- Making a deflector

- Required tools and materials

- Calculation of dimensions and scheme

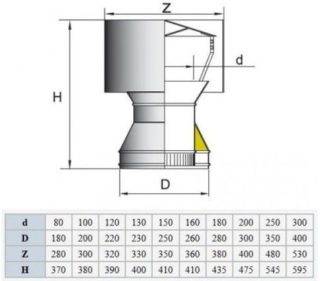

- Table: dimensions of the deflector parts relative to its diameter

- Instructions for making a deflector with your own hands

- Video: self-manufacturing of the TsAGI deflector

- How to make a TsAGI deflector on a chimney pipe with your own hands

- Required Tools

- Development of a drawing of the TsAGI deflector model

- Step-by-step instruction

- When you need a smoker

- Making a deflector with your own hands

- Required Tools

- Size calculation

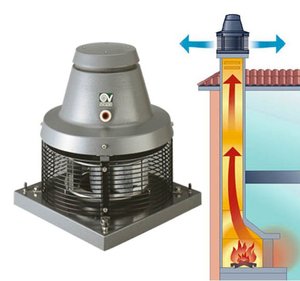

- Fan in the chimney for forced exhaust gases from the furnace

- What to do if backlash occurs

- Causes of Traction Overturn

- Supply valve for increased draft

- What is a deflector for? Functional Features

- What are some ways to increase traction?

- Helpful Hints

- Types of structures to increase draft in the chimney

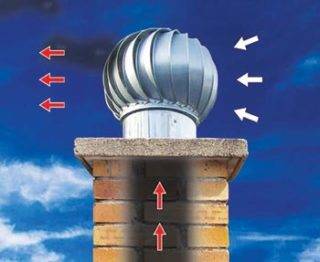

- Rotary or rotary turbine

- Vane

- Electric fan

- Stabilizer

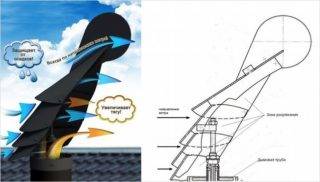

- Deflector

- System check

- Useful information about chimney draft

- Mounting the deflector

- Video - Making a deflector with your own hands

- purpose

- Main functions

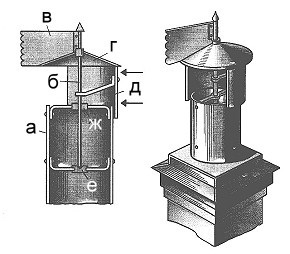

- Chimney cap construction

- Materials used to make a wind vane

Making a deflector

The simplest version of the Volpert-Grigorovich type deflector is quite easy to make with your own hands.

Required tools and materials

- Marker or marker.

- Ruler.

- Iron scissors.

- Mallet.

- Wooden beam for the stand.

- Riveting device.

- Drill, drill bits for metal (or - drill-tipped self-tapping screws).

- A sheet of galvanized iron with a thickness of 0.3-0.5 mm (aluminum sheet or thin stainless steel is suitable).

- Metal parts that are available: corner, studs, thick wire and the like.

Calculation of dimensions and scheme

Since the quality of the deflector depends on the accuracy of manufacturing, drawing up the correct drawing is the most important step in the entire process. The dimensions were verified by scientists in a wind tunnel, and they must be followed. The parameter to be based on is the diameter of the chimney channel D.

The dimensions of all parts of the deflector are set in proportion to its diameter

Table: dimensions of the deflector parts relative to its diameter

Instructions for making a deflector with your own hands

The deflector may not turn out to be very beautiful, but you will immediately feel its usefulness: the draft will increase by a quarter, the roof will be protected from sparks. The pipe with it can be lower by one and a half to two meters.

Video: self-manufacturing of the TsAGI deflector

When installing any traction booster, you will immediately feel the benefits. But a self-made deflector will also create a weighty reason to make you proud of yourself.

When a stove, fireplace or boiler is operating, most owners of private houses and cottages note a significant deterioration in the combustion process.

Most often this is caused by a change in traction parameters.To improve the quality characteristics, you should install a chimney draft booster, which, due to the simplicity of the design, can be done independently.

How to make a TsAGI deflector on a chimney pipe with your own hands

The process of developing and assembling a deflector on an exhaust pipe consists of four stages: drawing, creating blanks, assembling, installing the structure and fixing it directly on the chimney.

Required Tools

You will definitely need:

- a sheet of thick paper for drawing and layout;

- marker for marking;

- riveter for connecting structural elements;

- scissors for metal for cutting parts;

- drill;

- a hammer.

Do not forget about the right tool before installing the deflector

Development of a drawing of the TsAGI deflector model

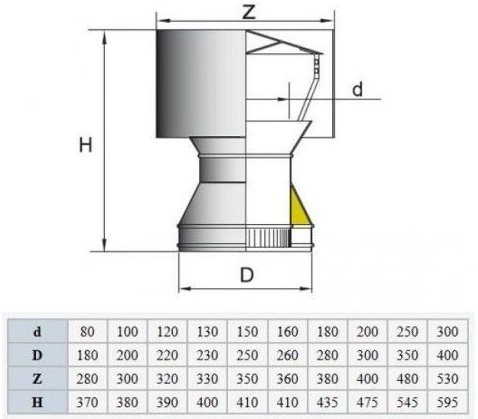

There is an algorithm for how to make a deflector on a chimney pipe with your own hands. The first step is recommended to be done on paper. First you need to calculate the dimensions of the diameter of the nozzle and the upper cap of the structure, as well as calculate the height of the reflector.

