- Device and principle of operation

- Vibration pump for domestic water supply fontanel - Well

- How does this pump work?

- Why choose this particular device?

- Model range and manufacturers

- Types of pumping equipment "Caliber"

- Division into classes

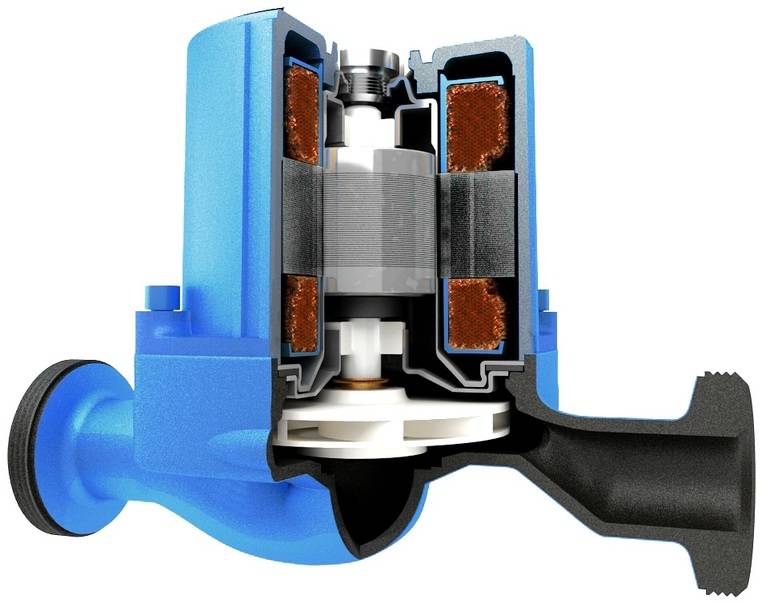

- Repair of pump parts "Gnome"

- Bearing replacement sequence

- Impeller replacement

- Repair of impeller shaft and casing

- Adjustment of the gap between the impeller and the diaphragm

- Repair of the electric motor of the pump "Gnome"

