- General supply ventilation

- Axial inline exhaust fans, their features and originality

- Air conditioner model

- Natural and artificial ventilation system

- Types of air ducts for different ventilation units

- Ventilation systems

- No. 2. How much fresh air is needed?

- Types of ventilation, basic concepts and classification

- natural ventilation

- Filters for kitchen hoods

- Features of ventilation design

- Description and application of axial fans

- Classification according to the principle of air removal

- Mechanical ventilation system

- Supply

- What is ventilation: basic definitions, technical parameters, general requirements

- Supply and exhaust ventilation, their main components

- Ventilation of welding production workplaces

- Local exhaust ventilation

- natural ventilation

- Ducted and non-ducted ventilation systems

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

General supply ventilation

General exchange supply ventilation is arranged to assimilate excess heat and moisture, dilute harmful concentrations of vapors and gases that are not removed by local and general exchange exhaust ventilation, as well as to ensure the calculated sanitary and hygienic standards and free breathing of a person in the working area.

With a negative heat balance, i.e., with a lack of heat, general exchange supply ventilation is arranged with mechanical stimulation and with heating of the entire volume of supply air. As a rule, before supplying the air is cleaned of dust.

When harmful emissions enter the air of the workshop, the amount of supply air must fully compensate for general and local exhaust ventilation.

Axial inline exhaust fans, their features and originality

Duct types are used for exhaust in various rooms.

Duct types are used for exhaust in various rooms.

In domestic rooms, round-shaped devices made of plastic are usually used. Such devices are capable of processing up to 350 cubic meters in 1 hour with a minimum noise level.

For industrial premises, devices that have a square or rectangular shape are suitable. Large volumes of recycled air require greater strength of the mechanism, so the case of an industrial duct fan is made of metal.

If the structure will be installed in rooms with high humidity, it is necessary to be especially attentive to the characteristics of the metal, giving preference to a material that is not susceptible to corrosion. The maximum capacity of industrial case fans is up to 17,000 cubic meters. for 1 hour.

Air conditioner model

When the type of system is selected, it remains to be determined which air conditioner is needed for a particular room.Experts give the following recommendations:

1. Wall-mounted and wall-ceiling type air conditioners are suitable for bedrooms and living rooms. They can be installed as close to the ceiling as possible, which saves wall space. The length of the track reaches 30 meters. You can clearly adjust the trajectory of the air flow - from a strictly vertical to a strictly horizontal position of the blinds, and warm air will be supplied to the floor. Most air conditioners are equipped with self-cleaning antibacterial filters with titanium apatite coating. Wall air conditioners are not only the usual snow-white, but also beige, and some manufacturers offer mother-of-pearl models. Separate air conditioners will look like a picture on the wall at all - the designers took care of the artistic execution of the case. By the way, you can apply the image to the air conditioner yourself, just remove the case and paint it in any color.

|

Wall type air conditioner |

Ceiling Type Air Conditioner |

2. Floor or column, floor-to-ceiling and ceiling type air conditioners are ideal for spacious living and dining rooms. The powerful unit is almost invisible: if necessary, it is mounted on the floor close to the wall or ceiling. A floor-to-ceiling air conditioner is indispensable when you need a wide and powerful air flow that can penetrate into the farthest corners of the room. The length of the track for some models is almost 50 meters.

In the ceiling version of the installation, a powerful air conditioner fan creates a wide high-speed air flow (up to 1660 mm), which first spreads smoothly along the ceiling, and then slowly descends, filling the entire room with uniform coolness, regardless of its footage and layout. This option is suitable for large areas that do not have false ceilings. The floor version is more suitable for air conditioning offices.

Column type air conditioner

3. Cassette-type air conditioners are appropriate for cooling rooms of complex shapes: L- or T-shaped, narrow and long corridors. The appliances are fixed to or under the ceiling (in the case of suspended ceilings). Such units are more compact compared to their wall and floor counterparts: the size of the front panel of some models reaches 650 × 650 millimeters. The air supply goes in four directions, the length of the route is about 20-25, and for some models even up to 70 meters.

