- Types of cylinder malfunctions and their elimination

- Rules for the operation of oxygen cylinders

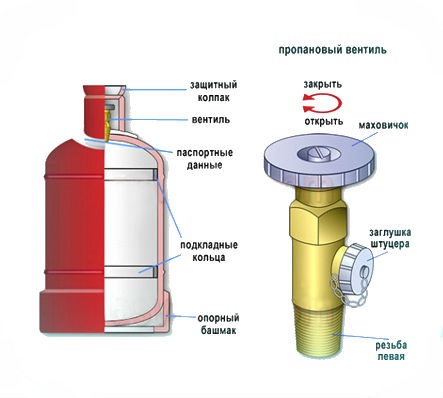

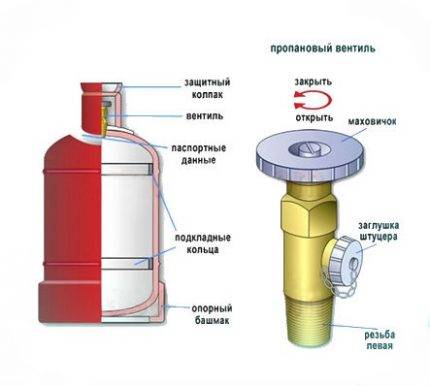

- Propane tank device

- Mass and size of cylinders of various capacities

- What is the thread on the propane tank?

- How many m3 of propane in 1 cylinder for 5, 12, 27, 50 liters?

- Gas cylinder device

- Gas tank device

- Gas tank device

- Oxygen Safety

- Oxygen cylinders 40 l

- Guarantee

- Performance requirements applicable to gas cylinders

- Types of cylinder malfunctions and their elimination

- At home

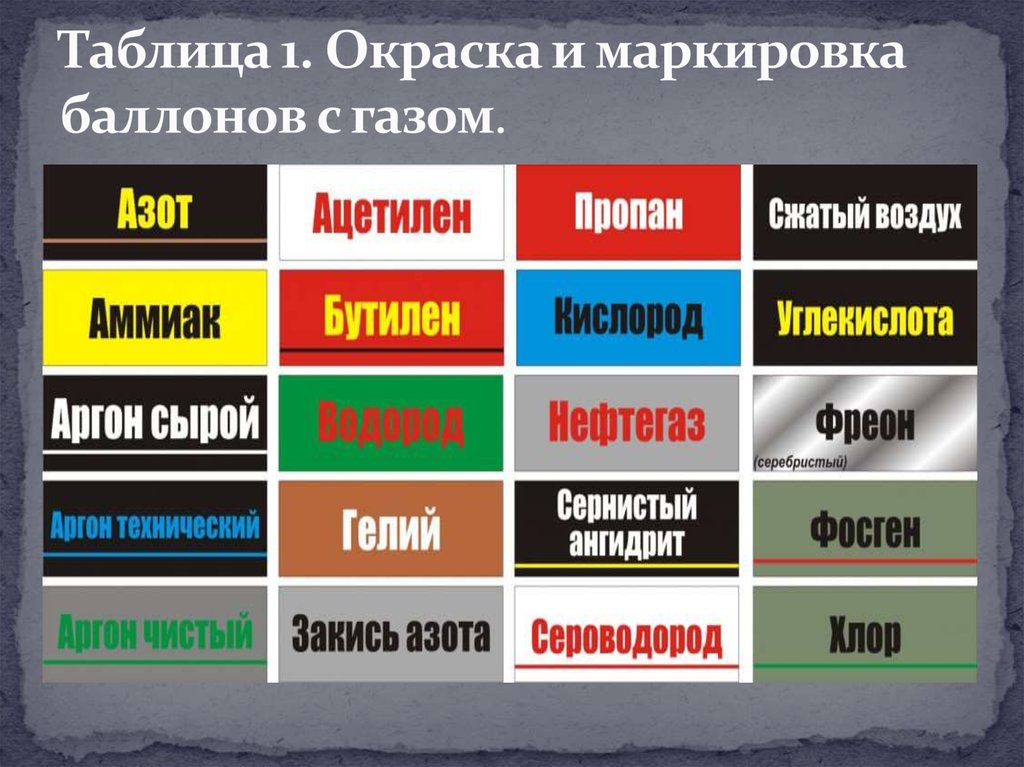

- Types of cylinders by area of use

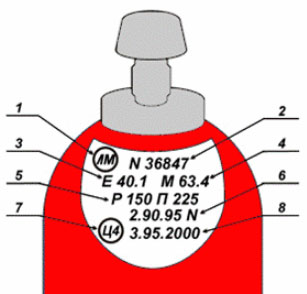

- Deciphering the marking of cylinders

- Rules for the safe operation of propane cylinders

- What is the gas pressure in a propane tank?