- Repair of pumping units of the Rucheek type

- Analysis of technical characteristics

- Unit performance

- Water intake options

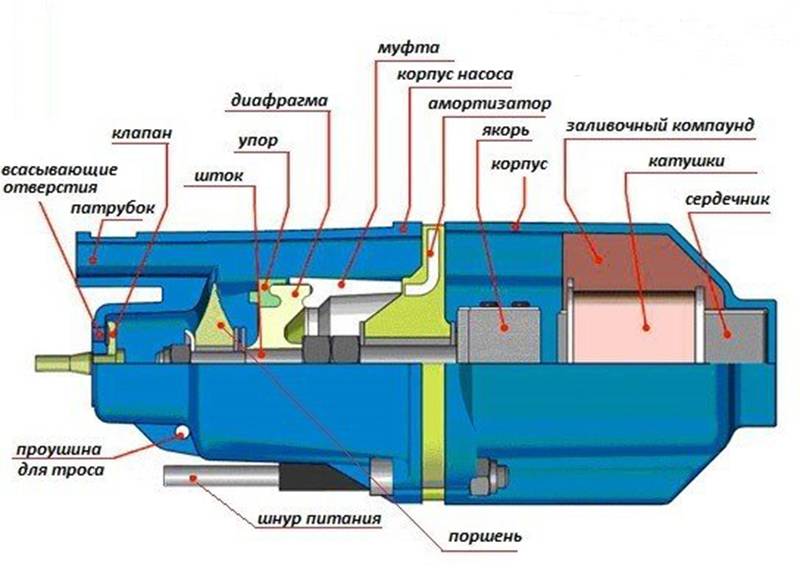

Device and principle of operation

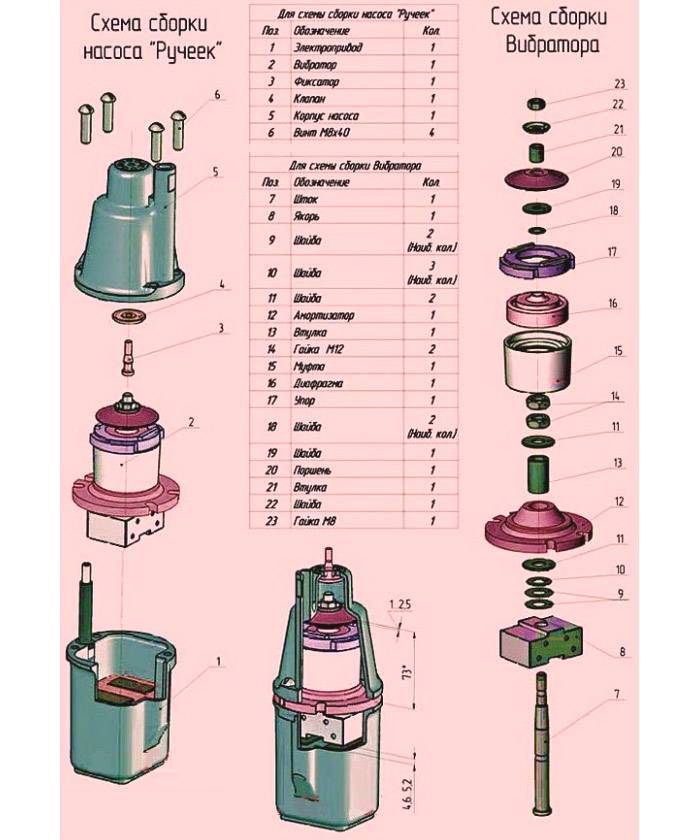

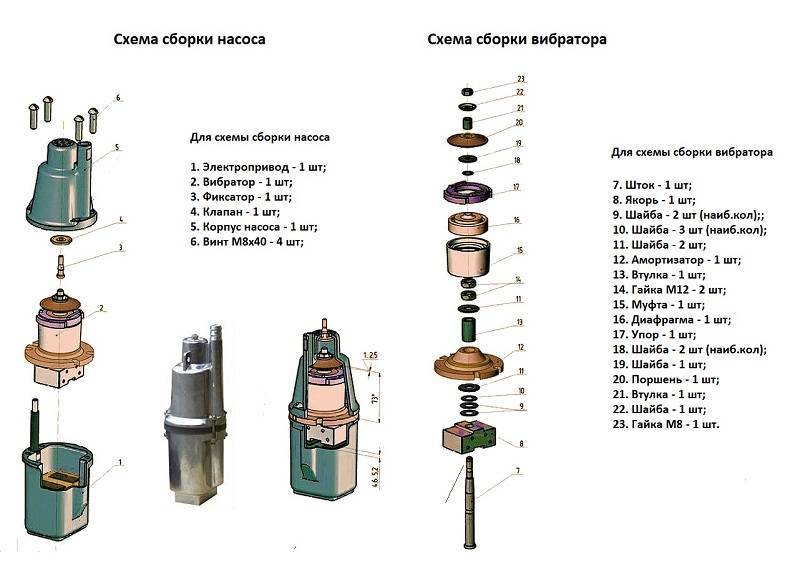

The brook submersible pump consists of the following parts:

- housing connected by four screws;

- electric drive;

- vibrator.

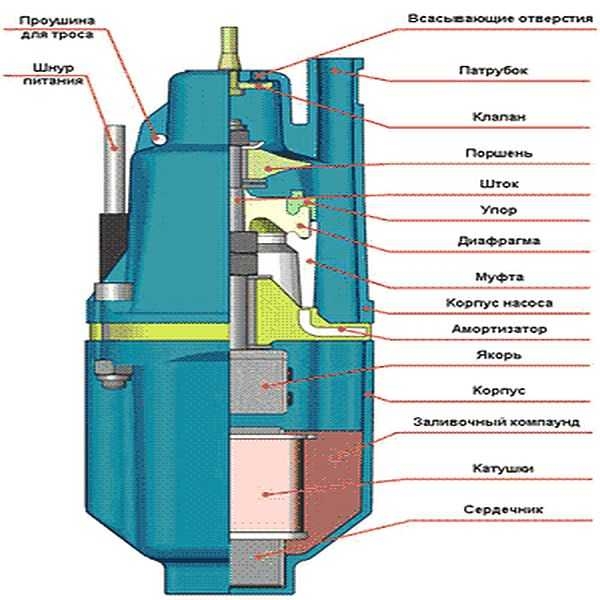

The body of the device is made in the form of a casing. In the upper section of the casing there is a glass for water inflow through the holes and a branch pipe for the water outlet. A special valve opens and closes the inlets.

