- Making an electrode boiler with your own hands

- Installation of a solid fuel heating boiler in the house

- Advantages and disadvantages

- Working method and design of induction heater

- Costs for heating a house with an electric boiler: an example of calculation

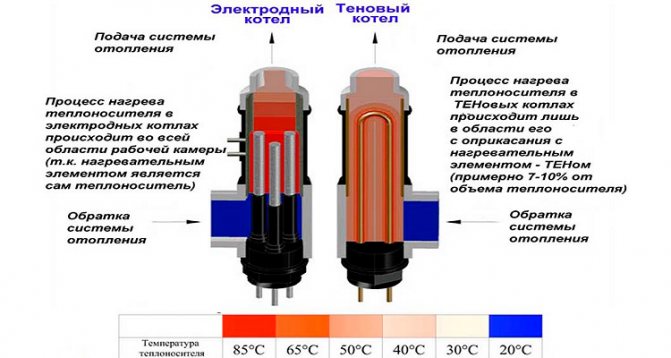

- How electric boilers work

- Some types of boilers and their characteristics

- Myths about induction boilers

- Features of installation of induction heaters

- Advantages and disadvantages of electric boilers

- Advantages and disadvantages of an induction boiler

- We recommend reading:

- New models of electric boilers

- Operating principle

- How to choose a heating device

- Types of electric boilers

- What is induction heating

- The principle of operation and the device of an induction electric boiler

Making an electrode boiler with your own hands

To assemble an ion boiler with your own hands, you need: a pipe, an electrode, hot metal.

If you have become familiar with the principle of operation of ion boilers, as well as the features of their operation, and still want to make it yourself, then you will need:

- welding machine and skills to work with it;

- steel pipe of the required dimensions;

- an electrode or group of electrodes;

- neutral wire and ground terminals;

- insulators for terminals and electrodes;

- coupling and metal tee

- desire and perseverance in achieving the ultimate goal.

Before you start assembling the boiler with your own hands, you should pay attention to several important points. First, the boiler must be grounded. Secondly, the neutral wire from the socket is fed exclusively to the outer pipe

And thirdly, the phase must be supplied exclusively to the electrode

Secondly, the neutral wire from the outlet is fed exclusively to the outer pipe. And thirdly, the phase must be supplied exclusively to the electrode.

The do-it-yourself boiler assembly technology is quite simple. Inside a steel pipe with a length of about 250 mm and a diameter of 50-100 mm, an electrode or an electrode block is inserted from one side by means of a tee. Through the tee, the coolant will enter or exit. The other side of the pipe is equipped with a coupling for connecting the heating pipe.

An insulator is placed between the tee and the electrode, which will also ensure the tightness of the boiler. The insulator is made of any suitable heat-resistant plastic. Since it is necessary to ensure tightness and at the same time the possibility of a threaded connection with a tee and an electrode, it is better to order an insulator in a turning workshop in order to withstand all design dimensions.

A bolt is welded onto the boiler body, to which the neutral wire terminal and grounding are attached. It is possible to secure with one more bolt. The entire structure can be hidden under a decorative coating, which will also serve as an additional guarantee of the absence of electric shocks. Restricting access to the boiler is the first and most important task to comply with safety regulations.

As you can see, assembling an electrode boiler with your own hands is an achievable goal for almost any person.The main thing is to know the principle of its operation and observe safety precautions. Warmth for your home!

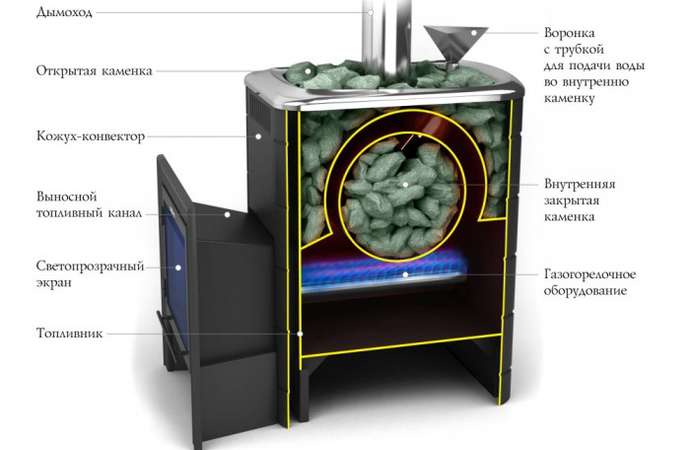

Installation of a solid fuel heating boiler in the house

Very often, the installation of a water heating system is carried out in a separate small room - a boiler room. The height of the ceilings in the boiler room should be at least 2 m, the volume should be at least 7.5 m2. When installing a solid fuel heating boiler, the room is equipped with a chimney, a ventilation duct or a window, as well as electric lighting. The boiler is located at a distance of 0.5 m from the wall.

