- How to build a canopy for a well

- Facing the above-ground part of the log house

- wooden traditions

- Stonework - a journey to the land of elves

- Metal but not plastic

- When is a bottom filter needed?

- Peculiarities

- Design options

- Roof finish

- Concrete ring framing

- Using an unusual gate shape

- Examples of decorative wells in the country

- Installation of an open well finish

- Material selection

- Wood

- Stone

- Plaster

- Tires

- Ceramic tile

- Siding and plastic panels

- clapboard

- Design Options

- Design features

- The process of creating a direct filter with a wooden shield

- How to make a mechanism for water supply

- Choice of finishing materials

- Wood

- Brick and its varieties

- Stone

- Finishing materials and their combination methods

- How to finish?

How to build a canopy for a well

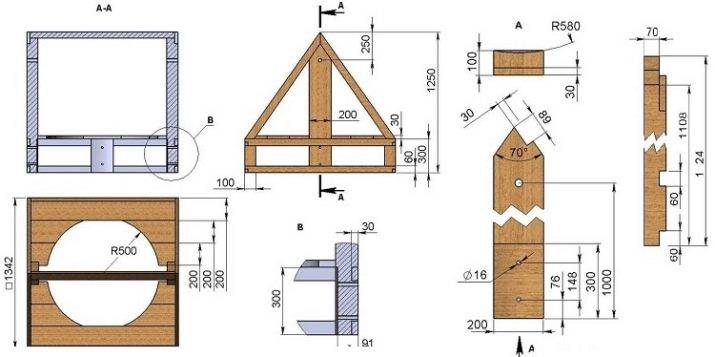

These structures are not limited. They can be round or rectangular, have one or more slopes. A canopy is installed directly on the house or in the ground, concrete, brick, and other bases. So, in order to build such an add-on, we will analyze in detail the following step-by-step master class:

- We are preparing the base. Pillars can be installed on a columnar, tape, monolithic foundation. Since the upper part is light in weight, there are no strict requirements for the base, and two shaped pipes or rounded logs are enough for support.

- After installing the supporting pillars, professional pipes in their upper part, you can put a finished metal roof, build a frame with your own hands. To do this, in the upper part, we attach the boards of the carrier strapping to the vertical posts.

- We proceed to the collection of the roof truss. It is better to assemble it on the ground, install it ready-made.

- After installation, we sheathe the farm with OSB board.

- We cover the roof with metal tiles, corrugated board, and other materials.

- We sew up the pediments with clapboard, plastic.

Facing the above-ground part of the log house

What we habitually call a log cabin of a well has actually been made of concrete rings for a long time. The top ring protrudes from the ground and looks unpresentable

It is especially important to veneer it when an open well is being built, since in closed ones the ring is hidden behind the walls of the house. But even in closed structures, a successful design of a log house can give completeness to the entire structure.

wooden traditions

To give the house above the well a purely rustic look, a frame is laid around the concrete ring. It is not necessary to adhere to the traditional square shape - the log house is made both hexagonal and octagonal. It is brought out above the level of the rings and covered with a wooden flooring, in which a hole with a door is cut - for a bucket.

House for a well in the form of a log house

For a Russian-style homestead, a log cabin made of round logs is the most suitable option. If Scandinavian traditions are traced in the buildings, then a rectangular beam or clapboard lining will be acceptable.

