- Buy parts on Aliexpress

- The principle of operation of devices

- The principle of operation of devices

- Assembly according to schemes

- About the principle of inductive heating

- Pros and cons of induction devices for heating water

- Advantages of induction type units

- Options for homemade devices

- We make a heating element from a pipe

- From a welding inverter

- Manufacturing instructions

- Blueprints

- Operation features

Buy parts on Aliexpress

|

Appliances that heat with electricity rather than gas are safe and convenient. Such heaters do not produce soot and unpleasant odors, but consume a large amount of electricity. An excellent way out is to assemble an induction heater with your own hands. This saves money and contributes to the family budget. There are many simple schemes according to which the inductor can be assembled independently.

In order to make it easier to understand the circuits and assemble the structure correctly, it would be useful to look into the history of electricity. Methods for heating metal structures by electromagnetic coil current are widely used in industrial production of household appliances - boilers, heaters and stoves. It turns out that you can make a working and durable induction heater with your own hands.

The principle of operation of devices

The principle of operation of devices

The famous 19th century British scientist Faraday spent 9 years researching to convert magnetic waves into electricity. In 1931, a discovery was finally made, called electromagnetic induction. The wire winding of the coil, in the center of which there is a core of magnetic metal, creates a magnetic field under the power of alternating current. Under the action of vortex flows, the core heats up.

Faraday's discovery began to be used both in industry and in the manufacture of home-made motors and electric heaters. The first foundry based on a vortex inductor was opened in 1928 in Sheffield. Later, according to the same principle, the workshops of factories were heated, and for heating water, metal surfaces, connoisseurs assembled an inductor with their own hands.

The scheme of the device of that time is valid today. A classic example is an induction boiler, which includes:

- metal core;

- frame;

- thermal insulation.

The features of the circuit for accelerating the frequency of the current are as follows:

- industrial frequency of 50 Hz is not suitable for home-made devices;

- direct connection of the inductor to the network will lead to hum and low heating;

- effective heating is carried out at a frequency of 10 kHz.

Assembly according to schemes

Anyone familiar with the laws of physics can assemble an inductive heater with their own hands. The complexity of the device will vary from the degree of preparedness and experience of the master.

There are many video tutorials, following which you can create an effective device. It is almost always necessary to use the following basic components:

- steel wire with a diameter of 6-7 mm;

- copper wire for the inductor;

- metal mesh (to hold the wire inside the case);

- adapters;

- pipes for the body (made of plastic or steel);

- high frequency inverter.

This will be enough to assemble an induction coil with your own hands, and it is she who is at the heart of the instantaneous water heater. After preparing the necessary elements you can go directly to the manufacturing process of the device:

- cut the wire into segments of 6-7 cm;

- cover the inside of the pipe with a metal mesh and fill the wire to the top;

- similarly close the pipe opening from the outside;

- wind copper wire around the plastic case at least 90 times for the coil;

- insert the structure into the heating system;

- using an inverter, connect the coil to electricity.

According to a similar algorithm, you can easily assemble an induction boiler, for which you should:

- cut blanks from a steel pipe 25 by 45 mm with a wall no thicker than 2 mm;

- weld them together, connecting them with smaller diameters;

- weld iron covers to the ends and drill holes for threaded pipes;

- make a mount for an induction stove by welding two corners on one side;

- insert the hob into the mount from the corners and connect to the mains;

- add coolant to the system and turn on the heating.

Many inductors operate at a power not higher than 2 - 2.5 kW. Such heaters are designed for a room of 20 - 25 m²

If the generator is used in a car service, you can connect it to a welding machine, but it is important to consider certain nuances:

- You need AC, not DC like an inverter. The welding machine will have to be examined for the presence of points where the voltage does not have a direct direction.

- The number of turns to a wire of a larger cross section is selected by a mathematical calculation.

- Cooling of working elements will be required.