For this, special formulas are used:

- diameter of the upper part of the deflector - 1.25d;

- diameter of the outer ring - 2d;

- construction height - 2d + d / 2;

- ring height - 1.2d;

- cap diameter - 1.7d;

- the distance from the base to the edge of the outer casing is d/2.

Where d is the diameter of the chimney.

A table will help to facilitate the task, which contains ready-made calculations for standard sizes of metal pipes.

| Chimney diameter, cm | Outer casing diameter, cm | Height of the outer casing, cm | Diffuser outlet diameter, cm | Cap diameter, cm | Installation height of the outer casing, cm |

| 100 | 20.0 | 12.0 | 12.5 | 17.0…19.0 | 5.0 |

| 125 | 25.0 | 15.0 | 15.7 | 21.2…23.8 | 6.3 |

| 160 | 32.0 | 19.2 | 20.0 | 27.2…30.4 | 8.0 |

| 20.0 | 40.0 | 24.0 | 25.0 | 34.0…38.0 | 10.0 |

| 25.0 | 50.0 | 30.0 | 31.3 | 42.5…47.5 | 12.5 |

| 31.5 | 63.0 | 37.8 | 39.4 | 53.6–59.9 | 15.8 |

If the chimney has a non-standard width, then all calculations will have to be done independently.But, knowing the formulas, it is easy to measure the diameter of the pipe and determine all the necessary indicators to use them when drawing up drawings.

When the patterns are made, it is recommended to first assemble a paper prototype of the future reflector. Even if you are an experienced craftsman and are sure that you will construct a deflector for a stove chimney with your own hands without problems, you should not skip this step, since it will help you identify possible errors and flaws, and correct calculations or a drawing. Only after creating the correct paper layout, which confirms that the deflector scheme is accurate, you can proceed to the next step.

Step-by-step instruction

There is a work order that must be followed, otherwise you will not be able to connect the individual parts deflector for chimney by yourself with your own hands.

The procedure is as follows:

- Using paper blanks, transfer the template to the surface of the metal from which you plan to make a reflector. Carefully trace the outlines of the paper details. You can use a permanent marker, special chalk and even a simple pencil for this purpose.

- Using scissors for metal, cut out the blanks of the necessary structural details.

- Along the entire contour on the sections, the metal must be bent by 5 mm and carefully walked with a hammer.

- Roll the workpiece into a cylinder shape, drill holes for fasteners so that you can connect the structure with rivets. Welding is allowed, but not arc welding. Care must be taken not to burn through the metal. The distance between the main attachment points, choose from 2 to 6 cm, it varies according to the size of the finished structure. The outer cylinder is folded and fastened in the same way.

- Bending and connecting the edges, make the rest of the details: an umbrella and a protective cap in the form of a cone.

- Fasteners must be cut out of the galvanized sheet - 3-4 strips: width 6 cm, length - up to 20 cm. Bend around the entire perimeter on both sides and walk along them with a hammer. From the inside of the umbrella, it is necessary to drill mounting holes, departing from the edge by 5 cm. 3 points will be enough. After that, fasten the metal strips to the cap with rivets. Then they need to be bent at an angle of 90 degrees.

- Connect the diffuser and cone using rivets to the inlet pipe. Having made a deflector for a round pipe with your own hands, you can proceed with its installation.

A Volper chimney deflector can also be created using a similar method. Its design is very similar to the TsAGI model, but there are some differences in the upper part. They are also made of stainless steel, galvanized or copper.

When you need a smoker

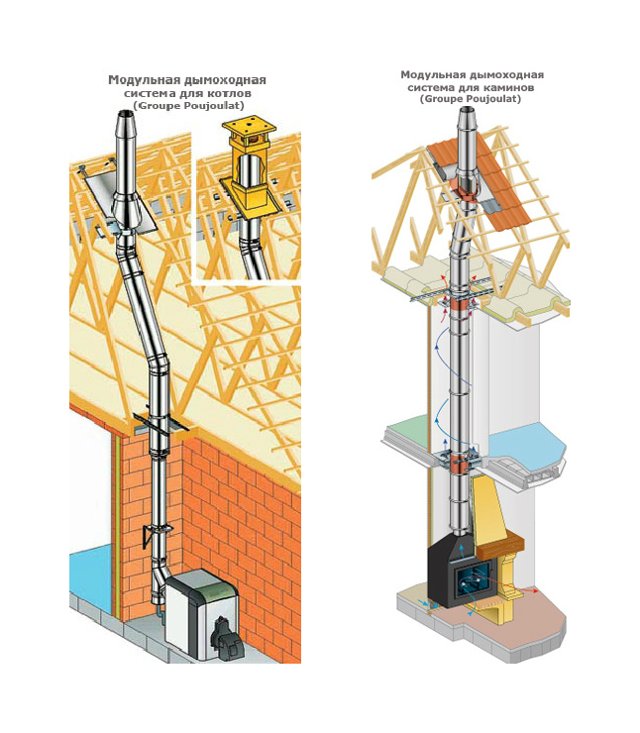

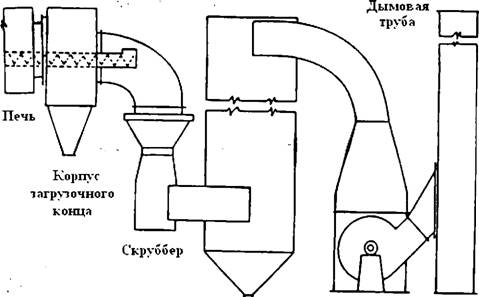

Manufacturers of heating equipment complete their products with traction fans due to the increased resistance of the heat exchanger, where gases change the direction of movement through the flame tubes several times. The goal is to take maximum heat from the combustion products and increase the efficiency of the boiler plant.

