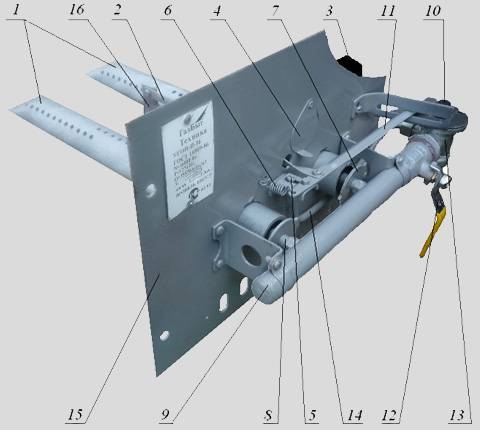

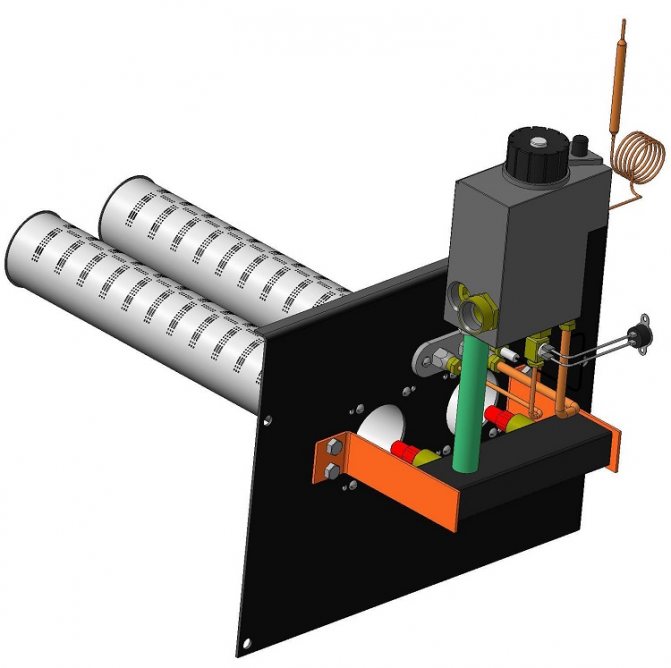

- Design features and types of burners

- Gas supply of residential buildings

- Protective automation system

- Advantages and disadvantages

- Pump

- The main varieties and classification of gas burners

- Purpose and advantages of nozzles

- Atmospheric boiler burners and manual gas burners

- How to make a gas burner for a boiler with your own hands?