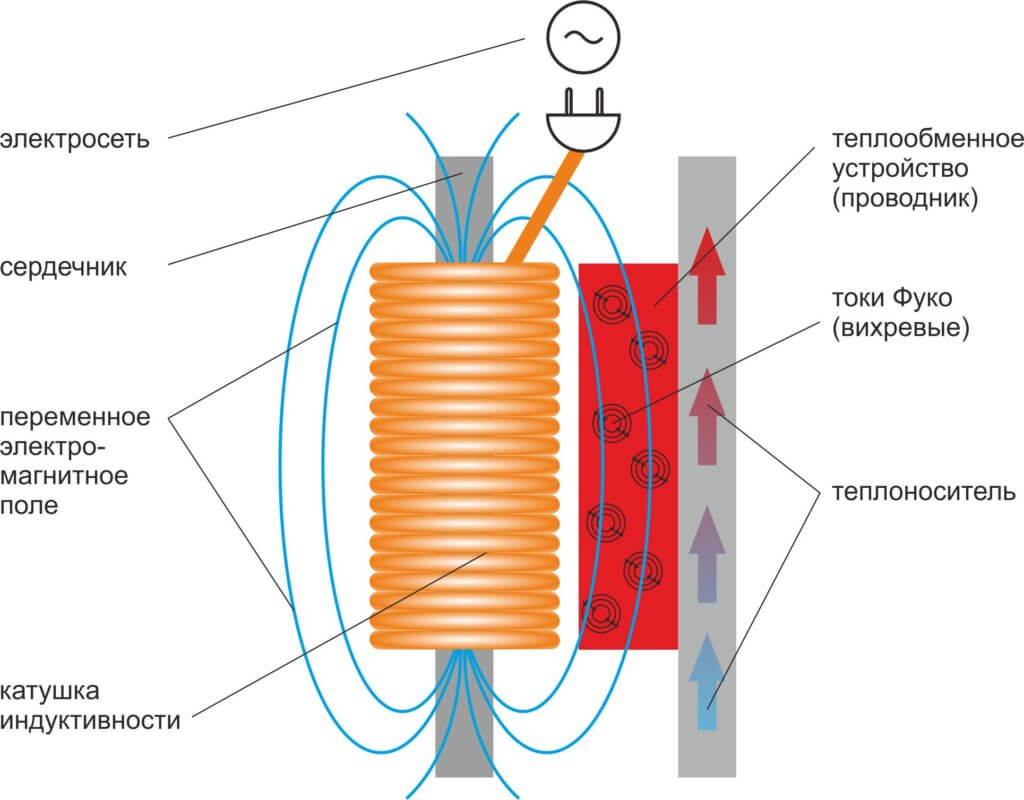

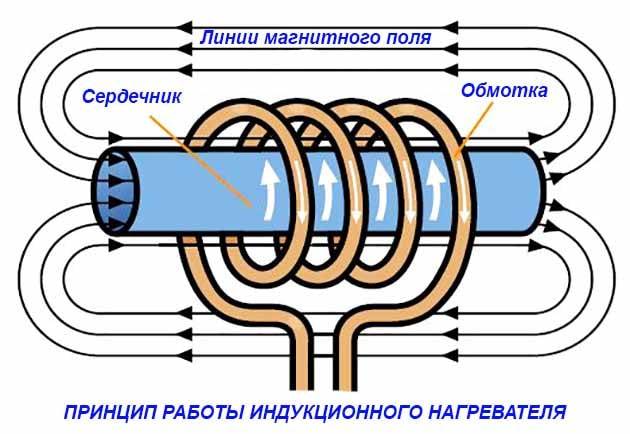

About the principle of inductive heating

First, let's explain how electric induction heaters function. Alternating current, passing through the turns of the coil, forms an electromagnetic field around it. If a magnetic metal core is placed inside the winding, then it will be heated by eddy currents arising under the influence of the field. That's the whole principle.

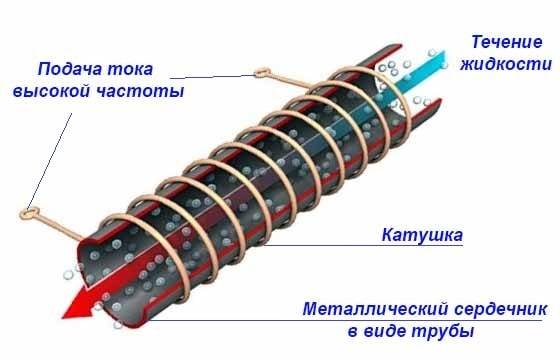

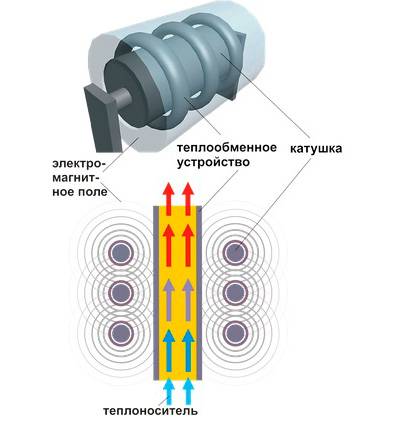

The heating element itself is called the inductor and is the main part of the installation. In heating boilers, it is a steel pipe with a coolant flowing inside, and in kitchen stoves, it is a flat coil as close as possible to the hob, as shown in the photo below.

The second part induction heater - diagram, increasing the frequency of the current. The point is that the voltage industrial frequency 50 Hz unsuitable for such devices. If you connect the inductor to the network directly, then it will begin to hum strongly and slightly warm up the core, and together with the windings. In order to effectively convert electricity into heat and completely transfer it to the metal, the frequency must be increased to at least 10 kHz, which is what the electrical circuit does.

What are the real advantages of induction boilers over heating elements and electrode boilers:

- A part that heats water is a simple piece of pipe that does not participate in electrochemical processes (as in electrode heat generators).Therefore, the service life of the inductor is limited only by the performance of the coil and can reach 10-20 years.

- For the same reason, the element is equally “friends” with all types of coolants - water, antifreeze and even engine oil, there is no difference.

- The insides of the inductor are not covered with scale during operation.

Pros and cons of induction devices for heating water

The device has a fairly simple design and does not require special documents allowing the use and installation. The induction water heater has a high degree of efficiency and optimum reliability for the user. When using it as a boiler for heating, you don’t even need to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

Also, the device has a number of advantages, which distinguishes it from other types of water heaters. So, induction heater:

In induction heaters, water becomes hot due to the pipe through which it flows, and the latter is heated due to the induction current created by the coil.

- much cheaper than their counterparts, such a device can be easily assembled independently;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to a person);

- vibrates during operation, due to which dirt and scale do not stick to its walls, and therefore does not need to be cleaned;

- has a heat generator that can be easily sealed due to the principle of operation: the coolant is inside the heating element and the energy is transferred to the heater through an electromagnetic field, no contacts are needed; therefore, sealing gum, seals and other elements that can quickly deteriorate or leak will not be needed;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Do not forget that the maintenance of an induction heater will be much cheaper than a boiler or gas boiler. The device has a minimum of parts that almost never fail.

Despite the huge number of advantages, the induction water heater has a number of disadvantages:

- the first and most painful for the owners is the electricity bill; the device cannot be called economical, so you have to pay a decent amount of time for its use;

- secondly, the device gets very hot and heats up not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- thirdly, the device has extremely high efficiency and heat dissipation, therefore, when using it, be sure to install a temperature sensor, otherwise the system may explode.

Advantages of induction type units

The undoubted advantages of this type of home heating devices include the following characteristics:

- efficiency - the processing of electrical energy into heat occurs almost completely without significant losses;

- ease of use - constant maintenance of units of this type is not required;

- compact dimensions - induction water heaters are small in size, they can be installed in the heating system in almost any room;

- quietness in operation - this equipment operates quite quietly, no noise occurs during its operation;

- long service life - induction units are durable, can function uninterruptedly for 30 years or more;

- high environmental performance - no harmful emissions occur during the operation of the device, a chimney and a ventilation system are not required.

Many people think that induction boilers are much more profitable than other home heating options. And compared to equipment equipped with heating elements, the heating time of these units is almost twice as fast. Due to the constant circulation and vibration of the liquid, scale does not form in the pipes and inside the device, which greatly facilitates the maintenance and care of the heating system.

Appearance of induction boilers

Appearance of induction boilers

But this type of device also has some disadvantages. And the main disadvantage is that induction equipment is quite expensive in terms of cost. But you can try to make such a heater for heating the house yourself.

