- Pros and cons, scope

- Where to use

- Advantages and disadvantages

- Where is it used?

- General sanitary requirements in GOST 30494-2011

- Types of plastic pipes and materials for manufacturing

- PVC

- Polyurethane

- Polypropylene

- What material to choose for a ventilation duct in a private house and why

- Choosing the optimal ventilation system

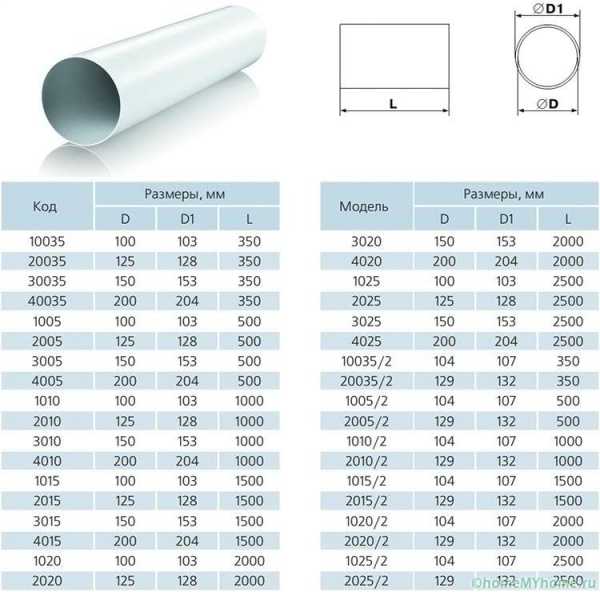

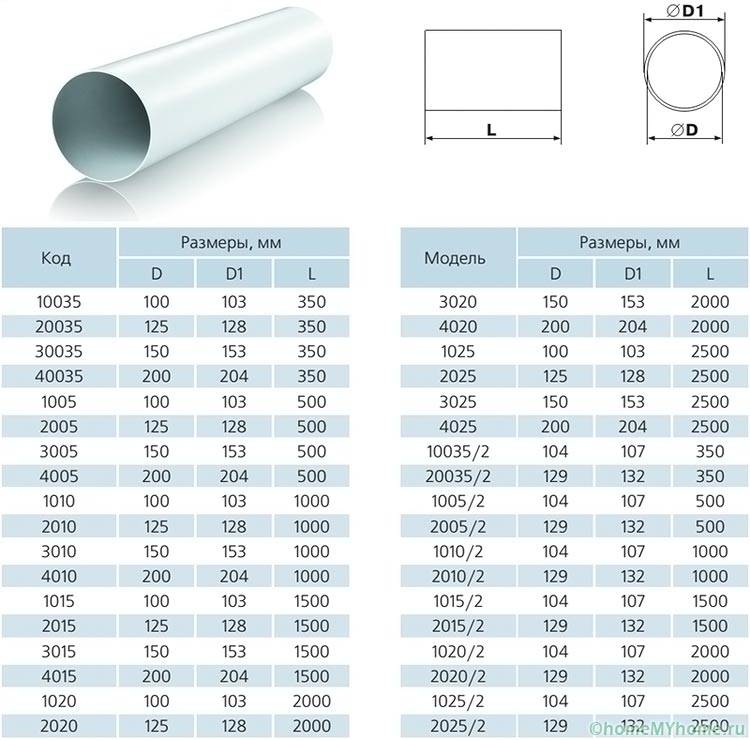

- Size range of air ducts

- Hoods for sewerage

- Frequent 2 mistakes

- Pros and cons, scope

- Where to use

- Advantages and disadvantages

- Choosing a pipe for an exhaust system

- Pipe material used

- Features of determining the length of ventilation pipes

- Table calculation

- Software use

- Conclusion

Pros and cons, scope

Plastic air ducts are perceived negatively by many, as they are not sure that plastic does not emit harmful substances during operation. It may be that low-quality plastic is unsafe, but even in household appliances there are so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here the most difficult operating conditions are elevated temperature, a large amount of fat, evaporation of chemically active substances.

Even the open laying of plastic pipes does not spoil the appearance

In general, experts recommend putting plastic for exhaust ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Where to use

Another reason for not recommending the use of plastic air ducts is problems with the fire department. There were cases that they did not sign permission to use gas equipment if the ventilation was made of plastic. But it was a frame house, and there the requirements are different. If in doubt, it is best to check with your local fire inspector. In general, there are recommendations in regulatory documents.

