- Features and secrets of the popularity of brick ovens

- Cleaning

- Video description

- Conclusion

- The process of laying the furnace Radonezh

- Video - Do-it-yourself heating furnaces

- Video - Do-it-yourself heating furnaces

- The process of the Russian stove

- Classification of brick kilns by purpose

- Cooking and bath brick models

- Types of modern wood-burning stoves for heating a private house

- Classic wood burning stove

- Classic Russian brick oven - a universal choice

- Classic metal oven

- Combined electric wood burning stove

- How to determine the optimal location of the furnace

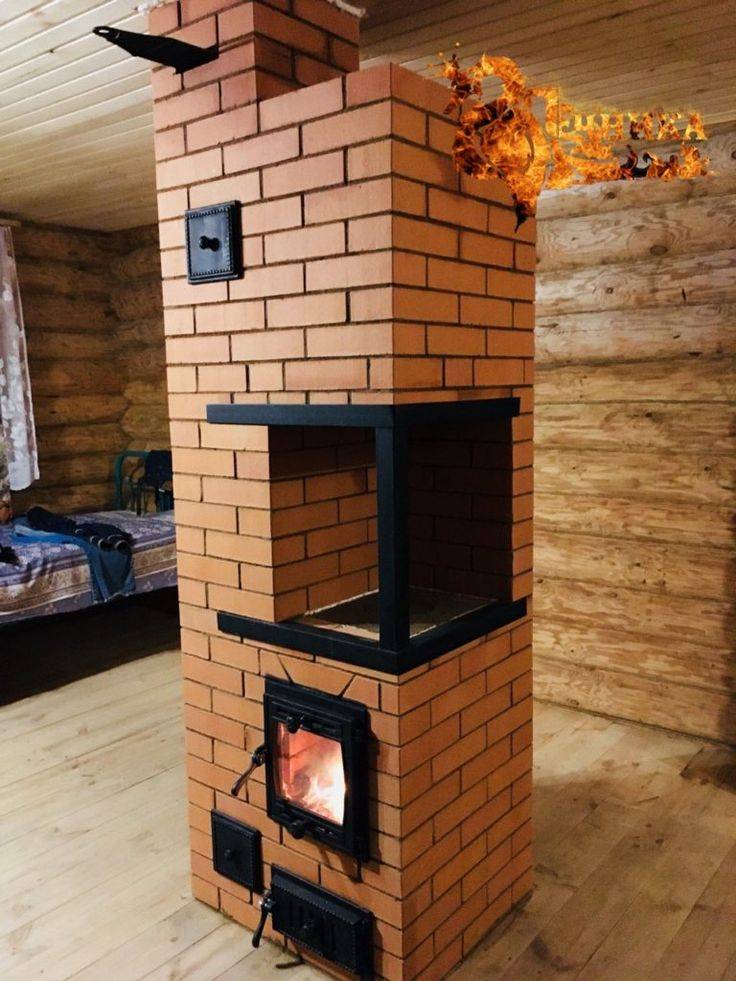

- Varieties of brick ovens

- dutch stove

- Sauna brick stoves on wood

- Russian oven

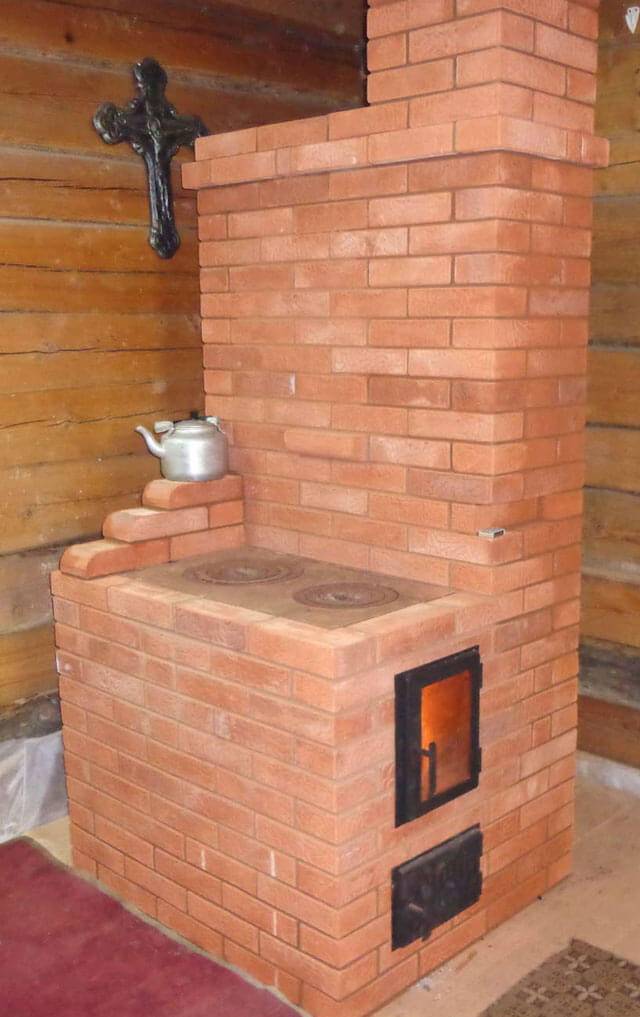

- Heating and cooking stove

- Heating of a one-room house

- How to choose a stove for a brick house

- Why brick construction

- dutch oven

- Where is the right place to put it?

- Features of a brick oven

- How to make a tandoor

Features and secrets of the popularity of brick ovens

A brick oven is not only a functional heating device, but also a stylish interior element.

Probably, there is no such person who would not like a living hearth with crackling firewood and especially comfortable warmth.But the good old brick oven will be able to please not only with this, but also with the ability to create the most favorable atmosphere for health. It's all about the material from which this amazing unit is built. Being the closest relative of ceramics, brick emits water vapor into the air when heated, and absorbs it back when it cools. The stove, as it were, “breathes”, due to which the optimum humidity is established in the room.

It is also important that the heat becomes already at a temperature of 18–19 ° C, while when using other types of heating, the comfort level starts from 20–21 ° C. In addition, being made of clay, brick is an environmentally friendly material, which means that during the operation of the heater, you can not worry about the release of compounds harmful to health.

