- Materials and colors

- Galvanized ventilation grilles

- aluminum grilles

- Wooden

- Plastic

- Steel

- Gypsum

- Instead of an epilogue

- Types and purpose of ventilation grilles

- Installation location

- Design

- Materials for manufacturing

- Product shape

- Features of the choice of air distributors

- Basic concepts

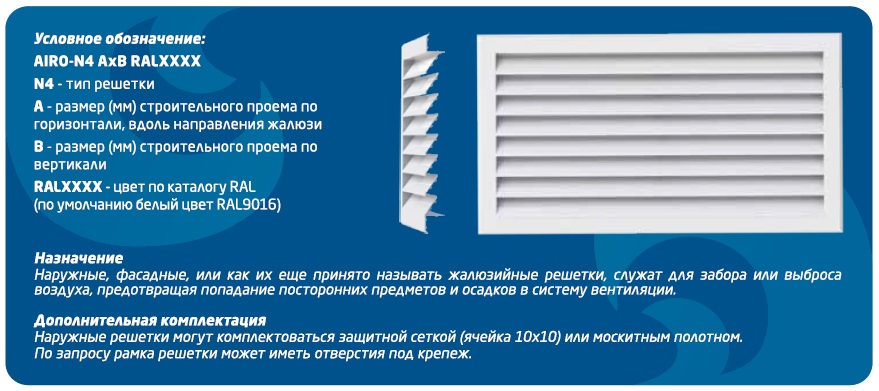

- louvred grilles for ventilation

- Step by step installation instructions

- Advantages and disadvantages

- Basic installation methods

- How to install a ventilation grill with your own hands

- Detailed instructions on how to install a ventilation grill

- Possible technical difficulties when attaching the ventilation grille

- Types of exhaust grilles

- Internal

- outdoor

- Internal overflow

- 1 Types of decorative ventilation grilles

- Choice by design

Materials and colors

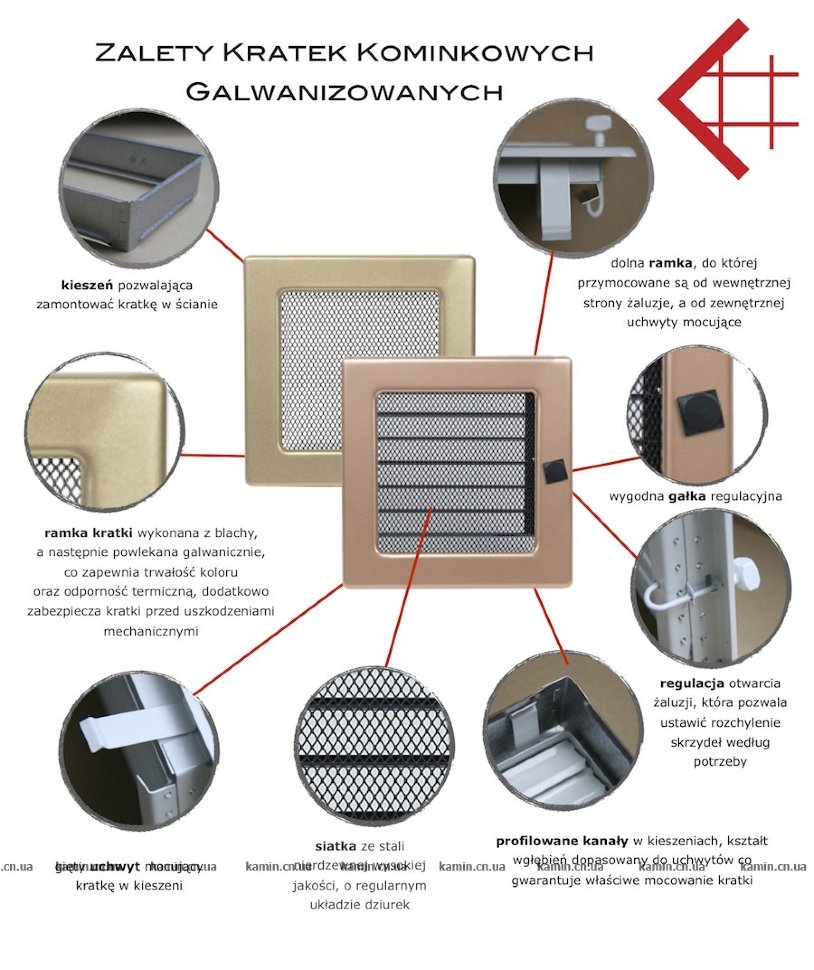

Galvanized ventilation grilles

Their main advantages:

- long service life - about 10 years;

- excellent strength;

- resistance to any serious impact.

aluminum grilles

They have many great features:

- quite light, and in a certain sense strong, although more fragile than steel products;

- do not rust;

- not afraid of temperature and humidity differences;

- resistant to various influences;

- look decent;

- easy to install;

- are inexpensive;

- been used for decades.

