- Selection of materials for installation

- Cast iron pipes

- plastic pipes

- PVC pipes

- Polypropylene pipes

- Polyethylene pipes

- Outdoor sewer system

- open way

- Hidden way

- External sewerage

- Installation of a drain well

- Installation of a septic tank

- What level of sewer slope to withstand

- Laying pipes of external sewerage

- Errors in the installation of sewer pipes

- Installation of branch lines

- Primary requirements

- The purpose of the water seal in the sewer system

- Ventilation of sewer risers

- Do-it-yourself work

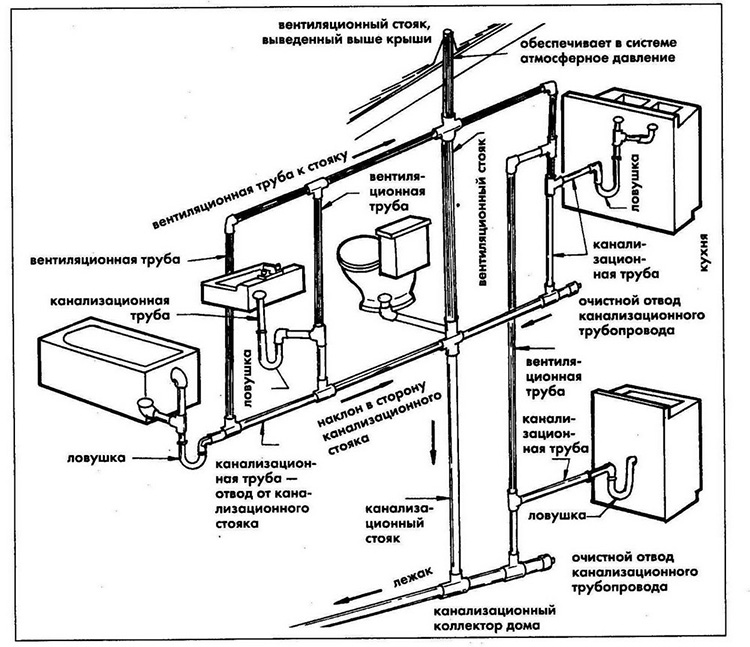

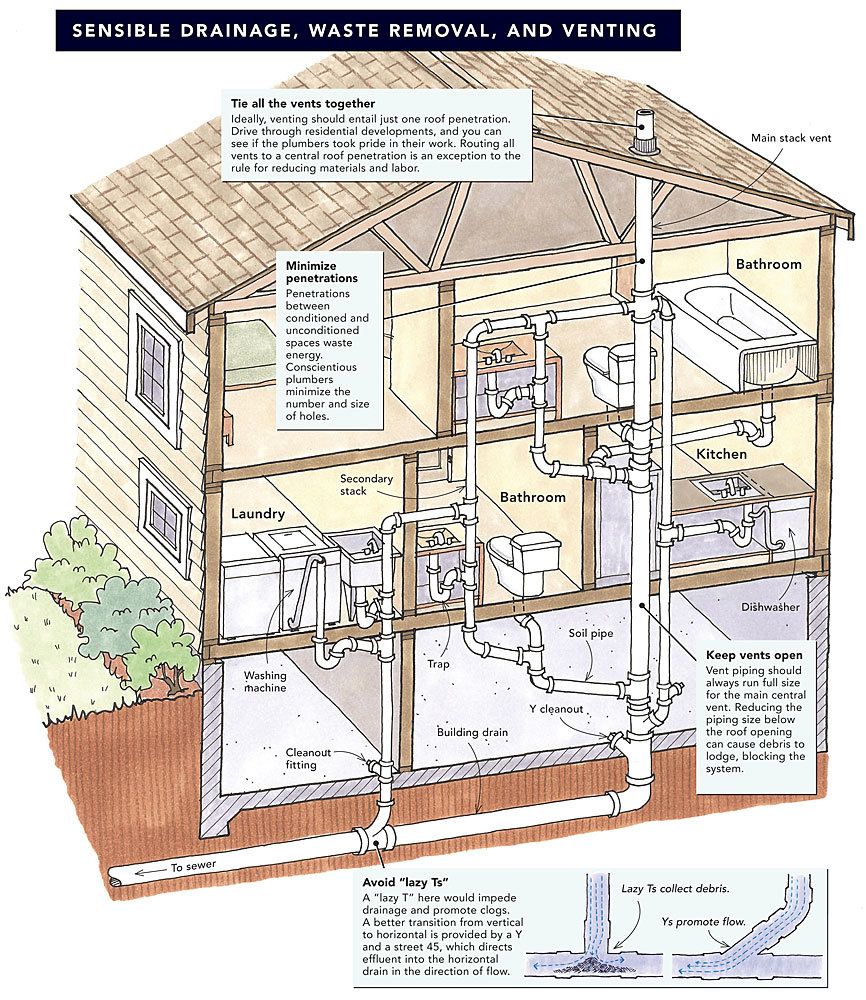

- Scheme of the sewer system

- Self-assembly

- Paving depth

- Pressure sewer elements

- Pipe selection

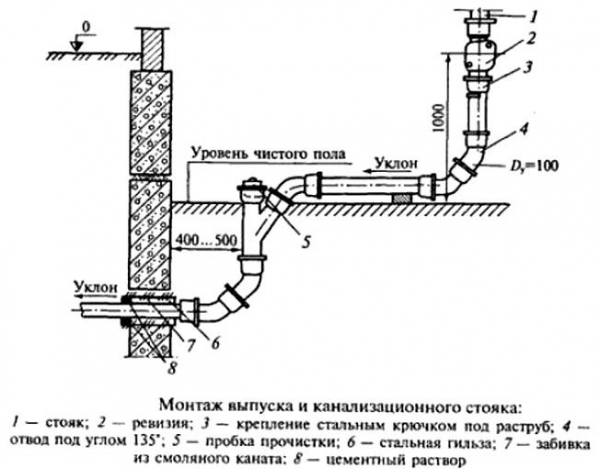

- The sequence of work during the installation of internal sewerage

- Execution of work

- Installation of plastic pipes with glue

- Installation of plastic pipes by welding

- General installation rules

- Sewer risers without hoods brought out above the roof

Selection of materials for installation

There is no unanimous opinion about which sewer pipes to choose after all. Each material has positive and negative sides. Consider the main materials that can be used when laying sewer pipes underground.

Cast iron pipes

Despite their strength and heat resistance, cast iron pipes are rarely used today. Developers have switched to new standards due to several reasons, the main of which is the susceptibility of cast iron to corrosive processes.