- Types of burners

- atmospheric

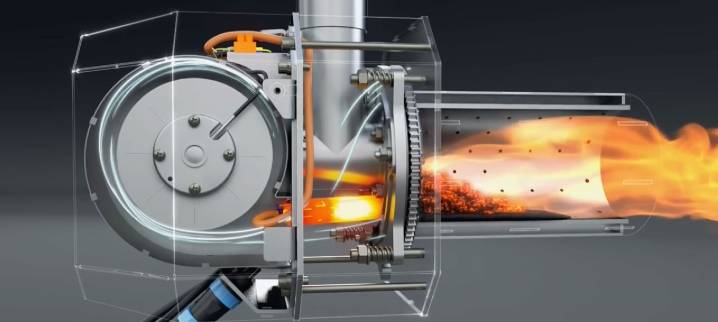

- Diffusion-kinetic

- Features of use

- Independent production of gas burners: to do or not

- The most efficient devices of 2018

- Varieties

- Operating rules

- Do-it-yourself oven installation

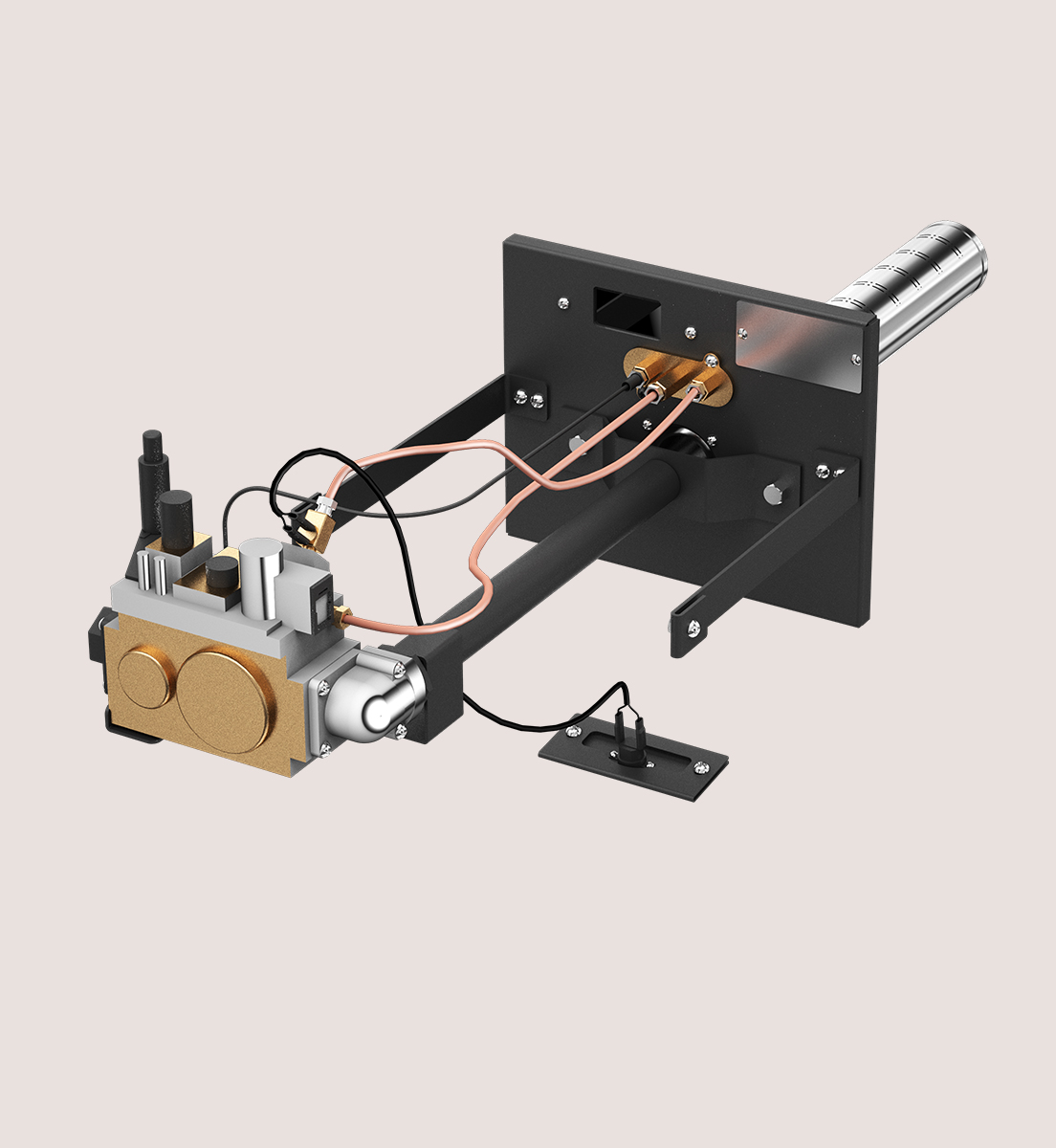

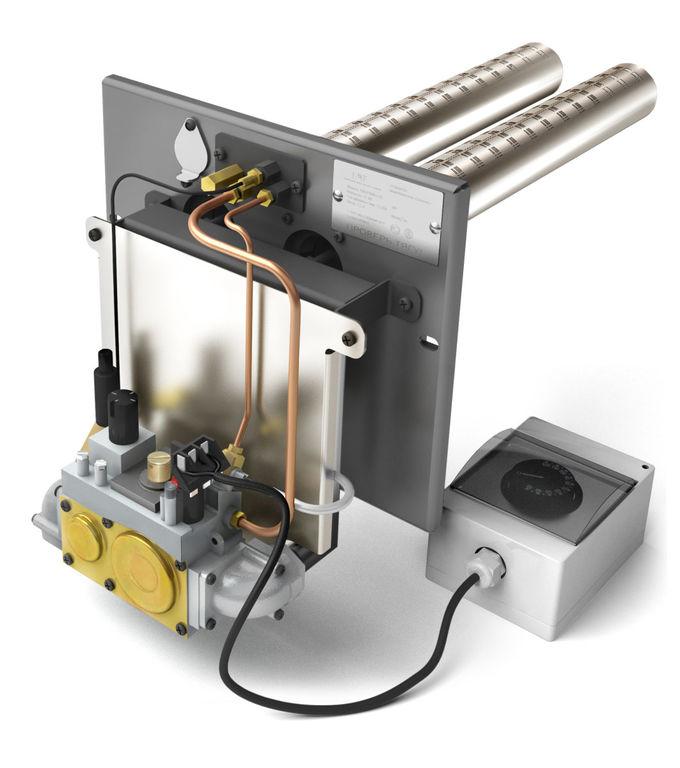

Design features and types of burners

Important parameters of a homemade gas burner are safety, ease of manufacture, suitability for work in specific conditions, and economy. There are quite a few options for choosing modifications of the device supplying the gas mixture. They are used for heating houses, heating water boilers, even for hiking trips.

It is necessary to navigate this variety of types of devices in order to make a high-quality burner for a bath with your own hands.

According to the way air enters the burner, they are conditionally divided into two types:

- Atmospheric, with natural air supply to the combustion zone.

- Fan, with forced air blowing, carried out by a built-in fan. They are inflated and inflated.

The physical parameters of both the sauna stove and the selected nozzle model should be taken into account. Before starting the manufacture of the burner, determine the dimensions

All these features will increase the reliability and safety of work, but at the same time increase the cost of your product. It is up to you to decide how expedient additional equipment is, based on financial capabilities and the frequency of operation of the burner.

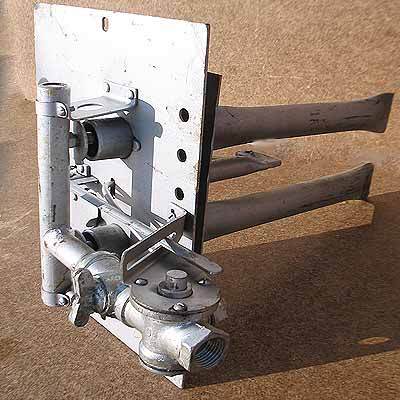

Such burners are one or more metal hollow tubes through which gaseous fuel is supplied under pressure. Ignition is carried out using a piezo lighter. Atmospheric nozzles are the cheapest and easiest to manufacture.

Usually, atmospheric gas burners are made with their own hands. Their advantages are independence from electricity and pressure drop in the gas pipeline.

The main disadvantage of atmospheric gas burners is considered to be the need for a constant high-quality air supply. It will have to be equipped in the bath additionally. Usually, an ash pan or an air duct connected to it is used for this purpose.

An effective ventilation pipe with air intake from an adjacent room. At a low draft level, most of the poorly burned fuel goes into the chimney. This threatens with the danger of gas leakage if there are microcracks in the brick massif.

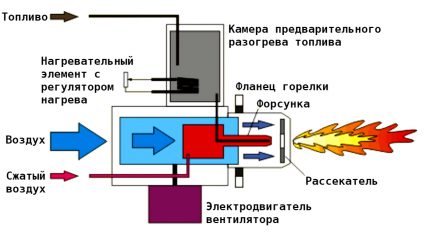

Fan burners are a unit with a fan, sensors and controllers. The intake and discharge of air from the street is carried out automatically, the operation of the equipment is controlled by automation. The combustion power in the blast device can be adjusted according to needs.

Forced uninterrupted air supply allows you to increase the efficiency of the heating device, due to the high-quality burnout of the gas. Accordingly, the fuel consumption for heating the sauna stove is reduced.

The fan burner is more difficult to install, but easier to operate. The intensity of the nozzle in this scheme is easier to adjust using automation.

Both types of gas burners can be converted from liquefied gas for mainline and vice versa. For translation, the jets are replaced, due to which the volume of the gas mixture injected into the combustion chamber changes. Replacement nozzles are selected in accordance with the manufacturer's recommendations, more precisely with the dimensions indicated by him.

We invite you to familiarize yourself with Legalizing a garage and a bathhouse on the garden plot

Each type of burner has its own power and gas consumption parameters. A volatile inflatable burner with more expensive accessories is used for the heating boiler of a large volume bath.

To heat small and rarely used rooms, it is recommended to install an atmospheric burner. A bathhouse of modest size is enough for a model with a flow rate of 1.5-4.5 m3 per hour.

To maintain a comfortable temperature in the bath, you need a burner with a uniform distribution of the flame. This problem is solved by all kinds of distributing tubes or flare dividers. Usually they are round holes. But sometimes the format is changed to narrow slots, such nozzles are called slotted.

The slotted gas burner demonstrates the difference in the physical parameters of the fire when the external shape of the holes changes. This small difference in the design of the burners significantly affects the overall picture of the flame.

Gas supply of residential buildings

The gas facilities must be equipped in full compliance with the requirements of the approved "Rules for the Construction and Operation of Gas Equipment in Residential Buildings". Installation of gas networks, gas equipment and household gas stoves of a residential building are carried out by a special organization according to an approved project. The project includes the development of an entrance to the building (yard gas networks), as well as gas distribution inside the house.

For domestic needs, it is allowed to use low-pressure gas (not more than 100 mm of water column). In order to be able to maintain a constant pressure in front of the appliances (stove, stove, water heater), an apartment regulator-stabilizer is installed.

The depth of the gas pipeline in the area, which ranges from 1.2 to 1.7 m, is taken depending on the climatic region and the depth of soil freezing.