Wooden

These products are installed only in rooms with an optimal level of humidity. They are quite expensive. Without a special type of processing, models quickly lose their decorative appeal. Most often, these devices can be found in saunas or baths. Wooden products are produced only for decorative purposes, they can be made from precious woods, and the pattern on their surface is usually developed by a designer to order.

Plastic

Lattices made of high-quality plastic will not be afraid of high jumps in temperature and moisture. Their cost is quite acceptable, which attracts buyers. They are produced in various types and parameters (from 15 × 15 cm to 30 × 30 cm). These grilles have a fine mesh that protects the ventilation from insects or dust. A significant disadvantage of this material is that the plastic may turn yellow, fade or become scratched over time.

Steel

They are quite heavy, but very durable. They are made to order and made by hand welding. To put such a grille on the hood, you will need to choose a serious mount for it.

Gypsum

Such lattices are considered an excellent addition to classic interiors, especially if they have other plaster elements. Lattices made of other types of materials would not look very harmonious in such rooms, but gypsum structures that cover the ventilation holes will help you maintain the unity of the chosen style.

Devices made of brass, copper or bronze are elements of a luxurious interior. All sorts of monograms, stylish and elegant ornaments - all this is the original attributes of these products.They are produced for arrangement on floors and walls, they can also be found in window sills. Quite rarely, such models are used on the ceiling. The owners are offered a choice of a certain number of already created options, but many companies are ready to offer the production of such products to order or recreate the drawing according to the sketch of the home owner himself.

Playing with color options, you can make the grille stand out from the crowd or make it invisible by matching it to the color of the main surface. Many experts advise choosing a product to match the colors of the facades of the building. But at the same time, you should not dwell on the red colors of the product for a green or blue background, if there are no minor details of the same color. Often, gratings that have contrasting colors can harmoniously modify, and even significantly embellish the decor of a room, but you should choose them so that they are in harmony with other decor items. For example, a black or brown grille on a light floor or ceiling will come in handy.

Instead of an epilogue

In the course of the analysis of the market for air diffuser grilles, it was found that the domestic buyer prefers mainly the Russian product, and not even in the most expensive, but in the budget segment. More expensive fixtures are often purchased for specific ventilation projects (large shopping malls, cinemas and industrial premises). At the same time, an ordinary buyer does not try to save money by purchasing all the necessary materials in a retail network. But it is better to purchase industrial designs in large quantities and directly from the manufacturer.It is worth mentioning that decorative models (art casting, laser cutting) are almost never found in retail and are made exclusively to order.

Types and purpose of ventilation grilles

Grilles for ventilation systems are presented on the modern construction market in a huge variety of shapes, sizes, designs and materials of manufacture. Depending on the parameters listed above, the price of a particular product also changes. In the following sections, we will tell you about the highlights of these products.

Installation location

Experts distinguish between ventilation grilles according to the main indicators. The main place in the classification of the products we are considering is the place and method of their installation. According to this indicator, the ventilation grilles are divided into:

- Internal - in most cases, excellent ventilation grilles are installed from the inside of the premises. Their structures are not subject to special loads, therefore they are made mainly of plastic.

Such products are characterized by:

- Small sizes.

- visual appeal.

- Variety of styles and colors.

All this allows any, besides the most demanding client, to choose the most suitable model, organically combined with the non-specialized interior design of the room.

In addition, the internal subclass is very simple and ergonomic in do-it-yourself installation and future operation. Often an internal ventilation grill with a valve, which allows you to easily adjust the direction and intensity of air exchange in the room.