Cassette type air conditioner

4. Duct-type air conditioners - for architecturally complex premises, where there are many differences between ceiling and inter-wall spaces, variable number of storeys, horizontal or vertical zoning. The indoor unit is a compact box that can be hidden in narrow ceiling and wall spaces. The main feature of this type of device is that cooled air can be supplied to several rooms at once.

Channel type air conditioning system

Natural and artificial ventilation system

The air flow in the ventilation system can be created in two ways:

- Naturally, due to the difference in air temperatures, pressure changes depending on altitude, wind pressure.Accordingly, such ventilation is called natural.

- Artificially with a fan. it artificial or mechanical ventilation.

Natural ventilation systems are used in the construction of typical housing: fresh air enters the room through leaks in windows and doors and is removed through ventilation ducts, the exhaust grilles of which are located in the kitchen and bathrooms. Such ventilation is cheap, reliable (no moving parts or automation) and durable.

The reverse side of the cheapness of natural ventilation systems is the strong dependence of their efficiency on external factors - air temperature, wind direction and speed, and others. In addition, such systems are, in principle, unregulated and, under certain weather conditions, simply stop working.

Artificial (mechanical) ventilation is used where there is not enough

natural. Since the mechanical system uses a fan, filter,

air heater and other elements that allow you to move, purify and heat the air, such systems can maintain comfortable conditions in the serviced premises regardless of the season and environmental conditions. That is why in apartments, cottages and offices they try, if possible, to install

artificial ventilation systems.

Types of air ducts for different ventilation units

An important part of the entire system is the air outlet channels that combine into a single whole the equipment from which ventilation is provided. Ventilation systems include various components, united by air outlet channels, which are an indispensable part of the entire structure.

Vents allow air to circulate. At the same time, three main factors influence how effectively the bends work - their type, the material from which they are made and the shape of their section. In addition to these factors, when installing ventilation, you should also take into account the dimensions of the outlets, sealants and sound insulation.

Ventilation systems include various components united by air outlet channels, which are an indispensable part of the entire structure. Vents allow air to circulate. At the same time, three main factors influence how effectively the bends work - their type, the material from which they are made and the shape of their section. In addition to these factors, when installing ventilation, you should also take into account the dimensions of the outlets, sealant and sound insulation.

Depending on the material from which they are made, there are plastic bends - for domestic use, and metal bends - used for production. According to the shape of the section, they are classified into: rectangular and round. In addition, their rigidity and flexibility can be an additional classification feature.

Ventilation systems

Still, air conditioners alone do not solve the problem of fresh air. The supply of oxygen from the street provides supply and exhaust ventilation

When arranging supply and exhaust ventilation, it is important to take care of how to make the noise that the installations will produce less noticeable.First of all, you should find out if the ventilation system provides for silencers, and the duct system itself must be calculated in such a way that the air flow rate is minimal

The ventilation of the cottage must necessarily include a supply system. Such a system in a country house will be most effective in combination with air conditioners - you will achieve both the desired climate and good air exchange. There is only one "but": "bad" air will not be removed from the room. This requires exhaust ventilation.

The exhaust ventilation scheme includes the fan itself and a network of air ducts with air intake grilles, or diffusers. There is also ductless exhaust ventilation: in this configuration, either an axial exhaust fan built into the window frame or a hole in the wall, or roof fans is provided.

To design supply ventilation, you need to know the following indicators:

- air consumption (calculated in cubic meters per hour and depends on the size of the room);

- heater power (kW);

- head or external static pressure (Pa);

- noise level (dB).

It is necessary to think about where and where the wind will blow in the house from at the design stage of the building. This is especially true of the communication part of ventilation and air conditioning systems: air ducts and outdoor units. The architect must also take care of how to fit air conditioners into the interior of the room. Sometimes a special column is installed to disguise them, or a box on the ceiling is decoratively played up.

No. 2. How much fresh air is needed?

