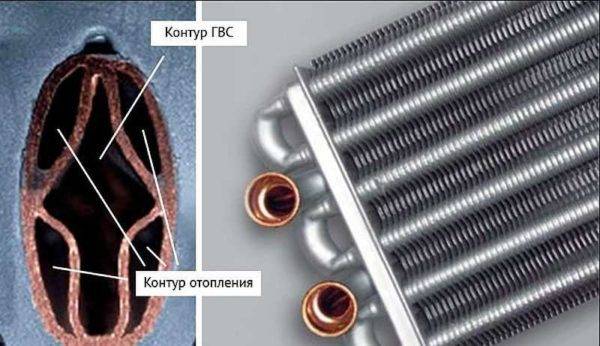

- With bithermic heat exchanger

- Floor or wall 1-circuit electric boilers

- Characteristics of a double-circuit boiler

- Criteria for choosing a gas boiler

- Ways to save money during operation

- Materials for the heat exchanger: which is better

- Steel version of the heat exchanger

- Copper type heat exchanger

- Boilers with cast iron heat exchanger

- The best models of boilers

- Protherm Skat 9 KR 13

- Vaillant eloBLOCK VE 9

- Buderus Logamax E213-10

- EVAN EPO 4

- RusNIT 209M

- ZOTA 9 Lux

- Ferroli ZEWS 9

- Kospel EKCO.L 15z

- Evan Warmos QX-18

- EVAN EPO 6

- Which manufacturer to choose

- Equipment Installation Rules

- How to choose the right boiler?

- Pros and cons of an electric boiler

- Disadvantages of an electric boiler

With bithermic heat exchanger

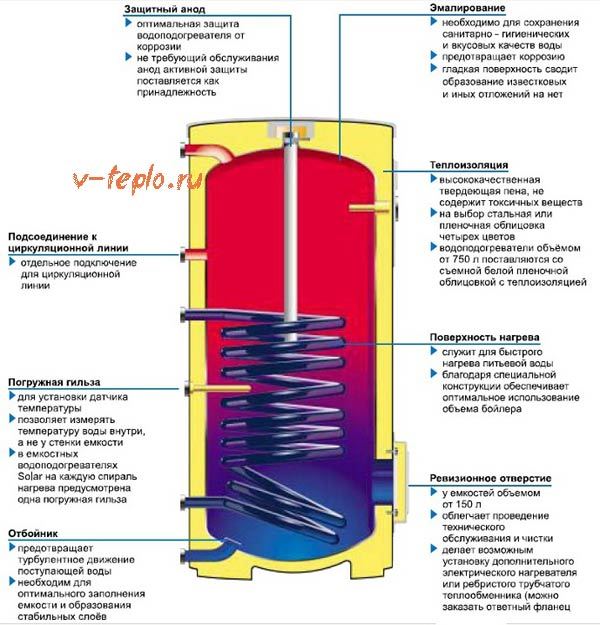

The bithermic heat exchanger is arranged according to the "pipe in pipe" principle. The internal structure can be different - firms are trying to improve their products and try different options. One thing remains unchanged: one large pipe is divided into parts - along. They are separated by metal partitions, sealed and not connected.

One of the options bithermic heat exchanger for double-circuit gas boilers heating

How does a double-circuit boiler with a bithermic heat exchanger work? On one part of the pipe - the outer one - the coolant circulates, which is supplied to the heating system. In the second part - the inner one - water appears only after a hot water tap is opened somewhere. The heating circuit that was working before is closed (by a signal from the control board), all the heat goes to the preparation of hot water. All this time the circulation pump does not work.