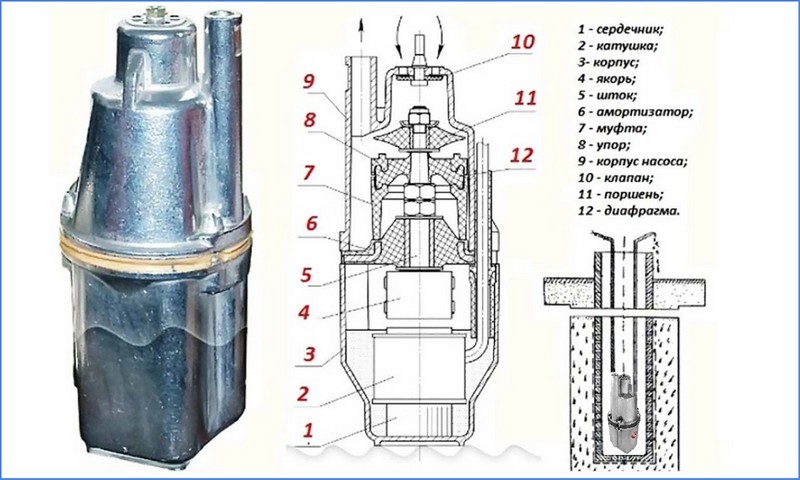

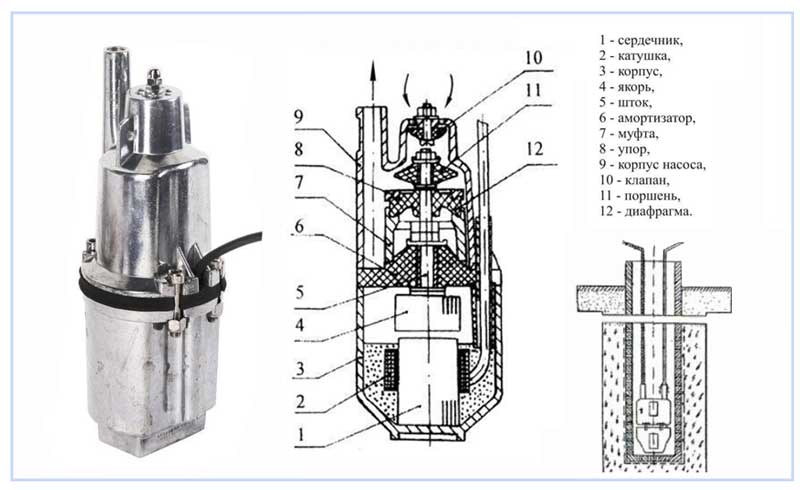

The electric drive of the device consists of a core with two coils and a power cord.

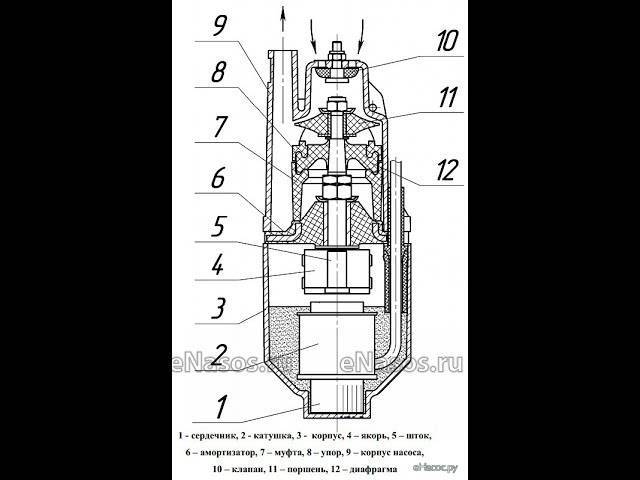

The vibrator is assembled with a shock absorber, a diaphragm, an emphasis, a coupling and a rod. At the top, the rod is connected to the piston, at the bottom - to the anchor.

The oscillations of the armature and the piston, which are created under the action of an elastic shock absorber, convert the electric power of the network into a translational mechanical vibration. The piston under the action of the rod creates pressure in the glass with holes, the valve closes simultaneously and water is squeezed out into the outlet pipe.

