- Peculiarities

- Kinds

- Troubleshooting and Troubleshooting

- Electric pump does not start

- The engine is running but the pump is not pumping water

- The pump starts and immediately stops

- The pump works, but the pressure is low

- Scope of use

- Specifications and markings

- 2 Overview of common models

- 2.1 Drilling unit NB 50

- 2.2 Drilling unit F 1300

- 2.3 Drilling rig UNBT-950

- 2.4 What are the features of the selection and calculation of the mud pump?

- Repair of pump parts "Gnome"

- Bearing replacement sequence

- Impeller replacement

- Repair of impeller shaft and casing

- Adjustment of the gap between the impeller and the diaphragm

- Repair of the electric motor of the pump "Gnome"

Peculiarities

The production of sediments "Gnome" is carried out in Russia. This equipment is characterized by wide functionality, wear resistance and ease of operation. Each such unit is designed to pump out both clean and contaminated liquids. As for pumping out fecal effluents, special models with individual technical characteristics are provided for this purpose.

The main advantages of pumps "Gnome" include:

- a large assortment;

- excellent quality;

- wear resistance;

- ease of repair and maintenance;

- durability;

- affordable cost.

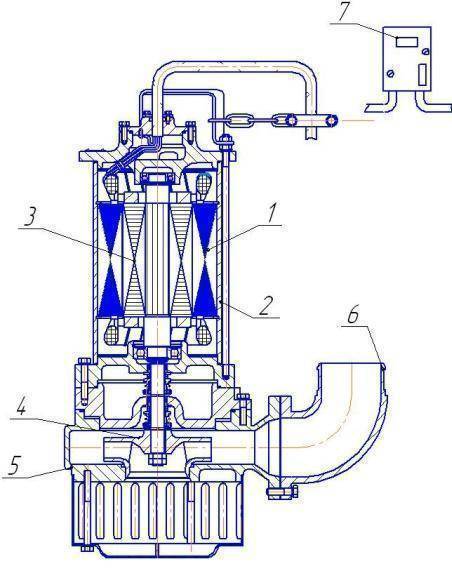

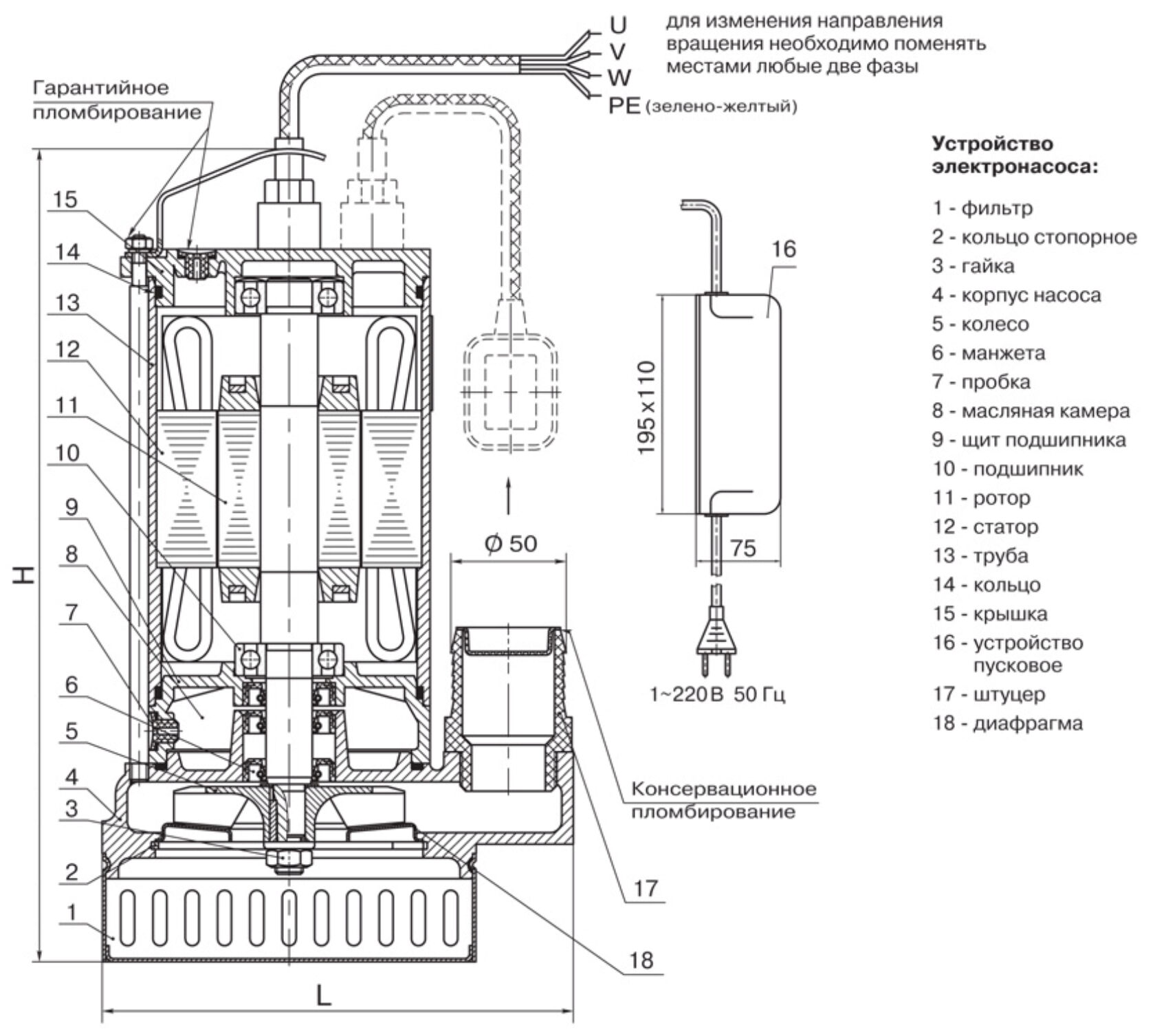

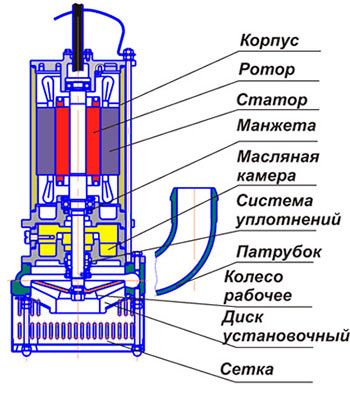

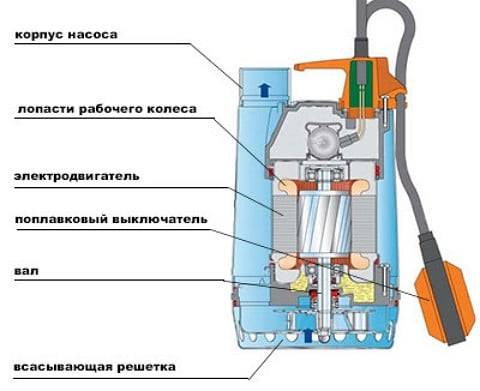

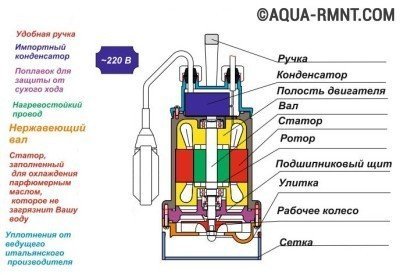

Each pump "Gnome" is designed for full or partial immersion in liquid. These devices operate according to the centrifugal principle, are made in an elongated form with a vertically mounted type of nodes in the inner part of the body. The process of pumping liquids is carried out under the influence of centrifugal forces that occur during engine operation.

Gnome pumps have the following technical features:

- the level of productivity, depending on the type of unit, can be in the range of 7-600 m3 / h;

- the permissible temperature of the liquid during pumping can reach +60 degrees;

- the concentration of impurities can be up to 10%;

- the pressure of the pumped liquid is at the level of 7-25 m;

- the power of the mechanism for each instance is individual, its maximum indicator is 11 kW;

- the mass of devices is within 112 kg;

- the shaft and the impeller of the device are made of durable steel, and the outlet is made of high-quality plastic.