The chimney must be at least 5 m high from the boiler connection to the top of the chimney, with a cross-sectional area of at least 190 cm2. If necessary, the chimney can be moved to a distance of 1 m at an angle of up to 30° to the vertical. The walls of the outlet must be smooth and have the same section along the entire length.

The boiler is connected to the chimney using a connecting pipe made of roofing steel, the thickness of which is at least 1 mm. A clay solution is used to seal the junction. The connecting branch pipe with one end is tightly mounted on the outlet of the boiler chimney, and the other end is inserted into the hole of the brick channel to the thickness of the chimney wall (at least 130 mm). The smoke channel is laid out from well-burnt red brick, which is placed on a clay mortar 3-5 mm thick, the seams must be carefully rubbed. From the attic, the flue can be made of a packed asbestos-cement or ceramic pipe. In this case, the insulation is made of mineral wool or foam concrete in a rigid casing.Having chosen the heating of a country house with a solid fuel boiler, in no case should silicate brick, cinder concrete or other large-porous materials be used for laying the flue.

At the base of the smoke channels, pockets with a depth of 250 mm are constructed, as well as holes for cleaning ash, equipped with doors that are sealed with edge-on brick in clay mortar.

Advantages and disadvantages

To begin with, it is worth saying that it is advisable to install electrode boilers only in those places where there is reliable wiring and a stable network. If there is a periodic power outage and strong voltage drops, then it is not worth mounting the electrode units, as they will not be able to work normally. However, even in this case, a solution can be found. For example, buy an uninterruptible power supply or a diesel generator.

It accumulates a small amount of energy, which should be enough for a couple of hours of operation of the boiler in an emergency. There are UPS models that correct the voltage using a built-in stabilizer.

You can read about the types and criteria for choosing a voltage stabilizer and an uninterruptible voltage source for a boiler here.

Advantages of an electrode heating boiler:

- Safety for human health is at a high level. Ionic boilers for heating are designed in such a way that current leakage is practically impossible. Fire is excluded, so the design can be used to maintain a minimum temperature without constant human supervision.

- Small dimensions and the possibility of installation in a heating network operating on gas fuel. It turns out that the electrode boiler starts after the gas fuel supply is stopped.

- Fast heating of the coolant, quiet operation, easy replacement of heating elements without replacing the entire device.

- If desired, it can be installed in residential premises without installing a chimney and the boiler room itself.

- High efficiency, which reaches 96% during operation, and when heated, the electricity saving is 40%. Plus the absence of dirt, dust, smoke and soot.

An electric electrode boiler consumes on average 40% less electricity than another heating device from the network

Users note this nuance as the most important advantage of the unit

Like any heating system, an electrode electric boiler has its drawbacks.

The disadvantages of these units include the following points:

- Considerable cost of electricity. Electricity is much more expensive than, for example, gas, but at the same time it is perfect for providing heat to a house that is far from the settlement and is visited from time to time.

- Not versatility. An ion boiler for heating a private house is often not compatible with certain types of pipes and batteries. As an example, one can cite the use of cast iron radiators in the heating system, when problems appear due to irregularities on the inside, as well as a large volume of liquid. Typically, one section of a cast iron battery is rated for 2.5 liters of water.

- Problems with the use of pipes made of metal-plastic. In this case, it is desirable to use polypropylene products.

- The requirement of an ion-exchange electric boiler for a constant resistance of the coolant. It can be corrected by adding additives that exclude the appearance of scale.