Nuance: the operation of the smoke exhauster in the boiler of the factory configuration is coordinated with the combustion process and is controlled by an electronic unit. When installing a fan unit on a "brainless" heater, such consistency is excluded, you need to buy an automation unit or adjust the speed manually.

Organize supply ventilation in the boiler room, and only then think about purchasing a smoke exhauster

We list the situations when a smoke exhauster will help improve the operation and maintenance of a solid fuel heat generator:

- traction problems - wind blowing, air jams in the gas duct, many turns, narrowing of the diameter;

- due to the design features, the boiler smokes into the room when the door is opened;

- the height of the chimney is insufficient or the cut of the pipe has fallen into the zone of wind backwater behind the roof ridge or another building;

- cracks appeared in the brick chimney, from which smoke seeps.

Some designs of wood-burning boilers (for example, shaft type) tend to emit smoke through an open loading hatch. A similar picture is observed in heat generators with a three-way fire-tube heat exchanger of increased resistance. The solution to the problem is the installation of a traction or blowing machine controlled by a controller.

Making a deflector with your own hands

Dimensions of deflectors for different chimney pipes

The walls of the upper cylinder take the pressure of the wind and direct the air around, the suction of smoke is obtained by sliding along the inner surface of individual jets. The deflector cannot be attributed to the group of fans, since the device has a simple shape and does not have working mechanisms.

On the cardboard, the contours of the parts that were calculated and applied on the drawing are drawn, and cut out. With the help of patterns, parts are transferred to metal with the addition of 1.5 - 2 cm along the edges of the lines for ease of assembly. Structural elements are obtained in expanded form after cutting with scissors for metal.

A hacksaw is used to cut metal strips or corners to connect parts into a finished product. The prepared parts are bent and rolled in accordance with the drawing. During assembly, the elements are superimposed on each other and connected with rivets.

Required Tools

In the manufacture, materials and tools are used that do not require professional skills from the master:

- rubber or wooden mallet;

- scissors and a hacksaw for metal;

- ruler, tape measure;

- chalk for drawing lines on the surface of the metal;

- electric drill, rivet gun;

- drills for metal;

- pencil and regular scissors.

The material is thin galvanized steel, a metal strip or a corner of a small section. The size of the rivets is selected according to the diameter of the drill. Nuts and bolts are used for pipe mounting.

Size calculation

A drawing is made on paper, which indicates the key dimensions for creating a pattern of a weather vane-draught booster for a chimney.

The ratio when calculating the dimensions:

- deflector height is 1.7 d;

- cap width is taken equal to 2 d;

- the size of the diffuser in width is taken 1.3 d.

The symbol d means the diameter of the chimney (internal). A different size ratio will result in poor efficiency.

Fan in the chimney for forced exhaust gases from the furnace

Draft is the natural movement of air masses from a heat generator into the external atmosphere, along with the removal of hazardous combustion products. If it is weak, then the fuel will burn very slowly. It can also adversely affect the human body - the gas content of the room in some cases leads to death. To create forced air circulation, install a fan for the chimney.

Draft is the natural movement of air masses from a heat generator into the external atmosphere, along with the removal of hazardous combustion products. If it is weak, then the fuel will burn very slowly. It can also adversely affect the human body - the gas content of the room in some cases leads to death. To create forced air circulation, install a fan for the chimney.

If there is any doubt that the draft in the chimney from the heater is weak, then a check should be made. The simplest method is considered to be an examination with an anemometer. A normal indicator is a traction force of 10-20 Pa.A big disadvantage of such devices is that inexpensive devices have poor measurement accuracy. If the indicator is below 1 Pa, then they will show that the system does not remove combustion products at all. Professional devices are quite expensive. They are often used only by stove-makers.

To check the chimney, you can use folk methods:

- 1. By smoke. Even a slight smoke in the room is an obvious sign of the lack of normal traction. If there is a lot of smoke, then there is a big risk of a fire. Residents can also be poisoned by carbon monoxide.

- 2. By the color of the fire. If there is a white tint in the flame, then the draft is too strong. An orange color with a red tint may indicate that the ventilation is not working properly. During normal functioning of the channels, the fire is golden yellow.

- 3. Using a match or a candle. It is necessary to bring them to the firebox of the heater. The flame should deviate towards the hood. A tilt in the opposite direction indicates reverse thrust.

- 4. Using a mirror. It must be brought to the firebox. If condensation forms on the surface, this means that the removal of combustion products is difficult.

The natural circulation of air masses occurs due to the difference between outdoor and indoor atmospheric pressure. The room temperature is much higher. Cold air presses on warm air from below, thereby removing it to an area with less pressure, that is, to the street. Summer measurements will be less accurate.

Before talking about the use of forced exhaust for the chimney, you should understand the process of removing combustion products. You also need to understand the reasons for the deterioration of draft in the chimney.All factors influencing this can be divided into three main groups:

- 1. Indoor conditions.