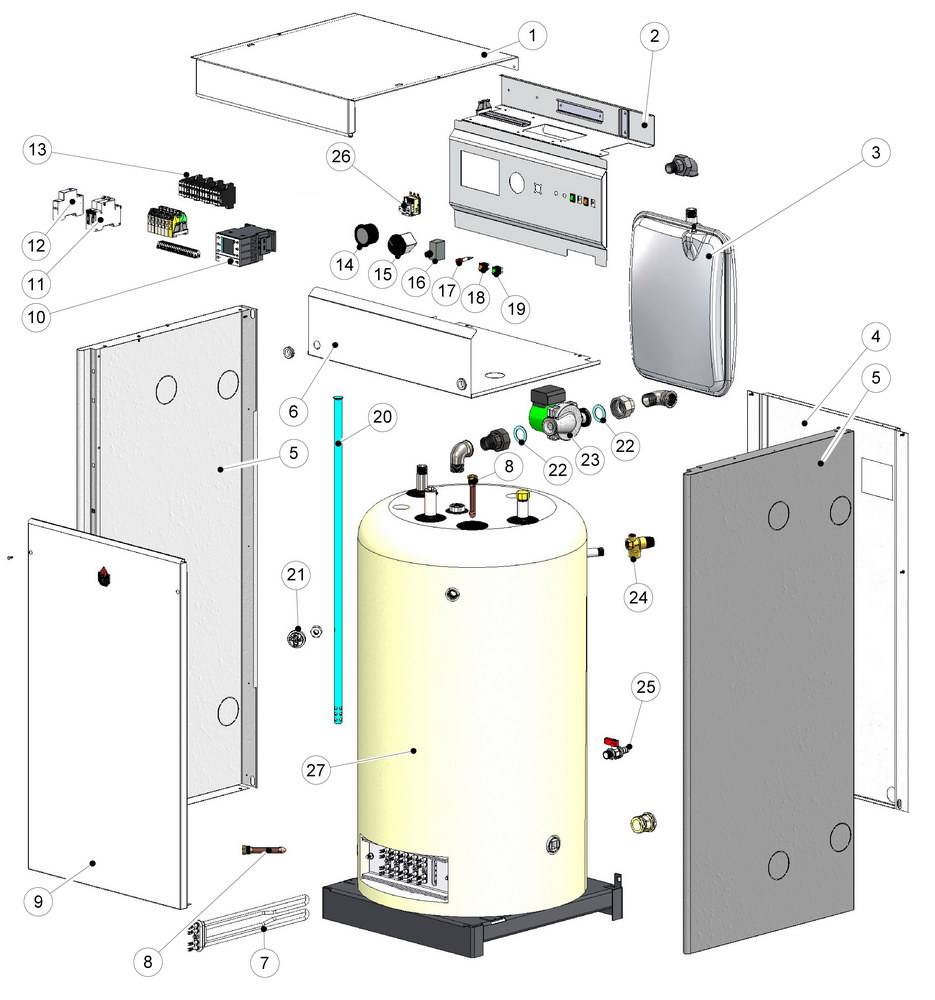

The device of a double-circuit boiler with a bithermic heat exchanger

When the flow of hot water stops (the tap is closed), the circulation pump turns on, the coolant is heated again, which circulates through the heating pipes. As you can see, the arrangement of double-circuit boilers with bithermic heat exchangers is simpler - there are fewer parts, sensors, and, accordingly, easier control. This is reflected in the price - they are a little cheaper. At the same time, the efficiency of such boilers in the water heating mode is slightly higher (93.4% on average, versus 91.7%).

There are also disadvantages - bithermic heat exchangers are often clogged. In DHW heating mode, there is no circulation in the heating medium circuit. This is not a problem if the system is sealed (it should be) and does not require constant replenishment.

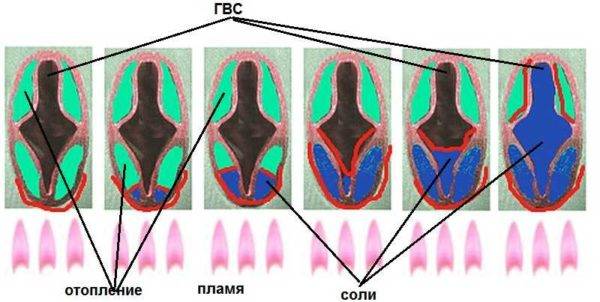

This is how a bithermic heat exchanger overgrows

But if there is a leak somewhere and in order to maintain the working pressure in the heating system, it is necessary to constantly add water, there is a gradual overgrowth of the lumen of that part of the pipe through which the coolant circulates. When this gap is clogged with salts, the part that conducts water for hot water is heated more actively. This leads to the fact that salts begin to clog and this part, the boiler, simply stops working.