An alternative to cast iron pipes is ceramic, iron, and steel. Of the minuses, the complexity of the installation stands out, and the difficult replacement in case of damage. The inherent roughness of cast iron contributes to the adhesion of dirt to its internal walls, which over time will complicate the passage of water.

plastic pipes

Construction companies offer several varieties of plastic pipes: polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), cross-linked polyethylene (PEX), and metal-plastic pipes. The following types are used for installation:

PVC pipes

Pipes made of polyvinyl chloride are used for both the external and internal parts of the sewer system. PVC pipes are used in many areas of activity, and are also suitable for sewer installation.

This material is recommended by building codes and regulations (SNiP). The advantages of PVC pipes include:

1) Resistant to corrosion and decay;

2) Installation of PVC pipes does not require special tools;

3) Pipe connections are sealed;

4) Low cost compared to metal pipes.

Polypropylene pipes

Pipes made of polypropylene have proven themselves positively in recent years. With its low weight, the pipes do not corrode and are resistant to mechanical stress. Calmly react to lower temperatures. The smooth surface prevents dirt from sticking to the pipe walls. Resistant to household chemicals. The disadvantages of polypropylene pipes include:

- Low flexibility of pipes;

- Pipes are made in the form of measured pieces. The need for a large number of connection elements complicates the installation;

- Sealing of joints is possible.

Polyethylene pipes

Polyethylene pipes are light in weight, which facilitates the transfer of material. Smooth inner walls prevent clogging. The flexibility of the material saves on connecting parts. The service life is from fifty years. The material is not exposed to corrosive processes and household chemicals. Withstands hydraulic shocks. Compared to metal and concrete counterparts, the price of polyethylene pipes is lower.

Outdoor sewer system

The laying of the external pipeline can be performed both before the assembly of the internal one and after. To start the installation, it is enough to have an installed home sewer outlet pipe, since the installation begins with it.

However, before assembly, it is necessary to decide on the method of laying the external pipeline. The outer part of the sewer can be carried out in an open and hidden way.

open way

This method consists in laying pipes in prepared trenches and backfilling. All the necessary work on digging trenches and installing the pipeline can be done by hand. Of the special equipment, only an excavator may be required if the length and depth of the sewerage system are large, and you want to save your own strength. However, it is possible to lay a drainage system in an open way only on a relatively empty area without trees and outbuildings.

The order of work in the presence of the project is as follows:

- They dig, clear stones and tamp trenches.The depth must be below the freezing level so that the sewage does not freeze during the cold season. If the pipeline is planned to be insulated, the depth of the trenches is made at least half a meter. The width of the trenches is 40 cm larger than the diameter of the pipes used, the slope is 1-3 cm per linear meter.

- Sand is poured into the trenches and tamped down - a shock-absorbing pillow is obtained that will support the pipe in the correct position.

- Collect the pipeline from the outlet pipe of the domestic sewer to the installation site of the well.

- Fall asleep layers of side shock-absorbing pillows and tamp them down.

- Perform backfilling without tamping: first sand, then earth.

Hidden way

On a personal plot there may be obstacles that interfere with earthmoving: trees, buildings and other landscape objects. In this case, it will not be possible to lay the sewerage in an open way, so you have to turn to specialists who can lay the pipeline without violating the integrity of the soil.

The hidden method of laying sewers is otherwise called the puncture method.

- With a special drilling rig, a pilot well is laid underground from the location of the well to the domestic sewer pipe.

- Expand the well to a diameter 1.5 times the cross section of the pipeline.

- Attach the end of the pipeline to the nozzle at the end of the drill and pull it into the well.

External sewerage

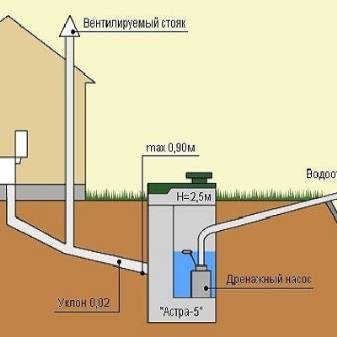

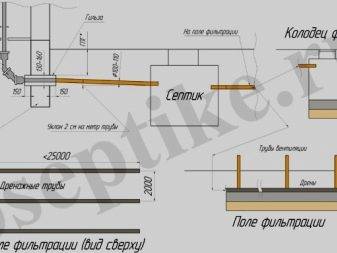

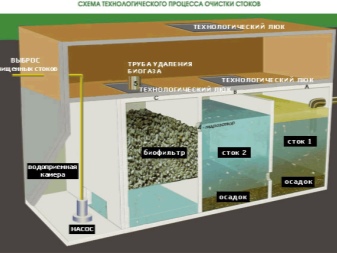

Scheme of the sewerage system

The external elements of the sewerage include sedimentation tanks, wells and supply pipes. The term of creation and features of operation directly depend on the type of system you have chosen.

The following factors influence the placement of any of the selected options:

- how deep is the sewage

- relief of the local area

- how hard does the soil freeze in winter

- availability of wells in the area

- soil structure

- passage of other communications on the site

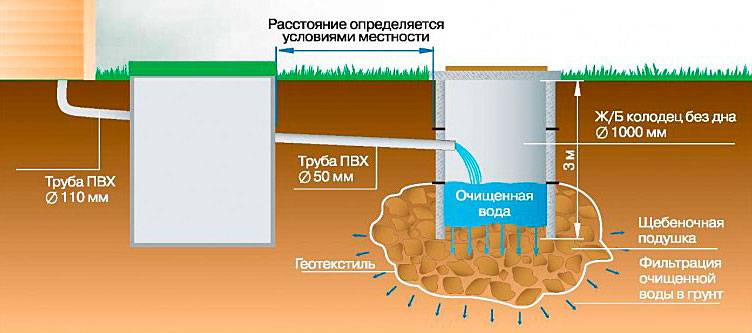

Installation of a drain well

sewer well

The easiest option for external sewage is a drain well. How to make it with your own hands?

- Decide where to dig the hole for the well. The well should be located slightly lower than the house

- Dig a supply channel from the house to the pit and the pit itself

Choose the material for lining the walls of the tank - Collect a well, bring a pipe from the house

- Fill in the moat and mount the cover for the tank

The most common tank wall materials are:

- ready-made concrete rings or blocks. For the installation of such structures, lifting equipment is required.

- monolithic structures. In this case, the prepared pit is poured with concrete using metal fittings. There are monolithic septic compartments.

The drain well can be airtight and screening. If you choose airtight, then the bottom of the pit will also need to be laid. At the bottom of screening wells, as a rule, crushed stone or pebbles are poured so that they pass part of the runoff into the soil.

