- Installation manufacturing process

- How to make a vibrating table with your own hands drawings

- Manufacturing of structural elements

- bed

- Elastic elements

- Eccentric

- Basic structural elements

- How to do it yourself?

- Universal vibrating table - design features

- Step-by-step instructions for making a vibrating table with horizontal vibration

- Materials and tools needed to assemble a vibrating table: prices and specifications

- Making a vibrating table

- bed

- table platform

- Engine installation

- homemade drive

- What is the device, requirements for its operation

- Note to craftsmen

- Other options to make your own vibrator at home

- Video: internal vibrator from a water pump engine

- Video: deep vibrator from a trimmer

- Instructions for the manufacture of vibrating tables

- Frequency and cycle of use of the vibration motor

Installation manufacturing process

The most difficult step in designing a homemade vibrating table at home is the selection of a suitable electric motor. A good option is the engine from the washing machine, the only drawback of which is the fragility due to bearing wear or axle disconnection.

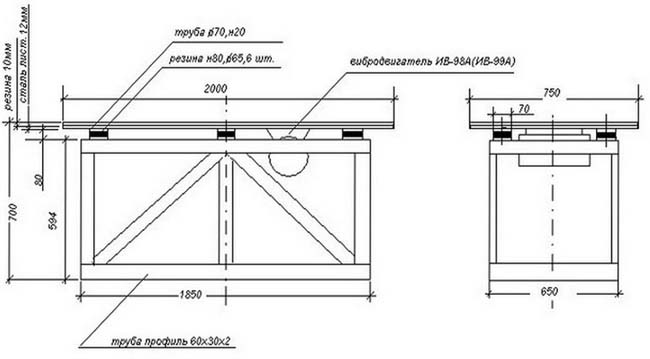

Before proceeding with the manufacture of the installation, it is necessary to find a drawing of the vibrating table in the relevant literature or on the Internet. Further work is recommended to be carried out in accordance with it.

Before proceeding with the manufacture of the installation, it is necessary to find a drawing of the vibrating table in the relevant literature or on the Internet. Further work is recommended to be carried out in accordance with it.

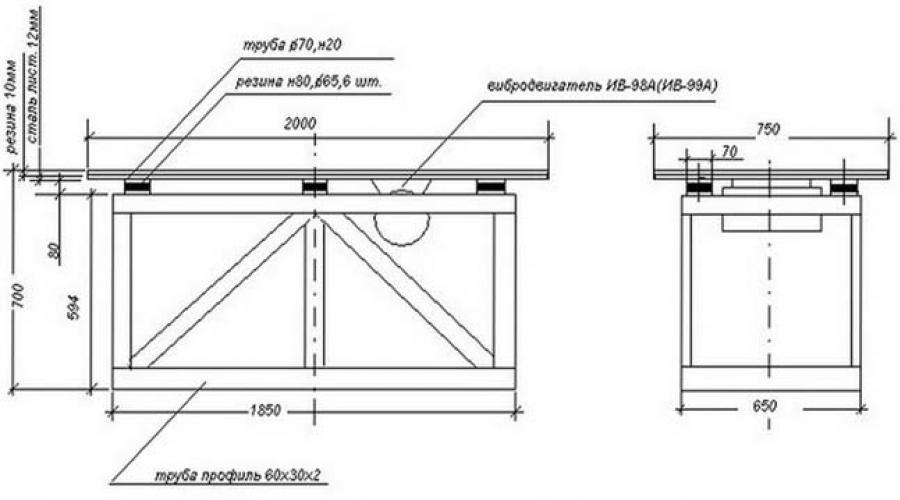

- The base is made from a channel or corner. The size can be arbitrary, experts consider 700x700 mm as standard. When planning the area of the working space, remember that it must correspond to the power of the electromechanical motor used.

- Support. The legs of the vibrating table are metal pipes. They are welded to the base using a welding machine. To ensure maximum stability, metal plates are attached to the legs, which are then fixed with concrete mortar. If there is a need to move the vibrating table, then you should not do this. Then the stability will depend on the quality of the flooring. The height of the table is chosen arbitrarily, but it should ensure the convenience of the wizard. The engine should be located at some distance from the floor.

- Springs are located in each corner and in the center of the structure and are welded to it. They can be taken from a moped or car and cut in two. They will ensure the vibration of the tabletop during the operation of the electric motor. Plates are welded to them, fixed on a metal sheet, the thickness of which should be at least 8 mm. If a thinner base is used, deformation of the working part may occur.

- The engine is attached to a square welded across the vibrating table on springs. Low-amplitude oscillations with a high frequency are provided by an eccentric, which is made of a metal washer, put on the motor shaft.On the side, a hole is made in it and a thread is created by 8. Amplitude adjustment is achieved by screwing in or unscrewing the bolt, which is fixed in the washer with a control nut.

You can simplify the work and purchase an unbalanced engine in the store. For this purpose, the IV-99 E 220 V vibrator is excellent. Its cost is 6000 rubles and it copes with the task perfectly. It will not be superfluous to purchase an alternating current potentiometer, which will allow, by changing the voltage, to adjust the oscillation frequency for each type of concrete mixture used.

The use of vibrating tables for the manufacture of paving slabs has a number of advantages. This is not only the strength and high quality of products, but also significant savings: hard mixes with a small amount of cement can be used without loss in quality. The performance of a homemade vibrating table reaches 50-60 m2 of tiles per day. This amount is enough to run a successful business for the production and sale of products for paving sidewalk paths.