Advice. If you have certain skills and technical knowledge, you can assemble an induction heater for your home with your own hands. But before proceeding with the process of assembling the device, you must first realistically assess your capabilities and experience in creating such units, since it is not so easy to make them.

Options for homemade devices

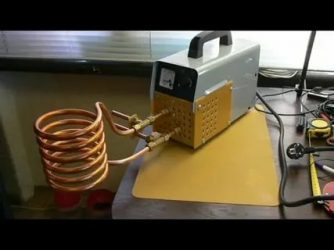

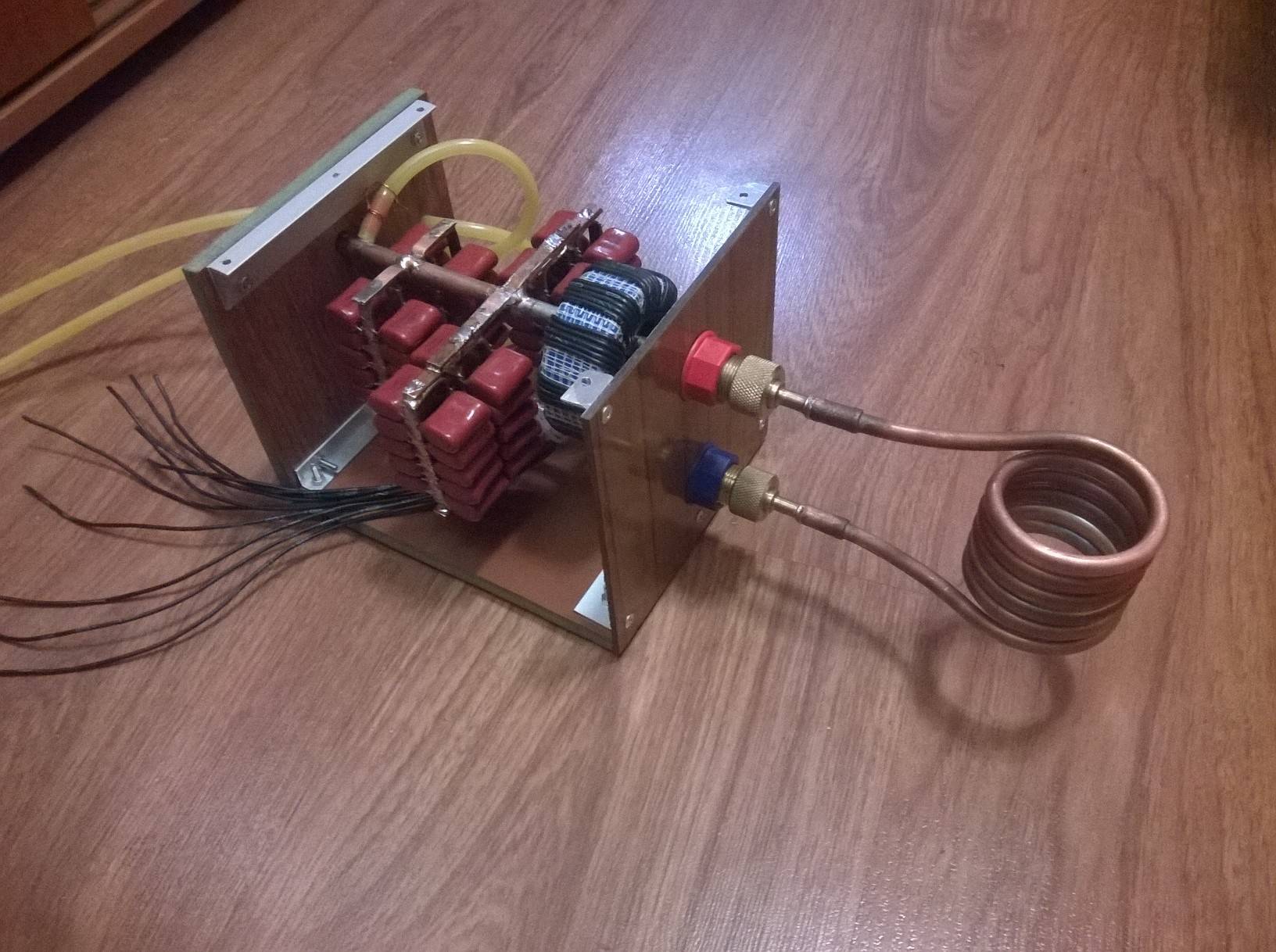

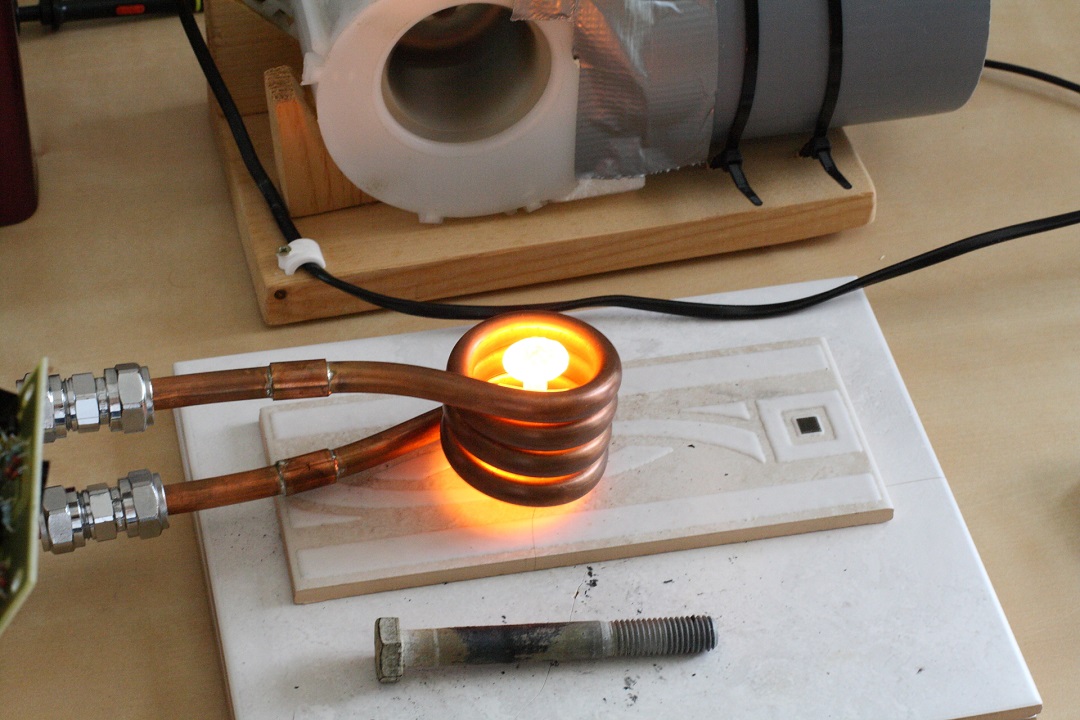

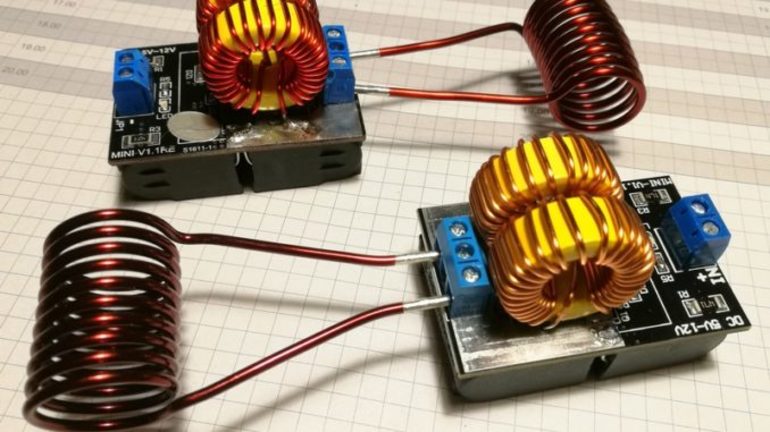

On the Internet there is a sufficient number of various designs created for various purposes. Take an induction small-sized heater made from a 250-500 W computer power supply. The model shown in the photo is useful to the master in the garage or car service for melting aluminum, copper and brass rods.

But for space heating, the design is not suitable due to low power. There are two real options on the Internet, whose tests and work are filmed on video:

- a water heater made of a polypropylene pipe powered by a welding inverter or an induction kitchen panel;

- steel boiler with heating from the same hob.

Now let's take a closer look at how do-it-yourself induction heaters are made, and most importantly, how they then function.

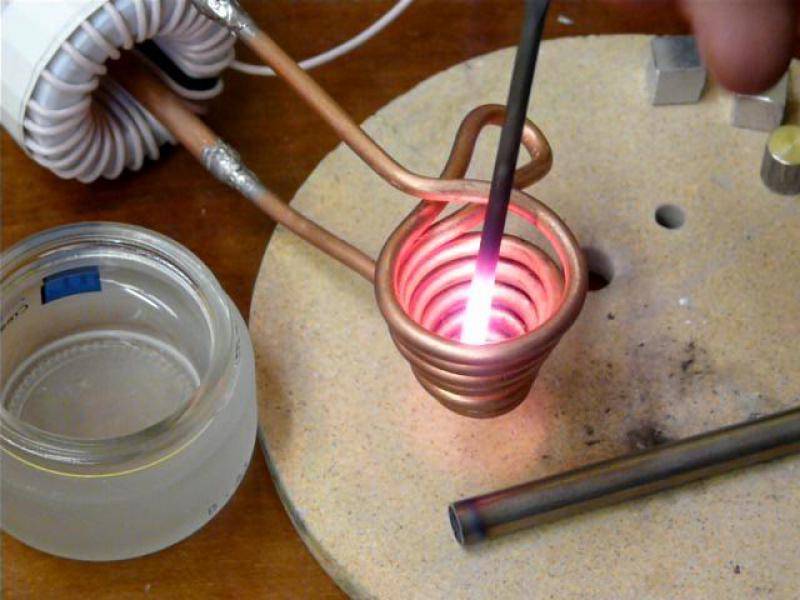

We make a heating element from a pipe

If you have been closely engaged in the search for information on this topic, then you have probably come across this design, since the master posted its assembly on the popular YouTube video resource. After that, many sites posted text versions of the manufacture of this inductor in the form of step-by-step instructions. Briefly, the heater is done like this:

- Inside a pipe made of polypropylene with a diameter of 40 mm and a length of 50 cm, metal brushes for washing dishes come across (you can chopped wire - wire rod). They must be attracted by a magnet.