Facing the well with clapboard

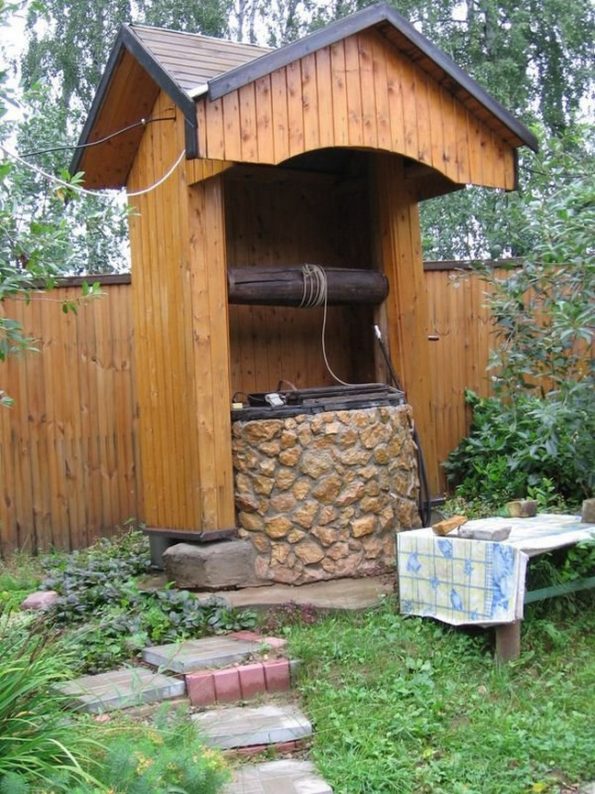

Stonework - a journey to the land of elves

European flavor carries a well with masonry.It will look fabulous on a plot with a small wooden house and a garden in the spirit of Provence or next to an English-style brick cottage.

It is not difficult to overlay a concrete ring with stones; this will require diligence, cement mortar and the stone itself. You can use large cobblestones, pebbles, limestone, and flagstone looks especially picturesque if laid flat. Along with stone, facing bricks and tiles imitating natural masonry are used.

Stone masonry in the design of the well

In open wells, it is necessary to line the upper edge of the ring and fix a wooden or metal cover (door) on it.

Metal but not plastic

There is nothing that prevents the use of non-traditional materials in the design of the upper part of the log house, from metal profiles to plastic. And if plastic could be immediately rejected as a short-lived material that cannot withstand low temperatures, then metal sheets can lead to interesting ideas. Of course, under such a lining it will be necessary to build a wooden frame.

Well cladding with metal

When is a bottom filter needed?

To determine whether to do bottom filter for do-it-yourself wells, should, after a thorough inspection, determine the rock that forms the bottom of the structure. In addition, it does not hurt to know the direction of the aquifer.

In total, several options are possible:

- The bottom is formed by dense clay, and springs gush out of it. Such rock does not dissolve or mix with water, so the well will be clean. This is one of the few cases where the filter can do harm by blocking the outlet of the springs.

- At the bottom there is soft clay, which is actively washed away by water. In such a well below, the water will be muddy.You can collect clean water from above, but the best option is to fill the bottom with rubble or pebbles. A layer of about 20 cm is able to prevent active erosion.

- If at the bottom sand and water seeps into the well, and does not bubble up, then a bottom filter device is required. Otherwise, with any movement of water, the sand will erode and fill the bucket. The pump cannot be placed here either, since all its elements will quickly become clogged.

- At the bottom, there may also be floating water - sand that has become fluid due to saturation with groundwater. In such a well, it is most difficult to get really clean water - you will need both a bottom filter device and additional protection in the form of a wooden shield.

Peculiarities

The design of the well must meet certain requirements. Firstly, it must be in harmony with the surrounding landscape and the exterior style of a residential building, and secondly, if it is used for its intended purpose, as a source of water, it must be protected from possible ingress of sewage, precipitation and other contaminants. Finishing can be done with stone, wood, brick, flowers. In the end, the well can simply be plastered or painted.

If the well is planned to be decorated with wood, then it is better to choose hard rocks that are not afraid of the negative effects of the environment. In any case, the selected material must be wear-resistant, insensitive to temperature extremes, precipitation. If, after finishing, it is plastered or painted, the service life will increase, and it will retain an attractive appearance longer. You can build a house over the well itself - this will additionally decorate it and protect it from precipitation.

Design options

When the basis of the design is made, it can be designed in various ways.As a result of the correct choice of the way in which this needs to be done, the well will acquire not only practical significance, but also aesthetic, design.

