- What do you need to pay attention to?

- About homemade windmills for home

- What do you need to pay attention to?

- Homemade wind generator: advantages and disadvantages

- Principle of operation

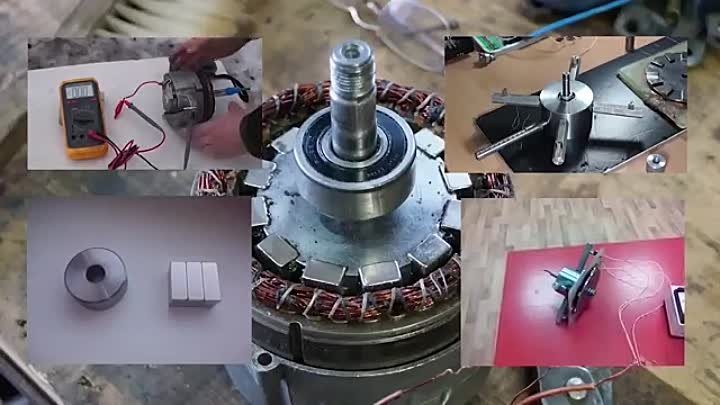

- How is the process of converting a car generator into a wind generator

- Wind turbine operating conditions

- Design choice

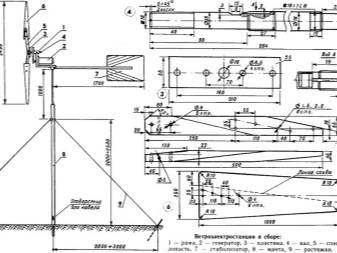

- Schemes and drawings

- Varieties of generators

- According to the location of the generator, the device can be horizontal or vertical

- By nominal generated voltage

- Device maintenance

- Device maintenance

- Manufacturing options

- Design choice

- Using an old computer cooler

- Generator test

- Conclusions and useful video on the topic

What do you need to pay attention to?

When choosing a wind generator for home use, you need to pay attention to the wind utilization factor and, of course, the most important thing is the power. In good home wind turbine options, the coefficient reaches up to 45%, which is very productive.

Power on home appliances starts from 300 W to 10 kW (the second indicator is enough to ensure that all electrical appliances work in your house).

A very important aspect when choosing a windmill for a home is its speed. In standard versions, it ranges from 5 to 7 units.For example, if you chose a windmill with a speed unit of “5”, then this means that with a wind of 10 meters per second, your propeller will spin at a speed of 5 times faster, that is, 50 meters per second.

Both standard wind generators with a horizontal axis of rotation and vertically oriented ones are created, their screw is not a vertical, but a horizontal impeller. When choosing a second device, you do not need to focus on the direction of the wind, but they are more difficult to manufacture, install and operate, so they are not very popular.

From what does efficiency depend on works:

- Designs of a specific unit. A lot depends on this, because each windmill has its own features in the assembly, therefore, each of them will differ in performance. Much depends on the size of the windmill itself and the lightness of its blades. The generator itself (the heart of the whole structure) also plays a significant role.

- The weather conditions of the area where the windmill is installed. As mentioned earlier, it makes no sense to install this thing in a non-windy area. If you install it in low wind conditions, you will not get any benefit from it.

About homemade windmills for home

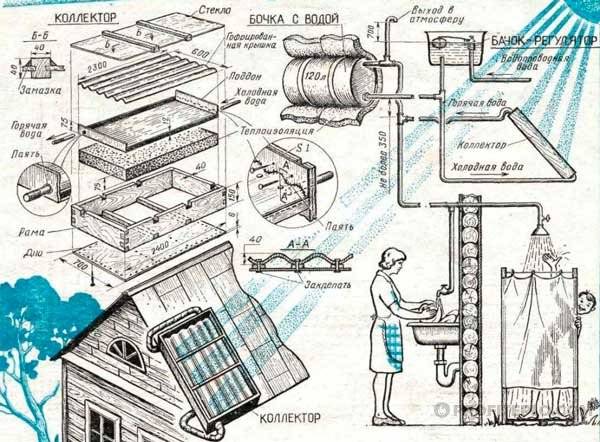

Particular interest in wind energy is manifested at the level of the domestic sphere. This is understandable if you look at the next bill for consumed energy from the corner of your eye. Therefore, all kinds of craftsmen are activated, using all the possibilities of obtaining electricity inexpensively.

One of these possibilities, quite real, is closely related to the windmill from a car generator.A ready-made device - a car generator - just needs to be equipped with correctly made blades in order to be able to remove some value of electrical energy from the generator terminals.