- Branches with threads are soldered to the pipe for connection to the heating network.

- Outside, 4-5 textolite rods are glued along the body. A wire with a cross section of 1.7-2 mm² with glass insulation is wound on them, which is used in welding transformers.

- The hob is disassembled and the "native" flat-shaped inductor is dismantled. Instead, a homemade heater from the pipe is connected.

As you might guess, the role of the heating element here is played by metal brushes located in the alternating magnetic field of the coil. If you run the hob to the maximum, while simultaneously passing running water through an impromptu boiler, then it will be possible to heat it by 15-20 ° C, which was shown by the tests of the unit.

Since the power of most induction cookers lies in the range of 2–2.5 kW, using a heat generator it is possible to heat rooms with a total area of no more than 25 m². There is a way to increase the heat by connecting the inductor to the welding machine, but there are some difficulties here:

- The inverter produces a direct current, but an alternating one is needed. To connect the induction heater, the device will have to be disassembled and the points on the diagram found where the voltage has not yet been rectified.

- It is necessary to take a wire of a larger cross section and select the number of turns by calculation. As an option, copper wire Ø1.5 mm in enamel insulation.

- It will be necessary to organize the cooling of the element.

The author demonstrates the performance check of an inductive water heater in his video below. Tests have shown that the unit needs to be improved, but the final result, unfortunately, is unknown. It looks like the craftsman left the project unfinished.

From a welding inverter

The simplest budget option is to manufacture an induction heater using a welding inverter:

- To do this, we take a polymer pipe, its walls must be thick. From the ends we mount 2 valves and connect the wiring.