Despite the fact that each type of brick heat generators has its own functional and design features, they are all similar to each other in terms of arranging the furnace and heat exchange parts. So, any stationary furnace of this type has:

a foundation that serves as the base of the heater and evenly distributes its weight over the entire area; a furnace that simultaneously acts as a firebox and a combustion chamber; a grate that allows for the lower air supply to the combustion zone. Due to this, the performance of the heating unit increases and it becomes possible to adjust the intensity of fuel combustion; an ash chamber that facilitates cleaning the furnace; a chimney that creates the necessary draft and emits exhaust gases into the atmosphere.

Construction of a channel-type brick kiln

In addition to their main purpose, wood-burning heat generators are also used for cooking, as well as arranging an additional place of rest. The structure itself can be installed both indoors and in the yard, for example, in a recreation area with a barbecue, barbecue or cauldron. If we talk about fireplace stoves, then their heat-generating function is completely relegated to the background, giving way to a visual and image component.

The advantages of brick ovens include:

quick heating of the surface; the possibility of using several types of fuel; low operating costs; the risk of burns is eliminated when touching the walls of the heater; especially soft, comfortable heat; the air in the room is not dehydrated; wide possibilities in terms of interior decoration.

The units under consideration also have disadvantages. The most significant of these is the potential danger of carbon monoxide poisoning, which appears when used improperly. Another is the large size and weight. That, perhaps, is all. As you can see, equipment of this type has solid advantages and the almost complete absence of negative aspects, which, however, determines its high popularity.