- Outdoor. In accordance with the name, these products are mounted on the outside of the building.The purpose of external grilles is to protect air ducts from the penetration of dust, dirt, insects, rodents and atmospheric precipitation. These are, in most cases, ventilation louvered grilles made of high-strength aluminum, resistant to aggressive environmental manifestations.

- Refineries. Ventilation overflow grilles are used for air exchange between rooms. Products for this type are equipped with V-shaped blinds, located so that they overlap each other. This provides light and sound insulation between rooms. There are special ventilation grilles for doors, partitions and walls, etc.

Design

The next indicator that determines the classification of gratings is their constructive highlights.

In accordance with them, the following structures are distinguished:

- Adjustable products are equipped with movable shutters, the opening and closing of which significantly affects the speed of air movement and the intensity of air exchange.

- Unregulated. The name speaks for itself. These are simple designs without additional features.

- Inertial grilles are able to automatically close the blinds in the absence of air mass movement.

Materials for manufacturing

Ventilation grilles are made from different materials.

Based on this, the products are classified into:

- Plastic.

They are distinguished by:

- Low price.

- resistance to biological action.

- Convenience and ease of maintenance.

- Probable change in color and shape under the influence of ultraviolet radiation.

- Aluminum products are light, durable, not afraid of direct sunlight, but more expensive than plastic ones.

- Wooden gratings are used only indoors.These eco-friendly, aesthetic products fit harmoniously into the most sophisticated interiors. Lattices are made of solid wood, therefore they require special care and cost a lot.

- Steel ventilation grilles are very strong and durable. They are much heavier than aluminum structures and are much more expensive.

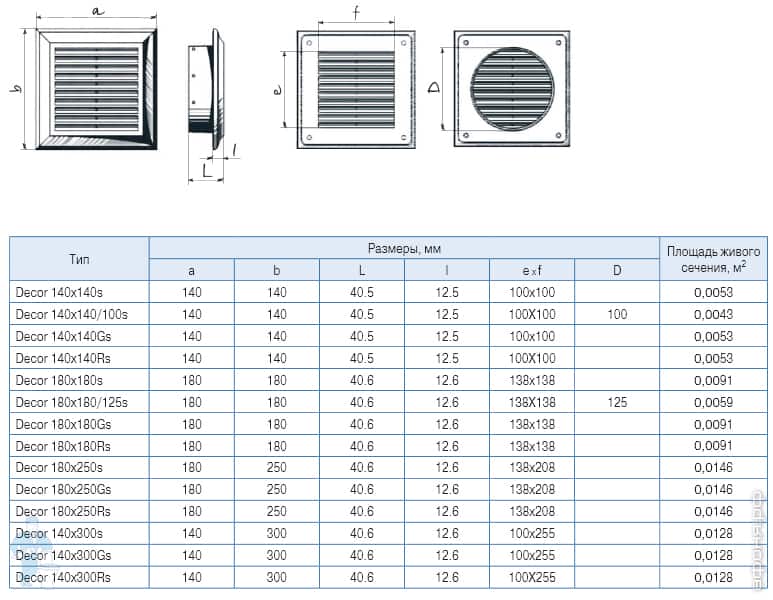

Product shape

The fourth of the main indicators that determine the classification of ventilation grilles is their shape.

In this case, there are much more options than the basic geometric shapes:

- Square.

- A circle.

- Oval.

- Rectangle.

Manufacturers of ventilation grilles, especially for indoor applications, do not stop looking for new shapes and decorations for their products.

Of course, for the design of ventilation ducts from the street, simple round ventilation grilles are used, external, or square and rectangular. It goes without saying, if we are not talking about special architectural solutions of the building, at a time when every little thing must correspond to a non-specialized ensemble.

Features of the choice of air distributors

As a rule, each room has its own ventilation project, which specifies all the necessary parameters for future ventilation grilles. From this it is clear that the selection should be carried out on the basis of the requirements of certain special monograms. In the case when a powerful ventilation system is supposed to be launched, the main selection parameters will be the air flow rate and speed (as mentioned above, for such projects it is better to use products from various metals and their alloys). In most cases, they are equipped with special regulators.

For domestic needs, users typically rely on the following criteria:

- Color and shade of products;

- Is it necessary to provide the model with a fine mesh;

- Aerodynamic characteristics and soundproofing properties;

- Place of installation (street, indoor premises, basement, attic, etc.);

- Ease of maintenance;

- Mounting method (overlay or built-in method);

- Dimensions of the air outlet;

- Estimated air mass flow.

