- Gas stove selection options

- Burner type

- Dimensions

- hob material

- hob grate

- Oven Features

- Popular Models

- How to choose for the burner

- Ways to connect gas stoves

- Rules for operation and repair

- Types of vessels

- Material and volume

- general purpose

- Connection method

- The device and features of gas stoves

- What hoses and tubes to use for connections

- Which oven to choose

- gas oven

- electric oven

- Cranes and other fittings

- Features of connecting a gas stove

- What you need to install and connect

- Balloon material and size

- Reducer

- Hose for gas stove

Gas stove selection options

Gas stove selection options

Parameters mean standard equipment. A certain type of plate is as clear and simple as possible

What is important to consider when choosing a stove:

- the structure of the burners;

- main parameters of the hull;

- the structure and coating of the hob;

- lattice strength.

Equally significant are the characteristics of the oven.

Burner type

Burners are the main part of the hob. They are usually made in different sizes. Each burner has a button or a regulating part - to control the temperature. The size of the burner is determined by the force of the gas supply: essentially pressure.

Burners consist of nozzles - gas flows through them. Usually there are 4 burners on the stove, in rare cases 6. The power of the burners is different. Usually the kit comes with one large and one small burner, the rest are medium. The more rows of flame, the faster the heating process will occur.

In combined devices, gas or electric burners are combined on the surface. Such a solution allows you to foresee any breakdowns in gas or electricity supply systems.

Dimensions

To choose a stove for the kitchen, it is necessary to take into account the main characteristics of universal devices. The size of the unit, if we are talking about a floor device, is 85 cm high, 50, 55 or 60 cm wide. Other characteristics depend on the model, configuration. Models without an oven or built-in devices have different specifications.

hob material

Steel is used to make the surface of the plate - it must be heat-resistant. The protective layer is stainless steel or durable glass. The enamelled surface also proved to be durable and reliable, especially in long-term operation. The only drawback of the enameled surface is that over time, scratches appear on it, and the appearance of the surface becomes worse.

If the surface is stainless steel, it is matte or glossy. It washes easily and is durable. The big disadvantage of stainless steel is the rapid process of contamination. To care for the surface, you will need to buy special cleaning products.

Glass ceramic or ceramic looks presentable, easy to clean. It is also called gas on glass. Glass ceramic is the best option if you need a special design.High-strength material is used for the manufacture of glass ceramics: it can withstand heavy loads, including high temperatures. Usually glass ceramics have a dark color, often brown. It is better to clean the surface immediately, then it is easier to clean them.

hob grate

There are also grates on the hob - they allow you to control the thermal effect. The gratings are sold together with the general complete set of the plate. Each brand offers its own grate design solutions - it is made in a dark color or the color of the hob.

Before choosing a product, it is better to scroll through the catalog and look at even minor, but important details, like grilles. A low inclination of the grates will quickly damage the pans; a grate that is too high will not allow food to warm up quickly.

The most profitable option is grates of medium height, firmly fixed to the hob. Any feedback on such a part is as positive as possible. The color scheme does not affect the functionality of the grating.

Oven Features

The oven is one of the most important parts of the stove. A conventional oven is designed for 45-55 liters. There are 2 different parts:

- Gas. Inside the oven is designed so that air circulates in it, there are 2 heating modes in total: in some models there is a burner, a fan, but only in one part, on the other there is a grill. The presence of a grill allows you to evenly heat the baking sheet. The gas part gives an effect reminiscent of cooking on charcoal.

- Electric. It has heating parts - from 2 to 4 pieces. The more expensive the model, the more heaters. Electric ovens are simpler in design, they heat up quickly, and have many modes.

For safe use, the oven doors of modern devices are equipped with thermal insulation. The thermostat is included in the main structure. There is also a baking sheet that fits in size and a timer.

Watch this video on YouTube

Popular Models

A country gas stove with a cylinder is presented on the market by various manufacturers who offer customers a huge selection of models. The most popular modifications, which received a lot of positive feedback, include such models.

"Hephaestus PGT-1 802". This is a table stove, which has four burners and electric ignition in the design. There is no oven included. Equipment dimensions are 11*37.4*50 cm (height*depth*width). The main advantage of this device is considered to be a long service life. The plate "Hephaestus" is available in various colors, which allows you to quickly choose it for any interior.