2

Firebox - heat transfer and fuel affect the device

The simplest device is for a heating stove, which has two parts: a firebox and smoke turns. Other types of ovens contain additional devices. The main part of any furnace is the firebox. Certain requirements are imposed on it, in particular, it must be of sufficient size: for one bookmark to contain almost all the fuel. Air must be supplied in the required volume, a high temperature must be constantly maintained.

With insufficient dimensions of the firebox, low heat transfer is observed. The width depends on the required heat transfer: up to 1 thousand. kcal - 12 cm, up to 3 thousand - 27 cm, if more - up to 50 cm. For convenience, the dimensions of the firebox are taken as multiples of a brick. The length is made from 26 cm to 51 cm, the longest is intended for firewood. Fuel used affects height: 6–15 rows (42–100 cm). The grate is laid a row or two below the door so that the coals do not fall out. Often the rear is tilted higher than the front for better combustion.

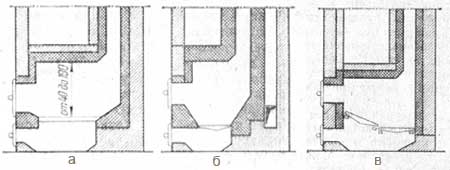

Fireboxes: a - wood-burning; b - peat; c - coal.

A fireclay brick is used for the firebox, with which it is laid out or lined from the inside. The total wall thickness is not less than ⅟2 bricks. The firebox, made in the form of a vault, improves the quality of combustion. All types of fuel burn well in a wood-burning firebox. For coal, reinforced grates 4 cm thick and good blowing are required, for which the dimensions of the grate are equal to the length of the ash pan under the firebox.

Cleaning

Major cleaning, as well as repair work, is best organized in the summer, but in winter it is also necessary to periodically assess the amount of soot in the chimney. Sometimes, due to improper kindling, bad firewood or other reasons, pollution occurs much faster and additional cleaning is required. With the accumulation of soot, at best, the thermal efficiency of the furnace is reduced, and at worst, all the smoke and carbon monoxide can go into the room.

Video description

For cleaning a brick oven, see the following video:

The ash chamber and grate cleaning should be carried out in each firebox.

Conclusion

If the house has a stove, it means that there is warmth and homeliness.But regardless of the chosen design of the brick oven, its proper functioning will depend not only on how well it is made, but also on its proper maintenance by the residents of the house.

The process of laying the furnace Radonezh

First step. Cut a hole in the wall for the oven. Hammer reinforcing dowels into the ends of the timber (if the wall is made of this material).

Second step. Pour the foundation.

Proceed to masonry 1-1.5 months after the arrangement of the foundation. It is during this period that the concrete will gain the desired strength.

Third step. Cover the dried foundation with waterproofing material.

Fourth step. Lay out the first row of the stove. Check the evenness of the masonry with a level. Make seams no wider than 3 mm.

Continue laying the furnace in accordance with the order.

The grates and the blower are arranged in the combustion chamber. The width of the furnace blower must be sufficient for the inflow of the required amount of air to the loaded fuel during the operation of the heating unit.

Lay out the furnace chamber and sew the channels. Cut off excess solution.

When laying the 26th row, make a 20 mm overlap on each side.

Complete the laying of the main part of the furnace in order and proceed with the laying of the chimney.

Continue the arrangement of the chimney in accordance with the previously prepared project.

Dry the finished oven. To save time, install a fan in the combustion chamber.

After the masonry has dried, do a few test runs. Don't make the first fires too intense.

If everything is done in accordance with the instructions, order and basic requirements, after an average of 30-40 minutes, the side of the stove that goes into the room will heat up.After about 1.5 hours, the unit will warm up evenly and begin to fully heat the room.

The self-made construction of a heating furnace is a rather complicated and lengthy process, but if you wish, you can cope with such an event. It is only necessary to follow the proven technology, use only high-quality building materials and adhere to the chosen masonry scheme in everything.

As a result, the heating unit will serve as long as possible, reliably and efficiently, and you will additionally save on arranging the heating system of your home by refusing the services of third-party stove-makers and doing everything with your own hands.

