- What are the features of using a 40 mm polypropylene pipe for heating

- Advantages

- Diameters of polypropylene pipes for heating

- Based on the test results, the following table was compiled

- Varieties of polypropylene pipes presented on the domestic market

- White polypropylene pipes

- Gray polypropylene pipes

- Black polypropylene pipes

- Green polypropylene pipes

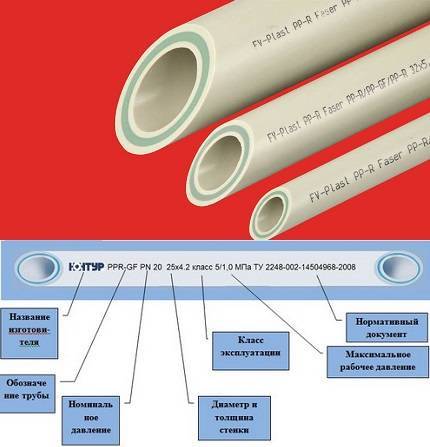

- About numeric and alphabetic characters in marking

- Rated pressure

- Operating class

- Dimensions

- What does PN and class with pressure mean

- Features of the operation of polypropylene heating pipes

What are the features of using a 40 mm polypropylene pipe for heating

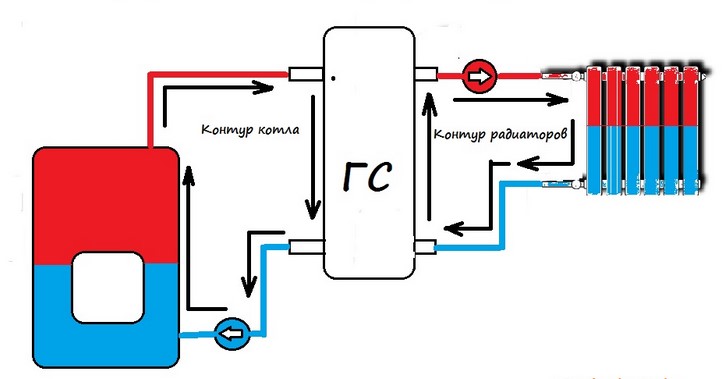

When designing and installing a heating system, the question always arises - what diameter pipes to use when working. The diameter (and hence the throughput of the pipes) is important, since it is necessary to ensure the coolant velocity is within 0.4–0.6 m / s, which is recommended by experts. At the same time, the required amount of energy must be supplied to the coolants (radiators).

At a speed of less than 0.2 m/s, air pockets stagnate.It is irrational to use a speed greater than 0.7 m/s in terms of energy saving, since the resistance to fluid movement becomes significant (it is directly proportional to the square of the speed). Also, if this speed is exceeded, there is a possibility of noise in pipelines of small diameters.

Polypropylene pipe 40 mm is increasingly used in heating systems, even if there are disadvantages in the form of the difficulty of ensuring the quality of the joints and significant expansion under the influence of heat. Such pipes are inexpensive and easy to install, and these are often decisive factors.

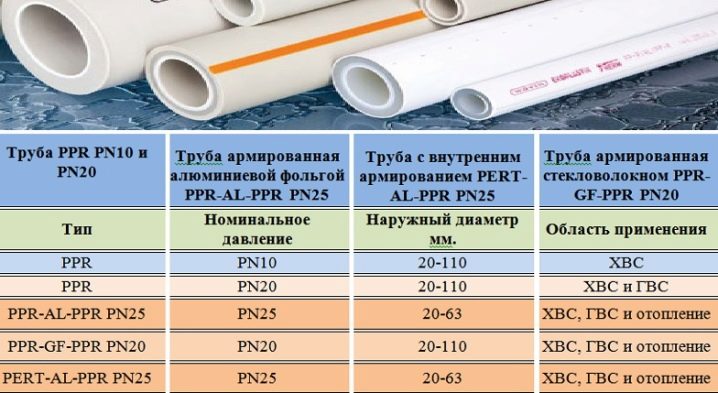

Polypropylene pipes are divided into several types, depending on the technical characteristics and operating conditions. For heating, PN25 (PN30) grades are used, designed for a working pressure of 2.5 atm at a liquid temperature of not more than +120 ° C.