How to choose for the burner

So you want buy a gas cylinder for your burner, but don't know which one you need, there are a few things to understand:

- Why do you need a cylinder (burner for tourism, burner for work).

- Under what conditions will it be used?

- Decide on a budget.

- Find out which balloon size is best for you.

What size cans do you prefer to buy?

SmallLarge

Most often, burners are used for two purposes - in tourism and as a blowtorch. If you need a blowtorch tank, then just buy a regular propane or butane tank. They are cheap, there are no special requirements for them. The main thing is to choose a cylinder that fits the size and shape of attachment to the blowtorch.

In the case of tourist balloons, everything is more interesting.You need to choose based on how long you will be hiking or traveling and what climatic conditions await you. Based on the distances and duration of the trip, you need to choose the size of the balloon - the longer, the more balloon you need. The exception is trips to "civilized" places where you can find a store with gas cylinders. On autonomous trips far from populated areas, it is worth taking spare cartridges with you.

In the case of climate, you need to look at the marking of the cylinder model. There are universal cylinders that are designed for 4 seasons, but they will not withstand too extreme temperatures. If you go somewhere where the temperature is below -15 degrees, then you need to choose winter cylinders. The same is true in very hot, humid climates.

Expert opinion

Torsunov Pavel Maksimovich

According to the budget: choose only those cylinders that will not burden your budget too much. The main thing is that they should not be some kind of handicraft or without certification. It is better to take one more spare cylinder with you than to spend all your money on one expensive one. The composition of the mixture for extremely expensive and medium-priced cylinders rarely changes so much that it affects the quality of the burners.

Ways to connect gas stoves

More recently, about 30 years ago, gas hoses were not common and the plates were connected with a steel pipe. Such a connection is very reliable and durable, because the pipe does not leak, withstands high temperatures and is resistant to oil. However, it is not possible to move a plate connected in this way, even by a centimeter.That is why, and also because of the complexity of installation, now such a connection is not practiced.

The first to replace a rigid connection were the so-called oxygen hoses, made on the same principle as car tires. The base is woven from heavy-duty cord threads, and they are already filled with rubber on both sides. Such hoses withstand enormous pressure - up to 20 atmospheres, they are available in a wide range of diameters (from 16 mm) and lengths, are easy to install and are quite cheap.

Rubber is subject to aging and cracking, especially when exposed to oil, and the use of gas hoses with a service life of less than 10 years is prohibited in the apartment. That is why oxygen gas hoses have sunk into oblivion

Rubber is subject to aging and cracking, especially when exposed to oil, and the use of gas hoses with a service life of less than 10 years is prohibited in the apartment. That is why oxygen gas hoses have sunk into oblivion

Rubber-fabric hoses - the closest heir to oxygen, differ only in the use of a special textile thread instead of cord. They are produced and sold today, and are inexpensive. However, due to the fragility of rubber, they also cannot be used in apartments, but for connecting the stove to a gas cylinder in the country, this is perhaps the most convenient option.

Rules for operation and repair

The serviceability of equipment and your personal safety largely depends on how you treat the equipment. This includes proper installation, careful operation, regular maintenance and replacement of parts with a limited lifespan.

Here are the basic rules for using a gas stove:

- regularly clean the grate, stove surface, burners, control knobs;

- keep in touch with representatives of Gorgaz and regularly carry out maintenance of equipment;

- ventilate the room, even if you use the hood;

- in case of a long absence, close the shut-off valve;

- make sure that the knobs are in the "off" position when the hob is not in use.

Care must be taken in the operation of the oven. He, like any equipment, requires cleanliness and serviceability of all parts.

It is not recommended to use the oven as an ordinary cupboard for storing dishes, especially cluttering it with flammable or melting objects.

Inside the oven should be only "working" accessories: baking sheets, grates, grilling tools and utensils or forms, if they are used in cooking

Inside the oven should be only "working" accessories: baking sheets, grates, grilling tools and utensils or forms, if they are used in cooking

If the ventilation is faulty and it is not possible to open the window or window, it is forbidden to use gas equipment.

If a specific smell of gas appears, it is necessary to open the fuel supply valve, open the windows and call the emergency service. During the waiting period, you can not turn on electrical appliances, light a flame, but it is better to leave the room altogether. Even the call is recommended to be made from the landing or from the street.

