- Technical characteristics of Agidel pumps

- Series #1 - model Agidel-M

- Series #2 - modification Agidel-10

- Agidel-M pump device

- Construction device

- Fundamentals of pump operation

- Rules for the use of pumps

- Pros and cons of Agidel models

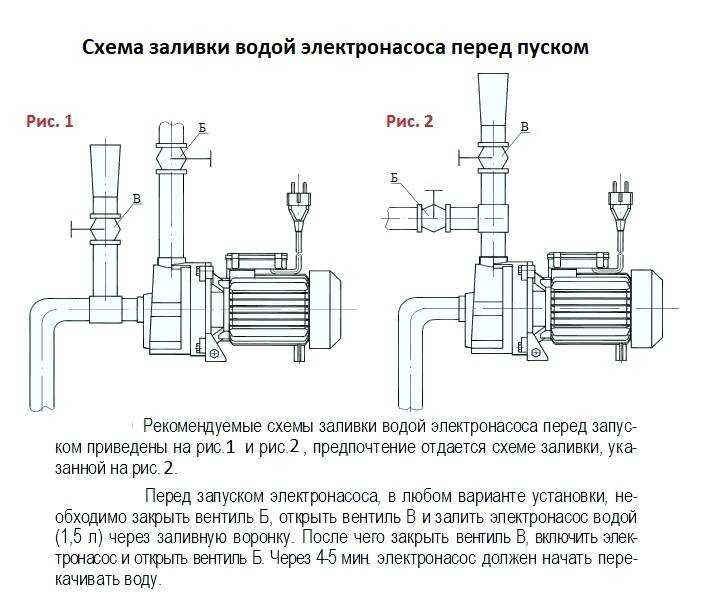

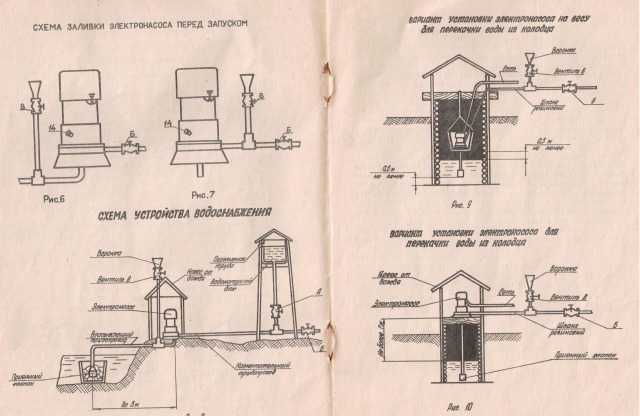

- Preliminary work before launch

- Minor do-it-yourself repairs

- The main malfunctions of submersible pumps

- The pump is not working

- The pump works but does not pump

- Low machine performance

- Frequent switching on and off of the device

- The buzz of the machine is heard, but the water does not pump

- Water is supplied with pulsation

- The unit does not turn off

- Main characteristics

- Technical characteristics of pumps "Agidel"

- "Agidel-M"

- "Agidel-10"

- Operation features

- Faults and causes for their elimination

Technical characteristics of Agidel pumps

Electric pumps "Agidel" can be used for pumping water from open reservoirs, shallow water wells, wells. Pumps are able to work for a long time, thanks to the presence of special protection against overheating.

Series #1 - model Agidel-M

The Agidel-M electric pump belongs to the class of small-sized pumps, its weight is 6 kg, and its dimensions are 24x25 cm. The unit is used for pumping water with a temperature of no more than 35º C.

The suction height, typical for most modifications of M, does not exceed 8 m.However, if you equip the unit with an ejector, then this figure will increase to 15 m.

There must be more than 0.3 m between the bottom of the suction valve and the bottom of the water intake source. Before starting, the pump requires filling with water.