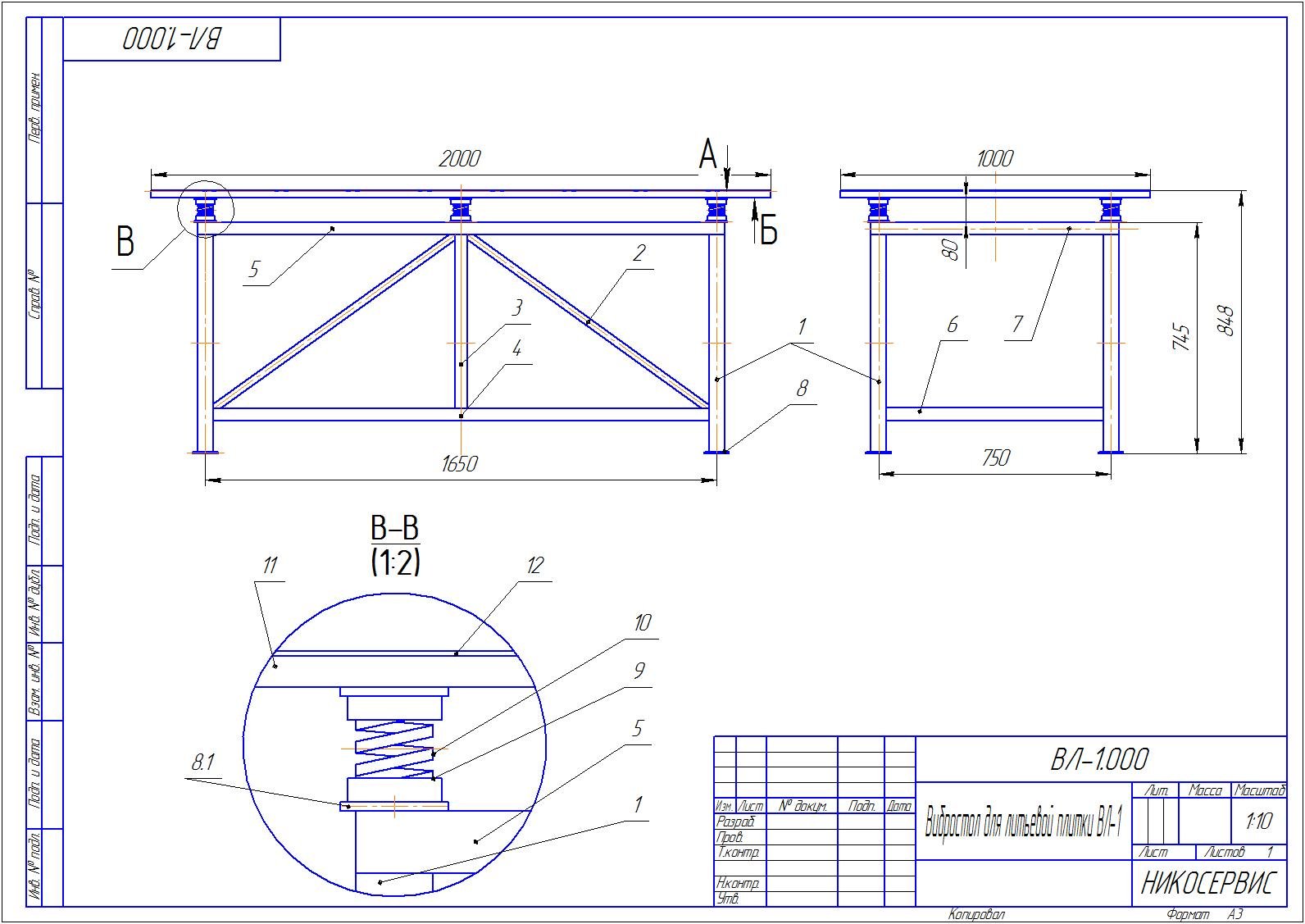

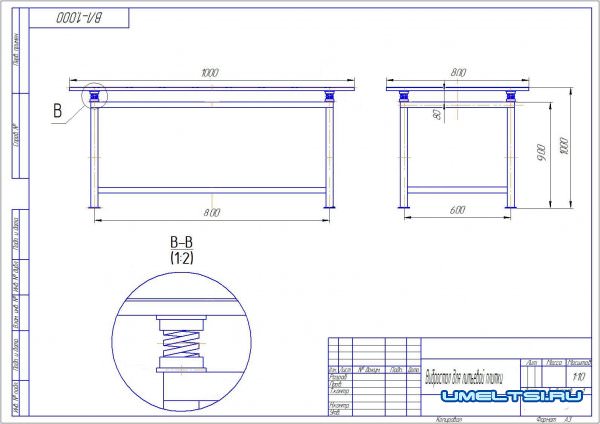

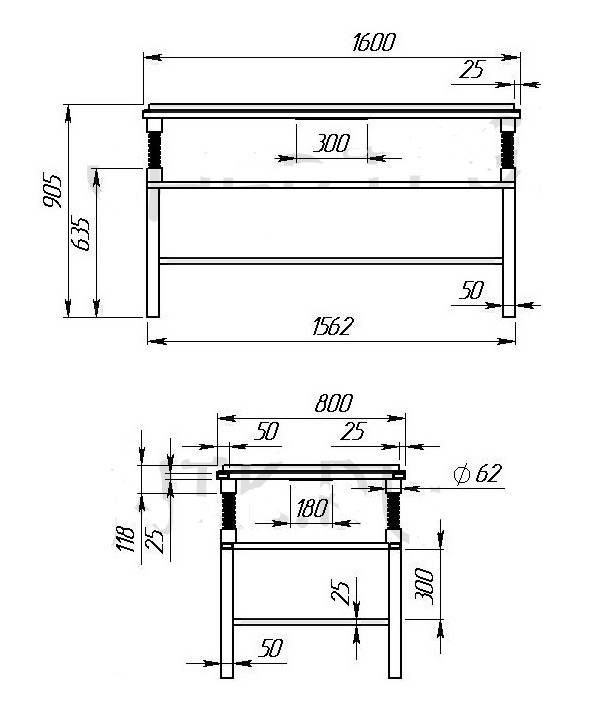

How to make a vibrating table with your own hands drawings

How to make a vibrating table with your own hands, drawings, diagrams, description.

The main purpose of the vibrating table

The vibration of the table allows you to expel excess air from the concrete solution, which in turn improves the strength properties of the concrete product.

What nodes does the structure consist of:

• base (metal frame) • tabletop (working plane of the table) • springs (round or rectangular section) • vibrator (platform single-phase vibrator)

BASE

Prepare the necessary material:

• rectangular metal pipe 25x50x3 (mm) GOST 8645-68 • square metal pipe 50x50x3 (mm) GOST 8639-82 • metal pipe 63.5x3.5 (mm) GOST 8734-75 • sheet metal thickness 4 (mm) GOST 19903- 74

