- Rules for the operation of a brick oven

- Video description

- Cleaning

- Video description

- Conclusion

- Features of a brick oven

- Do-it-yourself equipment and building materials for building a furnace

- Brick

- Sand

- Masonry mortar

- How to make a rough oven with your own hands

- Operation features

- The procedure for laying the furnace

- Varieties of oven-coarse

- Classification by characteristics

- By dimensions

- By device

- By position

- By appearance

- What kind of brick to lay the oven

- Furnace in a modern house

- Features of laying a brick oven with your own hands

- Materials that will be needed for laying the furnace.

- Additional heating for large houses

Rules for the operation of a brick oven

In order for the furnace to serve for a long time, certain operating rules must be observed:

- The invariability of the characteristics of the stove is ensured by maintaining the integrity of its body. Even a small crack of 2 mm in the area of the valve will lead to the loss of 10% of the heat generated during the combustion of the fuel.

- The stove must be fired correctly. Heat loss with an open blower reaches 15‑20%. If, during combustion, the door of the furnace compartment is open, all 40% will come out into the open air.

- For the furnace, be sure to use dry firewood, harvested in advance.When using damp, less heat is released and due to the formation of caustic condensate, brick walls are destroyed.

- Uniform heating is possible only when burning approximately the same logs - from 8 to 10 cm thick.

Video description

Clearly about the errors in the installation and operation of brick ovens, see the video:

- The laying of firewood should be done with an empty space between them of 10 mm. Firewood is loaded into the firebox in parallel rows or with an intersection. The best option for filling the firebox is 2/3. The gap between the laying of firewood and the top of the firebox should not be less than 2 cm.

- To ignite the fuel, ordinary paper, a torch, etc. are used. Combustible substances: gasoline, kerosene or acetone should not be used.

- As soon as the stove is melted, the view is covered a little, otherwise all the heat will immediately disappear.

- The reference point when adjusting the draft during kindling is the color of the fire. The yellow color of the flame is considered optimal. If the flame is white, this indicates an excess of oxygen - a lot of heat goes immediately into the chimney. Red flame - there is little air, the fuel burns partially with the release of harmful substances into the air.

Cleaning

Major cleaning, as well as repair work, is best organized in the summer, but in winter it is also necessary to periodically assess the amount of soot in the chimney. Sometimes, due to improper kindling, bad firewood or other reasons, pollution occurs much faster and additional cleaning is required. With the accumulation of soot, at best, the thermal efficiency of the furnace is reduced, and at worst, all the smoke and carbon monoxide can go into the room.

Video description

For cleaning a brick oven, see the following video:

The ash chamber and grate cleaning should be carried out in each firebox.

Conclusion

If the house has a stove, it means that there is warmth and homeliness. But regardless of the chosen design of the brick oven, its proper functioning will depend not only on how well it is made, but also on its proper maintenance by the residents of the house.

Source

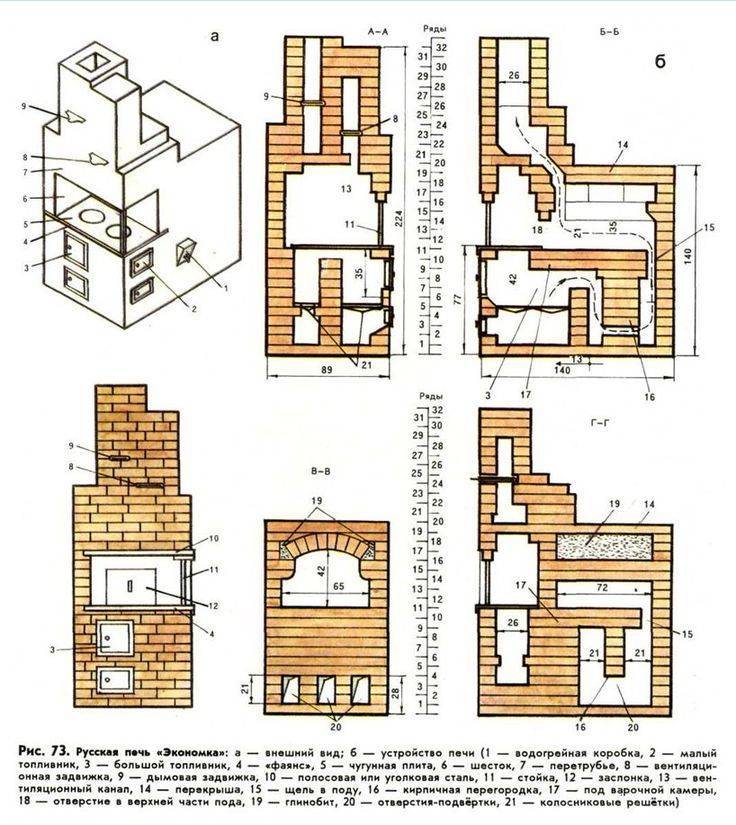

Features of a brick oven

The popularity of brick ovens is explained by the presence of a number of positive characteristics:

- High thermal conductivity. Brick is one of those materials that transfer the heat received as a result of fuel combustion into the room almost without loss.

- The ability to store heat. A brick oven is capable of heating a room for a long time even after the flame in the furnace has faded.

- Ease of construction. Unlike a boiler, it is quite possible to build a stove on your own, using suitable high-quality material for this. The main thing is to acquire the optimal and correct order, having studied the technology of masonry work in advance. You will also need to choose the most suitable type of firebox and furnace design. It is allowed to use only a special refractory mortar during the laying of the furnace.

- Brick walls are quite resistant to mechanical and other influences, differing in durability and safety. This allows, subject to all the rules for masonry, to acquire a reliable heating device for a long time.

As for the disadvantages of brick ovens, they usually include a long heating time. This should be taken into account when heating initially cold rooms, starting kindling in advance.

