- The importance of roof aerators

- Principles for choosing a ventilation pipe

- Types of air ducts and features of use

- Device

- Choosing a location for the ventilation outlet

- What is attic ventilation

- Cold attic ventilation device

- Warm attic ventilation device

- We collect the node of the passage of the roof

- The value of pipes for the ventilation system

- 2

- Manufacturers

- WirPlast

- TechnoNIKOL

- Kronoplast

- Conclusions and useful video on the topic

The importance of roof aerators

Air vent cover on bituminous roofing

In winter, condensation forms inside roof structures and in attics. In order to protect the roof from dampness, the formation of fungus and mold, you will need to ensure ventilation of the space under the roof.

The roof ventilation unit is extremely simple in design. Air must move naturally from bottom to top under the roof. For its entry, holes in the eaves will serve, and it will exit through aerators with a ventilation hole cover, arranged in the roof closer to the ridge.

To cover the hole from precipitation, a cover is used for ventilation of various configurations, including a ventilation fungus on the roof, which is actually a decorative cap.

Principles for choosing a ventilation pipe

Air ducts for ventilation installation must ensure the passage of air flow in accordance with the indicators specified in the design documents. In addition, they need to be different:

- tightness;

- resistance to fire;

- minimum dimensions;

- compliance with sanitary and hygienic standards, including the level of noise produced.

Types of air ducts and features of use

Depending on the various characteristics of pipes for ventilation, they are classified according to the following criteria:

- section shape;

- materials used.

The most popular are air ducts with a cross section of a round or square shape. Round tubes are easier to manufacture, require less material and have good aerodynamic performance. Square and rectangular air ducts are more difficult to manufacture, weigh more and are characterized by an increased noise level. But they take up less space and easily fit into a room with false ceilings. Typically, a rectangular ventilation pipe is used for installation in office buildings, apartments in multi-storey buildings and country cottages. Round ducts are more in demand in industrial premises, where functionality is more important than aesthetic characteristics.

Circular air ducts

As raw materials for the manufacture of ventilation pipes use:

- Galvanized steel.It is resistant to corrosion, retains its characteristics in temperate climates and can be used in rooms with high humidity.

- Stainless steel. It is used for the manufacture of air ducts, which provide the transfer of air flows at temperatures up to + 500 ⁰C. Ventilation pipes made of heat-resistant steel are used in aggressive environments - in heavy industry plants.

Rectangular stainless steel ventilation pipes

- Metal-plastic. Air ducts of this type are produced by connecting two layers of metal with foamed plastic. They are distinguished by good strength, low weight, do not require additional thermal insulation and have an aesthetic appearance. However, the high cost limits the use of metal-plastic ventilation pipes.

-

Plastic. Air ducts made of polymers are indispensable for the transfer of aggressive air masses in the chemical, food and pharmaceutical industries. The main material for their production is PVC, which is resistant to moisture, alkali and acid fumes. The smooth surface of the polymer pipes ensures minimal pressure loss of the air flow during movement, and the tightness of the connections of individual elements prevents the transported masses from entering the environment. In supply ventilation systems, polyethylene pipes are in demand, and their fiberglass counterparts are used for joining air distributors and fans.

In addition, air ducts can vary in design and rigidity. Depending on the production method, they are straight-seam, spiral-wound and spiral-welded, and in terms of rigidity - flexible and rigid.

The most popular are ventilation pipes of a rigid type, round or square. They are used for the construction of systems with high requirements for strength and are characterized by ease of operation and installation, but require reliable fastening, as they have significant weight.

Flexible ducts

Flexible air ducts are a corrugated sleeve, the basis of which is steel reinforcement made of wire, and metallized polyester is used for the manufacture of walls. They are lightweight, easy to install and maintain. The disadvantages of corrugated ducts include low sound insulation and a corrugated surface, which reduces the speed of air flow when it moves. Which pipes for ventilation should be chosen is determined, taking into account these characteristics.

Flexible duct with thermal insulation

To fasten air ducts during the installation of a ventilation system in a private house, a flanged or flangeless connection is used. In the second case, a band made of thin sheet steel and metal slats serve as a fixing element. With a flange connection, the air ducts are fastened together by flanges, and seals are used for tightness.