The manufacturer claims that all these features make it possible to use Gnome pumps to solve a variety of tasks both in domestic conditions and in large enterprises.

Basically, they are used for such purposes as:

- drainage of basements flooded during the flood;

- drainage of pits;

- pumping liquid in factories and enterprises;

- irrigation in the rural sector;

- pumping out wastewater from various systems and electrical engineering;

- neutralization of the consequences of accidents.

The design of the pumps "Gnome" is made of two parts - the pumping and motor sections, which are harmoniously combined into one block. The engine is cooled directly when pumping liquid, and its tightness on the shaft is ensured by an end seal.Oil is poured inside, which cools and lubricates the bearings of the device, ensuring their full working condition.

It must be remembered that immediately before turning on the unit must be in the liquid at a level of at least 50 cm. After starting the device, the pumped liquid is sucked through an additional mesh into the housing, from where it is pushed out of the pump room under pressure.

Kinds

All pumps "Gnome" are available in four varieties:

- Household. A submersible device that is characterized by an average level of power and performance. They are mainly used at home for pumping out dirty water. Their productivity does not exceed 10-25 m3/hour.

- High pressure. They belong to the category of industrial mechanisms, as they are characterized by impressive productivity, which can reach 50 m3 / h. The power of such models is up to 45 kW.

- Explosion-proof. Professional devices that are marked with the EX marking. They are actively used in industrial production and at large facilities. Compared to a mud specimen, it is characterized by a higher cost and power.

- Self-cooled. They are used not only for full, but also for partial immersion. Such a drainage unit is equipped with a special cooling jacket, which is responsible for the level of cooling in the process of pumping dirt or other aqueous liquid. The technical characteristics of this device allow it to be used in places where it is not possible to immerse the product in water.

It is worth noting that all types of Gnome pumps are distinguished by extremely simple and quick disassembly of the main components. This feature makes the cleaning and repair process as easy and affordable as possible.A special plug is located in the bearing shield, into which oil is poured. The manufacturer recommends carefully monitoring the quality and level of the oil used, since the full functionality of these mechanisms largely depends on this. Its timely topping up and replacement will allow the device to maintain its excellent working condition during the entire period of operation.

Devices that can be operated not only separately, but also in conjunction with other units, are pumps "Gnome" 25/20. They are a portable submersible type system with an electric motor. The tightness of the internal part of the electric motor is ensured by the assembly on which the mechanical seal is located. Such models are used for pumping groundwater, draining ditches, swamps, basements, and are also an integral technique at construction sites and hazardous production.

The vibration type of pumps "Gnome" remains quite relevant. In relation to other options, such devices are considered much more economical in terms of energy consumption and are distinguished by an affordable pricing policy. Their range allows you to choose the best option that will best meet your requirements.

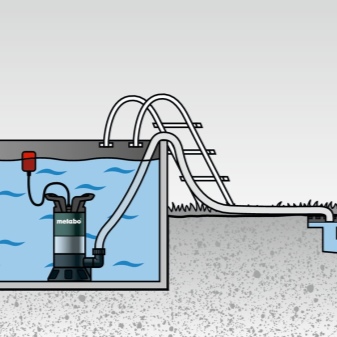

The fecal type of pumps "Gnome" is in great demand, which is used not only for pumping fecal effluents, but also for irrigation in agriculture or for pumping water from pools. These units are characterized by increased resistance to negative impact factors and perfectly retain their original qualities throughout the entire period of operation.

Pumping of water mixtures with a high density of solid particles, the level of which is about 2500 kg / m3, is able to provide the Gnome slurry pump. The technical characteristics of these models fully contribute to this.

Troubleshooting and Troubleshooting

Before proceeding with the disassembly of the pump and its repair, it is necessary to correctly determine what exactly caused the breakdown. Consider the most common symptoms that occur when the Gnome pumps malfunction:

Electric pump does not start

Possible causes and methods for their elimination:

- Stuck impeller.