The arrangement of ventilation or the modernization of an existing system is preceded by an analytical stage, which consists in determining the norms of air exchange.For different zones in the apartment, this parameter is different. There are many handy calculators on the web. programs for the most accurate calculation taking into account all the features, but you can use the average values, according to which:

- for residential areas, air exchange should be at least 30 m3 / h per person. If the area of the living area is less than 20 m2 per person, then it is necessary to ensure air exchange at the level of 3 m3 per square meter of the room;

- for the kitchen, air exchange should be 90 m3 / h if a 4-burner gas stove is used, and 60 m3 / h when using an electric stove;

- for the bathroom, air exchange is 50 m3 / h with a combined bathroom and 25 m3 / h for a bathroom and toilet with a separate one.

If there is a fireplace or stove in the apartment, the air exchange rates increase.

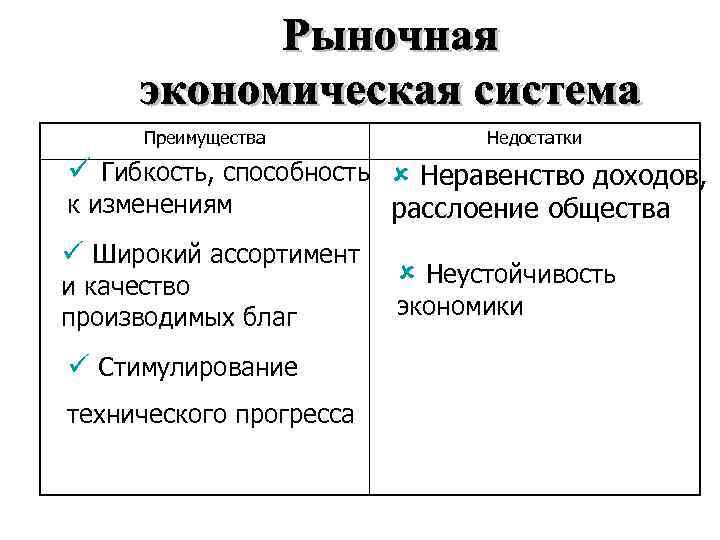

Types of ventilation, basic concepts and classification

Ventilation is a set of devices and measures to ensure normal air exchange in the premises. Based on this definition, different types of ventilation systems are classified as follows:

- according to the method of pressure and movement of air - natural and artificial;

- by appointment - supply and exhaust;

- according to the service area - local and general exchange;

- by design - channel and channelless.

Considering each type in stages, it is possible to determine the main advantages and disadvantages of ventilation systems. In order to maintain the desired microclimate, it is necessary to carefully study the issue of classification of ventilation units and apply them according to the required parameters. Types of ventilation in residential buildings do not differ much from those installed in public and industrial buildings.

natural ventilation

This type of ventilation works thanks to:

- temperature difference between atmospheric air and indoor air (aeration);

- air column pressure difference between the served room and the exhaust device;

- the effect of wind pressure.

Aeration is used in workshops with high heat releases when the permissible concentration of harmful gases and dust in the supply air in the working area is not exceeded.

Aeration is not used if, according to the conditions of the workshop technology, it is necessary to pre-treat the supply air or if, due to the inflow of atmospheric air, condensation or mist.

In ventilation systems in which air moves due to the pressure difference of the air column, the height difference (minimum) between the level of intake of internal air and its outlet through the exhaust device must be at least 3 m.

The recommended horizontal length of the air duct sections should not exceed 3 m, and the air velocity in the air duct should not exceed 1 m/s. If these requirements are not met, ventilation will simply work inefficiently.

The effect of wind pressure is expressed in the fact that on the windward sides of the building (facing the wind) an increased pressure is formed and, conversely, on the leeward sides, it is reduced (air rarefaction).

If there are openings in the fences of the building, then the outside air enters the room from the windward side, and leaves it from the leeward side, while the speed of its movement in the openings depends on the speed of the wind blowing the building and, accordingly, on the difference in pressures.

The natural ventilation system is simple, does not require electricity and expensive equipment.But since the efficiency of the use of this system depends on external variables (temperature of atmospheric air, wind direction and speed), more complex functions in the field of ventilation cannot be solved with their help.

