- We lay out a brick oven

- How to build a water oven at home?

- How to make such an oven yourself

- Manufacturing options and recommendations

- System installation

- The choice of pipes for wiring

- Underfloor heating system

- Register Size Calculation

- What is the stove made of?

- Other Tips

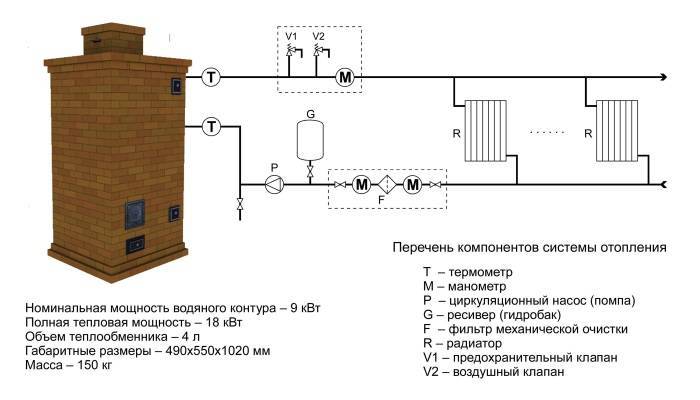

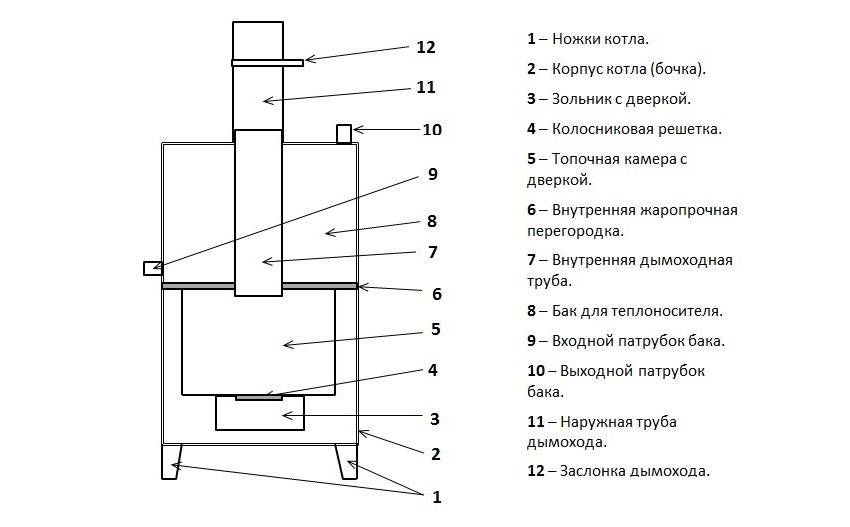

- 1 Design and principle of operation

- System features

- The main characteristics of furnaces with water heating

- Disadvantages of stoves with water heating

- Cooktop ovens

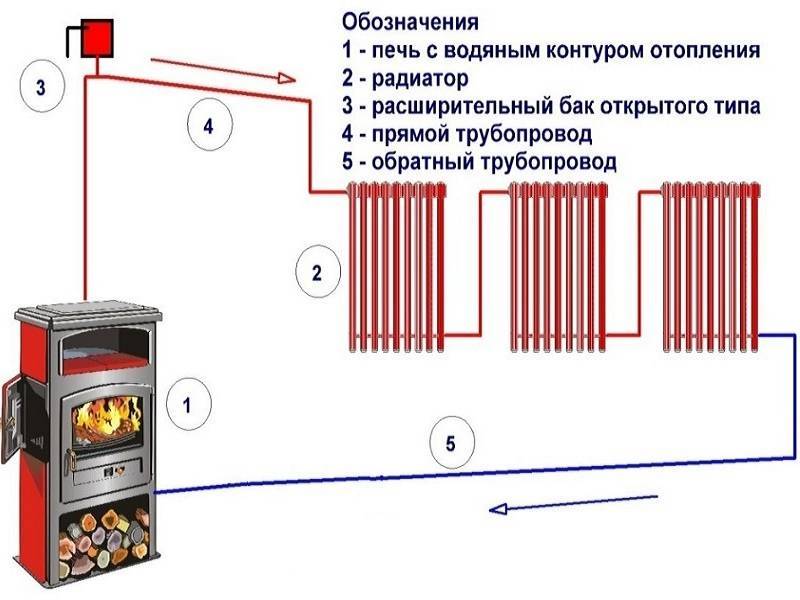

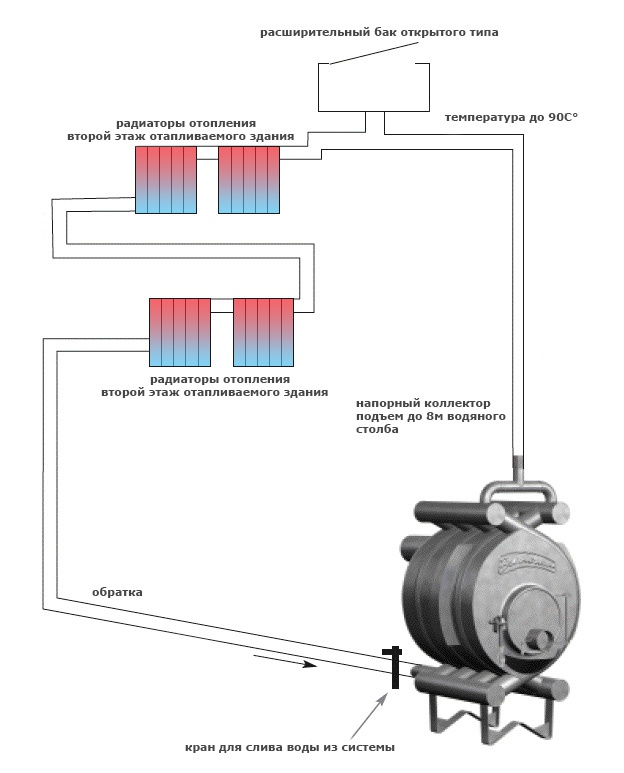

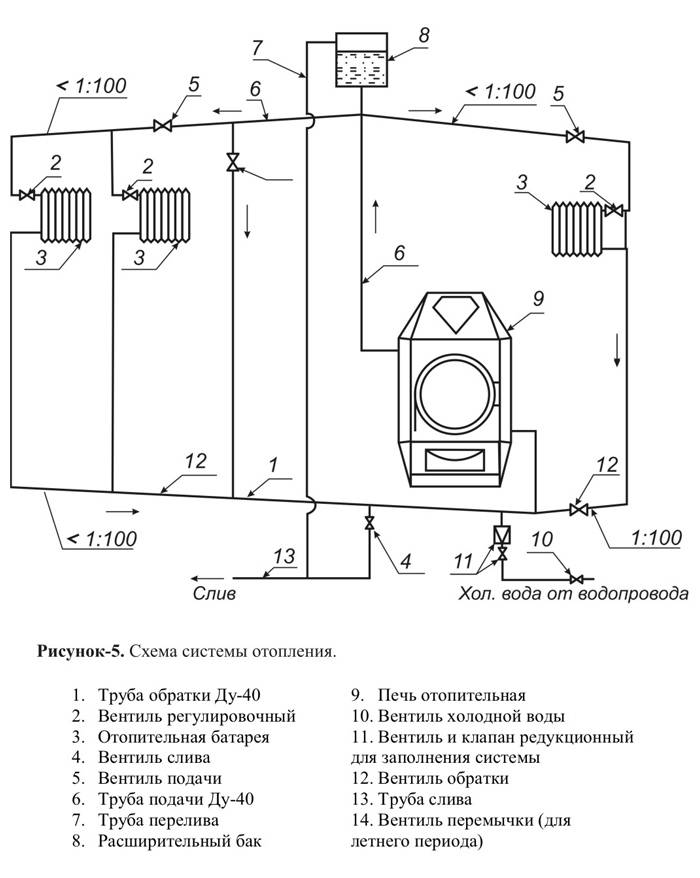

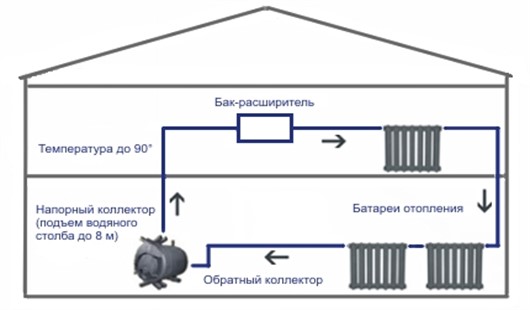

- Wood heating schemes at home

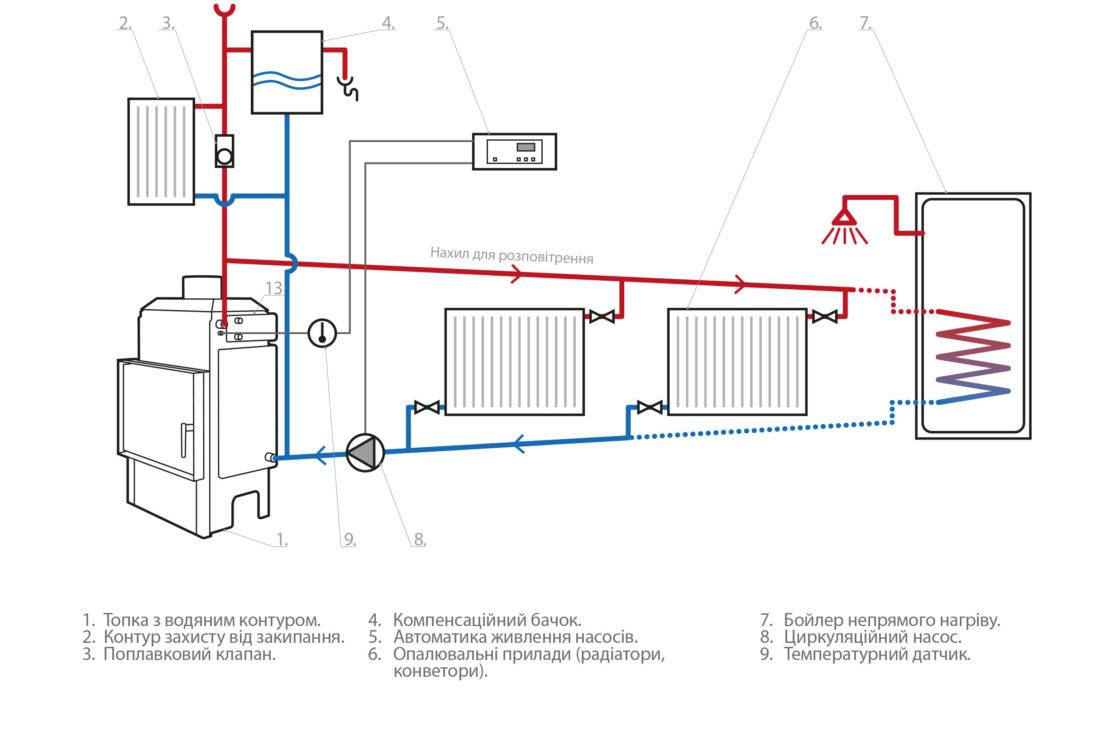

- Features of the device and the choice of the circulation scheme

- Several popular oven models

- Advantages and disadvantages of heating from a stove

- Technology for installing water heating in a conventional wood-burning stove

We lay out a brick oven

Choosing an oven for a bath with a tank for water, you should pay attention to the following parameters:

- Volume of the tank. The larger it is, the more hot water will be available for washing.

- The design of the furnace - the convenience of its operation largely depends on the location of the water tank and other design features of the device.

- The brand under which the equipment is produced. Today, dozens of manufacturers make stoves for a bath with a water tank, and only a few of them produce truly thoughtful and reliable devices.