- Faulty capacitor in the power supply circuit.

- Breakage of the electrical circuit, burning of contacts.

- Stator winding burnt out.

- Failure of the electric motor.

- Seized motor bearing.

- Lack of voltage in the network or interruption in the supply of electricity.

After making sure that there are no problems with the power supply, it is necessary to disconnect the Gnome pump from the mains and disassemble it to identify the reason why it does not start. Inspect bearings, impeller, assess the condition of the motor windings.

If the pump worked for a long time, and then turned off and does not start, then before removing the unit from the water and starting repair work, it is necessary to wait for it to cool completely

The engine is running but the pump is not pumping water

The engine of the pump "Gnome" works, but at the same time it does not pump water. The sound of a running engine may be weaker, uneven. Possible reasons:

- Clogged filter screen or outlet pipe.

- The engine is running with insufficient power.

- Bearing wear and reduced motor speed.

- The pumped liquid is missing or has become too viscous and dense.

- Damage to the water supply line (pipes, hoses).

In this case, you need to make sure that there is no damage to pipes and hoses, there is water in the water source. If everything is in order, then it is necessary to disconnect the equipment from the mains and inspect the inlet filter and outlet pipe. If necessary, clean them and try to start the pump. When the bearings are worn they will need to be replaced (see below).

The pump starts and immediately stops

When starting, the Gnome pump runs for several seconds, and then turns off spontaneously. This may be a symptom of the following problems:

- Float switch failure.

- Short circuit in the electric motor circuit.

- The pump has overheated and the thermal fuse has tripped.

- Extremely low mains voltage.

- Impeller lock.

- The liquid in which the pump is immersed does not correspond to its operating ranges (too hot, viscous, with a high density, etc.)

In this case, it is necessary to disconnect the Gnome electric pump from the network and try to turn it on again after 30-90 minutes, after making sure that the necessary voltage is present in the mains. This is enough time for the overheated pump to cool down. If the pump stop is repeated, then it must be removed and disassembled to identify and eliminate the malfunction.

The use of an automatic motor protection machine is recommended by the manufacturer and allows you to protect the Gnome pump from short circuits and voltage surges

The pump works, but the pressure is low

The Gnome pump pumps water, but the water pressure is much lower than it was before. Possible reasons:

- Leak on the water supply line (hoses, pipes).

- Low voltage in the mains.

- Contamination of the impeller and insufficient speed of its rotation.

- Wrong direction of impeller rotation.

- Large clearance between the wheel and the movable disk.

- Impeller wear.

If the low head is not due to a low voltage in the network or a leak in the line, then the pump should be disconnected from the power supply, removed from the pumped liquid and disassembled for inspection and repair work.

When the impeller is worn, it is replaced. In case of clogging or improper installation after self-assembly, the unit should be disassembled, cleaned and the wheel installed in the correct position.

Scope of use

Despite the release of a large number of modifications of this series from different manufacturers, as well as the fact that the Gnome submersible units may have different technical parameters, the scope of use for all models is quite extensive. Such pumping devices are used for pumping drainage and groundwater, non-fecal sewage.

Besides drainage pumps Gnome suitable for the following tasks:

- They are successfully used to drain inspection pits and basements that were flooded during the flood.

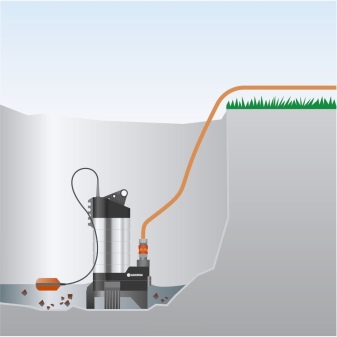

- Sometimes during construction it becomes necessary to drain the pit to continue installation work. The submersible pump of the Gnome series perfectly copes with this task.

- To pump liquids in industrial enterprises, such drainage pumping equipment is used.

- For irrigation and drainage in the agricultural industry.

- The pump allows you to drain waste from car washes, washing machines, as well as large volumes of condensate from ventilation and central heating systems.