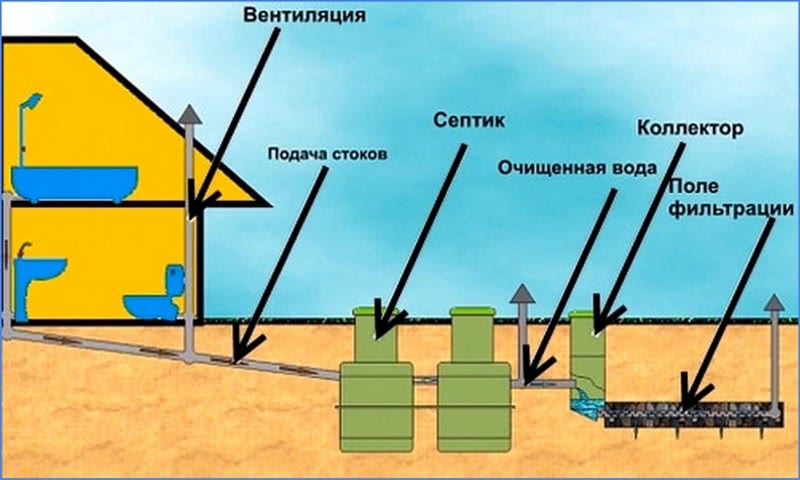

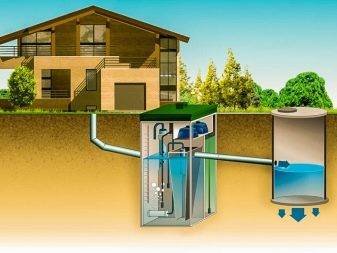

Installation of a septic tank

Installation of a septic tank

Installation of a septic tank

Before starting the construction of a septic tank, you need to prepare its project. The project must take into account the volume of the future structure, take into account construction and sanitary standards. Those who are faced with a similar problem for the first time are advised to seek help in drafting a project from specialists. But you can try to make a project yourself

The most important part of the preparation is the calculation of the volume of the septic tank compartments.In order for wastewater treatment to be carried out as efficiently as possible, wastewater must be in the drain chamber for 3 days. You need to calculate the volume of drained liquid according to the number of people living in the house

Preparation of pits, ditches. Roem a pit for cameras and a ditch from the house for a pipe

We determine the material for septic chambers

Camera assembly. We mount cameras in the pit

Pay special attention to the tightness of the compartments, the joints must be sealed, well sealed

Connection. At the final stage, we connect the pipes to the septic tank and conduct a test

It is necessary to take into account the norms for the placement of waste structures on a personal plot

The most common materials for septic chambers:

- ready-made concrete rings or blocks. For the installation of such structures, lifting equipment is required.

- monolithic structures. In this case, the prepared pit is poured with concrete using metal fittings. Monolithic septic compartments exit

Water filter for the country house: flow, main and other filters (Photo & Video) + Reviews

What level of sewer slope to withstand

Going into more detail in this article of the construction magazine at the level of the slope of the sewer pipes, it should be noted that errors in this lead to the most problems. Firstly, with a small pipe slope, the drains cannot independently move to the riser under the influence of gravity, so the pipes become clogged from time to time.

Secondly, as a result, sewer pipes can leak, especially if they are poorly sealed at the joints. Thirdly, an unpleasant smell may appear in the room, due to the fact that the drains are constantly in the pipes.

That is why it is so important to observe the correct level of slope of sewer pipes. With all of the above, you should be aware that too large an angle of the sewer clone is also not very good, due to the constant noise when draining the toilet or sink

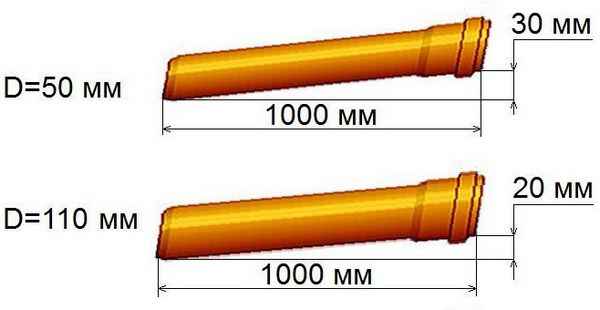

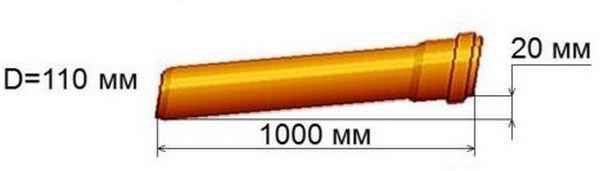

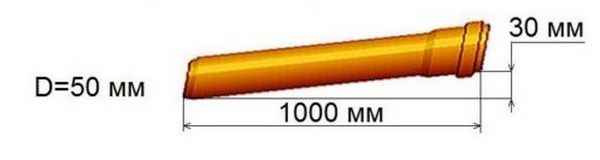

The correct sewer slope level should be at least 3 cm per 1 m for a 110 pipe, and at least 2 cm for a pipe 50 mm in diameter. Max level slope for pipes should not exceed 15 cm by 1 m. Otherwise, it will make a lot of noise while draining the sewer.

Laying pipes of external sewerage

Restrictions on the location of sewer facilities:

- from 5 m from the dwelling;

- from 20 - 50 m from a source of clean water;

- from 10 m from the garden.

The private building is removed for:

- 8 m from wells-filters;

- 25 m from filter fields;

- 50 m from aeration treatment equipment;

- 300 m from drain systems.

Water pipelines to the septic tank are insulated so that they do not freeze in winter with a heat insulator and are placed in asbestos-cement structures. External wiring is made by elements with a section of 10 - 11 cm, whose slope is 2 cm by 2 m. It is desirable to lay components without turns and corners.

Errors in the installation of sewer pipes

Firstly, so that the pipe is not pressed through with soil, it must first be covered with a layer of sand, the thickness of which would be at least 15-20 cm. Secondly, inspection wells with installed revisions on the pipes must be mounted after a certain distance. In this case, it will be possible to clean the sewer pipes from blockages.

Thirdly, we must not forget about the necessary slope of the sewer pipes, which should be approximately one centimeter per meter.The quality of the sewer system and its uninterrupted operation in the future directly depend on this.

When assembling sewer pipes, errors often occur due to poor-quality sealing of the seams. For sealing the seams of the sewer pipe it is recommended to use silicone sealant, which not only seals the joints well, but also allows you to quickly put a bend or tee on the pipe (used as a lubricant).

In this case, the rubber bands (seals) must be absolutely intact and not have any defects. They need to be able to properly put on the socket of the pipe, if they are one-sided. Otherwise, the seam of the sewer pipe will definitely leak.