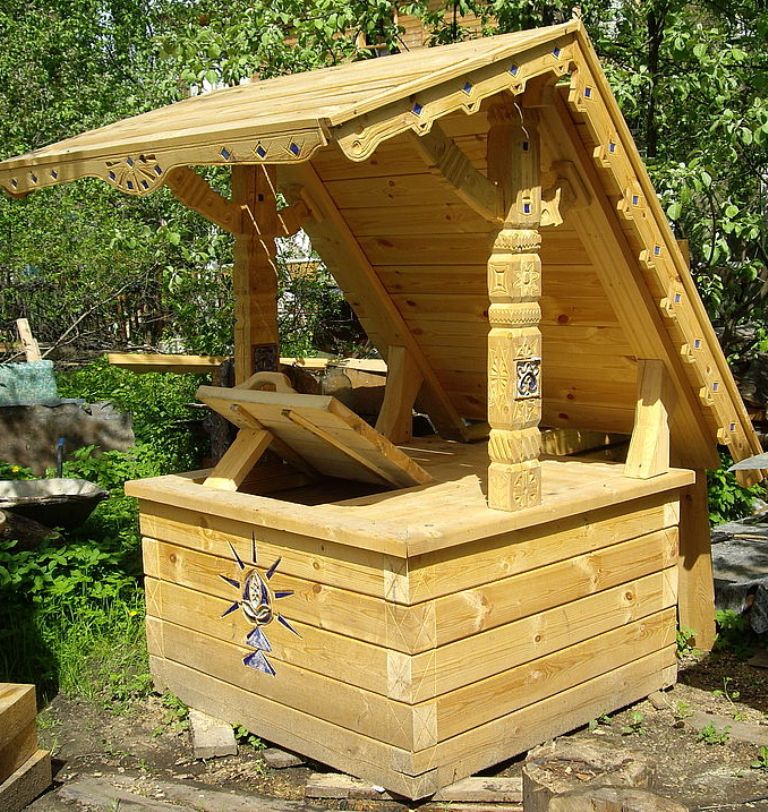

Roof finish

The roof can not only be made from neat beautiful boards, but also decorated with carved wooden details.

Unusual options for this part of the design may also be applied. One of these options involves a folding design made of thick glass. It is structurally made in the form of a cover over the well, which opens on door hinges mounted on the frame of the well.

It is possible to provide a semicircular metal roof, decorated with curls made of metal.

Decorative finish of the well with forged elements

It is possible to design this part of the well in the form of a six-slope pointed structure.

Sometimes when choosing how to cover a well, a soft roof can be a good choice.

Concrete ring framing

With the help of stone around the concrete ring, make a beautiful wall of stones that completely hides it. This can be done in various ways. For example, an imitation of a small door in a stone fence made of wood can look beautiful.

It is possible to use logs in the form of a log house in a folk style. Sometimes such a frame is made not quadrangular, but hexagonal.

This option can also be used when, with the help of varnished wooden boards, a design is made that resembles a wicker basket. To do this, they are laid out horizontally at each level so that they look like a polygon. At the same time, at each next level, a flat part of the plank is located above the corner.

Decorative finish - a well in the form of a basket

Using an unusual gate shape

This detail can be made, for example, in the form of a steering wheel of a sailing ship, or simply in the form of a wheel with spokes mounted perpendicular to each other.

Examples of decorative wells in the country

A few design examples:

- Wooden teremok. The head is decorated with boards and metal hoops, which makes it look like a wooden barrel. A gable roof is installed on top on carved posts-racks. Additionally, you can decorate the composition with flowers in wooden vases, decorative figurines of gnomes or fabulous animals.

- Decorative crane. The traditional design of the well without a visor, a long lever is used to lift the water. Its support can be made from a tall wooden figurine of a bird or animal. The upper part of the well is made out in the form of a wicker basket.

- Floating ship. The rotating lifting mechanism is equipped with a wheel stylized as a ship's steering wheel. The well itself and its top cover are finished with a deck board.

- Ceramic jug. The design is in the form of a jug, the surface of which is lined with ceramic tiles or natural stone. The water intake hole is covered with a lid.