Extract from SNiP 41-01-2003

According to SNiP 41-01-2003 clause 7.11, plastic air ducts can be used in low-rise residential, public, administrative and residential and industrial buildings of category D. They cannot be laid in basements, undergrounds, attics and technical floors, in rooms with standardized fire safety conditions.

Advantages and disadvantages

Plastic air ducts have both adherents and opponents. Their main disadvantages:

- Flammability. Everything is clear here. Only metal air ducts do not spread fire. Although not all plastics burn and propagate flame, such “reduced” flammability materials are expensive. Therefore, plastic air ducts are allowed only in one-story houses.

-

The accumulation of static charge, which leads to the accumulation of dust (it can flare up again). In fact, much more dust accumulates in corrugated areas.To reduce its amount, it is necessary to install a plastic duct after the completion of "dusty" construction work and install filters that catch most of the dust. In addition, plastic ventilation pipes are treated with a special compound. It forms a film on the surface that prevents the accumulation of static charge.

- With poor workmanship, thin walls or a large cross section, gaps may form at the joints due to changes in geometry. This can be fixed, but there is such a drawback.

These are the disadvantages of using plastic air ducts. More than enough advantages:

- Easy installation. The presence of fittings and fittings allows you to create a system of any configuration. Plastic is easy to cut, weighs little.

- Due to ideally smooth walls, the air encounters less resistance.

- Easier to seal. For reliability, the joints can be smeared with sealant.

- Modern plastic air ducts are joined using butt locks without overlaps, which reduces resistance to air movement.

- Low noise level. With a capacity of up to 100 cubic meters / min, the air movement is almost silent.

-

Not subject to corrosion.

In general, a plastic duct is not the ideal solution, but the ease of installation and good performance outweigh the disadvantages. In general, experts recommend putting plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Also, when choosing, it is worth proceeding from the operating conditions.For example, it makes sense to use a plastic air duct for an exhaust ventilation duct from wet rooms, since galvanized ones are susceptible to corrosion, and stainless ones are very expensive.

Where is it used?

Installation plastic ventilation pipes It is possible in any household room, but places with a high level of humidity and an unpleasant smell especially need air renewal. For example, in a bath, ventilation will prevent the rapid wear of materials that lose their resistance under the influence of moisture and high temperatures, and will prevent the growth of carbon monoxide and carbon dioxide levels. In the garage, the task of the installation is to remove automobile exhaust and fumes, dry the body, and blow out the inspection hole. In a chicken coop or other livestock building, the system eliminates harmful ammonia fumes.

The same problems are solved by ventilation in a private house. There are many bacteria and viruses in the air, the number of which increases after the illnesses suffered by the inhabitants of the house. Ventilating windows will not cope with invisible pests. This issue will be solved only by the arrangement of the system of channels for outflow and inflow of air.

General sanitary requirements in GOST 30494-2011

A collection of state-approved standards for creating a comfortable living environment in residential facilities.

Indicators for air in residential apartments:

- temperature;

- movement speed;

- proportion of air humidity;

- total temperature.

Depending on the stated requirements, acceptable or optimal values are used in the calculations. You can get acquainted with their full composition in Table No. 1 of the above standard. A condensed example is shown below.

For the living room are allowed:

- temperature - 18o-24o;

- humidity percentage - 60%;

- air movement speed - 0.2 m / s.

For kitchen:

- temperature - 18-26 degrees;

- relative humidity - not standardized;

- the speed of advancement of the air mixture is 0.2 m/sec.

For bathroom, toilet:

- temperature - 18-26 degrees;

- relative humidity - not standardized;

- the rate of movement of the air medium is 0.2 m / s.

In the warm season, microclimate indicators are not standardized.

The assessment of the temperature environment inside the rooms is carried out according to the usual air temperature and the resulting temperature. The latter value is a collective indicator of tо air and radiation tо of the room. It can be calculated using the formula in Appendix A by measuring the heating of all surfaces in the room. An easier way is to measure with a balloon thermometer.

For the correct measurement of temperature data and sampling to determine the organoleptic indicators of the air mass, the direction of the flows of the supply and exhaust parts of the system should be taken into account.