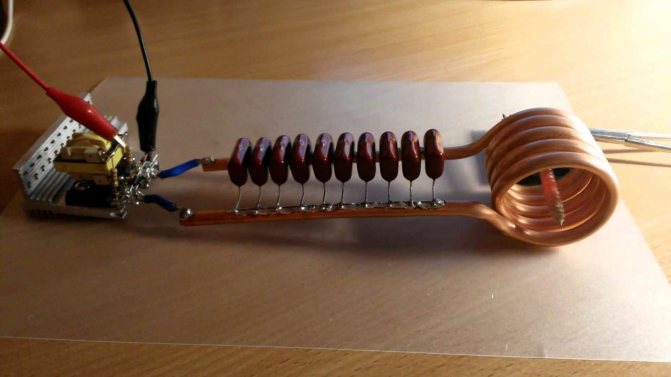

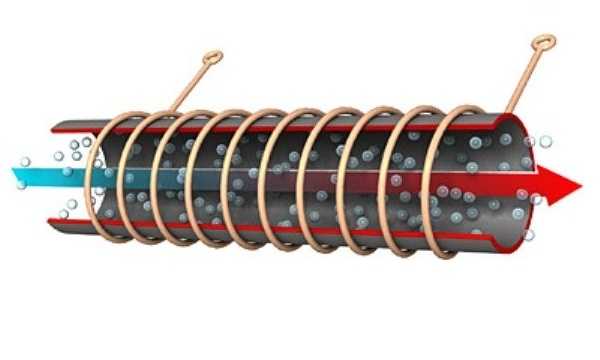

Working method and design of induction heater

Induction is a physical phenomenon based on eddy currents. They were discovered and studied by the French physicist Foucault at one time. The induction electric boiler for heating uses Foucault currents in its work, working according to the method of the same electromagnetic induction. An alternating voltage appears on the coil, a magnetic field is created, which causes the occurrence of eddy currents that heat the steel. Water is heated in the heat exchanger and, working in the system, heats the premises in the cottage.

An induction electric boiler for heating a private house consists of the following parts:

- heat exchanger;

- glued box;

- inductors;

- control box;

- conductors;

- inlet and outlet pipes.

For the comfort of using the system, there may be additional details in its design. A boiler of this type consists of an inductor, which is hidden in a small but very heavy iron alloy case. Instead of a heat exchanger, some systems install a simple metal tube with a heat source. But the presence of a heat exchanger evades the heat transfer distance.

Such a system has a high level of reliability and stability, since the induction coil is firmly closed in a sealed housing without coming into contact with the coolant. The appearance of holes in the turns is impossible, since they are not wound very tightly, and in addition they are covered with a special insulating agent. All this is packed in a massive case, which allows you to puff a long period of use. Manufacturers give a guarantee of up to 10 years, but sellers claim that an electric boiler with an inductor can last 30 years without maintenance.

Connecting an induction boiler

Costs for heating a house with an electric boiler: an example of calculation

Let's take into account several factors:

The efficiency of the electric boiler is 100%.

This means that the production of 1 kW of heat consumes about 1.04 kW of energy.

The price of 1 kW is 3.4 rubles

(we took the average value, since this figure is different for the regions of the country).

For a house with an area of 90 sq.m. from the southern part of the country we will need an average of 15 kW.

Daily consumption

will be 15*24= 360 kW/h

monthly consumption

electricity, if the device heated water constantly, would be 360 * 30 = 10800 kW / h

Money spent per month

- 10800 * 3.4 \u003d 36720 rubles.

We calculated this amount with a surplus, because the boiler will not plow 24 hours a day. Therefore, you can safely reduce it by 1.5-2 times: about 20-23 tr. he will "eat" you.

How electric boilers work

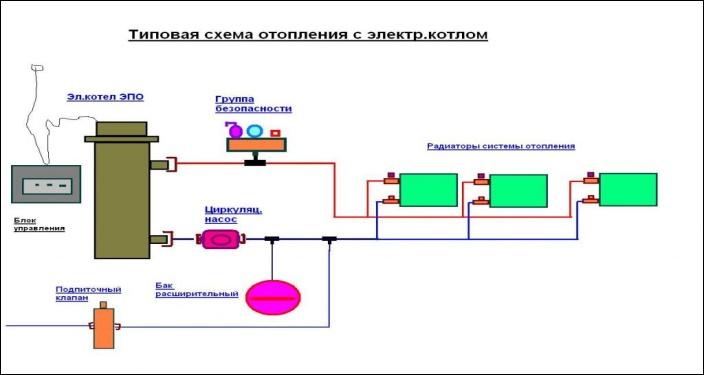

The general principle of operation of electric boilers for heating: the coolant (water) circulates with the help of a pump along the circuit of the heating system, through the boiler (inner chamber, flask, coil) and is heated there by heating elements, heat exchangers with electrodes, induction coils.

The main parts of the electric boiler: a body with heaters, a circulation pump, a power supply, an expansion tank, a control and safety system (pressure gauge, check valve and for releasing excessive pressure).

Economical electric boilers are required in such conditions:

- if it is not possible to use gas;

- a unit is required that is easier to maintain than fuel-powered appliances;

- preference is given to a cleaner source of energy;

- an additional heater is required in case the main unit is switched off.

Some types of boilers and their characteristics

Next, consider one of each type of electric boilers. It should be pointed out that many companies are engaged in the production of several types of boilers. One of these is the company Galan (Russia).

We took this company not for advertising purposes, but because this manufacturer really has a lot of models, so it's easier to find something for example.

Let's take average models. Of the heating elements, for example - Galan Geyser Turbo 12 kW.

This boiler has a cylindrical shape, can be used both floor and suspended.

