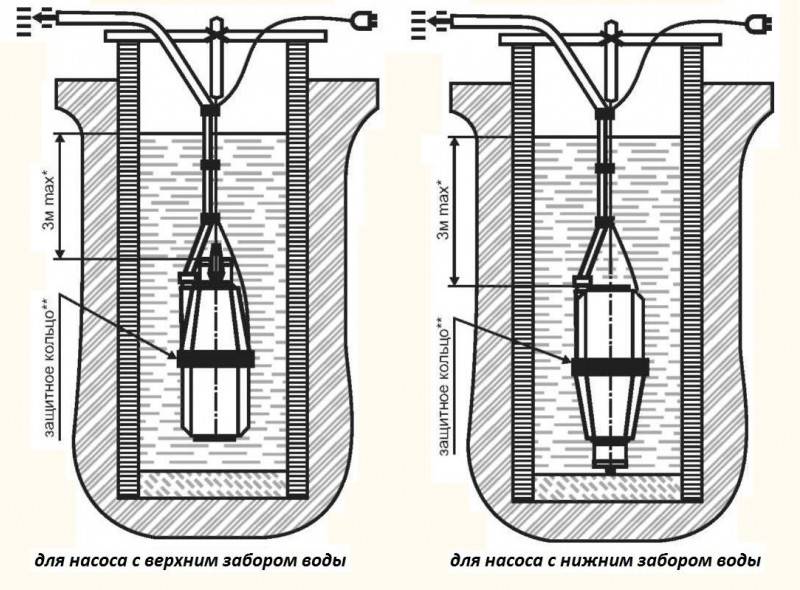

Installation in a well or well

The submersible pump Kid is suspended on a synthetic cable. A metal cable or wire is quickly destroyed by vibration. Their use is possible if a synthetic cable is tied below - at least 2 meters. There are eyelets in the upper part of the case for its fixing. The end of the cable is threaded through them and carefully fixed. The knot is located no lower than 10 cm from the pump housing - so that it is not sucked in. The cut edges are melted so that the cable does not unravel.

The cable clings to a special eye

Connecting hoses and pipes

A supply hose is put on the outlet pipe of the pump. Its inner diameter should be slightly smaller (by a couple of millimeters) than the diameter of the pipe. Too narrow a hose creates an additional load, due to which the unit burns out faster.

It is allowed to install flexible rubber or polymer hoses, as well as plastic or metal pipes of suitable diameter. When using pipes, the pump is connected to them with a piece of flexible hose at least 2 meters long.

Installation diagram of a submersible vibration pump

The hose is secured to the nozzle with a metal clamp. Usually a problem arises here: the hose jumps off from constant vibrations. To prevent this from happening, the outer surface of the pipe can be processed with a file, giving it additional roughness. You can also make a groove for the clamp, but do not get carried away too much. It is better to use a stainless steel clamp with notches - it gives additional rigidity to the mount.

It is better to take a collar like this

Preparation and descent

The installed hose, cable and electric cable are pulled together, installing constrictions.The first is placed at a distance of 25-30 cm from the body, all the rest in increments of 1-2 meters. The straps can be made from sticky tape, plastic ties, pieces of synthetic twine, etc. The use of metal wire or clamps is prohibited - when they vibrate, they fray the sheaths of the cord, hose or the twine itself.

A crossbar is installed on the head of the well or well, for which the cable will be attached. The second option is a hook on the side wall.

The prepared pump is gently lowered to the required depth. Here, too, questions arise: at what depth to install the Malysh submersible pump. The answer is twofold. Firstly, from the water surface to the top of the hull, the distance should be no more than the immersion depth of this model. For the “Kid” of the Topol company, this is 3 meters, for the PATRIOT unit - 10 meters. Secondly, there must be at least a meter to the bottom of the well or well. This is so as not to disturb the water too much.

Tie with plastic, nylon cords, adhesive tape, but not with metal (even in a sheath)

If the Malysh submersible pump is installed in a well, it should not touch the walls. When installed in a well, a rubber spring ring is put on the body.

Having lowered the pump to the required depth, the cable is fixed on the crossbar

Please note: all weight must be on the cable, not on the hose or cable. To do this, when fastening, the twine is pulled, and the cord and hose are slightly loosened.

Installation in a shallow well

With a small depth of the well, when the length of the cable is less than 5 meters, to neutralize vibrations, the cable is suspended from the crossbar through a springy gasket.The best option is a piece of thick rubber that can withstand the load (weight and vibration). Springs are not recommended.