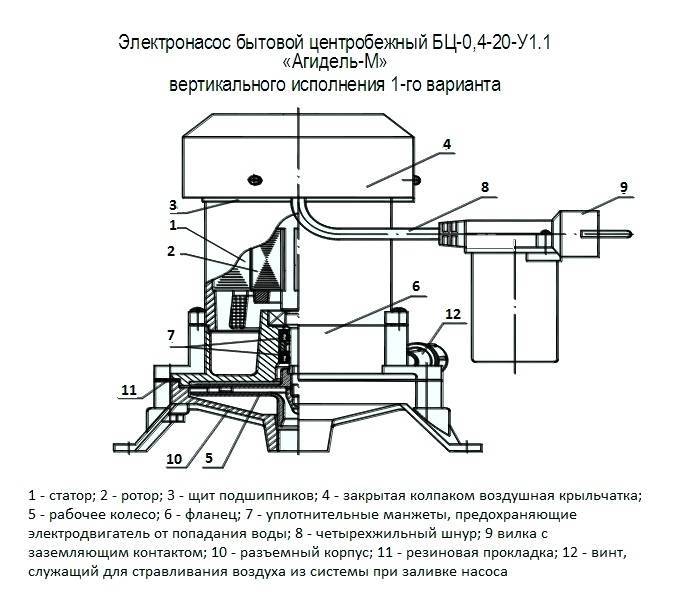

The monoblock design of the Agidel M pump includes two main components: a centrifugal pump and an electric motor designed for continuous operation (click to enlarge)

The maximum water pressure created by the pump of this brand is 20 m, productivity - 2.9 m3 / h. Model "M" belongs to the class of economical equipment for pumping water, its power consumption is 370 W. Mains voltage - 220 V.

Electric pumps of the Agidel brand are not designed to operate at sub-zero temperatures, therefore, insulation is required for operation in winter.

For example, when using a pump for a well, an insulated caisson is arranged, buried below the freezing level of the soil.

The pump body is made of high-strength aluminum, so the unit is lightweight, allowing it to be installed on almost any flat surface

Series #2 - modification Agidel-10

Unlike the M model, the Agidel-10 electric pump is a more powerful and large-sized device. Its weight is 9 kg, and the dimensions are 33x19x17 cm. The operation of the unit without filling with water is prohibited, otherwise the mechanical lip seal fails.

The suction height of this modification is 7m. The pump provides a maximum design head of 20 m, which is the sum of the suction, discharge and pipeline losses.