Air pollution inside the home is determined by the content of carbon dioxide - a product exhaled by people during breathing. Harmful emissions from furniture, linoleum are equated to an equivalent amount of CO2.

According to the content of this substance, indoor air and its quality are classified:

- 1 class - high - carbon dioxide tolerance of 400 cm3 and below in 1 m3;

- Class 2 - medium - carbon dioxide tolerance 400 - 600 cm3 in 1 m3;

- Class 3 - permissible - CO approval2 – 1000 cm3/m3;

- Class 2 - low - carbon dioxide tolerance of 1000 and above cm3 in 1 m3.

The required volume of outdoor air for the ventilation system is determined by calculation using the formula:

L = k×Ls, where

k is the air distribution efficiency coefficient, given in Table 6 of GOST;

Ls – calculated, minimum amount of outside air.

For a system without forced traction, k = 1.

The following article will acquaint you in detail with the implementation of calculations to provide ventilation to the premises, which is worth reading both for construction customers and owners of troubled housing.

Types of plastic pipes and materials for manufacturing

Today, the industry produces several types of plastic:

- polyvinyl chloride;

- polyurethane;

- polypropylene.

PVC

This is a fairly durable material that does not cause serious difficulties in processing. Its cost is available to any consumer. PVC is used in domestic and industrial environments.

The material does not emit any harmful substances and can be used for many years. The decomposition of polyvinyl chloride takes more than a dozen years, so plastic exhaust pipes can be called eternal.

However, it should be noted that the installation of such parts has severe limitations. Ventilation cylindrical products made of PVC begin to decompose at a temperature of 160-180 °C. This threshold is much lower than the melting point (200-220 °C). In other words, it is impossible to shape them with a welding torch. Such products should not be installed in systems operating at very high temperatures.

In domestic conditions, steam can heat up to 200 °C. It is strictly forbidden to install plastic pipes for ventilation in the sauna.

The material will begin to decompose and release chlorine, primarily HCl. Gas, getting into a humid environment, contributes to the formation of hydrochloric acid. This compound can cause blindness and also affects the functioning of the respiratory tract.The gas is almost invisible and has an unpleasant odor.

From the above, we can conclude that PVC is an excellent material for the ventilation system only in those places where the temperature does not exceed 120 ° C. PVC products should not be installed in the kitchen, near the fireplace and water heater.

Polyurethane

The properties of this material practically do not differ from the characteristics of PVC, except that PU is able to function at a temperature of 280 ° C. At higher values, polyurethane begins to decompose and release nitrogen compounds, which are much more dangerous than chloride ones.

The disadvantages of this material include its cost, which is an order of magnitude higher than similar pipes. But at the same time, PU combines two important properties:

- plastic;

- wear resistance.

The plasticity of polyurethane is amazing. This parameter is much superior to metal and granite in terms of fracture stress coefficient. Pipes made from PU can be molded into any shape without cracking.

Such polyurethane products are excellent for areas with many turns and curvatures, as well as for arranging systems that are constantly exposed to high temperatures.

Polypropylene

This material can be given absolutely any shape. After heating up to 180 °C, polypropylene pipes for ventilation become highly plastic. To do this, it is enough to use hot steam or a burner.

The service life of polypropylene is calculated in tens of years. With strong heating, the material does not emit any toxic substances.

The cost of polypropylene is not very high, so it is great for installing plastic ventilation.

Types of plastic ABS and PLA have found their way into the latest 3D printers. The use of a printing device makes it possible to produce any parts for plastic ventilation, from turn signals with non-standard angles to valves.

What material to choose for a ventilation duct in a private house and why

Not so long ago, ventilation in private homes was made of flexible and rigid pipes. Recently, plastic exhaust pipes with a cross section of 75 mm have been mainly used for ventilation.

Not so long ago, ventilation in private homes was made of flexible and rigid pipes. Recently, plastic exhaust pipes with a cross section of 75 mm have been mainly used for ventilation.

Aluminum flexible ducts are popular due to their ease of installation and low cost. The main disadvantages of this solution are bulkiness (usually caused by improper installation by unskilled workers) and the lack of cleaning channels. The advantage is very good sound and heat insulation, light construction and relatively low price.