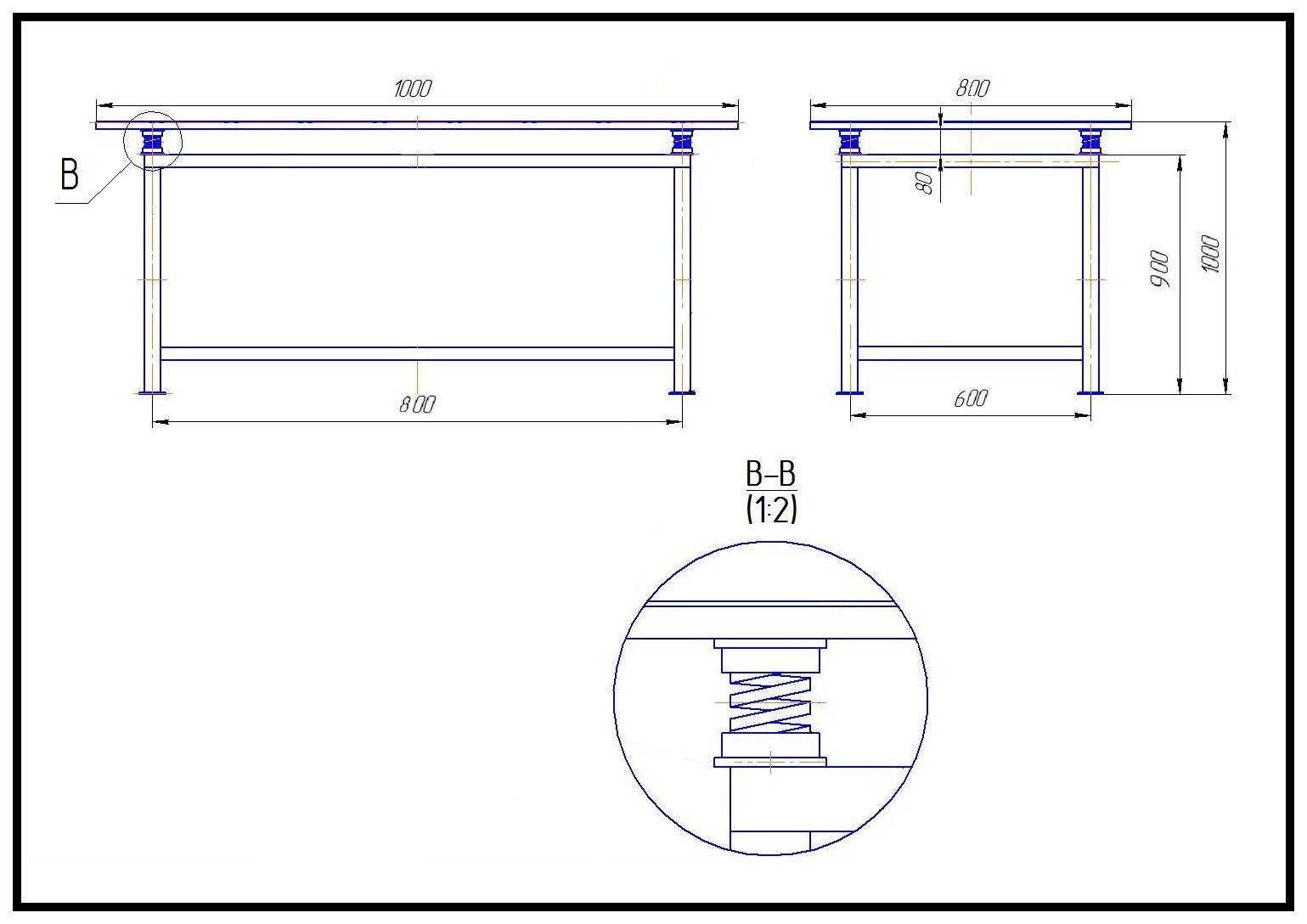

And so, how to make a vibrating table with your own hands according to the presented drawing?

From the pipes we will cut blanks of the required length. We cut square blanks from sheet metal and drill four through holes in each (at the corners). We weld all the parts together and get a rigid base, which we fix to the floor surface with an anchor connection.

WORKTOP

Prepare the necessary material:

• rectangular metal pipe 25x50x3 (mm) • metal pipe 63.5x3.5 (mm) • hot-rolled equal-shelf metal corner 25x25x3 (mm) GOST 8509-93 • sheet metal 3 thick (mm) • sheet metal 5 thick (mm)

According to the drawing

Prepare the blanks and weld them together. The corner, welded around the perimeter of the table, will be its boundary and hold its shape during the operation of the mechanism.

From the bottom of the table we will weld a metal plate with mounting holes for the vibrator.

SPRINGS

We choose from a standard range of manufacturers GOST 18793-80, the rigidity of which is taken based on operational loads.

VIBRATOR

We choose from the model range of domestic manufacturers, you can use the IV-99E brand

Specifications:

• operating voltage, V - 220; current consumption, A - 1.9; power consumption, W - 250; weight, kg - 14.5

The wiring diagram is in the vibrator's instruction manual.

Assembly order:

1. We fix the base to the floor.

2. We insert springs into the pipes at the corners.3. We fix the vibrator from the bottom of the countertop.4. We install the tabletop on the springs with the pipes down.

How to make a vibrating table with your own hands, drawings and a detailed description of the design at hand, all that remains is a desire, and allocate some free time.

Manufacturing of structural elements

Before you make a vibrating table yourself, you should draw up a detailed drawing. So it will be possible to calculate the amount of material and take into account the nuances of the design at the development stage.

You can use ready-made drawings of the vibrating table. During operation, strictly observe the specified dimensions.

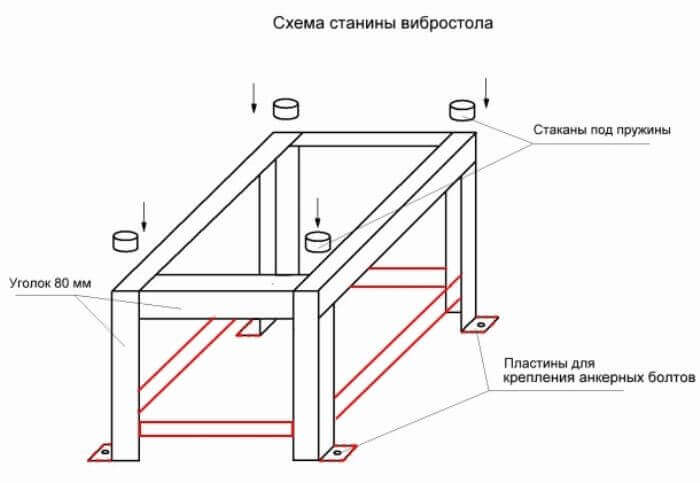

bed

To make the base, 4, 6 or 8 metal pipes are vertically installed. Between themselves they are welded with transverse stripes or corners. For work, a flat area is selected. The top and bottom edges of the pipes must be in the same horizontal plane. To do this, use the water building level.

In the lower part, pieces of sheet metal are attached to the legs. Holes are made in them for fastening to the floor covering. On the other hand, glasses from pipe scraps or brackets for attaching elastic pillows are installed on the legs.

A box is mounted on one of the sides, designed to mount the control unit. The height of the location is selected so that the operator does not lean towards the buttons during operation.