The water vapor contained in the gas cools in winter and creates ice plugs in the gas pipeline, thereby blocking the access of gas to consumers. Therefore, in the projects of yard gas networks, the issue of condensate drainage from the network must be provided for and correctly resolved.

In cases where the main gas networks are located at a great distance from the village and it is impractical to lay transit expensive gas pipelines, gas supply is carried out using imported liquid gas. As a combustible gas, a product of the secondary distillation of oil, propane-butane, is used.

For a stove designed for one family, at low gas consumption, two cylinders are needed, one of them is working, the other is spare. The capacity of the cylinder is 50 or 80 liters, which is enough to provide a family of 4-6 people for one week.Cylinders are installed in special metal cabinets at each house. Gas pipelines from cabinets with cylinders to the place of gas consumption are laid by a special organization.

Gas stoves and tagans are installed in kitchens with a height of at least 2.2 m. At the same time, the kitchen must have an exhaust ventilation duct measuring 130 × 130 mm, a window or an opening transom in the window. In kitchens without windows, it is allowed to install gas stoves or tagans if there is a ventilation duct and a direct exit to a non-residential premises, which has a window with a window or an opening transom. In kitchens with a height of 2 to 2.2 m, as well as in kitchens without windows, each burner must have at least 4 m3 of space.

There is no kitchen in the house and it is impossible to allocate a separate room for it, it is allowed to install gas stoves and tagans in a corridor with a height of at least 2.2 m, which has a window and a ventilation duct. In this case, the width of the free passage between the installed slab or tagan and the opposite wall must be at least 1 m.

The internal volume of kitchens or corridors equipped with gas stoves or tagans without exhaust hoods must be at least: for a stove or tagan for 2 burners - 8 m3, for a stove for 4 burners - 16 m3.

When installing exhaust hoods over stoves or tagans, it is allowed to reduce the volume of the room: with a stove for 2 burners - up to 6 m3, with a stove for 4 burners - 12 m3.

Gas water heaters are installed in bathrooms or combined bathrooms, the internal volume of which is at least 7.5 m3, equipped with ventilation ducts and having a grate near the floor with an area of at least 0.02 m2 or a gap between the door and the floor of at least 3 cm to ensure air flow.The doors of these rooms should open outwards.

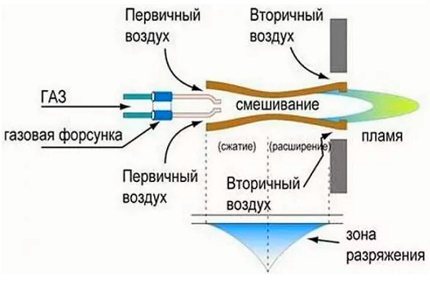

Heating stoves and cookers run on gas if they are connected to separate chimneys. Burners installed in furnaces and stoves must be of the ejection type and ensure complete combustion of the gas.

Ejection burners provide (unlike diffusion) due to the energy of the gas jet, the suction of ambient air into the burner, as a result of which a mixture of gas and air burns in the burner.

In views or valves of gas-fired stoves, holes with a diameter of 15, 20 mm must be made for constant exhaust from the firebox.

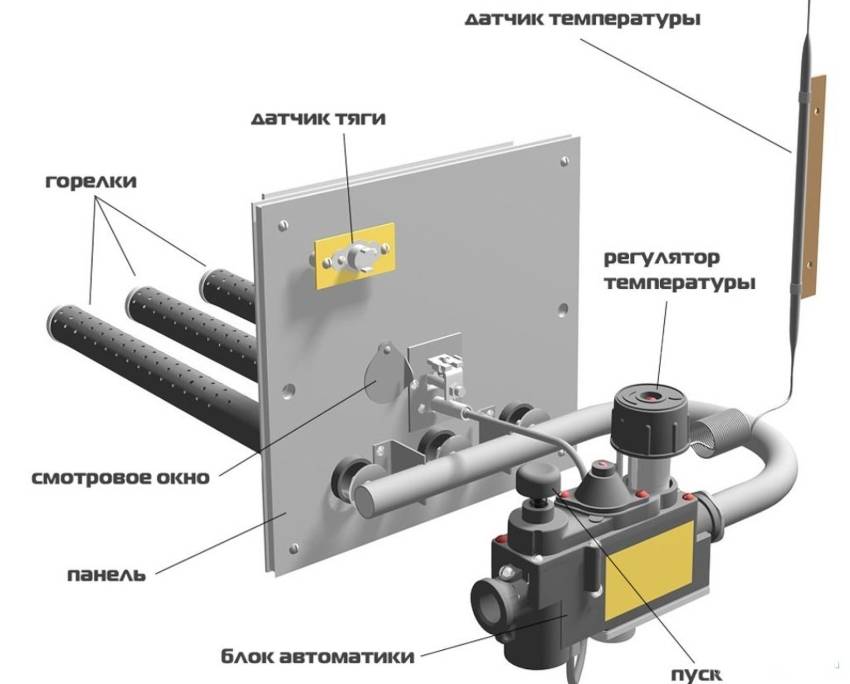

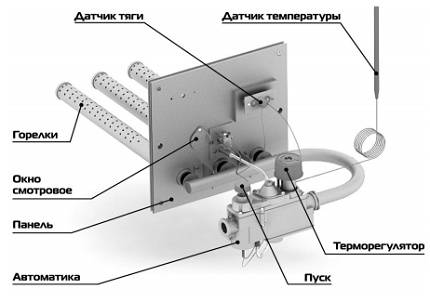

Protective automation system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, controlling the flame of a working nozzle is necessary for your safety. This can be done visually or with the help of automation with light-sensitive modern photocells.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in the dimensions of the modernized design. Especially for small bathrooms. If the size of the device is an important criterion for you, then for compactness, all automation can be placed outside.

You can add automatic schemes for working with simple elements. Compact placement will save the usable area of a small bath

To control the combustion process, you can use a factory-made automatic installation of the SABK-8-50S type.It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such a device will automatically stop in the event of a dangerous emergency.

Advantages and disadvantages

The use of burner equipment already has the advantage that you no longer have to spend a lot of time igniting the furnace itself. The combustion process will be initiated as quickly as possible and will not require any special efforts. You just need to unscrew the valve and put the system into operation. But it is also worth noting that gas fuel is significantly cheaper than heating with wood, coal, electricity or diesel fuel.

It should also be noted that the devices are quite safe in terms of fire. The designers did not stand still, but continuously solved the problems of fire protection with the means available to them. In addition, natural gas burns at a lower temperature than coal or other fuels. Therefore, the chimney will heat up less. However, in just 60-90 minutes, the room will be completely warmed up.

Pump

Pump in a gas boiler

Serves to transfer the movement of the coolant. This device causes the heating fluid to circulate from the heated primary heat exchanger to the radiators, heat them up and move back to heat up. The pump, as a rule, has several speeds and is adjusted by a service engineer based on the size of your heating system.