The length of this heater is 500 mm, the power is 12 kW, therefore it is indicated that it is capable of heating a room up to 300 cubic meters, although, as already mentioned, it all depends on the thermal insulation of the room itself.

This model comes with a control box. It is three-phase, therefore it works from a 380 V network.

But the model Galan Geyser-9 can already work from a network of 220 and 380 V.

This model is also very compact, its length is only 360 mm. Its power is 9 kW, and can work with a coolant up to 100 liters. The manufacturer indicates that this boiler is capable of heating room up to 340 cubic meters. m.

But this manufacturer does not produce induction boilers. Therefore, we will consider one of the models of the manufacturer SAV of the PROF series.

Consider the parameters of the SAV 5 model.

This boiler has a power of 5 kW. At the same time, it is able to heat a room up to 200 cubic meters. It works from a 220 V network, as for the size, you can’t call it small, its height is 640 mm with a width of 455 mm.

Popular with readers: Should I buy infrared heaters.

Myths about induction boilers

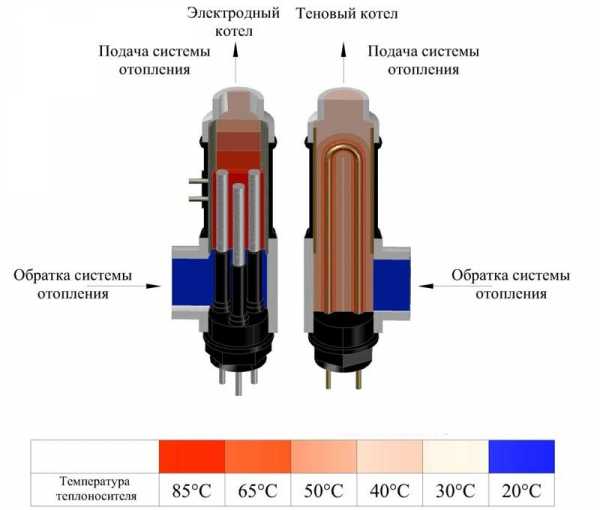

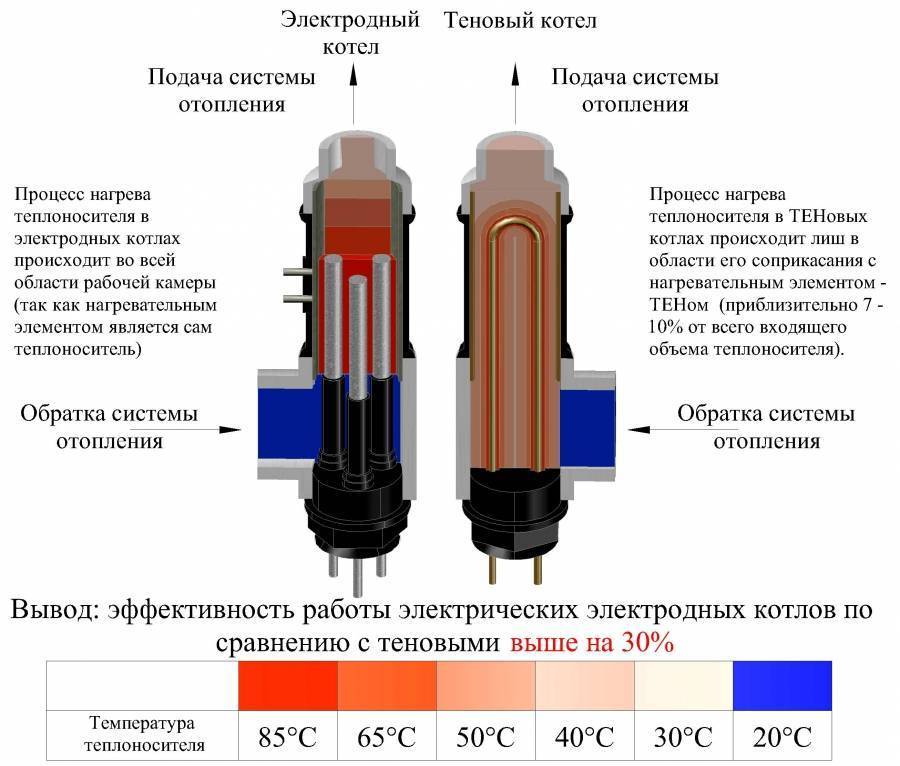

One of the most popular myths is created by sales representatives selling induction electric boilers. The bottom line is that these boilers are supposedly 20-30% more efficient than other heating electrical installations, especially heating elements. This information is not true, since all heat generators that convert electricity into heat operate with an efficiency of at least 96% in accordance with the physical law of conservation of energy. The only undeniable fact is that the heating elements heat up the coolant a little longer due to their multilayer structure. The tungsten coil first heats the quartz sand, then the tube material, and then the water. At the same time, energy is not lost anywhere, and the efficiency of the heating element unit is 98%, as well as the vortex one.