Do-it-yourself equipment and building materials for building a furnace

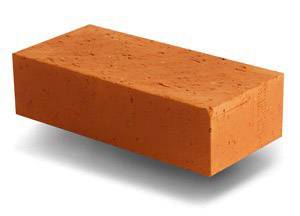

Brick

There are sources on the Internet claiming that brick for furnaces and refractory are one and the same. In fact, they have only linear dimensions in common. The dimensions of an ordinary single building brick are 250 by 125 by 65 mm., And the standard stove has a size of 230 by 114 by 40 mm. Sometimes there are 230 by 114 by 65 mm. In the construction of the furnace, a special high-quality brick of grade 150 is used. It is resistant to temperatures up to 800 degrees. It would be possible to build an entire furnace from it, but it cools quickly and is not suitable for a full-fledged furnace.

Fireclay bricks are used for laying furnace channels in the furnace part. It withstands high thermal loads. It is used in Swedish ovens or sauna ovens. It is able to withstand temperatures up to 1800 degrees, but in home ovens, this temperature does not happen. It is valued for other qualities - the ability to keep warm for a long time. It does not make sense to build the entire body of the furnace from it, since it is very expensive and has poor strength.

Bricks for oven

Bricks for oven

In order to distinguish high-quality fireclay from low-quality fireclay, there is an opinion that it should have a yellowish tint. But such a calculation is not correct, since chamotte can change color depending on its deposit. A sign of high-quality fireclay is the fine grain of the brick. Another way to check is to check for sound. The brick is tapped with a hammer. The sound should be loud and clear, not dull. The last way to determine the quality of the material is radical. The brick is broken in half and looked at the break. Qualitative fireclay is broken into large pieces.

As a substitute for expensive fireclay, clinker bricks are sometimes used in furnace construction.It is that de red ceramic, only it is fired at elevated temperatures. It has greater strength and fire resistance.

White silicate is not suitable for any parts. It is not resistant to thermal stress and absorbs moisture too much.

Sand

Quarry sand of medium fraction is used as sand in a cement-sand mortar. It is sifted through a sieve to sift out large fractions and various organic inclusions.

The presence of additional inclusions in this case is very important. All organic impurities will burn out from heating, due to which the masonry will crack and begin to crumble.

Masonry mortar

For laying the furnace, you will have to use several types of mortar based on:

- cement;

- Lime;

- clays;

- Fireclay.

A mixture of clay with the addition of fireclay is used in furnace parts. Such a solution withstands the highest thermal loads.

The lime mixture is used on the foundation masonry or for the chimney. This solution is strong enough, but can only withstand 450 degrees Celsius.

Cement-lime is even more durable than ordinary lime, but the fire resistance is reduced even more. Used in foundation.

Cement-sand mortar is used for laying a chimney. It has the best indicators of strength and resistance to precipitation. The seams of such a solution will not let smoke through and dig into the room and provide good draft for the firebox.