Both circuits of the bithermic heat exchanger have been scaled up

Floor or wall 1-circuit electric boilers

It is important for the consumer to divide electric single-circuit boilers for heating a private house according to the type of their location in the room. Like many other types of heat generators, they are:

- Wall-mounted - compact dimensions and low weight allow not only to hang the product on the wall, but also save quite a lot of free space, which is a very significant advantage in a small apartment or house. In addition, they are chosen for the versatility of the design. In other words, such a boiler fits well into the interior of almost any room.

- Floor-standing - structurally simpler and generally more reliable than mounted models. On the other hand, such boilers are bulky, so a place is prepared in advance for their placement.

Floor heat generators are purchased when the total heated area exceeds 100 sq.m.

Characteristics of a double-circuit boiler

When choosing a double-circuit electric boiler, you need to pay attention to:

- principle of water heating;

- heating element;

- water heating rate.

Some models of electric boilers heat water for domestic needs in a flowing way (water heating in a private house). They are characterized by high heating efficiency and take up little space. However, the performance of such boilers depends on many external factors, for example: water pressure in the system, heating time, number of simultaneously open taps, and so on.

Accumulative models are protected from such shortcomings. The heated water enters a tank surrounded by insulation.As a result, the heating electric boiler turns into a boiler, giving you constant access to hot water.

Models with heating elements are highly efficient and attractively priced, but have a short service life. In turn, induction electric boilers can boast of small size (even when buying powerful heating models), simple design and the ability to combine several devices into one.

Electrode models have the highest safety rates. In the event of a leakage of the coolant, the heating is automatically stopped.

This procedure does not require specialized knowledge.

When choosing a suitable model of an electric boiler, you also need to consider the rate of water heating. If you are interested in storage systems, then the operating time of the heating element depends on the capacity of the installed tank. For example, 40 liters of water can be heated in 20 minutes.

Criteria for choosing a gas boiler

When choosing a gas boiler, pay attention to:

- Power.

- type of combustion chamber.

- The presence of circuits in this boiler.

- Type of installation of a gas boiler.

- Functional.

When choosing gas equipment, we pay attention to what power the boiler is suitable for a given room. Very often, consumers, choosing a gas boiler, do not pay attention to power

Therefore, it turns out that they acquire a more powerful boiler than is necessary for the house where it will work. To select a boiler, consumers use averaged values, on average, for a room area of 10 m2, supposedly, 1 kW of heat is needed, but this is an approximate figure.The selection of boiler power is always based on the calculation of heat losses of that building, which the boiler will heat. To choose the right equipment, you must first contact either a professional, for this you need to make thermal calculations for the room where the boiler will be installed, that is, calculate the heat loss of this building, or use calculators.

Ways to save money during operation

To reduce energy costs when using an electric boiler as a heating device and water heater, you need to reduce the overall heat loss of the house.

First of all, it is worth replacing old wooden frames with modern windows with 2-3 air chambers and taking care of wall insulation (best external) with foam plastic, mineral wool or other materials with low thermal conductivity

Other savings options:

- An additional connection or separate devices powered by alternative energy (solar panels, wind turbines, wood burning fireplace) will significantly reduce electricity consumption.

- A multi-tariff meter will allow you to pay less for night heating, and for the period of morning and evening "peak hours" the device can be turned off (the most expensive is electricity consumed between 8.00 - 11.00 and 20.00 - 22.00). And if you supplement the system with an external heat accumulator, you can accumulate “cheap” energy at night in order to spend it during the day.

- The recuperator in the ventilation system will help to keep the heated air inside the house.

- The weekly programmer will collect system operation data for a specified period of time in order to select the most comfortable and economical mode of operation with minimal energy consumption.

- Room thermostats will monitor changes in the microclimate of the house and transmit data to a sensor built into the boiler, which will turn off / turn on the heating, protecting it from overheating and unnecessary heat loss.

With the proper organization of the operation of an electric boiler, you can reduce electricity consumption and related costs by up to 40%.

The following article will acquaint you with energy-saving options for heating suburban property, which analyzes this very interesting issue in detail.

Materials for the heat exchanger: which is better

The heat exchanger plays one of the main roles in the design of a gas heating device - the coolant circulates through it. The most common materials used in the manufacture of heat exchangers for gas boilers are copper, cast iron, and steel.