- Gnome units are used as the main and auxiliary equipment in sewage treatment plants and septic tanks.

- Due to the sealed housing, some pumps of the Gnome series are intrinsically safe. That is why these units are very often used to eliminate the consequences of accidents resulting in a leak of oil products.

Specifications and markings

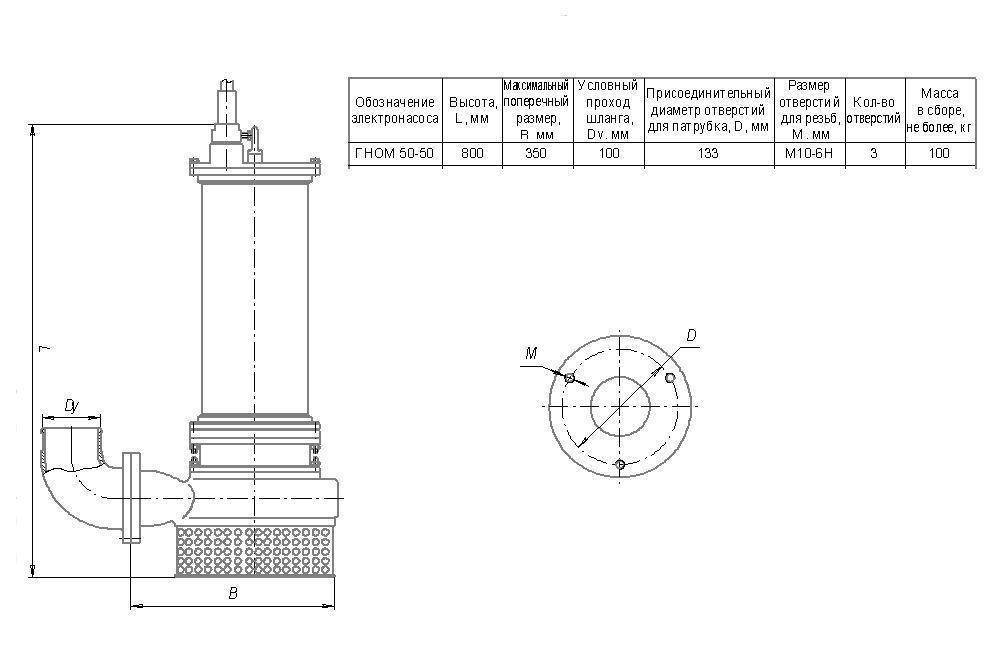

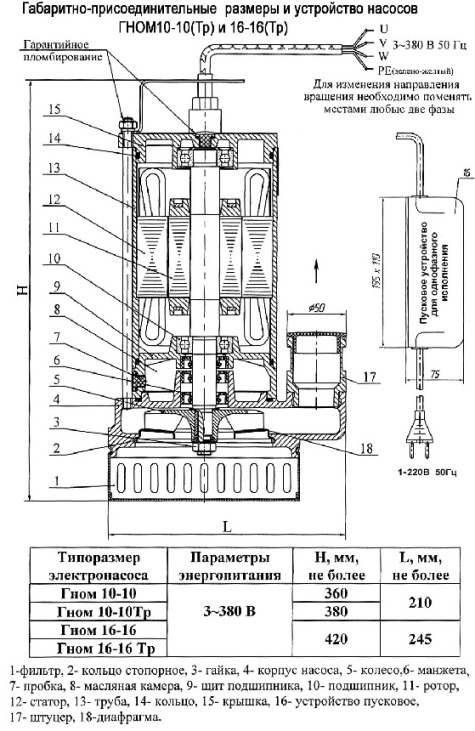

Pumps of the "Gnome" line belong to the class of single-stage vertical submersible pumps of a monoblock design. They are designed for pumping out drainage and ground water containing no more than 10% of solid mechanical particles by weight, the density of which does not exceed 2.5 thousand kg/m3. It is allowed to pump fractions no more than 5 mm. The temperature of the pumped liquid is up to +35ºС, and for models marked "Tr" - up to +60ºС.