Installation of branch lines

Sewerage wiring in a private house is one of the most important places. The branch line must be at least 1 meter long and not more than 10 meters long. Complex systems are always a big minus, since when clogging any area, you will have to disassemble many connections to determine the problem area. The first rule that a novice builder needs to remember is that the exit diameter must be exactly the same as at the connection point. That is, 1 branch line must consist of the same pipe, expansion or contraction is not allowed.

The sawing is carried out only perpendicularly, without chips, surfacing, "jambs" or other "improvements" to the grief of the masters. The use of PVC material is allowed, but undesirable, you need to buy reinforced plastic - it is much more reliable. The sewerage slope in a private house on branch lines should be as follows: 0.3% or 0.003 ppm (3 centimeters per 1 mp) for a pipe Ф50 mm, and 0.2% or 0.002 ppm for a diameter of 110 mm.It is impossible to make a smaller slope, since sediment will constantly accumulate, more is also impossible, in order to avoid strong cotton.

Primary requirements

In order to avoid any problems in the process of creating a sewerage system in your own home, it is best to follow as much as possible in this process all the requirements and standards that are described in the regulatory documentation - SNiP. In this case, everything will definitely function flawlessly for a long period of time.

In any building where a water pipe is laid and there is a water intake, a system must be made that will remove the runoff masses. Mechanisms for drainage should also be created at the sites. In general, such a network can not only provide a comfortable life, but also do not harm the environment, and will also significantly increase the time of using the building.

Typically, sewerage consists of the following systems:

- storm, which diverts water;

- outdoor;

- internal.

They must be laid in such a way that various building sanitation requirements for sewerage in your own home are met.

Among these requirements are:

- ensuring normal cleansing;

- no risk of flooding the building;

- ensuring the required volume of wastewater;

- tight accumulation and transportation of sewage.

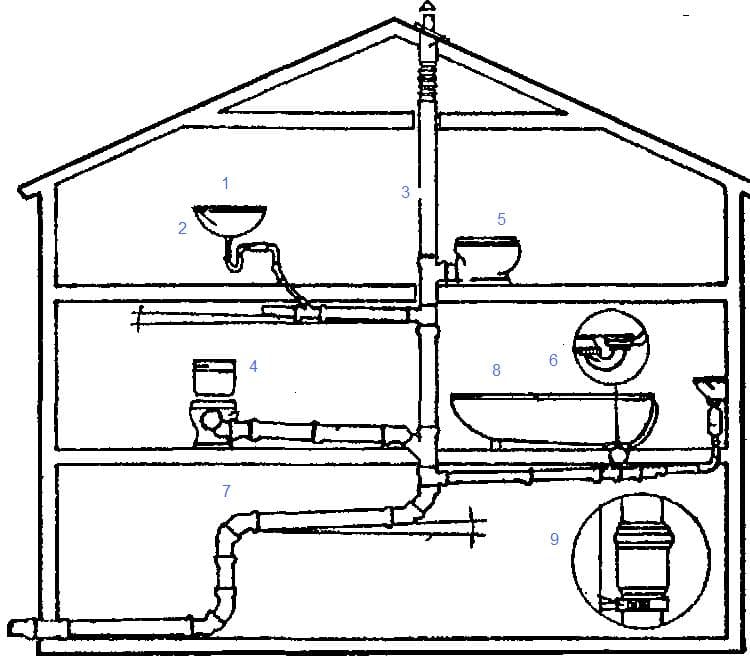

If we talk about the requirements for internal systems of this type, then they should consist of the following elements:

- a riser to which all pipes are attached;

- dilution of pipes, which pumps wastewater in the direction of the riser;

- plumbing fixtures for drainage.

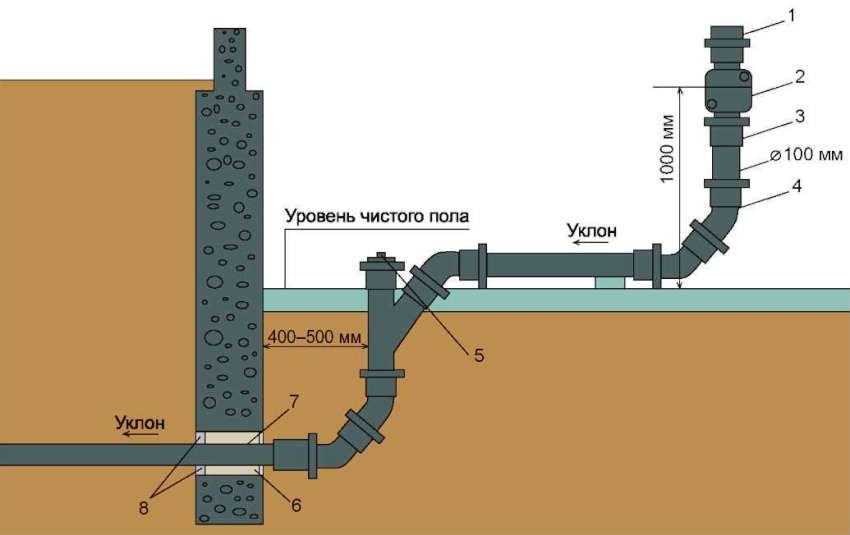

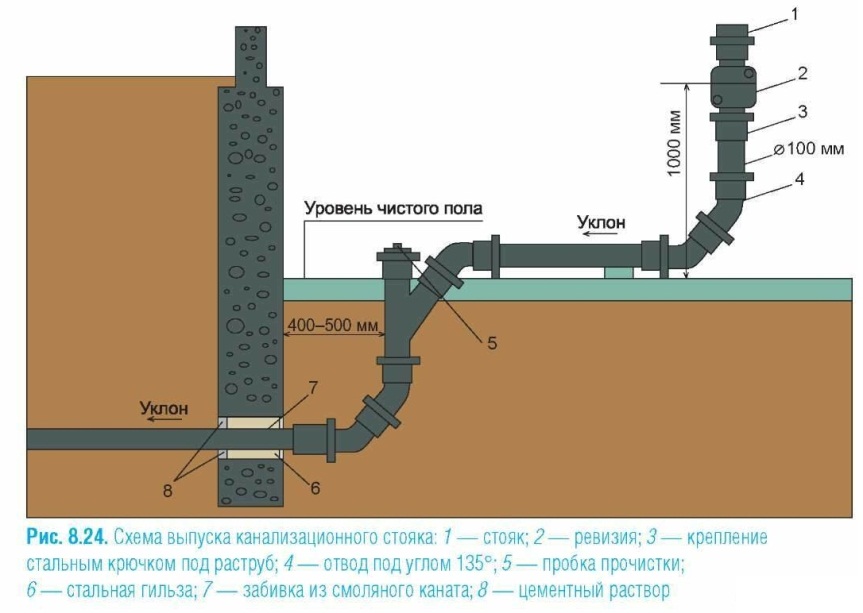

According to the norms, in the mechanism, part of which is located in the building, there must be enough space for the free transportation of liquid from the places where the drain is carried out to the pipes that lead out of the building. When laying sewers inside the building, pipes made of cast iron or some kind of polymers are used. At the outlet, the size of such a pipe should be 11 centimeters. Naturally, in this mechanism there must also be ventilation. Usually it is carried out through the riser. Above each element, an exhaust space is made that overlooks the roof.