Device

There are several elements in the roofing system:

- Openings located under the roof canopy. They are usually covered with soffit gratings, which provide protection from the ingress of insects, rodents and birds. Also, similar holes are located along the ridge. Details allow air masses to circulate under the roof. The holes under the overhangs can be replaced with a binder, in which there are small gaps.

- Dormer windows.They are located in the gable and are used as ventilation components for the attic area.

- Ventilation outlet. This piece of pipe is used to connect the exhaust duct from the general house ventilation system or to ventilate the attic.

- Aerators. Other names of elements - deflector, weather vane. They are cut into the roof next to the ridge. The components allow you to remove air from under the roof, performing a function similar to the hole under the ridge. Aerators are used when the snow cover on the roof exceeds 3 cm, due to which the ventilation hole under the ridge is blocked.

There are two types of aerators:

- point;

- linear or continuous (located along the entire length of the slope or ridge).

Also, aerators can vary in location. There are products that are located on a ridge or slope. Elements may have the form of "fungus" or tiles. Devices can be made of stainless steel, however, variations from polypropylene are currently in demand

They have an affordable price and attract attention with a variety of colors.

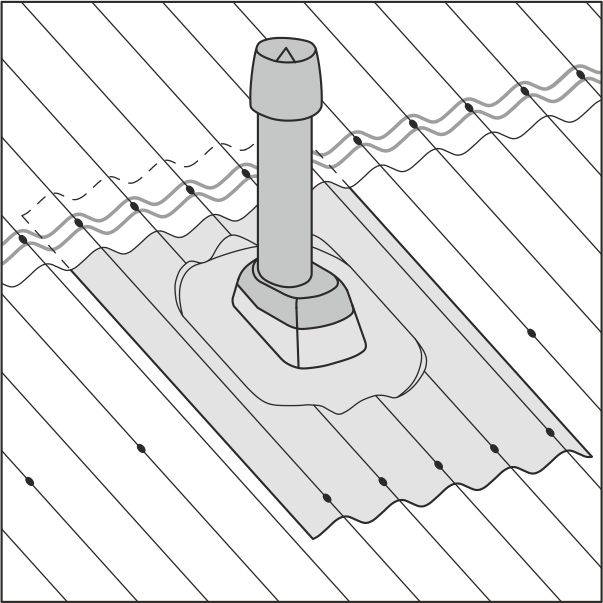

On the aerators there are replaceable elements, which are called penetration. Such a design should be selected based on the material used under the roof.

Choosing a location for the ventilation outlet

During the design and selection of the place where the ventilation outlet will be installed, several important factors are taken into account - the minimum number of pipe bends, its slope, what form of roofing (pitched or flat), SNiP requirements.