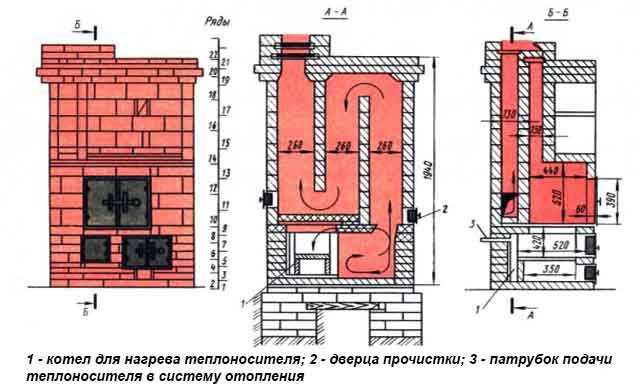

If you have some practical experience in building brick ovens, try building a massive sauna stove with your own hands. We offer a variant of a stove-heater with dimensions of 102 x 129 cm, equipped with a tank of 170 liters and designed to heat a bath with an area of 12 m².

To build the stove shown in the drawing, prepare a set of materials:

- solid clay brick (red) - 580 pcs.;

- fireclay stone of the SHA-8 brand - 80 pcs.;

- cast-iron grates measuring 30 x 25 cm - 2 grates;

- main door for loading firewood - 210 x 250 mm;

- ash chamber door - 14 x 25 cm;

- smoke damper - 320 x 450 mm;

- heater door - 51 x 42 cm;

- steel pipe with a diameter of 57 x 4 mm - 6.3 m;

- iron strip with a section of 40 x 5 mm - 2 m;

- the same, 80 x 10 mm in size - 2.5 m;

- basalt cardboard, roofing felt.

Also, before construction, it is necessary to weld a tank-boiler with dimensions of 102 x 77 x 25 cm from sheet steel grade St20 with a thickness of at least 3 mm. We will not describe the technology of the reinforced concrete foundation, the preparation of the mortar and the stove masonry - it is described in detail in the instructions for the construction of the fireplace.

We invite you to familiarize yourself: Finishing the bath inside with your own hands

Let's proceed to the construction of the furnace according to the presented orders:

- The zero and first rows fit into a solid line. Tiers 2 and 3 form an ash pan, a blower door is installed.