- In the style of minimalism. This fashionable style direction today suggests the absence of decorative elements. The head of the well is trimmed with plastic panels. Supports are made of forged metal. The roof can be covered with colored polycarbonate.

The design of the well should be in harmony with the landscape of the site and the style of the house. If the building is sheathed with siding, then a well in the old Russian or medieval styles will look alien. For its design in this case, it is better to choose plastic and metal.

Installation of an open well finish

Installation of the finish of an open well with a cover begins with the manufacture of a canopy. As the bearing elements of the canopy, you can use wooden beams, a steel corner or metal pipes. To cover the canopy, you can use any available roofing material: boards, plywood, plastic, galvanized iron sheets.

When using cover elements of a large mass, for example, slate or tiles, the load on the rafter system and the support posts of the well should be calculated taking into account the weight of snow in winter and the strength of the winds in the region.

After the canopy is made, the racks must be installed. They can be made from a wooden beam, a log or an H-shaped metal profile corresponding to the section load. Racks can be dug close to the concrete ring of the well and subsequently covered with some kind of decorative finish.

If the racks are made of wooden beams or logs and are themselves an element of decor, they can be installed on the outside of the decorative finish of the well pipe. The distance between the supports should correspond to the length of the canopy, this must be taken into account when designing and manufacturing it.

The lower part of the racks must be treated with moisture-proof and bactericidal compounds before being buried in the ground. It is necessary to dig in the racks strictly vertically along the plumb line. After that, a finished roof is installed on them and a gate is mounted.

The open-type summer well is also equipped with a sealed lid. It can be made of metal, plastic, waterproof plywood. If the weight of the cover is large enough, then it can be divided into two sections (shutters) and equipped with opening handles.The edges of the sections or covers can be attached to the support posts using metal one-piece door hinges.

For decorative design of the walls of the well, materials such as:

- brick - facade decorative;

- stone - artificial or natural;

- siding panels;

- lining board;

- tiles - ceramic or clinker;

- corrugated board;

- large pebble.

If desired, you can create a combination of different facing materials. The main thing is that the finish of the well harmoniously fits into the general line of landscape design.

Material selection

Cladding materials are used in a variety of ways. The main requirement for them is to withstand temperature changes, to be moisture resistant. Materials meet these requirements to varying degrees. Some require additional protection, others do without it.

Wood

For cladding, different types of wood are used: logs after rounding, edged boards, slabs, timber. The highest quality material is logs, but well-crafted boards and beams will last no less. The most moisture resistant are larch, cedar, birch, oak, aspen. Nevertheless, these breeds and the rest are treated with preparations against rot and insects before installation.

The advantage of wooden structures is that it is not necessary to repeat the configuration of a round well. You can make a square or polygonal lining. It harmoniously combines with elements of wood carving, which gives the design an expressive Russian style.

Well lined with wood.

Stone

Stone trim is a spectacular, but expensive option. For cladding, granite, sandstone, pebbles are used, laying on cement mortar. If there is a wild stone in the area, you can collect cobblestones.The best material is a flat shape, medium in size (10 cm). Properly laid out walls around the well will stand for decades, because the stone is not afraid of heat or cold, rain and snow. Installation for bricklayers without experience may seem like a daunting task, then it is better to hire a professional.

Plaster

Concrete rings are plastered if the surface is of poor quality. After drying, the finishing is carried out. It can be whitewashing, painting or decorative plaster. Lack of option in fragility. After some time, defects will appear, you will have to update or redo it.

Tires

An almost free method, the implementation of which will require used car or tractor tires. Tires with a larger diameter are hard to find, so in most situations they are limited to a maximum size of 17″. This is enough for a well from a narrow pipe.

Finishing the well with tires.

Ceramic tile

The original surface is created using ceramics. Mosaics are glued onto concrete rings; tiles can be used for rectangular wells. A variety of surfaces allows you to choose an acceptable option. The tile is smooth and corrugated, shiny and matte, with patterns, imitation of natural stone. It can decorate any surface.