True, it will work effectively only if there is windy weather.

An example from the practice of domestic use of wind generators. A well-designed and quite effective practical design of a windmill. A three-bladed propeller is installed, which is rare for household appliances

The use of virtually any automotive generator is acceptable for windmill construction. But they usually try to pick up a powerful model for business, capable of delivering large currents. Here, at the peak of popularity, the design of generators from trucks, large passenger buses, tractors, etc.

In addition to the generator for the manufacture of a windmill, a number of components will be required:

- propeller two- or three-bladed;

- car battery;

- electrical cable;

- mast, support elements, fasteners.

The propeller design with two or three blades is considered the most optimal for a classic wind generator. But a household project is often far from engineering classics. Therefore, most often they try to pick up ready-made screws for home construction.

An impeller from a car fan that will be used as a propeller for a home wind turbine. Lightness and a large usable area for air force allow the use of such options

Such, for example, can be an impeller from an external unit of a split air conditioning system or from a fan of the same car.But when there is a desire to follow the traditions of designing wind turbines, you will have to build a windmill propeller from start to finish with your own hands.

Before deciding on the assembly and installation of a wind turbine, it is worth evaluating the climatic data of the site and calculating the payback. Significant assistance in this will be provided by the information of a very interesting article, which we recommend for review.

What do you need to pay attention to?

When choosing a wind generator for home use, you need to pay attention to the wind utilization factor and, of course, the most important thing is the power. In good home wind turbine options, the coefficient reaches up to 45%, which is very productive.

Power on home appliances starts from 300 W to 10 kW (the second indicator is enough to ensure that all electrical appliances work in your house).

A very important aspect when choosing a windmill for a home is its speed. In standard versions, it ranges from 5 to 7 units. For example, if you chose a windmill with a speed unit of “5”, then this means that with a wind of 10 meters per second, your propeller will spin at a speed of 5 times faster, that is, 50 meters per second.

Both standard wind generators with a horizontal axis of rotation and vertically oriented ones are created, their screw is not a vertical, but a horizontal impeller. When choosing a second device, you do not need to focus on the direction of the wind, but they are more difficult to manufacture, install and operate, so they are not very popular.

What determines the efficiency of work:

- Designs of a specific unit. A lot depends on this, because each windmill has its own features in the assembly, therefore, each of them will differ in performance. Much depends on the size of the windmill itself and the lightness of its blades. The generator itself (the heart of the whole structure) also plays a significant role.

- The weather conditions of the area where the windmill is installed. As mentioned earlier, it makes no sense to install this thing in a non-windy area. If you install it in low wind conditions, you will not get any benefit from it.

Homemade wind generator: advantages and disadvantages

Installing a wind turbine may be necessary if electricity is not supplied to your site, there are constant interruptions in the power grid, or you want to save on electricity bills. The windmill can be purchased, or you can make your own.

A homemade wind generator has the following advantages:

- It allows you to save money on the purchase of a factory device, because the manufacture is most often made from improvised parts;

- Ideal for your needs and operating conditions, because you calculate the power of the device yourself, taking into account the density and strength of the wind in your area;

- It harmonizes better with the design of the house and landscape design, because the appearance of the windmill depends only on your imagination and skills.

The disadvantages of home-made devices include their unreliability and fragility: home-made products are often made from old engines from household appliances and cars, so they quickly fail. However, in order for the wind turbine to be efficient, it is necessary to correctly calculate the power of the device.

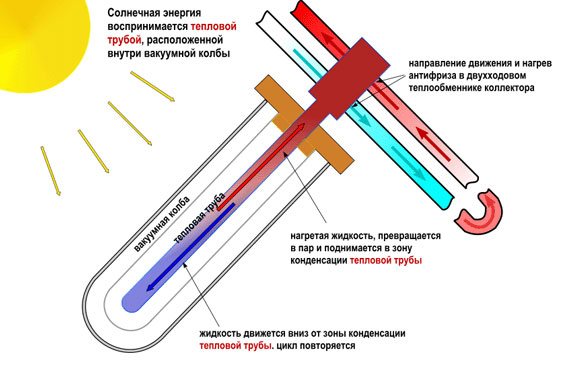

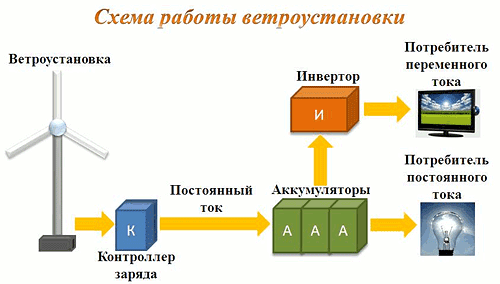

Principle of operation

When the lifting force begins to act, the rotor of the generator begins to rotate. This force arises when the blades begin to flow around the wind flow. Under these circumstances, the generator begins to produce variable and unstable current flows, which are rectified in the controller.