Video - Do-it-yourself heating furnaces

Video - Do-it-yourself heating furnaces

Everything is very well written. From myself I will add that there is no need to look for refractory clay. Now ready-made mixtures for laying stoves and fireplaces are sold on the building materials market. Everything is already mixed in the right proportion. Even after drying the oven, there is one point. Make the first run using only paper and cardboard as fuel. Firewood is highly undesirable. Then you will get the required temperature. Heat it this way for no longer than an hour. As the clay dries, it may smoke a little. That is, the smoke will be in the room. Don't be afraid of this. The clay will dry very quickly and the stove will work as it should.

I want to suggest one interesting idea that I myself experienced. Inside the furnace, you can lay out "Gabrodiabase". This stone is a type of granite and is used to make monuments.Trimmings can be requested at funeral services, after making sure that this is really gabrodiabase, and not simple granite. You can buy, but this stone is very expensive, because it can withstand high temperatures! Good luck!

On my own in the country, I twice made stoves in the house and in the bathhouse. In the latter, the second option turned out to be relatively successful, but there the design itself is simple. In the house, metal stoves lined with bricks served as the basis. I immediately rather modestly assessed my capabilities in the construction of a more complex structure, and still, having already had experience, I think so. That is, for the construction of a good stove and, moreover, a fireplace, it is best to turn to good stove-makers. By the way, my sister did just that, and until they installed the boiler, she worked great for them.

Have we answered your question?

The process of the Russian stove

Despite serious competition and a solid history, the construction is still in demand among owners of suburban real estate. According to the way the Russian stove is arranged from the inside, it will be possible to focus on the dimensions from the outside and, accordingly, plan a place for it and lay the foundation.

Before you fold the Russian stove, you need to understand its principle of operation - the design is a periodic heating device, that is, when burning firewood, it accumulates heat, then gives it away for almost a day. So the building can warm or languish for almost a day, which makes it possible to cook baked milk in it, steam porridges and soups without controlling the process.

Before you make a Russian stove, you should build a separate foundation base that is not connected to the tape, since the structure usually has a lot of weight

This is especially important when the house "dances" on heaving soil during freezing and thawing. In this case, the stove will move along its own amplitude along with its foundation, without destroying the finish and without affecting the walls and openings.

Russian stove in section during heating and languishing

Work principles:

- the whole structure stands on a brick guardianship or concrete;

- firewood for kindling is stored in the stove, where it dries very well and lights up instantly when ignited;

- the top of the stove is made with a hemispherical vault, like a trough;

- sand, clay, brick battle - any heat-intensive material is poured on it, and on top of it is laid out under the furnace - the front part of the furnace (cooking chamber), it is laid without clay mortar.

If you ignore the filling, then you can forget about real hearth bread and pies. By the way, they are baked on cabbage leaves.

Next comes the bail with an overtube and a hail in the form of a tapering nozzle. Ash pans are provided on the sides in the wall near the walls - recesses for smoldering coals (for the next kindling) and ash. Sometimes they are raked into an ocholok - a part of a cast-iron or stone slab (pole), protruding from the face (chela) of the furnace.

To reduce costs and cleanliness in the room, an ash pan and an eyeglass can be omitted. Previously, they were raked into the corner of the mouth, then the coals of birch, maple, elm, oak and aspen kept heat only for a day.

Cooking in a cast iron stove

Most likely, this is where the belief came from that the Russian stove is quite picky in the form of fuel. But this is not so - it works on any solid fuel, including:

- brushwood;

- dung;

- deadwood;

- sawdust

- straw;

- peat briquettes.

The zagnetok, thanks to this configuration, acts as an economizer, where the following happens: the smoke circulation heats up the air, which enters the furnace, without extracting oxygen from it and without preventing combustion - there should be no mixing of heat flows. In fact, the zagnetok is an energy recuperator (heat exchanger).