- Row number 4, blocking the door, is the bottom of the fuel chamber, partially laid out with refractory stones with a gap of 5 mm from red bricks. Trimming is done, a grate and a loading door are inserted.

- When laying tiers 5-9, the walls of the firebox are built. On the 10th row, cells are prepared for pipes, cut into blanks 1050 mm long.These parts are placed in nests and sealed with basalt cardboard, a water tank is installed.

- From the 11th to the 20th tiers, the walls of the furnace are being built around the tank. On the 20th row, the end of the boiler is covered with two steel strips L = 35 cm.

- On the 21st row, the heater door is installed, the laying of the outer walls continues according to the scheme up to the 26th tier. On top of the door we put 2 strips 650 mm long.

- On the 27th row, the overlap of the stove begins to form. Cutouts are made for laying large strips 120 cm long. Bricks of the 28th tier block the cavity of the heater, leaving a chimney opening.

- The flue valve is placed on the 28th row, tiers 29-32 finally form the furnace vault and the transition to the chimney.

How to build a water oven at home?

- There are three ways to carry out stove heating with a water circuit with your own hands:

- buy a steel furnace from a manufacturer whose services include installation of the system;

- hire a craftsman - a specialist will select the material, make the device, lay out the furnace and install the boiler;

- do it yourself.

How to make such an oven yourself

The principle of the boiler for water heating

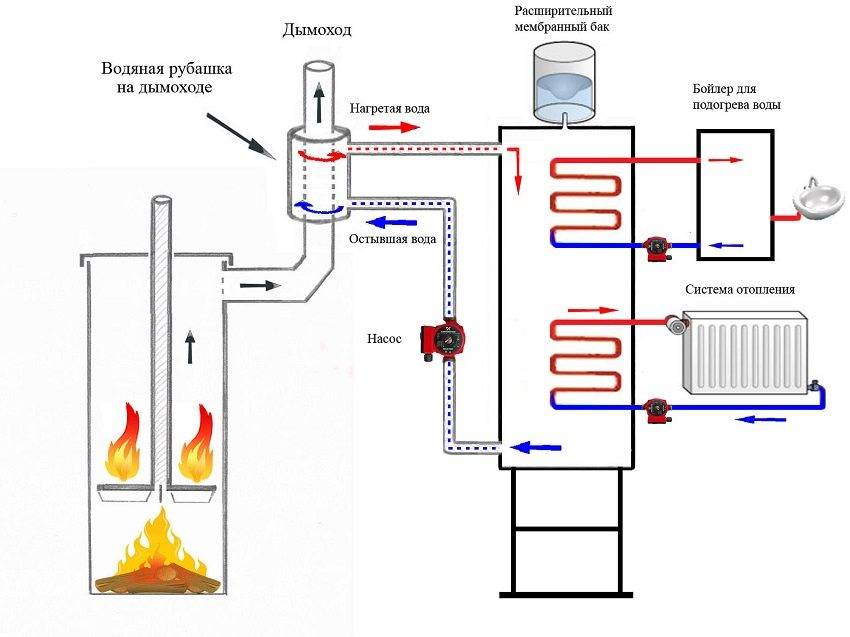

Can you make such a system yourself? Quite, just enough experience in welding and in laying bricks during the construction of the furnace. First you need to prepare the boiler (register, coil, heat exchanger).

Such a device can be bought or made independently using sheet metal and pipes. Since the complete process of manufacturing and installing a water circuit cannot be put into a short overview, the following are the main recommendations.