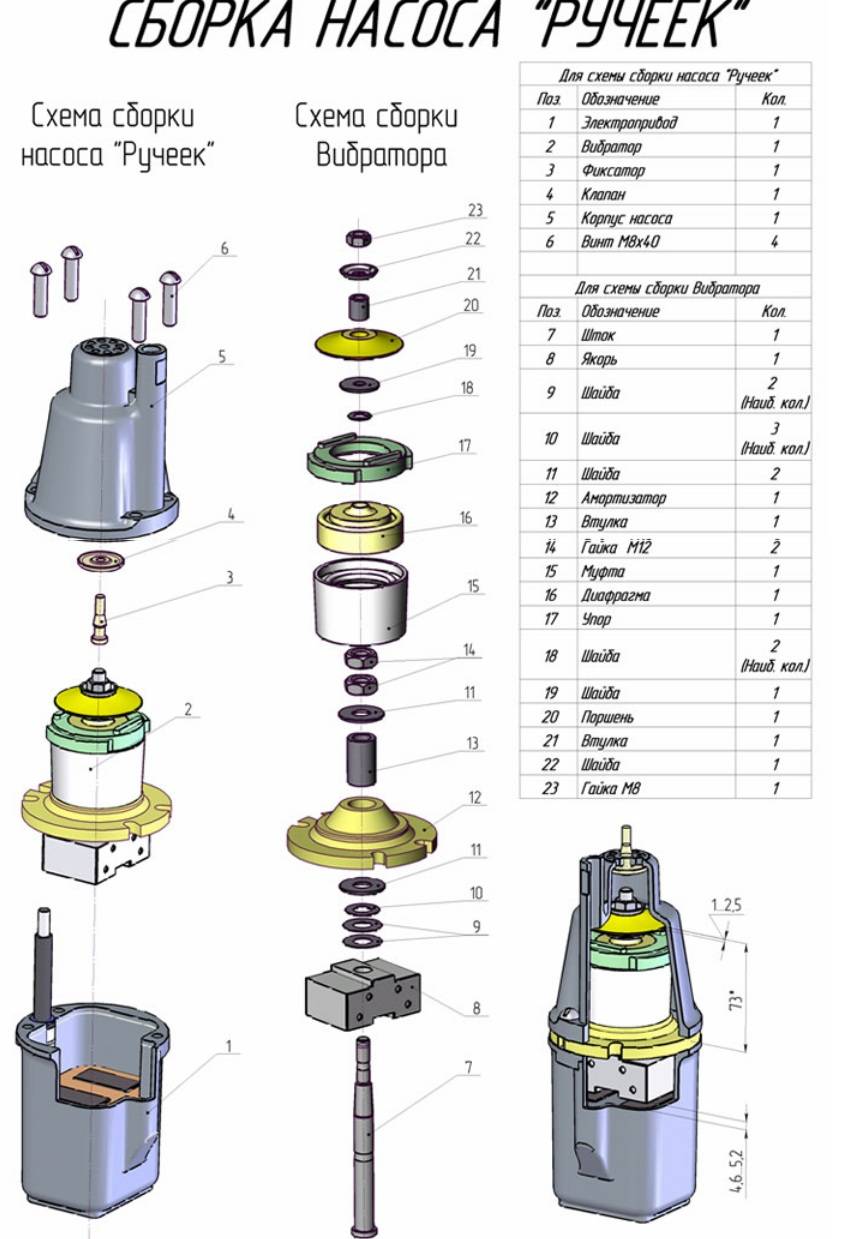

Assembly of the vibration pump Brook

Assembly of the vibration pump Brook

Advantages of the upper water intake of the pump:

- self-cooling of the system occurs during operation;

- there is no suction of sludge from the bottom by the working body.

Vibration pump for domestic water supply fontanel - Well

"Rodnichok" is a typical representative of domestic pumping equipment. Inexpensive, easy to use and fairly reliable unit. If you follow all the requirements of the technical operating instructions, the unit is able to serve the owners for many years.

Initially, the device was designed to work near the source of water intake. Modern models do not have this disadvantage. Pumps of the brand beloved by consumers are used without problems to supply water from wells and wells. They are also used to drain basements and water garden beds.