- Refueling rates

- Elements of sustainability and volume

- What are the requirements for the placement of individual balloon installations?

- Rules for using the cylinder

- Standard sizes of gas cylinder 50l

- Gas cylinder 40 liters and its dimensions

- Dimensions of household gas cylinders

- Dimensions of gas cylinders for cars

- Dimensions of toroidal gas cylinders - novelties in our market

Types of cylinder malfunctions and their elimination

All existing gas cylinder malfunctions are divided into two types: to be eliminated and not to be.

The first type includes:

- incorrect operation of the cylinder valve and pressure gauge;

- shoe damage or displacement;

- damage to the threaded connection;

- gas leak;

- peeling body paint in many places.

The second type of malfunction is a significantly damaged surface of the case in the form of dents, cracks, swelling, lack of marking. In this case, the balloon is rejected. The decision on the possibility or impossibility of repair is made by a specialist with the appropriate qualifications.

When repairing gas cylinders, a simple replacement of defective elements is often performed. Sometimes it is necessary to flush the tank internally and check for corrosion from the inside. Periodic inspection includes all these works, and upon its completion a certificate is issued.

The gas cylinder in the photo is in need of repair. It needs to be painted and the valve replaced. The first work can be done independently, and the second should be entrusted to a specialist.

This should not be done at home. All you can do yourself is paint the cylinder body

This must be done very carefully so as not to paint over the inscriptions and not to damage the markings. All other faults can only be repaired by a specialist workshop or the manufacturer.

Rules for the operation of oxygen cylinders

Welding works are classified as unsafe activities, as they involve the use of toxic, explosive substances. Therefore, for the transportation, storage, operation of gas containers under pressure, certain safety rules are provided:

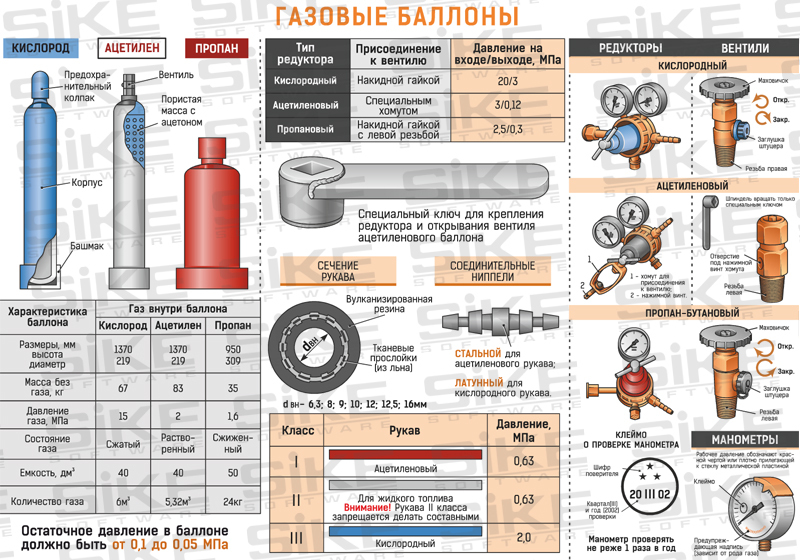

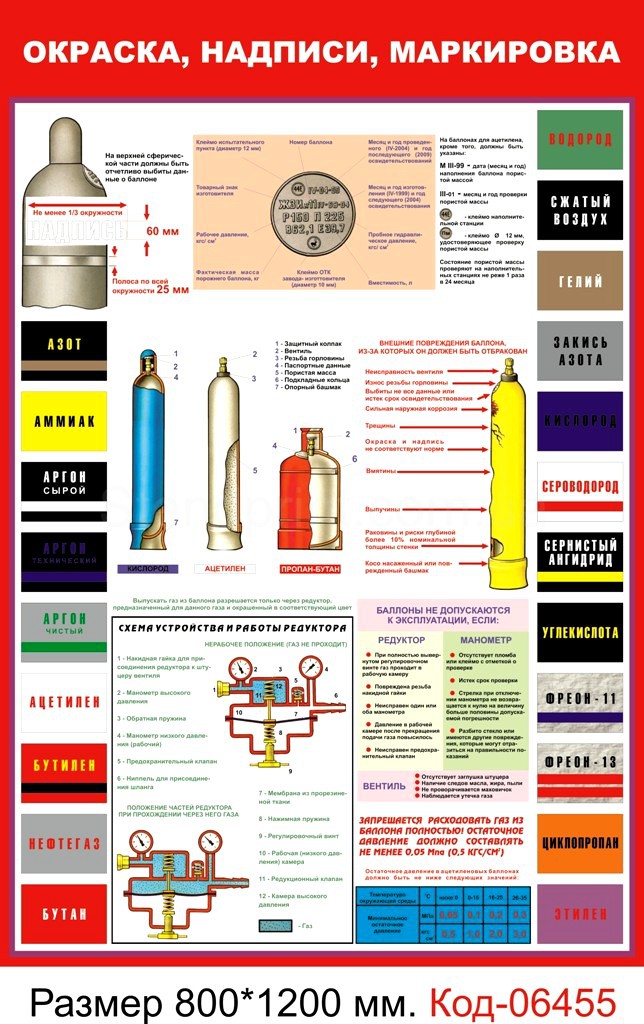

- the oxygen cylinder for welding is painted blue, and the inscription “oxygen” is printed on it with black paint, the rest of the information (manufacturer, date of manufacture, type, weight, individual number, etc.) is printed on the unpainted surface of the cylinder.There must be a stamp of technical control;

- in a forty-liter container, compressed oxygen must be under a pressure of 150 atmospheres. When gas is consumed, the pressure will drop, when it drops to one atmosphere, it is forbidden to use a gas cylinder. The empty container is conserved and sent for storage (the valve is twisted, a plug and a protective cap are put on it, the gearbox is removed);

- it is forbidden to completely consume oxygen from the tank, since it will be difficult to determine the type and amount of gas contained at the filling station;

- transportation of oxygen cylinders is carried out in specialized racks that cushion the cylinders when shaking on an uneven road, thus preventing the possibility of damage;

- at the construction site, gas containers are moved on special carts;

- in the process of performing welding work, gas cylinders are placed at a distance of at least five meters from sources of open fire, the welding zone;

- you can not keep a container with gas for a long time under direct sunlight;

- they also require protection from precipitation;

- the pressure when oxygen is supplied to the welding zone is automatically regulated by the reducer, which ensures the safety of welders. Therefore, the gearbox must be constantly clean and in working order.

Contact of oxygen with an open flame, fuels and lubricants can cause a strong fire, even an explosion.

Gas cylinders for welding must be certified - this event is also associated with the safety of welding. Tanks are checked for the first time directly at the production site, later at their recharging stations. Only containers that have passed certification are allowed to work.

Important! When using oxygen, you need to remember that it can be not only beneficial, but also harmful. For example, if you breathe pure oxygen long enough, you can harm the respiratory system, lungs

Propane tank device

Structurally, they are containers made of carbon steel 3 mm thick. On the one hand, a stamped bottom with a shoe stand is welded to a single-seam welded cylinder, on the other hand, a hemispherical neck for installing a valve. Various filling or dispensing equipment is connected to the latter. The bulk of propane consumer devices (gas stoves, titanium, welding torches, heating boilers) require reduced pressure. To do this, a gearbox is installed on the valve (the most common is BPO-5-5).

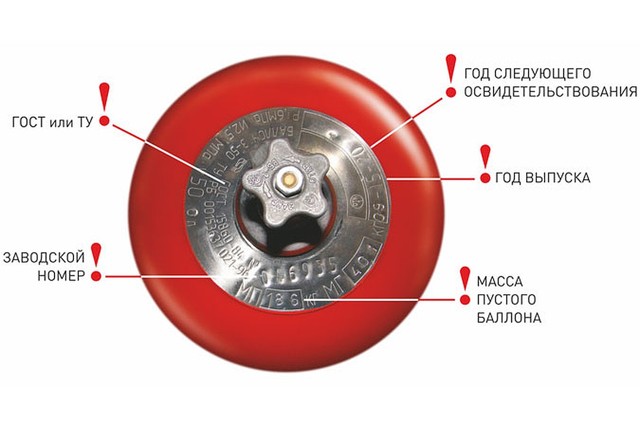

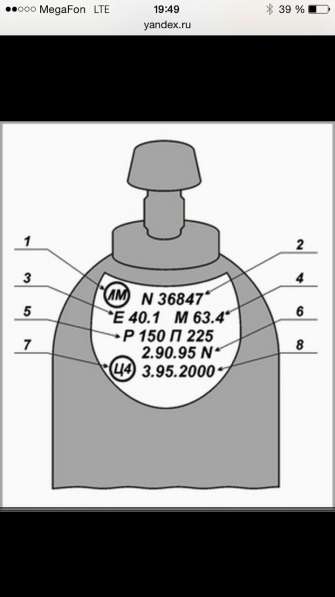

A passport is placed on the upper part of the neck, on which the main technical parameters of the device are stamped. These include: the name of the manufacturing plant, the mark of the Quality Control Department, individual number, month and year of manufacture, date of inspection (updated every 5 years), volume, weight in empty and filled condition.