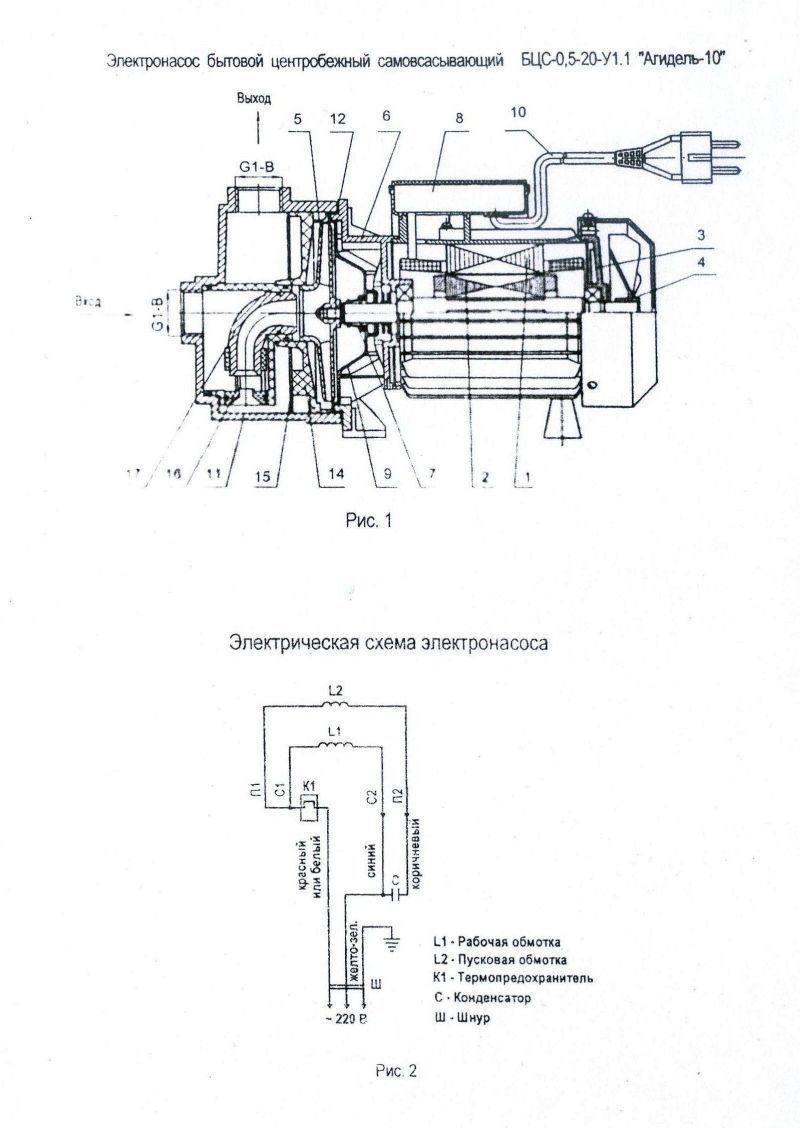

Productivity is 3.6 m3/hour. Installation method - horizontal. "Ten" consumes exactly twice as much electricity - about 700 watts.Operates from a single-phase electrical network with a voltage of 220V.

Unlike the previous model, Agidel-10 cannot be equipped with an ejector. The body of the electric pump is made of aluminum alloy.

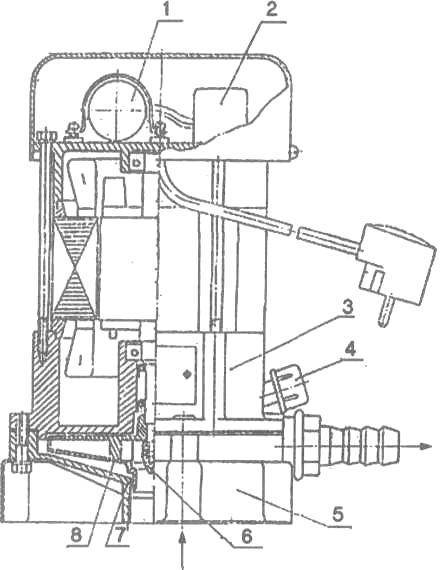

The structural parts of the Agidel 10 pump are an electric motor, a centrifugal and a jet pump

Agidel-M pump device

The device is mounted on a rigid base vertically. Water supply from a well and pumping over a distance of up to 35 meters is possible with a small motor with a power of 0.37 kW. If the well is up to 20 meters deep, an ejector is used, a remote working element. The pump motor remains on the surface.

Agidel pump specifications:

- lifting height - 7 m;

- performance - 2, 9 cubic meters. m / hour;

- diameter - 23.8 cm;

- length - 25.4 cm;

- weight - 6 kg;

- price - 4600 rubles.

A feature of the pump is the preliminary filling of the suction, including the working chamber. The device works only at a positive temperature or in a warm room. A light Agidel water pump is used to lift water, placing it in a deep pit or equipping a raft that holds the pump on the surface of the well surface from which water is drawn. Only the Agidel-10 pump can be sent to the voyage, which does not require refilling with water at start-up.

In accordance with the operating instructions, the Agidel pump must pump an agent with a temperature below 400 C. Under these conditions, the engine operates without overheating. Before starting the device, water is poured; working “dry” will lead to an inevitable breakdown. The pump must be protected from moisture and debris, from sub-zero temperatures.

Compared to the Agidel M pump, the later modification, Agidel-10, has a horizontal layout and is 2 times more powerful.This machine does not need to be primed before starting, it provides self suction. The pump weighs 9 kg, has a head of 30 m, and provides horizontal pumping of 50 meters. The productivity of 3.3 cubic meters per hour is sufficient for domestic needs.

- "Agidel" -M;

- "Agidel" -10.

Despite their power and price differences, the principle of operation and their internal structure are quite similar.

As self-priming centrifugal devices, Agidel water pumps consist of the following working elements:

- electric motor;

- motor housing and the pump itself, also referred to as a snail;

- impeller (impeller).