Manufacturing options and recommendations

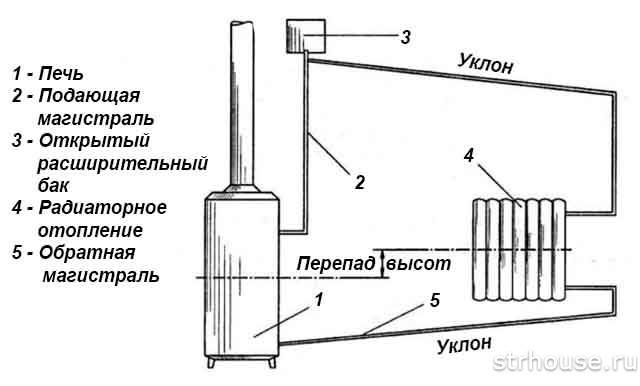

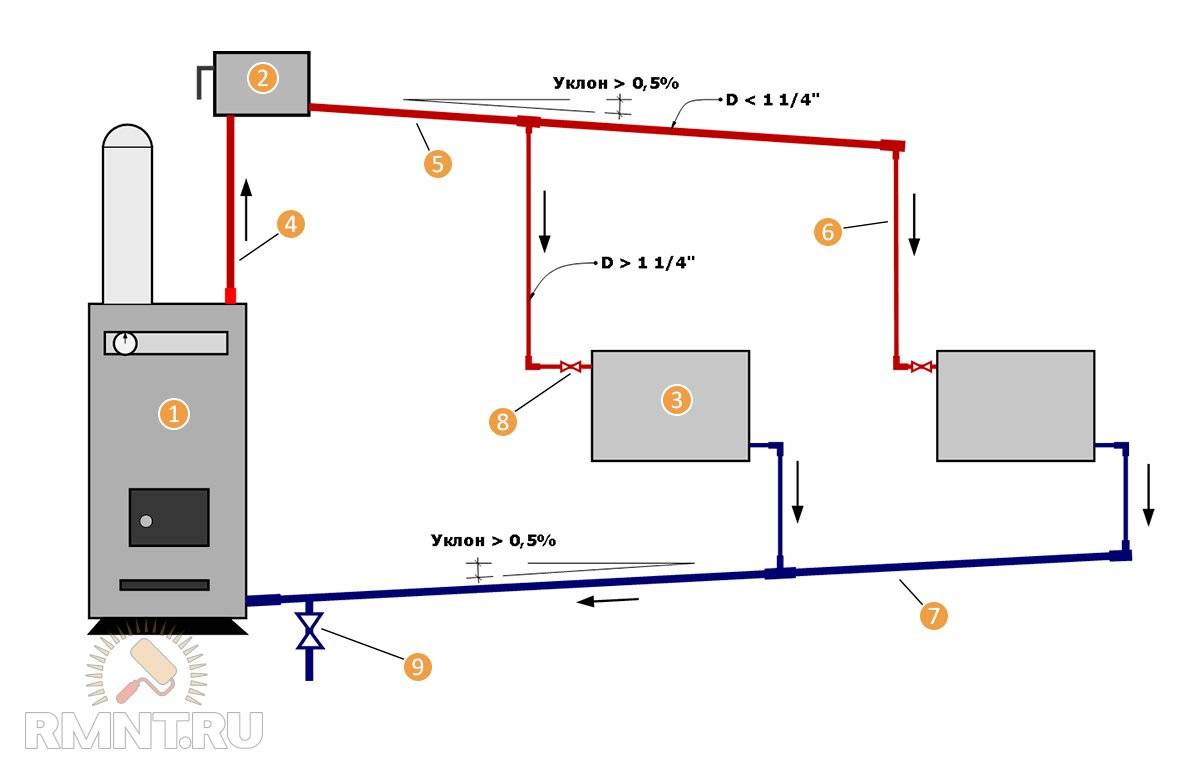

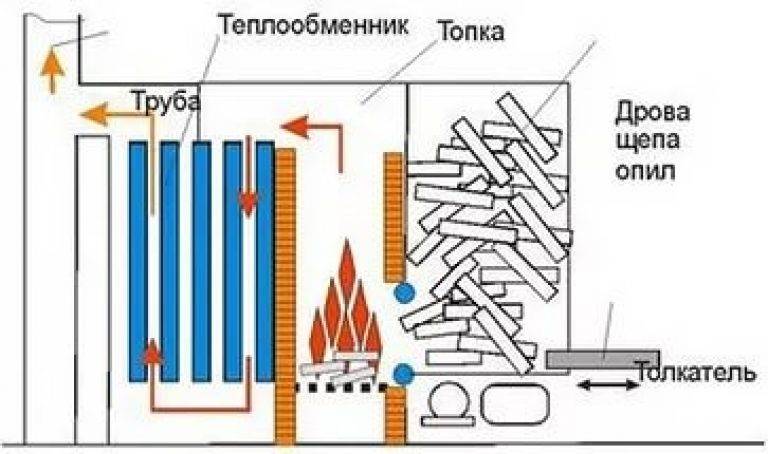

Water heating from a wood-burning stove - scheme

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made such that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate - it is easy to clean.

But such a heat exchanger has a smaller heating area, in contrast to the pipe register. It is difficult to make a pipe register at home on your own - you need an accurate calculation and suitable working conditions, usually such boilers are made to order by specialists who install the system on site themselves.

The easiest way to use a solid fuel heat exchanger is an ordinary potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welds must be doubled, since the temperature in the furnace is not lower than 1000 degrees. If you boil ordinary seams, then there is a chance that this place will quickly burn out.

The layout of the rooms of the house and the location of the furniture also need to be considered. Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit. Such a structure is not so troublesome to build. It is also convenient because after installation you can use the hob without problems, which cannot be said about some tube boilers

Follow the drawings of the register in accordance with the dimensions of the furnace at home. The layout of the rooms of the house and the location of the furniture also need to be considered.

Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit. Such a structure is not so troublesome to build.

It is also convenient because after installation it is possible to use the hob without problems, which cannot be said about some tube boilers.

Register of smooth pipes - drawing

When the coolant moves by gravity, then you need to raise the expansion tank higher, and use pipes of large diameters. If the pipes are of insufficient size, then a pump cannot be dispensed with, since there will be no good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler can simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Cast iron battery heat exchanger

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of bricks.

- You can lay the grate at different stages: before the boiler, if the double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually placed after the boiler is installed .

- A housing is installed - usually it consists of two containers connected by pipes.

- The entire heat exchange system is welded to the boiler: the outlet pipe goes to the expander, goes in a circle, through the radiators and, on the other side, the return pipe is welded to the boiler from the bottom.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

Having decided to independently make a heating system at home with a wood-fired water circuit, think through all the stages of work, and if there is any doubt about the successful outcome, then it is better to contact specialists.

The choice of pipes for wiring

The final result depends on the quality of each system part, which is to save and save heat, so the longest elements - pipes - must also be given some attention.

From a technological point of view, pipes and fittings must have the following qualities:

- strength;

- ease;

- suitability for repair;

- tightness;

- low noise level.

Low cost is also an important component when choosing, because heating system equipment requires a large number of products for various purposes. Polypropylene pipes - the best option for self-assembly of the heating system

You can learn how to use a soldering machine for sewing pipes in 10 minutes

Polypropylene pipes - the best option for self-assembly of the heating system. You can learn how to use a soldering machine for sewing pipes in 10 minutes

Now it is unlikely that anyone will undertake the installation of wiring from metal pipes. Steel, copper and galvanized products are becoming a thing of the past, giving way to cheaper and more functional counterparts.

The best alternative are polymer products. which can be divided into three groups:

- polypropylene;

- metal-plastic.

The advantages of polypropylene pipes are low cost, ease of welding, long service life.Minus - lack of elasticity. When replacing a pipe, you will have to change the whole fragment from connection to connection.

On a long section of the pipeline, polypropylene pipes sag, as they have an expansion of 6 mm / 5 m. Strong fixation is provided with brackets or clips mounted in the wall at intervals of 1-1.1 m

Durable metal-plastic pipes are resistant to sudden changes in temperature. Able to serve without major repairs up to 30 years. The weak point is the connecting elements - fittings with an unreasonably narrowed flow area. In the event of freezing of the coolant, a breakthrough is likely.

When choosing pipes, be guided by the main technical indicators of the equipment and the type of coolant.

Underfloor heating system

An excellent way to insulate private property would be an insulated floor system.

The main convenience is that you do not need a lot of equipment, different equipment.

Flexible, but high-strength hoses are laid out on the base, through which hot water or steam will pass. From above, the layout is poured with cement mortar, performing a floor screed. Due to the thermal conductivity of concrete, the surface warms up evenly.

Always warm floors do not allow the premises to cool down.

In a temperate climate, this measure is enough to create comfort.

Some homeowners successfully combine steam heating with an insulated base system, which is very important for residents of the cold regions of the country.

Example of combined heating

The main thing is that the installation is safe, and then it fits the requirements of the selection. Next - calculations taking into account the correction factors in order to buy the right equipment.

Calculations and drawing up a diagram are the most important stages in laying heating lines, so it is better to order them from professionals.

The principle of laying underfloor heating is clearly shown in the following video:

average rating

ratings over 0

Share link

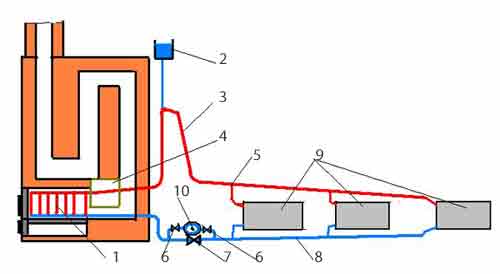

Register Size Calculation

In order to make a water circuit for the stove with your own hands, you need to determine its dimensions, or rather, the area of \u200b\u200bthe heat exchange surface. To do this, use the following algorithm:

- Find out what is the area of heated rooms and multiply it by 0.1 kW. If you live in one of the cold northern regions, multiply the area of \u200b\u200bthe premises by 0.2 kW. For a house of 100 m², you will need 10 and 20 kW of thermal energy, respectively.

- It follows from practical observations that a register installed directly in the firebox is able to transfer up to 10 kW of heat to the coolant from each square meter of its surface. Divide the heat demand value by this figure to get the radiator area.

- For an economizer and a tank mounted in a chimney channel, where the temperature is lower, take the value of specific heat transfer not 10, but 6 kW from 1 m² of surface.