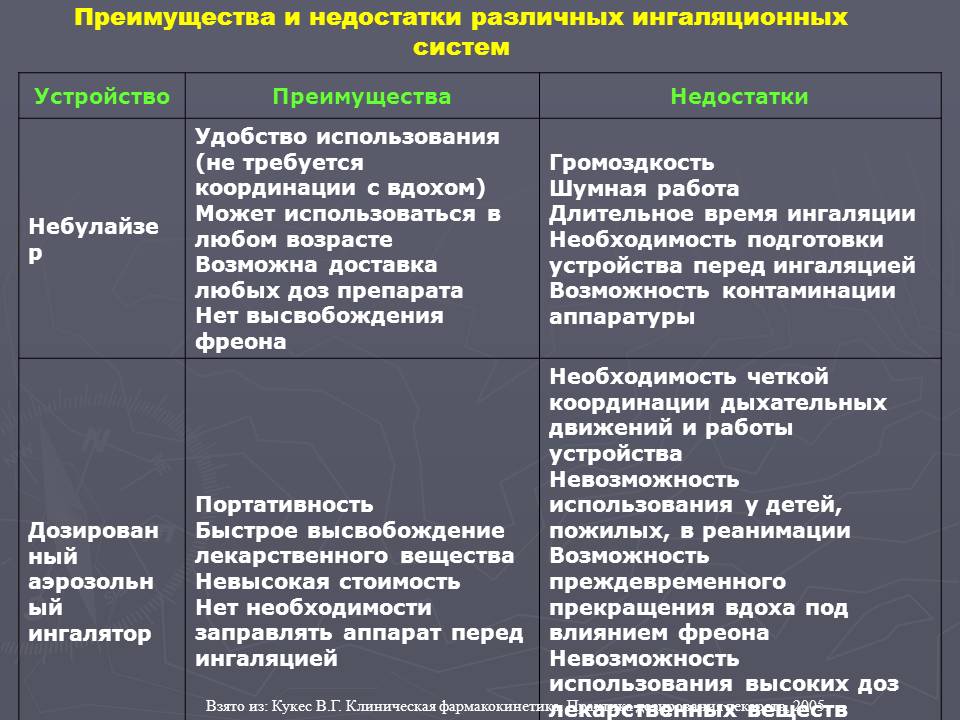

Filters for kitchen hoods

To date, filters for hoods are of the following types:

- Grease traps;

- Coal.

Grease filters are designed to protect the engine installed in the device from grease, soot, burning, soot. They are produced by the industry of two types:

- Replaceable acrylic filter (systematically it is necessary to change);

- Aluminum filter, which consists of several layers of thin aluminum. It is not changed, but washed as it gets dirty.

Carbon elements are usually included in the delivery set, in the amount of 1-2 pieces, depending on the number of motors in the device. If the device operates in the hood mode, then you do not need to use carbon filters, but if the hood works in the air purification mode, then it should be changed at least once every 4 months.

The technical characteristics of the hoods are different and therefore one specific type of filter is optimal for each of them.

Features of ventilation design

Considering what types of ventilation are and their main parameters, you can achieve the desired result. In buildings with poor ventilation, there is a risk of dust accumulation.

Do-it-yourself installation of a ventilation duct in a false box

The use of household chemicals, the operation of household appliances lead to a change in the chemical and physical characteristics of the air.The design of any residential or industrial buildings is not complete without a pre-designed ventilation system.

A properly planned system makes it possible to achieve the desired microclimate indicators. Different types of ventilation of premises - residential, public, industrial - have their own norms and requirements. This is an important engineering and technological aspect. Only competent implementation of the design of ventilation systems will guarantee consistently optimal conditions in any building.

Description and application of axial fans

An axial fan is a simple device in which the rotation of the axis leads to the vigorous rotation of the blades of the impeller mounted on the axis.

An axial fan is a simple device in which the rotation of the axis leads to the vigorous rotation of the blades of the impeller mounted on the axis.