Repair of gas equipment should be carried out either by invited specialists from a service organization, or by employees of a specialized service center.

Types of vessels

Gas cylinders can be subdivided based on three main criteria.

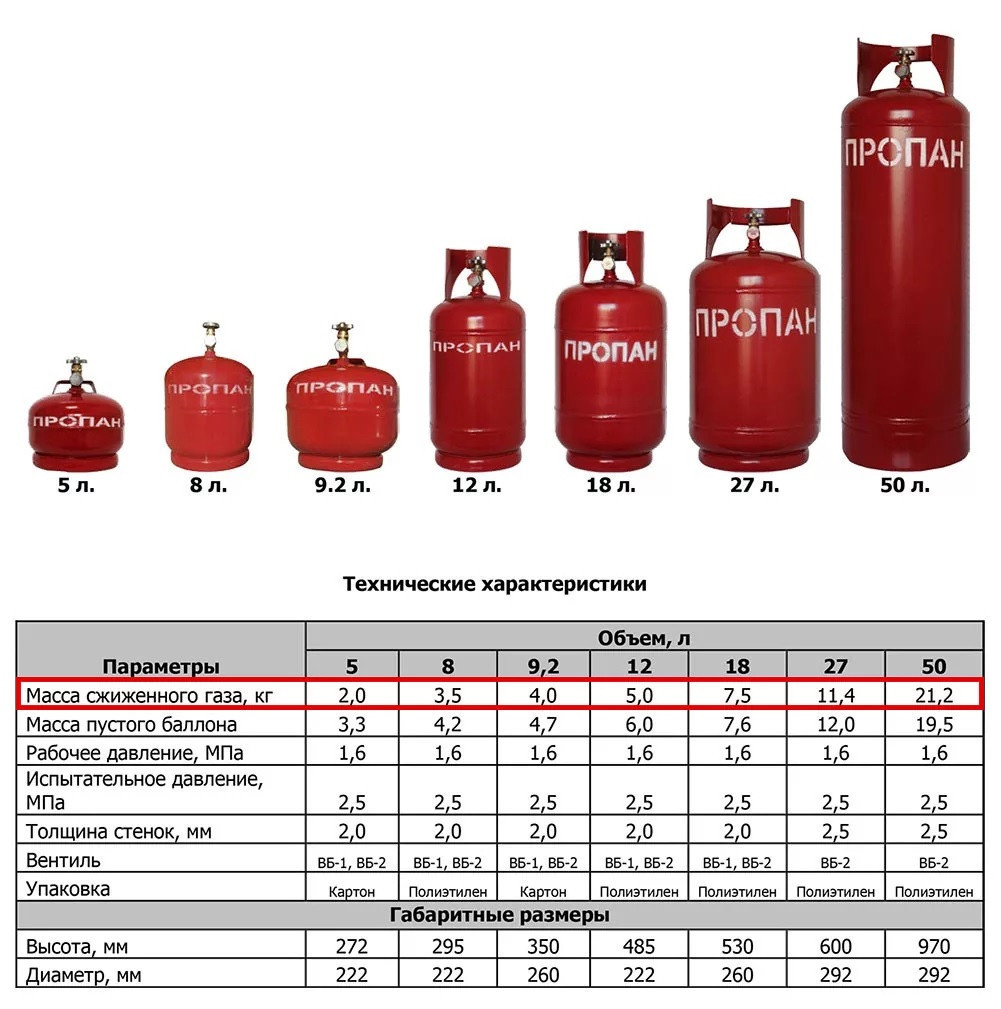

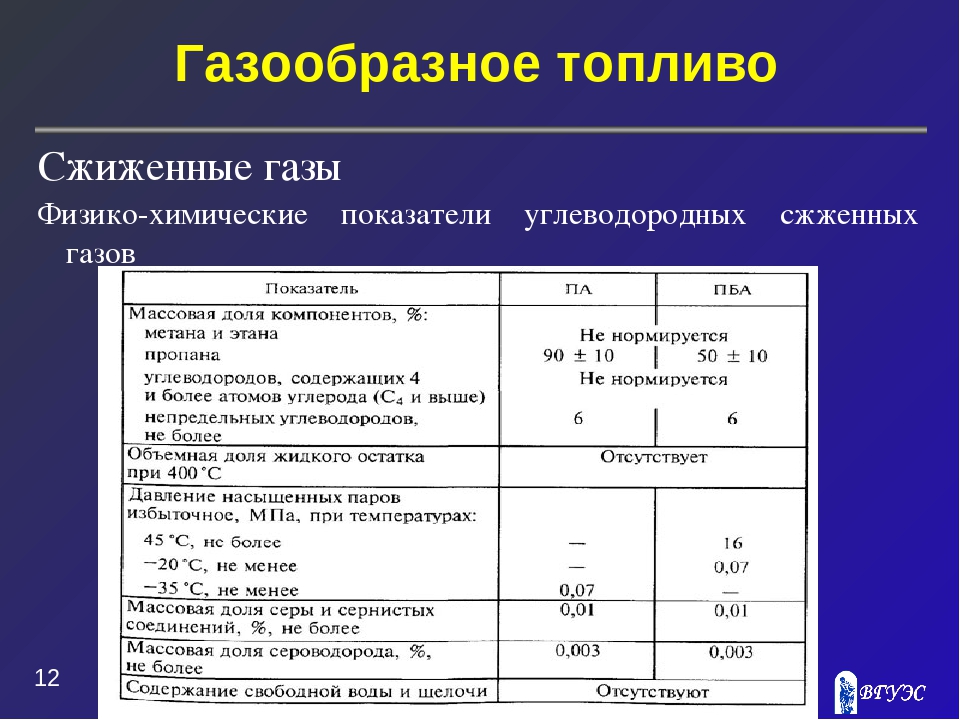

Material and volume

Metal vessels are made of steel, their capacity can vary from 5 to 50 liters. An empty vessel weighs from 4 to 22 kilograms. Smaller containers are installed indoors, while larger ones are installed outside. But then they must be protected from direct sunlight.

Such gas equipment is classified as explosive. It must not be exposed to high temperatures, impacts or shaking.

Composite cylinders are new generation tanks.They are completely safe for transportation and storage of liquefied gases. This is possible thanks to the innovative equipment with a special overpressure valve and a fusible link. Such vessels are not afraid of fire and any other external influences. Their weight is much less than steel counterparts, and the view is much more presentable. Modern design, transparent body, you can easily control the amount of gas in the cylinder. Polymeric material is not exposed to corrosion and will serve you for more than 20 years.

general purpose

According to the place of installation and purpose, the classification of gas cylinders is divided into several groups:

-

Household. They provide space heating, the operation of stoves and boilers;

-

Industrial. This type includes tanks for gas storage only. They are widely used in the chemical and metallurgical industries, as well as in pharmaceuticals;

-

Tourist. These are the most mobile cylinders. They are often used by lovers of hiking, fishing and hunting;

-

Automotive. Such equipment is popular among owners of transport on gaseous fuels;

-