The vibrating table is attached to the floor covering. To avoid displacement of equipment when ramming building mixtures, the legs are securely fixed to the floor with anchors. Under the action of vibration, threaded connections are spontaneously unscrewed. To eliminate this, a lock washer is installed under the anchor nut.

Elastic elements

In the upper part of the frame, spring parts are installed. The method of fastening is selected based on the type of element. Metal springs are mounted in glasses.automobile pillows are screwed with a threaded connection. At this stage, several rules are followed:

- The length of the springs must be the same. Skewed top surface will cause the molds to slip during operation. It will be impossible to use the vibrating table.

- When fixing the elastic elements, lock nuts are installed.

- The height of the springs must be sufficient so that the top surface and the frame do not come into contact with each other under the influence of the weight of building mixtures on the vibrating table.

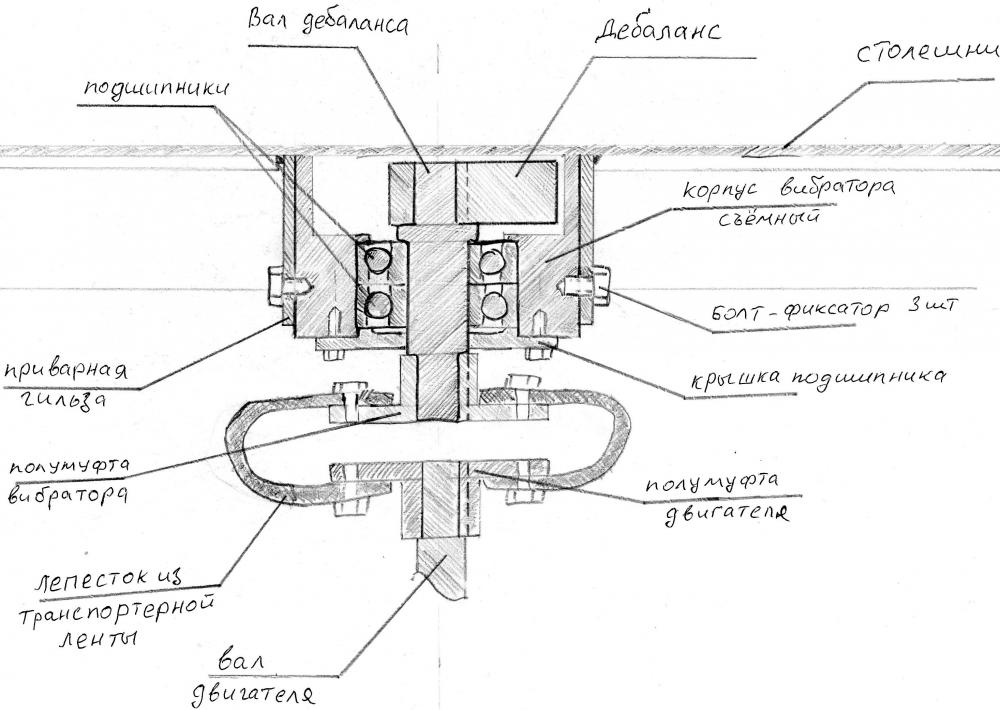

Eccentric

Oscillatory movements are transmitted to the vibrating table from a motor with an eccentric on the rotor shaft. It is a part with a displaced center of gravity. When the armature of the electric motor rotates, vibrations are formed under the action of centrifugal force. The force of vibrations transmitted to the vibrating table is changed by shifting the center of gravity. You can make the details yourself:

- Cut out 2 ovals from sheet metal 8-10 mm thick.

- Connect the workpieces to each other. In this case, a clamp or vice is used.

- Drill holes for attachment to the rotor shaft. The holes are not located in the center of the parts, but with an offset.

- A compass draws a line at the same distance from the hole made.

- Drill several holes along the line. They are needed to make the fastening of the ovals a threaded connection.

After that, the parts are installed on the armature of the electric motor. During operation, the center of gravity of the eccentric is changed by shifting one shaft relative to the other.