Polypropylene pipe 40 mm, reinforced with aluminum foil or fiberglass, used for heating. Reinforcement does not allow the material to expand greatly when heated.

Some experts choose pipes with internal fiberglass reinforcement. They are most often used in private heating systems.

Pipes are made in standard diameters, from which you need to choose the most suitable one. There are standard solutions with which you can choose the diameter of the pipe for heating a house. They allow in 99% of cases to choose the optimal diameter without performing a hydraulic calculation.

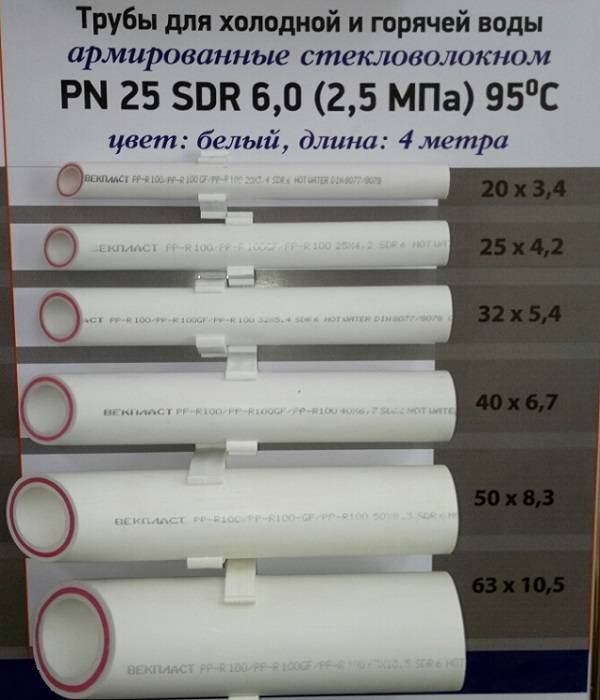

The standard diameters of polypropylene pipes include - 16, 20, 25, 32, 40 mm.

Standard outer diameters of polypropylene pipes are 16, 20, 25, 32, 40 mm. These values correspond to the inner diameter of PN25 pipes - 10.6, 13.2, 16.6, 21.2, 26.6 mm.

More detailed data on the outer and inner diameters and wall thickness of polypropylene pipes can be found in the table.

| Outer diameter, mm | PN10 | PN20 | PN30 | |||

| Inner diameter | Wall thickness | Inner diameter | Wall thickness | Inner diameter | Wall thickness | |

| 16 | 10,6 | 2,7 | ||||

| 20 | 16,2 | 1,9 | 13,2 | 3,4 | 13,2 | 3,4 |

| 25 | 20,4 | 2,3 | 16,6 | 4,2 | 16,6 | 4,2 |

| 32 | 26 | 3 | 21,2 | 5,4 | 21,2 | 3 |

| 40 | 32,6 | 3,7 | 26,6 | 6,7 | 26,6 | 3,7 |

| 50 | 40,8 | 4,6 | 33,2 | 8,4 | 33,2 | 4,6 |

| 63 | 51,4 | 5,8 | 42 | 10,5 | 42 | 5,8 |

| 75 | 61,2 | 6,9 | 50 | 12,5 | 50 | 6,9 |

| 90 | 73,6 | 8,2 | 6 | 15 | ||

| 110 | 90 | 10 | 73,2 | 18,4 |

Read the material on the topic: How to choose fittings for polypropylene pipes

We need to ensure the supply of the necessary thermal power. It will be directly dependent on the amount of coolant supplied, but the fluid velocity should not exceed 0.3–0.7 m/s.

Based on this, there is the following correspondence of connections (for polypropylene pipes, the outer diameter is indicated):

-

16 mm - when installing one or two radiators;

-

20 mm - when installing one radiator or a small group of radiators (radiators of "normal" power from 1 to 2 kW, the maximum connected power is not higher than 7 kW, the number of radiators is not more than 5 pieces);

-

25 mm - when installing several radiators (usually no more than 8 pcs., power not higher than 11 kW) of one wing (arm of a dead-end wiring diagram);

-

32 mm - when connecting one floor or the whole house, depending on the heat output (usually no more than 12 radiators, respectively, the heat output is not higher than 19 kW);

-

40 mm - for the main line of one house, if available (20 radiators - not higher than 30 kW).