How to make a rough oven with your own hands

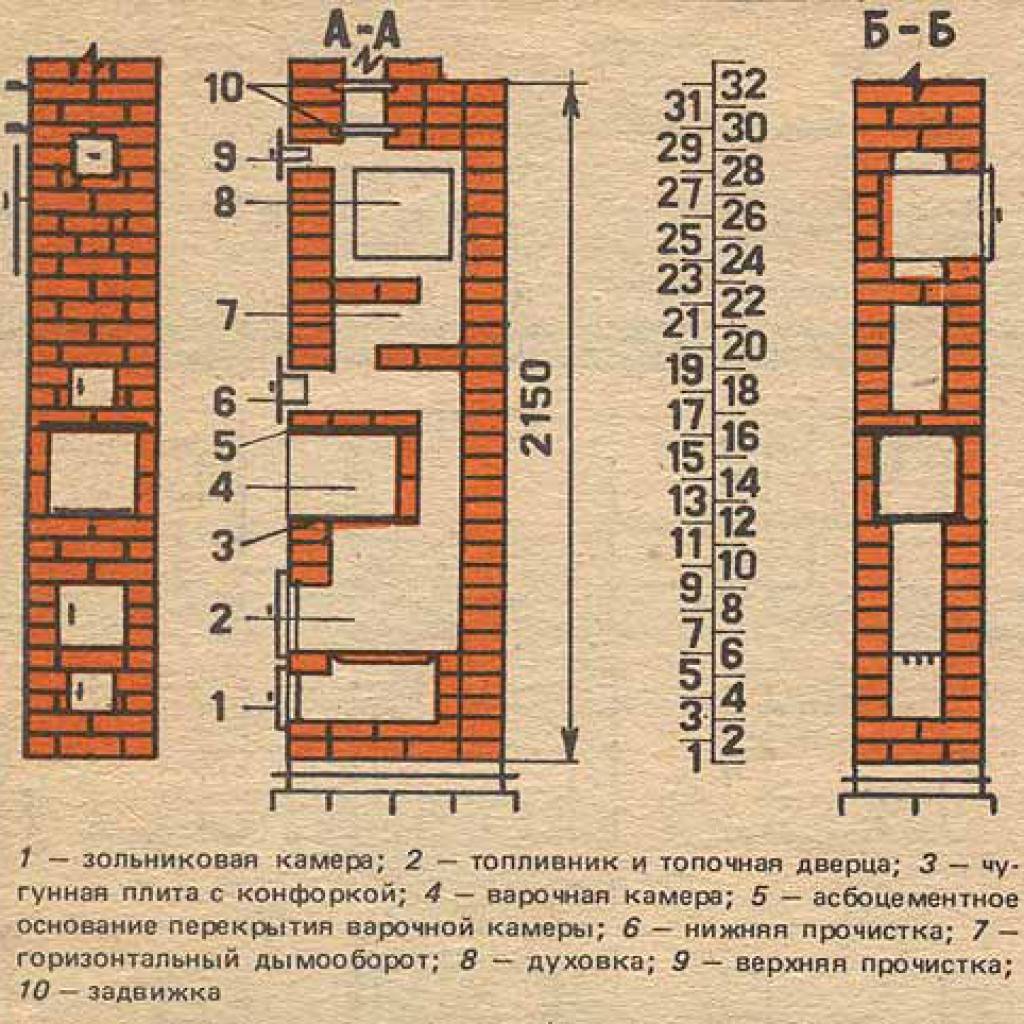

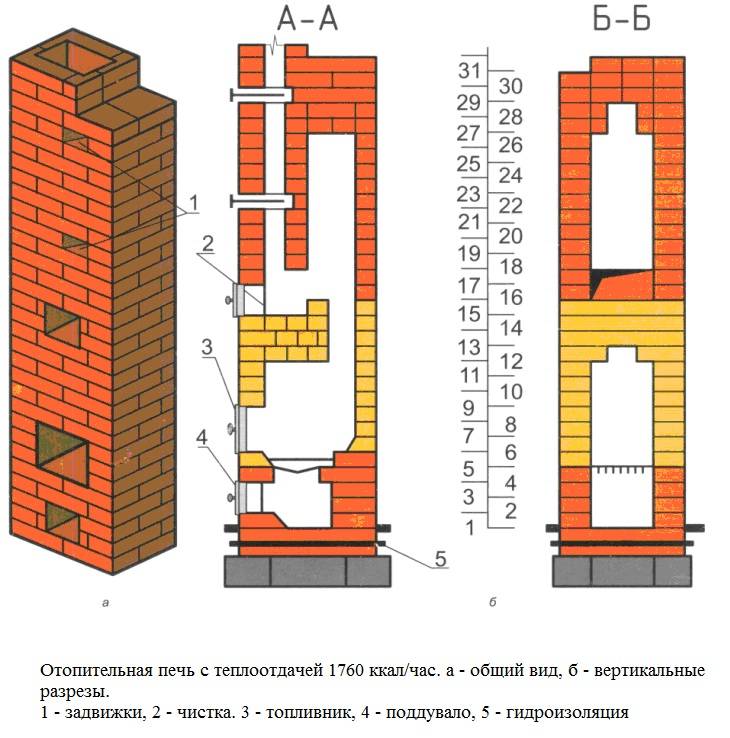

The oven consists of the following parts:

- A firebox is a working chamber into which fuel is loaded. Equipped with a door.

- Blower - a chamber attached below the firebox.Serves to improve traction. A door is also attached here to regulate the air supply. A grate is installed between the firebox and the blower.

- A chimney is a pipe that removes carbon dioxide from a home. Equipped with a soot cleaning door and damper.

- Smoke circulation (convector) - vertical (sometimes horizontal) channels through which hot gases from the firebox pass. They connect the firebox to the chimney and accumulate thermal energy.

Operation features

The scheme of operation of the furnace is as follows:

- Start.

- Adjustment.

- Maintaining the mode of operation.

- Stop.

- Carrying out repairs.

Start-up is carried out only after the specialists conduct a thorough check of all equipment. The oven is ready for operation if:

- Installation work is fully completed.

- Hydraulic tests of the coil and all pipes rotating along the furnace were carried out.

- The tightness parameters and the strength of the device coincide with the regulations.

- The furnace lining is completely dry and all elements are in good condition.

- Tested automation and blocking system.

Start-up is carried out in the prescribed sequence:

- The serviceability of all equipment and instrumentation installed on the furnace, as well as fuel suitable according to the instructions, is checked.

- The gate is in the open state.

- All hatches are tightly closed and purged with water vapor for 20 minutes.

- The fuel system is being prepared for operation.

- The pumps are tuned to an operational state in order to debug the flow rates above the minimum values.

- The flame of the injectors is ignited, fuel is supplied.

- There is a control over the stability of combustion. If the burners go out, they are started again.

To maintain the equipment in normal mode, it is necessary to gradually increase the combustion temperature. The heating rate should not exceed 50 degrees per hour. Also, during adjustment, the number of working burners is gradually increased. If necessary, increase the load. After reaching the required parameters, the entry into normal operation begins.

The start-up of tube furnaces is carried out only after the specialists carry out a thorough check of all equipment

The start-up of tube furnaces is carried out only after the specialists carry out a thorough check of all equipment

The stop can be emergency or normal. Emergency is carried out if the pipes burn out, or the supply of raw materials stops.

A normal stop looks like this:

- The burners are turned off until the temperature drops to 60 degrees.

- When the required temperature is reached, turn off the pump, close the valves.

- When the pressure in the coil drops below the water vapor pressure, it is fed into the coil and left for several hours until the desired concentration of the hydrocarbon mixture returns to normal.

Repair is carried out for the smooth operation of the equipment for a long time. A team of specialists is invited to ensure repair work. You should not open and replace the components on your own, as this can lead to serious, life-threatening consequences.