Mass and size of cylinders of various capacities

How many kg of propane in 1 cylinder for 5, 12, 27, 50 liters? You can find out in the quality certificate of the product or in the table below. Here you can also find how much a propane tank weighs for 5, 12, 27, 50 liters.

| Volume | 5 liters | 12 liters | 27 liters | 50 liters |

| Empty cylinder weight, kg | 4 | 5,5 | 14,5 | 22,0 |

| Propane tank weight, kg | 6 | 11 | 25,9 | 43,2 |

| Mass of stored gas, kg | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height, mm | 290 | 500 | 600 | 930 |

| Cylinder diameter, mm | 200 | 230 | 299 | 299 |

What is the thread on the propane tank?

Valves of the VB-2 type are installed on most household cylinders for propane-butane mixture.These locking devices are manufactured in accordance with GOST 21804-94 and are designed for pressures up to 1.6 MPa. The valve has a left-hand thread SP21.8-1 (6 turns), which allows you to connect any gearboxes with a union nut and a similar thread.

The valve provides a strong connection with the neck, full tightness, has a clear marking and a modern design. Threaded surfaces are lubricated with a special lubricant that reduces friction during operation. The screw plug with rubber seal prevents gas leakage during transport or storage. The device provides protection against unqualified repairs by persons who have not received appropriate training. The reliability of the locking device contributes to the long and safe operation of the gas cylinder structure.

How many m3 of propane in 1 cylinder for 5, 12, 27, 50 liters?

We made special calculations that conditionally convert propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Given the percentage of the mixture (60% prop.), the volume of combustible gas is calculated by the formula M * (0.526 * 0.6 + 0.392 * 0.4). How many cubes are in a propane tank, you can see in the table below. The last line contains the number of liters of propane-butane mixture (in the liquid phase).

| Tank capacity (l) | 5 | 12 | 27 | 50 |

| Capacity (cubic meters of combustible gas) | 0,95 | 2,59 | 5,38 | 10,01 |

| Volume of liquid propane (liters) | 4,3 | 10,2 | 22,9 | 42,5 |

It should be borne in mind that the calorific value of the propane-butane mixture is three times higher than that of natural gas (methane).

Gas cylinder device

Both for the storage and transportation of compressed and liquefied gas, gas cylinders have been created - special vessels in which these substances are under high pressure.The first type of gas under any pressure is in a gaseous state, and the second, with an increase in this parameter, passes into the liquid phase.

Nitrogen, fluorine, oxygen, methane, hydrogen, as well as chlorine, carbon dioxide, ammonia are transported and stored in a compressed and liquefied state.

The container itself is an all-welded construction with walls at least 2 mm thick with a cylindrical geometry. It is made of steel or polymer.

Its components:

- shell;

- neck;

- bottom.

The neck of the cylinder has a conical thread for a shut-off valve that hermetically closes the outlet. In the case when, for some reason, the gas expands, under the influence of pressure the valve will break, and the pressure inside the vessel will return to normal.

The gas inside such a vessel is under pressure of a maximum of 15 MPa. There is a welded single seam in the cylinder body or shell.

The volume of the cylinder depends on the material from which it is made, the type of filler and purpose. Oxygen cylinders are both small - from 2 to 10 liters, and medium - 20 - 40 liters

The volume of the cylinder depends on the material from which it is made, the type of filler and purpose. Oxygen cylinders are both small - from 2 to 10 liters, and medium - 20 - 40 liters

In order for the gas inside the vessel to exert the same pressure on its walls, each cylinder has a convex bottom - top and bottom. For greater stability, the cylinder is equipped with an annular support - a shoe. In addition, the gas tank has a metal or plastic cap in its kit that protects the valve during operation and transportation.

The cap is screwed onto the neck ring. Sometimes the cylinder is equipped with a pressure reducer designed to balance the pressure.The valve is a unit, which includes a steel body in the form of a tee, a flywheel, a locking element.

Each type of gas requires a valve of a special design

For safe operation, it is important that the type of container matches the filler. The assembly consisting of a bypass valve and a stem is called a shut-off element

Each part of the assembly performs its function

The assembly consisting of a check valve and a stem is called a shut-off element. Each of the parts of the assembly performs its function.

The valve is necessary to regulate the gas supply through the body, and the stem is necessary for the interaction of the flywheel with the valve through torque. By turning the handwheel, you can close or open the gas flow.

All 3 parts of the valve are threaded. At the bottom, it is needed to attach the part to the cylinder, at the top, the valve stem is attached by means of a threaded connection. Plug screwed onto side thread

All 3 parts of the valve are threaded. At the bottom, it is needed to attach the part to the cylinder, at the top, the valve stem is attached by means of a threaded connection. Plug screwed onto side thread

Gas tank device

The substance under high pressure is in a special vessel. Compressed gas under any pressure is in a gaseous state, and liquefied gas with an increase in this parameter turns into a liquid state.