This current is used to charge batteries. At the same time, a second device is connected to the batteries - this is an inverter that converts the DC voltage of the battery equipment into AC single-phase or three-phase, which is used by the consumer.

The wind generator normally does its job with the controller and inverter, but there are other ways to use it:

- Automatic battery operation.

- Automatic operation with battery and solar battery.

- Automatic operation with battery and diesel back-up generator.

- A windmill that does its work in parallel with the network.

The benefits of wind power are certainly good. Wind energy is abundant, does not harm the environment, is completely safe and reliable as a resource for generating electricity.

Components without which a wind generator cannot do:

- foundation base;

- electrical cabinet;

- towers;

- stairs;

- rotating mechanism;

- gondolas;

- electric generator;

- anemometer;

- brake system;

- transmissions;

- blades;

- systems for changing the angles of attack of the blades;

Required tools:

- electric drill with drills (5.5 - 7.5 mm);

- gas and adjustable wrench;

- electric jigsaw with a saw for metal;

- screwdriver;

- roulette;

- protractor;

- compass;

- marker;

- ¼ ×20 tap;

How is the process of converting a car generator into a wind generator

Since the cost of industrial windmills is high, it is best to make it yourself. In this case, a car generator is useful, which can be found in almost every motorist. Even a defective unit will do, since some of its parts may still work.

To get a good wind generator from a car do-it-yourself generator, it is necessary to properly remake such a device. Otherwise, it will not provide the necessary speed and will be ineffective. To get a windmill, you need to purchase or find some additional devices:

- controller;

- inverter;

- battery.

Given the design of a homemade windmill, it is clear that it will not be cheap. We must not forget that during its operation it is necessary to periodically change the batteries.

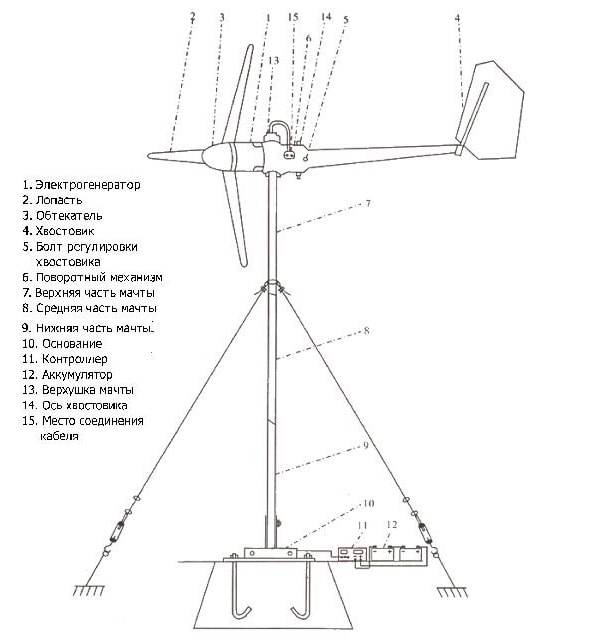

Wind turbine operating conditions

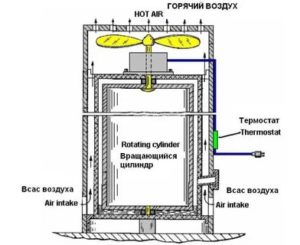

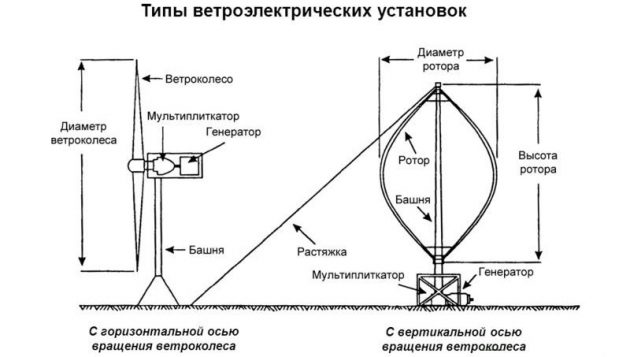

A wind farm is a device that converts wind energy into electricity. There are 2 types of wind farms:

- where the rotor is located horizontally;

- where the rotor is vertical.