An obligatory component of the device is an electric motor. It is he who ensures the movement of all parts of the device. Air circulation occurs due to the fact that it moves with blades, the size of which can be different.

Axial ventilation systems are widely used:

- Household devices with blades of several tens of centimeters are used in apartments and small office spaces.

- Industrial structures can have blades several cops long. They are installed in large areas (offices, restaurants, warehouses, etc.).

Axial structures are convenient because of the variety of existing types, you can choose the most convenient for installation and purpose.

Classification according to the principle of air removal

Ventilation is often arranged according to a combined scheme.

Ventilation is often arranged according to a combined scheme.

Ventilation is a system of structural elements interconnected according to a certain scheme. At the same time, there is a classification according to the method of organizing air movement.Based on this, natural air circulation and forced air circulation are determined.

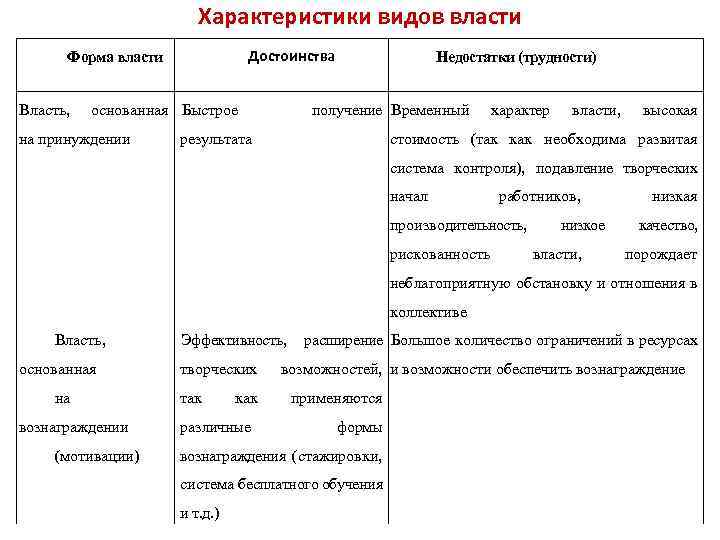

Mechanical ventilation system

If natural ventilation for some reason does not cope with its functions, it is supplemented or replaced by mechanical ventilation. Here, special equipment is used to force the movement of air into and out of the room. In addition to direct air supply and intake, mechanical systems allow for its additional processing: purification, heating or humidification. Depending on the method of organizing air movement, forced ventilation systems are:

Supply

Provide forced supply of fresh air to the room. At the same time, the exhaust air is removed naturally due to excess pressure, using air channels.

It looks like a ventilation system in a hotel complex

It looks like a ventilation system in a hotel complex

Already from the name it is clear that the system combines both types of forced movement of air masses, that is, their supply and output. Such a system is more efficient, because. during its operation, the same amount of air is supplied and taken. They can be installed as two separate systems operating independently of each other, or as a single structure.

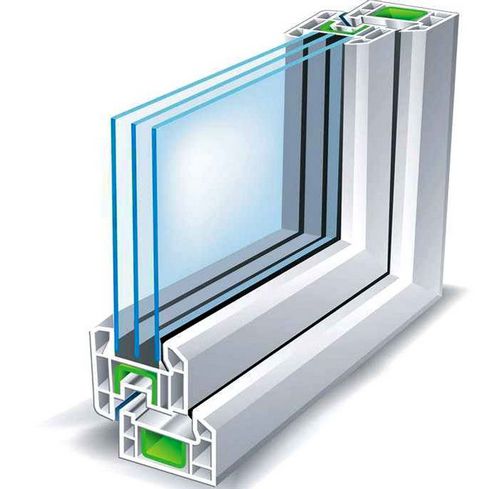

What is ventilation: basic definitions, technical parameters, general requirements

Engineering structures of this category provide fresh air to the premises. The required performance and other important parameters are determined taking into account the specific purpose. So, in residential and public facilities, office buildings, the main thing is the implementation of the relevant sanitary and hygienic standards.When equipping warehouses, they create optimal conditions for storing certain products.