The tank in the form of a cylinder is an all-welded structure, the minimum thickness of its walls is 2 mm. It is made of two materials either steel or polymer. Consists of a shell, neck and bottom.

Tapered thread on the neck of the cylinder allows you to hermetically close the shut-off valve. This is done so that when the gas expands, it can break off, and then the pressure in the vessel will quickly return to normal.

The bottom of such containers is convex from above and below. Due to this, the gas pressure on the walls in the tank is the same.

Classification of gas cylinders

Gas tank device

The substance under high pressure is in a special vessel. Compressed gas under any pressure is in a gaseous state, and liquefied gas with an increase in this parameter turns into a liquid state.

The tank in the form of a cylinder is an all-welded structure, the minimum thickness of its walls is 2 mm. It is made of two materials either steel or polymer. Consists of a shell, neck and bottom.

Tapered thread on the neck of the cylinder allows you to hermetically close the shut-off valve. This is done so that when the gas expands, it can break off, and then the pressure in the vessel will quickly return to normal.

The bottom of such containers is convex from above and below. Due to this, the gas pressure on the walls in the tank is the same.

Classification of gas cylinders

Oxygen Safety

Oxygen welding is one of the most dangerous processes in the workplace. When starting to perform such work, it is necessary to adhere to the general safety rules for handling O2:

Oxygen, interacting with other combustible substances, can cause ignition. To work with it, you can use only those materials that will make the welding or cutting process safe;

Compressed oxygen under a pressure of more than 30 kgf/cm2, in contact with fats and oils, oxidizes them. The result of oxidation with the release of heat is an explosion. Therefore, before starting work, you need to make sure that there are no greasy stains on the clothes of specialists, on the floor and on cylinders;

Welding with oxygen should take place in a room where the oxygen content does not exceed 23%;

After any work process that involves the interaction of man and oxygen, fire must be avoided. It is better to ventilate clothes for ½ hour;

Liquid oxygen causes frostbite of human soft tissues. Getting on the mucous membranes, oxygen causes a chemical burn. Any work with a liquefied substance must be carried out with protective gloves and goggles;

Under no circumstances should the O2 pipeline be used to transport other gases

An empty pipeline must be cleaned of grease, damage and heating must be prevented. Despite the fact that oxygen is an important substance for production work and for life support in medical conditions, it is dangerous. Prolonged stay of a person in a room with a high concentration of oxygen leads to a deterioration in health and frostbite of the skin.

You can work with this gas after all safety conditions are met.

Recommended! Types and classification of electrodes for welding

Oxygen cylinders 40 l

For welding, cutting of metal structures, forty-liter containers are most often used, the parameters of which are:

- volume - 40 l;

- empty container weight - 67 kg;

- cylinder diameter - 21.9 cm;

- cylinder height - 1.39 m;

- vessel wall thickness - 0.7 cm.

During operation, the oxygen cylinder is installed vertically, additionally secured with a clamp, preliminary preparation for work is carried out:

- the cap is removed, the plug of the fitting;

- the valve is checked for the presence of oil, fat (they should not be);

- the valve gently opens to purge the fitting;

- the valve closes again;

- the union nut of the reducer is checked for serviceability;

- the reducer is connected to the valve;

- adjusting screw sets the required working pressure of oxygen.

When working with cylinders, you must strictly observe safety precautions!

Guarantee

Gas cylinders are guaranteed for 1-2 years from the date of sale, depending on the body material. The service life of the tank is up to 30 years.

Conditions for fulfillment by the manufacturer of warranty obligations:

- the presence of a passport;

- safety of the factory marking and serial number on the device;

- strict observance of the instructions for transportation, storage, installation, operation and maintenance of the device, as well as the user manual;

- the presence of a warranty card filled out by the seller;

- for some manufacturers, a prerequisite is the registration of a guarantee on the official website of the plant;

- no traces of an attempt to self-repair or re-glue the marking.

The manufacturer is responsible for fulfilling the warranty obligations.

They include:

- testing;

- free repair;

- replacement with equipment of adequate quality similar in technical characteristics;

- financial compensation.

The warranty does not apply to the casing of the composite cylinder, as well as to containers with the following external defects that occurred during transportation and operation by the consumer:

- mechanical damage to the cylinder from contact with a sharp object or resulting from a fall, impact - scratches, gouges, dents, deformation, cracks, abrasions that caused a decrease in the thickness of the cylinder wall;

- darkening of the color of the valve or the appearance of inclusions on its body.

Upon the occurrence of a warranty case, a listing is drawn up, which must be sent to the manufacturer.