Siding and plastic panels

Plastic materials are fixed on a frame made of metal profiles or wooden slats. Installation is simple, you just need to cut the material to size and connect using the locks available at the ends. The elements are fastened to the wooden sheathing with staples using a stapler, to the metal sheathing - with self-tapping screws. The option is inexpensive, installation takes little time.Installation on glue on the thoroughly leveled and primed surface is possible.

clapboard

The lining looks good in the decoration of the well. Installation is no different from installing plastic panels. You will also need to build a frame and secure each element with screws. Between themselves, they are connected by locks: the spike is led into the groove.

The correct technology provides that before installation, the lining is treated with preparations against rot, beetles, and varnished. If the last operation is performed after installation, the locks will remain unprotected, the inner side, which will soon begin to deteriorate.

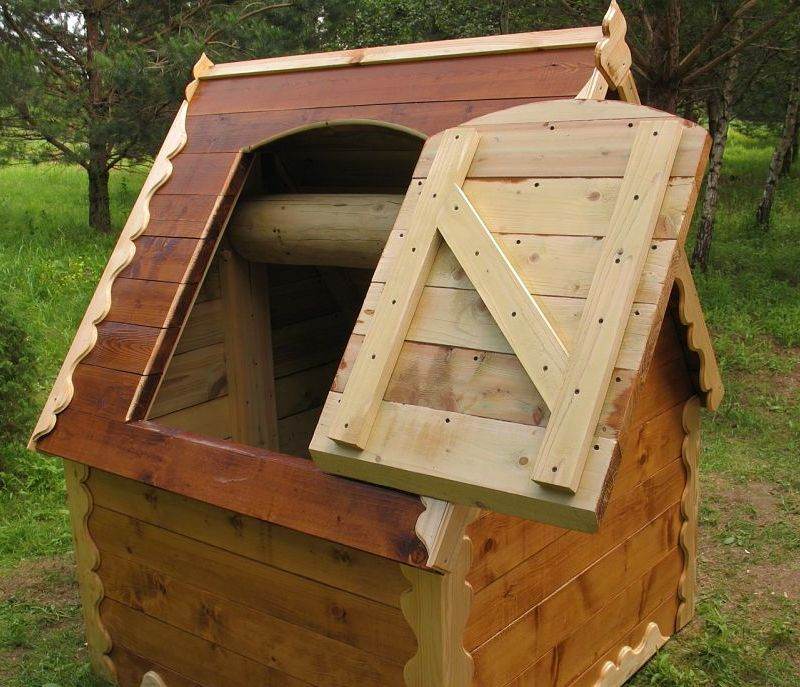

Design Options

There are several options for the design of the house for the well. Their shape depends on the original design of the well and the materials used. According to the form, all the houses can be divided into several types:

The easiest to build is a roof house, which is represented only by a gable roof triangular in cross section.

A beautiful well house will add a touch of originality and style to your suburban area.

More difficult to build are houses in the full sense of the word, which look like a quadrangular log house and a decorated roof. In the variant when the well is not made of logs, but of concrete rings, the base may have a round shape.

House for a well in the form of a quadrangular log house and a decorated roof

House for a well with carved decorative elements

House for an open well

Well house with a base in the form of a log house

Beautiful well house decorated with flowers

Even typical log cabins for houses can look completely different due to different roof shapes.They can be either gable (symmetrical or asymmetrical), or in the form of a pyramid with a different number of faces or in the form of a cone.

House for a well with a gable roof

Roof in oriental style looks very stylish

Spectacular house for a well with a roof in the form of a hexagonal pyramid

The drawing of the house for the well, as well as its further construction, will depend on the chosen configuration. The dimensions of the well house should always correspond to the structure of the well itself: a series of concrete rings or a log structure. Too small a roof will not protect the water in the well from dust, debris and other unnecessary things, and too large a structure can make it inconvenient to use the well.

If you arrange a house for a well, focusing on the rest of the objects of the suburban area, you can achieve the creation of a holistic composition

The dimensions of the house for the well should always correspond to the design of the well itself.