Medical. Filling is breathing mixtures. They are needed in the ambulance and for intensive care. Rescuers and firefighters cannot do without such a device.

There are also universal models that are suitable for any situation.

Connection method

There are four connection standards, depending on the type of cylinder.

Threaded is the most popular and safe standard. In this case, the hose or burner is wound to the gas tank.

Pierced. This standard, after the connection procedure, makes the cylinder disposable, since it cannot be disconnected until the tank runs out of gas.

Valve.European type of connection, leakage protection, high reliability and ease of installation.

The device and features of gas stoves

The first stoves were not connected to gas, and did not resemble a modern device much - over the years it became simpler, but multifunctional. Understandable to many, the modern unit has a set of standard characteristics:

- it runs on gas, without fail it is connected to the gas supply system in the house;

- requires minimal maintenance, low operating costs - all work on cleaning parts is carried out at home without additional help;

- the stove has at least 3 basic cooking functions;

- for the best work of the stove you will need a hood.

Gas stoves are still competing with newer models, such as those connected to the mains. They fit well into the interior of any kitchen, and allow you to optimize the space - the built-in oven allows you to save on buying a stove.

You need to think about which gas stove to choose at the time of installation work, if repairs are underway or when planning the arrangement in the kitchen in case of a change in the overall layout of the apartment or house.

Standard plate device: the body is essentially the frame of the plate, often made of steel, in burners are located on the top of the device, there is also a working surface. A cast-iron grate is installed above the burners to ensure the safety of their operation. At the bottom is an oven.