Watch the video

Exhaust structure made of aluminum are characterized by:

Exhaust structure made of aluminum are characterized by:

- high strength and the possibility of laying pipes in the floor under a screed, dry and wet plaster;

- low resistance due to the smooth inner surface of the pipelines and the absence of the need for additional elbows and tees;

- very good acoustic properties;

- simple sealing with gasket without the need for special tools;

- anti-static designs are available with additives that limit the growth of fungi and bacteria;

- the possibility of thorough cleaning of the channels.

All this makes these systems very interesting and advantageous compared to ventilation on flexible or rigid ducts.Simplicity and a wide range of installation options, combined with high strength and cleanability, favor the use of this type of solution when building a house.

Choosing the optimal ventilation system

Each house is unique. And the ventilation system suitable in a particular case will be different. Of great importance when choosing a system is the area of \u200b\u200bthe house, the number of floors, materials of walls and roofs.

You should also take into account the amount allocated for this

The larger the area of the house and the more airtight materials used in its construction, the more complex the system will be required. Another point is the additional possibilities of climate control. The cost of ventilation directly depends on this parameter.

The arrangement of the ventilation ducts themselves is inexpensive - you can pick up inexpensive pipes, valves, grilles, additional parts that are needed for installation

The more functions a ventilation system can perform, the more expensive it will cost. But with a modest budget, you can do without additional features - the flow of fresh air into the house does not depend on this.

To organize the flow of air use:

- windows with micro-ventilation;

- wooden windows. They have natural micro-ventilation, which provides an influx of fresh air from the outside;

- supply valve.

Inlet valves can be of various shapes and sizes. The materials from which they are made are metal and plastic. As for micro-ventilation in windows, this option is the most convenient - you do not have to additionally make holes in the walls and buy valves.

To remove air from the premises of a private house, ventilation shafts are used in the wall or separate air ducts are laid in the kitchen, pantry, boiler room and bathroom. It is convenient to install a fan in such channels, which will forcibly rid the room of polluted air.

Mechanical ventilation systems use filters that need to be changed periodically. Their service life is indicated in the manufacturer's instructions.

If the area of \u200b\u200bthe house is small, then it is enough to install windows with micro-ventilation, an extractor hood in the kitchen and ventilation ducts from the boiler room and bath. Such a seemingly modest system will completely cope with the ventilation of all the premises of a country house.

Size range of air ducts

According to the regulatory documents mentioned above, round galvanized steel air ducts are manufactured with diameters of 100, 125, 140, 160,180, 200, 225, 250-2000 mm. The parameters of rectangular elements vary from 100 to 3200 mm.