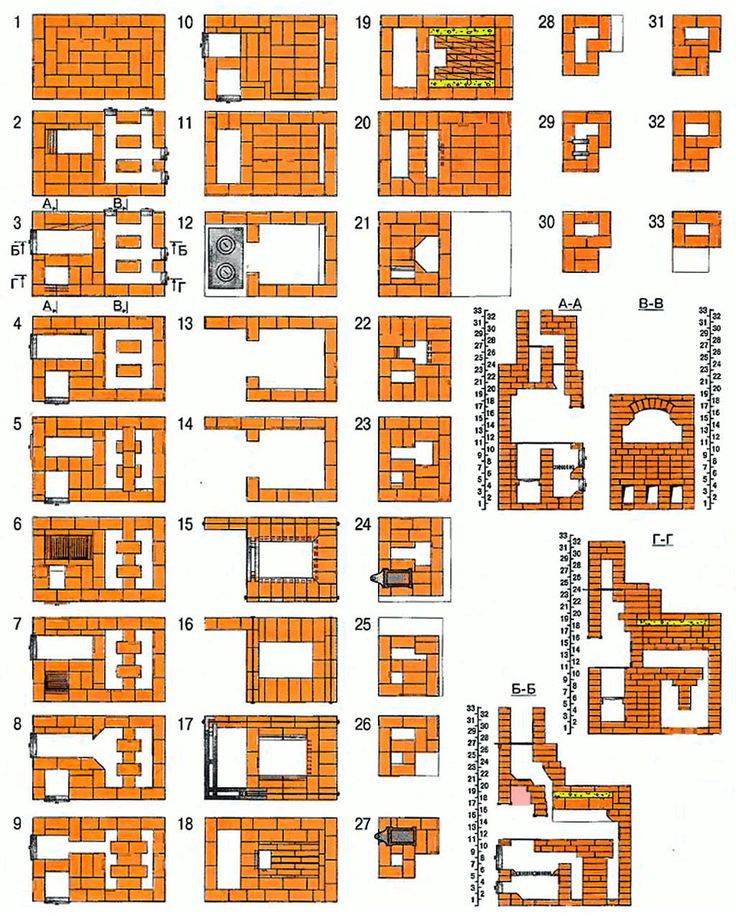

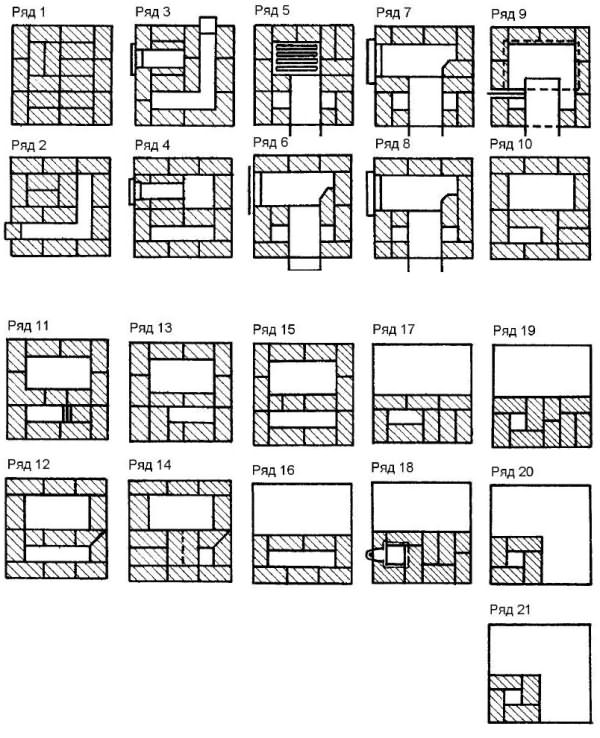

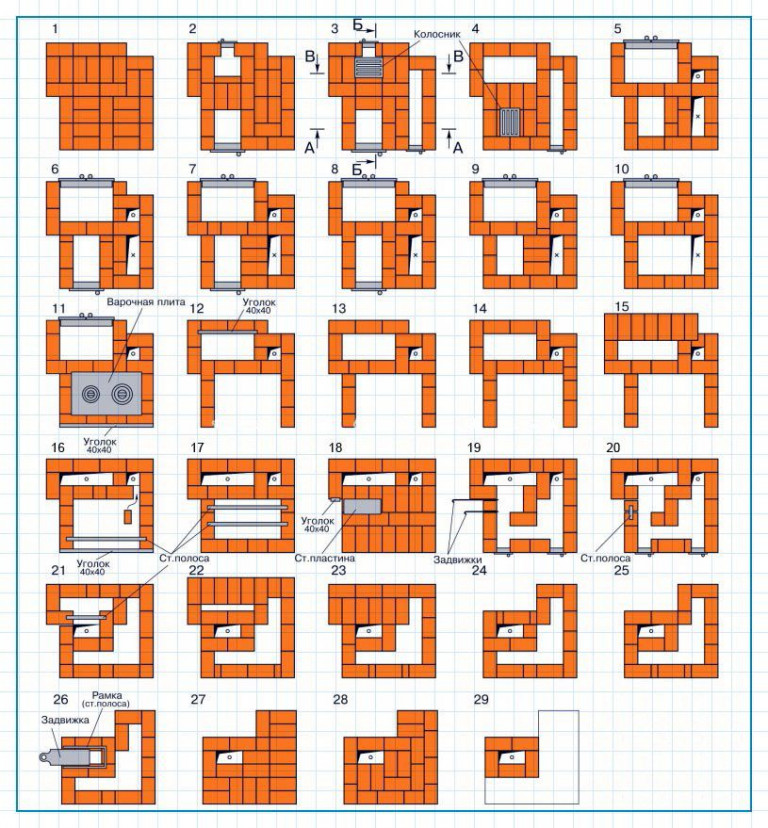

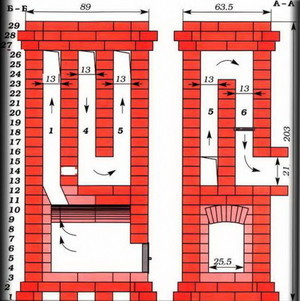

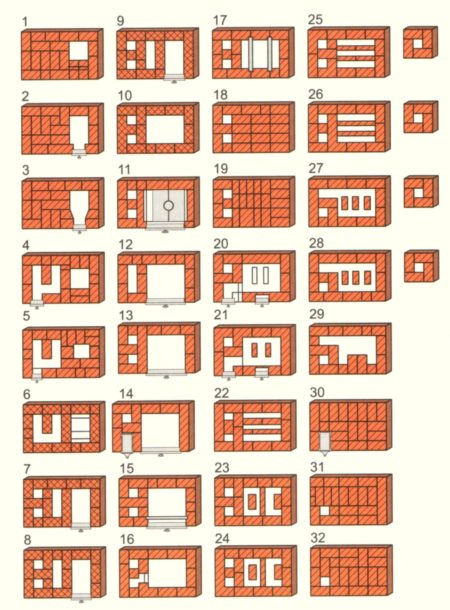

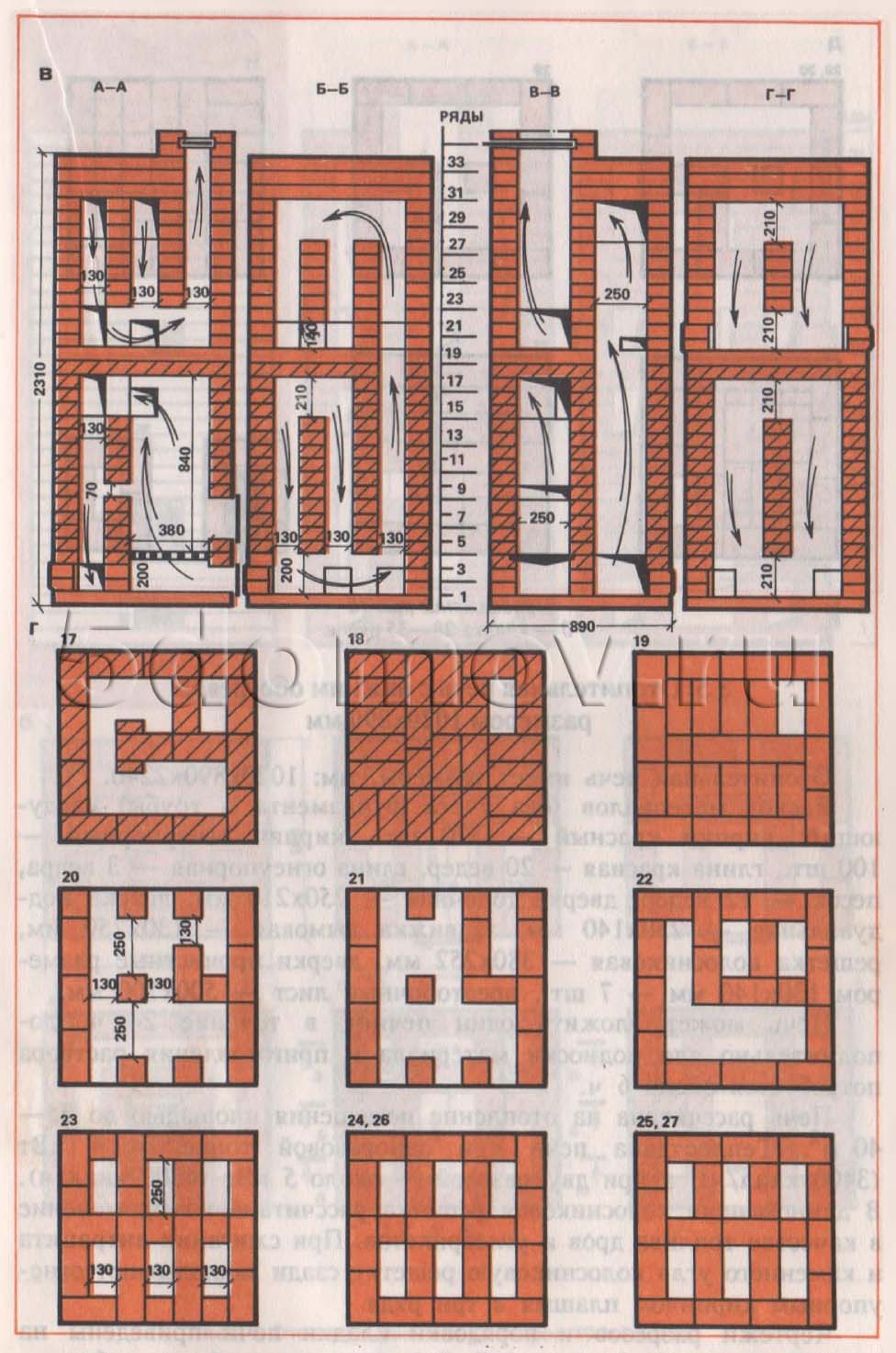

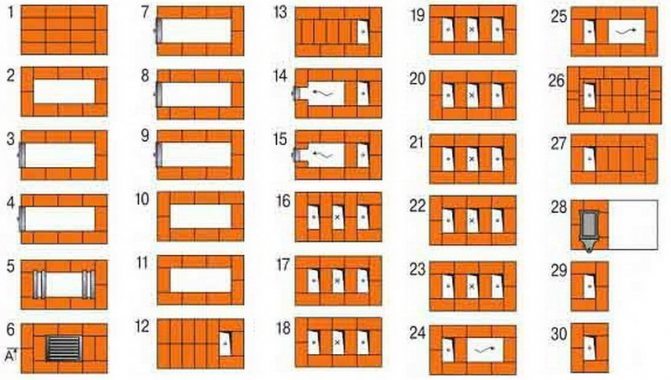

The procedure for laying the furnace

How to build the stove in the house depends on the materials used and the design chosen, but the main stages of work are always the same:

- The beginning of the creation of the stove - the first two rows of bricks form its underfloor part;

- Laying the third row of bricks - a blower door is installed in it;

- Laying the flame part;

- As soon as several rows are laid out, a grate is installed above the ash chamber. It is placed on fireclay bricks;

- The firebox door is installed. A combustion chamber is formed;

- A hob is laid on top of the combustion chamber;

- Continuation of masonry with the gradual design of the gas convector system;

- When the body of the stove is formed, they proceed to the construction of the chimney.

Varieties of oven-coarse

Rough (or coarse) is one of the variants of the Russian-Dutch oven. Appeared in Russia more than 200 years ago, "Dutch women" have established themselves as an economical and reliable heating unit that takes up little space in the house. However, domestic stove-makers, having decided to expand the functionality of the existing structure, added a stove bench to it. The original model has undergone significant changes: the height and location of the beds were constantly changing, materials were being improved, the rough began to perform not only heating and cooking functions, but also decorate the house, playing the role of a kind of fireplace.