To choose a gas stove with a gas oven, and then install it, additional costs will be required - the stove must be installed near the gas pipe, and safety must also be ensured during the operation of the stove.

How to choose a good gas stove: first of all, consider its functional features, in the modern world it is not enough to choose a stove for cooking, you need to choose a unit with the most convenient operation and cleaning process. Additional features will save you a lot of time.

Families in which the oven is often used should think about how to choose a gas stove with a good oven. The better equipped the lower part of the device, the longer the stove will last. The characteristics of the oven are considered separately. The final stage of selection is the selection of a suitable appearance of the device.

What hoses and tubes to use for connections

According to the rules for the safe operation of gas equipment, for laying gas pipelines do not use oxygen or hydraulic hoses. This is due to the high temperature difference between the transported gas and the external environment, which leads to accelerated degradation of the hose material and the appearance of microscopic leaks. With the properties of liquefied gas to accumulate in rooms, such phenomena pose an increased danger.

There are three options for connecting a gas cylinder to a stove. The first is to use special flexible rubber hoses for flammable hydrocarbons. In this case, their connection to the gearbox is carried out through a standard fitting with a screw clamp. The same fitting is installed on the inlet pipe of the gas stove, the hose is also connected to it with a clamp.If it is necessary to connect two pieces of hose, it is not allowed to use double-sided fittings, instead of them, threaded connectors with double crimping of the shank with clamps should be used. A distinctive feature of such connections for gas pipelines is the conical thread and the absence of elastic seals.

Connecting the plate to the cylinder using flexible hoses has a number of limitations. The length of the hose must not exceed 150 cm, its gasket must remain visible in order to constantly monitor the condition of the sheath and avoid damage. Some of the restrictions can be partially circumvented by using metal bellows hoses. They form a semi-rigid frame, which can have an almost unlimited length, while maintaining resistance to temperature effects and mechanical damage.

At the same time, safety rules prohibit the passage of flexible and semi-flexible ducts through walls where their condition cannot be visually assessed. If it is necessary to connect the stove with a cylinder installed on the street, a steel pipe case should be embedded in the cement mortar in the hole in the wall. Inside the case is a steel tube of smaller diameter with threads at both ends, the space between the walls is filled with a plastic sealant, such as mounting foam or silicone. The connection of bellows or flexible hoses must only be carried out through threaded adapters of the appropriate type.

Which oven to choose

The oven in the gas stove can be gas or electric. Both types have a number of advantages and disadvantages.

gas oven

The main disadvantage of a gas oven is that the heating elements are located at the bottom.The burners can be mounted in a linear, circular or horseshoe pattern.

The dish warms up in such an oven unevenly. The top of the cake or casserole may remain pale and the bottom will burn. But if you get used to this feature and determine how to properly place the dishes with food inside the device, you can easily achieve the desired result.

The convection function smooths out this drawback a little, but not all models have it. The heated air in this case is distributed inside the oven by means of a fan.

The second function that is found in gas ovens is the grill. It can be gas or electric. The grill will provide more uniform heating, will allow you to cook meat, fish or poultry on a spit and skewers.

Have gas oven and advantages:

- The gas oven warms up quickly and raises the temperature to the set level.

- You can instantly increase or decrease the temperature by adding or decreasing the flame.

- Gas-powered devices are more economical.

- The gas oven will work even if the power goes out.

electric oven

Heating elements in electrical devices are located at least in 2 places - above and below. Some models have additional elements on the sides. Uniform heating in such an oven is ensured.

Other pluses:

- The ability to regulate the temperature of each heating element individually or turn it off completely.

- Setting the temperature to the nearest degree.

- The gradual decrease in temperature with decreasing heat provides the effect of languishing.

- Many additional functions (defrost, heating, automatic programs, self-cleaning).

For all their advantages, electric ovens consume a large amount of electricity, which costs more than gas.

It will take more time to heat the electric oven to a certain temperature than to heat the gas oven.

Cranes and other fittings

At the point where the gas pipeline is connected to the stove, a gas cock must be installed to block the gas supply in the event of a stove failure. It can be either a ball valve with a yellow handwheel or a plug gas valve. The disadvantage of the latter is the need for periodic maintenance.