Old-style well house

Various options are considered as materials for houses:

A house for a well made of wood is valued for the environmental friendliness of the material, accessibility, beauty and durability.

The most popular material for wells is wood.

Beautiful wooden house for a well with carved elements

Stone well houses blend particularly well with other similarly designed buildings on the property.

Stone for wells can be natural and artificial

Stone wells take on a medieval look

Some well owners prefer to use galvanized steel to create a house. Such buildings are carried out quite simply, but they are not always pleasing with their appearance. It should also be taken into account that house on the well galvanized without additional insulation will not be able to protect water from freezing.

A well is not only a place to store water, but also a magnificent decoration of the site.

A house for a well with a brick base will last a very long time

House for a well with a base of concrete rings

Any well is worthy of decoration in the form of carved elements on wooden products, ceramic sculptures on stone buildings or an interesting pattern on galvanized structures.

Rustic well house

House for a well with antique decoration

It's interesting: Examples design of country wells - we understand carefully

Design features

The finish of the structure is selected depending on the style of the entire site, and should be combined with the exterior of the main building. It can be made from the following materials: savage stone, wood, concrete, plastic, brick, plaster, using other raw materials. The main thing is that the building material is wear-resistant, does not deteriorate from temperature changes.

When considering the design of the facility, attention should be paid to the need for periodic maintenance of the spring, namely, cleaning and disinfection. Accordingly, access to the head should be free, and decorative elements should not interfere with the implementation of auxiliary work.

Ordinary facing materials can look rather dull, so wells are often painted with multi-colored paints, decorative painting is done, which you can freely do on your own, even in the absence of painting talents, it is enough to use stencils. In addition to painting, you can use floristry, create a composition of flowers around.

If practical application is considered, then it is necessary to protect it from sewage getting inside, for this the head is made higher, a blind area is poured around, it is covered or a roof is installed.

The process of creating a direct filter with a wooden shield

The sequence of manufacturing a well bottom filter is as follows:

- A shield is made with a diameter corresponding to the size of the well. The shield will require strong boards in which holes are specially drilled to ensure water circulation.

- A beam 5 cm high is attached to the bottom of the shield - these will be the “legs”.

- The finished shield should be lowered to the bottom of the well, and a layer of large stones should be laid on top of it. So the shield is fixed.

- For the first layer of the filter, river pebbles or gravel are used, for the second - pebbles, but smaller, for the third - quartz sand, and for the fourth - shungite. The optimal thickness of each layer is about 150 mm, but the upper layers can be smaller, up to 5 cm. Thus, the bottom filter will take about half a meter of the entire well depth.

It is quite possible to make such a filter for a quicksand well with your own hands. Do not forget that the bottom filter requires cleaning and rinsing every 6 years. As for the shield, it is necessary in cases where there are quicksands below or the rate of water inflow is very high. It is recommended to make it from wood with antibacterial properties - for example, from juniper, oak is also suitable, but you can also use a metal mesh with cells no more than 2 * 2 mm.

How to make a mechanism for water supply

There are 2 types of structures that can be used to manually raise water. It is worth highlighting the following:

There are 2 types of structures that can be used to manually raise water. It is worth highlighting the following:

- "crane";

- "gate".

"Crane" can be made on your well, but it will require a lot of space. It is quite difficult to install, so it is rarely used. But to install the "gate" you will need 2 pillars, they need to be dug into the ground immediately after the well is brought to the surface. In order to prevent rotting, it is useful to cover a wooden pole with a special compound. It can be replaced with resin.

First, the pillars are covered 2 times with a liquid composition, and then 1 layer of thick resin is applied. Pillars should be made from coniferous trees, then they will not need repairs for a long time. Such material is less prone to decay.

It is easy enough to make a concrete head with your own hands and equip it with a wooden roof. If the well shaft is made of brick or monolithic structures were used in construction, then they may have embedded parts. For example, sewerage can be made from concrete rings with factory-installed embedded parts. They can be used to securely fix supports. The step by step instructions are as follows:

- It is necessary to measure the rack welded to the embedded reinforcement. The plate must be bent to its size.