Performance requirements applicable to gas cylinders

Only those cylinders that are not damaged and that have been examined within the prescribed period are allowed for use in domestic and industrial needs.Before use, it is necessary to conduct an external inspection of the cylinder. Its walls may not show any damage, dents, cracks, corrosive changes, cracks or severe swelling. The outer surface of the cylinder must be marked and painted in accordance with the requirements of the State Standard. In this case, the area of the painted surface cannot be less than seventy percent. If the residual paint is less than this level, then the cylinder is withdrawn from service and sent for maintenance and inspection.

After an external inspection, it is necessary to inspect the valve. It must be completely correct. Also, the cylinder must contain residual pressure. On the outer surface of the cylinder there must be a clearly readable passport, in which there is a mark on the passed examination.

All work on the repair of the cylinder, repair of its outlet, painting, inspection and other technological procedures can only be carried out by the organization that has received a special permit to work with high pressure vessels.

Types of cylinder malfunctions and their elimination

All existing gas cylinder malfunctions are divided into two types: to be eliminated and not to be.

The first type includes:

- incorrect operation of the cylinder valve and pressure gauge;

- shoe damage or displacement;

- damage to the threaded connection;

- gas leak;

- peeling body paint in many places.

The second type of malfunction is a significantly damaged surface of the case in the form of dents, cracks, swelling, lack of marking. In this case, the balloon is rejected.The decision on the possibility or impossibility of repair is made by a specialist with the appropriate qualifications.

When repairing gas cylinders, a simple replacement of defective elements is often performed. Sometimes it is necessary to flush the tank internally and check for corrosion from the inside. Periodic inspection includes all these works, and upon its completion a certificate is issued.

The gas cylinder in the photo is in need of repair. It needs to be painted and the valve replaced. The first work can be done independently, and the second should be entrusted to a specialist.

This should not be done at home. All you can do yourself is paint the cylinder body

This must be done very carefully so as not to paint over the inscriptions and not to damage the markings. All other faults can only be repaired by a specialist workshop or the manufacturer.

At home

The rules for the use of gas cylinders, as well as their manufacture and storage, are set out in several official documents:

- “Industrial Safety Rules for Hazardous Industries Where Equipment Under Excessive Pressure is Used”, approved by Order No. 116 dated 25.03. 2014 Federal Service of Rostekhnadzor.

- PPR in the Russian Federation.

- GOST 15860-84, establishing those. conditions for cylinders with liquefied hydrocarbons pressure up to 1.6 MPa.

The recommendations of the Federal State Institution VNIIPO dated June 13, 2000 on the tactics of fire departments in the event of the possibility of an explosion of gas-balloon equipment in the fire seat provide the following information:

- Cylinders for storage and transportation of liquefied/compressed hydrocarbon gases (LHG) are widely used in various industries, as well as in everyday life.

- In accordance with GOST 15860, 25 enterprises in Russia produce welded steel cylinders for LPG storage.

- Their total number is about 40 million pieces.

- The main types with a capacity of 27.50 liters, which is up to 85% of the total.

Storage and use of gas cylinders

Considering that, according to GOST, the allowable service life of cylinders subject to compliance with the rules, technical examination once every five years is 40 years, it is easy to imagine that in recent years their number has been used both in everyday life for cooking, and at construction sites, in the workshops of industrial enterprises for conducting fire , including gas welding, works only increased; as well as the number of fires where explosions took place, loss of life.

The main requirements of the PB standards for the use of cylinders with propane, butane, their mixture when used in everyday life:

- It is forbidden to store LPG cylinders in private houses, apartments, stairwells, basements / attics, loggias / balconies of multi-storey residential buildings.

- Cookers, gas units for heating water must have an LPG supply from tanks installed outside residential buildings in annexes / cabinets made of non-combustible material located at blank external walls, at least 5 m away from the entrances to the house, basements / plinths. Exception - 1 tank up to 5 liters connected to the stove.

- Cabinets for tanks with LPG must be locked, equipped with blinds for constant ventilation, provided with inscriptions: “Flammable. Gas".

- At the entrances to private houses, townhouses, block sections, premises of buildings where tanks with LPG are used, an inscription / plate is placed: “Flammable. Cylinders with gas.

The simplest precautions are also mentioned - it is forbidden to use household appliances in case of a gas leak that has a characteristic odor; in no case do not check the tightness of any connections of the gas path from the entrance to the apartment to the appliances using an open flame. At home, you can check a gas leak with a soapy solution, but it’s better not to engage in amateur activities; but shut off the supply and, depending on the situation, call representatives of the emergency gas service or a service organization / enterprise

At home, you can check a gas leak with a soapy solution, but it’s better not to engage in amateur activities; but shut off the supply and, depending on the situation, call representatives of the emergency gas service or a service organization / enterprise.

Rules for storing gas cylinders

Types of cylinders by area of use

Gas cylinders are easy to transport and use in places where there is no gas pipeline or other source of gas. All cylinders are classified into groups:

• Tourist (for travelers, hunters, fishermen). These containers have a small volume, designed for heating and cooking in natural conditions.