Basic concepts

The movement of indoor air is very often restricted by closed doors. This does not allow even distribution of both temperature and humidity. One solution to this problem is the use of ventilation grilles.

This type of construction for doors belongs to the overflow ventilation devices. They consist of several structural elements:

- Lattice. This part is made in the form of a solid frame, between which the strips are located at a certain angle. This allows the air to move freely.

- Decorative overlay. The product is a small design that repeats the previous element in shape. Install it on the other side of the door to hide the places where the hole was cut.

You can install overflow grilles in almost any door, but often they are found only in a few rooms:

Kitchen

This is important if the hood is constantly working here. It removes dirty and hot air, and a fresh stream enters the room just through the holes in the door.

Bathroom and toilet

In such places, ventilation systems are used very often.

This is especially important for the bathroom, where a large amount of moisture accumulates.And to prevent the formation of mold, surfaces should be thoroughly and constantly dried.

Interior doors. This approach is relatively rare. These structures are used in large offices where it is necessary to create comfortable conditions for workers. Such doors can also be seen in large archives or libraries, where it is necessary to maintain an optimal mode for storing paper.

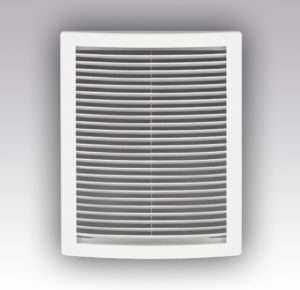

louvred grilles for ventilation

The required speed of air movement through the ventilation system varies depending on the season or even the time of day. With a forced ventilation system, it can be regulated using a fan, and with a natural one, this is done using louvered ventilation grilles. Their slats (or they also say “cilia”) of the gratings are movable, depending on their position, the amount of air passing through them changes. There are two extreme positions - fully open and fully closed, and many intermediate ones.

There is a second option - with a movable valve. The principle is different, but the essence is the same - to block or open the air flow.

Louvre grilles are also called adjustable, as they have a movable damper

These gratings can be controlled manually - there is a small lever, by moving which we change the position of the slats. There are models with automatic control, but they are built into the ventilation system, the operation of which is controlled by the processor.

Blinds are external and internal. You can regulate both the incoming flow from the street and the outgoing one. It is convenient to put outdoor ones on ventilation ducts in the foundation. In winter, you can almost close them, reducing the ventilation of the subfloor to a minimum.

For indoor installation, adjustable grilles are placed for natural ventilation on supply or exhaust ducts. In general, it is convenient, but the mechanism requires maintenance, periodically the grate must be removed, cleaned and lubricated with movable joints. They become clogged with dust and dirt, which reduces the range of adjustment.

Step by step installation instructions

Whatever the configuration of the system, the ventilation grill with a non-return valve must be placed so that the back draft is blocked, regardless of the number of fans and hoods running.

Before installing the grate, do the following:

- Test the valve for possible jamming. Incorrect orientation will prevent airflow from opening the damper.

- Compare the dimensions of the product with the shape of the ventilation duct.

- Strengthen additionally on the wall the area adjacent to the hole.

- Mark the places for fasteners by applying the grid to the ventilation hole.

- Drill holes for the dowels and install them.

Next, mount the grill using self-tapping screws. If the installation is carried out on wood or drywall, use a drill with the appropriate drill bits.

Concrete, brick can be drilled with a puncher with a drill bit. For ceramic tiles, special drills are used. The disadvantage of this method is the visibility of the heads of the screws.

Indoors, gratings are also installed on clip-on latches, which are produced for products made of aluminum. They are mounted on a frame and inserted into the ventilation opening.

Indoors, gratings are also installed on clip-on latches, which are produced for products made of aluminum. They are mounted on a frame and inserted into the ventilation opening.

For outdoor installation, this method is not recommended, because.fasteners may loosen due to weather conditions.

Sometimes grilles are mounted on self-tapping screws from the inside to the end of the ventilation opening. You need to act here very carefully and do not over-tighten the bolts. Otherwise, the grille in the corners may be damaged.

This method of fastening is reliable, while the screws are not visible.