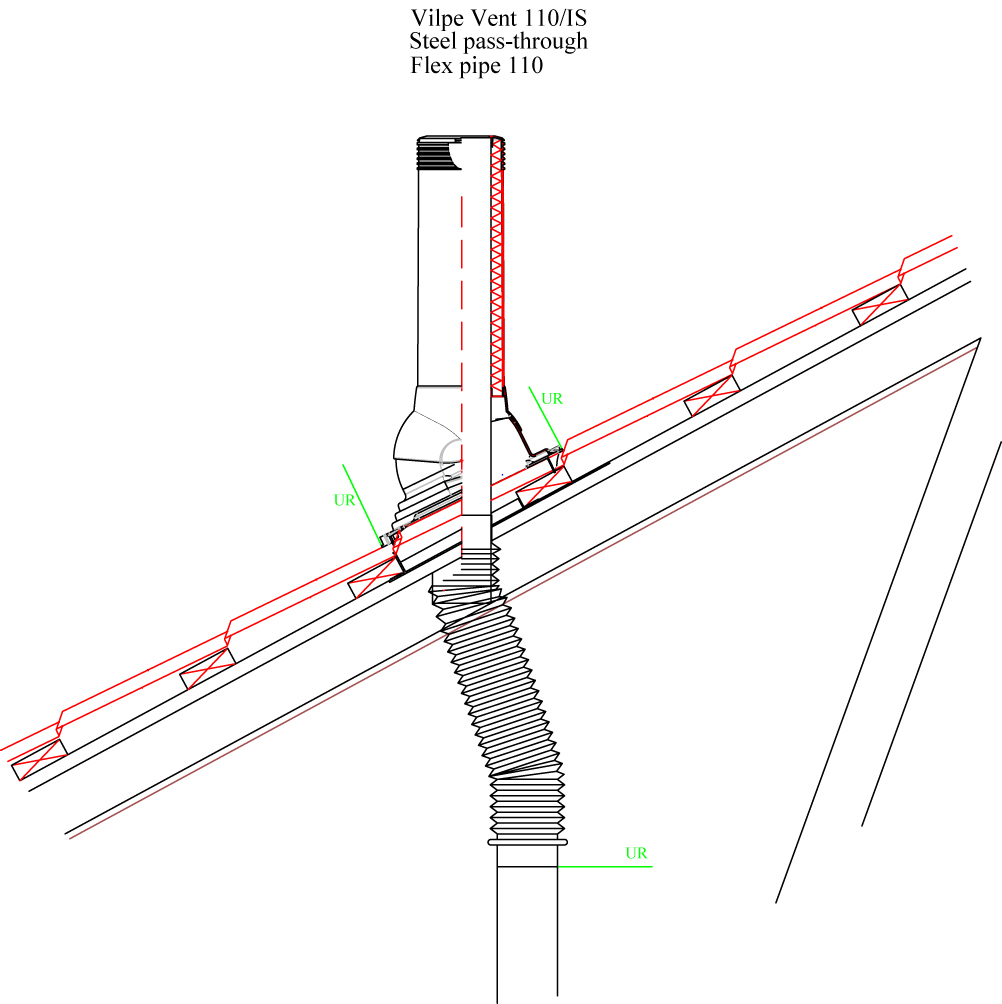

When the design has a minimum bend and slope, its performance tends to be maximum. The ideal option is to install a pipe directly above the internal riser of the ventilation system. When for some reason bends cannot be avoided, a corrugated pipe is used. With its help, installation is carried out with the necessary turns.

In some cases, the best solution would be to make several ventilation outlets.

On a pitched roof, the upper part of the ventilation system is mounted as close as possible to the ridge. In this case, the largest part of the entire column remains in the attic. As a result, there is a uniform heating of the inside of the ventilation pipe and protection from temperature drops and exposure to ultraviolet radiation. The entire pipe is better able to withstand even strong winds, because most of it is protected.

When installing on a flat roof, the geometry of the ventilation riser is taken into account first of all. It is located directly under the exhaust pipe so that the air has an unhindered exit to the outside.

The height of the outlet pipe is also taken into account. If the ventilation outlet for the roof is low, then the traction force and the efficiency of all ventilation in the house will decrease. A high pipe also reduces draft and creates the need for additional fastening so that the shaft does not suffer due to strong gusts of wind.

During design and installation, they are guided by the requirements of SNiP. A number of rules depend on the type of roof, the presence of other elements on the roof and other conditions.

Some of the requirements:

If the ventilation outlet is installed next to the chimney outlet, then its height should be at the same level as the chimney.

Height of the ventilation outlet in relation to the roof ridge

- On a flat roof, adhere to the recommended level of at least 50 cm.

- Consider how far the roof ridge is. Make the height more than 50 cm if the distance from the pipe to the ridge is within 1.5 meters.

- If the distance from the ridge to the pipe exceeds 1.5 meters, then the height must be at the level of the ridge or be higher than this part of the roof.

Based on these factors and the requirements of SNiP, choose a place for the ventilation pipe.

What is attic ventilation

In fact, attic ventilation is an engineering system that ensures the free movement of air flows inside it. They come from the street through special devices, such as dormer windows, ventilation grilles and openings.

The main functional purpose of the attic air exchange system is to constantly supply the required volume of fresh air and remove stagnant air.

If it is improperly designed, then the microclimate in the premises is disturbed. This entails damage to the truss structure and its destruction.