• Household. Filled with propane or propane-butane mixture. Used in private homes and cottages for connecting gas stoves and boilers.

• Automotive. For vehicles with a gas engine.

• Medical. Most often - oxygen. Are intended for medical and preventive procedures, preparation of oxygen cocktails. The same applies to aviation and rescue services.

• Industrial. Filled with gas for metal welding, electrical engineering, for the needs of the chemical industry.

There are also universal cylinders, but it is preferable to use special ones, since their safety standards and volume correspond to the requirements of operation in certain conditions.

Deciphering the marking of cylinders

By reading the label correctly, you can get complete information about the gas cylinder. If it is a propane cylinder, then its passport is in the valve area, on a metal mug.

The passport of the propane cylinder indicates: working pressure in MPa, test pressure in the same units, volume of the tank in fact in l, serial number, date of manufacture in the form "MM.YY.AA", where the first characters indicate the month, the second - the year , the third - the year of the upcoming certification.

Next comes the weight empty container in kg, the mass of the filled balloon. The last line is the letters "R-AA". "R" - the stamp of the recertification site or the plant. The combination of the characters "AA" reveals information about the year until which this certification will be valid.

The decision on the suitability of the cylinder should be taken only after a complete decoding of all data about it. If defects are found on it, then it is emptied and sent for repair.

The marking of the oxygen cylinder has its own order and consists of four lines. The first contains information about the manufacturer, as well as the container number. The second contains the release date and the recommended review date. In the third - hydraulic and working pressure. In the fourth - the volume of gas and the mass of the cylinder without a valve and a cap.

When buying a balloon, you should pay attention to how information is applied to it. On the body, it is not applied with paint, but is beaten out, and then covered with a special colorless varnish in order to protect against corrosion

Often the last line contains the brand of the manufacturer.

This is interesting: Dewalt Cordless Drill Driver - Consider Together

Rules for the safe operation of propane cylinders

- During use and storage, overheating of cylinders should not be allowed (for example, left in direct sunlight for a long time);

- it is not recommended to etch the propane-butane mixture until the tank is completely empty (under certain conditions it can suck in air, and this is dangerous);

- when transporting, be sure to use plugs and protective caps;

- in case of detection of dents or other defects, the product must be sent for an unscheduled recheck;

- individuals are allowed to transport no more than five cylinders in one vehicle (they must be separated by gaskets from each other).

- it is necessary to constantly monitor the condition of the cylinders, because it is not in vain that they are considered fire and explosive objects.

What is the gas pressure in a propane tank?

According to GOST 15860-84, the working pressure in the tank should not exceed 1.6 MPa. In this case, the proportion of propane in the hydrocarbon mixture must be at least 60%

This is very important for the safe operation of LPG installations. Of course, products are designed for a much higher pressure - more than 5.0 MPa

Production and periodic tests are carried out at a pressure of 3.0 MPa.

Refueling rates

At gas cylinder filling stations, employees are familiar with the regulations. Since an overfilled cylinder can explode or its valve can be torn off. So, if you refuel from a reliable supplier, you have nothing to worry about.

| Cylinder type (l) | 5 | 12 | 27 | 50 |

| The maximum allowable amount of propane, l | 3,5 | 8,4 | 18,9 | 35 |

Elements of sustainability and volume

It allows you to stably set the container in a vertical position, which is important when welding. During operation, you can move the cylinder together with the semi-automatic welding machine on a special trolley. It is a convenient method of maintaining a welding spot in any work area.

This is a convenient method of maintaining a welding spot in any work area.

On sale are containers from 10 liters to 40 liters. It seems tempting to purchase for welding a smaller volume. Its price is less, but after using gas, it will not be so easy to fill a new one.

Most gas stations are designed to fill 40 liters. The exception is carbon dioxide. Due to the fact that it is pumped into fire extinguishers, the capabilities of gas stations allow filling small volumes.

What are the requirements for the placement of individual balloon installations?

What are the requirements for accommodation individual balloon installations?

Clause 7.2, 7.4-7.6 PBGH.

P. 9.49, 9.54 SNiP 2.04.08-87 "Gas supply".

It is allowed to provide individual balloon installations both outside and inside buildings. When supplying LPG with a high butane content, it is necessary to provide for the placement of cylinders, as a rule, inside buildings. Placement of cylinders inside buildings with more than two floors is not allowed.

Cylinders placed during the installation of liquefied gas cylinder installations in a building must be located in the same rooms as gas appliances. Moreover, in one room it is placed to install, as a rule, one cylinder with a capacity of not more than 50 liters.

It is allowed to install two cylinders with a capacity of not more than 27 liters in one room. Each (one of them is spare).