Autonomous water supply is not a luxury at all. Not a single country cottage or country house can do without it. Different devices can be selected for arranging the system.

It is necessary to take into account many factors: the depth of the well or well, the amount of water required by the consumer, the type of soil, and much more.

Many summer residents decide to buy a spring water pump, and are satisfied with their choice.

How does this pump work?

The design of Rodnichka is very simple. There are two main elements in the body that allow the mechanism to pump water.This is a vibrator and an electromagnet. The first is an anchor with a pressed rod with a rubber spring acting as a shock absorber.

It is rigidly fixed on the shaft. The movements of the shock absorber are limited by a special sleeve. A rubber diaphragm, fixed at a certain distance from the shock absorber, guides the rod and is an additional support for it. In addition, it closes the hydraulic chamber and separates it from the electric one.

Scheme of the device of the pump Rodnichok

In the electrical compartment there is an electromagnet consisting of a winding and a U-shaped core. Two coils connected in series form a winding.

Both elements are housed in a housing and encapsulated in a compound that performs several functions: it helps remove heat from the coils, holds the parts in place and provides the necessary insulation.

In addition, the fontanel pump device involves the installation of a special valve in the housing that closes the inlet holes. If there is no pressure, water flows freely through a special gap.

When the device is turned on, the core begins to vibrate at a speed of 100 times per second

After the device is turned on, the core begins to attract the anchor. The shock absorber drops the anchor once every half cycle.

A hydraulic chamber is formed, whose volume is limited by a valve on the body and a piston. The water pumped by the pump has a certain elasticity due to the dissolved and undissolved air present in it.

Thus, when the piston moves, it expands like a spring and pushes excess fluid through the pressure pipe.The valve on the body allows water to enter and prevents it from leaking through the inlets.

Why choose this particular device?

Initially, the vibration pump "Rodnichok" was designed to supply water from wells, wells, pump out liquid from basements, drain flooded areas and aerate. Due to their design features, the first models could only work close to the power source, the latter are free from this drawback. The installation has a number of undeniable advantages:

- The maximum pressure of the device is 60 m, which makes it possible to raise water from a well or well into a two-story building.

- Rated power - 225 W, so the pump can be used in tandem with low-power generators.

- The maximum particle size that can be passed by the mechanism is 2 mm.

- The outlet pipe has the most common and popular diameter ¾ inch.

- The installation is completely safe thanks to full waterproofing and double insulation of all electrical parts.

- The maximum pump capacity - 1500 l / h makes it possible to equip several points of water intake at once.

- A non-return valve built into the system prevents fluid from draining from the mechanism.

- The device does not require additional special maintenance during the entire period of operation.

- The inlet fitting is located at the top of the mechanism, which prevents the capture of dirt and sludge from the bottom of the tank or well.

Model range and manufacturers

Initially, "Rodnichok" was developed for industrial purposes.But given that powerful pumps of this type need a lot of electricity, the developers decided to focus on the private consumer.

As a result, a compact model of a vibrating submersible type was created, which is still successfully used in everyday life.

To date, the official manufacturer of the classic Rodnichok pump is UZBI - the Ural Plant of Household Products, which produces two pump modifications:

- "Rodnichok" BV-0.12-63-U - version with an upper water intake;

- "Rodnichok" BV-0.12-63-U - a variant with a lower water intake.

Both models can be equipped with a 10m, 16m, 20m or 25m power cord.

Also, the Moscow plant Zubr-OVK CJSC is engaged in the production of Rodnichok pumps, producing a model called Rodnichok ZNVP-300, which is not much different from the classic electric pumps produced by UZBI.

Vibratory submersible pumps for domestic use, manufactured under the brand name "Rodnichok" comply with GOST and are reliable, safe and durable equipment

Considering that the “Rodnichok” pump is not as well-known and popularly loved as the same “Baby”, it is extremely rare to find its fakes.

The affordable price of the electric pump is explained by the simplicity of its design and the use of only Russian parts for its production.

Image gallery

Photo from

Inexpensive, but extremely durable vibration pumps are ideal for drawing water from country wells. In the organization of permanent autonomous water supply systems, they are used much less frequently.