It is possible to decide whether the house needs a rough one, or whether it is worth looking at another option, only after carefully weighing all the pros and cons of the design in question.

- It is easier to build a rough than most known channel power furnaces. This can be done both during the process of building a house, and in an already landscaped room. No major building work or alterations required;

- the cost of materials "affordable" for almost any person;

- the stove is easy to operate, compact and takes up little space;

- its appearance depends on the taste of the owner, who, at will, selects the shape and size of the bricks, the colors of the plaster and the design of the constituent elements;

- thanks to the installed hob, it is easy to cook on coarse.

the heat efficiency of such a stove is extremely low: it can warm up a room with an area of only. If the owner certainly wants to use coarse wood to heat a larger room, he will be unpleasantly surprised by the amount of kindling material leaving.

The extension of a heated bed is another plus of coarseness. But this option is only possible with wood heating. Coal heats the surface of the couch too much.

Types of acceptable designs:

Attaching a shield to the outside allows you to give the stove a more decorative look, making it look like a fireplace. If the work is done carefully, using tiles or decorative ceramic tiles, such a stove will give the room a special charm. But it will be a very costly work: both in terms of the efforts made and in terms of the volume of materials. Such a furnace is more difficult and harder to fold; a foundation is a must. Both wood (up to and coal) are suitable as a heating material (up to However, the thermal power of such a unit is much greater than that of a stove with a built-in shield.

With built-in shield

Outwardly, it looks like a conventional hob. Such a unit is easier to build, and materials are spent many times less compared to the first option. This is a compact stove of small size, the amount of thermal energy of which is limited. Therefore, this option is only suitable for rooms in which they live from spring to autumn, and visit occasionally in winter. A rough house can be built without a foundation, but the bearing capacity of the floor must be from 500 kgf / sq.m.

Classification by characteristics

Classification is carried out according to such criteria as dimensions, internal structure, position and even appearance. Some models are traditional, others combine classic and modern features, including stoves, cast iron grills, fireplaces.

By dimensions

According to the dimensions, it is customary to distinguish three types of construction:

- a large Russian stove, dimensions from 1.5 * 2.3 m, often has a stove bench, a large hob, a place to heat a container of water;

- small, dimensions 1.5 * 1.75 m (used for a small kitchen, living quarters, may have a stove, built-in fireplace);

- non-standard (the advantage for the bath is used).

Fact: the largest Russian stove is located in the Kaluga region. It is 11 meters high and 5 meters wide.

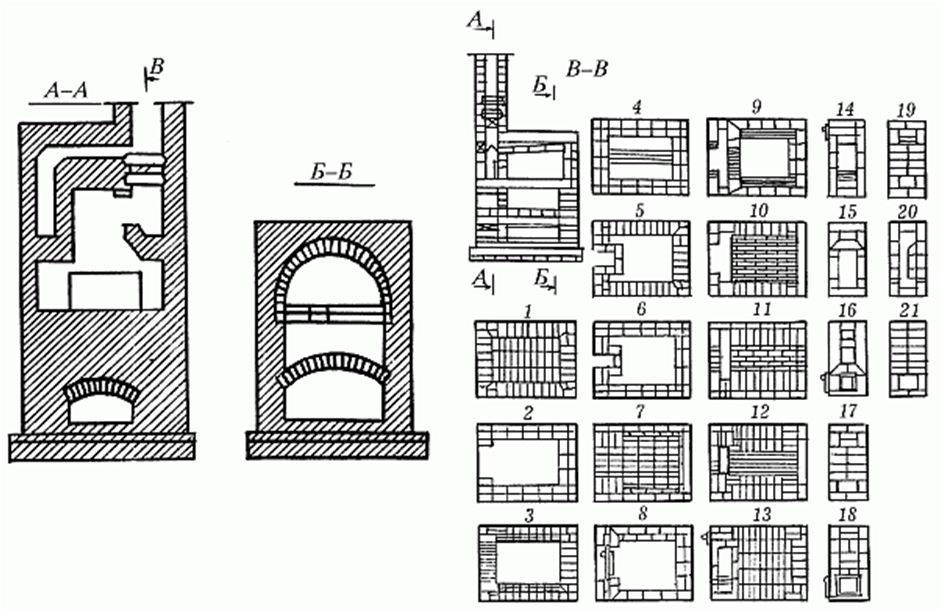

By device

According to the device, all Russian stoves can be divided into two large groups: traditional and modern.

Traditional designs are distinguished by the presence of a lower unheated part, a hollow under-furnace, where you can store utensils and a supply of firewood. The modern oven is more functional, the lower part is made of brick and is a channel, it warms up well. For the upper part, a cast iron hob is usually mounted, a grill grate, which makes the design suitable for cooking various dishes.

By position

By position, stand-alone and combined models are distinguished. In the first case, this is a variant of a simple Russian stove used for cooking, heating water and heating a room. In the second case, the design is more complex, it is combined with other stove elements, can be used for heating the whole house and requires more complex maintenance.

By appearance

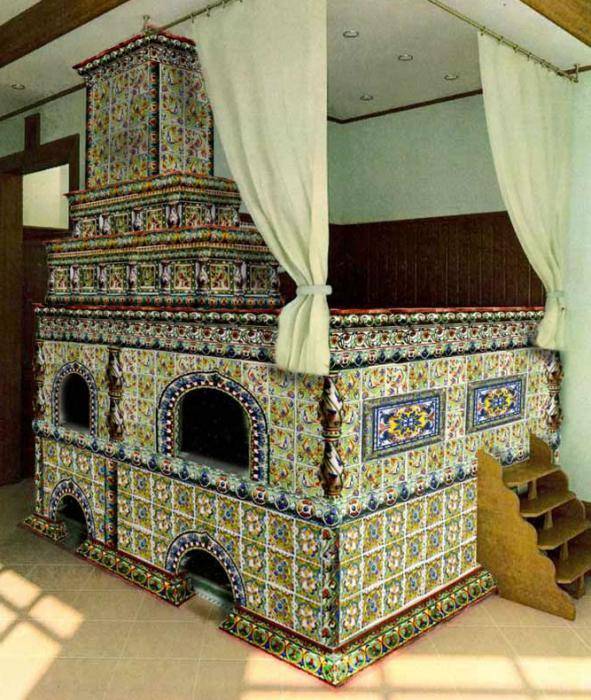

Russian stove designs also look very different from others. There are several options - this is a simple geometric shape with a plastered, whitewashed surface, a decorative finishing layer, for which tiles or ordinary ceramic tiles are often used.