Before building a Russian stove, you should check the dimensions in advance - this is important so that the building does not smoke, does not cool down quickly and does not use a lot of firewood. For the same purpose, perfectly smooth hail vaults are made.

Moreover, they cannot be plastered, so the bricks on the inside are hewn and polished to a gloss - then there will be no turbulence in the overtube.

The smoke from the oven goes up the chimney

Classification of brick kilns by purpose

There are several classifications of stoves for the home. They differ mainly in their design. A brick oven can be of the following variations:

- cooking;

- heating;

- bath.

The heating stove is the least demanded type among the owners of country houses. This is due to the narrow purpose of such products, mainly it is used only for heating the building. Currently, most houses are equipped with a water heating system, in connection with this, stoves that can only heat a room and are not capable of anything else are a thing of the past, now you can rarely find such a structure.

Scheme of the heating and cooking furnace.

Heating ceramic furnaces have their own classification:

- High heat dissipation structures. Such models can heat up the air in the room well and quickly.

- Designs with different duration of kindling.Products belonging to this variety have different times for burning the fuel and heating the building.

- Models with high thermal conductivity of the material of manufacture are built from raw materials capable of dissipating heat as quickly as possible.

Such a stove takes up a lot of space, while performing only one “action”. In addition, the bulky appearance causes a large number of bricks consumed during the construction, as well as significant time costs.

The brick cooking and heating model has a different set of functions compared to the previous one. In addition to heating the room, the design is also used for cooking. Its productivity is 50% higher than a conventional oven. Such stoves with an oven and stove are able to heat the room. Additionally, structures can be equipped with a boiler designed for steam heating.

Cooking and bath brick models

A cooking oven with an oven and a stove, like the previous variety, does not have a 100% heating function. The design can heat the room, but only a small size. The advantages of a stove with an oven and stove include small dimensions, which significantly reduces the amount of building material required for its construction.

If you wish, you can build a stove with an oven and a stove yourself, without involving specialists

It is only important to consider that the correct location of the shields in such a product is of fundamental importance.

A brick sauna stove is designed for bath procedures. The advantage of such a furnace is that the brick is capable of retaining heat for a long time after heating. In terms of their effectiveness, such designs are inferior to sauna stoves made of metal.Special types of stoves are also in demand, designed for heating technical rooms, drying wet laundry.

Types of modern wood-burning stoves for heating a private house

Modern wood-burning stoves come in various types: devices differ in power, according to the principle of operation, and in appearance. Such appliances also often have additional features that make the oven a complete replacement for the stove and water boiler. Most often, for country houses, they choose an ordinary wood-burning model with a connection to the mains.

Classic wood burning stove

A conventional stove, for which firewood is used, is the most common option for heating a country house. The device is not afraid of the absence of a gas pipeline or any problems with electricity, and reliability and long service life distinguish it from other types of devices.

Photo 1. A classic wood-burning stove made of brick and equipped with a place for cooking and storing firewood.

There are several types of devices that differ in the material of manufacture.

Classic Russian brick oven - a universal choice

A perfect example of a multifunctional device. With its help, the house was heated, food was cooked, and water was heated for household and personal needs. She often served as a sleeping place, her ability to keep warm for a long time made the winter cold fearless.

Modern Russian brick ovens represent various improved versions of the historical prototype. They are even more functional. Such stoves are easier to maintain, they evenly heat the room, thanks to the long-burning system.It is possible to install an oven and hob, as well as a heat exchanger for water heating.

Classic metal oven

Favorably differs from the brick device in compactness and ease of installation. Despite their small size, such devices are designed to heat a fairly large space due to the long-term combustion system. For manufacturing, steel or cast iron is usually used, often combined options.

Photo 2. Wood-burning metal stove with installed thermal glass and a place for cooking.

It is possible to connect a water circuit to devices of this type, add additional functions, for example, a hob. By installing a thermoglass door, it is possible to produce an analogue of a home fireplace, which creates a special comfort.