The installation of the Rodnichek pump unit is extremely simple: a pressure pipe is connected to the pump nozzle (1) through the check valve, a fixing nylon cord is threaded through the lugs (2)

In order to fix the position of the cable, it is attached to the pressure pipe with tape. The first hitch (3) is 20 -30 cm from the nozzle, following every 1.0 - 1.2 m

In order to leave the distance indicated by the manufacturer between the bottom of the well and the bottom of the pump, as well as the top of the unit and the water mirror, a bright mark must be made on the pressure pipe before immersion in water

In order for the vibration pump not to hit the walls of the well during pumping water, it is better to place it in the center of the working

For normal operation of the vibrator in the well, it is necessary that the inner diameter of its casing is 10 cm larger than the maximum diameter of the pump

So that the vibration unit does not hit the well casing during operation, it is equipped with protective rings from a hose or rubber rolled into a tube

The rubber rings working as shock absorbers must be changed periodically, because. they rub against the walls of the well

Vibration pumps in the dacha

Connecting the vibration pump

Power cable couplers with pressure pipe

Pump installation depth mark

Vibrator installation tool

Well for installation of a vibration pump

Pump and Well Protector

Replacing the protective rings on the vibrator

Types of pumping equipment "Caliber"

When it comes to pumping equipment of this brand, they first of all remember a small vibration pump suitable for use in shallow wells.It is often purchased because of the low price and in the event of a breakdown, they are in no hurry to repair it, because it is easy to buy a new one.

In fact, the name "Caliber" is used by units for various purposes (well, borehole, drainage) and even pumping stations.

Division into classes

Brand pumps are divided into classes, according to the depth of water rise, the type of working chamber and the position of the unit (in the well and well, or on the surface).

The depth of the equipment can be:

- deep;

- or ordinary.

According to the type of construction, all pumps are divided:

- for those working on the vibrational principle;

- and centrifugal.

According to the location relative to the source of water supply, the units are divided:

- on the surface;

- and submersible.

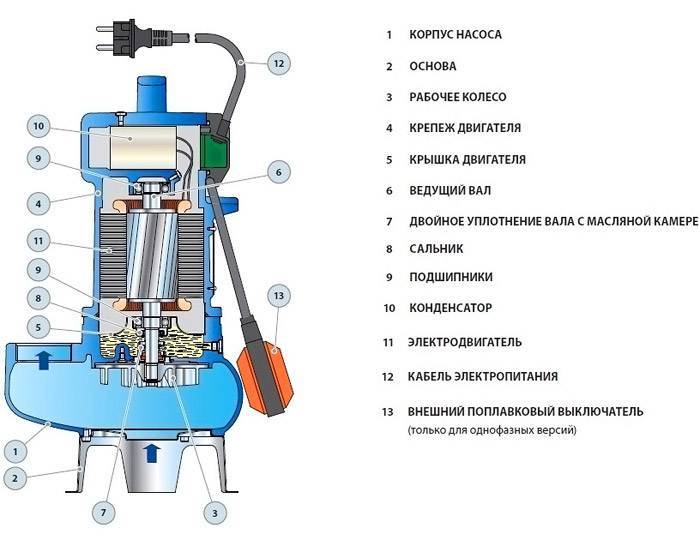

Repair of pump parts "Gnome"

Having considered the causes of malfunctions of pumps of the Gnom brand, you can see that almost all problems are solved by replacing the following parts: bearings, impeller, impeller shaft. Also, some malfunctions are eliminated after adjusting the gap between the impeller and the diaphragm.

Bearing replacement sequence

If the bearings are worn, the pump may pump water, but make unusual sounds due to friction and swaying of worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit.Do not use self-made similarity of bearings or from analogues from repair kits of other modifications, because. this can again disable the equipment in the very near future.

Impeller replacement

To replace the impeller, it is necessary to disassemble the Gnome electric pump and remove the impeller. Then install a new impeller and assemble the pump in reverse order. When installing a cover with a setting-moving disk, it is necessary to screw the fasteners onto the studs and tighten them simultaneously until the minimum clearance between the impeller blades and the cover with the disk is reached.

After assembly, it is required to check for tightness and, if it is broken, then refuse to use a permanently damaged electric pump.

In some cases, if you have experience and appropriate equipment, you can not replace the impeller with a new one, but try to fix the existing annular workings with the help of surfacing, followed by its processing on a lathe.