If it is impossible to install the grate using the usual method, there is another way. Installation is also carried out on self-tapping screws using mounting plates of various lengths

If it is impossible to install the grate using the usual method, there is another way. Installation is also carried out on self-tapping screws using mounting plates of various lengths

It is easier, but less reliable, to fasten the grate to glue such as liquid nails, budamex, foam, dragon, titanium.

The adhesive layer is applied evenly on the reverse side of the grate or around the hole along a pre-applied contour. Fix the product with mounting tape, which is removed after the glue dries.

After the installation of the ventilation grate is completed, the joints must be sealed.

Advantages and disadvantages

A conventional grill allows air to pass in both directions, equipped with a check valve - in one direction, and this is its advantage.

It also has other advantages:

- protects against the ingress of debris, insects, dust, allowing you to maintain the performance of the hood;

- reduces the noise level when the valve is closed;

- acts as a thermostat, not letting in cold or too warm air, prevents condensation;

- blocks the penetration of odors from other rooms or the mine.

- easy to install;

- inexpensive;

- has a reliable design, can last for many years;

- Available in different designs, you can choose to any interior.

There are practically no disadvantages of using it, but the following can be noted:

- during frosts, the damper may freeze and not allow air to pass through, especially for private houses with a grille outside. Solution to the problem - models with a heater;

- periodic cleaning of the structure from accumulated dirt is required, which can be difficult when installing the grate inside the duct;

- slightly reduces the performance of the hood, because the grate is still an additional obstacle to ventilation.

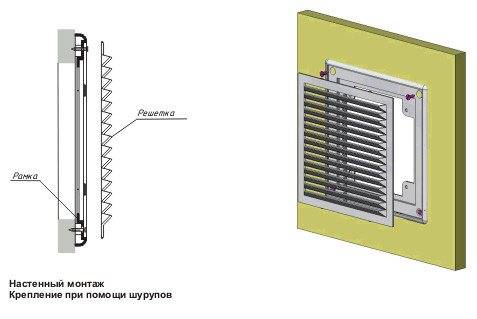

Basic installation methods

Installation of a ventilation grill does not require special knowledge and skills. It may well be produced by a home master with patience and accuracy. Most industrial products consist of two parts:

- the main body, mounted directly on the hole in the wall or door;

- a removable part inserted into the openings of the housing, which allows you to easily inspect and clean the channels of the ventilation system.

They begin to hang the internal ventilation grill from the first part, which plays the role of a frame. Do this with the help of fasteners or adhesives. Prior to this, the outer surface of the ventilation hole is suitably prepared. It must be flat and clean. Usually the grate is placed on the wall after applying the finish coat to it. You can do this in different ways:

- Fastening with screws or self-tapping screws is carried out on a solid wall made of concrete, wood or drywall. To do this, through holes are drilled in the lattice body in places closed by a removable part, which are countersinked in the shape of a cap. In concrete or brick, dowels will have to be installed using a drill in appropriate places.When constructing a lattice without a removable part of the screw head, after installation, putty and paint over the color of the base material.

- Fixing with a plinth or glazing bead is usually used for wooden products that fit well into a country-style interior, entirely made of wood. In this case, self-tapping screws or finishing nails with a reduced cap size are also used.

- Industrial models with standard spring-loaded spacers included in their device can simply be inserted into the vent, which must have standard dimensions for this.

- Attaching a plastic grate to any base is easiest with glue. This is especially true for walls lined with fragile materials such as ceramic tiles. For this, liquid nails are usually used. They are applied in a continuous strip on the back side of the part, which is pressed against the wall and fixed using masking tape until completely dry. In this case, it will no longer be possible to dismantle a fragile part without destroying it.

The removable part of the grille is tightly inserted into the base fixed on the wall. At the same time, for aesthetic reasons, it is better to turn it so that the holes between the slats of the blinds are not visible to a casual observer standing on the floor of the room.

During the selection and installation of overflow gratings, care must be taken to ensure that no direct passage of light rays through them is obtained. This can degrade soundproofing and does not look very nice.

Plastic models usually include a thin mesh that quickly becomes clogged with dust, reducing the effectiveness of the ventilation system. Therefore, most masters do not install it.Otherwise, you will have to regularly clean the grid.

How to install a ventilation grill with your own hands

The ventilation system itself is a complex device that requires a professional approach. The grid can be installed independently.

The ventilation system itself is a complex device that requires a professional approach. The grid can be installed independently.