Too high pump speed can create additional noise and reduce boiler efficiency. And too small - will lead to uneven heating of the radiators

Therefore, it is very important to contact qualified service engineers for correct adjustment.

The main varieties and classification of gas burners

For a long period, there was no particular abundance of this type of product on sale. The simplest boilers, titans and gas water heaters were in short supply. The appearance of a gas burner for an automatic boiler was regarded as something fantastic. But these appliances also needed ventilation with a full chimney. Nowadays, even mobile infrared picnic burners powered by gas are offered.

According to modern requirements, gas burners for heating boilers must be characterized by low toxicity.

According to modern requirements, gas burners for heating boilers must be characterized by low toxicity.

Modern fuel units are very diverse. Their advantage is the almost complete combustion of fuel and the absence of toxic impurities during operation in closed conditions.

Traditional heating equipment is characterized by design variability:

- atmospheric boilers;

- universal;

- low temperature;

- turbocharged;

- fan;

- injection;

- gas burners with piezo ignition.

Do-it-yourself devices are also far from uncommon. Homemade gas burners can be assembled using the drawings, diagrams and sketches of the masters containing detailed descriptions, as well as watching the video.

The boilers have different types of flame ignition - using a piezo lighter and using a spark when the electronics are triggered.

The advantage of modern gas burners is the almost complete combustion of fuel. Pay attention! Piezo ignition - a single ignition, after which the flame is maintained in operating mode as long as there is a gas supply. This device should not be confused with burners for a gas stove (nozzle with a divider) and a grill.The electronic ignition must be activated during the start of the supply valve: the gas is ignited by means of an electrostatic spark

This option is considered the most economical and reliable, but during power outages, the boiler is often idle (if there is no alternative way to ensure it is turned on)

The electronic ignition must be activated during the start of the supply valve: the gas is ignited by means of an electrostatic spark. This option is considered the most economical and reliable, but during power outages, the boiler is often idle (if there is no alternative way to ensure it is turned on).

Purpose and advantages of nozzles

Gas burners (or nozzles) are designed to operate the stove on gas. Like other similar devices, the nozzle mixes fuel - natural or liquefied gas with air. As a result, the temperature rises in the oven.

Most often, such gas products are installed in baths where a high temperature is required for a long time. However, nothing prevents you from installing a nozzle in the house in order to rid yourself of the usual kindling methods. In addition, such products have a number of significant advantages:

- Safety. Since these products work with explosive material, strict requirements regarding reliability are applied to them. This can be verified by reviewing the quality certificate.

- The presence of automation. Most gas products are equipped with automatic temperature control, which provides not only economical fuel consumption, but also protection against overheating or explosion of the furnace.

- Profitability. As you know, gas is much cheaper than the cost of firewood, coal or electricity.

- Variety of fuels used. Many devices can run on natural or liquefied gas.

- Ease of management. The operation of gas devices for furnaces does not require any specific skills. In addition, some models can be operated from a special remote control.

- Ergonomics. A lot of space is required to store coal, firewood or other combustible materials. The flow of fuel into the nozzle comes from the gas column.