For ventilation to work flawlessly, you must follow the rules:

- cold air should come from the bottom of the attic, and exit from the top;

- air masses must move freely throughout the area of \u200b\u200bthe room.

In the most problematic places of the roof, spot ventilation is done if the angle of inclination of the slope is 450, for example, at the installation sites of the valley, hip. For this, aerators are used, mechanisms for the forced induction of air movement - inertial turbines.

Cold attic ventilation device

In a cold attic, the air flow freely enters through special openings, due to which natural ventilation occurs.The design features of the system are determined roof shape and type of materialwhich is used for roofing.

When installing ventilation ducts, the following conditions must be observed:

- the air flow should move freely over the surface of the ceiling without rising to the ridge;

- ventilation ducts should be equipped with valves to control the intensity of the ventilation process.

If the roof is gable, then in the attic it is possible on the opposite gables put dormer windows or arrange vents with ventilation grilles.

They must be covered with nets to protect against the penetration of mosquitoes and other insects. There will be a horizontal air flow in the room.

With a hip shape, gaps should be provided on the overhangs of the cornice through which air will freely enter the attic room. For its withdrawal, holes should be made at the ridge.

If the angle of inclination of the roof is 450 or more, then the ventilation of the room is carried out due to the difference between the external and internal temperatures.

At small angles of inclination, the ventilation system can be reinforced with electric fans or inertial turbines.

Ventilation openings must be placed at an equal distance from each other around the entire perimeter of the house. But the lining of wooden overhangs should be made loose.

Otherwise, holes are drilled in the outer walls. The total area of ventilation ducts should be 0.2% of the area of the house.

Ventilation can be omitted if ondulin or slate is used for the roof.Air moves freely between waves of material.

Warm attic ventilation device

The space between the ceiling and the roof can be used as an additional area for permanent living.

It is recognized as residential if it meets the requirements for residential premises by sanitary and hygienic rules and regulations.

If an attic is provided, then the attic ventilation design should be carefully considered and the best option chosen.

Features of the system depending on the type of roof:

- galvanized metal sheet - creating a ventilated area by sewing a counter rail onto the truss structure;

- metal tile - it is necessary to lay a vapor barrier layer of a polymer film on the crate;

- slate, ondulin - free flow of cold air from the lower part of the roof and removal of warm air through the material waves.

In modern houses, special aerators are used to remove exhaust air from under the ceiling of the attic room. Devices prevent the occurrence of condensate and its penetration into the living space.

Ventilation schemes:

- installation on the roof of a pipe equipped with a deflector;

- use of frontal ventilation grills or grids;

- the device of a heat-insulated ventilation duct through an opening located in the upper part of the roof or outer wall.