- Using long self-tapping screws, the timber must be attached to the plate. Self-tapping screws can be replaced with nails. If there is no plate, then instead of it it is worth putting a piece of pipe with a square section. It is selected, taking into account the dimensions of the timber.

- In order to install the pillars for the well with your own hands, you need to dig holes. Their diameter depends on the diameter of the column. The depth of the pit is 1.3 m. Before installing the pillars, you need to prepare the bottom of the pit. First, sand should be poured, forming a pillow. It is enough to make a layer 20 cm thick, it must be well compacted.Then the bottom must be covered with a piece of roofing material, overlapping the walls. It is necessary to pour concrete at the bottom of the pit with a layer of 30 cm. Roofing material is required so that water does not leave the concrete into the sand.

- The pillars must be completely covered with antiseptic impregnation. When it dries, the end is wrapped with waterproofing material. You can replace it with ruberoid. The column is placed in a pit, the verticality of the installation is adjusted using a plumb line. Then it is fixed with spacers, the pit is poured with concrete mortar. It takes 2 days to dry the foundation, then proceed to further work.

The gate to the well is made of a smooth log; it is a rotating drum. It is best made from solid wood. Ash is perfect, but beech or more expensive oak can be used. To remove friction, the drum must be made 40 mm less than the distance between the supports.

Make a gate for the well with their own hands simple enough. It is necessary to find a central point at the end of the drum, make a hole 50 mm deep. The hole must be drilled on the other side as well. Through holes of the same diameter should be made in the gate posts. They need to be strengthened, for this you can use steel bushings. After that, a handle is attached to the gate. Since it is quite difficult to make high-quality drilling, it is easier to order a gate in a workshop.

At the last stage of arranging the head, it is sheathed. If the log house is made of calibrated logs, then it already has an excellent appearance. It is enough to make a roof, equip the source with a mechanism for lifting water, and hang a door. If there is a desire, then the design can be decorated with carvings.

The head of the manhole does not require decorative design; the space around the shaft can be filled with concrete.

Drinking water well heads made of other materials require additional finishing. The easiest way is to sheathe the surface with a board; you can use lining or a material that imitates timber.

First you need to make a frame by buying beam with a section of 50x100 mm. A do-it-yourself structure made for the well should be attached to the gate pillars; fixation to the concrete wall of the mine is possible. Next, the frame must be sheathed, the missing elements attached to the gate pillars. The sheathing can completely cover the head, imitating a well house. The door will be on the roof.

If there is a desire and there is free time, you can close the head with a house for a well in the form of a mill. There are a lot of design options, so you should choose a drawing in advance

It is important to take into account the landscape design of the site, the style of other buildings

The head of a concrete well can be lined with ceramic mosaics. The house made of natural stone looks impressive.

Choice of finishing materials

Work can be done using different building materials. Each of the options you choose has its pros and cons. In order not to make a mistake, to make the right decision, it is necessary to evaluate the components used.

Wood

Wood can be called a classic material, it is suitable both for finishing shafts and as a basis for heading, well pillars, and roofing. With its help, decorative finishing is performed, for example, carving, painting, complemented by a drawing, an image.

Wood cladding has its own characteristics:

- The material is inexpensive.It can be found on the market, in hardware stores, at sawmills.

- The raw material is malleable. Allows you to create beautiful structures that harmoniously fit into the overall style of the cottage. Tools for work can be found in almost every home.

- For landscaping, you can use ready-made finishing products, for example, imitation of timber (false), lining, blockhouse. Such components can significantly reduce the time spent on work, get an excellent result.

- The design can be additionally decorated with original carved elements.

- It is better to install a roof over the mine, which will protect the recess from precipitation, leaves, and other foreign objects. Plus, it's a great decorative item.