- We fill the pipe with pieces (diameter 5 mm) of metal wire and mount the top valve.

- Next, we make 90 turns around the pipe with copper wire, we get an inductor. The heating element is a pipe, the generator is a welding machine.

- The instrument must be in high frequency AC mode.

- We connect the copper wire to the poles of the welding machine and check the work.

Working as an inductor, a magnetic field will be radiated, while eddy currents will heat up the chopped wire, which will lead to boiling water in a polymer pipe.

Manufacturing instructions

Blueprints

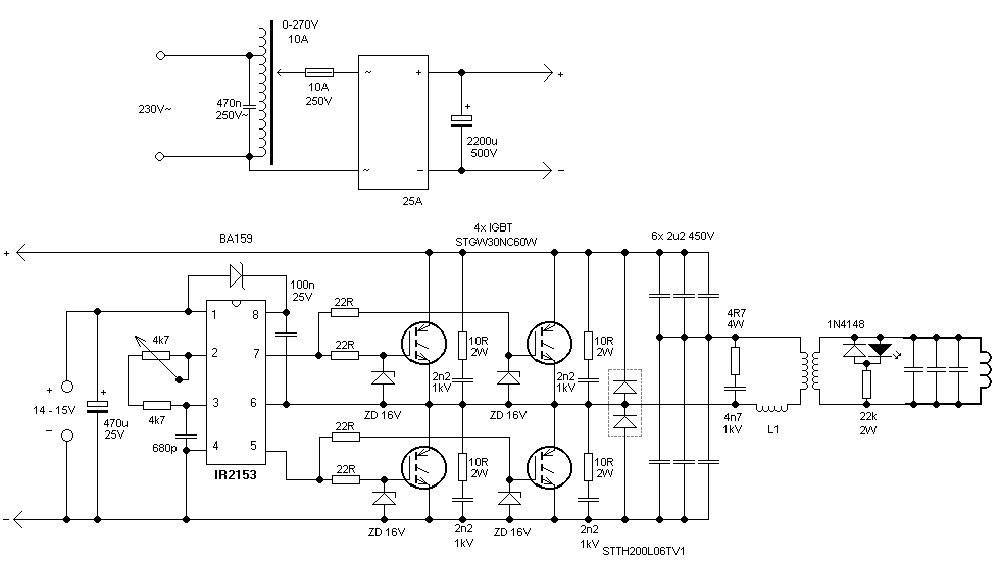