Repair of impeller shaft and casing

If the working shaft is damaged (bent, cracked), it is best to replace it completely. The Gnome hull is theoretically repairable, but in practice it is almost impossible to carry it out correctly. In nine out of ten cases, the tightness of the case will be broken, and this defect can only be corrected at the factory or at a service center.

Given that such breakdowns are found in pumps that have worked for a long time, and therefore not subject to warranty service, it is necessary to think about the feasibility of repair. In most cases, it is faster, cheaper and easier to purchase a new submersible pump.

Adjustment of the gap between the impeller and the diaphragm

The main reason for the decrease in pressure and performance of the Gnome electric pump is the increase in the gap between the impeller and the diaphragm during operation. To reduce the gap, you need to adjust it. To do this, remove the bottom of the filter and unscrew the top nut. Then tighten the parts of the diaphragm with nuts located on different sides until it comes into contact with the impeller.

Then loosen the lower nuts half a turn. With this adjustment, the gap will be 0.3-0.5 mm. Adjusted layout diaphragm relative to the impeller secured with top nuts. After completing the adjustment, it is necessary to check the ease of rotation of the impeller, it should rotate without any effort.

Repair of the electric motor of the pump "Gnome"

Gnome brand pumps are equipped with a reliable asynchronous electric motor. It is very difficult to repair an electric motor on your own. The maximum that can be done without special stands is to determine the resistance of the motor windings using a household multimeter. If the resistance indicator tends to infinity, then this indicates that the winding is damaged and needs to be replaced. To replace the winding, a complex disassembly of the electric motor and the presence of a rewinding machine will be required.

But the main difficulty lies in the assembly process - the unit must be assembled in such a way as to provide an impeccable barrier against water penetration into the electric motor. That is why it is better to entrust the repair of the Gnome pump engine to professionals.

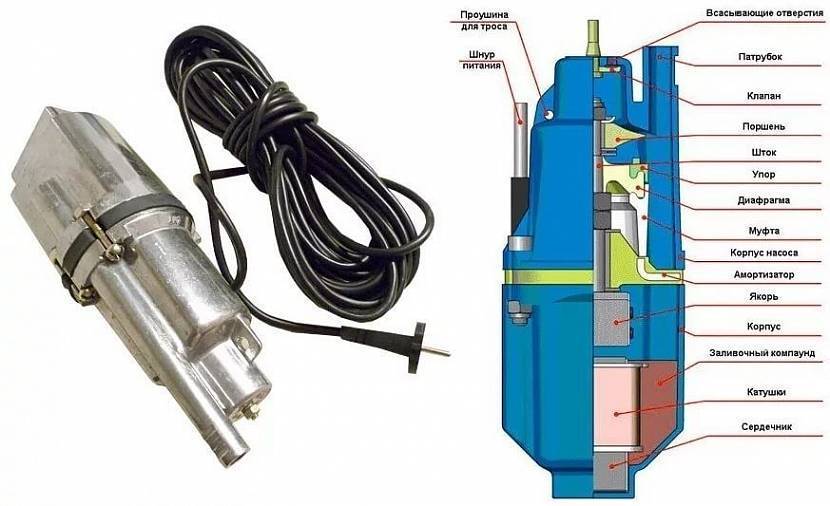

Repair of pumping units of the Rucheek type

Pump repair

Despite the fact that the unit of this brand is highly reliable, there is no one hundred percent guarantee against possible damage. During long-term operation, various breakdowns are quite possible and repair of the Brook pump becomes a necessity. Although in most cases a faulty pump is simply sent to a landfill and a new one is purchased, which is facilitated by the low price of products in this class.

The main problem, due to which the repair stops at the initial stage, is the inability to unscrew the fixing bolts. As a result of long-term operation without periodic lifting from the well, these bolts are covered with a layer of rust. In this case, it is impossible not only to unscrew the bolt, but even to determine the type of screwdriver required. According to statistics, at best, only 1-2 bolts can be unscrewed, dismantling the rest becomes a significant problem. In some cases, the use of a rust remover helps, but most often you have to cut off the heads of these bolts with a grinder. Therefore, experts recommend not to suffer in search of a solution, but to immediately pick up a cutting tool.