It is necessary to choose the right product so that it does not interfere with proper ventilation.

Detailed instructions on how to install a ventilation grill

Each product is equipped with a split body, the rim is mounted in the air outlet section. Next, the second part of the structure is installed on it, which can be easily removed and cleaned during operation.

Requires the presence of rubber gaskets, they prevent the occurrence of vibrations. The back wall is often equipped with a specialized mesh, which will subsequently filter the air flow.

Fixing the product is possible in several ways:

- The use of screws, suitable for overhead grilles, holes are made under them in the base, then the fastening elements are mounted and decorated.

- Plinth, is rare and performs mainly a decorative role.

- Taper head bolts, the method requires accuracy. For this, hidden-type corners or brackets are installed, which are mounted around the entire perimeter of the ventilation hole.

- Glue and spacer clips are hidden fasteners. For installation, ordinary ceiling glue is used, like Titanium, it is applied with a gun and the grate is pressed around the perimeter of the hole. In this case, there must be perfect tightness. Spacer spring parts are also used.

Each method is individual and requires care.

Possible technical difficulties when attaching the ventilation grille

Difficulties can arise only with inattentive handling of materials and non-compliance with installation recommendations. In general, fixing the ventilation grille takes a little time, and it does not require special skills and materials.

Types of exhaust grilles

Metal and plastic types of ventilation grilles, depending on the purpose and place of installation in the duct, are: exhaust and supply. Given the installation location, these products are:

- outdoor;

- internal;

- reflow.

Internal

One of the most popular types on the market. Taking into account the features of functioning and fastening, they are:

overhead - are used mainly in residential facilities, in systems where natural draft prevails. The presence of a mosquito net prevents insects from entering the premises. Often equipped with a check valve. Throughput can be adjusted using movable slats;

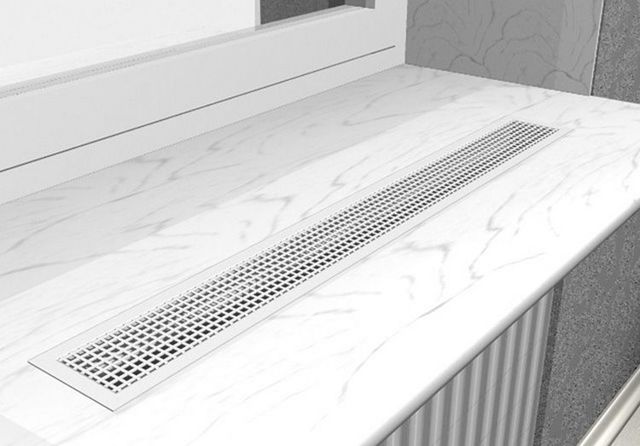

- slot models - the installation of ventilation grilles of this type is in demand primarily in areas where it is necessary to ensure the invisibility of the product. Their design and appearance matches the room;

- check valve models. Popular solutions equipped with inertial shutters, backdraft damper. Often used as a functional element for an exhaust device.

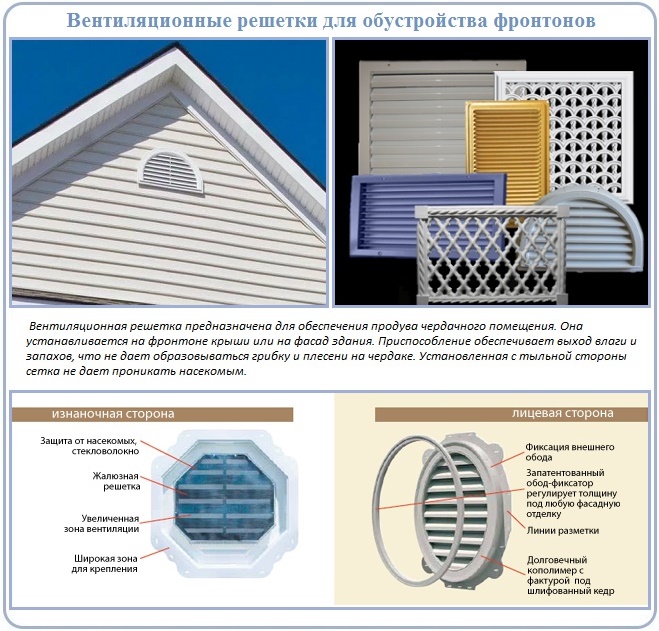

outdoor

Outdoor products are commercially available in several types of structures:

- frontal models - installed mainly in attics. Differ in a wide fringing and magnificent appearance;

- door models - functionally replace the supply valve, which is important primarily for those rooms where it is necessary to provide natural air supply;

- floor models - the perfect solution for organizing the supply of fresh oxygen to the lower part of the room. These can be stationary or adjustable solutions;

- plinth gratings - used mainly as a protective element against rodents. Installing a ventilation grill will protect basements and attics, basements from small pests.