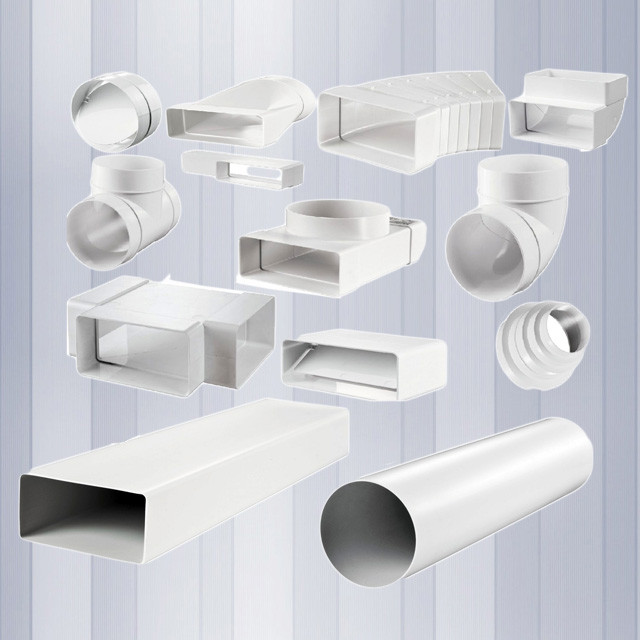

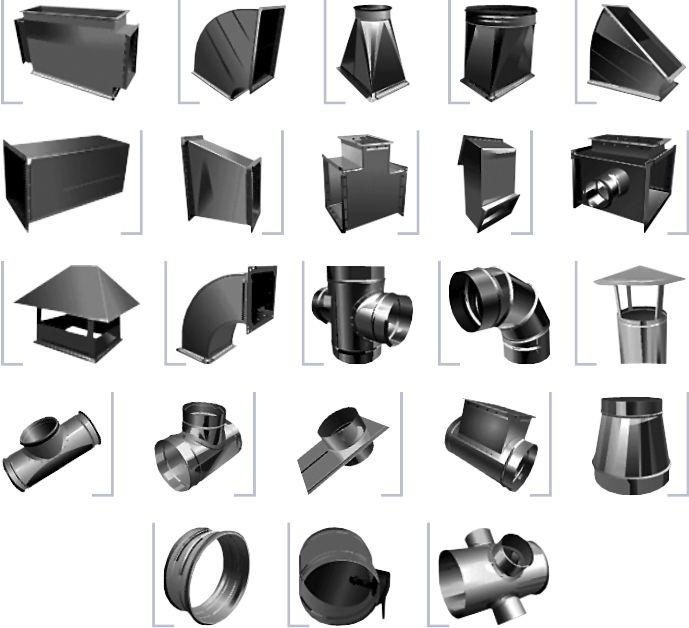

In one ventilation system, parts with different configurations and parameters can be used. To connect them, various shaped elements are used: tees, bends, adapters, diffusers

In one ventilation system, parts with different configurations and parameters can be used. To connect them, various shaped elements are used: tees, bends, adapters, diffusers

To select products of the right size, it is necessary to know the design value of the air velocity. In residential buildings with natural ventilation, this figure should not exceed 1 m / s, and with forced ventilation, it should be 3-5 m / s.

For each dwelling, you need to calculate the amount of air supplied. When calculating, you need to focus on the regulatory documentation - SNiP 41-01-2003 and MGSN 3.01.01.

There are also special diagrams compiled by specialists that make it easy to find the duct of the desired diameter. for various options standard systems.

Hoods for sewerage

Frequent 2 mistakes

There are at least two common misconceptions about such devices:

- Since I have a fan pipe in my house or apartment, that is, ventilation of the sewer riser (bed), it means that all unpleasant odors from the system should come out through it

. However, we are very surprised if this does not work. But the thing is that the most common source of stench is either damaged pipes, or the lack of hydraulic valves due to the banal non-use of any bathroom (a column of water can evaporate). - But the second mistake concerns the residents of the upper floors who have access to the fan pipe - when repairing or replacing plumbing equipment in the toilet or bathroom, it is removed altogether

. The reason here is the poor condition of this pipe - due to the long service life, they are pretty damaged by corrosion. But by drowning out the riser, you create a problem not only for yourself, but also for all your neighbors living below on all floors. The smell will penetrate into the apartments with each descent of the toilet.

Let's start with the fact that ventilation from sewer pipes in a private house, especially if there is more than one toilet, should be at least 4 m above ground level. As a rule, the fan pipe is led out through the roof. This will keep the water in the hydraulic seals from evaporating too quickly, and will also allow you to compensate for the difference in air pressure when flushing a toilet bowl or two toilet bowls at the same time from the cistern.

When the water is drained from the toilet, its volume completely fills the diameter of the pipe and, when moving, rarefies the air after it, which leads to the exhaustion of these same water seals. But the fan pipe compensates for this difference. As a result, you get the absence of unpleasant odors in the room.

I have already said about the diameter - it should be the same as in the system itself. But is it possible to use pipes from another material, for example, to combine the laying of a PVC system with an asbestos-cement or metal fan riser?

The answer here in any case will be unequivocal - yes, you can. Only in this case, another question arises - is it necessary? It is best to use polyvinyl chloride for a fan riser, even if your wiring is made of metal or asbestos cement (it happens) - PVC is very light, strong, and its service life is 50 years or more.

The ventilation insert is made at the highest point of the sewer system, made from the widest pipe. That is, if the main system has 110 mm, then the connections to it will be made from a diameter of 50 mm, but they, of course, will be higher, although it is desirable to make a tie-in on the 110th pipe (you can also on the 50th, but the effect is diminished ). Most often, this point is the connection point of the toilet.

One of the options is to bring ventilation through, as in the top photo - this will most likely increase the price of the structure, but this option is quite convenient. Such a letter G should be made with the same material as the system itself, and the riser can already be mounted from PVC.

Pros and cons, scope

Plastic air ducts are perceived negatively by many, as they are not sure that plastic does not emit harmful substances during operation.It may be that low-quality plastic is unsafe, but even in household appliances there are so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here the most difficult operating conditions are elevated temperature, a large amount of fat, evaporation of chemically active substances.