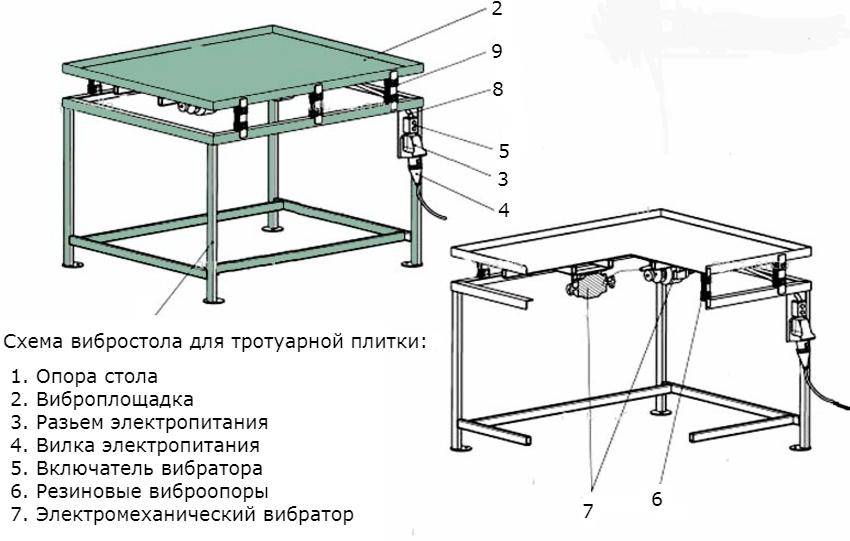

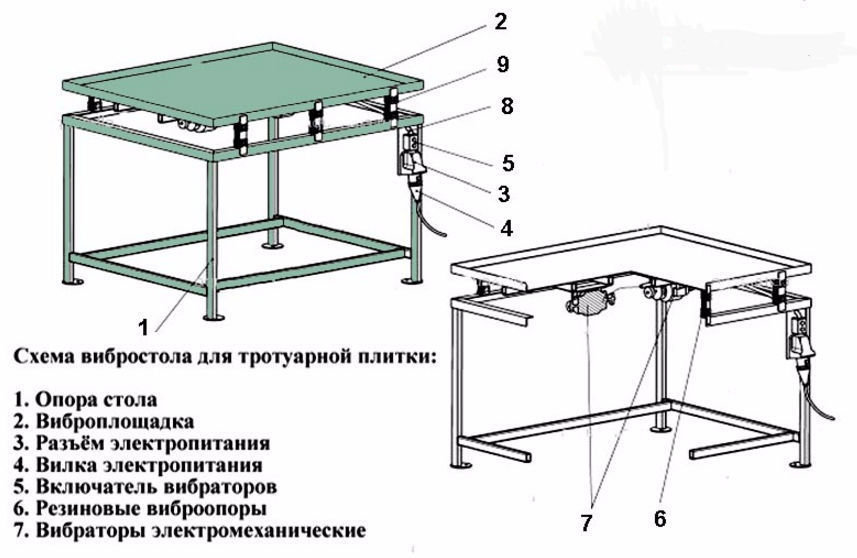

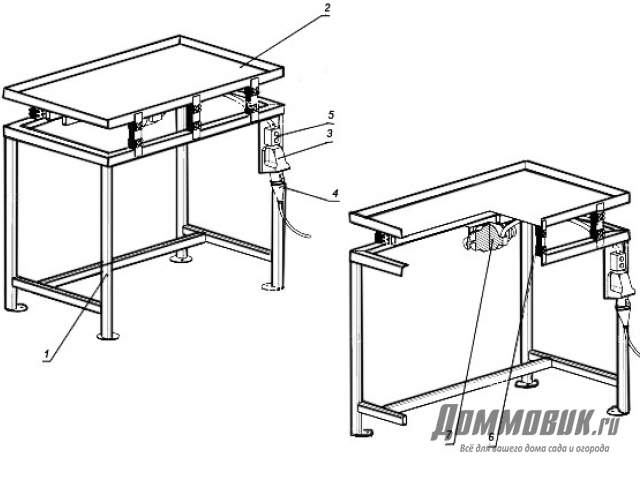

Basic structural elements

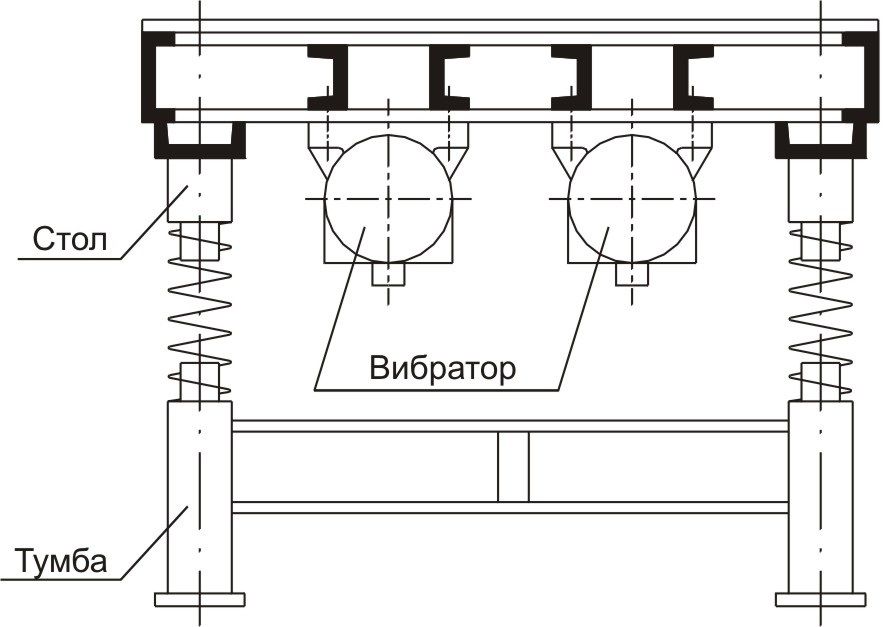

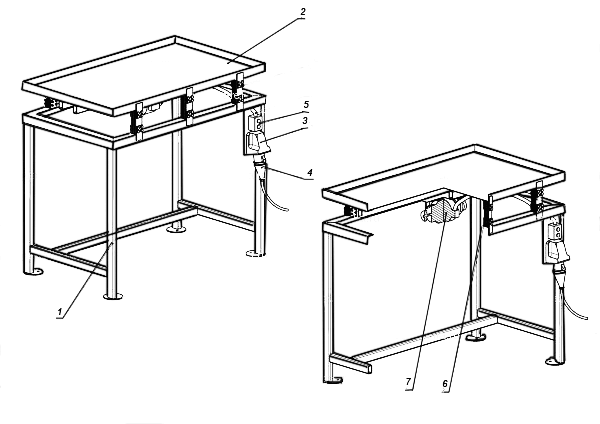

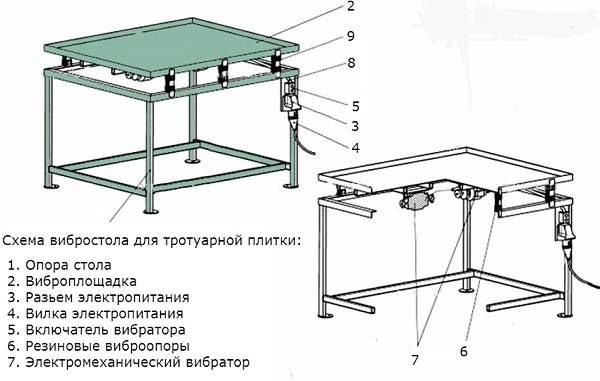

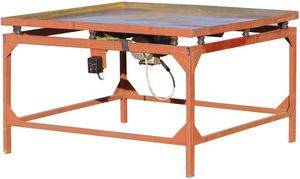

In fact, the table consists of three large elements: a base, a vibrating tabletop with corresponding movable supports, and a drive that creates force for vibration.

If we consider the design in more detail, we can distinguish:

- power frame of the product. It consists of four racks connected by longitudinal beams. For the manufacture of these elements, rolled metal is used - a profile pipe, a corner, a channel, and so on;

- countertop. A flat slab (usually made of sheet metal) must be provided with sides. This is necessary so that the forms with the solution installed on it do not “move out” from the table during vibration;

- socket for power supply;

- respectively the plug of the power supply wire;

- toggle switch to turn on the vibrator;

- shock absorbers (springs). These devices soften jerks during vibrations of the tabletop, make the vibrations more uniform and smooth;

- electromechanical vibrator.

Interesting: depending on the power of the vibrator and the dimensions of the table, the device can be used to compact not only paving slabs, but also blocks of various sizes.

The dimensions of the mechanism can be varied. Considering that the main "reference point" in the calculations is the size of the form, it is better to make the length / width of the table a multiple of the length / width of the most commonly used forms. At the same time, do not forget about a small margin: although the forms are placed on the countertop as tightly as possible, there should be a small gap between them.

How to do it yourself?

Buying a vibrating table is expensive, although its purchase will help you get started faster. And yet, we will do it ourselves and we need the following tool for this:

- Welding machine. For such work, a 190 A inverter is suitable.