- 2. External factors.

- 3. The design of the chimney.

Internal also includes the temperature and volume of air in the house, the number of oxygen consumers, the conditions for the movement of air masses. The design of the house also affects the traction. For example, installing plastic windows often impairs air circulation. This is due to the higher tightness of double-glazed windows, which reduces the volume of incoming oxygen.

Internal also includes the temperature and volume of air in the house, the number of oxygen consumers, the conditions for the movement of air masses. The design of the house also affects the traction. For example, installing plastic windows often impairs air circulation. This is due to the higher tightness of double-glazed windows, which reduces the volume of incoming oxygen.

External factors include the humidity of the air in the street, its temperature, atmospheric pressure, wind currents, and the speed of the flow of air masses. Because of all this, there are constant changes in draft in the chimney. The process of removing carbon monoxide from furnaces and other heat generators should be constantly monitored.

Factors related to chimney design include:

- 1. The location of the structure. The chimney can be located outside near the wall or inside the room.

- 2. Pipe length and number of turns.

- 3. The quality of the surfaces of the inner walls of the channel. A large amount of soot narrows the chimney, which is the main cause of poor draft. On rough flue pipes, it accumulates more actively.

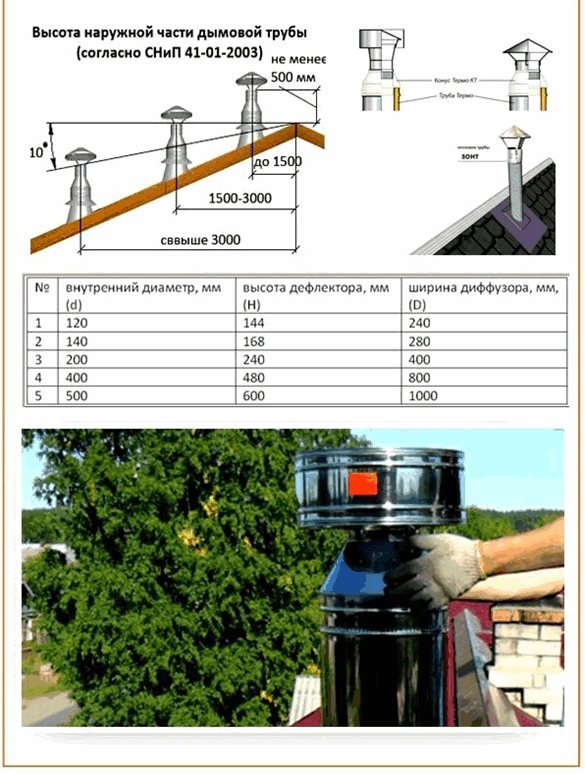

- 4. How high is the chimney relative to the top of the roof.

- 5. Heat transfer of materials from which the chimney is made. Insulated constructions contribute to good traction.

What to do if backlash occurs

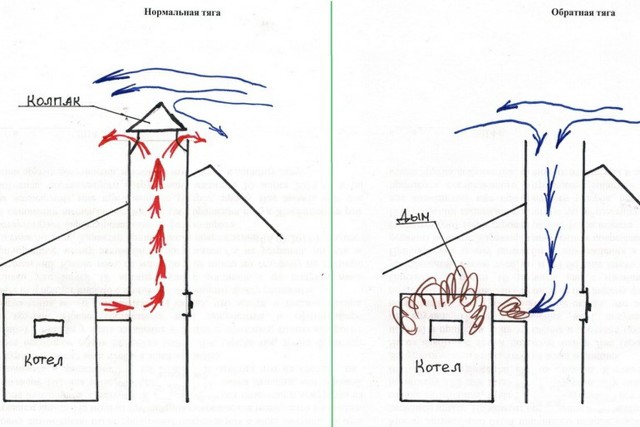

A special term has been coined to refer to this phenomenon - thrust overturning. It fully corresponds to the essence of the physical phenomenon of the occurrence of air flow in the opposite direction. As a result, combustion products enter the room through the furnace.

Before each start-up of the heating unit, the direction and thrust force must be checked using available means.

When the draft is overturned, the flue gases change their direction of movement and begin to escape into the room

This will avoid unpleasant phenomena when smoke begins to enter the room.

Causes of Traction Overturn

Analyzing the circumstances of the occurrence of reverse thrust, they should be divided into two categories:

- requiring cardinal intervention in the operation of the heating unit and the smoke exhaust system;

- temporary circumstances that can be easily eliminated with your own hands.

Speaking about the first group of reasons, the following points should be pointed out:

- Structural flaws in the flue gas removal system - insufficient section of the chimney, the presence of excessive turns in it, the wrong height of the pipe above the roof in relation to the ridge. The only way to eliminate it is to correct the engineering flaws of the chimney.

-

Clogging of the chimney. Debris can accumulate in it if protection in the form of a cap is not installed, or a large layer of soot can form if cleaning and preventive maintenance of the chimney are not carried out in a timely manner.

- The presence of tall trees or newly erected buildings near the house. In such cases, it is most often necessary to build up the chimney.

- Wrong decisions when organizing the ventilation system of a room with a heating unit. To identify such shortcomings, detailed diagnostics are needed to make the right decision on its reconstruction.

Temporary traction overturning can occur due to:

- Setting cool weather. At the same time, the chimney and the air column in it are cooled.Heavy air exerts pressure that prevents normal thrust.