The perfection of modern window designs prevents access to fresh air

The better the room is isolated from external influences, the easier it is to create comfortable conditions in it. A cursory analysis of thematic recommendations and the corresponding segment of the construction market will quickly convince you of the accentuated attention to this parameter. Perfect sealing and insulation help to further save money by reducing ongoing heating and cooling costs. However, the conditions of oxygen starvation are harmful to human health, cause fatigue, provoke the occurrence of dangerous diseases.

The need for a ventilation device in a private house (apartment) is understandable. It remains to figure out how to implement the project at a reasonable cost, without unnecessary difficulties. To do this, you need to study the available ready-made solutions, choose the option that suits you. Next, you need to make adjustments taking into account the characteristics of a particular property, your own preferences.

When studying materials, you should pay attention to the following factors:

- the air outside can be heavily polluted, so cleaning will be required.

- in practice, there is a need to increase / decrease performance.

- such systems are built inside building structures - it is required to provide access for inspection, repair.

- for the same reason, they positively evaluate the durability, the absence of difficult requirements for the frequent performance of routine maintenance.

- it is necessary to check the compliance of the chosen solution with the architectural features of the building.

- check the possibility of performing installation operations on your own.

The filter of the ventilation system prevents mechanical contaminants from entering the premises

Supply and exhaust ventilation, their main components

In my own way purpose of ventilation systems are divided into two groups: supply and exhaust. The supply system is one of the types of mechanical ventilation. The principle of its operation is based on the forced supply of fresh air into the room. The exhaust air is expelled to the outside by means of natural ventilation systems.

All types of supply ventilation consist of:

- Supply fans - provide air flow.

- Silencer - reduces the noise level generated by the unit.

- Heater - The supply air can be heated. This is especially true in the winter season. If the heating comes from the mains, then this type is called electric. If the heating comes from a central heating system, this is a water type.

- Air intake grille - designed to filter mechanical contaminants that may enter from the outside.

- Filter - cleans the supplied air from various impurities. There are filters of coarse, fine and extra fine cleaning.

- Valves - do not let air into the premises at a time when the system is turned off.

- Air ducts - channels through which air masses circulate.

Ventilation of welding production workplaces

Ventilation in welding production is designed to clean the air masses of harmful impurities with high quality and thoroughness, since welding work is one of the most harmful types of work for human health, nitrogen, carbon, fluorine oxides and many other various chemical compounds are certainly formed during the welding process.

The type and organizational type of ventilation of such a workshop depends, first of all, on the dimensions and capacity of the production of welded products.

If the capacity of the welding shop is small, and the volume of products produced is also small, then local ventilation can be arranged at the welding workplace.

Industrial ventilation has long ceased to be a simple production necessity. In various industries of modern directions (capacities and volumes), ventilation has begun to act as the most important engineering complex, because the correct organization and subsequent implementation of measures to equip production with ventilation systems contributes to the creation of a healthy microclimate in workshops and production sites. This means that it makes it possible to carry out high-quality technological processes, aimed at observing the basic safety provisions, and also contributes to the proper organization of each workplace, and most importantly, eliminates harm to the health of an employee involved in production.

Local exhaust ventilation

local exhaust

ventilation is used when

hazardous areas in the room

localized and can be prevented

distribution throughout the room.

Local exhaust ventilation in

production facilities provides

capture and removal of harmful emissions:

gases, smoke, dust, mists and partly

heat released from the equipment.

Used to remove pests

local suctions (shelters in the form of cabinets,

umbrellas, side suctions, shelters in the form of

casings for machine tools, etc.).

Primary requirements,

which they must satisfy:

place of education

harmful emissions, if possible, should

be completely covered;

design

local suction should be

so that suction does not interfere with normal operation

and did not reduce labor productivity;

harmful secretions

must be removed from the place of their formation

in the direction of their natural movement

(hot gases and vapors must be removed upwards,

cold heavy gases and dust

way down).