Even the open laying of plastic pipes does not spoil the appearance

In general, experts recommend putting plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Where to use

Another reason for not recommending the use of plastic air ducts is problems with the fire department. There were cases that they did not sign permission to use gas equipment if the ventilation was made of plastic. But it was a frame house, and there the requirements are different. If in doubt, it is best to check with your local fire inspector. In general, there are recommendations in regulatory documents.

Extract from SNiP 41-01-2003

According to SNiP 41-01-2003 clause 7.11, plastic air ducts can be used in low-rise residential, public, administrative and residential and industrial buildings of category D. They cannot be laid in basements, undergrounds, attics and technical floors, in rooms with standardized fire safety conditions.

Advantages and disadvantages

Plastic air ducts have both adherents and opponents. Their main disadvantages:

- Flammability. Everything is clear here. Only metal air ducts do not spread fire.Although not all plastics burn and propagate flame, such “reduced” flammability materials are expensive. Therefore, plastic air ducts are allowed only in one-story houses.

- The accumulation of static charge, which leads to the accumulation of dust (it can flare up again). In fact, much more dust accumulates in corrugated areas. To reduce its amount, it is necessary to install a plastic duct after the completion of "dusty" construction work and install filters that catch most of the dust. In addition, plastic ventilation pipes are treated with a special compound. It forms a film on the surface that prevents the accumulation of static charge.

An example of using plastic air ducts to connect a kitchen hood - With poor workmanship, thin walls or a large cross section, gaps may form at the joints due to changes in geometry. This can be fixed, but there is such a drawback.

These are the disadvantages of using plastic air ducts. More than enough advantages:

- Easy installation. The presence of fittings and fittings allows you to create a system of any configuration. Plastic is easy to cut, weighs little.

- Due to ideally smooth walls, the air encounters less resistance.

- Easier to seal. For reliability, the joints can be smeared with sealant.

- Modern plastic air ducts are joined using butt locks without overlaps, which reduces resistance to air movement.

- Low noise level. With a capacity of up to 100 cubic meters / min, the air movement is almost silent.

- Not subject to corrosion.

Here is a set of shaped elements that allows you to make a ventilation system of any complexity from plastic pipes

In general, a plastic duct is not the ideal solution, but the ease of installation and good performance outweigh the disadvantages. In general, experts recommend putting plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Also, when choosing, it is worth proceeding from the operating conditions. For example, it makes sense to use a plastic air duct for an exhaust ventilation duct from wet rooms, since galvanized ones are susceptible to corrosion, and stainless ones are very expensive.

Choosing a pipe for an exhaust system

For the productivity and reliability of the entire structure of the removal of polluted air, the choice of a pipe for ventilation is of great importance. Consider the main criteria.

Pipe material used

Corrugated aluminum pipes are the cheapest and easiest to install option for organizing the removal of polluted air from the hood. The basis of the pipe are metal rings. They are covered in several layers of laminated foil. Initially, the rings are in a position pressed against each other, the upper shell is folded into an "accordion". During installation, the corrugation is able to lengthen several times, bend at the required angle. Therefore, it is easily laid in cramped conditions and hard-to-reach places.

An incompletely stretched corrugated pipe becomes a source of characteristic noise of the exhaust system due to the increased resistance of the irregularities of the inner surface to the air flow. The noise level is also increased by additional kinks in the pipe.

Corrugated pipes for ventilation can withstand significant heat (up to +250 ° C), have considerable strength, are resistant to aggressive environments, can be extended if necessary (metal tape is used for connection), and can last up to 50 years.

Exhaust systems made of plastic have a number of advantages that make them leaders in consumer demand:

- Light weight allows one person to mount the entire system, does not require additional fasteners or supporting elements, eliminates additional load on the suspended modules of kitchen furniture.

- High resistance to many chemicals and moisture.

- Excellent tightness of air ducts with high strength of the mounted structure.

- UV resistant.

- Simplicity and ease of care, availability and low cost of the necessary detergents.

- Ability to operate the system over a wide range of temperatures.

- Creation of good sound insulation that does not disturb a comfortable stay in a room with an exhaust system.

- Durability.

- An impressive range of plastic elements of the exhaust pipeline of various shapes and sizes, from various materials: polypropylene, polyurethane, polyvinyl chloride.

- Aesthetic strict view of the assembled system.