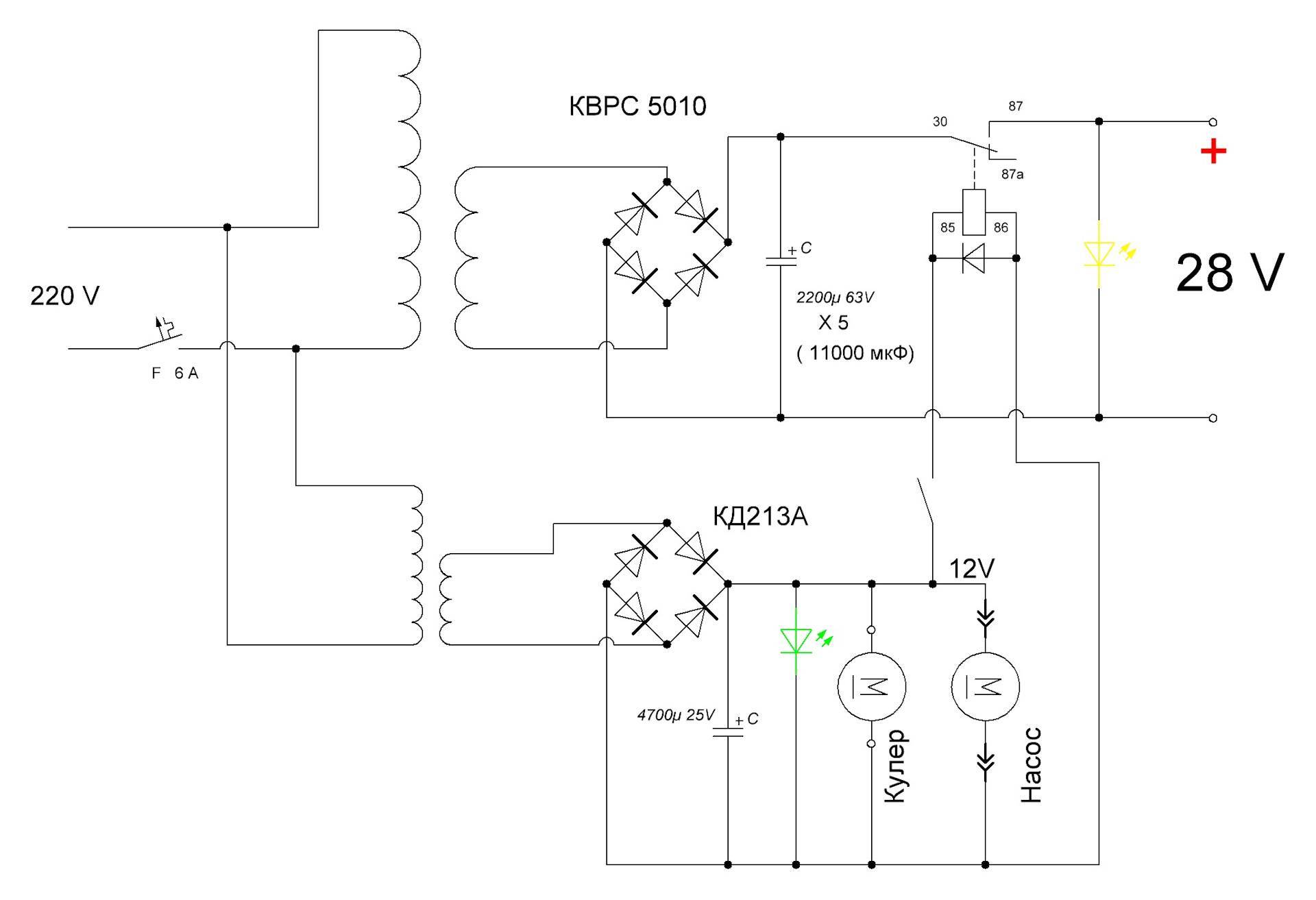

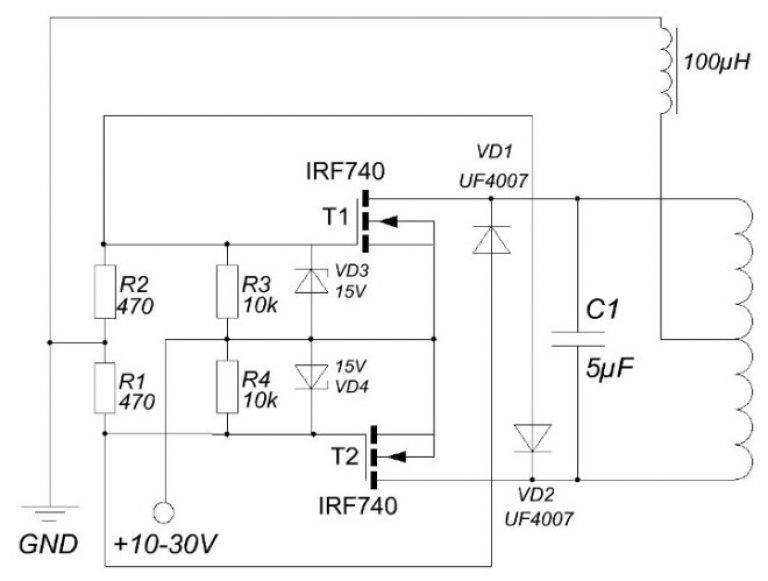

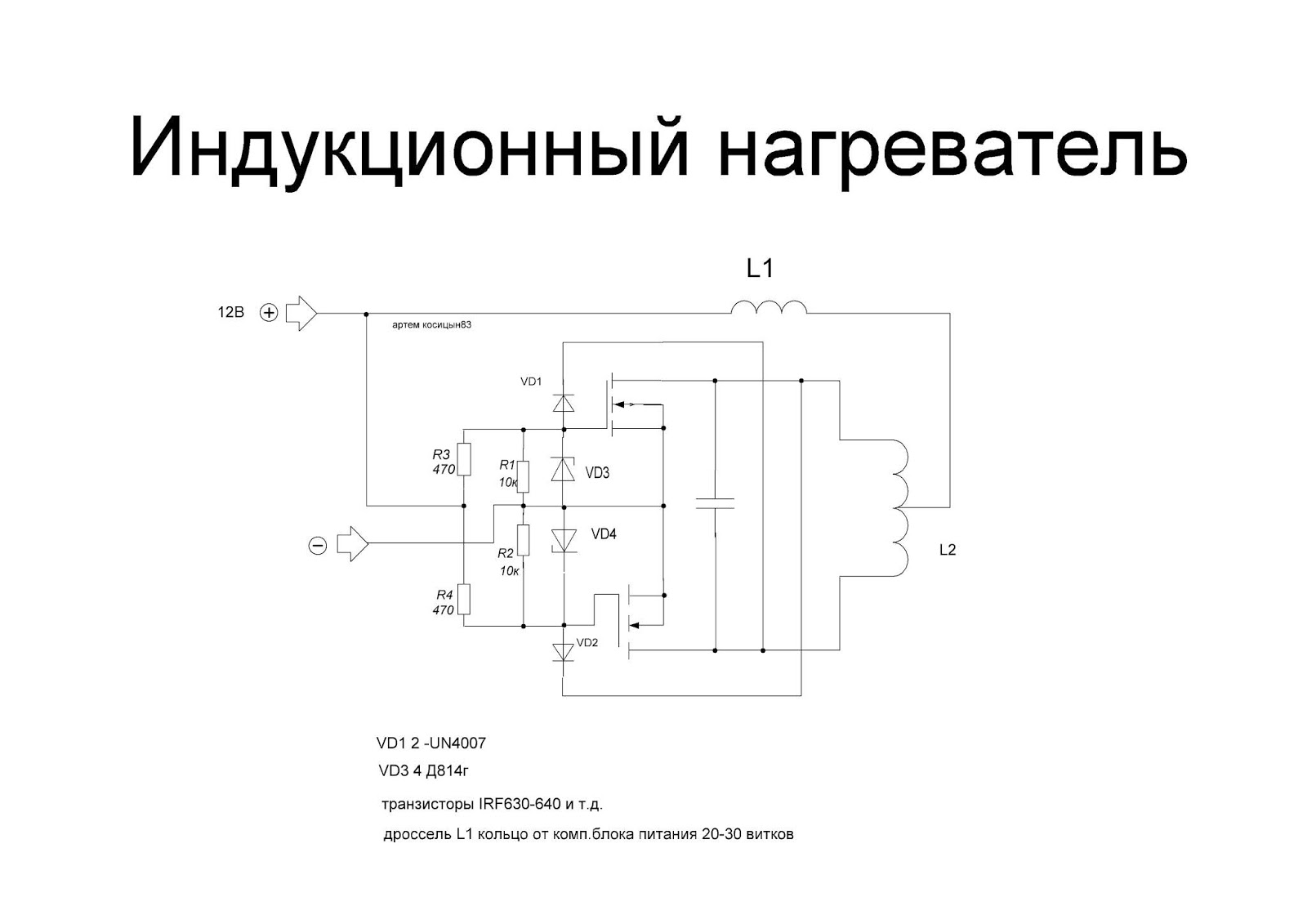

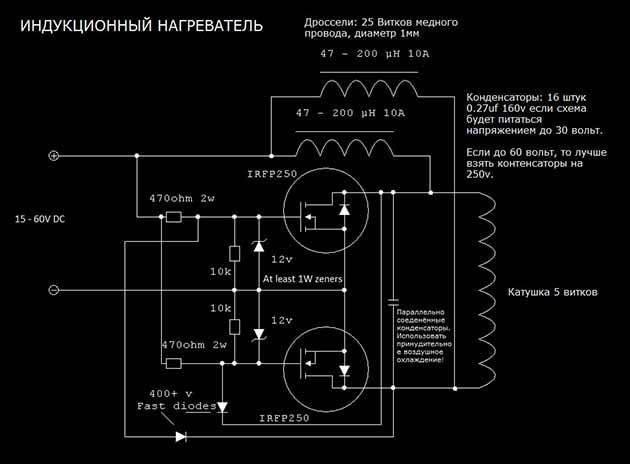

Figure 1. Electrical diagram of the induction heater

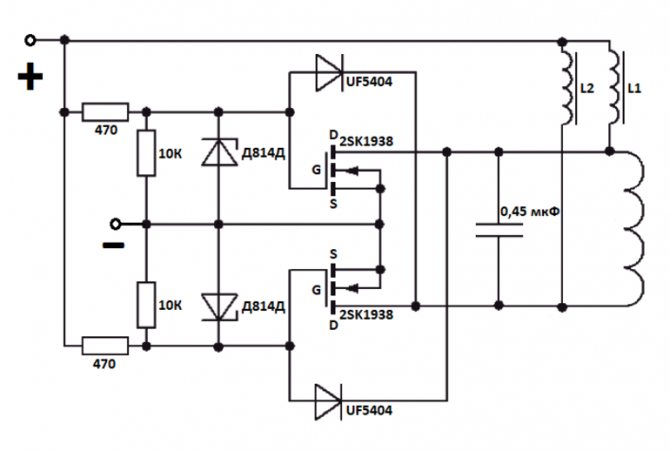

Figure 2. Device.

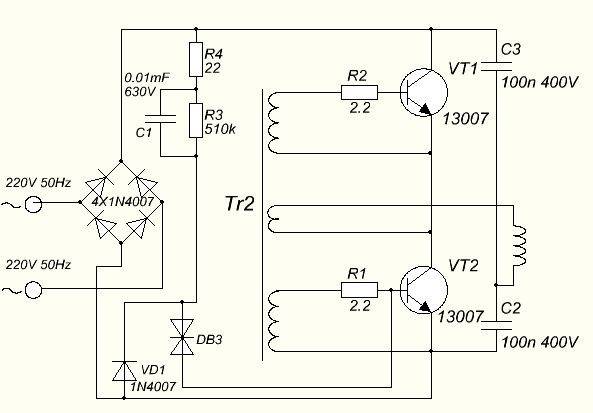

Figure 3. Scheme of a simple induction heater

For the manufacture of the furnace you will need the following materials and tools:

- soldering iron;

- solder;

- textolite board.

- mini drill.

- radioelements.

- thermal paste.

- chemical reagents for board etching.

Additional materials and their features:

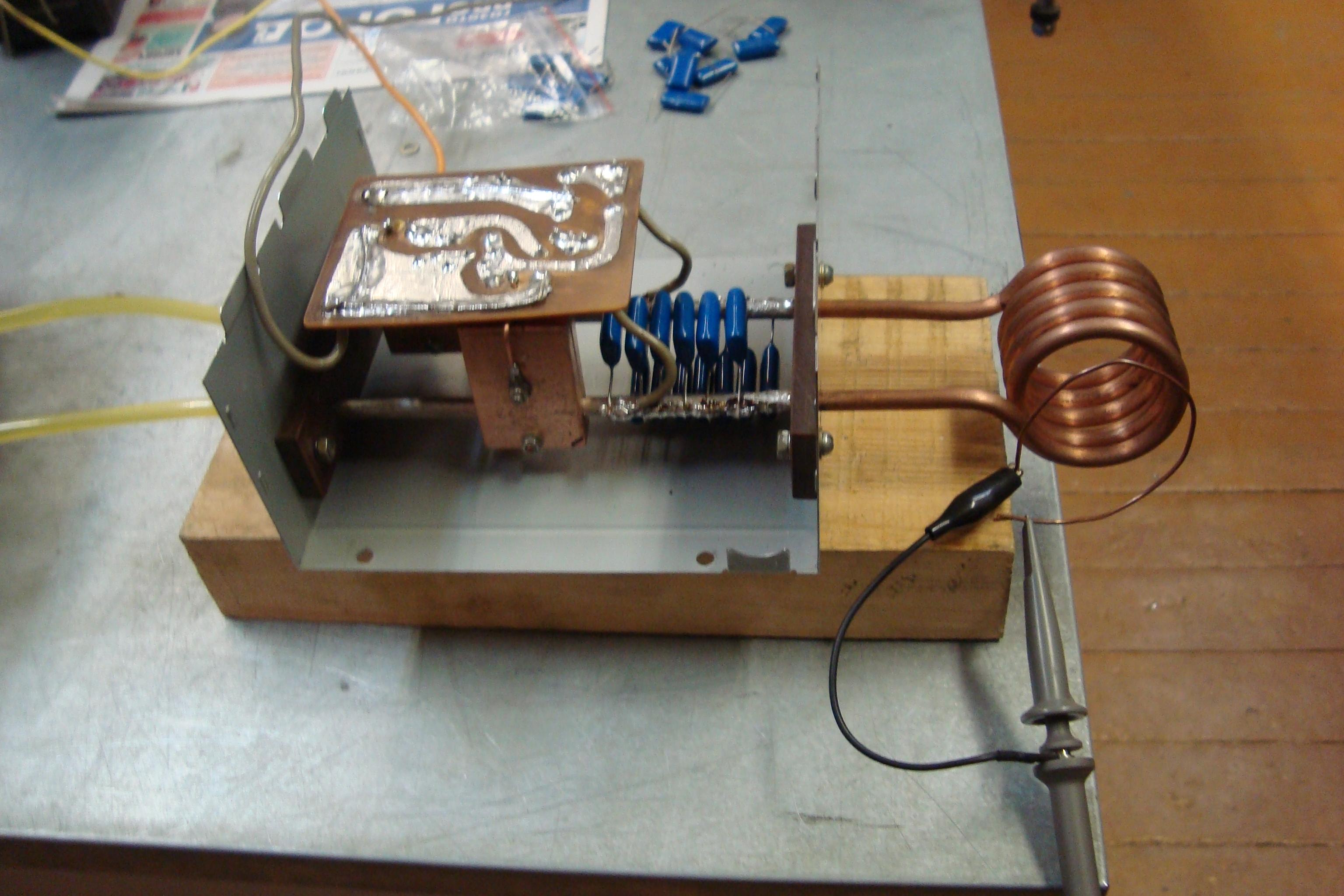

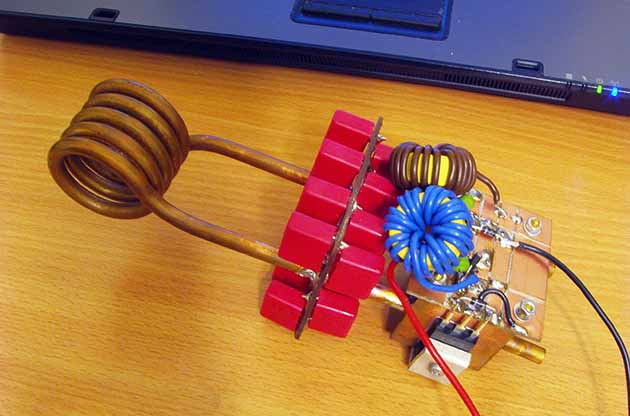

- To make a coil that will emit an alternating magnetic field necessary for heating, it is necessary to prepare a piece of copper tube with a diameter of 8 mm and a length of 800 mm.

- Powerful power transistors are the most expensive part of a homemade induction setup. To mount the frequency generator circuit, it is necessary to prepare 2 such elements. For these purposes, transistors of brands are suitable: IRFP-150; IRFP-260; IRFP-460. In the manufacture of the circuit, 2 identical of the listed field-effect transistors are used.

- For the manufacture of an oscillatory circuit, ceramic capacitors with a capacity of 0.1 mF and an operating voltage of 1600 V will be needed. In order for a high-power alternating current to form in the coil, 7 such capacitors are required.

- During the operation of such an induction device, the field-effect transistors will be very hot and if aluminum alloy radiators are not attached to them, then after a few seconds of operation at maximum power, these elements will fail. Putting transistors on heat sinks should be through a thin layer of thermal paste, otherwise the efficiency of such cooling will be minimal.

- The diodes that are used in the induction heater must be of ultra-fast action. The most suitable for this circuit, diodes: MUR-460; UV-4007; HER-307.

- Resistors used in circuit 3: 10 kOhm with a power of 0.25 W - 2 pcs. and 440 ohm power - 2 watts. Zener diodes: 2 pcs. with an operating voltage of 15 V. The power of the zener diodes must be at least 2 watts. A choke for connecting to the power outputs of the coil is used with induction.

- To power the entire device, you will need a power supply unit with a capacity of up to 500. W. and a voltage of 12 - 40 V. You can power this device from a car battery, but you will not be able to get the highest power readings at this voltage.

The very process of manufacturing an electronic generator and coil takes a little time and is carried out in the following sequence:

The very process of manufacturing an electronic generator and coil takes a little time and is carried out in the following sequence:

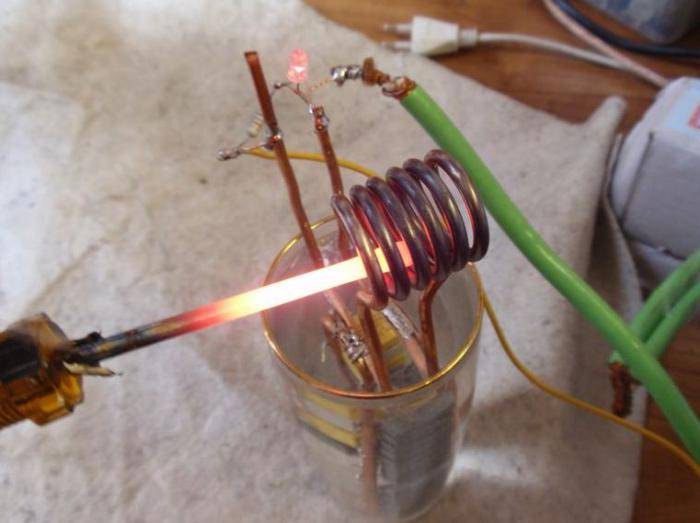

- A spiral with a diameter of 4 cm is made from a copper pipe. To make a spiral, a copper tube should be wound onto a rod with a flat surface with a diameter of 4 cm. The spiral should have 7 turns that should not touch. Mounting rings are soldered to the 2 ends of the tube for connection to the transistor radiators.