- Knowing the area, it is not difficult to calculate the dimensions of a rectangular container. But the length of the pipes from which the register is brewed is calculated by the formula: L \u003d S / πD (S is the area, D is the pipe diameter).

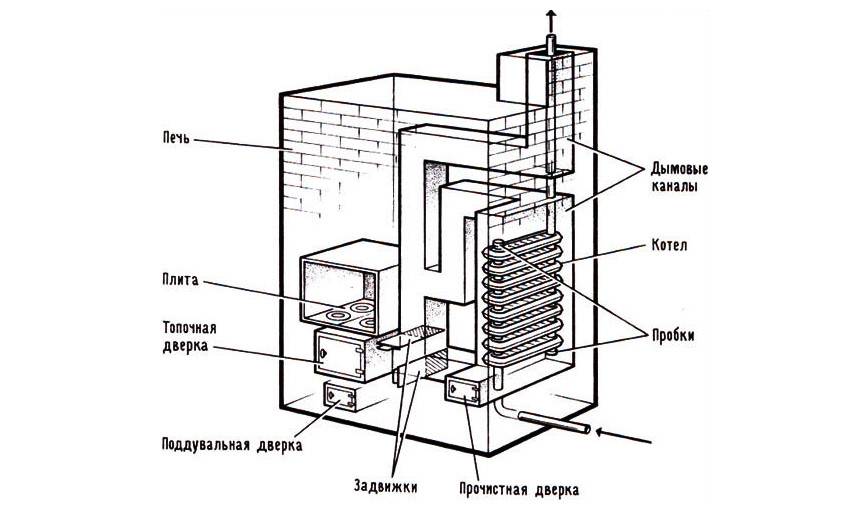

Scheme of a brick oven with a hot water boiler placed in the furnace

If, as an example, we take cottage rooms with a square of 100 m², then the heat exchange surface of the radiator built into the furnace should be at least 1 m². When installed in a gas duct, this area will increase to 10 / 6 = 1.67 m².

What is the stove made of?

Durable steel or cast iron are good options for making stoves

They have excellent heat dissipation and, which is very important, warm up the room very quickly. If earlier there was no worthy alternative to brick ovens, today the advantages of metal models have already been appreciated by many owners of houses and cottages.

The heating surfaces of cast iron units have a temperature several times higher than brick stoves for a wood-burning house. They are compact and safe if the operating requirements are met.

Cast iron is heavier than steel, they must be placed on a solid foundation. But they have a great advantage - they can accumulate heat, withstand high temperatures. They are more durable. The most interesting design models are made of cast iron.

Other Tips

The living room with the kitchen can be combined and decorated with various shortcomings.

It is important to calculate and anticipate everything in advance.

Designers and craftsmen share tips that will help you avoid problems during repairs and arrangements:

The result depends on how detailed the project will be. Oddly enough, it is worth considering the growth of loved ones and relatives. It is also advised to calculate the approximate number of possible guests.

You can get rid of the smell of food if you install a strong hood or ventilation system.

Small models are more suitable for housewives who cook little.

If a sleeping place is planned in the living room, then it is important that the ringing of appliances and other kitchen utensils is not heard. Silent dishwashers and other appliances will come in handy.

In addition, you can install a sliding door and install a soundproof partition. If there is sensitivity to ultraviolet light, the owners hang thick curtains made of opaque fabric.

If household appliances do not fit the direction of the interior, they are hidden behind furniture or put away in kitchen cabinets.

When installing fixtures and lamps are guided by several criteria

It is important that the light falls evenly throughout the space. Particularly bright lighting is preferred in the kitchen area and where the dining table is installed

In the living room, designers create a subdued atmosphere using wall lights and table lamps. Multi-level stretch ceilings with LED strip also look good in this room.

Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time.

The kitchen, combined with the living room, combines:

- personal tastes of the owners;

- reliable finishing materials;

- current design ideas;

- convenience;

- trends. The best photos of living room kitchen design

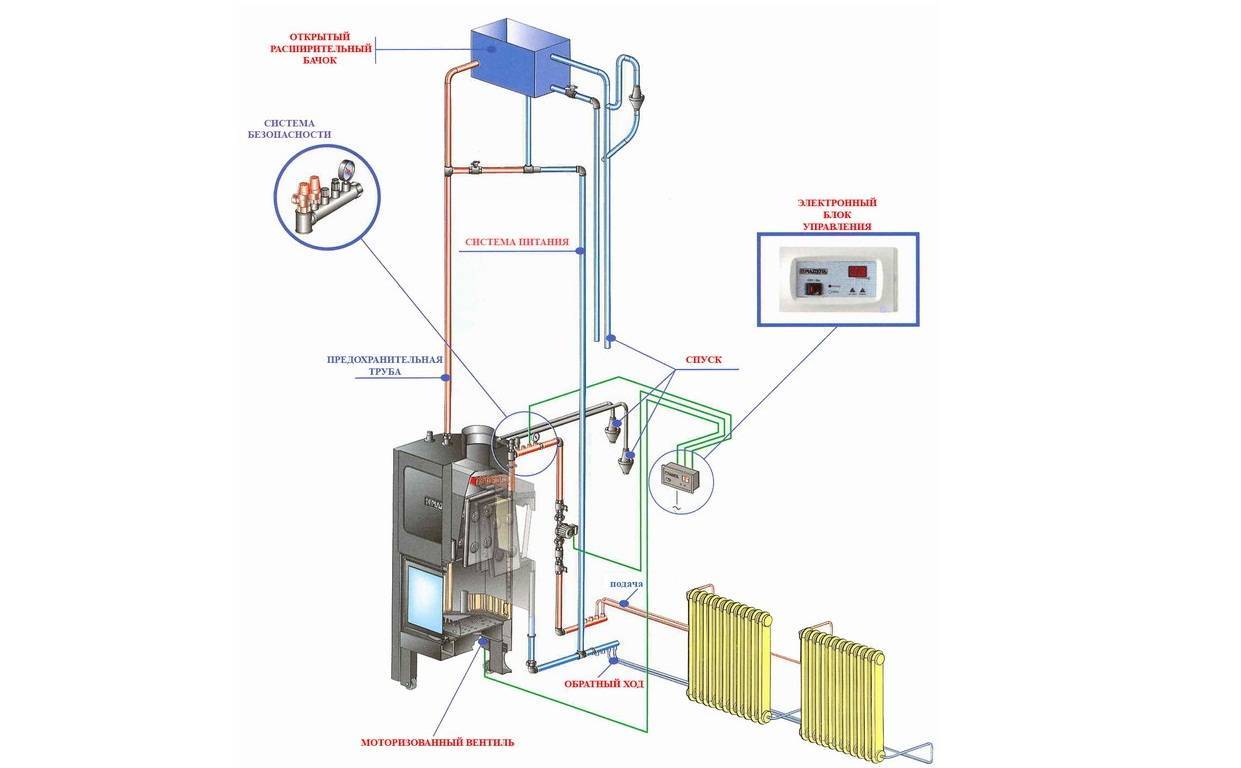

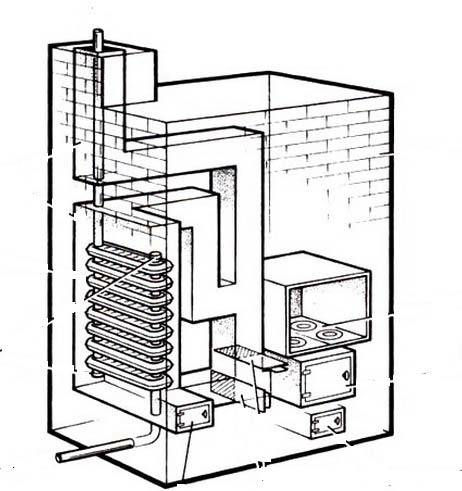

1 Design and principle of operation

A furnace with a water circuit quickly heats up the room thanks to the coolant. It can be water or other liquid that moves in the system. It is heated by heat from the stove itself. This is how the system works.