- Bulgarian.It is desirable to have two varieties, 230 mm and 120 mm in disc diameter. A large one will be convenient to cut, a small one will adjust parts and subsequently grind the weld.

- Electrodes, tape measure, pencil and chalk, drill, as well as bolts, nuts, drills, drill and other tools that may be required in the work.

So, first you need to weld the legs of the table. The easiest way to make them from a professional pipe. A professional pipe is suitable, with a metal wall thickness of at least 2 mm, preferably 3 mm. The basis is best cooked based on the area of the table top, which must be calculated individually, taking into account the power of the engine and the forms that will be laid at a time.

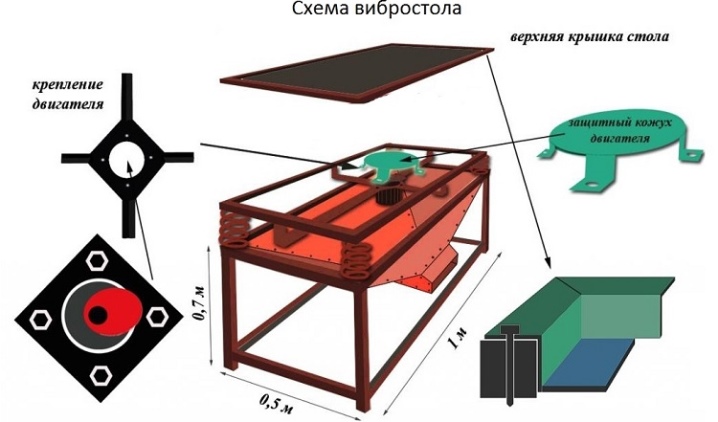

Vibrating table scheme

We weld the legs from below and above the professional pipes. It is advisable to buy adjustable legs, which in the future will help to level the table. From the top of the table, along the perimeter, it is recommended to weld the base under the springs. At least 4 springs, but it is better to put 6-8. As a basis, it is best to use round pipe trimmings of a suitable internal diameter. The spring should enter freely.

As for the springs, their stiffness is selected individually, depending on the load on the table, plus the weight of the countertop itself. Many people recommend taking shock absorbers from a moped, but if they are not at hand, you can go to any car store and buy what you need.

Next, make a countertop. From the bottom, along the perimeter, a frame is also cooked under it, preferably from a profile pipe. In places where the springs touch, also cut off a round pipe so that the spring does not move out. In the center of the table frame, from the bottom, two crossbars are welded, holes of the required diameter are made in them for the bolts for installing the engine.A frame is welded from the outside so that in the process of work the “forms” filled with concrete do not run over the edge of the table. You can cook pointwise, using the thinnest corner or a professional pipe 20 n 20 for the curb. For the countertop itself, you can use sheet steel, 2-3 mm thick.

Next, we refine the engine. The easiest way is to weld an eccentric to it. It is understood as an ordinary bolt, which is welded onto the shaft with a head. Take the bolt longer, but so that during rotation it does not rest against the table top. On the bolt, after welding, individually, screw the nuts. By increasing or decreasing their number, you will adjust the vibration and vibration level.

Vibrating table drawing

As for the engine, it is recommended to use a model with a power of at least 1000 watts. There will be no load on it, the most important thing is that it quickly brings the lid into resonance from rotation. Be sure to connect it through the button, which you place on the surface of the case. Before installation, draw approximate drawings of a vibrating table for paving slabs with your own hands, on the basis of which you assemble.

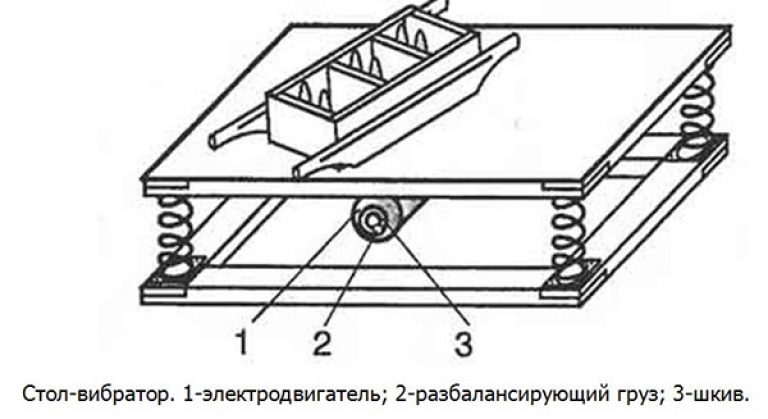

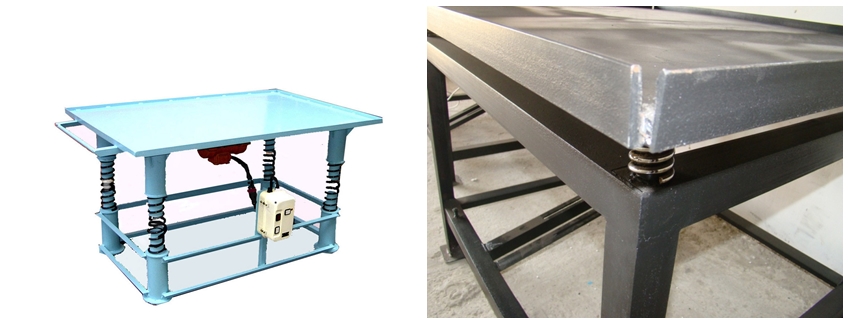

Universal vibrating table - design features

Vibration platform (table) is a technical device that includes the following components:

- Support frame made in the form of a metal frame. The welded frame structure must be rigid and massive to ensure the stability of the unit.

-

A working platform in the form of a steel horizontally located and ideally smooth table top. The movable fastening of the plate to the frame is carried out with the help of four rigid springs.

- The drive mechanism is rigidly fixed on the bottom of the steel plate.The motor for the vibrating table rotates an eccentrically fixed load, transmitting the vibrations of the working surface.

- A starting device, which is a start button (vibration mode) and a stop button (stop position) assembled in a common housing. The connection diagram also uses a thermal and current relay that protects the vibration motor from overloads.

An important design feature of the vibrating table is:

- ensuring uniform vibrations of the tabletop;

- small amplitude of oscillations.

Step-by-step instructions for making a vibrating table with horizontal vibration

The first thing you should pay attention to before starting work is the size of the countertop. It is believed that the minimum surface size should be 600x600, since with narrower sides, the forms will fall in the process of movement.

In addition, a narrow design will have less stability.