Most often, generators of the first type are used. They are characterized by high efficiency (efficiency - up to 50%). Their main disadvantages are:

- high degree of noise and vibration;

- their installation requires a large amount of free space (up to 100 m) or the presence of a mast from six meters high.

The efficiency of a wind turbine with a vertical rotor is three times less than that of a horizontal counterpart.

Do-it-yourself vertical wind generator diagram

Do-it-yourself vertical wind generator diagram

The operation of a wind generator consists of 5 key stages:

- Under the influence of wind, the blades of the wind generator begin to spin.

- As a result, the electric generator and the rotor begin to work.

- The generated energy is transferred to the charge converter, and then to the car battery.

- Then the energy goes to the inverters and it is converted from 12 (24) Volts to 220 (380) V.

- Electricity is transferred to the power grid.

Design choice

A wind generator with a rotary turbine is made of two, sometimes four blades. This design is simple due to the fact that improvised materials are used. A two-story house with such a wind generator, of course, cannot be provided.

Suitable for lighting outbuildings, lanterns and for supplying energy to small household appliances. Such generators will last a long time and will not create problems. The advantages include a low initial price for manufacturing and repair. According to the noise level, this design belongs to low noise.

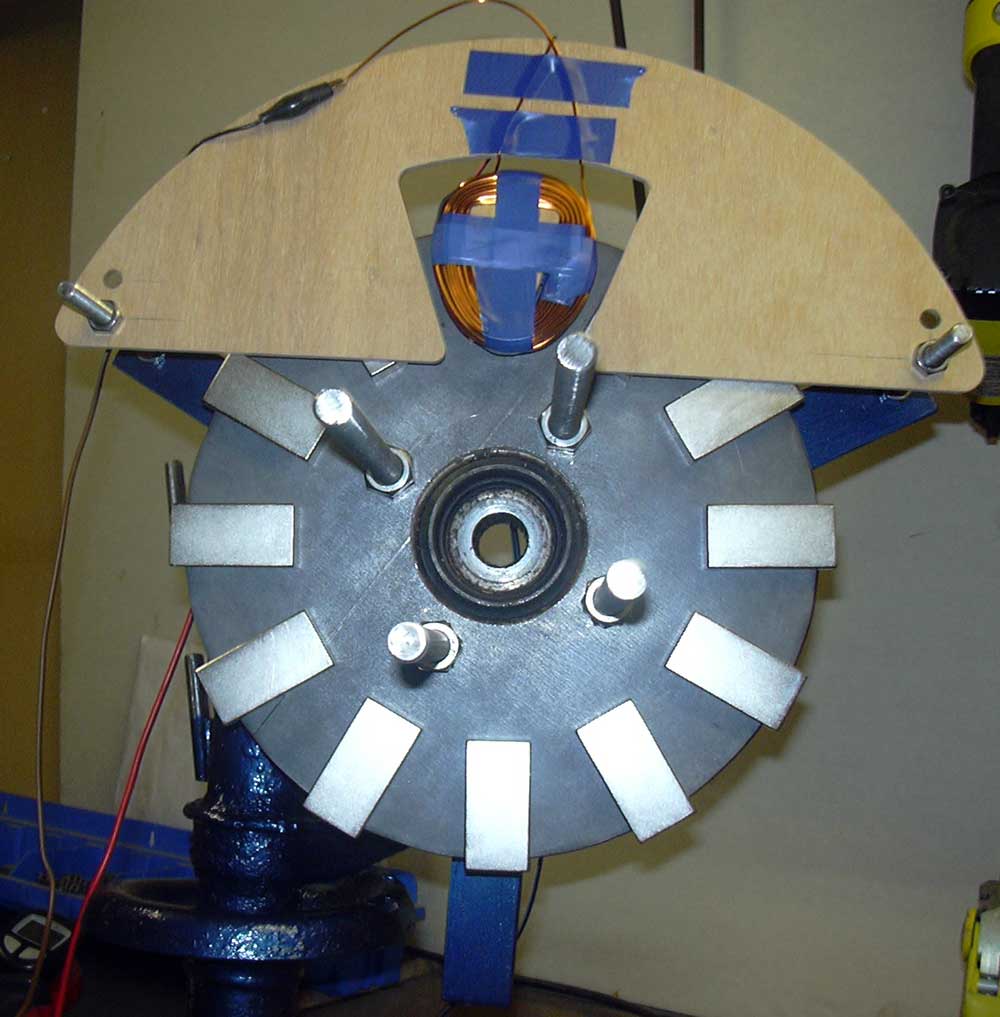

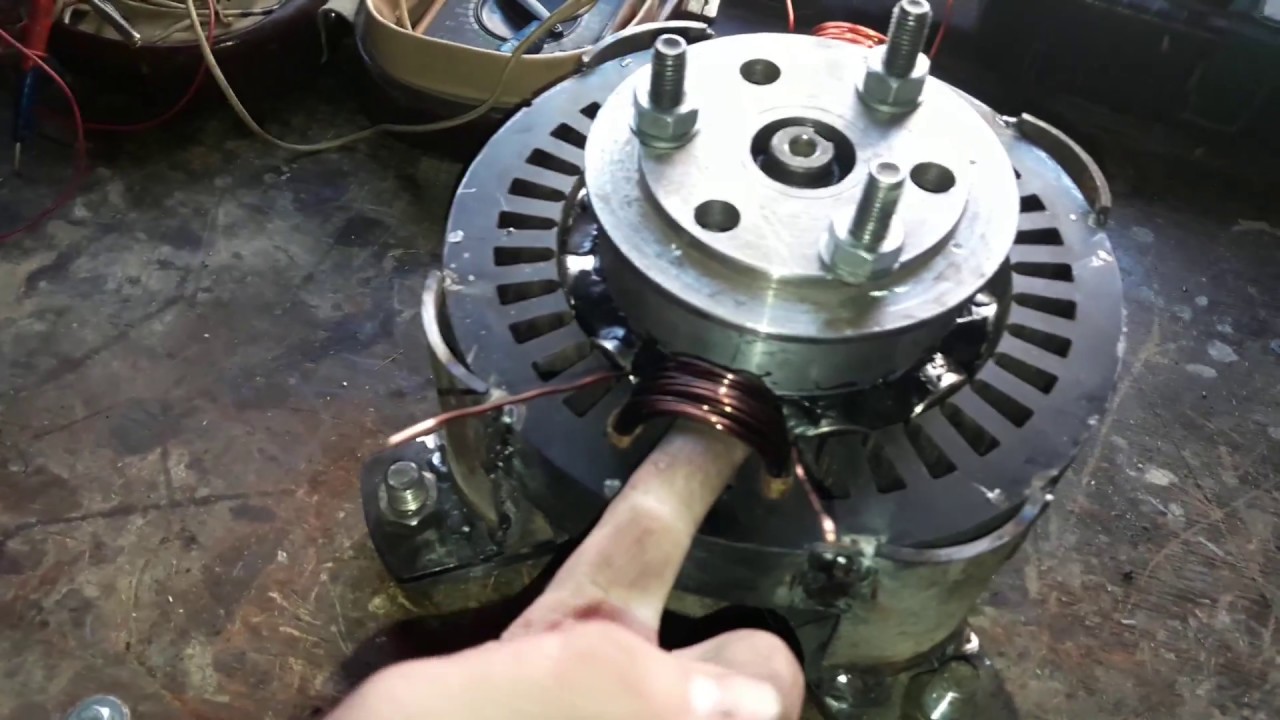

The axial design of wind turbines is made using neodymium magnets. The main structural element is the wheel hub of the car along with the brake discs. Since recently magnets have become cheaper, this design can also be attributed to the budget. It differs from the rotary type in that it generates more electricity.

Schemes and drawings

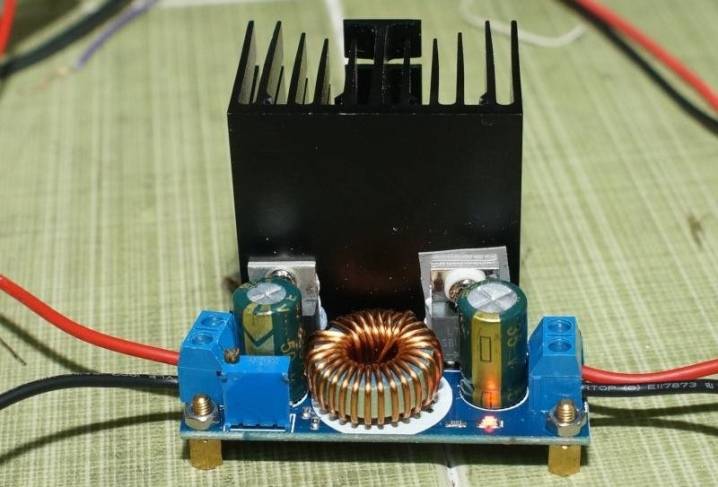

The generator as a device generates alternating current, which must be converted to direct current, brought to the required voltage value. If the motor-generator is putting out, say, 40 volts, then this is unlikely to be a suitable value for most consumer electronics that consume 5 or 12 volts DC or 127/220 volts AC.