If we talk about the project of external systems, then its creation is carried out taking into account the requirements prescribed in SNiP number 2.04.03-85.

The following points should be taken into account in this document:

- wells for maintenance and cleaning should be installed in the mechanism;

- to clean up effluents, an installation using biomethods is needed;

- if we are talking about a gravity network, then polymer, ceramic or asbestos-cement pipes are used;

- pipes that are located outside the boundaries of the building should be about fifteen centimeters in diameter and laid at the level of ten to twelve centimeters;

- if there are few floors in the building, then several houses can be combined into a single network;

- if it is impossible to arrange a gravity system, then it is better to opt for a pressure sewer.

Another important point is the choice of design

This is really important when designing an autonomous sewer network.

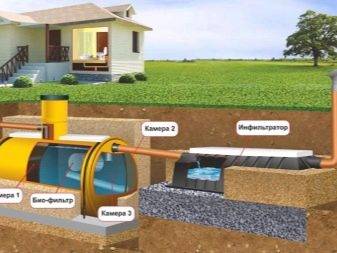

There can be three options for septic tanks that are used:

- aeration tanks;

- storage septic tank;

- treatment.

Now let's talk about them a little more. Aerotanks are the latest solutions using several cleaning methods.After using such a septic tank, the liquid is cleared to almost 100 percent. Water can be easily drained into the ground, a reservoir and used for irrigation. The storage category septic tank is an improved version of the cesspool, in which cleaning is not carried out, but only drains are collected. When the septic tank is filled to a certain level, it becomes necessary to clean it. This is usually done with the help of special sewage equipment.

If we talk about the differences from the cesspool, then no filtration into the soil in this case is carried out. This means that no harm is done to the environment. But still, this type of septic tank has been used extremely infrequently in recent years due to the high cost of the cost of services of special sewage equipment. This type can be used only if you live in the house relatively infrequently.

Treatment septic tanks are used not only for accumulation, but also for the purification of sewage. As a rule, at first, the effluents in them are settled, after which decomposition occurs at the biological level with the help of special bacteria - anaerobic and aerobic, which are specially added to the ground for this purpose.

For this reason, the best types of soil for this category of septic tanks will be sandy and sandy loam. If the earth is clay, then it is better to use another septic tank, although this option is not prohibited in this case. It’s just that then the installation of a septic tank will turn out to be too expensive, since there will still be the necessary special installation to create filtration fields.

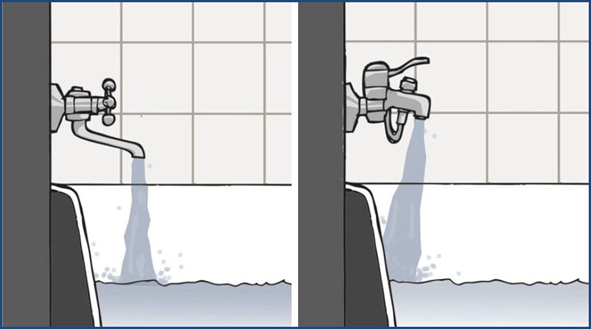

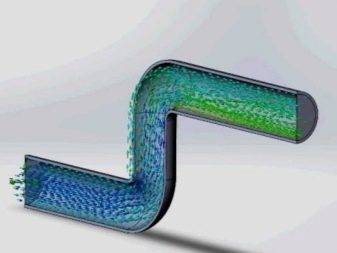

The purpose of the water seal in the sewer system

Drains and sewage have an unpleasant odor, but they are absent in the apartment, due to the presence of water seals in plumbing fixtures. They are a water plug formed as a result of the difference between two pipes relative to height. There is always water in the pipe, completely covering it in cross section, even when the plumbing is not in use. This water barrier prevents sewer gases from penetrating pipes into the room. After draining, the old water plug is replaced by a new one.

To avoid drying out of the water seal, a little vegetable oil is poured into the drain holes before leaving. It forms a film and thus prevents the liquid from evaporating. Toilets and bidets have water seals. "Replacement of sewers in do-it-yourself apartment».

For connecting kitchen sinks, showers, bathtubs and sinks to the sewer system use siphons, which have dual functions:

- water seal;

- connecting element between the pipe and the plumbing fixture.

Solving the question of how to make a sewer in an apartment is an important stage in preparing for repair work. But for this you need to have a clear idea of \u200b\u200bhow the sewer system functions during its operation.

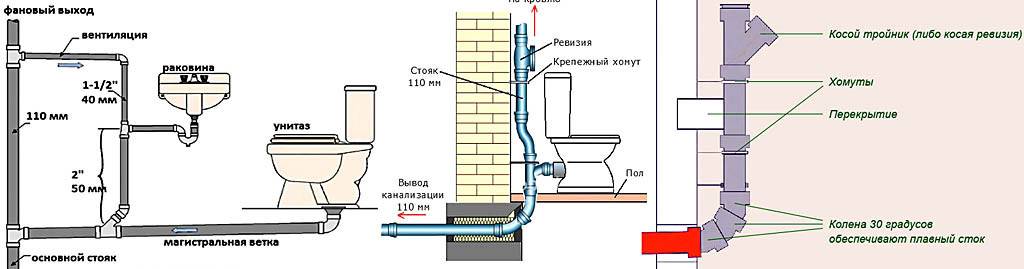

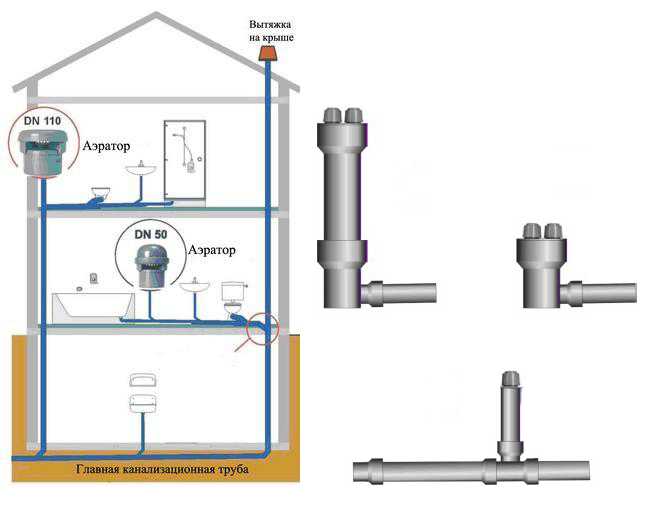

Ventilation of sewer risers

In order to avoid discharge in sewer pipes and reverse flow of sewage, the sewer riser should not have a blind upper end - the vertical sewer pipe must be led out on the roof for ventilation.