Let us analyze the choice of pipe diameter in more detail, based on pre-calculated tabular correspondences of energy, speed and diameter.

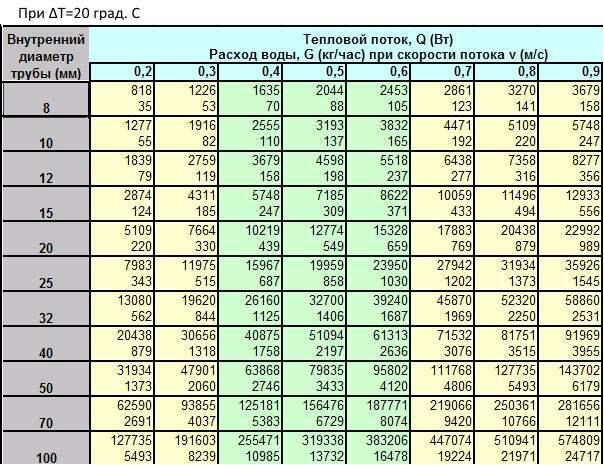

Let us turn to the table of correspondence of speed to the amount of thermal power.

The table shows the values \u200b\u200bof thermal power (W), and below them the amount of coolant (kg / min) is indicated when supplying at a temperature of +80 ° C, return - +60 ° C and room temperature +20 ° C.

The table shows that at a speed of 0.4 m/s, the following amount of heat is supplied through polypropylene pipes of the specified outer diameter:

-

4.1 kW - inner diameter about 13.2 mm (outer diameter 20 mm);

-

6.3 kW - 16.6 mm (25 mm);

-

11.5 kW - 21.2 mm (32 mm);

-

17 kW - 26.6 mm (40 mm);

At a speed of 0.7 m / s, the supplied power increases by 70%, which is easy to see in the table.

Advantages

Polypropylene is a unique modern material that has a high rating in construction. So, the advantages of polypropylene include the following characteristics:

- reliability and durability - service life of at least 50 years;

- ease of installation and design, the possibility of repair on their own;

- autonomy from the electric wire;

- resistance to corrosion and resistance to chemical liquids;

- smooth inner surface that does not collect various deposits;

- high thermal insulation properties, reducing heat loss and good sound insulation, absorbing the sounds of flowing water;

- pleasant aesthetic appearance;

- price availability.

Diameters of polypropylene pipes for heating

The main characteristic of products is the size of the cross section - the diameter, measured in mm. The heating home network consists of different sections, which are equipped with pipes of different diameters for the best effect:

- from 100 to 200 mm are used for centralized hot water supply of multi-storey buildings, public buildings for civil purposes.

- from 25 to 32 mm are used to connect private houses and small buildings.

- Hot water is supplied through horizontal sections of wiring with a diameter of 20 mm, vertical risers are equipped with a diameter of 25 mm.

The presented table clearly shows the gradation of the change in diameter depending on the amount of heat flux.

Based on the test results, the following table was compiled

| Trademark | Pipe diameter x-Wall thickness, SDR (in fact) | PN - declared on the pipe | Pipe marking | Reinforcement according to the designation on the pipe | Burst pressure at 20ºС, bar |

|---|---|---|---|---|---|

| VALTEC | 20.63×3.44 SDR6 | PN20 | VALTEC PP-R | No | 120 |

| HEISSKRAFT | 32.16x 4.8 SDR 6.7 | PN20 | HEISSKRAFT PPR | No | 110 |

| VALFEX | 20.27x3.74 SDR 5.4 | PN20 | VALFEX PPR100 | No | 110 |

| TEVO | 20x3.5 SDR 6 | PN20 | PP-R/PP-R-GF/PP-R SDR6 | Fiberglass | 120 |

| TEVO | 25.21×3.44 SDR 7.3 | PP-R/PP-R-GF/PP-R SDR7.4 | Fiberglass | 90 | |

| VALTEC | 20.15×2.97 SDR 6.8 | PN20 | PP-FIBER PP-R100 | Fiberglass | 95 |

| VALTEC | 25.7×3.57 SDR 7.2 | PN20 | PP-FIBER PPR100 | Fiberglass | 85 |

| SANPOLIMER | 20.54×2.3 SDR 8.9 | PN20 | SANPOLIMER PP GLASS FIBER SDR 7.4 | Fiberglass | 80 |

| HEISSKRAFT | 20.15×3.0 SDR 6.71 | PN20 | PPR-GF-PPR 20×2.8 | Fiberglass | 110 |