Proven by time and millions of users, the scheme of the entire installation includes a rectifier, controller, battery and inverter.A car battery with a capacity of 55-300 ampere-hours is used as a buffer storage of stored energy. Its operating voltage is 10.9-14.4 V with a cyclic charge (full charge-discharge cycle) and 12.6-13.65 with a buffer (portioned, dosed, when you need to recharge a partially discharged battery).

The controller converts, for example, the same 40 volts into 15. Its efficiency in terms of volt-ampere ranges from 80-95% - without taking into account losses in the rectifier.

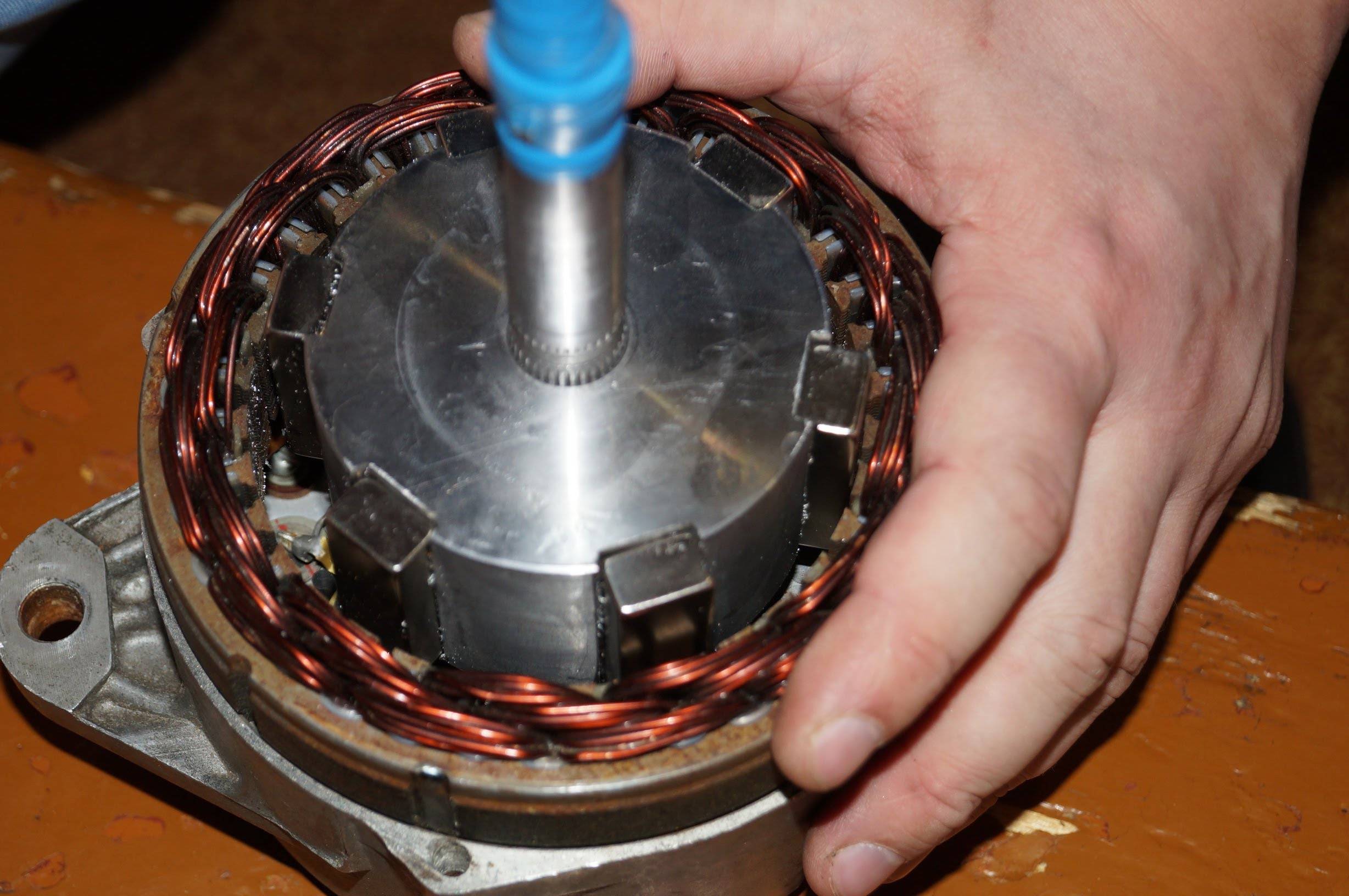

A three-phase generator has the highest efficiency - its output is 50% greater than that of a single-phase generator, it does not vibrate during operation (vibration loosens the structure, making it short-lived).