Network ventilation must be provided through ventilation risers connected to the highest points of pipelines.

Domestic and industrial sewer networks that discharge wastewater into the external sewer network must be ventilated through risers, the exhaust part of which is brought to a height: through the roof or prefabricated ventilation shaft of the building:

a) from a flat unused roof ………. 0.3 m;

b) pitched roof ………………………………………….0.5 m;

c) operated roof …………………………… 3.0 m;

d) cutting edge of the prefabricated ventilation shaft …….. 0.1 m.

The diameter of the exhaust part of the sewer riser should be equal to the diameter waste part of the riser.

It is allowed to combine several sewer risers on top of one exhaust part.

Outlet diameter riser for a group of combined sewer risers a private residential building, as well as the diameters of sections of the prefabricated ventilation piping that unites the sewer risers, should be taken at least 100 mm.

Connection of an additional ventilation riser to the sewer should be provided from below below the last lower device or from above - to the upwardly directed process of the oblique tee installed on the sewer riser above the sides of sanitary appliances or revisions located on this floor. The prefabricated ventilation pipeline connecting the sewer risers at the top should be provided with a slope of 0.01 towards the risers.

The exhaust parts of the sewer risers brought out above the roof should be placed from the opened windows and balconies distance of at least 4 m (horizontally).

Attention! It is not allowed to connect the exhaust part of the sewer risers with ventilation systems and chimneys

Do-it-yourself work

To organize a sewerage device in a house with your own hands, you need a scheme with which you can calculate what types of materials and plumbing will be needed and in what quantity. The drawing must be drawn to scale.

You also need to take into account factors such as:

- Soil type;

- Groundwater level;

- Volume of water use;

- Climatic features of the area.

Several types of laying sewer pipes are possible: under the floor, inside the walls, outside, but this is less aesthetically pleasing. Pipes laid in walls or under the floor are plastered 2 cm or filled with cement. To reduce the noise of the system, the pipes are wound without air gaps.

Scheme of the sewer system

The sewer system in a private house has a complicated scheme; it must take into account, in addition to depth and materials, the location, taking into account the requirements.

Namely:

- To install a septic tank or other type of wastewater treatment, the lowest place on the site is selected.

- The distance to the source of drinking water is at least 20 m.

- To the roadway - at least 5 m.

- To an open reservoir - at least 30 m.

- To a residential building - at least 5 m.

Plastic pipes are well suited for arranging sewage

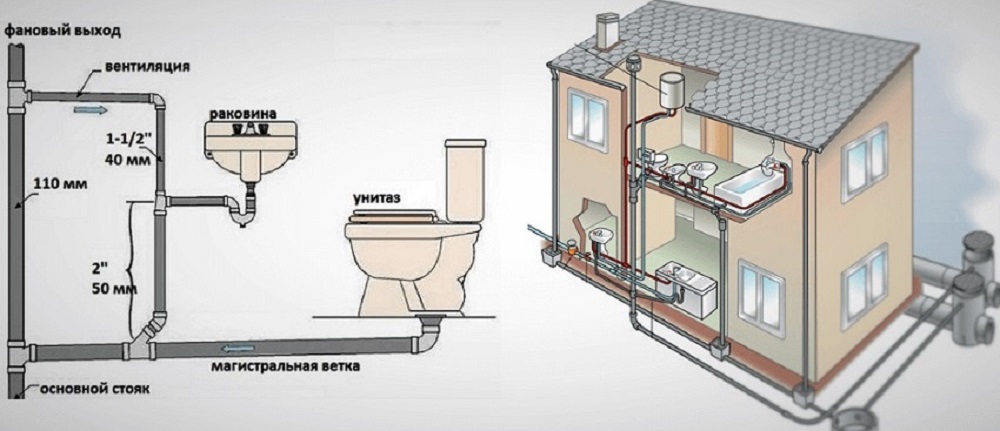

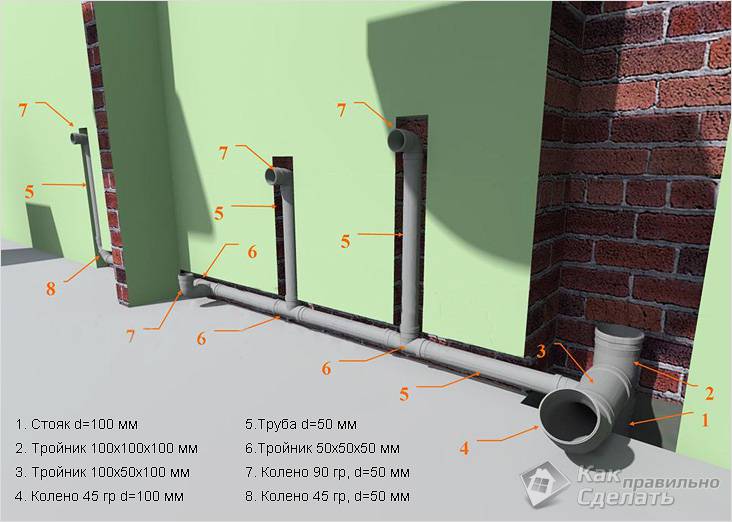

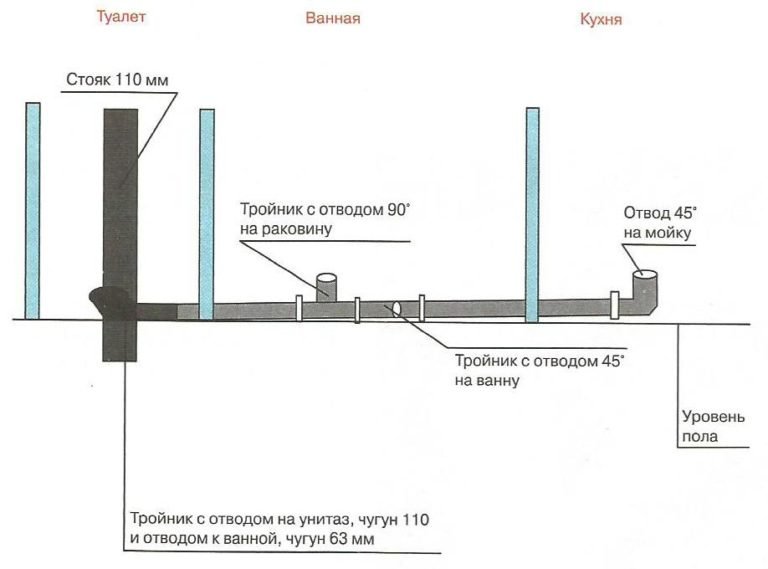

When drawing up a diagram, it is necessary to mark all the water drain points and the riser. The stand must be within easy reach. Usually it is installed in the toilet, because the toilet drain pipe has a diameter of 110 mm, like that of the riser.