If the pump does not turn on when voltage is applied, then the reason most often lies in the failure of the electromagnet winding. It is quite possible to rewind and reanimate the unit. Such a repair of a submersible pump Brook should be trusted to an electrical specialist who can select the right wire and restore the winding with all the recommended parameters.

Quite often, another type of breakdown occurs, in which the pump buzzes, but does not pump water. In this case, the reason lies in the wear of the valves or the membrane.In case of failure of rubber parts, the pump is easily repaired, for which it is necessary to purchase a repair kit, which includes all the main elements of the pump. We recommend changing all parts at once, even if only one valve fails, this will eliminate the need to disassemble the pump in just a week, when another worn part fails.

Restore the exfoliated fill of the electromagnet using auto-sealant, which is used when installing the windshield on the car. Before applying it to the surface of the magnet, it is necessary to apply a number of chaotic grooves (no more than 2 mm deep) using a grinder. Such strips provide a more reliable connection between the sealant and the product.

The probability of breakdowns in the first 2-3 years of operation is negligible (subject to the rules of operation). Therefore, you can safely purchase a pump of this type, you can be sure that it will not let you down.

Published: 23.09.2014

Analysis of technical characteristics

Vibratory pumping devices "Rodnichok" are designed for pumping clean and slightly polluted water. The allowable size of solids in the pumped liquid must not exceed 2 mm.

Unit performance

The pump is great for water supply of 2-storey houses, because. the maximum pressure given out by the equipment is 55 - 60 m.

Before starting the pump, carefully inspect the casing in order to detect mechanical damage. Particularly meticulously should examine the condition of the power cable and network connector

It is allowed to use a pump for pumping soapy water, it is also in a chlorinated state from artificial reservoirs.

The unit can pump water from flooded private river boats and basements. Approved for draining containers.

The productivity of the “Rodnichok” pump is approximately 432 l / h, which allows uninterrupted supply of water to several water-consuming points at once.

The performance of the electric pump directly depends on the height of the water supply. The maximum immersion depth specified by the manufacturer is 5 m, however, thanks to the robust housing, the pump can be successfully used at a depth of 10 m and even more.

The spring is intended for the intake and transportation of water with a slight degree of pollution. The pump can supply water to a height of 55 - 60 m

“Rodnichok” is designed for use at ambient temperatures from +3 °C to + 40 °C. The weight of the unit is only 4 kg, making it mobile and easy to install.

The overall dimensions of the pump do not exceed 250 x 110 x 300 mm, which makes it possible to operate it in narrow wells and wells with a diameter of more than 12 cm.

If such a cable is not included in the kit, then it must be purchased separately. Lowering the electric pump using the power cord is strictly prohibited!

The dependence of performance on the height of the water supply: the greater the delivery height, the lower the performance of the electric pump when using standard pipes

Water intake options

Pumps "Rodnichok" are produced in two variations: with upper and lower water intake. In the first case, the suction pipe is located at the top of the housing, in the second - from the bottom. Each model has its own advantages and disadvantages.

Advantages of a pumping device with an upper intake:

- continuous provision of cooling of the pump casing, which means a longer period of operation;

- there is no suction of bottom sediments, which means that the optimal quality of the supplied water is ensured;

- the pump does not suck in sludge, therefore, it needs less frequent cleaning.

The disadvantages of modifications with an upper intake include the inability to pump out water to the end, but only to the point where the inlet pipe is located. This is inconvenient if the unit is used to pump water from flooded visits, pools, boats.

The “Rodnichok” electric pump with a lower water intake, on the contrary, is capable of pumping liquid to a minimum level.

The negative side of a pump with a lower intake can be considered the possibility of capturing bottom sediments, which means that such a pump will quickly become clogged, which will lead to its failure.

When choosing the “Rodnichok” electric pump, it is necessary to decide in advance in what conditions it will have to work. If the pump is purchased to supply water from water intakes, a well or a well, then preference should be given to equipment with an upper intake.

If an electric pump is needed for pumping flood water from flooded premises, draining tanks, eliminating the consequences of utility accidents, then a model with a lower intake is the best choice.

If you find it difficult to make a choice, we recommend that you read our article with tips on choosing pumps for wells.

A pump with a lower intake can be operated in a well and a well, but it must be suspended so that the suction hole is located at some distance from the bottom