The second type is a decorative element of any interior; such stoves are often a real work of art, especially when lined with painted tiles.

What kind of brick to lay the oven

The main building material for the construction of the furnace is red ceramic brick grade 150, made from baked clay. Its dimensions are standard - 250 x 120 x 65 mm, although in the past other stones were also produced for the furnace business. But now all the dimensions are unified, so that the fireclay (refractory) brick, from which the furnace firebox is often laid out, is the same size as the usual one.

In construction, a stone 88 mm high is still used, but it is not suitable for laying furnaces, since it has voids. Here, only full-bodied material is required, which does not have voids and cracks. For the latter, each unit must be carefully studied; a good quality brick is required for work. True, there is one exception - the Dutch oven, it can also be laid from less quality stones. But it’s not worth it to reach the point of absurdity, a heat source made of cobblestones will definitely not heat.

The fact is that a heating and cooking stove built with your own hands from low-quality red brick can crack even at the stage of drying the masonry mortar. It should be noted that the clay mortar dries up, and does not harden, like cement.Therefore, beginners are not recommended to experiment with bad or used bricks, otherwise the newly built furnace will immediately require repair.

Chamotte stone for the formation of a firebox

A separate recommendation concerns masonry mortar. At first, you should not go to the nearest ravine for clay, because it still needs to be brought to the correct condition. It is better to buy a ready-made mortar for laying furnaces, clay or fireclay.

Furnace in a modern house

First of all, a heating furnace for a home should take into account the predicted dynamics of energy prices for at least the next 20-30 years, as well as changes in their nomenclature on a wide sale.

Thermonuclear energy will give an industrial output no earlier than in 70 years, the bottom is already visible in the natural reserves of organic fuel, therefore liquid fuel furnaces are not considered further, but attention will be paid to the quality and properties of furnaces when fired with alternative fuel. If now somewhere else it is profitable to heat diesel fuel or fuel oil, then in the near future the inhabitants there will have to think seriously about switching to gas or pellets

Based on this, the heat transfer coefficient of the furnace (it is equivalent to efficiency in the furnace business) should be at least 65-70%. In addition, the furnace must operate on any type of solid fuel, taking into account the fact that new types of it may appear. A gas heating furnace should consume fuel an order of magnitude less than the current ones - gas will not become cheaper either. Therefore, for gas heating, a catalytic combustion furnace with a ceramic burner would be preferable; we will dwell on them in more detail below.

The second most important point is safety and the simplicity and ease of use that are inextricably linked with it.A good stove should not burn out in any mode of the firebox and in any position of its controls. But it should provide uniform heat transfer for at least 12 hours from one fuel load, exclude the possibility of fire in any mode of the furnace and require unloading of ash no more than 1 time per day. Additional requirements: the ability to touch the oven without immediate burns and, if the oven is equipped with automation, pressurization, circulation systems, maintaining operability and safety when the power is turned off.

Further, a brick oven must have an estimated service life no less than the house itself. It is unrealistic to replace the stove in an already built house, and it was not for nothing that in the old days they were built from the stove. Then, stove heating is also promising from an environmental point of view: the cost of delivering alternative solid fuels to individual consumers, taking into account the efficiency of stoves, is already less than heat losses in the mains of heating plants and electricity in power lines. In the future, a massive transition to stove heating would avoid an explosive jump in global warming.

Modern fireplace stoves

However, brick stoves, with all the age-old sympathy for them, are the losers here. The reason is the very materials from which they are created. Obtaining bricks, fireclay, cement, river sand, high-quality clay harms the environment more than saving non-renewable natural energy resources by stove heating. Brick stoves, of course, will not die out, they are very pretty, but building a stove in a house is already very expensive and over time this work will steadily rise in price.

High technologies concern not only electronics, space, fine biochemistry, etc. They also transformed many traditional materials.To say, for example, to the Demidov brothers, what kind of iron people are now able to get - they would not believe it. The quiet revolution in materials science has also affected stoves: now, for heating a house, a purchased factory-made collapsible stove is the most profitable. Such stoves can also be installed in city apartments with a separate smoke channel, because. they are already certified for fire safety. And replacing the stove with a new one will no longer require at least a major overhaul of the home.

Finally, such an indicator as the aesthetics of the furnace is important. The design that has developed over the centuries cannot but be perfect, and a technically perfect device simply must be beautiful. Any, without exception, a stove, if properly executed, organically enters a modern interior, see fig. at the beginning. But the construction of a custom-made furnace inscribed in the interior is an extremely expensive pleasure, so those who want to build do-it-yourself oven does not decrease, which can only be welcomed: a home master who successfully folded the stove will then cope with any repair work.

The aesthetics of the furnace is important not only for the sake of beauty and prestige, but also for the recommendations of doctors. Contemplation of the fire after dinner, like nothing else, removes the negative accumulated during the day from modern hectic life and gives you a charge of vivacity, strength and common sense tomorrow. By the way, the same doctors advise: taking natural cognac at the same time at the rate of 1 ml per 1 kg of body weight with a slice of lemon is an excellent means of preventing cardiovascular and oncological diseases.

Features of laying a brick oven with your own hands

What are the nuances you need to know before proceeding with the laying of the furnace?