- Long-term downtime of the heating unit, as a result of which cold air has accumulated inside the chimney duct.

Elimination of temporary causes is possible in several ways:

-

Warming up the air in the chimney. To do this, you can burn several sheets of newsprint inside the firebox, as a result of which the draft can be restored. If this measure is ineffective, you can use a hair dryer or fan heater for the same purpose.

- Use of a traction stabilization device.

Before the first ignition of the stove after a long period of inactivity, close all doors and windows to eliminate drafts.

To avoid clogging the chimney with soot, it is recommended to apply some preventive measures. Among them:

- Periodically burn potato peelings in the firebox. They need to be prepared in advance and be sure to dry. After the accumulation of 1.5–2.0 kg of cleanings, they are burned at the end of the combustion of the firewood. Starch softens soot deposits, and it exfoliates from the walls of the chimney, partly falling into the furnace, partly flying out into the chimney.

- For the same purpose, you can burn walnut shells or aspen wood. They burn at high temperatures, contributing to the burning of soot on the walls of the chimney. This method is not recommended when soot accumulates in a thick layer, because its combustion can lead to a fire.

- To lay in the furnace specially produced compositions for cleaning pipes, the action of which is based on both thermal and chemical principles.

Supply valve for increased draft

Without air entering the room or directly into the stove, the chimney will not work. A vent or slot in an old window is not the best method for getting air in.

The disadvantages are obvious:

- Cold air enters the room through the cracks even when the stove or fireplace is not working.

- In winter, the air from the street constantly changes the environment in the room. At the same time, the relative humidity of the air drops sharply, which adversely affects health. A person's mucous membranes dry out, conditions for colds arise.

- The window must be opened and closed manually.

It is much more efficient to provide air flow with a valve. It closes automatically when the furnace equipment or gas heaters are not in operation.

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

For the operation of the heaters, a valve for boiler rooms is needed. The device has other characteristics than those similar in principle to the design for airing a room.

The supply valve is placed diagonally or above a heated surface so that cold air rises to the ceiling. But it is best if oxygen is supplied directly to the furnace. At the same time, the humidity and temperature conditions in the room are not disturbed.

What is a deflector for? Functional Features

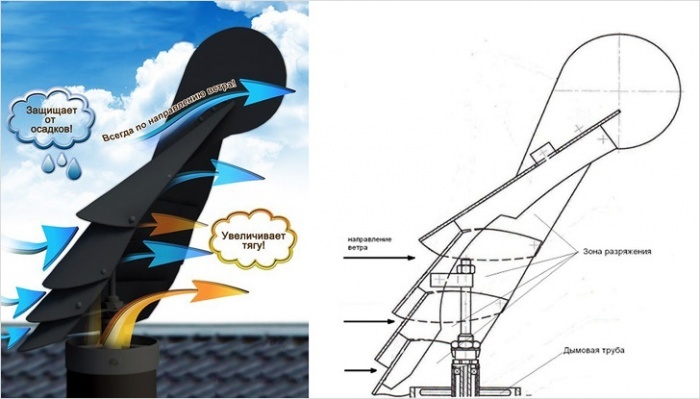

Deflector (translated from English. "Reflector") - a pipe structure installed on the head to protect the upper part of the chimney.

The main purpose of the deflector is to strengthen and equalize the draft of heating equipment (furnace or boiler) for the safe removal of combustion products.In the absence of a deflector, air masses can penetrate, which further impede or counteract the good draft of the heat generator.

The presence of such a device helps to increase the efficiency of heating equipment up to 20%.

In addition to the main purpose - smoke removal, the device is used to perform a number of important functions:

- Traction alignment. Good traction ensures the supply of oxygen, which leads to savings in fuel material - it burns faster and completely in the heat generator.

- Spark extinguishing. The formation of sparks occurs as a result of an increase in the combustion temperature of the fuel and draft in the chimney structure, which can cause a fire. The device provides safe burning out of sparks.

- Protection from the negative effects of precipitation. Such a device provides reliable protection of the smoke channel from rain, snow, hail and strong winds. This contributes to the efficient and uninterrupted operation of heating equipment, even in bad weather.

h2 id="kakimi-sposobami-mozhno-usilit-tyagu">What are some ways to increase traction?

Before starting work, it is worth knowing how to check the draft in the chimney? Now there are a lot of devices that make it easy to find out if there is thrust and how much. The most affordable do-it-yourself chimney repair is an anemometer. However, there is one condition - it shows the flow rate if the value is more than 1 m / s. He certainly does not recognize smaller indicators. But, even if the device shows a certain indicator, this should not be taken with certainty. It is necessary to take into account a lot of factors, for example, when measurements were taken.

Digital anemometer - a device for measuring flow velocity

Digital anemometer - a device for measuring flow velocity

Because, if in the offseason, the indicators will be unreliable. For this, specialists are involved, with more advanced devices.

But, do not despair, you can find out the strength of the flow, the wind in the usual old-fashioned way. If the room is filled with smoke, there is only one conclusion - the chimney does not work. In addition, if there is a white tint in the flame, and a characteristic hum is also heard, then the draft is probably too good. A sign of the normal separation of smoke are - golden "tongues". In addition, an effective way to check is to simply set fire to a piece of paper and bring it to the channel, if you notice a characteristic deviation towards the chimney, then everything is in order.