The coils in the winding of each of the phases alternate with each other and are connected in series - like the poles of the magnets, facing one of the sides to the coils.

Modern household appliances and electronics are capable of operating from 110 volts (the American standard for household networks) up to 250 - it is not recommended to give more to network appliances and devices. All converters are pulse, in comparison with linear ones, their heat losses are much less.

Varieties of generators

Before deciding how to make a wind generator with your own hands, consider the design features:

According to the location of the generator, the device can be horizontal or vertical

- The classic design - the axis of rotation is parallel to the ground, the plane of the blades is perpendicular. Such a scheme provides for free rotation around the vertical axis, for positioning "downwind". In order for the plane of rotation to always occupy an effective position perpendicular to the direction of the wind, a tail unit is required, which works on the principle of a weather vane.The principle of operation is simple: the wind changes direction, affects the tail plane, the axis of rotation of the generator is always located along the movement of the air flow. The only difficulty is connecting the power cables. If the generator housing makes several turns around the vertical axis, the wires will wind around the mast and break. Therefore, a limiter is required. It does not allow a full turn, but leads to freezing) of the body in dead zones. Industrial designs have an electronic direction tracking controller, and rotates the body using a built-in electric motor. The problem can be solved using a cylindrical propeller that receives air flow both across and and along the axis of rotation. True, the effectiveness depends on the angle of attack. The more the wind deviates from an angle of 90 °, the lower the efficiency. But such a design is difficult to do with your own hands, due to the difficulties in the aerodynamics of the mover.

- The best option is vertical generators (that is, the axis of rotation of the shaft is perpendicular to the ground). With this arrangement of the aerodynamic propulsion, you do not depend on the direction of the wind at all. Rotation is equally effective, and depends only on the strength of the air flow. The shape of the blades can be very different, there is room for engineering. There are many interesting aerodynamic projects developed by scientific institutions. Moreover, the drawings of most of them are freely available.Moreover, the designs published in the technical literature of the times of the USSR sometimes turn out to be the most rational. Rotor screws have an undeniable advantage: the vertical generator is fixed statically, which simplifies the electrical connection. There is no need to install rotation stops, as in horizontal schemes.

By nominal generated voltage

- Do-it-yourself wind turbines for 220 volts do not require additional voltage converters, and are direct-use designs. However, their work depends on the strength of the wind. At a minimum, an output stabilizer is needed, which acts as a regulator at different shaft speeds. In the absence of wind, the system simply does not work. The advantages are undeniable: as a rule, a powerful electric motor is used, on which a screw can be installed, directly fixing it to the rotor shaft. Alterations are minimal in terms of labor costs, such motors already have a convenient pedestal, it remains only to make a support platform. Electric motors can be found with minimal financial costs: from any decommissioned electrical installation. For example, an industrial fan. Motors from household appliances are also suitable: washing machines, vacuum cleaners.

- 12 volts (rarely 24 volts). The most popular design is a do-it-yourself wind generator from a car generator. Moreover, it is dismantled from the donor car complete with a voltage converter. Alteration of the circuit is not required: at the output we get either 14 volts (in a car, the battery is charged with this voltage), or the 12 volts required to power your power system.The presence of a pulley allows you to design a belt drive with the required ratio of revolutions. The counterpart can also be removed from the donor car. If desired, the blades are mounted directly on the shaft. Such wind generators can be used both for direct connection to the consumer and in car mode, reproducing the charging system complete with battery. If 12 volts is required for power supply, power is taken directly from the battery terminals. To get 220 volts, a converter is used. A suitable option is an uninterruptible power supply. The system works as follows: if the power taken is lower than the generator can provide, the batteries are charged. If the threshold is exceeded, power is generated from the battery.

Device maintenance

To make the windmill work for many years and without interruption, it is necessary to carry out periodic technical control and maintenance.

- Clean, lubricate and adjust the current collector once every 2 months.