Example of a heating system

Another myth says that the induction electric boiler does not require maintenance at all, since the alternating magnetic field prevents deposits from settling on the heating elements. This question depends on the quality of the water and scale on the core of the coil appears in the same way as in heating elements, if the coolant is not desalinated. Therefore, at least once every 2 years, the heat generator itself and the heating system must undergo a flushing procedure.

Contrary to the assurances of the sellers, the water heater cannot be placed in any room. There are two reasons: the danger of electric shock and the presence of an electromagnetic field around the device. It is better to place it in a technical room with limited access (boiler room).

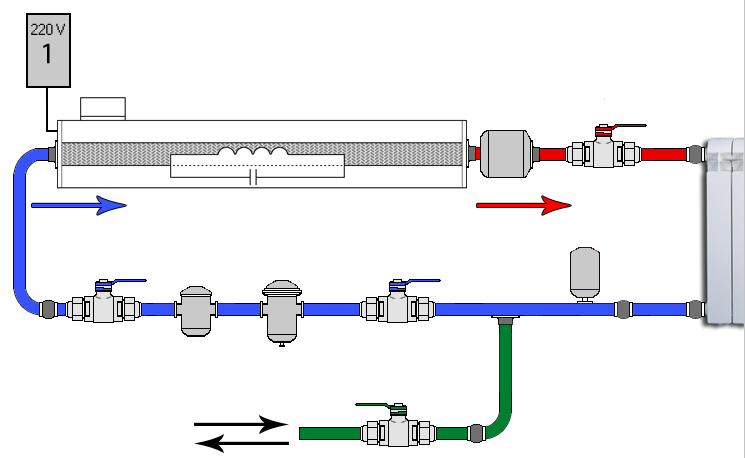

Features of installation of induction heaters

Current induction electric boilers for heating should only be installed in a closed circuit with a membrane expansion tank and a circulation pump.Forced circulation is needed primarily due to the fact that intense heating and a small volume of the heat exchanger prevent the creation of natural circulation, the water will boil before the conditions for gravitational circulation are created.

In the event that an induction heating electric boiler is used as a heat generator, then it is necessary to use plastic pipelines in the circuit or to isolate metal pipes from the boiler by installing plastic fittings. The boiler must be provided with mandatory and high-quality grounding.

Installation requirements, as for all electric boilers: from the surface of the floor or ceiling - 80 cm, from the wall - 30 cm Installation of a safety unit, which includes a pressure gauge, air and safety valves, is mandatory as for all closed heating systems. In private homes, they usually use a standard connection system.

Installation of induction boilers must be carried out in accordance with the instructions or requirements specified in the technical data sheet. The device must be located strictly in a vertical position, the lower inlet pipe is connected to the return, the upper, respectively, to the supply. For this, only metal or metal-plastic pipes should be used.

If you decide to install an electric boiler yourself, you need to remember about grounding. In the immediate vicinity, it is necessary to install a safety group control cabinet, at the inlet - filters and a flow sensor.

During the acquisition, you need to carefully look at the power of the equipment, which does not fall during use. The optimal ratio is 60 W per 1 m2.In order to calculate this characteristic, it is necessary to take into account the dimensions of all rooms.

If there is not enough thermal insulation, you need to take a more powerful heating boiler. Current induction units can maintain a low temperature in rarely used rooms. Accordingly, an electric boiler of 6 kW is quite suitable for a house.

Thus, the simplest and most optimal solution for heating is the installation of an electric boiler. They are really more economical due to the lower inertia of the system, reliability (if you use well-thought-out technology and high-quality materials) and good operation of automation, which includes only a system to maintain the temperature. This equipment is mounted as a backup in private homes and for heating offices and trade pavilions.

Advantages and disadvantages of electric boilers

Experts identify a number of undeniable advantages:

- An electric boiler for heating a private house is the safest unit. The combustion of fuel is not associated with open fire, there are no products of combustion of energy carriers. To connect the device, reliable electrical wiring is useful, but in a private house this is a necessary requirement for the operation of all household appliances.

- The equipment can be installed in or near residential areas. You do not have to equip a separate boiler room.

- Installation does not require permits from government organizations. When installing a unit with a power of up to 10 kW, you need a solid power supply network, for equipment of greater power - a separate line, which will be allocated by an invited specialist.

- Ease of operation. The automation and control system minimizes the user's participation in maintaining the network's performance.