The device of a conventional wood-burning stove includes two chambers - the main furnace and a chamber for burning the gases released during combustion. For efficiency, such devices often use not the combustion of firewood in the firebox to heat the room, but the process of their smoldering. For this, a system is equipped that blocks the access of air to the combustion chamber at the right time.

Combined electric wood burning stove

To increase the efficiency of heating equipment, as well as to cover large areas, a variant of combined devices has been developed - wood-burning stoves equipped with one or more heating elements and requiring connection to the mains.

Reference. It is often advantageous to equip such electrical devices with a water circuit to maintain heat throughout the house.

The principle of operation of such equipment at the first stage of operation does not differ from the operation of a conventional wood-burning stove: firewood is laid in the furnace, after it burns out, an electric heating system is connected, most often these are two electric heaters installed on the sides of the combustion chamber, which turn on as soon as the temperature starts to drop below a certain mark.

This method allows you to effectively extend the duration of heat from a single load of firewood, more expensive models can also be equipped with an automatic fuel loading device, which eliminates the need to directly monitor the operation of the stove. In the event of a power outage, such a device can be used no less effectively for space heating in the mode of a conventional wood-burning stove.

How to determine the optimal location of the furnace

It is necessary to determine the place in the house for the furnace according to certain parameters. The following indicators are taken into account:

- area of a residential building;

- how many rooms should be heated;

- what is the oven for and what kind;

- how will the gases be removed during combustion;

- the location of the furnace must comply with fire safety requirements.

The stove should heat every room in the house as evenly as possible. If this condition is not met, either an additional furnace or water heating system equipment will be required.

In order to heat the rooms adjacent to the kitchen, a heating and cooking stove is used. It is placed in the kitchen, and the rest of the rooms are heated by a heat-releasing wall.

When building a stone house, you can immediately think over the layout of the chimneys in the walls, which will increase the usable area of \u200b\u200bthe house and ensure optimal heating.

When placing the stove on the border of the rooms, it is necessary to think over the place of its most successful placement so that the surfaces that transfer heat from the stove allow for a uniform and maximum distribution of heat.

Options for the location of the furnace in the house

Typically, a hallway or kitchen serves as a place to place the firebox. If the stove is well planned, it is almost invisible in the house. It does not clutter up the living space and is in perfect harmony with all interior elements. For example, a combination is often used. In one room there is one side of the building - a stove, and in the adjacent room, its second part - a fireplace. General chimney system.

Varieties of brick ovens

Next, we will consider all the main models of furnaces. At the same time, you will learn that they can be not only cooking, but also heating and cooking. Another variety is a wood-fired sauna brick oven (it can be equipped with a conventional or fireplace insert). Let's take a closer look at them.

dutch stove

She is a rough oven - the simplest and most compact, which is why its efficiency suffers somewhat. Therefore, a large amount of generated heat simply flies into the pipe. Furnace heating with coarse is characterized by its simplicity. For example, a Dutch woman may simply not have a blower - in this way she is somewhat similar to the most ordinary fireplace. But in order to increase efficiency, it is still recommended to make a blower.

But such a brick oven is extremely simple in laying - the scheme of the stove is distinguished by its simplicity. Because of this, she earned her popularity. But it does not have a cooking surface. And this is also a plus, since the unit is compact.Channels for the passage of smoke rise in it like a snake from the bottom up, located one above the other. The main advantages of this furnace:

- Compactness - if you want to create stove heating for a private house of a small area, with a limited area of \u200b\u200brooms, then the Dutch rough stove will be the best option;

- A simple masonry scheme is available for a beginner stove-maker;

- The ability to give any shape - from rectangular to round or some other.

It should also be noted that there is a small load on the foundation - this is due to the low weight of the Dutch wood-fired brick oven. Therefore, a strong foundation can not be done.

Sauna brick stoves on wood

In some ways, they are similar to the above-described coarse ones, but they differ in a special design - in their design there are heaters filled with stones. The firebox in them does not go into the steam room, but into the next room. If necessary, the doors of the fireboxes are made of glass - thanks to this, a fireplace is formed in the dressing room, which serves as an excellent decoration.

