- Why do you need a check valve for ventilation: problems and how to fix them

- Main types

- Forced ventilation device and its pros and cons

- How does the check valve interact with the fan

- Ventilation grill with check valve: how to install it

- Exhaust tees and how to use them

- Installation of a non-return valve on the hood in the kitchen

- The principle of operation and types of check valves

- Valve types

- Types of check valves

- Design differences

- Device advantages

- Types of devices by design

- Types of ventilation

- How to make a check valve for ventilation systems

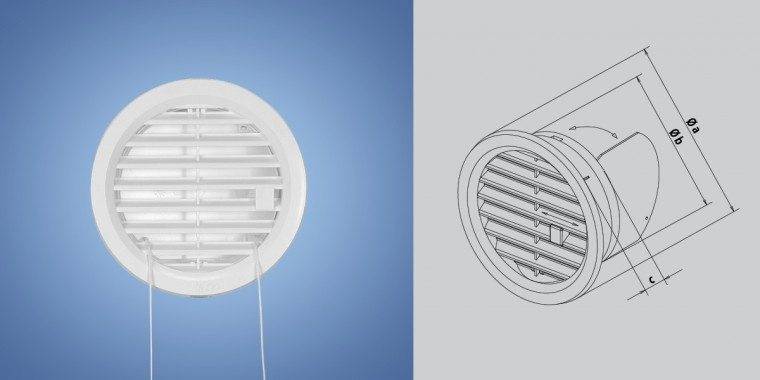

- Ventilation grills

- Advantages and disadvantages

Why do you need a check valve for ventilation: problems and how to fix them

With the help of an open flame, the actual state of the draft is checked. In this case, it is missing.

Signs of a violation of the normal operation of the system are extraneous odors penetrating from other premises (apartments in a multi-storey building). The penetration of cold air in winter disrupts comfort and increases heating costs. Together with the reverse flow, various contaminants from the ventilation system enter the room. Some of them can be harmful to health.

It is clear that such shortcomings are best eliminated. But first you need to understand the reasons for their appearance. Some - can be eliminated to improve the functional state of ventilation.

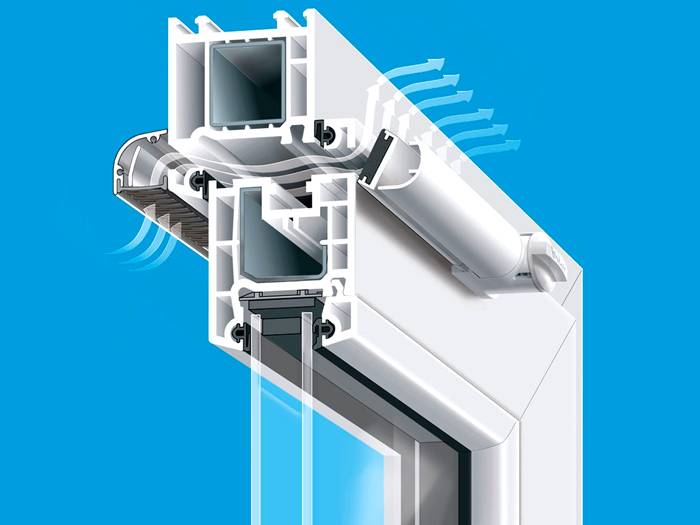

Modern window design

Sometimes problems arise after replacing old frames and installing double-glazed windows. New window blocks provide perfect tightness, completely blocking the access of fresh air to the room.

To eliminate the shortcomings, the design is equipped with a built-in supply valve

Special kit for wall mounting

As a rule, filters are installed in these products, which can become clogged over time. Regular inspection and cleaning will help restore lost functionality to the fullest.

A change in the direction of the air flow can occur when connecting several sampling points to one channel. Similar manifestations are not excluded in strong winds, in frosty weather. It is especially difficult and even impossible to influence the actions of neighbors in an apartment building. Claims against them can only be made if the duct is completely blocked. If smells come from someone else's kitchen, where a powerful hood works, the problem will have to be solved independently.

Main types

In fact, there is a huge selection of gratings, you can choose products for every taste, color and even wallet. But, despite this, all devices have their own distinctive features by which they can be differentiated.

The primary classification feature of the difference is the place and method of installation, it can be as follows:

- outdoor - this option involves mounting the grate on the outer wall of the building, where the ventilation pipe exits;

- internal type - most often mounted in a kitchen or bathroom, the structure is installed in the opening of the exhaust shaft;

- overflow type - such products allow you to regulate the air exchange between adjacent rooms.