Outflow pipes from the bathtub and sink are usually combined into one line.

It is important to remember that the toilet pipe should not have any inlets from other pipes. In addition, the diagram should include the location of the vent pipe.

Self-assembly

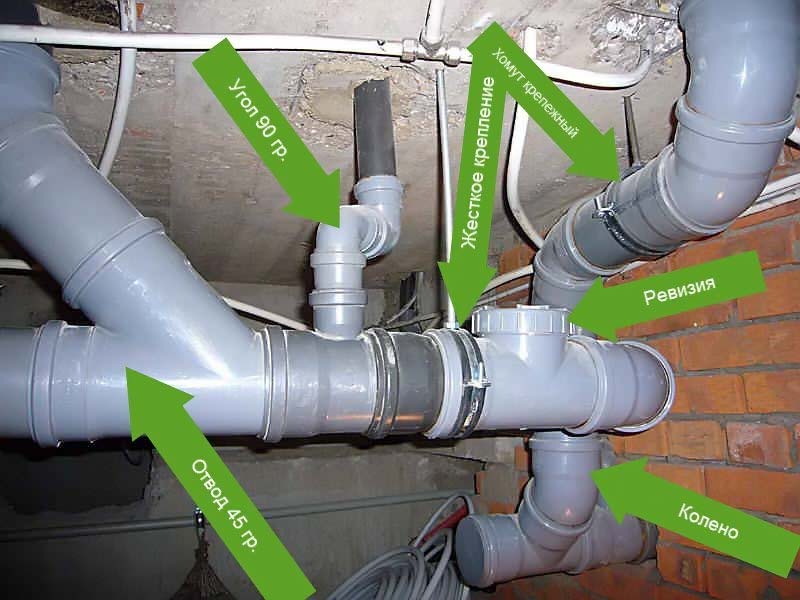

Do-it-yourself installation at home it is recommended to start with the inside of the sewer, as well as ventilation for it. The sewer system must contain hatches in the pipeline for inspection and repair. Pipes are fastened to the walls with clamps, hangers, etc. Crosses, tees and manifolds of large diameter (about 100 mm) must be used at the joints. Adapters will help to connect pipes of different diameters.

Ventilation is also important, which performs 2 functions at once - air inflow in rarefied areas, exhaust gases. Vacuum is more often formed when water is drained in the toilet bowl and when the pump for draining the washing machine is running. The influx of air prevents the capture of water in the siphon and the formation of a water seal, which has a loud unpleasant sound. Continuation of the riser on the roof is a fan pipe.

To install it correctly, you need to follow the rules:

- The diameter of the fan pipe is 110 mm to prevent ice blocking the passage.

- The height of the pipe on the roof is higher than the rest, including stoves, fireplaces, etc.

- Location at a distance of 4 m from windows and balconies.

- The fan pipe must be separate from the general ventilation and with a subsequent exit to the attic.

When arranging sewerage, safety regulations must be observed

Through a sleeve with a non-return valve, the collector in the foundation exits to the external sewer. The sleeve diameter is 150-160 mm. The reverse flow of wastewater in the presence of a check valve is not possible in the event of contamination of the pipeline or overflow of the wastewater receiver.

Paving depth

At what depth to lay the pipes depends on the deepening of the septic tank and the depth of soil freezing in the region. Moreover, pipes must be laid below this level.

They are laid according to the following scheme and rules:

- Lack of turns from the house to the septic tank to prevent blockages.

- Pipes of the correct diameter.

- The same pipe material in the same pipeline.

- Compliance with the slope (approximately 0.03 m per 1 linear).

If there is no slope or it has an insufficient degree, then you will need to install a sewer pump. Also, additional wells should be included in the external sewerage scheme, especially if there are pipeline turns from the house to the septic tank. They will help in the maintenance of sewers and the elimination of blockages or freezing.

Sewerage, like plumbing, is recommended to be supplemented with thermal insulation made of polyurethane foam and polyethylene or to lay an electric cable.

Pressure sewer elements

Pressure sewerage differs from gravity sewerage by the presence of additional equipment and consists of the following elements:

- pipeline from special pressure pipes;

- fecal pump or pumping station;

- well or container for collecting wastewater.

- The pump is placed in a well and pumps waste through pipes to the required distance and height.

On a note!

Pressure sewerage is done only in one case, when it is impossible to equip a gravity one.

The need to organize a pressure system depends on factors such as:

- the building is located below the level of the central sewer networks;

- it is required to make pipeline passages through a road or railway;

- the site has a different relief;

- the need to use pipes of small diameter.

Pipe selection

current

stores offer a wide selection of sewer pipes. Unlike

Soviet times, when there were no options other than cast-iron pipelines

was, today there is a wide choice of material:

- PVC (polyvinyl chloride);

- PPRC (polypropylene);

- HDPE (polyethylene).

Pipe selection

Pipe selection

Plastic pipes are much more convenient

in installation. They are lighter, equipped with connecting sockets with sealing

rings, look

much more accurate and do not need to apply a protective layer of paint. Lay horizontal

a system of such pipes is much simpler and faster. There are all necessary

connections, tees, crosses, etc. In addition, under the plastic pipeline

of any diameter, mounting clamps are sold that provide a secure fit

systems. This makes the montage

sewerage in the apartment is a quick and high-quality event.

Untrained people are often not

can determine the size (diameter) of sewer pipes. Exists

the generally accepted method of installing 110 mm pipelines in the toilet. Sewerage in the kitchen or

in the bathroom does not require such dimensions, 50 mm is enough. If none

there are no specific requirements, you can be guided by this rule.

The sequence of work during the installation of internal sewerage

Installation of the sewer system inside the house is carried out in the following order:

First, risers are installed, bringing their ends to the roof and to the basement. They should pass in the immediate vicinity of the toilets. In the basement, they are connected to an inclined pipe that goes out into the septic tank, and the upper ends are left open. or provided with check valves.