- Multifunctionality.Thanks to the control panel, the user will be able to set different heating modes. For example, set the heating level in the daytime to no more than 40% so that the coolant maintains a temperature sufficient for the system to work, in the evening start the boiler to work with a return of 100%. It is also possible to control the settings remotely via a mobile phone or other device.

- The simple design of the boilers is a plus for their durability.

Equipment disadvantages:

- high price of energy;

- the obligation of high-quality insulation of the house to reduce heat loss;

- search for an economical solution - it is impractical to launch open-type gravity systems due to an increase in energy consumption;

- restrictions on heating devices, heavy cast-iron and light steel batteries cannot be built into the network, because they will lead to a loss of thermal energy and are not efficient enough.

It is also worth remembering the exactingness of the equipment to the quality of the coolant and the volatility of the network - the device will not work without electricity. Under the condition of frequent power outages, the output can be in the installation of generators or a universal boiler operating on different types of fuel.

Advantages and disadvantages of an induction boiler

Induction boilers have the following advantages:

- High efficiency;

- Absence of consumables, design reliability;

- Small overall dimensions;

- Ease of installation and operation;

- High heating rate;

Boilers of induction type have an efficiency of up to 99%, exceeding the efficiency of heating elements and electrode units. The efficiency of the boiler in 20 - 30%, declared by the manufacturers, contradicts the principles of the law of conservation of energy.

But some savings can still be achieved due to the absence of scale. The fact is that the core, when exposed to electromagnetic induction, not only heats up, but also acquires a stable microvibration. The formation of deposits and scale in such conditions is almost impossible.

In heating elements and electrode boilers, scale formation is a stable constant process. Lime deposits have a certain thermal resistance and reduce the heat transfer coefficient from the heating element to the coolant. Scale 0.5 mm thick impairs heat transfer by 8-10%. In induction boilers, there is no such obstacle and electrical energy is spent more rationally.

The presence of the vibration phenomenon also makes it possible to use water in the heating system even with a high content of hardness salts. In general, untreated water, antifreezes, even oil can be used as a heat carrier during the operation of inductor boilers - that is, there are no chemical composition requirements that are inherent in other electric boilers.

Induction boilers do not have wearing elements (heating elements, electrodes) in their design. The service life of the equipment is declared at 25 years (with a guarantee of 2 years). Regular replacement of heating elements is not required - this reduces the cost of operating the equipment.

Household boilers have small dimensions (height does not exceed 1 meter), they can be located in any room. Installation of the product does not require any permits, installation can be done independently. A prerequisite for installation is the grounding of the device to prevent electric shock.

The independent manufacture of an induction-type boiler should be discussed separately. The implementation of this task is possible with the presence of a welding machine and certain skills. But a prerequisite is the knowledge of electrical equipment and devices, because any complex equipment requires a serious system of security, control and management. Self-assembly of the control unit and security systems is not for everyone.

Induction boilers can be called multifunctional. They can be used not only for heating, but also for the production of hot water in instantaneous water heater mode.

Induction boilers practically do not have any serious drawbacks. It can only be noted that according to user reviews, there are complaints about the noise of the product during operation. This is caused by the presence of vibration. In principle, this negative factor can be eliminated - the boiler should be mounted with shock-absorbing inserts (made of rubber, etc.), which will prevent the transmission of vibration to building structures.

It can also be noted that an uncontrolled leakage of the coolant poses a serious danger. If the flow control system fails, the equipment will be destroyed and become unrepairable. And another significant drawback inherent in all electric heating equipment is the very high cost of electrical energy.

Induction heating boilers are high-quality and efficient equipment from a technical point of view. By their design, they are more perfect than heating elements and electrode electric boilers. In the absence of energy sources other than electricity, this type of equipment may eventually become more popular for heating private houses and summer cottages.

(Views 418 , 1 today)

We recommend reading:

Types and choice of shower cabins

Heat accumulator for heating system

Types of heating convectors

Which radiator is best for heating

Water supply device for a private house from a well

Heating circulation pump

New models of electric boilers

Modern electric boilers allow you to save electricity and at the same time heat the premises well. First of all, this is achieved by multi-stage equipment. The meter also has a great influence on the cost of electricity. It is very beneficial to install a multi-tariff meter that takes into account the operation of the boiler at night. Also useful is the function of delaying the shutdown of the post-circulation pump after the equipment has been turned off.

Modern electric boilers are distinguished by the fact that they have built-in circulation pumps. Thanks to this design, the efficiency of the equipment is significantly increased. The pump increases the rate of passage of the coolant through the system. This results in rapid heating of the room. The profitability of this type also increases heating due to the same pipes of minimum diameter. The coolant in such conditions heats up faster. This means that the energy consumption is significantly reduced.

control panel automation

Also, by insulating the house, you can greatly increase the efficiency of the electrode boiler.