Internal overflow

As for the overflow internal options, they can be different not only in color, but also in shape. They have an attractive design. Among professionals, products of round and rectangular shape are in demand first of all. Their main feature is the absence of valves.

Fireplace protective elements are widely used in fireplace rooms, which ensures the supply of heat to the room. The penetration of cold air masses is carried out through the lower part of the lattice, and after warming it is redirected into the room.

The installation of several ventilation grilles within the same fireplace is an important component of effective air exchange.

Note! Fireplace models are made from refractory and refractory materials. Given the variety of ornaments and shades, they are considered decorative.

1 Types of decorative ventilation grilles

Depending on the conditions of installation and installation of louvered grilles for ventilation, they are divided into several varieties.There are options that are designed for external installation - they have additional ribs in order to withstand various adverse environmental influences on the construction material as much as possible. Beautiful design visually have interior installations. Such a condition is mandatory, because most people strive to hide, as best as possible, all the flaws and shortcomings. A hole in a wall, ceiling or floor can have a different diameter and shape, so choosing the right size and style of the louvre will solve the problem with an aesthetic appearance. It is with their help that all holes that are made in partitions or walls in a conspicuous place will be closed.

Figure 3 shows different variations of sizes and shapes.

A supply unit can ensure the correct organization of air exchange between rooms and rooms. Thanks to the presence of such a system in your home, the microclimate will always be comfortable and convenient. There are cases when louvered ventilation grilles are installed in the floor

They must be as strong and reliable as possible, so special attention is paid to the material from which they are made. We must not forget about such a variety of louvered ventilation grilles as ceiling

Very often they are found in commercial buildings and shopping centers. The design of the ventilation grille must meet several parameters and criteria:

- it is made, as a rule, from a durable and wear-resistant material that will allow you to use the structure for a long time;

- have an optimal shape for maximum comfort during installation;

- a clear specific size is selected, respectively, for the grooved hole.

Many people think that in order for the room to have normal ventilation, it is enough to equip the windows with grate adapters. This, of course, will not be enough, since only in combination natural and adjacent ventilation create an optimal microclimate in a particular room. With the help of such details as ventilation louvered grilles for ventilation, supply and exhaust, exhaust and supply ventilation is fully provided, with the help of which the mass of air that is inside the room is fully compensated by the outside.

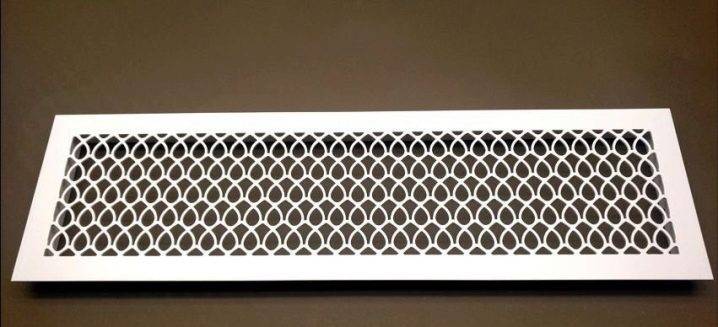

Choice by design

Thanks to successful design solutions, ventilation grilles have different shapes. You can make an individual order for the manufacture of grating with a pattern on the hole that you want. At the same time, the product can be in any color suitable for your interior. A kind of "revitalization" of the lattice is given by additional stripes and lines that are applied to the body of the product. Leading designers have also introduced innovations that have affected the choice of material for manufacturing. So, ventilation grilles can be ordered from:

- brass;

- galvanized metal;

- aluminum;

- plastic;

- silver.

However, despite all this, the lattice must first of all fulfill its functional aspects. Whether it is louvered, slotted, flow or exhaust, it must fully meet the requirements of your premises.