Another useful addition to the gas pipeline can be a flow meter. Its inclusion in the transportation chain will help to promptly respond to the exhaustion of the mixture in the cylinder and replace it. The metering device should not have the outstanding accuracy required to control gas consumption in main networks, a device worth up to 2 thousand rubles will be enough.

When connecting several cylinders at the same time, a connecting ramp can be used. Its installation helps to reduce the rate of gas evaporation from each cylinder and make the risk of freezing of the mixture in the reducer less likely. The installation of the ramp can be done independently with any material for the manufacture of the gas pipeline.

Features of connecting a gas stove

The first thing you should remember if you decide to connect the stove yourself is that now you yourself are responsible for your life, and for the safety of the kitchen, and the stove itself. The manufacturer's warranty is not valid if the work was carried out by an unqualified gas master.

If the risks do not bother you, here is a brief instruction of actions.

- evaluate all the initial data and, if necessary, buy the missing one;

- if the diameter of the thread on the hose and on the plate or tap does not match, stock up on a suitable adapter;

- check for the presence of a paronite gasket in the hose kit. If it is not there, buy the one with the mesh;

- if the stove has 2 outlets, buy a plug and screw it tightly into the outlet farthest from the gas pipe;

- when connecting a hose with an open metal sheath, it is better not to skimp on the dielectric - a special insert with a plastic core that does not conduct current;

- install all necessary adapters, but try to minimize their number. The dielectric is screwed into the gas valve, and a hose is already wound onto it;

- screw one end of the hose to the gas cock or to the dielectric, or to the fitting, if any;

- tighten with an open-end wrench tightly, but do not be too zealous so as not to strip the threads;

- place the paronite gasket at the outlet of the plate;

- screw the other end of the hose to the stove. The nut rotates freely on the hose, so that it should not twist or break;

- dissolve solid soap or mix liquid soap with water. Apply the resulting solution to all connections, including factory ones on the hose;

- open the gas cock, but do not turn on the burners of the stove, but carefully observe. If soap bubbles do not appear at any joint, the stove can be used.

When connecting the gas stove yourself, remember that the hose should not come into contact with electrical appliances and wires, and also hide behind furniture - this is unsafe.

If you still have an old petal gas valve installed, it is better to replace it with a ball valve, and only a ZhEK employee can do this by blocking the entire riser

If you still have an old petal gas valve installed, it is better to replace it with a ball valve, and only a ZhEK employee can do this by blocking the entire riser

What you need to install and connect

You will need:

- gas stove for giving under the cylinder (configured for the use of liquefied gas);

- gas cylinder;

-

reducer;

- a hose for connecting a gas stove or copper pipes of a suitable diameter.

- clamps 2 pcs for attaching the hose (on the one hand - to the adapter for connecting the stove, on the other - to the gearbox);

- gas cock (not required, but desirable).

How to choose a gas stove is already clear, we will now deal with the rest of the components. Nothing complicated, but there are features.

Balloon material and size

First, let's talk about the material from which the liquefied gas cylinder is made. Until recently, there were no such conversations. The gas cylinder was exclusively metal, and made of metal of decent thickness. Now there are also composite gas cylinders (also called Eurocylinder) and they are approved for use by gas services. If possible, it is better to buy just such. Why are they better? Here is a list of their advantages:

- Easier 2 times.

- They have a fusible link that prevents an explosion in case of overheating / fire.

- Approved for transportation in conventional cars.

-

Do not accumulate static voltage.

- There are polymeric cylinders with transparent inserts. They allow you to control both the degree of refueling and the presence of gas.

There are few disadvantages of a polymer balloon. The first is that it costs two to three times more than a metal one, but it is much easier to carry / transport it. The second - with an equal volume in size, it is larger than the metal counterpart.

Now about the size of gas cylinders.The larger the volume of the gas cylinder, the longer the period between refueling. But, on the other hand, larger cylinders have large dimensions and weight, and it is more difficult to carry / transport them. In addition, it is easier to find a place for installation under a small cylinder.

In general, the choice is yours. Moreover, with the advent of composite, they appeared in different sizes - high and narrow, low and wide.