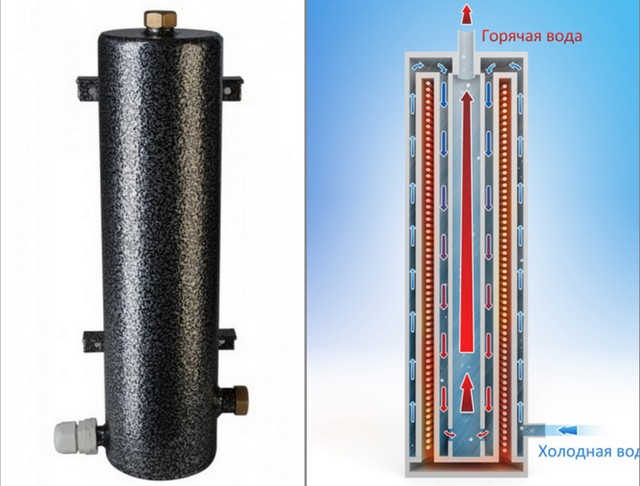

Operating principle

When heating the coolant in induction boilers, energy is used that is released when induced currents occur in the heat exchanger housing. This is, in fact, an induction coil enclosed in a massive ferroalloy housing.The case itself is the secondary winding. It heats up due to the passage of currents induced in it. To increase the heat transfer area, it is made in the form of a labyrinth with thick walls. The coolant, passing through the labyrinth, heats up.

The principle of operation of induction heating boilers is based on the release of heat when Foucault currents occur in the metal

The system has a high degree of reliability, since the coil is hermetically sealed in the housing and has no contact with water or other coolant. The probability of breakdown of the turns is small - they are not wound tightly and are additionally filled with an insulating compound. All this, together with a massive thick-walled body, allows us to talk about a long service life. Sellers claim 30 years of operation without maintenance, but manufacturers put a much shorter warranty period.

How to choose a heating device

When choosing an inverter boiler for heating, it is worth considering many factors.

First of all, you need to pay attention to its power. Throughout the life of the boiler, this parameter remains unchanged. It is taken into account that 60 W is needed to heat 1 m2

Making the calculation is very easy. It is necessary to add the area of \u200b\u200ball rooms and multiply by the specified number. If the house is not insulated, then it is better to choose more powerful models, as there will be significant heat losses.

It is taken into account that 60 watts are needed to heat 1 m2. Making the calculation is very easy. It is necessary to add the area of \u200b\u200ball rooms and multiply by the specified number. If the house is not insulated, then it is better to choose more powerful models, as there will be significant heat losses.

An important factor is the features of the operation of the house.If it is used only for temporary residence, then there is no need to constantly maintain the temperature in the premises at a given level. In such cases, you can completely get by with a unit with a power of not more than 6 kW.

When choosing, pay attention to the configuration of the boiler. Convenient is the presence of an electronic program unit with a diode thermostat. With it, you can set the unit to work for several days and even a week in advance

In addition, in the presence of such a unit, it is possible to control the system from a distance. This makes it possible to pre-heat the house before arrival.

With it, you can set the unit to work for several days and even a week in advance. In addition, in the presence of such a unit, it is possible to control the system from a distance. This makes it possible to preheat the house before arrival.

An important parameter is the thickness of the walls of the core. The resistance of the element to corrosion will depend on this. Thus, the thicker the walls, the higher the protection. These are the main parameters that should be considered when choosing a device and constructing a heating system. If the price is not acceptable, then you can use analogues or build a boiler yourself. To do this, you just need to have certain knowledge and skills.

Types of electric boilers

All electric boilers can be divided into three groups:

- heating elements

- electrode

- induction

The main element of the first group of electric boilers is a thermoelectric heater, abbreviated as a heating element. In addition, it has built-in power controllers and temperature sensors.

The principle of operation of such an electric boiler is quite simple: the heat exchanger of the equipment heats the water, and that, in turn, transfers heat to the room. A big disadvantage of this type of boiler is that during long-term operation scale can be deposited on its walls. This, in turn, has a negative impact on his future work.

The principle of operation of such an electric boiler is quite simple: the heat exchanger of the equipment heats the water, and that, in turn, transfers heat to the room. A big disadvantage of this type of boiler is that during long-term operation scale can be deposited on its walls. This, in turn, has a negative impact on his future work.