| HEISSKRAFT | 20.13x2.85 SDR 7.1 | PN20 | HEISSKRAFT PPR-GF-PPR SDR7,4 | Fiberglass | 100 |

| EGEPLAST | 25.48x4.51 SDR 5.6 | PN20 | EGEPLAST GF | Fiberglass | 130 |

| SANPOLIMER | 20×3.15 SDR 6.3 | PN20 | SANPOLIMER PP GlassFiber SDR6 | Fiberglass | 100 |

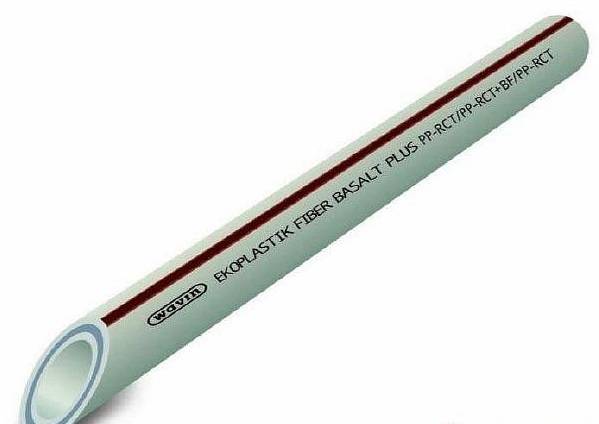

| WAVIN EKOPLASTIK | 25.45x4.05 SDR 6.3 | WAVIN EKOPLASTIK FIBER BASALT PLUS PP-RCT/PPRCT+BF/PP-RCT | Basalt fiber | 80 | |

| SANPOLIMER | 25.6x3.8 SDR 6.7 | PN20 | SANPOLIMER PP Al-Inside | Al central reinforcement | 110 |

| COMFORT SUPER | 20.48×3.55 SDR5.7 | PN20 | COMFORT SUPER PPR-AL-PPR | Al central reinforcement | 120 |

| Master Pipe | 20×4.22 SDR 4.7 | PN20 | Master Pipe PPR-AL-PPR | Al central reinforcement | 140 |

| DESIGN | 25.7 (longitudinal ribs, wall thickness variable) | PN32 | DIZAYN HI-TECH OXY PLUS combi | Al central reinforcement | 140 |

First of all, it should be noted that the data obtained do not contradict the data of manufacturers and suppliers of products. For example, specialists from Vesta Trading, in one of their training videos, clearly indicate the maximum pressure that the pipe samples they tested withstood, as can be seen from the following figure:

Note also that we did not choose a pipe with a special wall thickness - see the values indicated in the second column.

Pay attention to the burst pressure values of the glass fiber reinforced pipe. The difference in burst pressures between PPR100 and PPR80 should be approximately 20%. From the table it can be seen that the PPR80 pipe withstands the same burst pressure as the pipe made of PPR100 for equal SDRs, and the pressures are almost the same

Where the SDR of the pipe is 6, the burst pressure is 120 atm.; where SDR = 7.4, pressure = 90–95 atm. The SANPOLIMER pipe has a thicker wall (actual SDR = 6.35), so it has a slightly higher burst pressure: 100 atm.

Note that for an unreinforced VALTEC pipe with a normal wall thickness and made of PPR100 (20 × 3.44), the burst pressure is also 120 atm. The conclusion is obvious: these pipes are made from the same raw material - this is PPR80. But for a HEISSKRAFT pipe with SDR = 6.7, the burst pressure is 110 atm., Therefore, it is possible that it is made from PPR100 raw materials

From the table it can be seen that the PPR80 pipe withstands the same burst pressure as the pipe made from PPR100 for equal SDRs, and the pressures are almost the same.Where the SDR of the pipe is 6, the burst pressure is 120 atm.; where SDR = 7.4, pressure = 90–95 atm. The SANPOLIMER pipe has a thicker wall (actual SDR = 6.35), so it has a slightly higher burst pressure: 100 atm.