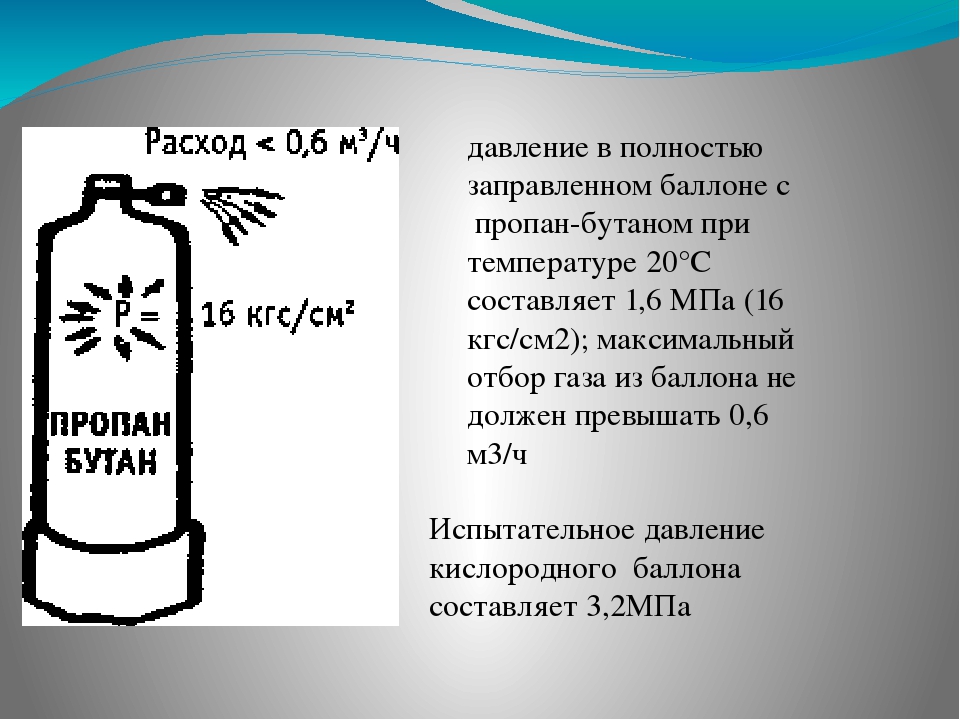

Reducer

Why do you need a reducer on a gas cylinder? It performs several functions at once:

- Stabilizes the pressure at the outlet of the cylinder.

- The gas in the cylinder is under high pressure, for a stove it should be lower. This is what the reducer does.

-

When there is little gas left in the gas cylinder - 5-10% - the pressure reducer increases.

- Prevents air from getting inside. When combined with oxygen, an explosive mixture is formed, so this function is also important.

- There are models that work as a pressure relief valve. If the specified parameters are exceeded, part of the gas is released - until the indicators normalize.

So the reducer on the gas cylinder helps to increase safety and stabilize the operation of the stove. Without it, it is better not to connect the stove. In this case, the more you open the tap on the stove, the more powerful the gas flow will come out. In addition to being uneconomical, it can create a situation where the balloon starts to jump. In general, it is better not to operate without a gearbox.

Please note that different types of reducers are used for metal and composite cylinders. Therefore, when buying, specify the type of cylinder and its volume.

And most importantly, to work with a liquefied gas cylinder, you need a propane reducer.

Beware of Chinese made gearboxes….

If we talk about manufacturers, it is better to take Russian or European products.Chinese are better avoided. Even those that have passed certification are made of very thin metal and quickly fail (begin to poison). In addition, many do not withstand the size of the fittings. When connected, this becomes a problem, since the hose is not put on tightly, you have to somehow seal the connection.

Hose for gas stove

You can buy it in Gorgaz stores or in hardware stores / markets. But be sure to specify that you need it to connect the gas stove. It is correctly called "gas hose-sleeve". The inner diameter should be 16 mm, the outer one depends on the type of hose, there should be an inscription (in yellow) on the surface that the hose is gas.

There are such gas hoses:

To connect the cylinder to the gas stove, you need a hose about a meter long - in order to fulfill the condition about the distance between the cylinder and the stove of 0.5 meters and leave a margin for freedom of movement.

On one side, a union nut with a gasket must be installed on the hose. This end is connected to the outlet from the gas stove. If you buy just a piece of hose, you can install the corresponding gas adapter yourself by tightening the mount with a metal clamp (do not forget the silicone thick gasket for sealing). On the other hand, the hose is connected to the reducer - it is pulled onto the fitting, then tightened with a clamp (do not forget to put the clamp on the hose, and then connect it to the fitting).