Helpful Hints

So, how can you improve your chimney draft? If you are still sure what is wrong with smoke emission, you can use some tips, like increase draft in a private chimney?

- Stabilizer installation.

To improve the draft in the chimney, the installation of a kind of "umbrella" on the pipe will also help. From below there will be free access of air, and from above there will be a visor that will allow the formation of an air pocket. - Height increase.

It is realistic to increase the draft in the chimney by simply increasing the height, but it is worth focusing on the requirements for such a chimney. Keep in mind that the normative standard height is considered to be a height of 6 m from the grate. Take into account the turns, slopes of the pipe. - Installation of turbines.

This method is not very popular, however, it is necessary to mention it. How to make it so that in the furnace to increase the "return" many do not even think about simple physical aspects. For example, the creation of turbulences above the head of the pipe allows you to create a vacuum, which is necessary in the channel.In addition, the turbine is powered by wind, that is, no additional costs will be required from you. The only way to get rid of the "return" such a design will not be able to in calm weather.

We hope the above solutions have helped you. By the way, the presented methods of installing various devices on the chimney pipe to increase the draft are also suitable for solid fuel boilers.

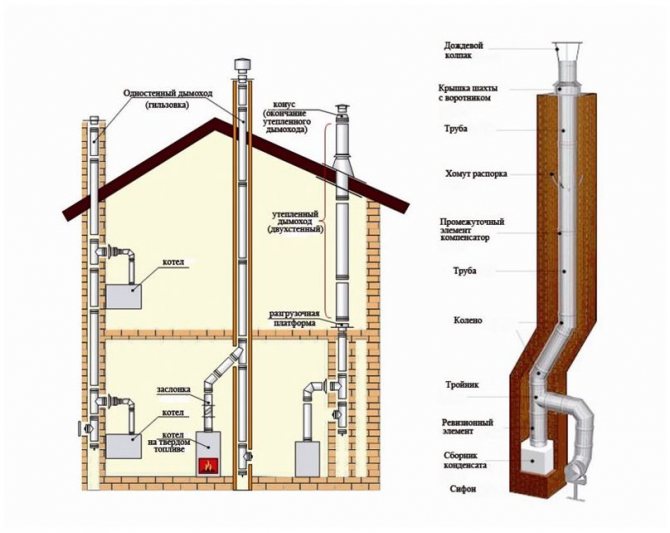

Types of structures to increase draft in the chimney

Types of structures for the chimney

Types of structures for the chimney

The installation of technical devices helps to increase the removal rate. Mechanical and electrical devices increase and decrease the speed of movement of smoke, while maintaining optimal pressure in the pipe.

You can increase the draft in the chimney by installing:

- rotary turbine;

- vane;

- electric fan;

- stabilizer;

- deflector.

The solution is selected taking into account the design of the smoke channel, the type of heating equipment. What matters is the height of the pipe above the roof level and the presence of multi-storey buildings in the neighborhood. Any device on the pipe causes the accumulation of soot and condensate inside the channel, so it is better to design and install smoke exhaust channels correctly.

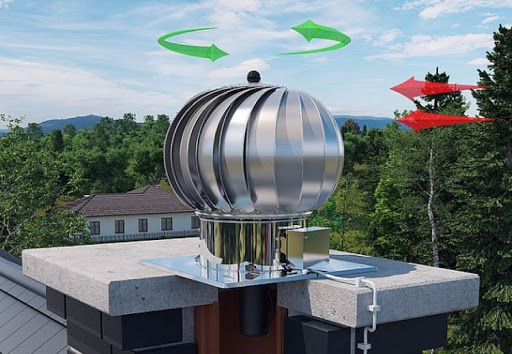

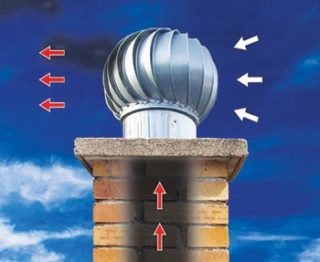

Rotary or rotary turbine

The turbo deflector is driven by air and helps the smoke escape.

The turbo deflector is driven by air and helps the smoke escape.

The traction amplifier contains one or more rotary devices in the design, it is placed at the end of the pipe and operates due to the movement of the wind. The temperature of the outgoing smoke should not exceed 150 - 200°C, depending on the type of turbine. Most often, such devices are placed on gas stoves and boilers.

The device rotates in one direction and by rotation creates an area of reduced pressure above the top of the channel.The nozzle additionally protects the outlet from debris and precipitation.

The disadvantage is the impossibility of working in calm weather. The turbine continues to rotate when the heating is turned off during the summer months and creates increased draft in the room.

Vane

The weather vane turns against the wind and protects the pipe from blowing out

The weather vane turns against the wind and protects the pipe from blowing out

The nozzle on the chimney to increase the draft is made in the form of a weather vane, which turns against the wind due to a special design. The task of the chimney is to resist back draft and give an aesthetic appearance to the pipe head.

Construction details:

- central axis;

- figure;

- Rose of Wind.

The cap has bearings inside that require regular lubrication. In frost, frost appears on the surface of the body, it needs to be knocked down.

Electric fan

You can increase the speed of the smoke with an electric fan

You can increase the speed of the smoke with an electric fan

It is used to extract smoke from solid fuel, gas boilers, stoves in baths and saunas, fireplaces, open hearths, with a temperature of combustion products not higher than 200 ° C, as well as in an air purification system. A chimney fan to improve draft is a draft device to increase heating efficiency. Installing the device allows you to make the boiler furnace and other elements compact, and the combustion process does not depend on the weather.