Note that for an unreinforced VALTEC pipe with a normal wall thickness and made of PPR100 (20 × 3.44), the burst pressure is also 120 atm. The conclusion is obvious: these pipes are made from the same raw material - this is PPR80. On the other hand, the HEISSKRAFT pipe with SDR = 6.7 has a burst pressure of 110 atm, so it may be made from PPR100 raw materials.

So, all pipes, except for HEISSKRAFT pipes, are made of PPR80 and correspond to the nominal value PN16 at SDR = 7.4, PN20 at SDR = 6.

Having carried out the same analysis of pipes with central reinforcement, we come to a similar conclusion. They are all made from PPR80 and are classified as PN20 - even those labeled or advertised as PN32. For pipes with central reinforcement, as for others, there are other types of tests. Critical for pipes with aluminum reinforcement will be tests for 1000 hours at a temperature of 95 ° C, and not the short-term tests described in this article. Therefore, based on long-term tests, all pipes with SDR = 6 with central reinforcement are PN20 pipes. The service life of PN16 and PN20 differs quite significantly: for example, at a coolant pressure of 8 atm. it is equal to 11 years and 38 years, respectively.

Varieties of polypropylene pipes presented on the domestic market

Currently, pipes made of polypropylene in a wide range of colors are available for domestic consumers. The colors of polypropylene pipes are selected depending on the area of future operation.

The color of the pipe will tell about the features of its application.

White polypropylene pipes

When mounting water communications, it is recommended to use white pipes made of polypropylene. They are easy to weld, so installation is carried out in record time. Since at a temperature of 0 degrees polypropylene begins to change its structure (crystallizes), it is not recommended to use white pipes made of this material outdoors

Even the transportation of polypropylene pipes at such a temperature regime should be carried out with extreme caution, since any mechanical and physical impact can cause damage to them.

The white polypropylene pipe has a lot of advantages:

- maximum useful life;

- the ability to withstand pressure up to 25 bar;

- low cost;

- resistance to corrosive changes, etc.

White polypropylene pipes

The white pp pipe cannot be used in the installation of outdoor communication systems that will be operated in adverse climatic conditions, at low temperature conditions. This should be taken into account when drafting future communications.

Gray polypropylene pipes

Gray polypropylene pipes are often used when installing plumbing, and are also suitable for creating both centralized and individual heating systems. They have excellent technical properties:

- thermal stability;

- chemical resistance;

- long operational period;

- environmental friendliness;

-

tightness, etc.

Black polypropylene pipes

When creating sewer communications, as well as drainage systems, it is recommended to use black polypropylene pipes. In their manufacture, special additives are used that improve their technical capabilities. Black polypropylene pipes have the following advantages:

- resistance to ultraviolet radiation;

- resistance to various aggressive environments;

- resistance to drying out;

-

high strength, etc.

Green polypropylene pipes

When mounting irrigation systems in household plots, green polypropylene pipes are most often used, since they are not too resistant to internal pressure exerted by water.

Such pipes are sold in a fairly low price range, so land owners do not pay too much attention to their strength characteristics. Recently, some manufacturers have begun to pay more attention to the technical characteristics of pipes made of green polypropylene, so that on the domestic market you can buy such material suitable for mounting cold plumbing in residential premises. Green polypropylene pipes

Green polypropylene pipes

Green polypropylene pipes do not tolerate any physical impact, including pressure

It is important to regularly monitor the status of the created communication, as there is a high risk of pipe rupture.

About numeric and alphabetic characters in marking

Many letters and numbers are applied to this material. Manufacturers usually open official websites, where, among other things, there is information on the label and the information that it indicates. But it is best to translate these explanations into a language that everyone can understand.

Pressure. The unit of measurement is kg\cm2. Designated as PN. Indicates how long the pipe has been operating normally while maintaining certain characteristics.

The thicker the wall, the higher this indicator is likely to be. For example, they produce grades PN20, PN25. Such options are needed for supplying hot water, heating systems.

Sometimes red or blue stripes are also applied. This will make it clear what kind of water future pipelines are intended for.

The marking of polypropylene pipes for heating includes data related to materials and structure. Large tables are compiled to describe this parameter. But it is enough to be aware of the basic designations in order to perform the correct installation of heating in an ordinary building.