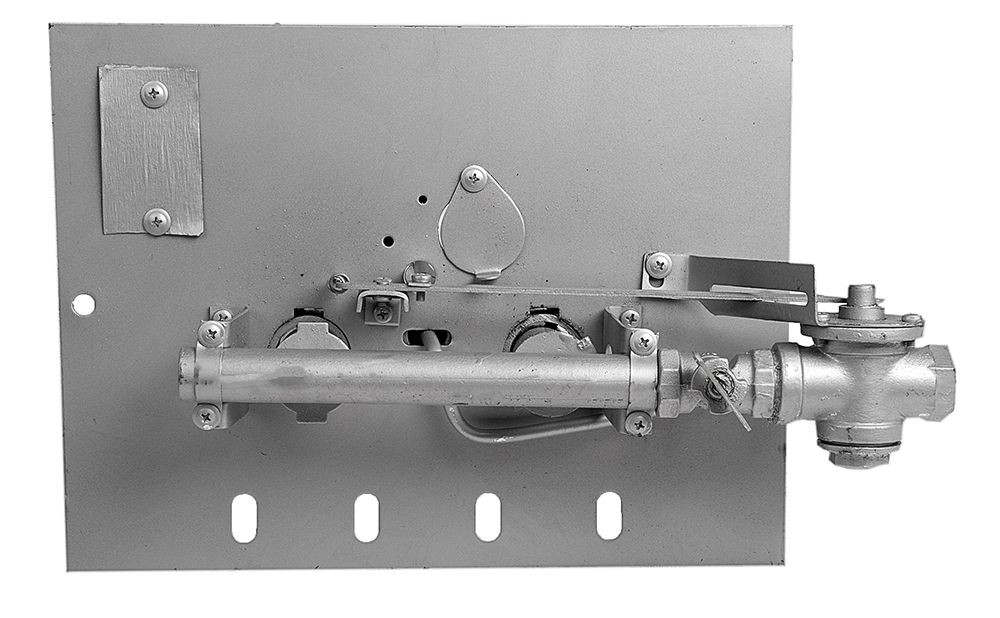

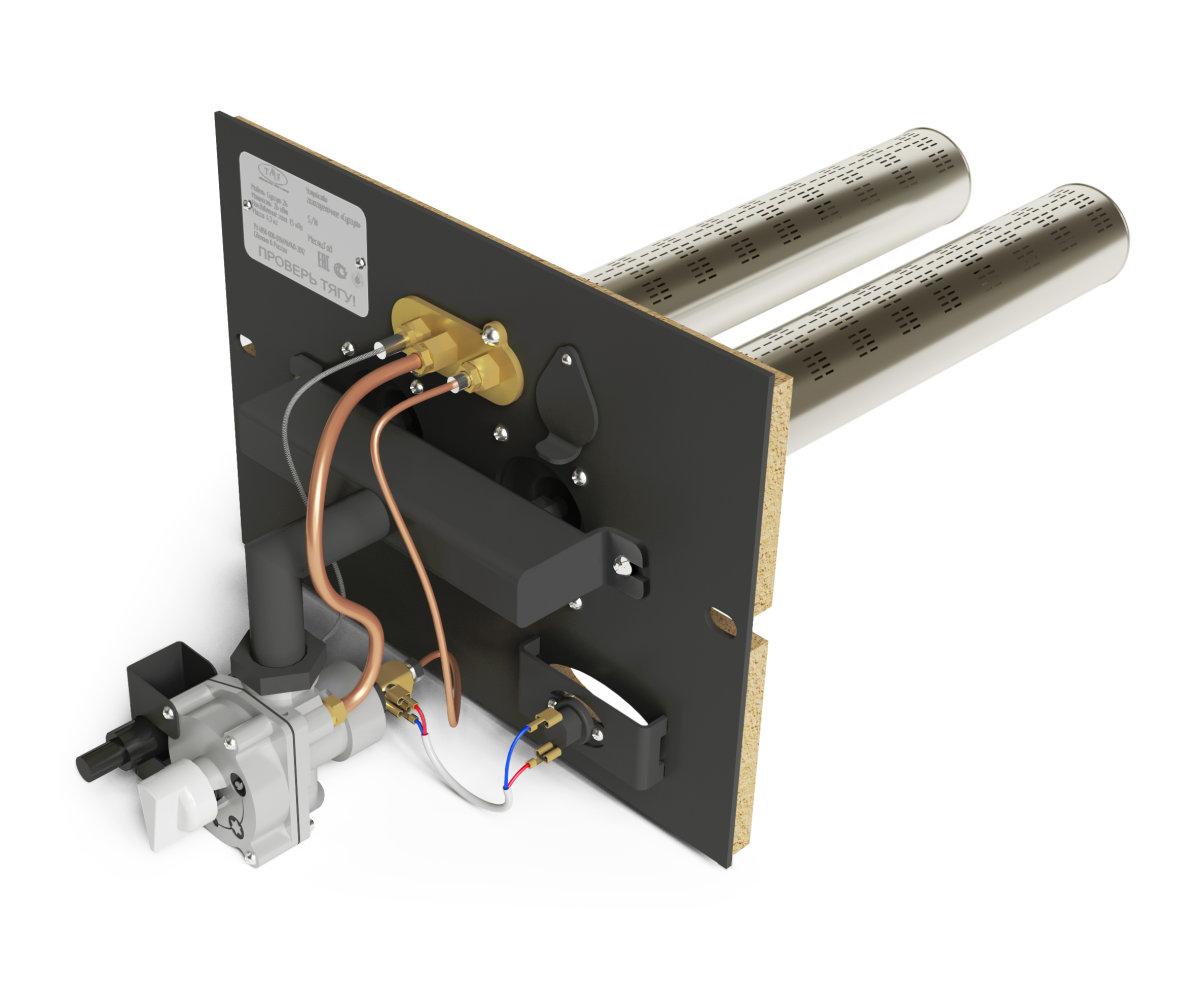

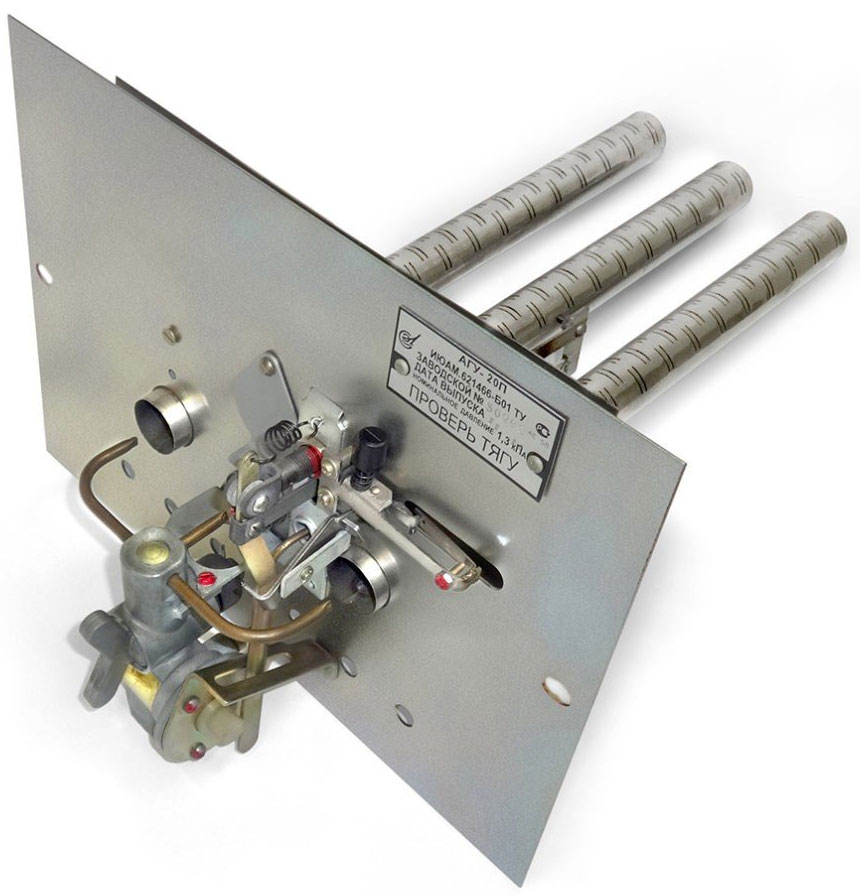

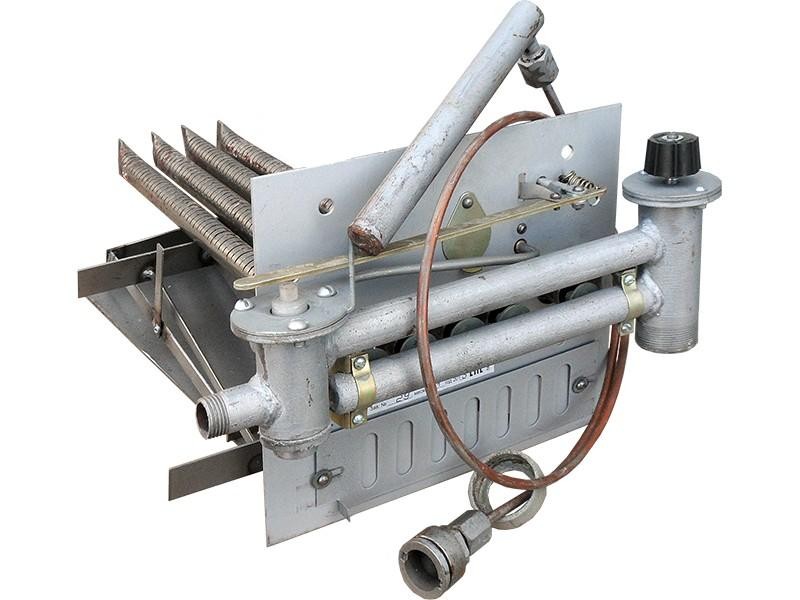

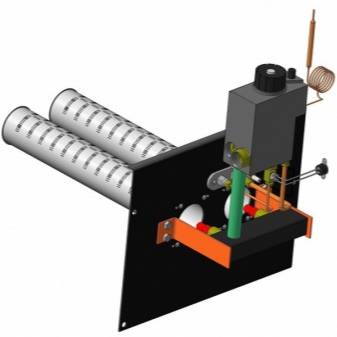

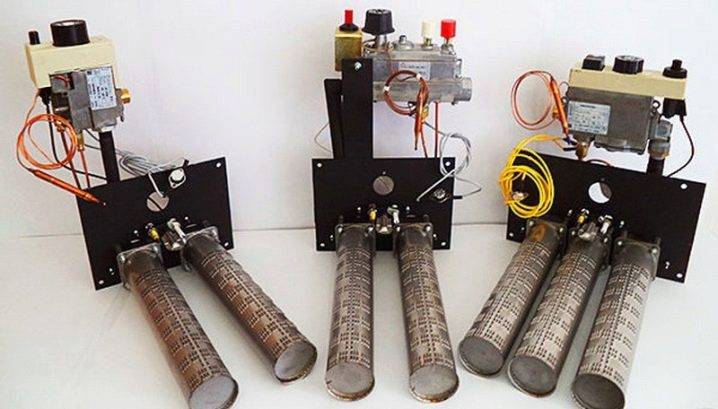

Atmospheric boiler burners and manual gas burners

Work due to the influx of oxygen in a natural way gives a full-fledged combustion of fuel, the removal of combustion products is carried out through a conventional chimney. The operation of the equipment has been simplified with the use of atmospheric devices and special nozzles for gas burners.