In many ways, the size of the vibrating table is determined by the required production volume. We can say that there is a direct relationship here - the more elements must be made at a time, the larger the countertop area should be. Naturally, a large vibropress will require a more powerful engine, and the materials from which the structure will be assembled must be very durable.

Vibrating table base and unbalance fastening

As for the height of the vibrating table, everything here depends on the individual data of the person who has to work on it. The standard height, optimally suited for a person of average height, is considered to be 90-100 cm.

Materials and tools needed to assemble a vibrating table: prices and specifications

In order to independently assemble the structure, you will need a grinder, a welding machine, a drill, as well as the ability to handle them.Consider a list of necessary materials that can be found among the handy materials.

An example of the implementation of a vibrating table for the manufacture of paving slabs with a molding nozzle

For the countertop, you can use plywood or a sheet of metal of a suitable size. In this case, the plywood sheet should be 14 mm thick. This will allow you to transmit more vibration due to the small thickness, but at the same time provide the necessary structural strength. In addition, this way you can significantly reduce the noise level during operation of the device. If a metal sheet is used, then its thickness should be in the range of 5-10 mm.

The cost of a sheet of plywood of the required thickness, made from birch veneer, will be about 650 rubles with a standard size of 1525 × 1525 mm. But a sheet of hot-rolled metal 5 mm thick will cost more, about 1000 rubles.

Unbalances are used to excite oscillations in the vibration mechanism of the vibrating table

Metal corners 50×50 mm in size. They will be required to create the edging of the table top and during the operation of the vibrating table will not allow the forms to production of paving slabs move off the surface due to vibration. Their cost will be about 140 rubles per 1 r.m.

Channel for mounting the motor (about 210 rubles / m.p.). It will need to be welded in the center of the back of the tabletop, pre-drilled holes that will be used for the bolts holding the motor.

Metal pipes for table legs. Typically, elements 2 mm thick and 40 × 40 in size are used for this purpose. The price will be 107 rubles per 1 r.m.

Reliability of fastenings of all elements of the vibrating table ensures the correct operation of the device, the quality of the manufactured products and the duration of the service life

Pipes for forming the upper and lower parts of the frame. Since the main load will fall on these elements, it is worth choosing a fairly strong material - 40 × 20 and 2 mm thick for the upper part and at least 20 × 20 of the same thickness for the bottom. The cost will be 84 rubles/m.p. and 53 rubles / m.p. respectively.

Metal plates to be used as soles for supporting feet. For this, pieces of metal with a size of at least 50 × 50 and a thickness of 2 mm are suitable.

You will also need a plate for installing electrical equipment and springs, which are designed to provide vibration. It is quite possible to purchase these items at auto-dismantling. Numerous reviews indicate that the ideal option is to use springs from mopeds, the cost of which, with a height of 113 mm and a diameter of 54 mm will be about 500 rubles. They are installed in the corners of the table, and with a large surface area, another one is additionally mounted in the center.

Vibrating table for the manufacture of paving slabs can be made from improvised materials without significant financial investments

Making a vibrating table

In order for the device to work for a long time and efficiently, the following recommendations should be followed when assembling the structure:

- Before starting the process, all metal elements should be coated with an anti-corrosion material to prevent rust.

- Only a seam is used to connect the elements (no spot welding).

- When creating a collapsible structure (on bolts), regular tightening of the joints during operation is required.

- Under no circumstances should the vibration motor come into contact with the ground or the floor. To avoid this, the device must first be tested and, if necessary, make changes to the design.

- The working surface of the vibrating table must be flat and not skewed, which will ensure an even distribution of fractions throughout the product. To do this, the legs of the unit are attached to the ground or floor with anchors or concreting.

- The engine is recommended to be placed in the center of mass of the metal structure.

bed

The optimal height of the fixed support is considered to be 0.8-0.85 m, which, together with shock absorbers and a vibration platform, makes this parameter equal to 0.9-1 m. For people with a height of 155 to 190 cm, these are quite comfortable working conditions.

A common practice is to assemble the bed in the following sequence:

- 2 frames of the selected size are welded;

- 4 legs are welded to them;

- diagonals can be welded to provide additional strength;

- a plate is welded to the racks to place a socket and a push-button switch on it.

table platform

The tabletop is made from a single sheet of metal with a thickness of at least 5 mm. If the sheet is thinner, it needs to be reinforced from below with a support frame or platform made of wood, plywood or chipboard. Common dimensions are 60x60 cm, but they are determined individually, based on the needs of production and engine power.

A corner of 25x25 mm (32x32) is welded along the perimeter in order to create a fencing rim so that the molds do not fall from the surface during operation. To remove excess concrete, grooves should be provided in the sides.

Engine installation

To install the vibration motor on the bottom side of the plate, 2 channels are welded with holes for fastening the paws. To create horizontal oscillations, they are welded vertically, and vertical oscillations - horizontally. An important point is to prevent moisture from entering the motor from the surface of the molding site. This can lead to a short circuit, fire and failure of the entire unit.

homemade drive

The simplest homemade construction that can be completed in less than an hour is a sheet of plywood with an unbalanced engine attached to it from below, mounted on 2 car tires from a truck connected with screws. The dense rubber from which they are made acts as a bed and shock absorber. The performance of such a device will be low, you will need to constantly monitor that the forms with the solution do not fall from the surface, but it will cope with the task of compacting concrete and getting rid of air bubbles.

What is the device, requirements for its operation

The process of solidification of concrete, accompanied by small frequent fluctuations, proceeds with the release of air bubbles, compaction of the concrete structure and an increase in the density and strength of the material. To ensure this mode, a vibrating table is used. It is a surface that makes frequent oscillatory movements (about 3000 / min).

Forms filled with concrete are installed on this surface and vibration treatment is performed. The mode significantly compacts the structure of concrete, which significantly affects the quality of paving slabs, the operating conditions of which require great strength.

There are different types of devices, from large industrial ones with a hydraulic source of vibration for processing large concrete blocks, to smaller electric ones that create vibration using an eccentric mounted on an electric motor shaft. Since only the second option is available at home, we will not consider the hydraulic drive device.

The frequency and amplitude of vibrations are characteristics that determine the texture of the processed material. They are set up empirically, it is too difficult to calculate all the nuances in advance, because too many variables are involved in the process.

Therefore, the design of the table should provide for the possibility of some adjustment of the oscillation amplitude.

Find out on our website how to lay paths in the country from paving slabs. Let's talk about the successive stages of the work performed.

About which tile is better - vibrocast or vibropressed, and how to make a choice, read in our special review.

And in this article you will find a lot of useful information about preparing the site for laying paving slabs.