- Al - aluminum.

- PEX is the designation for cross-linked polyethylene.

- PP-RP. It is high pressure polypropylene.

- PP - Common varieties of polypropylene material.

- HI - fire resistant products.

- TI is a thermally insulated version.

- M - designation of multilayer.

- S - icon for single-layer structures.

The marking of polypropylene pipes for water supply can also indicate data related to:

- The presence or absence of certificates.

- Issued batch numbers, serial designation and time, and so on. Such designations can consist of 15 characters or more.

- Manufacturers.

- Wall thicknesses and sections.

Thanks to this information, each buyer himself will choose a material for water supply that satisfies all his needs.

Rated pressure

The letters PN are the designation of the permitted working pressure. The next figure indicates the level of internal pressure in bar that the product can withstand during a service life of 50 years at a water temperature of 20 degrees.This indicator directly depends on the wall thickness of the product.

PN10. This designation has an inexpensive thin-walled pipe, the nominal pressure in which is 10 bar. The temperature maximum that it can withstand is 45 degrees. Such a product is used for pumping cold water and underfloor heating.

PN16. Higher nominal pressure, higher limiting fluid temperature - 60 degrees Celsius. Such a pipe is significantly deformed under the influence of strong heat, therefore it is not suitable for use in heating systems and for supplying hot liquids. Its purpose is cold water supply.

PN20. The polypropylene pipe of this brand can withstand a pressure of 20 bar and temperatures up to 75 degrees Celsius. It is quite versatile and is used to supply hot and cold water, but should not be used in a heating system, since it has a high coefficient of deformation under the influence of heat. At a temperature of 60 degrees, a segment of such a pipeline of 5 m is extended by almost 5 cm.

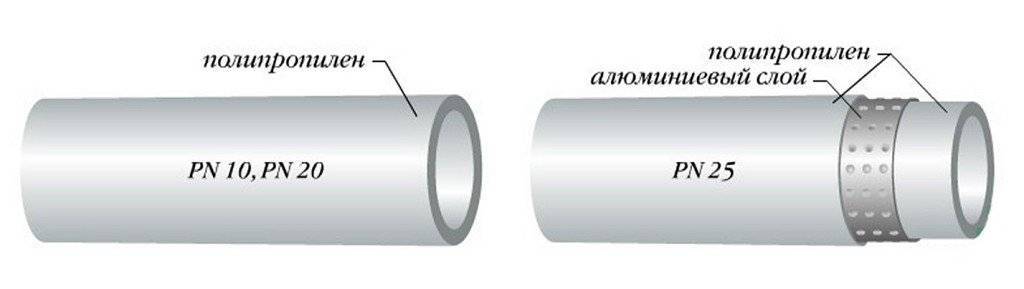

PN25. This product has a fundamental difference from the previous types, since it is reinforced with aluminum foil or fiberglass. In terms of properties, the reinforced pipe is similar to metal-plastic products, is less susceptible to temperature effects, and can withstand 95 degrees. It is intended for use in systems of heating, and also in GVS.

Operating class

When choosing polypropylene products of domestic production, the purpose of the pipe will tell you the class of operation according to GOST.

- Class 1 - the product is intended for hot water supply at a temperature of 60 °C.

- Class 2 - DHW at 70 °C.

- Class 3 - for underfloor heating using low temperatures up to 60 °C.

- Class 4 - for floor and radiator heating systems that use water up to 70 ° C.

- Class 5 - for radiator heating with high temperatures - up to 90 ° C.

- HV - cold water supply.

Dimensions

The dimensions of polypropylene pipes vary widely. Values for external and internal diameters, wall thicknesses can be found in the following table.

What does PN and class with pressure mean

PN on plastic pipes - this is the nominal working pressure that the pipe will withstand for 50 years of operation, at a transported water temperature of 20℃.

The unit of bar is taken as a pressure measurement, 1 bar is equal to 0.1 MPa. In simple terms, this is the pressure at which the pipe will serve for

cold water for a very long period of time.

If it is necessary to take into account the pressure in atmospheres - 1 st.at. (standard atmosphere) = 1.01 bar = 0.101 MPa = 10 meters of water column.