The housing of the submersible electric pump is made of plastic, cast iron or steel. Impellers and motor casing are made of cast iron. The equipment is produced with different types of motor, depending on which it is determined whether it can be powered from a household power supply with a voltage of 220 V or from a three-phase industrial one with a voltage of 380 V and a frequency of 50 Hz.

Manufacturers of Gnome centrifugal pumps offer a wide range of products with different technical characteristics, so you can choose a model with the necessary parameters

The electric pump package includes: a 10 m power cord for a three-phase power supply or a power cord and a starting device for a single-phase power supply.Most manufacturers, for a fee and at the request of the buyer, include in the kit an automatic machine for protecting a motor operating from a 380 V network.

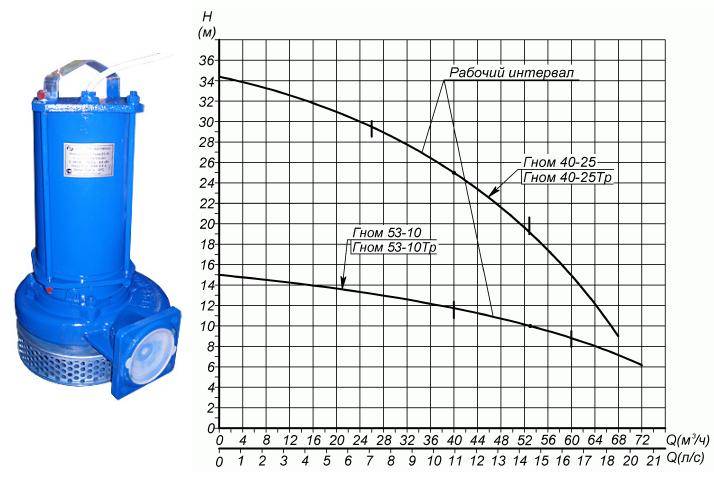

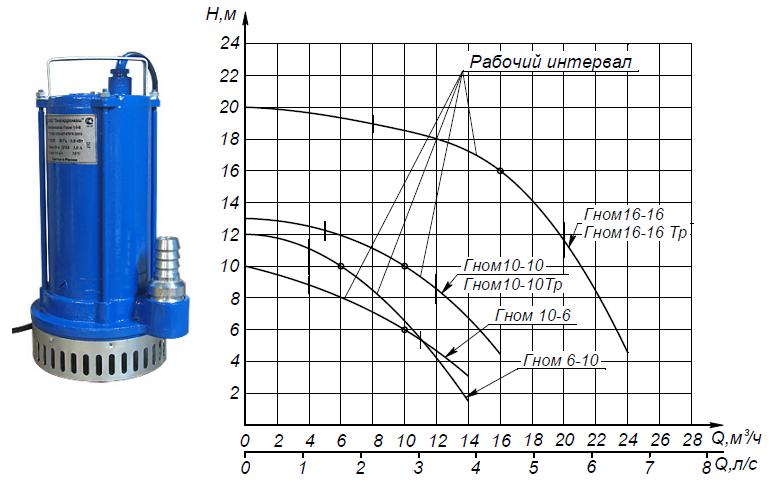

Specifications such as power, power supply parameters, performance (pumping speed), maximum head, as well as the dimensions and weight of the equipment depend on the specific model. You can compare the technical characteristics of the Gnome pump models using the table:

The technical characteristics of the pumps are indicated in the nominal mode and may differ by no more than ten percent for pressure indicators and no more than three percent for efficiency

All pumps produced under the Gnome brand are marked. Knowing what is hidden behind the numbers and designations, you can easily understand what characteristics and features the pump has. The word "Gnome" itself is an abbreviation and stands for: G - dirty water, H-pump, O - single-stage, M - monoblock.

The main advantage of the Gnome series of pumps is the simplicity of design. You can disassemble for cleaning and assemble the unit without problems with your own hands

The first digit in the marking indicates the capacity in m3 / h, the second - the head in meters. For example, "Gnome 10-10 Tr" is a pump with a capacity of 10 m3 / h and a head of 10 m. The designation "Tr" indicates that this equipment can pump water with a temperature of up to +60 C. The letter "D" means, that the equipment is equipped with a float switch (level sensor).