When connected to the mains, the motor initiates the injection mechanism. Its main element is the impeller or impeller, which, rotating in the volume of the swirling body, generates centrifugal force and directly the working head of the unit. As the body is filled with liquid, the water rises higher until it reaches the outlet pipe, through which it enters the consumer's water supply.

Both models are equipped with a centrifugal type blower driven by a single-phase electric motor.

The principle of operation of centrifugal pumps is to impart rotational motion to the pumped medium (a wheel with blades rotates inside the pump), as a result of which a centrifugal force creates pressure. Pumps of this type are characterized by simple design, wear resistance and high efficiency.

Self-priming centrifugal water pump device

All Agidel pumps are self-priming, that is, they are able to create a vacuum and draw water into themselves from a certain depth.Thus, units of this brand, unlike submersible options, do not need to be lowered into water, which made it possible to use cheaper materials for the manufacture of external elements and seals.

All Agidel pumps have built-in overheating protection.

Construction device

Pumps of modification M have two parts of a design: an electric motor with a centrifugal pump. Model 10 additionally has a jet pump. With the help of it, the liquid is self-absorbed, enters the chamber using a centrifugal device.

At the heart of the electric motor device is a stator, which has a built-in thermal fuse. It protects the winding of the device from overheating. The motor also consists of a rotor with a flange and a end shield. During operation, the parts are cooled by a vane fan equipped with a hood.

Fundamentals of pump operation

The principle of operation is based on centrifugal force, which affects the flow of fluid. The force comes from the rotation of the wheel mounted inside the rotor shaft. The flange has sealing cuffs so that water does not get into the engine.

Attention! The main reason for the breakdown of Agidel devices is water that has entered the engine, so the pumps should be well sealed from water. Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock

This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

It prevents the penetration of large elements, pieces of rock.This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock. This valve of the M brand pumps serves as a shut-off valve when water is poured into the pump before starting.

The flange with body connector is equipped with seals made of rubber material. Pumping equipment of modification M is equipped with a screw to release excess air. To mount the pump in a vertical position, fasteners are inserted into the prepared holes. To install horizontally on the rack, special holes are made.

Rules for the use of pumps

Attention! You can install the pump in the basement, but the pressure level of the unit will decrease because the pump will be located far from the well

Pros and cons of Agidel models

Agidel electric pumps are considered reliable devices. They are used for watering the garden, for pumping liquid for domestic purposes. Pumps have many positive properties:

1.Affordable price.

2.easy operation.

3. You can replace individual parts.

4.Low energy consumption when working.

5.The units are reliable, durable.

Among the shortcomings, they note the inability to pump water from wells over 8 meters high. Units should be mounted near wells with water.

Important! There are many Chinese fakes of Agidel pumping devices on the market. They are made of plastic, have a low level of build quality.

Preliminary work before launch

The process consists in manually pouring water into the pump tank or using a column, where the necessary pressure for injection is easily created. After water appears from the pump hose, the unit is turned on, the impeller begins the rotation process, which creates a force that can supply water to the above distances. After each break, the cycle is repeated - you can not start working with a dry tank.

Minor do-it-yourself repairs

Any equipment eventually fails. A simple sign of a pump failure is a stopped water supply. There can be several reasons: leaving the horizon, leaky hoses, defective seals. Problems are solved on their own if the cause is determined. Hoses are changed to new ones in the same way with oil seals, but the process is somewhat more complicated:

The pump is lifted and dried

It is important to immediately inspect the outer, and during disassembly, the inner part for rust - this is fraught not only with a worse quality of work, but also indicates poor sealing of the caisson, the occurrence of condensate or leaks.

Release the engine from the casing and remove it by unscrewing the fasteners holding the casing.

The volute seals are dismantled, having previously removed it from the pump.

An anchor is knocked out from under the loosened screw of the impeller

Use a wooden hammer to avoid damaging the structure.

When the oil seals are already visible, evaluate their condition equal to other details.

When deformed, they are changed together with the gaskets, being careful not to damage the separating insert.