- The printed circuit board is made according to the scheme.If it is possible to supply polypropylene capacitors, then due to the fact that such elements have minimal losses and stable operation at large amplitudes of voltage fluctuations, the device will work much more stable. The capacitors in the circuit are installed in parallel, forming an oscillatory circuit with a copper coil.

- The heating of the metal occurs inside the coil, after the circuit is connected to a power supply or battery. When heating the metal, it is necessary to ensure that there is no short circuit of the spring windings. If you touch the heated metal 2 turns of the coil at the same time, then the transistors fail instantly.

Operation features

Homemade heater assembly is only half the battle

Equally important is the correct operation of the resulting structure. Initially, each such device poses a certain danger, since it is not able to independently control the level of heating of the coolant. In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

First of all, the pipe outlet is equipped with a standard set of safety devices - a safety valve, a pressure gauge and a device for venting air. It should be remembered that induction water heaters will work normally only if there is forced water circulation.The gravity flow circuit will very quickly lead to overheating of the element and the destruction of the plastic pipe.

To avoid such situations, a thermostat is installed in the heater, connected to an emergency shutdown device. Experienced electrical engineers use for this purpose thermostats with temperature sensors and relays that turn off the circuit when the coolant reaches the set temperature.

Home-made designs are characterized by rather low efficiency, since instead of free passage, there is an obstacle in the path of water in the form of wire particles. They almost completely cover the pipe, causing increased hydraulic resistance. In emergency situations, damage and rupture of plastic are possible, after which hot water will certainly lead to a short circuit. Typically, these heaters are used in small rooms as an additional heating system during the cold season.

The use of induction coils instead of traditional heating elements in heating equipment has made it possible to significantly increase the efficiency of the units with less electricity consumption. Induction heaters have appeared on sale relatively recently, moreover, at fairly high prices. Therefore, craftsmen did not leave this topic without attention and figured out how to make an induction heater from a welding inverter.