Pumps marked with the abbreviation "Ex" belong to the explosion-proof group. Such units are capable of pumping water with impurities of oil products, which contain no more than 3% sulfur.In emergency cases, the pump can be used to work in an environment containing up to 100% crude oil products.

Image gallery

Photo from

Gnome submersible pumps are designed for pumping liquid media containing mineral inclusions up to 1250 kg/m3

Modifications of this brand are used both for pumping water from open reservoirs, and for draining basements and pits

Water is sucked in by a centrifugal device located in the lower part of the body, then the liquid is pushed out to the branch pipe with a pipe connected to it

Gnome models can pump liquids with mineral particles ranging in size from 5 to 25 mm. In order to prevent larger particles from entering the system, the suction part is protected by a filter

Models Gnome brand pumps

Scope of pumps Gnome

The principle of operation of centrifugal units

Submersible pump filter Gnome

2 Overview of common models

The main manufacturers of equipment of this class in Russia are the companies "UralMash" and "NefTechMash". Among the common models of pumping units, we highlight:

- NB 50;

- UNBT-950;

- F-1300.

Let's consider each of the presented units in more detail.

2.1 Drilling unit NB 50

NB-50 is a two-cylinder horizontal type equipment. The unit is focused on operation in exploratory and structural exploration drilling of oil and gas wells. Also, this model is widely used to work with non-aggressive liquids in the food and chemical industries.

NB-50

A characteristic feature of the NB-50 is the presence of a built-in pressure compensator, which ensures that there are no problems with pressure drops.This is a reliable, durable and easy-to-maintain equipment with good technical characteristics:

- power - 50 kW;

- piston stroke - 160 mm;

- the number of strokes per minute - 105 pcs;

- suction height - 3 m;

- nozzle diameters: supply - 50 mm, suction - 113 mm.

The cost of this model in the secondary market starts from 250 thousand rubles.

2.2 Drilling unit F 1300

The F1300 is a large, three-cylinder, extended-stroke unit with increased suction and delivery power. The pump was developed by the American company LTV more than 20 years ago, under the patents of which it is being manufactured in Russia.

Among the design features of this model, we highlight the use of a chevron gear, equipment with a cast crankshaft made of alloy steel, as well as the presence of a built-in lifting device for convenient replacement of frame liners. Thanks to an efficient lubrication system, the F1300 can be operated in continuous operation, while the design of the unit involves the combination of two lubrication systems - forced and splash lubrication.

F-1300

Consider the technical characteristics of this model:

- power - 970 kW;

- piston stroke - 304.5 mm;

- the number of strokes per minute - 120 pcs;

- suction height - 9 m;

- nozzle diameters: supply - 102 mm, suction - 203 mm.

Also noteworthy is the F1600 mud pump, an upgraded version of the F1300 model. In it, the drive power is increased to 1194 kW, the suction pipe is expanded to 304.8 m, the supply pipe is up to 127 mm, which generally provides a 20-30% higher plant productivity.

2.3 Drilling rig UNBT-950

Like the F series units, the UNBT-950 pump is designed for operation in deep oil and gas wells. This is a three-piston, single-acting device with a forced lubrication system - oil is supplied directly to the crankcase, an auxiliary gear pump is responsible for pumping it.

UNBT-950

UNBT-950 was developed by Soviet engineers in 1981, on its basis, over 30 years of operation, many modifications have been made - NBT-1000, NBT-750, NBT 600 and NBT 475. This model has good characteristics by the standards of modern analogues:

- power - 1000 kW;

- piston stroke - 290 mm;

- the number of strokes per minute - 120 pcs;

- suction height - 7 m;

- nozzle diameters: supply - 95 mm, suction - 200 mm.

In the secondary market, UNBT-950 in good condition can be bought for 3-3.4 million rubles.

2.4 What are the features of the selection and calculation of the mud pump?

There are three main groups of criteria that must be considered when choosing pumping equipment for drilling:

- Structural and technological requirements for the unit;

- Characteristics of the pumped solution (viscosity, density, solids content);

- Required design parameters.