Russian oven

Considering the schemes of brick ovens for the home, you should definitely pay attention to the scheme of the Russian wood-burning stove. Such a stove will become a worthy decoration of the home. It is universal in use - it acts as a heater, is used for cooking (and right in the firebox), and is used to dry clothes at home.

And you can sleep on it, enjoying the warmth emanating from it.

It is universal in use - it acts as a heater, is used for cooking (and right in the firebox), and is used to dry clothes at home. And you can sleep on it, enjoying the warmth emanating from it.

Sleeping on a Russian stove is a special pleasure, now almost inaccessible.But at least once in your life you should give yourself such pleasure and sleep on a Russian stove heated with firewood.

Heating and cooking stove

The assembled brick oven for the house with your own hands can be made according to the universal scheme - according to Swedish. Such a stove (often referred to as a Swede) is wood-burning and is a multi-purpose device. It works as a heating unit, it can heat water and bake pies in the oven, it can be used to cook food in traditional dishes - using a simple hob.

Let's look at the features and advantages of such a brick oven:

- Large firebox for laying firewood - provides long-term burning;

- The presence of an impressive convector - efficient heating of rooms;

- The possibility of embedding water tanks and ovens - expands the functionality of the stove;

- The maximum use of the generated heat - the temperature of the combustion products here is quite low.

It is quite difficult to bring any specific typical drawing of the stove, since the laying patterns are different everywhere. There are also differences in filling - ovens are used somewhere, and somewhere there are built-in tanks for heating water.

The sizes of Swedish brick ovens on wood can be very different. Narrow options include the use of only the hob. If you need an oven, then the stove will increase slightly in size. That is, it can be not only compact, literally a few bricks wide, but also quite overall, occupying a decent area.

Some of these versatile wood-fired brick ovens require a strong foundation for themselves, which imposes restrictions on the possibility of their construction.

Heating of a one-room house

small stove

small stove

There are three ways to place a stove in a house where there is only one room and not a single wall is supposed to be, even separating the kitchen or hallway.

- If the room is not very large, such a fact as free space comes to the fore. A stove, even the smallest, if placed in the middle, will steal a lot of it. The heat transfer in this case will be maximum, there is nothing to say here, but constantly cruising around it is not very convenient. This option is suitable only with a spacious room.

- If you put the stove against the wall, there will be more free space. But, you say, in this case, one working surface of the wall will work idle, directly heating the wall near which it is located. This is true, and in this case, the wall must be protected from overheating with the help of heat-insulating materials. Or put the stove so that there is a small gap between it and the wall, at least 15 centimeters wide. And the wall will be safe, and the warm air circulating in this opening will also work to heat the entire room.

- In very small houses, a stove of a special design is placed in the corner, observing all safety measures. Usually two working surfaces are enough to heat the entire room.

However, we must not forget that real craftsmen-stove makers can even make a small stove in such a way that it can fit a stove, an oven and other accessories.Well, with proper operation, it will heat no worse than a real Russian village stove.

How to choose a stove for a brick house

When choosing a brick oven in the house, you should decide on the functions that it should perform. In addition to the presence of a cooking panel, the following criteria should be noted:

- If it is intended to use the stove as a heating device, it must be economical;

- We decided to lay out the oven on our own - make sure that the design has a simple appearance, this will allow you to easily cope with subsequent installation;

- The oven must have a water circuit;

Many owners of country cottages prefer to install decorative stoves to give a special design to the room. In this case, the classic Russian stove will be the best option; ease of use.

Why brick construction

Initially, it is important to highlight that brick structures are the most optimal and suitable, and this is due to their parameters and characteristics. The positive properties of brick stoves include:

Brick is a material that perfectly transfers heat into the room with the help of heated walls, which allows optimal and high-quality heating of rooms.

Furnaces made of this material are able to accumulate heat, and also, even after the cessation of adding fuel to the structure, they will heat the premises for quite a long time.