Note! The only condition for the operation of the device on oxygen taken from a heated room is excellent supply ventilation.

Important advantages of boilers with atmospheric gas burners:

independence from power sources, which is important when working in rooms without electricity;

high reliability (no complex components that require frequent repairs);

low noise threshold;

constructive simplicity;

affordable price.

Note! Information for those who are interested in how much a gas burner of the simplest sample costs - its price starts from 250 rubles. And the cost of a gas burner ugop-P-16 "Coal", for example, is approximately 1000 rubles.

The manual gas torch with a cylinder is popular with people doing repairs.

The disadvantages of atmospheric units include:

- the need for a full-fledged chimney that removes smoke and fuel mist to the outside;

- relatively low efficiency (compared to modernized samples);

- the probability of incomplete combustion of fuel with a lack of oxygen;

- the difficulty of adapting to other heat sources;

- the need to install forced ventilation or a small window.

On a note! Electronically ignited burners require a mains-operated high-voltage converter. In this they differ from such simple devices as manual gas burners.

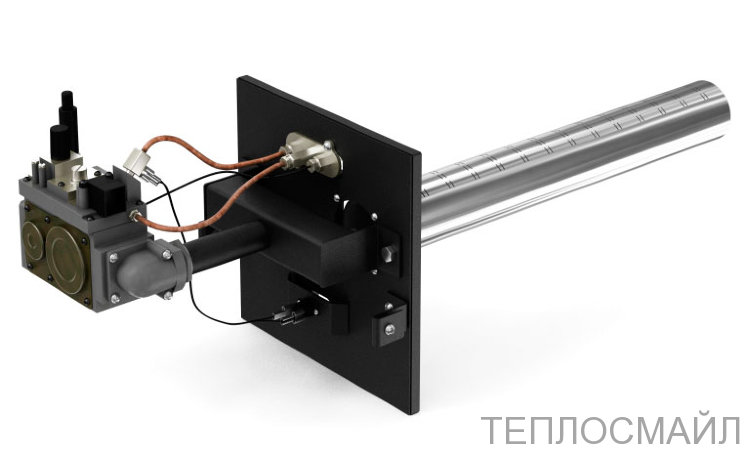

How to make a gas burner for a boiler with your own hands?

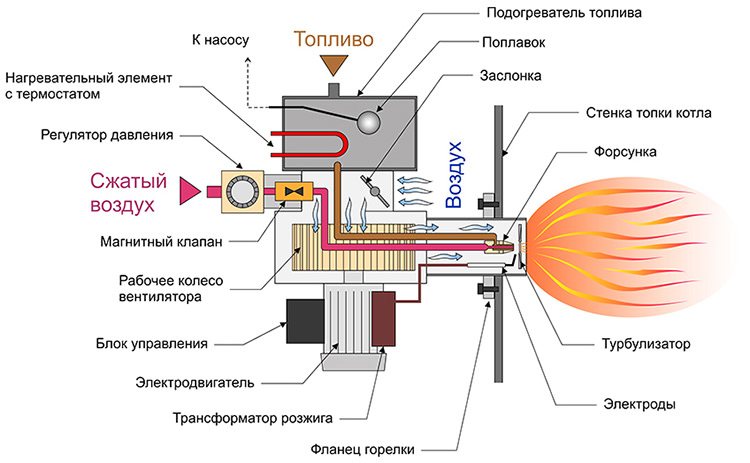

The main element of the gas boiler is the burner. It is around it that all other elements are exposed. Many aspects of the use of the equipment depend on the node design.

First of all, it is safety and economy. Therefore, many people want to make such a gas burner for the boiler with their own hands, which will meet all the requirements of the owners.

At first glance, this may seem like a complicated process, but in fact it is not.