Ennobling a storehouse with a tree is a great option. However, the building material has two important drawbacks - poor resistance to a humid environment, it is a good food base for pests. Therefore, before using raw materials for cladding, it must be treated with special varnishes, antiseptics.

Brick and its varieties

There are several types of such building materials - silicate, ceramic, raw. You can finish the building with any of the above. For example, red brick will give the object a bright color, it will look good in a summer cottage. A versatile material is the burnt clay option. It can be both overlaid with a finished head, and completely lined up.

For the construction of a brick wall or its sheathing, it is necessary to adhere to certain rules:

- The arrangement is made only from raw materials that have a full-bodied structure.

- The material absorbs moisture, so the surface must be periodically treated with waterproof varnishes.Apply a layer of plaster, when it dries, rub in additional cement.

- For work, it is desirable to use the same building material with which the house is lined outside.

- The masonry is made both round and square. For the first option, less raw materials are used.

- The width of the masonry should not exceed the size of two bricks (25 cm).

Stone

Stone structures are popular. To decorate a building with such material is much more expensive than the options considered. But the result is worth it. The result is a stylish structure with increased wear resistance.

The main characteristics of such a cladding are as follows:

- For work, you can use both natural and artificial stone.

- For decoration, small rounded stones and large cobblestones are used.

- The material is used to finish the shaft and head.

- If the work is done with high quality, the building will last more than a decade.

- To emphasize the structure, you can lay out a path to it from the same building material, install a roof covered with metal tiles from above.

Finishing materials and their combination methods

In addition to these options, you can use plastic or siding. The set up is fairly fast. Looks good porcelain or ceramic tiles. It can be smooth or rough, matte or glazed, antique. Separately, clinker tiles, consisting of burnt slate clay, can be distinguished. Over the years, this material does not change the external structure, is resistant to moisture, resembles brickwork.

If you choose the option of ordinary painting and plastering of the structure, then you do not need to use wood, brick or stone for cladding.It is enough to clean the surface of the concrete ring, plaster it, cover it with a primer layer, and paint it. Also, plaster is often used for brick buildings, and painting in its pure form - for wooden ones.

Metal and forged elements are mainly used for pillars and roofing. Combined structures are often made, for example, heads made of wooden slats for a barrel, tied with metal rings.

How to finish?

Arrangement wells in the country includes several stages, and finishing is the last of them. First of all, the place where it will be located, the type of its device and the method of water supply (if the well is aquiferous, not decorative) is selected.

It can be equipped with a gate or a so-called crane - a lever for lifting water. In the first version, the rope on which the bucket is tied is attached to the collar and, winding it around the collar, raises water from the bottom.

Head - the upper, protruding element of concrete rings or a log house - can be open or closed with a house.

To build a house over a well, you need to stock up:

- edged board 100x25 mm;

- wooden beam 100x80 mm;

- door hinges;

- bitumen or ruberoid mastic;

- flat slate;

- self-tapping screws, nails;

- hacksaw;

- jigsaw;

- planer;

- bayonet shovel;

- water level;

- tape measure;

- pencil.

Below is the sequence of work.

- First of all, the ground near the mine is leveled and covered with 5 cm of pebbles, watered with water, well tamped.

- Then they begin to assemble the frame - boards are used for this. Racks are taken out on a level place, boards are nailed to them, which will serve as the upper and lower trim of the frame. Fix boards with screws. Connect the rest of the racks.

- The assembled frame is installed around the well and the assembly is completed.

- Then proceed to the truss system. After the rafters are combined, the entire structure is assembled into one.

- The next step is the door. It is made in the roof of the house, hanging on hinges.

- When everything is ready, go to the crate. With the help of bituminous mastic, roofing material is fixed, after that - flat slate.

- At the end, the whole structure is sewn up with boards - the house is ready.

Here, too, there are some nuances. For example, a vibroform is often used to make well rings. It is better to choose just such products - they have increased wear resistance and durability, they tolerate vibrations more easily.

Then it remains only to decorate the well from the outside so that it looks attractive and harmonizes not only with the landscape, but also with other buildings.