The foundation for the furnace must be strong and solid. But at the same time, in no case should it be connected with the main foundation for the house.

The fact is that the house shrinks over time, which is reflected in the foundation, so it is very important to separate these two elements. With seasonal shifts of the soil and general shrinkage of the house, the design of the furnace may suffer.

The foundation must exceed the dimensions of the furnace by 15-20 cm on each side. It can be made of ordinary concrete, cement mortar or made of concrete blocks.

For laying the furnace, it is necessary to purchase 2 types of bricks: ordinary solid ceramic and fireclay (refractory), from which the firebox, smoke channels and all heated elements will be folded

The cost of such material is much higher than the price of ordinary red brick, so usually only those surfaces that will have direct contact with fire are laid from it.

All other elements are laid from solid red brick, while using a solution based on red oven clay. The composition of such a solution must necessarily include heat-resistant cement. But between ceramic masonry and fireclay bricks, it is imperative to maintain a gap of 5 mm. When heated, fireclay bricks will expand. Therefore, in order to prevent deformation of the furnace structure during operation, this gap must be taken into account.

All purchased elements for the oven (grate, door, hob, oven, etc.) are set in accordance with the general scheme and purpose of the oven

It can be made of ordinary concrete, cement mortar or made of concrete blocks.

For laying the furnace, it is necessary to purchase 2 types of bricks: ordinary solid ceramic and fireclay (refractory), from which the firebox, smoke channels and all heated elements will be folded. The cost of such material is much higher than the price of ordinary red brick, so usually only those surfaces that will have direct contact with fire are laid from it.

All other elements are laid from solid red brick, while using a solution based on red oven clay. The composition of such a solution must necessarily include heat-resistant cement. But between ceramic masonry and fireclay bricks, it is imperative to maintain a gap of 5 mm. When heated, fireclay bricks will expand. Therefore, in order to prevent deformation of the furnace structure during operation, this gap must be taken into account.

All purchased elements for the oven (grate, door, hob, oven, etc.) are set in accordance with the general scheme and purpose of the oven.

Grate

When inserting the door of the combustion chamber or ash pan, it is necessary to tie it with annealed steel wire. In this case, one end of the wire is inserted into a specially designed hole, and the other end is twisted into a bundle and laid between the bricks, tightly clamped with mortar.

When installing a cast-iron firebox or cast-iron stove, it is imperative to lay an asbestos cord between the brick and the metal element to compensate for the different thermal expansion of materials.

The chimney for the stove can be made of red ceramic bricks, or you can use a ceramic block chimney, which is purchased ready-made.

Facing is the final stage in the construction of a brick oven. To give a beautiful aesthetic appearance, the stove can be lined with red ceramic bricks, clinker (under wild stone), decorative tiles. This coating gives a unique authentic look to the stove, and also protects it from the negative effects of the environment.

Materials that will be needed for laying the furnace.

-

Red solid ceramic brick (M-150.)

M 150

- Chamotte (refractory) brick.

- Masonry mortar (sand, red oven clay).

- Foundation material (cement, graphite, sand).

- Ruberoid.

- Asbestos cord, galvanized wire.

- Boards for creating formwork.

- Reinforcing mesh.

- Grate.

- Cooking surface (stove).

- Ash pan and ash pan door (blew).

- Furnace door.

- Chimney flue.

- Chimney valve.

Tools that will be needed for laying the furnace:

- Building level.

- Owl shovel.

- Construction marker.

- Measuring tape (roulette).

- Construction slope.

- Goniometer.

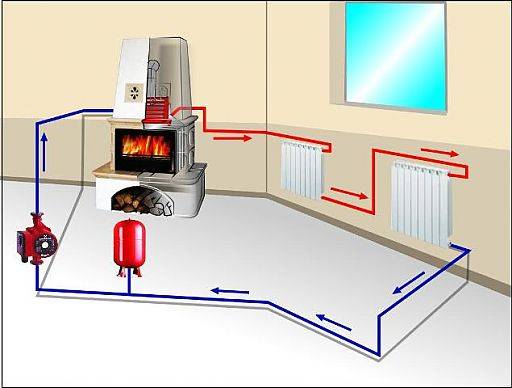

Additional heating for large houses

Scheme of furnace heating with a coolant.

A properly built brick oven radiates soft and healthy heat without the smell of burnt dust. It is suitable for a temporary or permanent home and is able to heat a one-story building. If the estate has more than 3 rooms, then in addition to the heating and cooking stove, one more stove should be built - a heating one. In a 2-storey cottage, a heating and cooking stove is arranged on the first level, and a heating stove on the second. Fireboxes can be made separate or 1 common combustion chamber can be installed on the ground floor, and the heating shield can be placed on 2 levels.

Another option for heating a large building is the installation of a brick stove. The principle of operation of the design is as follows: the 1st floor is heated by the radiation of the furnace array, and pipes from this heating device are led out to the 2nd floor, through which warm air rushes upwards. The advantage of a caloriferous stove is that it releases heat almost immediately after kindling.

Many install water heating in large houses using a brick or factory iron boiler. It should be noted that experts advise combining a stove with a boiler in buildings with an area of \u200b\u200bno more than 120 m². This warning is due to the fact that the stove and boiler have a different mode of operation. Usually the stove is heated for about 2 hours, and then it gives off its heat throughout the day. If you increase the time of the firebox, then the brick walls of the building will begin to collapse. The boiler needs to be heated continuously: when the process stops, the batteries immediately cool down.

If there is no particular desire to constantly work as a fireman in your house, then it is best to supplement the heating system with an electric boiler. It does not require a significant amount of electricity. Another option is to purchase an electric battery that will serve as a heat storage device. With the proper arrangement of heating devices in a residential area, you can achieve the optimal temperature for a comfortable stay. It is always pleasant to sleep in a room heated by a brick stove, so a brick building has been unrivaled from time immemorial.