Steel version of the heat exchanger

The cheapest and, as a result, the most popular material for a heat exchanger is steel. Therefore, it is actively used by domestic manufacturers in order to reduce the cost of the final product. Unlike cast iron, it is not brittle.

Compared to cast iron, steel is much lighter, but compared to copper, it significantly exceeds its weight and makes the boiler structure heavier.

The steel heat exchanger quickly heats up and cools down. In addition to convenience, this leads to negative consequences - the "fatigue" of the metal causes damage. The disadvantage of steel is also susceptibility to corrosion.

During operation, both the inner and outer sides of the steel heat exchanger are subjected to corrosion. Over time, this leads to its destruction.

Copper type heat exchanger

The material has many positive properties - corrosion resistance, small volume, low inertia.Due to its compactness and low weight, copper is actively used for the production of light wall-mounted boilers.

Corrosion resistance is one of the main qualities for heating equipment, which is intended for heating industrial water.

The opinion about the fragility of copper heat exchangers has long been refuted by manufacturers of modern heating equipment - in them the burner power is reduced by 30%, which reduces the thermal effect on the metal and has a good effect on the duration of work.

Boilers with cast iron heat exchanger

The main quality of cast iron, which should be noted - inertia. The material heats up for a long time and cools down for a long time, which increases the efficiency of heat transfer.

Such inertia can be considered both a positive quality and a negative one - in the event of a sharp warming on the street, the boiler will maintain a high temperature in the heating system for a long time.

A cast-iron boiler weighs twice as much as a steel one, so the design of the boiler is made sectional so that it is convenient to deliver, install and repair

Cast iron is exposed to dry and wet corrosion. The latter contributes to the appearance of rust, but, due to the thick walls, the corrosion process stretches for a long time.

The disadvantages of cast iron boilers include the fragility of the material, which manifests itself as a result of improper operation - temperature changes, mechanical damage during transportation and installation.

The best models of boilers

Below are the top 10 coolant models. To select the most suitable option, be guided by the criteria listed above.

Protherm Skat 9 KR 13

Boiler with single-circuit system.Easy to install, silent, high efficiency. Powered by 220 V. Quickly adjustable to within a degree. The design includes an expansion tank and a circulation pump. All information is displayed on the liquid crystal display. In addition to it, you can purchase a boiler.

The cost is from 44,000 rubles.