Reassembly occurs after the installation of components, as the pump was disassembled. Before this, it is necessary to lubricate the moving parts with a suitable composition and continue not to neglect this prevention.In order not to have to repair the country pump soon, owners are advised to adhere to the above operating rules

With careful handling, the unit is able to work up to 20 years

In order not to have to repair the country pump soon, owners are advised to adhere to the above operating rules. With careful handling, the unit is able to work up to 20 years.

The main malfunctions of submersible pumps

If failures are noticed in the operation of a submersible pump, then it is not always necessary to remove it from the well for inspection. This recommendation applies only to pumping stations in which a pressure switch is installed. It is because of him that the device may not turn on, turn off or create poor water pressure. Therefore, the operability of the pressure sensor is first checked, and after that, if necessary, the pump is removed from the well.

Water pump malfunctions will be easier to diagnose if you first familiarize yourself with the most common failures of this unit.

The pump is not working

The reasons that the pump does not work may be as follows.

- The electrical protection has tripped. In this case, disconnect the machine from the mains and turn on the machine again. If it knocks it out again, then the problem should not be sought in the pumping equipment. But when the machine is turned on normally, do not turn on the pump anymore, you must first find the reason why the protection worked.

- The fuses have blown. If, after replacement, they burn out again, then you need to look for the cause in the power cable of the unit or in the place where it is connected to the mains.

- An underwater cable has been damaged. Remove the device and check the cord.

- The pump dry-run protection has tripped.Before starting the machine, make sure that it is immersed in the liquid to the required depth.

Also, the reason that the device does not turn on may lie in the incorrect operation of the pressure switch installed in the pumping station. The start pressure of the pump motor needs to be adjusted.

The pump works but does not pump

There may also be several reasons why the device does not pump water.

- Stop valve closed. Turn off the machine and slowly open the tap. In the future, pumping equipment should not be started with the valve closed, otherwise it will fail.

- The water level in the well has dropped below the pump. It is necessary to calculate the dynamic water level and immerse the device to the required depth.

- Check valve stuck. In this case, it is required to disassemble the valve and clean it, if necessary, replace it with a new one.

- The intake filter is clogged. To clean the filter, the hydraulic machine is removed and the filter mesh is cleaned and washed.

Low machine performance

Also, performance degradation causes:

- partial clogging of valves and valves installed in the water supply system;

- partially clogged lifting pipe of the apparatus;

- pipeline depressurization;

- incorrect adjustment of the pressure switch (applies to pumping stations).

Frequent switching on and off of the device

This problem occurs if the submersible pump is paired with a hydraulic accumulator. In this case, frequent starts and stops of the unit can be provoked by the following factors:

- in the hydraulic tank there was a decrease in pressure below the minimum (by default it should be 1.5 bar);

- there was a rupture of a rubber pear or diaphragm in the tank;

- the pressure switch is not working properly.

The buzz of the machine is heard, but the water does not pump

If the pump is buzzing, and at the same time water is not pumped out of the well, then there may be several reasons:

- there was a “gluing” of the impeller of the apparatus with its body due to long-term storage of the device without water;

- defective engine start capacitor;

- dipped voltage in the network;

- the impeller of the pump has jammed due to dirt collected in the body of the apparatus.

Water is supplied with pulsation

If you notice that the water from the tap does not flow in a constant stream, then this is a sign of a decrease in the water level in the well below the dynamic one. It is necessary to lower the pump deeper if the distance to the bottom of the shaft allows this.

The unit does not turn off

If the automation does not work, the pump will work without stopping, even if excessive pressure is created in the hydraulic tank (seen from the pressure gauge). The fault is the pressure switch, which is out of order or incorrectly adjusted.

Main characteristics

Compact device operating on the centrifugal principle. It is placed on the surface in a vertical position. The model without an ejector is designed to lift water from wells up to seven meters deep. And if you use an ejector with this unit, the efficiency of the pump will double, and the owners will be able to receive water from a depth of up to 15 meters.

The movement of water is provided when the electric motor is turned on by rotating the shaft with blades located on the axial sleeve. The liquid inside the pumping chamber is displaced into the pipeline under the influence of centrifugal force.And in the center of the impeller there is a zone of low pressure, which ensures a continuous flow of water from the well through the intake hose.