Mounting options for submersible vibration pumps with upper and lower water intake

Installation in a river, pond, lake (horizontal)

The Malysh submersible pump can also be operated in a horizontal position. Its preparation is similar - put on a hose, fasten everything with ties. Only then the body should be wrapped with a rubber sheet 1-3 mm thick.

Vertical installation option in open water

After the pump is lowered under water, it can be turned on and operated. It does not require any additional measures (filling and lubrication). It cools down with the help of pumped water, which is why switching on without water has an extremely bad effect on it: the motor overheats and can burn out.

Brief overview of popular models ↑

More than ten popular models, however, the owner himself must finally decide which vibration pump is best for a particular well. To do this, you should take into account the design features and technical characteristics of each product. Consider five known models.

The compact device has several modifications with the following characteristics:

- voltage - 220 V;

- power - 225-300 W;

- productivity - 400-1500 l / h;

- head - 40-60 m;

- weight - 5 kg;

- cost - 2250-2500 rubles.

About the pump "Rucheyek-1"

This equipment is universal, but not very suitable for pumping dirty water (for example, sewage). It does not have special fastenings to the walls of the well; it is suspended on a cable or a strong rope. Has long service life, replacement of rubber parts is made easily.Operating time - up to 12 hours a day, constant monitoring is not needed.

The household pump "Malysh-M" is intended for use in summer cottages:

- voltage - 220 V;

- power - 240-245 W;

- productivity - 1.3-1.5 m³ / h (up to 1.8 m³ / h without pressure);

- immersion depth - 3 m;

- weight - 4 kg;

- cost - 1400-1800 rubles.

This model is designed for pumping clean drinking water, but there are also drainage modifications that can deliver liquid with a high degree of contamination. Most often used to provide 1-2 points of water intake or for watering the garden (garden). There are options with upper and lower water intake. The main element of thermal protection is an enlarged copper winding that protects against overheating.

Simpler models are suitable for watering the garden, powerful modifications are suitable for providing water to homes, farms, and small businesses.

- voltage - 220 V;

- power - 225-240 W;

- productivity - 24 l / min;

- maximum pressure - 60 m;

- weight - 3.8-5.5 kg;

- cost - 1400-1800 rubles.

The advantage of the brand's products is the duration of continuous operation up to 200 hours (the maximum value of analogues from other manufacturers is up to 100 hours). The easy-to-use vibrating well pump has an upper water intake, which prevents the intake of dirt and debris, however, it allows particles up to 2 mm to pass through, so it can also be used for cleaning purposes.

The minimum diameter and compact dimensions of the equipment allow it to be used both in wells and in wells.

- voltage - 220 V;

- power - 180-280 W;

- productivity - 960-1100 l / h;

- water rise height - 60-80 m;

- weight - 4-5 kg;

- cost - 1700-3000 rubles.

When buying, pay attention to the length of the power cable - from 10 to 40 m.More powerful models are equipped with a more powerful motor and a built-in thermostat that protects against overheating. Inexpensive products are used for pumping only clean drinking liquids

Inexpensive products are used for pumping only clean drinking liquids.

Small lightweight pumps are designed for gardening and farm work in suburban areas.

- voltage - 220 V;

- power - 200 W;

- productivity - 660-1050 l / h;

- water rise height - 40-75 m;

- weight - 4-5 kg;

- cost - 1200-2500 rubles.

Some models have a lower water intake, which is convenient for functioning in deep waters. Sheet steel and copper motor winding ensure a long service life. In addition to a set of cables, the kit includes spare membranes.

Troubleshooting

Unfortunately, the pump may fail, and repairs in the workshop will be unavailable for some reason. Some breakdowns the owners can fix on their own. Moreover, they can be diagnosed by the nature of the operation of the unit.

No water flow or low pressure

The failure has three main causes:

The failure has three main causes:

- The problem is related to the loosening of the bolts located on top of the shock absorber. To eliminate it, it is necessary to open the casing and tighten the nuts until it stops. To further prevent their loosening, it is required to lock the upper nut. If the bolts of the outer casing are rusted and it is impossible to get inside the pump, they must be cut off with a grinder and then replaced with new ones.

- There was a rupture of the valve that serves to regulate the discharge of water. It is located inside the case. The item will be replaced with a new one.