Prices for Protherm Skat 9 KR 13 boiler

Protherm Skat 9 KR 13

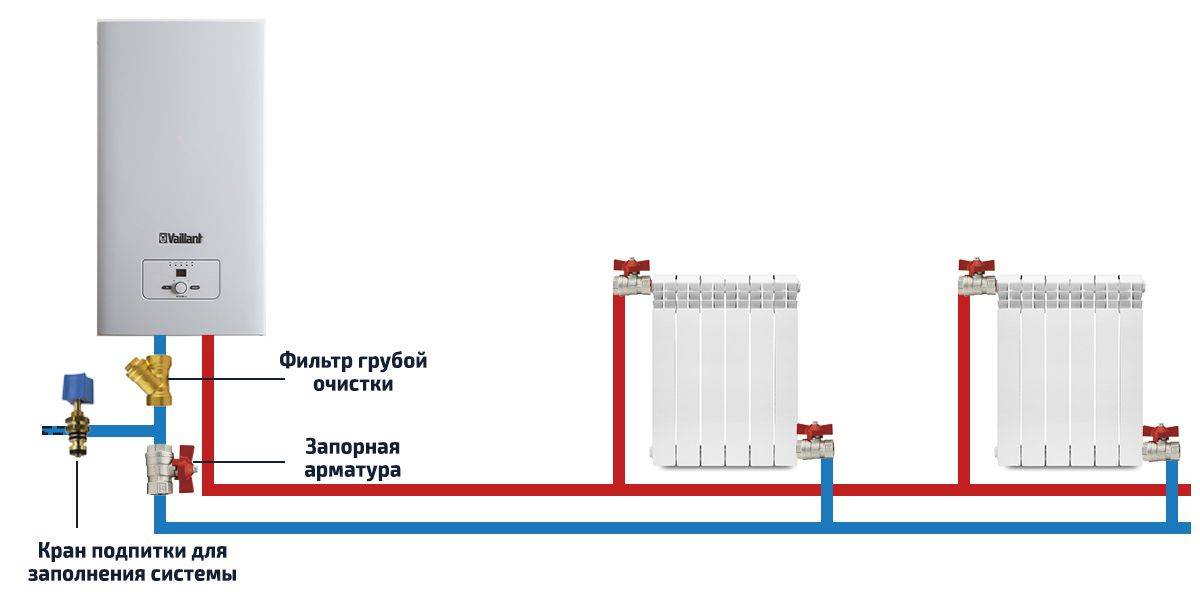

Vaillant eloBLOCK VE 9

Suitable for the manufacture of an individual heating system. Warms up quickly. It is possible to connect to the "warm floor" system. Also supplied with a boiler. There is a very convenient external control panel.

The cost is from 33,000 rubles.

Prices for the boiler Vaillant eloBLOCK VE 9

Vaillant eloBLOCK VE 9

Buderus Logamax E213-10

Differs in small dimensions. There is a frame for wall mounting. Power - 10 kW. The device is controlled by a room thermostat. Inside there is an expansion tank with a volume of 7 liters.

The cost is from 28,000 rubles.

EVAN EPO 4

domestic model. Budget and reliable. Long service life. Of the minuses: lack of housing; the need to purchase related devices.

The cost is from seven and a half thousand rubles.

Prices for the boiler EVAN EPO 4

EVAN EPO 4

RusNIT 209M

Uninterrupted functionality. Nice appearance. Connects to single-phase and three-phase networks. The pump operates in automatic and forced mode. Temperature control sensor included.

The cost is from 15,000 rubles.

ZOTA 9 Lux

There is a reliable system of protection against overheating. A bit noisy. The device is simple and easy to connect. Room thermostat included. It is possible to manage operations through the GSM module (in the phone).

The cost is from 16,000 rubles.

Ferroli ZEWS 9

Convenient automation system. Small size. Excellent balance of safety and reliability. You can connect additional equipment. A little capricious, requires connection through a stabilizer.

The cost is from 25,000 rubles.

Kospel EKCO.L 15z

It is used with radiators or boilers of indirect heating. Controlled by room regulator. Lots of protective features. Automatic circulation pump.

The cost is from 43,000 rubles.

Evan Warmos QX-18

Easy access control panel. Built-in pump. Works from 220 and from 380 V. System of the emergency notification. The devices are electronic, but they work mechanically. Quite heavy and bulky.

The cost is from 30,000 rubles.

EVAN EPO 6

Suitable for heating large areas. High reliability and service life. Convenient to maintain. Smooth temperature control. Controlled by the GSM module. Efficiency - up to 93 percent. Lots of security systems.

The cost is from ten and a half thousand rubles.

Which manufacturer to choose

The market offers a wide selection of electric boilers from different manufacturers. However, products from European brands are in the greatest demand, as they are characterized by economical energy consumption, safety of use and reliability.

Source

Source

At the production stage, companies use innovative technologies that contribute to the maximum protection of the heater from scale. The Vaillant energy-saving electric boiler deserves special attention, which can be installed both in a private house and in an apartment.

Among the popular models of domestic production are:

- Evan Ecowatti.

- Thermostyle EPN.

- Savitr Premium.

The list of the best foreign units includes the ACV E-tech S, Jaspi Fill-B and Wespe Heuzung Kombi models.

These models belong to the premium segment and meet the highest standards of safety and economy.

Equipment Installation Rules

Most non-volatile boilers are produced on the floor. For equipment, it is necessary to arrange a separate room

But this is also important for conditionally wall-mounted models, since the devices burn out oxygen by taking air directly from the room.

When installing, it is important to ensure normal pressure in the gas line. In most residential buildings, it is 50 mbar, and for a non-volatile boiler, 13-15 mbar is enough

But in some regions, this indicator is characterized by sharp drops. In such cases, it is better to abandon the installation of non-volatile equipment.

How to choose the right boiler?

The only objective criterion for choosing a combined boiler for your home is the required power to ensure the functioning of the heating system. Moreover, this indicator should not be affected by the number of connected circuits.