- Ease of installation allows you to assemble reliable exhaust structures from standard fittings.

- Plastic elements of pipelines are not subject to corrosion, their material is environmentally friendly.

- The smooth inner surface of the pipes does not allow dirt and grease to accumulate.

- Exhaust systems with plastic pipes (especially round ones) are almost silent in comparison with air ducts made of other materials.

Plastic pipes are more expensive than corrugated ones. Their installation is more complicated, it requires additional transitional and connecting elements. After the assembly of the pipeline, unused trimmings remain. These are the main disadvantages of plastic pipes.

Features of determining the length of ventilation pipes

Another important parameter in the design of ventilation systems is the length of the outer pipe. It combines all the channels in the house through which air is circulated, and serves to bring it out.

Table calculation

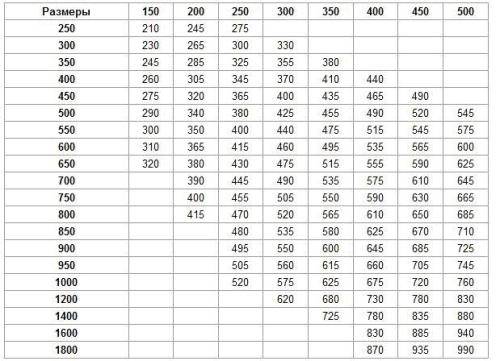

The height of the ventilation pipe depends on its diameter and is determined from the table. Its cells indicate the cross section of the ducts, and in the column on the left - the width of the pipes. Their height is indicated in the top line and is indicated in mm.

Selection of the height of the ventilation pipe according to the table

In this case, you need to take into account:

- If the ventilation pipe is located next to the chimney, then their height must match in order to avoid the penetration of smoke into the premises during the heating season.

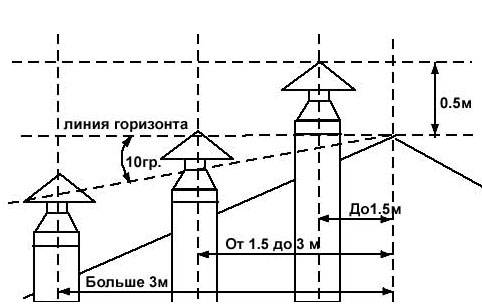

- If the duct is located from the ridge or parapet at a distance that does not exceed 1.5 m, its height must be more than 0.5 m. If the pipe is within 1.5 to 3 m from the roof ridge, then it cannot be lower than his.

- The height of the ventilation pipe above the flat roof cannot be less than 0.5 m.

The location of the ventilation pipes relative to the roof ridge

When choosing a pipe for the construction of ventilation and determining its location, it is necessary to provide sufficient wind resistance.It must withstand a storm of 10 points, which is 40-60 kg per 1 m2 of surface.

Software use

An example of calculating natural ventilation using special programs

The calculation of natural ventilation is less laborious if you use a special program for this. To do this, the optimal volume of air flow is first determined, depending on the purpose of the room. Then, based on the data obtained and the features of the designed system, the calculation of the ventilation pipe is made. At the same time, the program allows you to take into account:

- average temperature inside and outside;

- the geometric shape of the ducts;

- roughness of the inner surface, which depends on the pipe material;

- resistance to air movement.

Ventilation system with round pipes

As a result, the necessary dimensions of the ventilation pipes are obtained for the construction of an engineering system, which must ensure air circulation under certain conditions.

In the process of calculating the parameters of the ventilation pipe, attention should also be paid to the local resistance during air circulation. It can occur due to the presence of grids, gratings, bends and other design features. The correct calculation of the parameters of the ventilation pipes will allow you to design and build an effective system that will make it possible to control the level of humidity in the premises and provide comfortable living conditions

The correct calculation of the parameters of the ventilation pipes will allow you to design and build an effective system that will make it possible to control the level of humidity in the premises and provide comfortable living conditions.

Conclusion

Forced type of ventilation allows you to eliminate extraneous odors, toxic fumes and moisture from the room. This type of device is considered to be the best solution for a private home. When installing products in apartment buildings and high-rise buildings, special requirements apply, which should be familiarized with at the initial stage of planning the system. The outlet for the hood is connected to a common duct system, so stagnant air masses are released into the street. For each type of building, different laying schemes are used, the design of which should be handled by specialists.