Note to craftsmen

When compacting concrete with an internal vibrator, the appropriate recommendations must be followed.

- Freshly poured mortar may contain about 50% air. The percentage depends on the brand of cement and the degree of its mobility. These voids must be eliminated by using a deep vibrator.

- A battery-powered vibrator must reach all the places of the poured foundation, otherwise the remaining voids will bring trouble in the future.

- Remember that it is impossible to stop pouring the foundation in any case, so you need to constantly monitor the operation of the vibrator so that it does not break at an unforeseen moment.

- To avoid the formation of air voids in the solution, the foundation must be poured from a low height.

- The tip of the device is recommended to be immersed in the solution only vertically and not to make horizontal movements.

- You should always exercise control over the distance between the points of immersion. It should not exceed 10 times the diameter of the tip itself.

- When pouring a layered foundation, the tip must be immersed in each previous layer by at least ten centimeters in order to ensure the strongest adhesion of all layers.

- If you hold the vibrator for too long at one point, the concrete may delaminate. The operating time of the device is from 5 to 15 seconds. The frequency depends on the brand of cement and the power of the vibration device.

- The working tip must not touch the walls of the formwork or the reinforcement structure.

- Remove the tip carefully, making slow “up and down” movements so that street air does not get into the place where it was located.

- If there are no bubbles on the entire surface of the concrete, then the work was done correctly.

- The factory vibrator must not be turned on “idle”, as this will ruin the device and shorten its life.

Other options to make your own vibrator at home

Although the manufacture of a drill or hammer drill is the most common, there are other options for assembling a deep vibrator at home.It is enough to choose the appropriate vibration source and adapt a suitable vibrotip to it.

Video: internal vibrator from a water pump engine

The main advantage of concrete vibrators made from improvised tools is that you do not have to spend money on the device, and after the work is completed, it is dismantled, and the components can be used for their intended purpose.

Video: deep vibrator from a trimmer

In order to independently pour a monolithic foundation, a vibrator from a drill or a puncher, assembled at home from improvised means, is perfect. Such a tool is not suitable for large-scale construction, but it will be simply indispensable in the construction of structures for a summer residence or a country house. It should be noted that with the length of the device, which will exceed one meter, you will need an assistant to work. When assembling a vibrator at home, it is necessary to make all joints as reliable as possible, since the concrete solution creates strong pressure on the device and is able to actively counteract vibrational vibrations.

Instructions for the manufacture of vibrating tables

If you are not ready to spend money on a unit that will come in handy for you once, but the desire to save money on buying paving slabs is high, you should try to make a vibrating table with your own hands. What is needed to make a vibrating table with your own hands:

- drawing;

- four steel pipes;

- corner (channel);

- metal sheet for the manufacture of countertops;

- grinder or electric scissors for working with metal elements;

- vibration motor for 220 V of the required power and four bolts for fixing it;

- welding machine;

- drill.

In the event that you have everything you need available, you can start making a vibrating table with your own hands.

- The optimal dimensions of the table base are 70 cmx70 cm, however, each craftsman has the right to make a table of such dimensions that meet his needs. The larger the production volume, the wider the vibrating table surface and the more powerful the motor. The base is easy to make from a metal corner (50 × 50 mm is enough) or a channel. Its individual elements can be connected using electric welding or bolts. In the latter case, the design will be collapsible. This is useful if you are going to move it from one object to another. However, the bolts tend to loosen, so the rigidity of the structure will decrease.

- It is necessary to attach legs made of steel pipes to the finished base. To give stability to the unit, metal plates are either welded to them, or they are buried in the ground and poured with cement mortar. The first option is used if a mobile structure is required. In the second case, the table will be stationary.

When making legs, three points must be taken into account:

- the vibration motor must not touch the ground;

- the height of the legs should be such that it is convenient for the master to work without bending down;

- all 4 legs must be exactly the same size, otherwise the tabletop will be at an angle and the concrete mixture will flow out during vibration.

After you have prepared the base, it's time to start making the countertop. To do this, six steel springs must be fixed to each corner, as well as to the center of the base. You can buy them at the car market. Springs from a moped, cut into two parts, are perfect for making a vibrating table.Springs from shock absorbers or automobile engine valves are also suitable.

After you have prepared the base, it's time to start making the countertop. To do this, six steel springs must be fixed to each corner, as well as to the center of the base. You can buy them at the car market. Springs from a moped, cut into two parts, are perfect for making a vibrating table.Springs from shock absorbers or automobile engine valves are also suitable.

As a working vibrating surface, a sheet of steel with sides is often used, to which a vibration motor is attached from below. The place where it should be fixed is marked on the drawing. Forms are placed on the countertop into which concrete is poured. Another option for the design of the work surface is a steel frame with a sheet of OSB, chipboard or plywood inside.

You can connect the tabletop and the bed in different ways:

- weld the spring with one end to the working surface, and with the other end to the base (one-piece connection);

- fix one end of the spring by electric welding on the tabletop, and insert the other end into a glass with a height equal to a third of the spring, mounted on the frame;

- you can swap the places of attachment of the spring and the location of the glasses.

The vibration motor is fixed on the tabletop motionlessly. If you use the IV-98 or IV-99 models, then the vibration will be very strong. The working surface in this case must be made of steel sheet with a thickness of at least 10 mm or be weighted (concrete ballasts).

This is not required if you take the most ordinary electric motor and install a homemade eccentric on it instead of a pulley. However, you can cut off individual parts of it or drill several holes in it, thus making it unbalanced.

The vibration motor can be positioned in three ways:

- in a horizontal plane (vibration will then turn out to be horizontal);

- in the vertical plane (with horizontal oscillations);

- at an angle of 45 degrees to the countertop (to obtain vibration in all planes).

As you can see, the design is simple and it is quite possible to make a vibrating table with your own hands. There would be a desire.

Frequency and cycle of use of the vibration motor

First of all, it is necessary to determine the frequency of vibration of the engine. It can vary from 750 to 3000 rpm. It may also be necessary to have a high frequency with a small amplitude, or a low frequency of vibration with a large amplitude. In construction, as a rule, vibration motors with a high vibration frequency of 2 to 3 thousand revolutions per minute are used. In this case, a lot depends on the size and weight of the installation.

The higher the frequency, the more the installation structure is subjected to fatigue stresses, therefore, the steel of the load-bearing frame must be stronger and thicker. If the permissible frequency limit is exceeded, the structure will quickly deform. In this case, it is also necessary to take into account the cycle of operation of the installation. With a heavy load and with frequent use of the vibration unit, it is not recommended to use an engine with a frequency of more than 1500 rpm.