It makes no sense to pay more for a powerful boiler in the hope of adjusting its operation with automation. This approach contributes to the "idle" operation of the device, which leads to a faster failure. In addition, this mode of operation contributes to the acceleration of the condensation process.

As for the calculation of power, theoretically, to heat an area of 10 m2, it will be necessary to use 1 kW of heat energy.

But this is a rather conditional indicator, which is adjusted based on the following parameters:

- ceiling heights in the house;

- the number of floors;

- degree of building insulation.

Therefore, it is advisable to use a one-and-a-half coefficient in your calculations, i.e. in calculations, increase the margin by 0.5 kW. The power of a multi-circuit heating system is calculated with a surcharge of 25-30%.

So, in order to heat a building with an area of 100 m2, a power of 10-15 kW is required for single-circuit heating of the coolant and 15-20 kW for double-circuit heating.

To select a gas burner for a solid fuel boiler, you need to accurately measure the dimensions of the combustion chamber. It is these proportions that will correspond to the size of the gas burner

An equally important criterion when choosing a combined heating boiler is the price category. The price of the device depends on the power, the number of functions and the manufacturer.

For users, other characteristics are no less important:

- DHW;

- material of manufacture;

- ease of management;

- dimensions;

- accessories;

- weight and installation features;

- other.

The issue with hot water supply will immediately have to be resolved: a boiler will provide hot water or there is an electric boiler for this.

In the case of determining the first option, the preferred method is chosen - storage or flow, as well as the parameters of the water reservoir according to needs (calculated based on the number of residents).

As for the dimensions of the equipment, they only matter in the case of installation in a room with a small area.

According to the material of manufacture, a wide range of boilers is presented. But the most popular options are steel or cast iron. Also, such a boiler is able to withstand a high and prolonged temperature load, has a longer service life.

Judging by the intensity of sales and relying on consumer reviews, the following models are actively in demand:

Automation of control affects the usability, and the security system depends on how automated the process of combustion of energy carriers is. Most models can be controlled using convenient remote controls or panels.

Most models are optional. This includes the presence of a hob for cooking, injectors, draft regulators, burners, a soundproof casing, etc.

The choice of a boiler according to this parameter should be based on personal preferences and the allocated amount for the purchase.

When choosing a heating boiler with a combination of wood / electricity, it is necessary to calculate the required power of the heating element. It is recommended to choose models with an indicator of at least 60% of the required coefficient for home heating

But the weight of the equipment and the complexity of its installation should immediately pay attention. Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load

The best solution is to equip a separate boiler room

Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load. The best solution is to equip a separate boiler room.

Knowing the main parameters that affect the choice of a combined boiler, you can choose the most suitable model.

Additional selection recommendations, as well as a comparative overview of different heating units for a private house, are given in.

Pros and cons of an electric boiler

This equipment, like others, has positive and negative sides. An electric boiler for heating a private house has the following advantages:

- no need for a supply of fuel;

- safety of use;

- ease of management;

- relatively small size;

- no special requirements need to be met for installation;

- environmentally friendly work;

- no need for cleaning from soot;

- silent operation.

However, a single-phase electric boiler and other models have disadvantages. These include the following points:

- a powerful model requires three-phase wiring;

- relatively low efficiency;

- the most powerful unit will hardly heat an area of \u200b\u200bmore than 100 m²;

- to save the heater, you need to install a filter.

Disadvantages of an electric boiler

For example, for warming up a house with an area of 120 sq.m. within a month it will be necessary to pay 17.5 thousand rubles. Moreover, the mentioned figure is only a minimum value - in remote cities and villages, the bill for electricity can be much higher.

Another disadvantage is the dependence on the existing power grid. So, in villages and villages it is almost impossible to use this heating system due to the lack of a 380 V line (how to choose a gas boiler). In addition, power wires are often stolen in remote areas, as a result of which you will be left without light and heat.Also, the elimination of the consequences of bad weather in such regions takes a long time, which will negatively affect the electric heating of your home.

Thus, the use of an electric boiler is justified if:

- the electric boiler will be operated as an additional heating system;

- no other heating options;

- in the area there is a line with a voltage of 380 V.