The list of design parameters includes such characteristics as unit performance (feed rate - Q), pressure (H) and power consumption of the drive.

The flow rate for any piston type pumps can be calculated using the formula Q = S*D*k*kv, where:

- S is the cross-sectional area of the piston;

- D - stroke length of the piston;

- k is the speed of rotation of the shaft (rpm);

- kv - coefficient. useful action.

The head of the unit is determined by the formula: H \u003d (d1-d2) / (f * g) + V + p, in which:

- d1 - liquid pressure in the intake tank, d2 - in the receiving tank;

- f is the density of the liquid;

- g is the gravitational acceleration at a given density;

- V is the suction height of the solution;

- p is the head loss.

Repair of pump parts "Gnome"

Having considered the causes of malfunctions of pumps of the Gnom brand, you can see that almost all problems are solved by replacing the following parts: bearings, impeller, impeller shaft. Also, some malfunctions are eliminated after adjusting the gap between the impeller and the diaphragm.

Bearing replacement sequence

If the bearings are worn, the pump may pump water, but make unusual sounds due to friction and swaying of worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit. Do not use self-made similarity of bearings or from analogues from repair kits of other modifications, because. this can again disable the equipment in the very near future.

Impeller replacement

To replace the impeller, it is necessary to disassemble the Gnome electric pump and remove the impeller. Then install a new impeller and assemble the pump in reverse order. When installing a cover with a setting-moving disk, it is necessary to screw the fasteners onto the studs and tighten them simultaneously until the minimum clearance between the impeller blades and the cover with the disk is reached.

After assembly, it is required to check for tightness and, if it is broken, then refuse to use a permanently damaged electric pump.

In some cases, if you have experience and appropriate equipment, you can not replace the impeller with a new one, but try to fix the existing annular workings with the help of surfacing, followed by its processing on a lathe.

Repair of impeller shaft and casing

If the working shaft is damaged (bent, cracked), it is best to replace it completely. The Gnome hull is theoretically repairable, but in practice it is almost impossible to carry it out correctly. In nine out of ten cases, the tightness of the case will be broken, and this defect can only be corrected at the factory or at a service center.

Given that such breakdowns are found in pumps that have worked for a long time, and therefore not subject to warranty service, it is necessary to think about the feasibility of repair. In most cases, it is faster, cheaper and easier to purchase a new submersible pump.

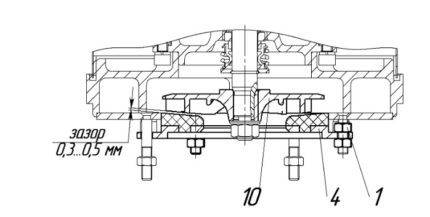

Adjustment of the gap between the impeller and the diaphragm

The main reason for the decrease in pressure and performance of the Gnome electric pump is the increase in the gap between the impeller and the diaphragm during operation. To reduce the gap, you need to adjust it. To do this, remove the bottom of the filter and unscrew the top nut. Then tighten the parts of the diaphragm with nuts located on different sides until it comes into contact with the impeller.

Then loosen the lower nuts half a turn. With this adjustment, the gap will be 0.3-0.5 mm.The adjusted location of the diaphragm relative to the impeller is fixed with the upper nuts. After completing the adjustment, it is necessary to check the ease of rotation of the impeller, it should rotate without any effort.

Repair of the electric motor of the pump "Gnome"

Gnome brand pumps are equipped with a reliable asynchronous electric motor. It is very difficult to repair an electric motor on your own. The maximum that can be done without special stands is to determine the resistance of the motor windings using a household multimeter. If the resistance indicator tends to infinity, then this indicates that the winding is damaged and needs to be replaced. To replace the winding, a complex disassembly of the electric motor and the presence of a rewinding machine will be required.

But the main difficulty lies in the assembly process - the unit must be assembled in such a way as to provide an impeccable barrier against water penetration into the electric motor. That is why it is better to entrust the repair of the Gnome pump engine to professionals.