As for outdoor structures, they differ from all other types in their dimensions, high level of strength, as well as good resistance to sudden temperature changes and other external climatic conditions. A rigid frame is additionally installed on them, which goes inside the ventilation hole. And then it is securely fixed with steel anchors or with the help of special factory spacer elements. It is this installation method that is considered the most reliable and durable.

Will be useful: Photo frames do-it-yourself from the plinth

Fixing the ventilation grill inside the room is absolutely not difficult, everyone can do it. These products are distinguished by their aesthetic appearance, lightness and compactness. For the bathroom, it is advisable to purchase devices made of waterproof material, such as lightweight plastic.

Forced ventilation device and its pros and cons

It is quite convenient when, if there is any smell in the kitchen or dampness in the bathroom, you can turn on the fan, which will quickly remove unwanted air from the room. Often such devices are installed on windows or vents. And yet, in addition to positive qualities, they also have negative ones, such as the need to supply electricity to them.

And yet there are cases in which forced ventilation is indispensable, and they have already been mentioned earlier.However, the most interesting thing is that the devices that require connection can be both stationary and mobile. And if you choose a fan with a built-in check valve directly to the size of the window, then you can install it only at the necessary moments. The rest of the time he will clean up. For such devices, a dedicated connection is not required, because. for a while they can be powered through an extension cord.

Let's try to consider such devices in order to understand how they work.