The nominal pressure is not chosen by the manufacturer arbitrarily - there are generally accepted values: PN10; PN16; PN20 and PN25. Generally, values below 20 are used

only in cold water.

A very important point is that with an increase in water temperature, the service life and operating pressure are reduced. Therefore, this symbol characterizes the behavior of the pipe on

cold water, but indirectly indicates performance in hot water and heating.

To more accurately determine the properties for transporting hot water, there are operating classes and their corresponding temperatures - often this information is not available on

the pipe itself.However, pipes with a PN value and with classes come across, in general, these two characteristics, which are different at first glance, are interconnected, more on that below.

Class/pressure (specified in bar or MPa) - This is the operating class and the pressure corresponding to it. In human language - what pressure is long

the pipe will withstand hot water, the temperature of which corresponds to a certain class according to GOST 32415-2013. According to the same document, the working pressure should

correspond to one of the values: 0.4; 0.6; 0.8 and 1.0 MPa. At its core, this is the same PN parameter, only for hot water and heating. Operating classes and temperatures

shown in the table below.

| Class | Working temp. Tslave, ℃ | Service time at Tslave, years | Max. pace. TMax, ℃ | Service time at TMax, years | Emergency temp. Tavar, ℃ | Application area |

|---|---|---|---|---|---|---|

| 1 | 60 | 49 | 80 | 1 | 95 | Hot water supply 60℃ |

| 2 | 70 | 49 | 80 | 1 | 95 | Hot water 70℃ |

| 4 | 204060 | 2,52025 | 70 | 2,5 | 100 | High temperature underfloor heating. Low-temperature heating appliances |

| 5 | 206080 | 142510 | 90 | 1 | 100 | High-temperature heating appliances |

| XV | 20 | 50 | — | — | — | Cold water supply |

Try turning your phone to landscape or change the browser zoom.

To display the table, you need a screen resolution of at least 601 pixels in width!

*Notes to the table: Operating time at Tavar 100 hours. The maximum service life of the pipeline for each class of operation is determined by the total time

operation of the pipeline at temperatures Tslave, TMax and Tavar, and is 50 years old. With a service life of less than 50 years, all time characteristics, except for Tavarshould be proportionally reduced.

Some confusion with temperature and service life for classes 4 and 5 is due to the fact that tests according to GOST 32415-2013 are carried out at temperatures of 60℃ and 80℃

Despite the fact that the designations PN and class / pressure are different characteristics, when studying the documentation for specific pipes, a dependence emerges. Generally PN20

corresponds to classes 1 and 2 (hot water), and PN25 to all 5 classes. Only now the pressure for the desired class will have to be looked for in the documentation. So if

the pipe will not be used on cold water - the class / pressure designation is more complete and preferable. Naturally, pipes of all five classes are suitable for

cold water operation. Do not forget that the above dependence PN is very conditional and if the class and pressure are not indicated in the marking, then it is more correct

will study the documentation, unless of course the pipe is selected for hot water or heating.

Features of the operation of polypropylene heating pipes

In view of this property of polypropylene, it should be operated in compliance with certain rules:

Use as a basis for the heating circuit only those pipes that are treated with reinforced material with a lower coefficient of expansion, for example, fiberglass or the more common aluminum. At the same time, the use of such pipes will not require serious financial costs.

However, when performing the installation of the heating system with your own hands, it would be best to use those pipes that are reinforced with fiber. This will save a fairly significant part of the budget, since during the installation process it will not be necessary to use a special stripping tool called a shaver.However, if such equipment is not used to install pipes reinforced with aluminum-based foil, then it is undesirable to connect their components using fittings.

It would also be useful to remember the fact that products reinforced with fiberglass are not as whimsical in operation as other samples. This is due, first of all, to the fact that their structure does not imply the use of adhesive-based layers, which in practice is realized by simply fusing the fiber into the pipe.

This measure prevents potential delamination of pipes.

When installing polypropylene pipes, it is very important that their straight parts do not rest against any surfaces (walls, ceilings, etc.). This means that when laying the heating circuit, it is important to leave some space at the ends of the pipes necessary for thermal expansion, since reinforcement, although it reduces the expansion of the material, is not a complete means of getting rid of it.

If the pipe is too long, then in this case it is best to use special U-shaped compensating elements (as an option - pipe coils).