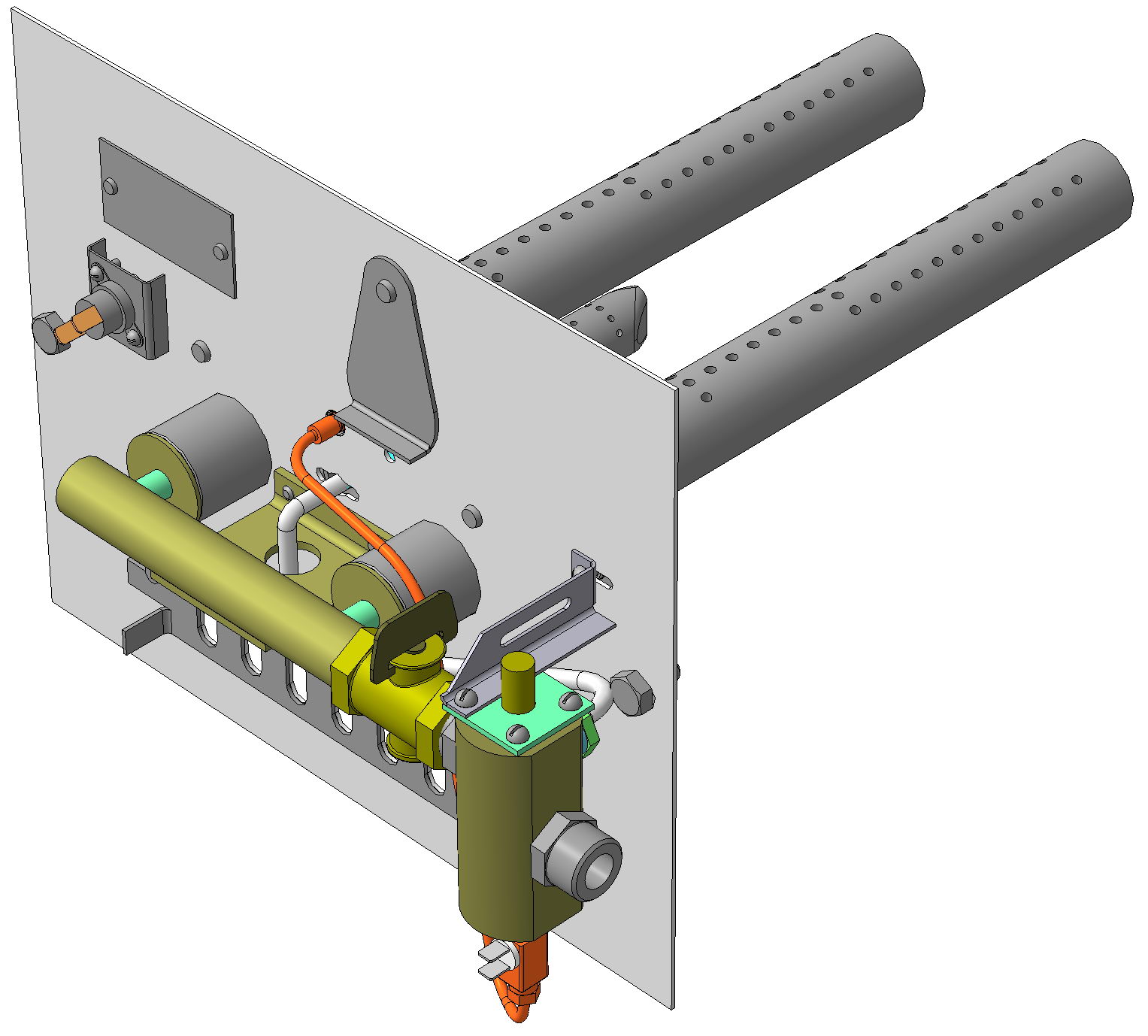

Types of burners

Many people think that the burner is just a nozzle through which gas is supplied. But it is not so. It also mixes air into fuel.

At the same time, it is important to take into account that the product must have a special design that makes it possible to make the mixture stable.

The device can be of several types, depending on the method of adding oxygen to the gas:

- atmospheric burner;

- fan;

- diffusion-kinetic.

atmospheric

The principle of operation of this component is simple: the gas passes through the ejector, where its pressure is reduced. In this case, air enters due to different atmospheric indicators.

These devices have a lot of advantages:

- simple design;

- compactness;

- quiet work;

- acceptable cost;

- the possibility of converting a solid fuel boiler for this equipment - the burner is simply installed in the ash pan chamber.

At the same time, such devices cannot have high power. The fact is that due to their design, atmospheric heaters cannot draw in a large amount of oxygen.

Diffusion-kinetic

Basically, such equipment is found in large industrial heaters. The principle of operation is based on both atmospheric and fan heaters.

Features of use

Gas burners are unpretentious in service. The main feature is the annual cleaning. In this case, the procedure should be carried out only by highly qualified specialists, since for this it is necessary to disassemble the boiler. Most often, the service center is engaged in cleaning the burners.

Dirt is easily removed with compressed air

It is important to set the right pressure for this. The fact is that some modern parts may not withstand a flow of 10 atm.

To make the cleaning process faster and less frequently required, a special filter is placed on the gas supply. This is done by the master after submitting an application to the appropriate structure.

Well, despite the fact that the gas burner in the heating boiler, although it seems to be the most complicated engineering unit, you can nevertheless make it yourself without any problems. To do this, you need to prepare all the necessary materials and have the skills to work with metal. In addition, it is necessary to have several units of a special tool.

Independent production of gas burners: to do or not

Another point: you will never get permission to use a homemade burner.You can, of course, put the equipment on your own, but the fines are too high.

It is not without reason that people call gas stoves “bombs” among the people - but all because people are used to trusting sellers at their word and at one time purchased stoves of dubious origin. Because of what - explosions, fires, burns. Because of what - a common myth that gas and electric stoves for steam rooms is a taboo.

Each burner for a gas furnace has its own specific fuel consumption value, which determines the efficiency and power of the unit. So, for a small bathhouse, a gas burner for a boiler with a flow rate of 1.5-4.5 cubic meters will be enough. in hour. Moreover, you can purchase it with the required power for an existing furnace - this is a replaceable element

But it is important that the characteristics of the threaded connection of the burner itself and the source of gas supply to the boiler completely coincide.

And, finally, all gas stoves for baths must have documentation confirming the state safety and quality standard - if the seller did not find one, then it is better to bypass his store on the tenth side.

Absolutely unacceptable for a steam room and a burner for boilers of unknown production, with damage or leaky connections, without a technical passport or after the end of the permissible service life

In a word, the burner for a gas sauna stove must be in perfect condition and periodically subjected to preventive inspection - this is important for the health and life of people relaxing in the bath

Gas-fired sauna stoves are modern universal designs that differ from traditional ones in the possibility of using various types of fuel in them: natural gas, liquid hydrocarbon gas, and firewood.All this is ensured by the fact that gas-fired stoves have additional removable elements - devices for solid fuel and gas burner equipment.

Responsibility must be approached to the process of installing a gas stove - both the efficiency of the stove and the safety of its use depend on it. It is best to entrust this to qualified workers - such services are offered by all sellers. And in any case, during the installation process, you need to follow this:

- The distance from the wall to the stove must be at least 5 meters, and the walls themselves must be made of fireproof materials or upholstered with such.

- The refractory base of the furnace must protrude at least 10 cm from all its edges.

- The dimensions of the opening for the burner without lining should be as follows: 47-55 cm high and 35-45 cm wide; with overlay: 61.5-68 cm high and 51.5-66.5 cm wide.

An example of marking openings for installing a stove. They may vary depending on the model.

In the dressing room, it is imperative to make exhaust ventilation and a window with a window - gas after all. Doors should be made to open outward, and the height of the chimney should be planned no less than 5 meters from the level of the burner

Very important: the place where the stove is connected to the chimney must be perfectly sealed.

An approximate diagram of the installation of a gas stove and its structural components

If you are thinking about whether it is worth buying such a stove for a sauna, do not hesitate: gas sauna stoves are not only easier and cheaper to operate, they are also cleaner, more environmentally friendly, and much more functional.

The most efficient devices of 2018

The most efficient certified boilers and gas burners this year:

- Bosch Greenstar series.The boiler is small, very quiet, environmentally friendly and uses an economical condensing technology that achieves an AFUE rating of 95%. Greenstar is available in two models - combi for spatial and pointless water or space heating, which can be used with domestic hot water tanks. It is equipped with a heat exchanger with a 5 year warranty.

- Bradford White Brute Elite series. The boiler with 95% efficiency has a condensing multi-pass stainless steel heat exchanger with an advanced modulation system. Innovative design features make the Brute Elite easy to install in both new and existing heating systems.

- Bradford White Brute Elite 125 Series. Customizable models based on combi, for heating only, are 95% efficient with the combi unit providing heating and hot water from a single installation. Requires only one gas connection, one ventilation system and built-in expansion tank and boiler pump, has good accessibility for repairs.

- Buderus GB142 series. Condensing gas boiler. Using state-of-the-art condensing technology with 95% AFUE, the Boer Buderus GB142 wall mounted condenser maximizes the heating value of every m3 of natural gas or LPG.