The rate of circulation of gases increases, the air supply to the burners is organized, the air is distributed evenly over the combustion zones. The use of a fan is not always justified in small household stoves, low power boilers, because they make the design complicated and depend on electricity.

Stabilizer

The device is an interrupter for metered supply of oxygen and maintaining the traction force in the chimney. The design has a safety valve to stop work in case of excessive pressure in the pipe.

The stabilizer is installed on the outlet of the chimney and performs the following functions:

- stabilizes the pressure in the furnace;

- weakens excess draft in the pipe and improves the efficiency of the boiler;

- protects the room from the occurrence of reverse suction of smoke.

A draft sensor is mounted under the umbrella head, which reacts to an increase in the temperature of the combustion products. Smoke accumulates under the dome when the flow is reduced and heats up the controller, which interrupts the gas supply to the burner.

Deflector

A deflector with different nozzle diameters enhances the speed of the smoke

A deflector with different nozzle diameters enhances the speed of the smoke

The device is placed at the end of the pipe and converts the energy of the wind flow to reduce the static pressure in the channel. The Bernoulli effect is used, which means that with an increase in wind speed and a decrease in the diameter of the channel, rarefaction appears in the pipe and an additional traction force is created.

The standard version includes three parts:

- the upper cylindrical body, which has an extension at the bottom, it is attached to the base using racks;

- lower metal cup, sometimes asbestos cement or ceramics are used as the material;

- conical cap.

System check

Before checking the draft, it is necessary to make sure that the gas duct is in good condition, that there is no clogging, that the dampers are opened along the path. You can verify the normal operation of the exhaust system using the instrumental method. Gas workers use an anemometer.There are vane, thermal and ultrasonic anemometers.

If you choose this option, replace single wall double wall pipes or double wall pipes with three layer pipes. Place a brick under each leg of the fire grate. Light the fire and see if the chimney smokes. If not, go to the next step. Cover the bottom half of the holes on the front of the wood stove. Watch the smoke to see if it goes up the smoke system. If this works, permanently raise the floor of the wood stove by placing a layer of cladding over the surface of the floor.

Position the extension ladder safely on the side of the house

Move carefully into the metal chimney and remove the top cover. When removing the chimney cover, observe all precautions. Take a professional if you're unsure or don't have the right tools

Slide the new section of metal chimney pipe onto the current chimney. The pipe section has a "male" and "female" end. Rotate the new pipe so that the female end is at the bottom. Position and insert the female end into the male end of the top tube

Take a professional if you're unsure or don't have the right tools. Slide the new section of metal chimney pipe onto the current chimney. The pipe section has a "male" and "female" end. Rotate the new pipe so that the female end is at the bottom. Position and insert the female end into the male end of the top tube.

Useful information about chimney draft

Secure them with the appropriate screws. Different brands of furnace metal pipes use different connectors.Slide the metal chimney cap onto the top of the newly installed piece of chimney pipe. Add another section if necessary. Increasing the chimney height by 2 feet when the chimney is 10 feet high will result in a 20 percent increase in draft. But adding 2 feet to a 30-foot chimney only adds a 7 percent increase. An easy way to experiment with height is to temporarily add a section of pipe and start a fire.

- The fire is drawn into the chamber. Indicates the readiness of the furnace for kindling.

- The flame burns evenly, without deviations. This case indicates that the traction is gone.

- The tongue of fire is directed towards the room. Characterizes the appearance of a reverse flow.

The magnitude of the thrust force can be judged by the color of the flame. Dark red indicates insufficient oxygen for complete combustion of the fuel. Traction is not enough. Otherwise, with excessive exhaust, the fire is painted in bright, white shades. Burning is usually accompanied by a hum.

Check if the project has been improved. Permanently install the pipe if it matters. Measure the width and height of the firebox. Repeat the process with the chimney opening. The width and height of the firebox should be no more than 10 times the opening for the chimney. Let's say the firebox is 20 by 20 inches for a total of 400 and the chimney opening is 6 by 6 inches for a total you multiply 36 by 10 by 360 showing that the firebox is going to be too big.

Determine the correct size for the firebox. For example, the firebox should be reduced by 40 inches. Divide the excess according to the depth of the firebox. For example, 40 divided by 20 in total The answer is the height of the required smoke protection.Cut a piece of aluminum foil to the width of the firebox and the height of the required smoke protection. For example, you cut a piece of aluminum foil 20 inches long and 2 inches wide.