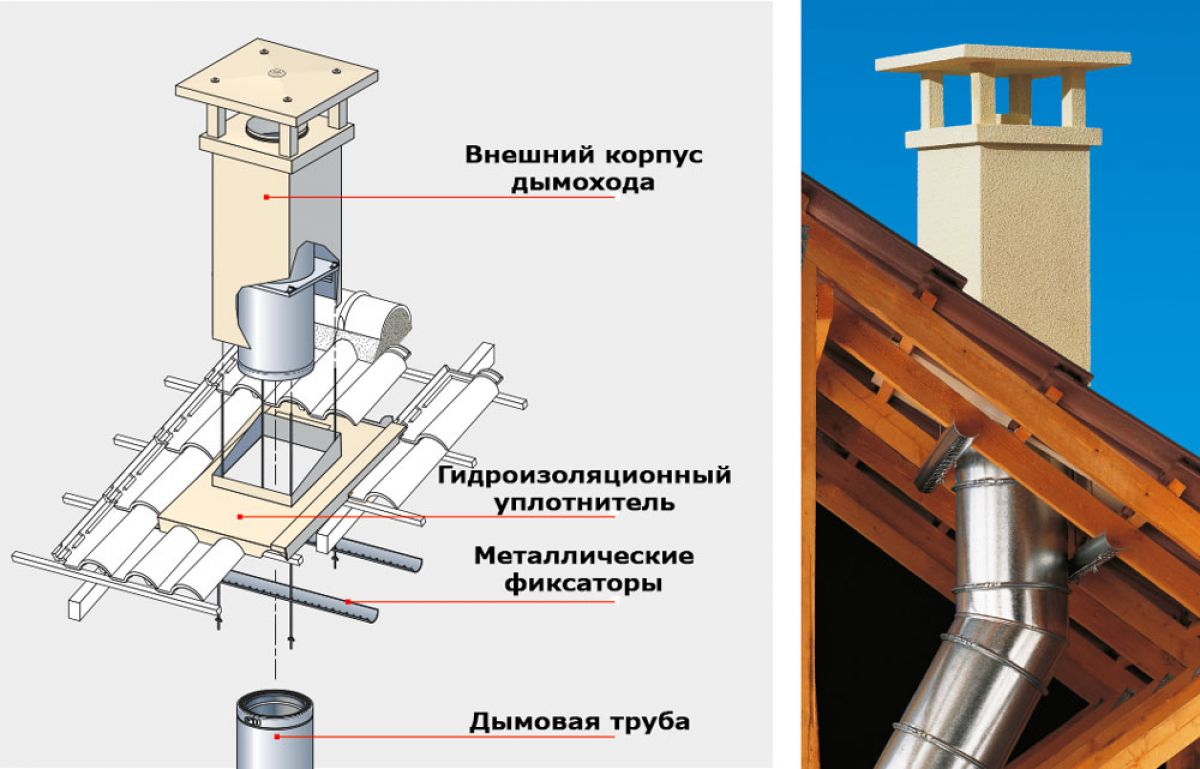

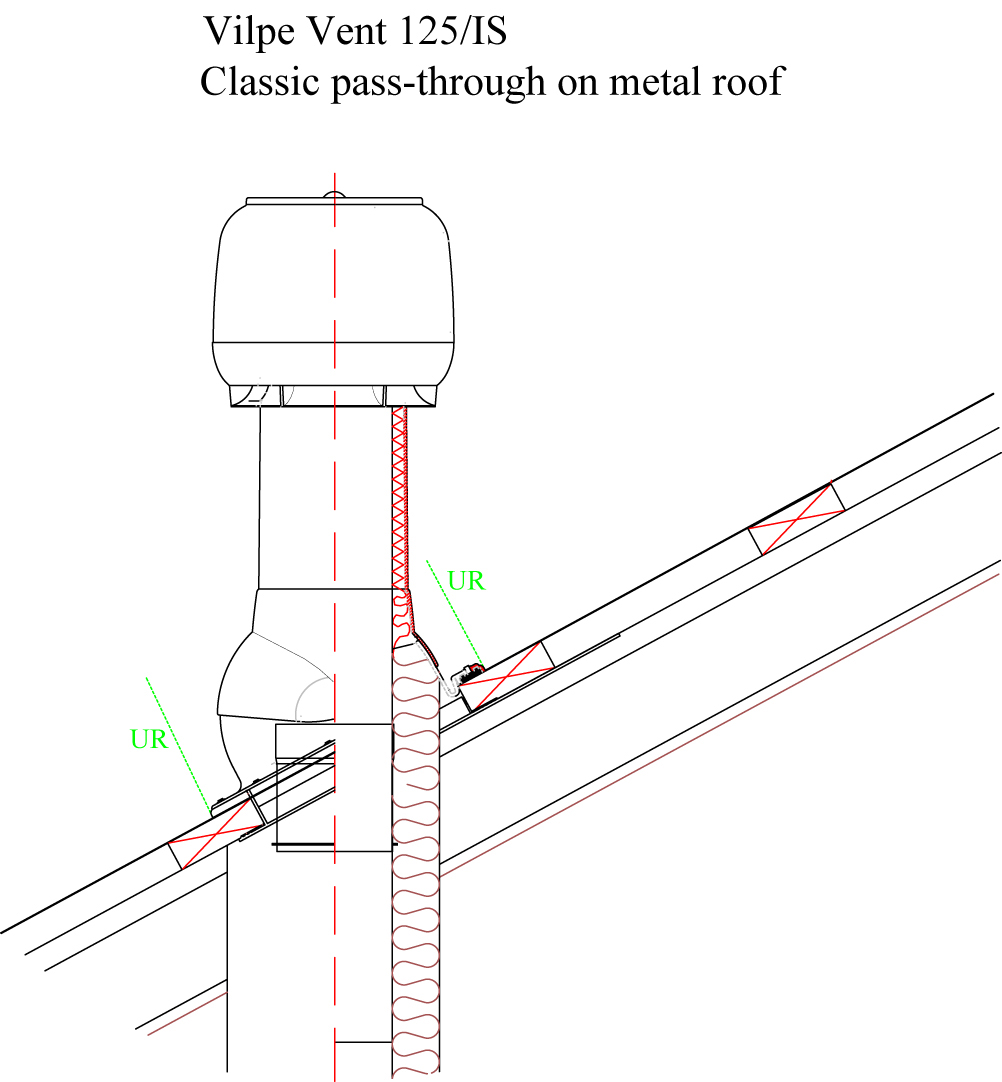

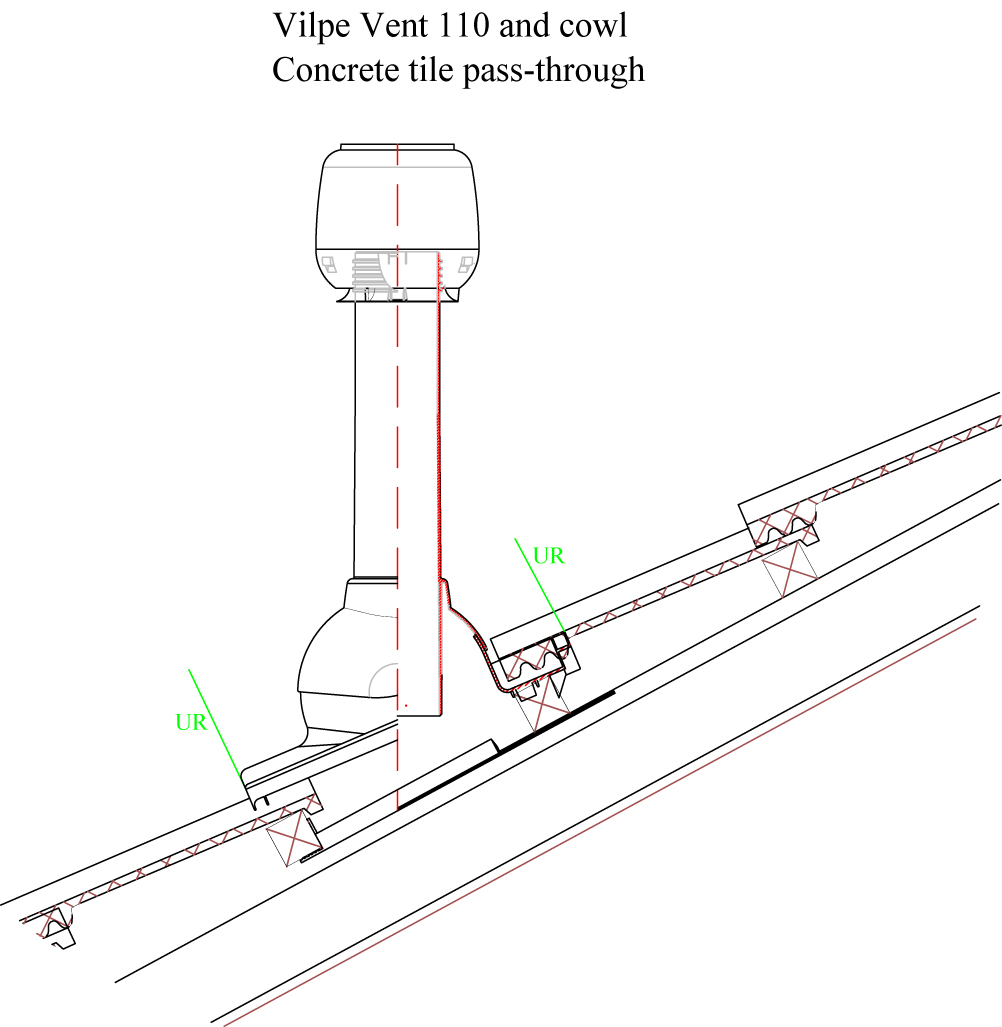

We collect the node of the passage of the roof

The main difficulty with setting the angle of passage is due to the fact that it is necessary to mark and cut a hole for the body as accurately as possible.Usually, ventilation, with the exception of under-roof options, is installed from the bottom up, so it is easier to make a passage unit, but in this case it will be necessary to try as accurately as possible to transfer the vertical line of the duct axis to the crate. The more accurate, the smaller the size of the hole in the roofing will be, and the assembly itself will be more compact.

To do this, remove the plywood lining from the inside of the roof, covering the insulation and vapor barrier. Using a sharpened metal pin, you can take a welding electrode with a suspended plumb line, we punch a small hole in the roofing from the inside.

Using an adapter plate and an electric jigsaw, we cut a hole in a metal tile sheet, cut the waterproofing with a cross and bend the petals to the edges of the hole. If the hole touches the board of the crate, then it will be necessary to fill a box of wooden planks from the side of the attic, reinforcing the load-bearing boards.

At the next stage, we treat the rubber gasket and the adapter plate with glue and lay them on the roofing waterproofing layer, fasten the mating part of the plate to the hole from the attic side. After the ventilation pipe is installed in the adapter plate, the joint between the wall and the gasket is filled with silicone.