- Boiler Alpine Series. It is a natural or liquefied gas condensing boiler with a stainless steel heat exchanger. Equipped with Sage2 boiler control system. 1 TM, which supports multiple firing speeds, is also equipped with an external reset and a touch interface.

- Carrier BMW Performance Series. 95% AFUE. Stainless steel.The modulating condensing boiler is equipped with a unique vertically oriented stainless steel heat exchanger, 5 to 1 ratio, compact design with low weight, compact wall mounting, primary and secondary piping, with a 15-year warranty.

Having familiarized yourself with the device and principle of operation of gas burners and popular models, you can easily choose exactly what is suitable for your needs.

Varieties

Now let's talk about the categories of burners. It is better to use the model that is indicated by the manufacturer in the regulatory documentation. The heat exchanger, like the design of the boiler, is usually created with the expectation of installing a specific burner.

If we take the purpose, then there are two categories of burners.

- For high power industrial boilers. Injection fan burners are usually mounted in this category. Their performance will be from 120 to 250 kW.

- household options. In this case, the power will not be more than 120 kW. This includes an atmospheric boiler burner. Its disadvantages are high fuel consumption and serious installation requirements.

If we talk about the type of fuel, as a classification criterion, then there are two types of burners:

- operating on liquefied gas;

- on a natural analog.

The difference between the types of burners will be in the gas operating pressure and nozzle sizes. In household designs from European brands, universal options are usually installed that can work with both types of gas.

There are also injection diffusion and other solutions with preliminary partial or 100% mixing. But such options are used only in industrial models. It should be noted here that the type of burner will affect the design features of the heat exchanger, combustion chamber, gas outlet option, and exhaust system.

According to the type of burner regulation, there are:

- 1-speed;

- 2-speed;

- 2-speed modulated gas version;

- modulated.

The control type determines whether an open or closed burner will be used. The category of the device will affect the standards that will apply to the installation and operation of such a boiler.

Now let's talk more about each of the categories. One-step solutions are the most common option. Their principle of operation is that they turn on and off. The frequency of changing operating modes will depend on how quickly the coolant cools, as well as on the mode of operation.

The features of these burners are:

- work regardless of the availability of electricity;

- high gas consumption;

- excellent reliability;

- the presence of an ignition mechanism.

If we talk about two-stage burners, then they are suitable for boilers where there is precise regulation of gas flows. By the name, you can understand that such a device can work in two modes. Usually we are talking about 30 percent and 100 percent of the power.

The features of this solution will be:

- constant burning;

- heating of the heat carrier by one hundred percent;

- models with automation control the transition from one mode to another.

If we talk about the third category, then here the working principle is identical to the previous version.The only difference will be that the switching is performed without quick jerks.

Features of this type of burners will be:

- low fuel consumption;

- universality;

- electrodependence;

- adjustment of the heating temperature of the thermal carrier.

The last type is modulating burners. They are considered the most economical. Changing the burner power is usually carried out in auto mode.

Features of the modulating burner are:

- the presence of automatic control;

- universality;

- high economy.

Operating rules

It is necessary to turn on the heating gradually, starting from the minimum intensity of heating. The warm-up process should go continuously, smoothly, but steadily. In furnaces that do not allow power regulation, they operate cyclically, turning the device on and off

This is most important for brick hearths. Powerful continuous heating of the cooled brick can provoke the appearance of cracks. It is essential that the prescribed operating periods are observed.

You need to use a gas burner for 8-15 years. Then they must be replaced. Ideally, repairs and service work, as well as the installation itself, should be carried out by qualified gas specialists.

The prescribed operating periods must be observed. You need to use a gas burner for 8-15 years. Then they must be replaced. Ideally, repairs and service work, as well as the installation itself, should be carried out by qualified gas specialists.

Atmospheric burners can be used under three conditions:

- maintaining carefully controlled traction;

- decent ventilation in the room;

- the minimum volume of the room is not less than 12 m3.

If an oven with a gas burner is initially designed or converted to use liquefied fuel, care must be taken to ensure the safe placement of the cylinder. It is not necessary to allocate a separate room for it, you can get by with a metal cabinet. The reservoir (gas tank) is placed strictly underground at least 5 m from the house and other buildings.

Devices cannot be used:

- mechanically damaged;

- with broken tightness of connections;

- after the loss of the technical passport.

When the heating season comes, check the condition of chimneys and ventilation; in the event of a failure in them, the normal operation of the burner is not guaranteed. Before each ignition, the draft in the chimney is evaluated and the devices themselves are adjusted. Furnace compartments and rooms are ventilated for at least 5 minutes. The ignition of the main tap is carried out only with a steadily burning igniter. If it goes out, it is necessary to turn off the tap, ventilate the firebox again and duplicate all the previous manipulations from scratch.

Turn off the gasified furnace by closing the valve of the main burner. Only in the second turn close the valve at the entrance to the furnace. Do not ignite the device when a reverse thrust occurs. The color of the flame and its appearance should be carefully monitored - in case of such problems, it is necessary to immediately turn off the device and check it. The valve of the burner to be started without ignition can be kept open for a maximum of 5 seconds.

Overview of gas burners in the video below.

Overview of gas burners SABC 3TB4 P, SABC 4TB 2P, UG SABC TB 16 1, UG SABC TB 12 1

Do-it-yourself oven installation

In order to properly install the oven, you need to follow a few rules.

- Choose the right place. It would be best to put the stove in the center of the building, near the walls and partitions, so that all rooms are heated.But it should be noted that the distance between the furnace and fire hazardous elements must comply with established standards in order to avoid trouble.

- Prepare enough quality materials.

- Follow the order of work, carefully consider each stage.

- Think carefully about fire safety.

You need to start from the foundation. We dig a hole of the right size, fill it with sand, then in turn: water, broken brick, crushed stone. On top there will be a frame, concrete, moisture insulating material (bitumen). In general, the foundation should be about 70-80 cm in height (from the bottom of the pit).

The walls of bath stoves are ordinary brickwork based on cement or clay-sand mortar. Where the stove will be installed, you need to make a blower at the bottom of the wall, leaving a space free from bricks and installing a door of the right size. A little higher is a well (ash pan) and a grate.

Next, the door of the heating boiler itself is installed, and then you can make the beginning of the chimney with a special partition. And do not forget that the ovens can have a built-in or remote water tank. Provide a place for her too. The pallet for stones can be made from a sheet of durable steel and expanded clay.

When you install the stove itself, attach a chimney, all kinds of doors, etc., proceed to plastering it. Again, clay with sand will do, although you can add gypsum, alabaster, or use ready-made heat-resistant plasters. From the side of the door (and preferably from all sides) on the floor near the stove there should be a metal plate, but in no case a tree.

Advice from the master!

Follow these rules and tips, and then you will not have problems with a gas stove, and relaxing in the baths will bring real pleasure.