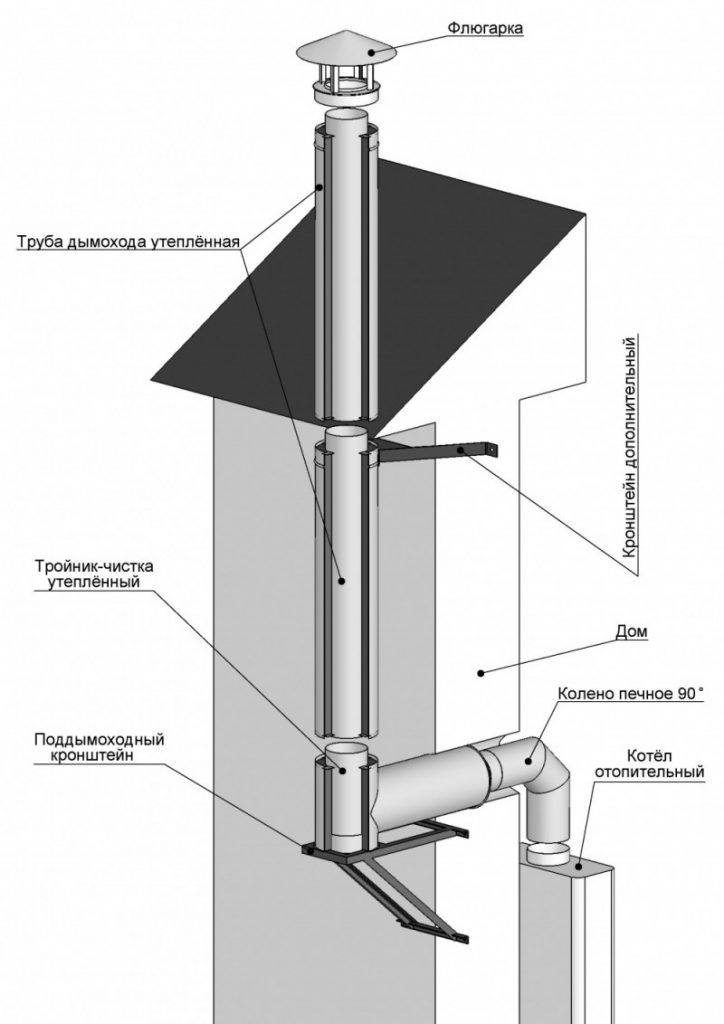

Mounting the deflector

There are two ways to install the structure - directly on the chimney and on a pipe section, which is then put on the chimney channel. The second method is much more convenient and safer, since the most time-consuming process is carried out below, and not on the roof. Most factory models have a lower pipe, which is simply put on the pipe and secured with a metal clamp.

Fixed deflector - photo

To install a homemade deflector, you will need a piece of pipe with a diameter slightly larger than the diameter of the chimney, and threaded studs.

Step 1.

At one end of the pipe, stepping back from the cut 10-15 cm, the drilling points for fasteners are marked along the circumference. The same marks are placed on the wide part of the diffuser.

Step 2

Drill holes in the diffuser and pipe, try on the elements to each other. The top and bottom holes must match exactly, otherwise the fasteners will not be able to install evenly.

Step 3

The studs are threaded through the holes and fixed with nuts on both sides on the diffuser and on the pipe. The nuts should be tightened evenly so that the deflector body is not deformed.

Step 4

They raise the structure to the roof, put the pipe on the chimney and fix it with clamps.

It is very important that there are no gaps between the elements in this area, and therefore it is necessary to tighten the clamp very tightly. Additionally, you can process the joint around the perimeter with a heat-resistant sealant

The installation of such a deflector is performed a little differently, since its design has certain differences.First, three holes are drilled in the chimney at the same level for the mounting bolts. The annular part of the device is inserted into the cut of the chimney and fixed with bolts. Next, an axle is inserted into the annular bearing, a cylinder is put on it, then a weather vane sheet, a protective cap. All elements are connected with brackets or rivets.

When choosing a deflector with a wind vane, remember that the bearings require regular lubrication, otherwise the device will not rotate. Also, icing of the hull should not be allowed, and frost should not be knocked off as soon as it appears.

Video - Making a deflector with your own hands

The chimney is one of the most important components of stoves and fireplaces.

Also a very important detail is the cap on the chimney, which ensures the correct and stable removal of combustion products.

It is quite possible to install a chimney cap with your own hands, but first you need to find out the characteristics of these devices, their main functions and the principle of operation. We will also find out what reasons contribute to smoke, that is, the occurrence of reverse thrust in the pipe.

A cap on a chimney pipe (it is also called an umbrella on a chimney, a visor, a chimney, a deflector, a weather vane) is an old architectural element that in our time bears the imprint of antiquity and refined taste. Some modern chimneys are a real work of art that makes the chimney original and the roof complete.

purpose

An umbrella is installed on the chimney in order to increase draft by deflecting air flows. Deflectors of the correct design prevent atmospheric phenomena from entering the chimney - snow, slanting rains (see).

Also, the chimney cap prevents debris and birds from getting inside.To do this, a mesh is installed, which at the same time freely allows smoke to be released outside.

Main functions

Thus, the chimney cap performs the following functions:

- traction gain;

- increase in the efficiency of the chimney pipe (up to 20%);

- protection from snow, rain, debris;

- an obstacle to the destruction of the brickwork of the chimney.

Chimney cap construction

- cover or umbrella;

- drip or tap for water.

A cover or umbrella is designed to protect against atmospheric phenomena entering the chimney. A drip or water outlet is designed to drain the flowing moisture from the top of the pipe, thereby reducing the formation of ice in the winter.

Materials used to make a wind vane

When planning to make a do-it-yourself chimney cap, you should use materials that are heat-resistant and corrosion-resistant. These characteristics have materials such as:

- galvanized iron;

- stainless steel;

- copper.

It is important to remember that chimney caps are located in hard-to-reach places. Based on this, it is necessary to choose a cap, which is made of high-quality material, and is resistant, according to its characteristics, to various atmospheric phenomena.

One of the most resistant is the cap on the chimney pipe, made of copper.