When properly installed, the outer walls of the ventilation pipe should not touch the edges of the adapter plate, there should be a thick rubber gasket and an applied layer of protective silicone between them.

Before proceeding with the processing of seams with silicone, the ventilation pipe must be aligned vertically using a building level. Usually, during assembly, the duct housing is temporarily attached with plumbing clamps to the wooden parts of the roof frame.

Even if at first glance it seems that everything is running smoothly, do not be too lazy to go down to the ground and see how the pipe looks from a distance of 10-20 m. Usually, all imperfections are very clearly visible from the ground. If there are no problems with vertical installation, install all remaining fasteners.

The value of pipes for the ventilation system

The ventilation duct of PVC sewer pipes can have any bend shape

In the process of air exchange, about 30 cubic meters of fresh air should be supplied to each citizen living in this living space. The ventilation system must provide it. Pipes are the arteries of a complex ventilation mechanism. According to them, from the most polluted premises (toilet, kitchen, bathroom, workshop, etc.), vapors, gases, odors are removed. In "prosperous" rooms (bedroom, living room, etc.) - served.

When organizing natural ventilation in areas with the formation of pollution, vertical channels are mounted for air movement with an outlet to the roof. Through them, the stale air flow escapes into the atmosphere at a considerable height: the higher the nozzle, the more effective the thrust. Log cabins and frame buildings, as well as buildings where ventilation was not provided at the design stage, are equipped with plastic pipes.

With mechanical air exchange, the use of pipes is simply necessary. The system of pipes, shafts is supplemented by ventilation installations for supply and exhaust. The forced system consists of a special piping of a rectangular or round section. The supply is carried out to each room, producing air exchange in it.

Along with metal hoses, plastic pipes are increasingly being installed. It can be both polyurethane and polyvinyl chloride.Type of pipe - medium and hard. The temperature of the passing air must not exceed +70°C, otherwise the strength of the material is impaired. This applies in particular to the kitchen hood. The recommended list of rooms where pipes for sewerage can be used as ventilation:

- one-story residential buildings of a small area;

- production sites of small enterprises;

- garages;

- cabins;

- warehouses;

- corridors.

As you can see, these are objects where there are no increased requirements for ventilation, but it is needed, and the traditional air exchange system is too expensive.

2

The width of the ventilated under-roof space depends on the roofing material you have used. The under-roofing space is called the air gap between the bottom of the roofing material and the waterproofing film or membrane, behind which there is a layer of insulation. For example, if the roof of your house is covered with metal tiles or any other metal-based material, the ventilated gap should be at least 2.5 centimeters.