Air expelled

from the premises with local exhaust

ventilation before it is released into the atmosphere

must be pre-cleaned

dust. The most complex exhaust

systems are those in which

provide for very high degree

air purification from dust with installation

consecutively two or even three

dust collectors (filters).

Local exhaust

systems are generally very efficient,

because they allow you to remove harmful

substances directly from their place

education or excretion without giving them

spread indoors. Thanks to

significant concentration of harmful

substances (vapours, gases, dust), usually

succeeds with a small amount of removed

get good air

sanitary and hygienic effect.

Local ventilation is a system of air exchange in a limited part of the space, the microclimate of which differs from its general atmosphere. That is, in fact, this type of ventilation is intended for installation at a separately considered workplace.

If the ventilation tasks that the premises and its purpose set for the specialists of VeerVent LLC can be solved by the method of general and local ventilation, the latter option is always chosen, since it not only has high efficiency, but is much more economical in terms of electricity consumption compared to the general exchange counterpart . But in terms of performance, a separate local ventilation system, without a general exchange supply and exhaust system, is not very effective. HVAC designers estimate such efficiency from 40% to 70%, from the required 95-100%, since the health of personnel depends on the local exhaust system.

In rooms with a local emission of harmful substances, the use of local ventilation can reduce the amount of supplied and exhausted air by several times!

natural ventilation

Proper natural ventilation

Proper natural ventilation

Contains absolutely no accessories. Air exchange occurs under the influence of external factors: the difference in temperature and pressure inside and outside the room, as well as the force of the wind. There are the following types of natural ventilation:

- unorganized - one that occurs under the influence of exclusively external factors: temperature, pressure and wind strength. Air from outside enters the room naturally through cracks and leaks in doors or windows. Cement or wood also have a fairly porous structure, so air exchange occurs even through the walls of the house. Covering the walls with oil paint or concrete significantly reduces the flow of fresh air into the house in an unorganized way;

- organized - also achieved without the use of technology, only air enters through a specially created system of air channels, which are removed through holes in the walls to the roof and end with a deflector. This is a special device that is mounted on a pipe on the roof to enhance the outflow of air from the room using the meteorological conditions on the street. Such a ventilation system is designed during the construction of the house.

A properly organized ventilation system is the key to a comfortable microclimate in the room, the absence of dust accumulation, the development of mold and fungus. The issue of designing a ventilation system should be approached responsibly, and not try to save money on it, because violations of its operation can lead to deterioration in well-being, fatigue and the development of diseases. And excessive humidity, in addition to health, can also spoil furniture, books, wallpapers and paintings.

Ducted and non-ducted ventilation systems

The duct version includes a system of air ducts made of steel or plastic. The main factors affecting functionality are:

- the selected material, plastic with a smooth surface that creates fewer obstacles to air masses, metal that tolerates temperature changes well;

- duct size;

- channel section (there are round, rectangular and flexible options).

A striking example of a ductless ventilation system is a general exchange view. A similar type may consist of a fan installed in a wall or window, which is responsible for the circulation of air masses.

Conclusions and useful video on the topic

This video is a kind of educational program about ventilation.Here, the very concept of ventilation is considered in detail and all issues related to its competent design are covered:

Both business leaders and private developers must understand that the normal life of those for whom they are responsible depends on the efficiency of ventilation. Sometimes people's lives are at stake. You can not miss this moment and save on it.

Have questions about the topic of the article, found flaws or have valuable information that you could share with our readers? Please leave comments, share your experience, participate in discussions.

Conclusions and useful video on the topic

Characteristic features of plastic, asbestos-cement, corrugated aluminum and galvanized steel pipes for ventilation of basements and cellars:

The organization of the ventilation system requires a competent approach to the choice of the main structural elements - ventilation pipes. Most of the requirements for the air ducts of private houses are met by products made of galvanized steel, stainless steel and plastic.

The form is of no fundamental importance. Its choice depends on the characteristics of the trajectory of the passage of the ventilation network.

Or do you have knowledge / practical experience in the installation of ventilation pipes and want to supplement our material with useful clarifications and comments? Write your opinion, add tips, supported by practical experience.