Cylinders placed indoors must be located at least 0.5 m from the gas stove and 1 m from the heating radiator or stove. When installing a screen that protects the cylinders from heating, the distance between the cylinder and the heater can be reduced to 0.5 m. The distance between the cylinder and the screen must be at least 10 cm. When placing the cylinder against the furnace doors, the distance between the cylinder and the furnace door should be at least 2 m.

Outside buildings, cylinders must be placed in lockable cabinets or under lockable covers that cover the top of the cylinders and the gearbox. Cabinets and casing should have slots or louvres for ventilation.

Cylinders near the walls of buildings should be installed at a distance of at least 0.5 m from the doors and windows of the first floor and 3 m from the windows and doors of the basement and basement floors, as well as sewer wells and cesspools.

It is not allowed to place cylinders at emergency (fire) exits of their premises, from the side of the main facades of buildings, in driveways with heavy traffic. Cylinders placed on the sunny side must have shade protection or a canopy. Cabinets for cylinders and cylinders under lockable casings must be installed on non-combustible bases, excluding subsidence, fastened to the bases or to the walls of buildings. The height of the base must be at least 0.1 m from the ground level.

Gas supply of LPG units, installations and various burners located in the basement and basement is not allowed.

The installation of LPG cylinders in industrial premises should be provided in places protected from damage by internal transport, metal splashes and exposure to corrosive liquids and gases, as well as from heating above 45 ° C.

It is allowed to place cylinders directly at units that consume gas, if this is provided for by the design of the unit.

Each cylinder installation, both with the placement of cylinders in the building and outside it, must have a regulator (reducer) to reduce gas pressure. Pressure regulators mounted on cylinders located inside the building should not have a safety relief valve.

Rules for using the cylinder

For any type of welding, the following algorithm of actions is used:

- Pre-prepare the connected elements.

- Determine the welding mode.

- Connect the controlled protective atmosphere to the welding machine via a hose and reducer.

- Set the operating pressure of the medium.

- Open the valve on the cylinder without sudden movements.

- After 30 seconds, ignite the electric arc.

At the end of work, the protective atmosphere should be turned off no sooner than after 20 seconds. After emptying the gas tank, the latter must be disposed of, and a new one must be bought in the distribution network. Only 40-liter cylinders are subject to refueling at enterprises.

Standard sizes of gas cylinder 50l

50-liter gas cylinder - its dimensions are standard. The height is 96, and the width in diameter is 29.9 cm. The thickness of the steel wall is 3 mm, and the weight is 22 kg. For cylinders of this volume, the working pressure is up to 1.6 MPa (kg / cm2). Well suited for gas transportation, gas storage, and bulk production applications.

Gas cylinder 40 liters and its dimensions

40 liter gas cylinders have the same diameter as 50 liter ones, but their height is different, and can reach 146 cm. It is also used for storage, transportation and bulk work.The working pressure in 40 liter cylinders can vary, and besides 1.6 MPa (kg/cm2), it can also be 1.47 MPa (kg/cm2). Gas containers with a volume of 27 liters are considered convenient and are used in everyday life. The height of the container is 59 cm with a diameter of 29.9 cm, which is convenient for location in the kitchen, in case of bringing the gas cylinder to the stove.

The working pressure of gas in a 27 liter cylinder, as well as in a 50 liter one, is 1.6 MPa (kg / cm2), which is standard for all household gas vessels.

The weight of an empty cylinder of 14.5 kg will not become an obstacle for its movement, but it is important to remember that it is better to give an empty cylinder to a gas station immediately than to store it at home

Dimensions of household gas cylinders

Household gas cylinders differ in volumetric capacity of gas and can be: 2, 12, 27 and 50 liters. The diameter of 5 and 12 liter cylinders is 22.2 cm. The height varies and depends on the capacity: 5 liter - 28.5 cm, and 12 liter - 48.5 cm. And since the gas cylinder has different sizes, the mass of the empty container will be different. A 5 liter jar has a weight of 4 kg, and a 12 liter vessel has a weight of 6 kg. Such small containers are very convenient for summer residents. They do not need to heat the house all year round, and for the cooking season these are quite suitable volumes.

Dimensions of gas cylinders for cars

One of the requirements for a car gas cylinder was originally its compactness and that it could easily fit in the trunk. The developers took this requirement into account, and as a result, they issued gas tanks for cars with a length of 66.5 to 121.5 cm and a diameter of 35.6 cm. not one day.

Dimensions of toroidal gas cylinders - novelties in our market

On the Ukrainian market, there are also toroidal gas cylinders that are used to equip cars, and due to their shape they fit very well in the spare wheel compartment, saving space in the car trunk. Their capacity is from 40 to 42 liters, and the average size is 60x20 cm.