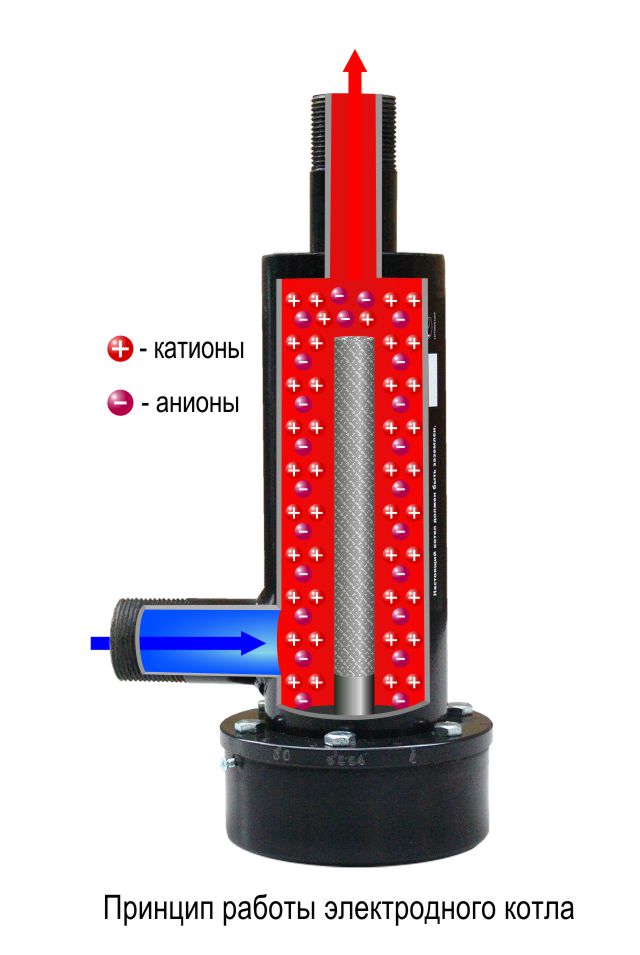

There is also another type of boiler - electrode. As a heat exchanger, an electrode is presented in it, which transfers electricity to the coolant. Under the influence of current, water is split into ions, which pass to the electrodes of the corresponding polarity. During this process, a rapid heating of the coolant occurs.

In this boiler, the electrodes will have to be replaced periodically, as they tend to dissolve

Another modern option for electric boilers are induction boilers. They heat the room at the expense of an inductor that heats the coolant. The disadvantages of this installation are the large size of the boiler and the high price.

What is induction heating

The work is based on the phenomenon of electromagnetic induction. An electromagnetic field is created inside the boiler, which heats the ferromagnetic core. It is he who gives off heat to the water in the system instead of the usual heating element.

When sellers and manufacturers of VINs (vortex induction heaters) talk about its efficiency, they mean the heating rate of the element and the transfer of heat to the system.

If the heater heats the water in the heating system at best after 20 or even 30-40 minutes, then the induction element is 10-15 minutes faster.

Important! In induction heating, the choice of coolant is quite wide: it can be not only water, but also oil, ethylene glycol and any antifreeze

The principle of operation and the device of an induction electric boiler

Similar to a transformer. The induction current generator consists of primary and secondary short-circuited windings. The primary winding converts electrical energy into eddy current, and the secondary winding serves as the body of the inductor.

The following example will explain the operation of the induction heater device even more simply:

- A coil is wound on a pipe made of dielectric material (non-conductive electric current).

- A core of martensitic or ferritic steel (ferromagnet) is placed inside.

- The coil under the influence of electricity creates a magnetic field.

- The magnetic field heats the core (up to 750 °C).

- The core heats the water passing through the pipe.

Reference. Despite the fact that an induction boiler can quickly heat a large amount of coolant, and the phenomenon of induction itself creates a convection movement of the carrier in the system, in order to heat a two-story house without problems, you need to put a pump in the system.

Most often, an induction boiler is a fairly compact, not too high (40 cm), but weighty (up to 23-30 kg) wide balloon-pipe. Therefore, so that it does not collapse, it is placed on strong additional fasteners. Sometimes, to enhance the effect, a soldered section of several of these balloon-shaped boiler tubes is used.

Photo 1. Induction boiler connected to the heating circuit. It is a small balloon.

Less common are designs in the form of a locker.

But in any case, the induction boiler consists of:

- Housing consisting of dielectric metal.

- electrical insulating layer.

- Ferromagnet core (thickness up to 7 mm).

- Temperature sensor in the boiler body.

- Inlet and outlet pipes for connection with a system of pipes and radiators.

- Auto switches (in the control panel).

- Temperature controller (electronics in the control panel).

And this is what the heating system might look like, where:

- The pump for circulation of the heat carrier.

- Heating batteries.

- Induction boiler.

- Membrane expansion tank (for pressure regulation).

- Control panel cabinet.

- Shut-off ball valve.

Attention! The induction boiler is only suitable for a closed heating circuit