- a pressure of 20 meters is created;

- productivity - 2.9 cubic meters per hour;

- power - 370 watts.

Advantages:

- low price;

- the possibility of application at a sufficient depth when using an ejector;

- ease of maintenance and operation;

- high reliability;

- low power consumption.

unit afraid of dry running (must be filled with water at the beginning of operation).

The average price is from 4,500 rubles.

This is a more powerful and overall model of a self-priming vortex type. It is placed on the surface in a horizontal position. The main advantage of the unit is the possibility of a “dry start”. That is, at the first start-up, the pump does not need to be filled with water.

Turning on the pump starts the rotation of the impeller (impeller), which creates a vacuum and causes air to be sucked in. The water in the housing is mixed with air. The movement of water and air creates a vacuum zone, which ensures the suction of liquid through the intake hose. The remaining air is removed through a special technical opening. Further, the unit functions as a standard centrifugal pump, the operation of which was described above.

- pressure up to 30 meters;

- productivity - 3.3 cubic meters per hour;

- power - 700 watts.

- budget cost;

- long service life;

- the unit is not afraid of dry running;

- ease of maintenance;

- reliability.

- can not be used at a depth of more than seven meters;

- relatively high power consumption.

The price is from 6,000 to 7,500 rubles.

If we compare the technical data, it becomes clear that the second pump has better performance and is able to create more pressure. The main advantage of the first type model is low power consumption (370 watts) and light weight. It is allowed to use an ejector with it, which is important for owners of wells and wells fifteen meters deep. If power is not the main choice for owners when buying a pump, you can safely purchase a more economical and compact model. In terms of build quality and service life, the units are no different.

When installing pumps of this brand, three main parameters should be followed:

- positive operating temperature;

- as close as possible to the source of water;

- flat mounting surface.

Obviously, the ideal solution would be to equip an insulated caisson chamber with a flat bottom. In such conditions, the equipment will be able to work even in the winter cold. A close location to a well or well is required due to the sensitivity of the equipment to depth - this is an indicator from 7 to 15 meters, depending on the model and the presence of an ejector.

It is allowed to install directly on the head of the well or the cover of the well (this is a good solution for summer use). The caisson is set up five or ten meters from the house below the freezing point of the soil.

A good solution would be to mount it on a special raft, which is then lowered into the well. But in this case, there will be a problem with connecting the electrical cable. It needs to be extended and waterproofed. The standard cable length is 1.5 meters.

Experts recommend using Agidel-10 for installation in a caisson or mounting on a raft for year-round use. And for seasonal use, Agidel-M should be used - a unit that requires adding water before starting and is extremely sensitive to low air temperatures. It can be installed on a flat surface near the well or attached to a special bracket at the head of the well.

For the winter, the pump is dismantled, dried and stored in a warm room for storage.

Technical characteristics of pumps "Agidel"

Let's start a detailed acquaintance with UAPO products with a junior representative.

"Agidel-M"

The cylindrical pump housing has dimensions of 254x238 mm (including the motor). The mass of the device is 6 kg. The pumped water must have a temperature of no more than 40 degrees, otherwise the unit may overheat.

Main characteristics:

- suction depth limit is 7 m;

- when connecting a remote ejector, the suction depth will increase to 15 m;

- power consumed by the electric motor - 0.37 kW;

- maximum head - 20 meters of water column (m.w.st).

"Agidel-10"

This unit has dimensions 190x332x171 mm with weight in 9 kg. It is also designed to pump cold water (up to 40 degrees).

Unlike the previous modification, the Agidel-10 model is capable of developing a head of 30 mw.

Maximum performance - 3.3 cubic meters. m/hour. The power consumed by the electric motor is 0.7 kW.

Model Agidel-10

The reasons why the pump pumps poorly do not always depend on the device. The intake hose must be reinforced, do not change the section.When using soft plumbing, the vacuum in the system causes the profile to compress under atmospheric pressure. A sticky hose does not let water through. To avoid problems, a reinforced or rubber hose with a wall thickness of more than 4 mm and an inner diameter of 25-30 mm is connected to the suction fitting.