- Failure of the rod used to fasten the armature and piston. It is theoretically impossible to repair this detail. But in practice, there are cases when a curved part was subjected to pressing out, followed by cutting of internal and external threads, and welding the transition by welding (for safety reasons). However, such a complex repair is beyond the power of most pump owners. And in repair shops they do not always take up such filigree turning work. Therefore, many owners throw away a failed pump and buy a new one.

Cable charring occurs

The breakdown can have two reasons:

- Violation of the cable insulation. Experts recommend replacing it entirely, instead of partial replacement using twisting or soldering. However, it is impossible to perform such a correct repair from the point of view of electricians in this case. The fact is that the cable is filled with compound in the engine compartment, and the cable can be repaired only by replacing the damaged area.

- Winding burnt out. The problem is diagnosed by a home tester - no voltage is detected on the winding. The winding needs to be replaced. It is better to do this in a repair shop.

The pump generates very little pressure.

The reason may be: poor fastening of the shock absorber nuts or a small gap in the vibrator. Nuts need to be tightened. Or increase the gap by adding washers. Their number is determined empirically. The purpose of the addition is to ensure sufficient water pressure.

The average market price is from 1,200 to 1,700 rubles. It is believed that the cost of the pump pays off on average in two years of continuous operation. Therefore, experts recommend using pumps of this brand to provide autonomous water supply for country houses and cottages.

Strong pump vibration heard

Probable cause: detachment of the magnet. To fix the problem, you will need to disassemble the unit. Notches are made in the magnet and on the inside of the engine compartment using a grinder. Then the inside of the compartment is lubricated with epoxy glue and sealant. The magnet is inserted into place. After complete drying, you can assemble the pump.

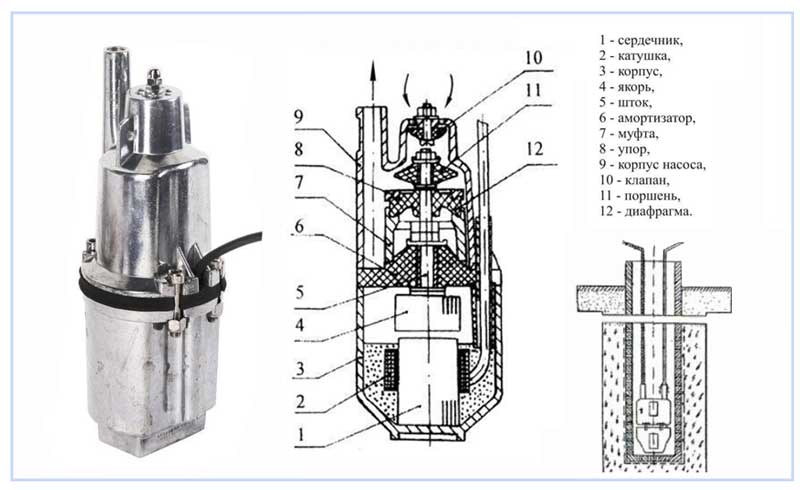

Specifications

The unit consists of a waterproof housing containing two main components - an electric magnet and a vibrator. The vibrator is an anchor with a rubber spring used for shock absorption. The assembly is securely fastened to the motor shaft, and its movements are limited by a bushing. At a small distance from the anchor there is a rubber diaphragm that serves as a dividing wall between the pumping chamber and the electric motor compartment.

Inside the engine compartment is a magnet (winding and core). The magnet is filled with a special material that removes heat and prevents overheating of the motor and coil. The pump also has a valve for draining water when the engine is turned off.

When the power is turned on, the magnet begins to attract the armature, causing it to vibrate.

The main characteristics of the unit:

- maximum pressure - 60 meters;

- productivity - 1,500 liters per hour;

- power 225 watts;

- filters are designed for dirt particles up to 2 mm in size.

Advantages:

- budget cost;

- the ability to work with water containing impurities of silt and sand;

- economical energy consumption;

- double insulation of all electrical parts;

- sufficiently powerful pressure (you can supply water to a two-story building);

- the ability to equip several points of water intake at once;

- the presence of a built-in check valve;

- upper water intake, preventing the capture of bottom sediments;

- ease of maintenance;

- use at a depth of more than ten meters is available.

Flaws:

- not very long power cable;

- cannot be used in wells with old rings (vibration causes cracking of concrete);

- sensitivity to voltage drops in the electrical network (may stop working at the most inopportune moment);

- installation near the bottom filter is not recommended - vibration raises silt and sand from the bottom;

The Rodnichok pump has a relatively low performance compared to other types of pumps used in wells and wells with a depth of more than ten meters.