In order for the system to work, it is imperative to install a metal container that will perform the functions of a heat exchanger. It looks like an ordinary tank with fittings with pipes connected to them. Modern prototypes of such devices are made of metal and fire-resistant bricks, can be equipped with various decorations on top, colored tiles, etc.

The design can be done in two ways:

- 1. The heat exchanger is in the furnace.This design is designed for heating large areas, is characterized by long-term operation and durability. But there are also disadvantages. These include proximity to the fire, which contributes to the burning of metal parts. If you do not clean the chimney from soot, then the efficiency will constantly fall.

- 2. Heat exchanger in the chimney. Ease of use and operation, high performance and long service life this unit also has. But it is unlikely that it will be possible to heat large rooms with the help of such a device.

System features

A conventional brick oven consists of components such as a fire chamber, an ash pan, grates and chimneys. These components of a simple Russian stove are probably familiar to any villager. In visual terms, modern types of stoves are practically no different from traditional rustic designs.

The main characteristics of furnaces with water heating

Traditional ovens are characterized by such characteristics as:

- A simple rustic stove can release more than 6500 kcal of heat in one hour. This amount of heat is enough to heat a house with a small area. Such a heating system will be an ideal solution for a small country house. A water-heated stove, in which the main component is a water boiler, will be about 2.5 times more efficient. Through such a heating system, you can already heat a house with a much larger area. In order to heat the house, the same amount of fuel is required, which means that such a system will be more economical.

- A heating system that combines a stove and a boiler will also be effective.If both systems work simultaneously, then their performance increases many times over. A tandem of two such heating systems can produce more than 21,000 kcal of heat in one hour of operation. This amount of heat is enough to heat a house with an area of up to 300 square meters. meters.

Furnace connected to water heating

Furnace connected to water heating

- Most often, such a heating system uses fuel such as coal or wood. The price of such fuel is not high, and its transportation should not cause any special difficulties. Firewood can be combined with coal at the same time.

- There is no need to constantly heat stoves with water heating. Fuel can be put into the furnace several times a day. You can create comfortable conditions indoors, no matter what the weather or temperature is outside.

- If we compare the efficiency of traditional stove heating with a combined system, then this figure will increase from 50% to 85%. For heating on wood, this indicator can be called ideal.

- The materials that are needed to organize such a heating system are quite affordable and are not included in the expensive price category.

Disadvantages of stoves with water heating

Stove heating also has its drawbacks, and it would be unfair not to list them.

A brick oven with water heating can be installed not only in a rural or country house, but also in elite cottages. Usually, the owners of elite houses strive to ensure that such a furnace for water heating, in addition to its usual functions, also performs a decorative role. During the operation of such a combined system, it is necessary to observe some safety and care rules for the system:

The furnace for water heating at home should be under human control at all times

This concerns not only the issue of fuel loading, but also the cleaning of the ash chamber.

Smoke channels also require attention. Before starting a fire in the lever, make sure that the smoke channel valves are in the open position.

Such systems can only be used in the cold season.

In the warm season, it will not be practical to use such a heating stove with a water circuit for cooking. If you need to cook food, it is better to use another alternative heat source for this purpose.

If you want to make custom-made furnaces for water heating at home, it is better to seek help from professionals. If your oven is made by an unqualified person, there is no guarantee that the oven will function normally or be completely safe. Overheating the oven can cause some problems, which will eventually lead to a complete breakdown of the oven.

A conventional stove is usually designed to heat a small room.

A conventional stove is usually designed to heat a small room.

Since the flame has high temperature indicators, it will eventually violate the integrity of the boiler walls. This means that the time will come when the heat exchanger will need to be changed. This is not so easy to do, since you need to remove a good part of the masonry.

Cooktop ovens

If the oven has a hob, this is a great advantage. You can cook food and boil water in a kettle without using an additional heat source. In the conditions of a country house, which does not have a separate kitchen, such a stove will help out. There are many similar models, the hob is even built into ordinary potbelly stoves.Burners are removable or stationary.

Typically, the hob is located in the upper part of the firebox, the distance to the fuel is minimal, this ensures quick cooking or heating of dishes with little wood consumption.

It is also possible to install a tank in which water is heated for household needs. Models with a built-in oven are of interest.

Such models optimally use the thermal energy of the fuel.

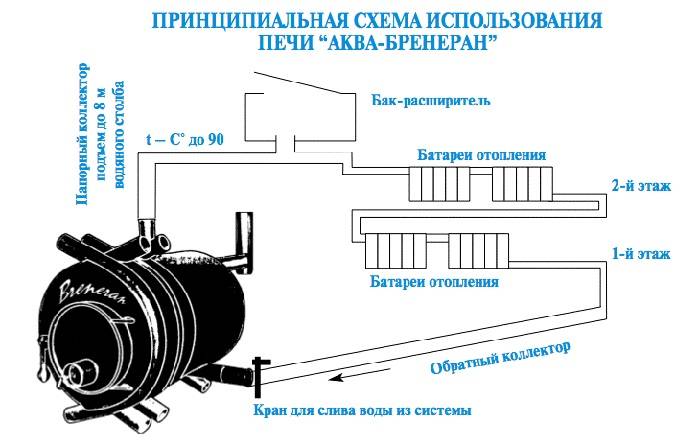

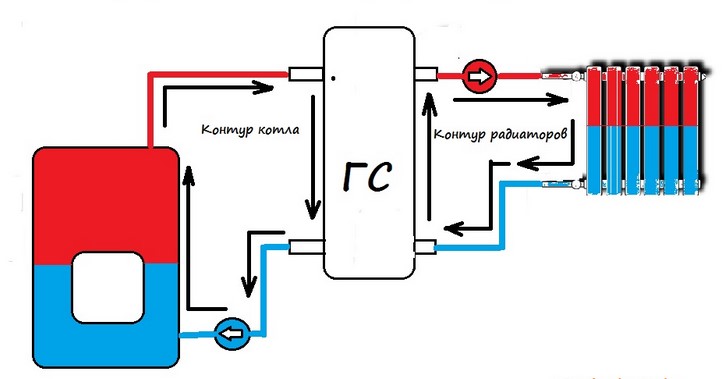

Wood heating schemes at home

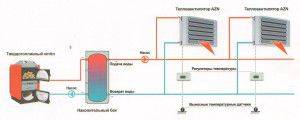

Boiler connection diagram with heat accumulator

The key point in the design of wood heating is the choice of scheme. It depends on it - whether a wood-burning heating boiler will be installed with your own hands or whether a stove or a fireplace will perform its functions. To determine the optimal option, it is necessary to take into account all possible factors.