In order to get the seals, you need to release the impeller, remove it from the anchor. Inside the bushings there are 2 glands, through the partition

They are changed carefully, the partition is restored. Assemble the pump in reverse order

Maintenance consists in periodically disassembling the apparatus, cleaning the impeller and lubricating the rotating parts. Usually such operations precede winter conservation. Measures to prolong the life of the pump include the installation of a quality check valve on the supply line. All connections must be sealed to prevent air leakage.

The Agidel M unit is a centrifugal mechanism that is installed on the surface, not immersed in water, near a water source (well, well, reservoir). If you install an ejector as an additional force, you can get up to 16 liters instead of the guaranteed 8. The electric motor, installed under a plastic cover, makes revolutions along the axis of the sleeve using blades.

Agidel M

Agidel 10

Operation features

Pumps "Agidel-M" must be installed on a hard, flat surface. The quality of the work will depend on this. To protect against precipitation and direct sunlight, it is recommended to build special containers, or install units in utility rooms.

Faults and causes for their elimination

The main malfunctions of household pumps are:

- cavitation;

- insufficient power;

- overcurrent;

- the presence of deposits;

- hydraulic shocks;

- increased noise during operation.

Cavitation is a process when a pump pumps water with air. There are several reasons that lead to this:

- clogged ventilation and supply pipes;

- the presence of particles of gas or air in the water;

- a long pipeline for liquid suction is installed;

- pump operation with increased load on the right side.

Clogged pipes are cleaned. The hydraulics of the device are carefully examined. If there is a blockage, it is cleaned. If possible, pipes are changed to products with a larger diameter.

The problem of air content in water is solved by:

- deep immersion of the unit in water;

- fastening of fender shields (will prevent the water jet from entering the area near the pump).

To reduce the loads on one side of the device, the resistance on the pressure pipe is increased. For this, additional elbows are installed or a pipe with a smaller diameter is installed.

Insufficient power, when the pump does not pump water well, can be caused by:

- incorrect rotation of the pump (typical for 3-phase products);

- damage or clogging of the impeller;

- blockage of the supply line or jamming of the check valve;

- the presence of air particles in the pumped water;

- inaccurate location of the valve on the pressure pipe.

The direction of rotation of the device is changed by correctly connecting the two phases on the power cable. Impeller failure is usually caused by corrosion and abrasion. It can only be eliminated by replacing damaged parts. In case of blockage and jamming of the pump mechanisms, they are thoroughly cleaned.The gate valve located on the discharge pipeline must be fully open.

The main causes of excess current in the pump are:

- voltage drop in the electrical network;

- increased viscosity of the liquid for pumping;

- increase in engine temperature;

- shutdown of one of the phases.

Elimination of these faults is carried out using:

- continuous check of the voltage indicator in the network:

- installation of an impeller having a smaller diameter;

- limiting the number of stops and starts;

- careful inspection of the contacts for connecting the cable;

- replacement of broken fuses.

Blockage of the pressure pipe and pump with deposits occurs when:

- the device is constantly turned on when pumping a small amount of water;

- the fluid velocity decreases.

This problem can be corrected by setting new parameters on the control device or by changing the height of the water level when the pump is started.

The occurrence of hydraulic shocks is associated with:

- the appearance of air pockets in the pipes;

- frequent pump start;

- pumping a large volume of water at the time of inclusion;

- quick exit of the unit to the operating mode.

Water hammer can be avoided or reduced by:

- installation of a ventilation valve at the top of the pipe;

- checking the diameter of the pipeline and the operating point of the pump for their compliance with the speed of water movement;

- the use of soft start frequency;

- settings of parameters optimal for operation on the control device.

The increase in noise during the operation of the pump does not directly affect the amount of pumped water. But this fact indicates that after some time other malfunctions will appear.And they can lead to the fact that the pump will not be able to pump water. After all, the causes of increased noise are completely different, ranging from blockage of the ventilation pipe or supply line to the effect of corrosion on the impeller.