If you wish, you can build this structure using high-quality and suitable bricks on your own, since it is only important here to have the optimal and correct order available, as well as to know how to lay the material, what kind of furnaces and stoves themselves will be chosen, and what mortar will be used for masonry .

Brick is a material that is resistant to mechanical and other types of impact, and is also safe and durable, as a result of which the resulting structures have a long service life and excellent reliability.

The disadvantages of a brick stove for a house include the fact that it heats up for a long time, so it will be possible to heat a completely cold room after a rather long time after the start of heating the structure.

dutch oven

This type of furnace units owes its appearance to Russian stove-makers, it was they who invented it. The "Dutch" is intended for heat supply of premises. The stove is very compact and has a high degree of heat transfer. It will take 10 hours to completely warm up a cold room with it.

During the off-season, a do-it-yourself Dutch brick stove is able to retain heat for a day. Its structural device provides high heat transfer due to the winding chimney. In addition, the stove has a capacious firebox.

"Dutch" is erected only with the use of oven bricks, which accumulate heat quickly and release it gradually. This building material for the construction of furnaces is very expensive.

Where is the right place to put it?

If you decide to build a stove for a brick house with your own hands with a stove, you must first choose a suitable place, wherever you have to destroy the ceiling and underground bearing supports. If the floors are located on logs, for example, as is done in a wooden house, it is recommended to strengthen the floor base with additional jumpers before installing the heating device.

In the case when the base under the dwelling is solid, concrete, a separate foundation for the stove is not needed. The distance between the pipe and the roof ridge must be at least 1.5 meters, the pipe is located 0.5 m higher above the ridge. If the walls in the room are wooden, home-made stoves are built at a distance of a meter and a half from the wooden wall. If this option is not possible, to prevent fire, the walls are protected with metal sheets with a non-combustible layer.

Features of a brick oven

The popularity of brick ovens is explained by the presence of a number of positive characteristics:

- High thermal conductivity. Brick is one of those materials that transfer the heat received as a result of fuel combustion into the room almost without loss.

- The ability to store heat. A brick oven is capable of heating a room for a long time even after the flame in the furnace has faded.

- Ease of construction. Unlike a boiler, it is quite possible to build a stove on your own, using suitable high-quality material for this. The main thing is to acquire the optimal and correct order, having studied the technology of masonry work in advance. You will also need to choose the most suitable type of firebox and furnace design. It is allowed to use only a special refractory mortar during the laying of the furnace.

- Brick walls are quite resistant to mechanical and other influences, differing in durability and safety. This allows, subject to all the rules for masonry, to acquire a reliable heating device for a long time.

As for the disadvantages of brick ovens, they usually include a long heating time. This should be taken into account when heating initially cold rooms, starting kindling in advance.

How to make a tandoor

The most important part for making a stove is a cauldron. You should choose the largest and deepest. It must be put upside down, greased with sunflower or olive oil and wrapped with paper sheets. Then a special mixture is prepared: clay is mixed with sand in proportions of 1:2, a small amount of wool is added. Coat the outer surface of the boiler with this solution. A hole with a diameter of 40 cm is left in the upper part. The layer of the mixture should be quite thick - about 8 cm, and closer to the base - 10 cm. Be sure to let the product dry for 7-10 days.

There is another way to make the case: a thick solution is rolled into rollers (5 cm in diameter), and then tier by tier is wrapped around the cauldron. For the strength of the structure, it is necessary to tightly connect the resulting turns with each other - press them with your fingers and make tucks. After drying, the cone is removed from the cauldron, installed on a brick or stone foundation. A blower is made at the bottom of the furnace. In Asian countries, adobe is used for the foundation - a building material consisting of clay, straw and various additives.

You can decorate your creation with figures and patterns molded from the solution.Next, the tandoor should be burned - close the lid, heat with dry firewood and leave to cool slowly. Such a product will become the pride of the owner of the cottage, because he created it with his own hands.