First of all, the area of \u200b\u200bthe building and the number of rooms are taken into account. Most often, wood-burning heating stoves for summer cottages are installed if there are a maximum of two rooms. In this case, it is not necessary to make a water heating system.

Consider the main factors influencing the choice of type of heating:

- Water. It consists of a boiler (stove, fireplace) connected to the pipeline. The transfer of thermal energy occurs due to installed radiators. The best option for a house with an area of 80 m²;

- Furnace. Wood burning stoves are used to heat the air in the room. They are characterized by low efficiency, small heating area. However, their arrangement requires the least effort. The exception is fireclay brick constructions. This type is used to heat houses with an area of less than 60 m²;

- Fireplace. Analogue to furnace heat supply.The difference will be pumped in the size of the combustion chamber - it is much larger near the fireplace. In addition, heating a private house with a wood-burning boiler sometimes implies the presence of a hob in the design.

Heat exchanger in furnace

As you can see, the choice of option directly depends on the area of \u200b\u200bthe house. It should be borne in mind that the wood heating scheme can be upgraded. It is enough to install a heat exchanger in the furnace to make it possible to make a full-fledged water heat supply.

But the most common option is to install a wood-burning boiler for home heating. It is much more practical and easier to operate than a fireplace or stove.

For the normal operation of wood-burning heating of a country house, it is necessary to think over the chimney system in advance. The optimal diameter of the pipe and its height are taken into account.