- Repair blades if vibration and imbalance occur during rotation.

- Once every 3 years, paint metal elements with anti-corrosion paint.

- Check and adjust mast anchors and cable.

The efficiency of the device is affected by the area where the wind generator is installed (wasteland, the presence of winds). But in any case, having this source of energy, independent of a stationary power supply, will never be superfluous.

Device maintenance

To make the windmill work for many years and without interruption, it is necessary to carry out periodic technical control and maintenance.

- Clean, lubricate and adjust the current collector once every 2 months.

- Repair blades if vibration and imbalance occur during rotation.

- Once every 3 years, paint metal elements with anti-corrosion paint.

- Check and adjust mast anchors and cable.

The efficiency of the device is affected by the area where the wind generator is installed (wasteland, the presence of winds). But in any case, having this source of energy, independent of a stationary power supply, will never be superfluous.

Manufacturing options

For a long time of the existence of alternative energy, electric generators of various designs have been created. They can be made by hand. Most people think that this is difficult, because it requires a certain amount of knowledge, various expensive materials, etc. In this case, the generators will be of very low performance due to the large number of miscalculations. It is these thoughts that make those who want to abandon the idea of making a windmill with their own hands. But all statements are absolutely wrong, and now we will show it.

Craftsmen most often create electric generators for a windmill in two ways:

- From the hub;

- The finished engine is converted into a generator.

Let's consider these options in more detail.

Design choice

There are many designs, the article will consider two types: a rotor type design and an axial design with magnets.

There are many designs, the article will consider two types: a rotor type design and an axial design with magnets.

A wind generator with a rotary turbine is made of two, sometimes four blades. This design is simple due to the fact that improvised materials are used. A two-story house with such a wind generator, of course, cannot be provided.

Suitable for lighting outbuildings, lanterns and for supplying energy to small household appliances. Such generators will last a long time and will not create problems. The advantages include a low initial price for manufacturing and repair. According to the noise level, this design belongs to low noise.

The axial design of wind turbines is made using neodymium magnets. The main structural element is the wheel hub of the car along with the brake discs. Since recently magnets have become cheaper, this design can also be attributed to the budget. It differs from the rotary type in that it generates more electricity.

Using an old computer cooler

To make a windmill, you need a large cooler, it gives the best results and is easy to use. First of all, you need to disassemble it. The sticker is removed, the plug and the retaining ring are removed. After that, the cooler can be easily disassembled along the rotation axis into two halves of approximately the same size.

One of them is a rotor, the blades of which will have to be changed to larger ones. To do this, the old blades are carefully broken off or cut off, new ones are made from a plastic bottle, about 4 times longer than the previous ones. It is most convenient to make three pieces, they will have a sufficient base area for strong gluing.

The stator has four windings. They can be left intact, or the number of turns can be changed. A thinner wire is taken and wound on all the coils in turn, moreover, in a different direction. The coils are connected accordingly.

After that, it is necessary to make a rectifier, for which four diodes are needed. They are connected in pairs in series, then in parallel.Wires are connected, the device is ready. To install it in the wind, you will need a stand or a small mast, which is easiest to make from cutting a metal tube. In order for the windmill to independently steer into the wind, you need a tail stabilizer, like an airplane tail.

To check the performance, a tester or an LED flashlight is attached.

Generator test

You can test the wind generator on a lathe. For 125 rpm, the voltage indicator should be 15.5 V, and at 630 rpm - 85.7 V.

With a load on the nichrome wire at 630 rpm, the voltage indicator will be 31.2 V, and the current level will be 13.5 A.

For the purpose of creating a wind power plant, it is recommended to use an autogenerator with as much power as possible. You can use a generator from a truck or tractor, along with a battery and relay.

It is desirable to install a wind turbine on a hill or in areas where there is no dense building that interferes with wind flows.

Conclusions and useful video on the topic

Even an ordinary electric screwdriver can become a windmill if you know the basics of a wind generator.

Interest in wind turbines is not decreasing. On the contrary, this option for the production of electrical energy is increasingly being considered at the level of owners of suburban real estate.

Obviously, if you combine several types of energy at once - wind, solar, hydro turbines or nuclear power plants, such a combination can give an economic effect. At the same time, the risks of the user being left without electricity are reduced to zero.

Do you want to talk about how to build a wind turbine to provide electricity to the cottage? Would you like to share useful information not mentioned in the article? Please write comments in the block below, share your impressions, technical nuances known only to you and photos on the topic of the article.