Secondly, they bring carts from toilet bowls to the riser. They must be separate.

Thirdly, they are connected to the risers from other devices above the entrances of the toilet bowls.

Fourthly, siphons are installed on all devices.

Fifthly, they connect the siphons with eyeliners.

On this, we can consider the installation of the internal sewerage system completed.

It is important that all joints are tight, and all pipes are rigidly attached to walls or ceilings, and their divergence would be excluded

In conclusion, let's say that a properly designed and assembled sewerage system will work all it needs for a long time without serious problems.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Execution of work

After carrying out all the preparatory work, you can proceed directly to the installation. First of all, you need to disassemble the old system. The work is carried out as follows:

- First, problem areas are identified in which additional work will have to be carried out. This may be the place where the pipe passes through the wall.

- With the help of a chisel, the dismantling of cast-iron pipes begins. At the same time, cast iron must not be allowed to enter the main line of the sewer system. Otherwise, it may malfunction.

Working with a cast-iron sewer is not the most aesthetic sight.

If the replacement of the main riser is not foreseen, then the pipe is sawn off from it with the help of a grinder.

After the dismantling has been made, work is stopped until the connecting nodes have completely cooled down.

Installation of modern plastic pipes can be done in two ways.

Installation of plastic pipes with glue

- pipes are cut into pieces of the required length;

- the edges are cleaned with sandpaper;

- the edges are degreased;

- pipes are checked for compatibility;

- glue is applied in the right places;

- processed elements are interconnected;

- when two pipes are compressed, a roller is formed, resembling liquid honey in color;

- The glue dries within an hour.

Installation of plastic pipes by welding

- installation also begins with cutting pipes of the required length and stripping;

- the soldering device is heated to a temperature of at least 260 degrees;

- connectors and a pipe are fixed on a soldering iron;

- parts are heated to the desired temperature;

Welding of plastic pipes

- pipes are connected in heated places;

- seams are checked for integrity.

General installation rules

Internal sewerage in a private house is equipped with a number of rules:

- The riser elements with a 90° turn are assembled from two plastic elbows rotated by 45°. If a cast-iron pipeline is installed, two 135 ° bends are used.

- In order to be able to eliminate possible blockages in pipeline sections, an oblique plastic or cast-iron tee is installed at 45 ° with a plug and one elbow or a cast-iron branch. Cast-iron fitting differs from plastic in names and gradations. For example, a 45° plastic elbow will fully match a 135° cast iron elbow.

- Branch pipelines, which are located in the basements, under the ceiling of the premises, are connected to the risers using crosses or oblique tees.

- The height from the lower section of the horizontal socket of the tee or straight cross to the floor should be no more than 20 mm.

- The length of the pipeline from the toilet to the riser should not be more than 1 m. For other plumbing fixtures - no more than 3.5 m.

- 90° crosses or straight tees can be used to make turns on risers or transitions to horizontal runs.

- To prevent the appearance of odors from the sewer in the room, an exhaust hood must be equipped. The so-called fan pipe is brought out through the roof to a height of about 0.7 m. It is unacceptable to connect it to a chimney or ventilation.

- If the installation of a fan pipe is not possible, a special air valve for sewerage is installed.

- The diameter of the riser must be equal to the diameter of the exhaust part. With one hood, you can combine two or even more risers on the top floor or in the attic. The horizontal sections of such a pipeline are fixed with hanging brackets or simply wire to the rafters.

- On risers that do not have indents in the upper and lower floors, revisions for the sewer are installed. The standard height of the revision arrangement is 1000 mm from the floor level. If the part has to be installed in the corner of the room, it should be turned at an angle of 45 ° relative to the walls.

- When installing the internal sewage system, all plastic pipes passing through the floors are installed in special metal sleeves. The height of the element depends on the width of the overlap. The top of the part should protrude 20 mm from the floor level, and the bottom should be flush with the ceiling.

- The riser is installed with a sleeve on. In order for it not to fall from the pipe, it is tied with a thin wire to the superior socket of the cross or tee, or bursting with pieces of foam.

- If it is assumed that a toilet bowl and other plumbing fixtures will be connected in series on a horizontal section, a sewer adapter must be installed between them. Plastic parts must not be turned high. This threatens with problems with the subsequent connection of equipment, especially with a shower or bath.On average, the turn should be carried out at half the socket of the tee in height with a direction towards the wall.

- Clamps are used to secure the sewer. Plastic pipes are fixed in horizontal sections as necessary, so that no fractures occur. On average, one clamp is installed per half meter - a meter of the length of the line.

- Cast iron pipes are mounted on steel brackets with a bend at the end, which prevent the pipeline from moving. Fasteners are installed under each pipe near the socket.

- The risers are fixed to the side walls with 1-2 clamps per floor. Fasteners are installed under the sockets.

It is important to note that at the end of the installation work, tests for tightness are mandatory.

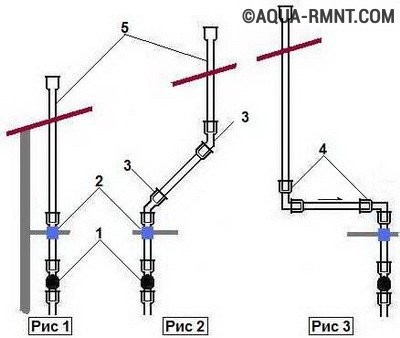

Fanovaya the pipe may be brought to the roof in various ways. On the The diagram shows three possible options. designs

For the arrangement of internal sewage, various connecting elements are used. It should be borne in mind that the same cast-iron and plastic elements may differ in names and markings.

Sewerage is a necessary element of any comfortable home. Its arrangement does not require special special knowledge, but, at the same time, it cannot be called a simple matter. There are many nuances and features of the arrangement of the system. Start with development piping plans, which will become the basis for subsequent work and will help to correctly calculate the amount of materials needed. Already at this stage, you can evaluate your strengths and understand whether you will be able to cope with the work on your own or you will need to look for assistants. Many companies specialize in providing plumbing services.Professionals will quickly and competently carry out the installation of a sewer system of any complexity.

(2 votes, average: 3.5 out of 5)

Sewer risers without hoods brought out above the roof

In this case, wastewater will not drain well. Since they do not have any opportunity to draw in air filling the entire section of the pipe (for example, flowing out of the toilet bowl), they will suck water out of the siphons instead of air (through the hood or aeration valve). In this case, sewer gases will enter the rooms.

In the house, at least one, the most distant, located from the drain outside the house, the sewer riser must have an exhaust hood above the roof

It is important that the height of the hood prevents backfilling with snow. It provides aeration of the installation and removal of sewer gases to the outside.

The rest of the risers can end with aeration valves.