When using soft (bituminous) tiles or other rolled materials, the thickness of the air gap must be at least 5 centimeters. The specified norms must be observed when attic ventilation is done. The main elements of the under-roof ventilation system are aerators and spotlights. The former play the role of exhaust openings, while the latter provide an influx of fresh air, and, therefore, prevent the formation of condensate and dripping moisture.

Aerators are ordinary, mounted on an inclined plane of the roof slope, and ridge aerators, which are installed at the highest point of the roof, that is, on the ridge. The number of aerators depends on the type of roofing material and the manufacturer's recommendations, but there is a general rule. It says that for every 500 sq.m. ventilated area should be 1 sq.m. ventilation holes. This ratio allows you to efficiently ventilate the room, avoiding tangible heat leaks.

Ridge aerators are considered the most effective, as they have a large outlet area. Ventilation of the attic floor with the help of ridge aerators is quite simple and does not cause difficulties even for beginners. The main thing is to follow the instructions, use high-quality fasteners and ensure good waterproofing at the junction of the roofing material.

As mentioned earlier, soffits are an important part of roof air exchange systems. Soffits are perforated siding panels designed for sheathing cornice overhangs of the roof around the entire perimeter of the building. In addition to the assigned functional load, they give the roof a complete look.

Soffits are not only perforated, but also non-perforated. The required number of perforated soffits is determined taking into account the area of the roof slopes. The use of these elements is possible only if a special gap between the materials was provided during the installation of the "pie"

In addition to the assigned functional load, they give the roof a complete look. Soffits are not only perforated, but also non-perforated.The required number of perforated soffits is determined taking into account the area of the roof slopes. The use of these elements is possible only if a special gap between the materials was provided during the installation of the "pie".

To achieve the maximum effect, it is better to use one type of aerator: either ridge or inclined, to ensure better air exchange. Proper installation of spotlights and aerators negates the formation of condensate and dripping moisture. When forced ventilation is used, supply fans are installed in the under-roof space.

Particular attention should be paid here to connecting the fan or fans to the mains. At the same time, it is necessary to ensure fire safety and more or less free access for their maintenance, replacement or repair.

Manufacturers

There are many manufacturers on the market that offer their customers roof ventilation systems. Before buying, you should study the offers of each brand and make a choice based on your preferences and operating conditions.

WirPlast

The company offers equipment designed for different purposes. The manufacturer's assortment includes devices for installing ventilation in rooms, for sewage, kitchen hoods, and there are also composite components for a solar battery.

The WirPlast roof ventilation system has the following advantages:

- ease of installation due to the built-in level, which does not allow errors;

- full tightness on the roof;

- attractive product design;

- a wide range suitable for all types of roofing;

- The product warranty is 10 years.

TechnoNIKOL

TechnoNIKOL is a popular manufacturer that offers its audience two types of ventilation:

- to ventilate the space under the roof;

- devices for forced ventilation in attics.

The product has the following advantages:

- attractive appearance of ventilation systems;

- affordable price category;

- high quality;

- reliability and high level of resistance to shock loads;

- easy installation.

Kronoplast

The manufacturer is in demand, as it produces almost all elements for arranging roof ventilation in private homes. The products are characterized by complete impermeability in each roof exit, which acts as a guarantee of full ventilation. On sale there are systems for any roof.

About the five elements of high-quality roof ventilation, see the following video.

Conclusions and useful video on the topic

You can learn more about the placement and meaning of the fan riser from the following video:

A comfortable environment in the house is the main factor that encourages owners of private residential buildings to pay attention to standard sewer ventilation technology. Whether to apply this method or be content with a simplified ventilation scheme is up to the homeowners to decide.

Extra construction plans "fly out" for a pretty penny. True, there is always a price to pay for comfort.

Whether to apply this method or be content with a simplified ventilation scheme is up to the homeowners to decide directly. Extra construction plans "fly out" for a pretty penny. True, there is always a price to pay for comfort.

Are you thinking about installing a ventilation riser for your home's sewer system? Maybe you still have unanswered questions after reading our article? Ask for advice - our engineer will try to help you.

Or do you already use simple sewer ventilation, arranged by yourself? Tell us what scheme you used, what difficulties you encountered in the design and whether you are satisfied with the efficiency of the riser - leave your comments, add a photo in the block under this article.