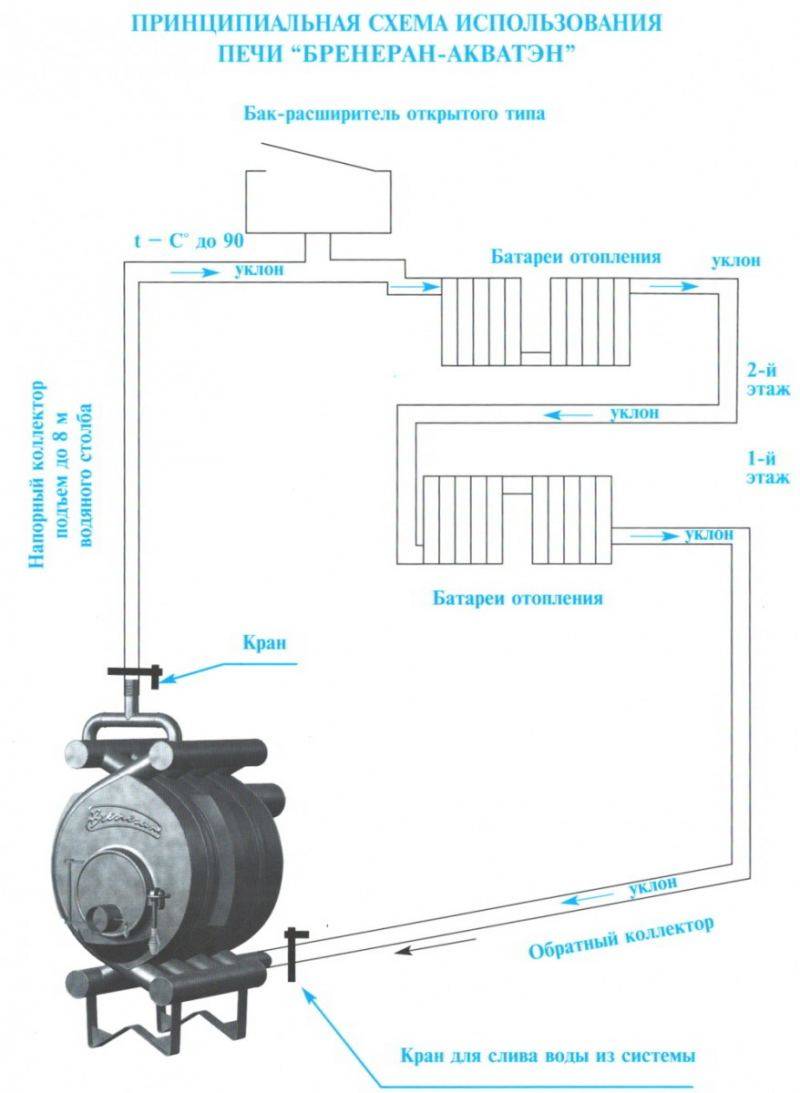

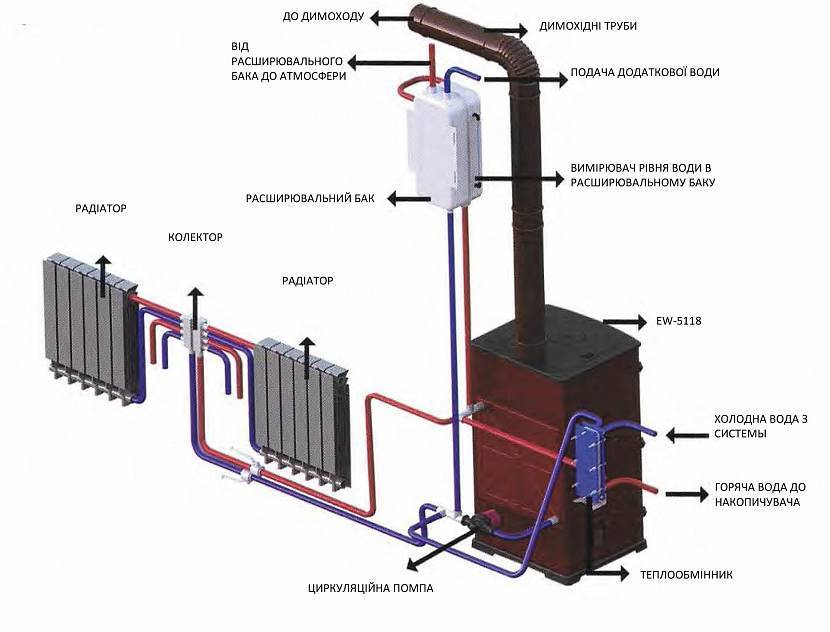

Features of the device and the choice of the circulation scheme

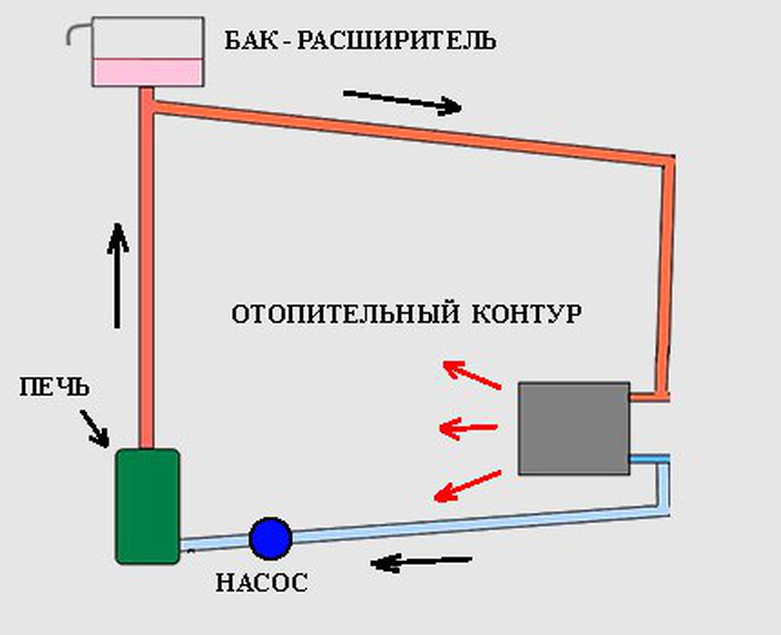

Circulation is based on one of the following methods:

- The natural process is based on the difference in density between hot and cold water. In the process of heating, the density of the liquid decreases, the specific gravity decreases, and therefore it begins to move up the pipes. As it cools, on the contrary, the density increases, the solution tends to go down. The main advantage of this method is absolute autonomy, independence from electricity, as well as constructive simplicity. The main disadvantage is the increased consumption of materials, the circuit consists of a large number of pipes of impressive diameter. In addition, during installation, a slope of approximately 2 degrees must be maintained.

- Heating system of a one-story house with a circulation pump.Excess water, which inevitably forms during heating, is inside a special expansion tank, usually closed, which prevents the phenomenon of evaporation. Additionally, pressure gauges are required to control the pressure. The advantages of such a scheme are the minimum required volume of coolant, the small diameter of the pipes and their lower consumption. The main disadvantage is the dependence on electricity supply, which is often a problem for the private sector.

- Combination. The pump is installed in an already made circuit with natural circulation. This option works without a pump, but with its inclusion, power and efficiency increase significantly.

Several popular oven models

Among the most popular models of stoves for heating houses and cottages are the following:

Furnace for home TOP-model 200 with a cast-iron door from a domestic manufacturer Teplodar. Provides high-speed convection heating of rooms and maintains heat in the long burning mode up to 8 hours. Suitable for heating houses up to 200 cubic meters. The stove is made in a laconic style and therefore will perfectly fit into any interior.

Termofor Fire-battery 7 - wall-mounted unit with a capacity of 10 kW, can heat a room with a volume of 15 cubic meters. meters. The appearance is similar to a swollen cast-iron heater with powerful fins. The transparent fuel door is a viewing window through which you can observe the flame of fire. The design includes a hob.

Breneran AOT-06/00 is a floor model for home or summer cottages. For heating efficiency, the structure is reinforced with hollow pipes. With only 6 kW of power, the stove will make a warm room up to 100 square meters. meters.The volume of the combustion chamber is 40 liters

Her design is unusual, will attract the attention of exotic lovers.

META Angara Aqua is a fireplace type stove equipped with a large transparent firebox door reinforced with three glasses. Firewood shelves included

A 13 kW unit will easily heat up to 230 cubic meters. meters. Can be installed in large households, as it is possible to connect a water circuit.

There are hundreds of thousands of models of heating stoves on the market. These samples are considered the best stoves for a wood-fired home, they are most often chosen by consumers. Each of the models fits certain requirements and has its own price category.

Advantages and disadvantages of heating from a stove

Furnaces with a water circuit are easy to make on your own, but you can buy ready-made heating appliances in the store. Models are characterized by the following advantages:

- Furnaces with a water circuit do not need to be connected to the mains. They do not use gas as fuel. The appliances run on coal, peat and wood, which are renewable fuels.

- Furnace water heating is completely autonomous, while it can be combined with other systems.

- Adjustment is carried out by a manual damper.

- The walls of the furnace are massive, they transfer heat, heating the air and surrounding objects. The room is heated evenly through the use of coolant. It passes through the pipes, heating them and radiators.

- Heating a private house does not require large expenses. Coal, peat and wood are available to everyone.

- Furnaces not only heat the room, they are used for cooking and heating water.

- Devices, the front of which is covered with glass, allow you to contemplate an open flame. Fireplaces create a comfortable atmosphere in homes.

- The design of the furnace is massive, in the cold season it accumulates a large amount of thermal energy. The stove cools down gradually, so it heats the room for a long time after the fuel burns out. In summer, the processes proceed in the opposite way. If the stove in a wooden house is built on a separate foundation, during the warm season it removes excess heat into the ground, working as an air conditioner.

- The natural fuel that the stove runs on moderately pollutes the environment.

- Water is used as a heat carrier. It has a volumetric heat capacity, which allows heat to be transferred over long distances. Water is affordable. It does not burn, it is not toxic.

But furnaces with a water circuit also have disadvantages. It is necessary to constantly monitor them, lay firewood in time and regulate traction. The chimney should be cleaned and the ashes removed.

A powerful brick oven is large, so it is placed on a solid foundation. It occupies the usable area of the room, because of this, large structures are installed in spacious rooms. Such a furnace has a low efficiency.

When installing the stove, you need to build a chimney. The draft must be strong, then the fuel burns intensively, and the smoke is quickly brought out. The pipe is isolated from the wooden elements of the roof and floors. Having installed a furnace in the house, it is necessary to maintain a supply of fuel, dispose of ash and slag in time. This adds work to the owners of a private house.

The main disadvantage of water heating can be called the fact that the water quickly freezes. Turning into ice, it expands, damaging the devices. Combining with air, it contributes to the appearance of corrosion on the metal elements of the heating system.If the water is hard, scale will form inside the radiators and pipes.

Technology for installing water heating in a conventional wood-burning stove

The design of the furnace with a water circuit contains instructions for its location and dimensions

It is important to consider how the interior partitions and furniture are located. For large structures of considerable weight, a solid foundation of concrete is laid.

The base of the stove and the finishing material on the floor must be separated by a protective indent to protect against fire.

For the implementation of the masonry, a special mortar and high quality bricks are used. Given the complexity of preparing the mixture and the quality requirements, it is sometimes more reliable to purchase it ready-made. The foundation needs mandatory waterproofing. Before laying the bricks, it is recommended to immerse them in water for a day. Armed with the dimensions of the masonry elements, they select the appropriate order.

A register coil is mounted inside the structure under construction: the supply and return pipes are subsequently switched to it. One of them serves to supply hot coolant through the expansion tank to the system. The second pipe is a channel for returning the cooled liquid back to the register. The movement of water is provided by gravitational forces. The dimensions of the connecting seams are allowed within 4 mm. It is necessary to ensure that there are no sharp corners inside the firebox and chimney. It is better to use rounded connections that do not affect the efficiency of smoke extraction. This will significantly reduce the amount of soot formed in the firebox.