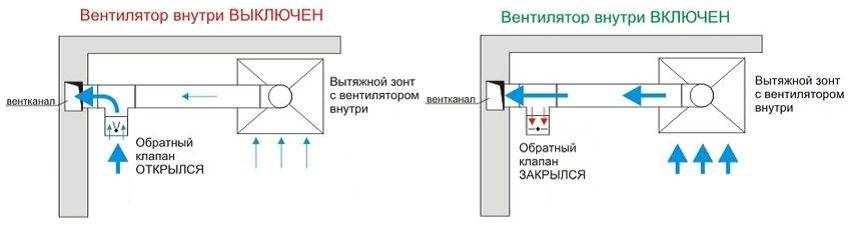

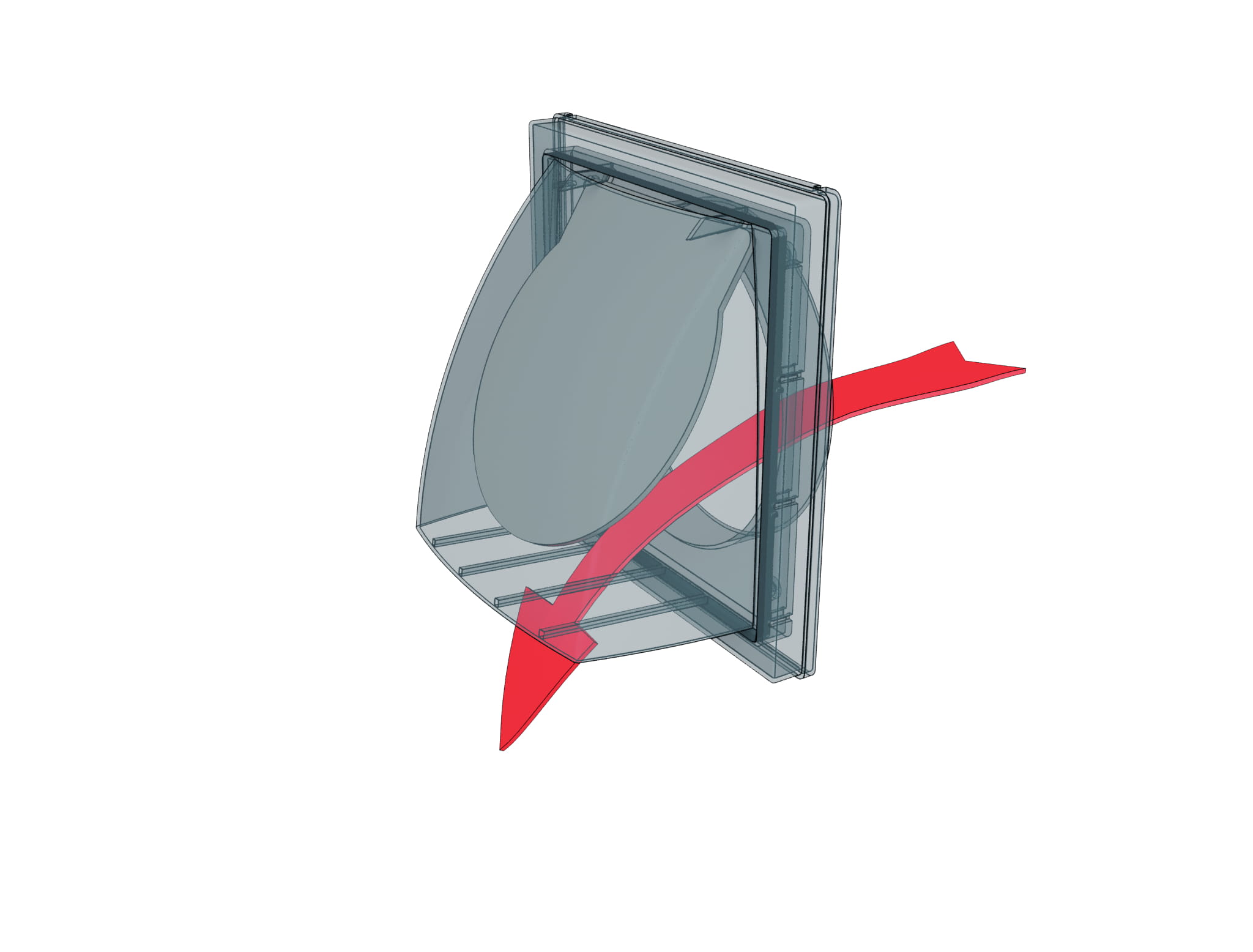

How does the check valve interact with the fan

When installing a fan on the window of the room, it becomes possible to ventilate it faster. When voltage is applied, the blades begin to rotate, pulling air out of the room and opening the valve petals. Well, when turned off, the valve closes, blocking the access of cold street air to the apartment. As you can understand, the essence of the device is elementary.

It is also possible to install a valve with a mechanical drive, when the owner himself, manually, can close it or open it. In fact, the non-return valve on the hood with a fan works exactly according to this principle. The difference is only in the location - horizontal or vertical.

Ventilation grill with check valve: how to install it

Such a device is very convenient not only to use, but also to install. The fact is that special skills for its installation, as well as a specialized tool, are not required. It is enough to dismantle the old grate, and install a new one equipped with a check valve in its place.

In fact, working like blinds, deployed in the opposite direction, the device regulates air flow.With the help of such a grille equipped with a check valve for ventilation, extraneous odors are cut off, as well as cold street air. As for the acquisition of such devices, there are no problems with it. And the cost of ventilation grilles with a valve these days is quite acceptable.

Exhaust tees and how to use them

It is no secret that when installing a built-in hood, a tee is required, which will allow you to both connect the equipment to the ventilation system and leave natural air exchange in the room. Nowadays, they are produced quite a lot, and various modifications. Of interest are just tees for hoods with check valves, while their number may be different.

Usually two check valves are built in - for the hood and for natural ventilation, but sometimes a backup valve is installed - on a common pipe. In general, tees with check valves for ventilation are not used so often. It is believed that one air damper at the input is enough. But here, of course, the taste and color.

Installation of a non-return valve on the hood in the kitchen

Just such an arrangement of the air damper is the most common. Well, this is quite natural, because putting one check valve for the hood is much cheaper than buying a tee with two or three. In addition, most often, such devices are already installed in modern forced ventilation devices. And if a conventional hood with an old-style check valve can still let a small amount of air back, then newer models are devoid of such a “sore”.

Expert OpinionAndrey PavlenkovHVAC Design Engineer (Heating, Ventilation and Air Conditioning) ASP North-West LLC Ask a Specialist Some technical documentation says that an anti-return damper for the hood is built in. What is it to remember. In fact, this is the same check valve, but it works much faster and thereby prevents even the slightest ingress of external air. But what can be said for sure - it works only with forced ventilation, or it connects to the network and is controlled automatically.

The principle of operation and types of check valves

The non-return valve for mechanical systems and natural ventilation belongs to the group of air dampers and regulators designed to change and shut off the air movement in supply and exhaust systems. If the device accepts only the "open" or "closed" positions, then it is considered to be on-off. In multi-position products during operation, the air damper takes several positions (with different throughput). Check valves are used to move air in only one direction and are two-position devices.

Structurally, check valves are available in the following types:

- petal;

- with a gravity grid.

Models with a gravity grate are installed at the end of a branch of the ventilation system. For example, at the exit from the exhaust network to the street. They are lattices in which the blinds are freely raised by air pressure and lowered by gravity. Such check valves are used only when air moves in a horizontal position.

Gravity type check valve.

In a natural ventilation system, such a product is not applicable, due to the peculiarities of its functioning. If you install it at the outlet of the ventilation shaft, then the pressure of the flow of air naturally rising through the channel rarely reaches such a value that the blinds on the grille can lift.

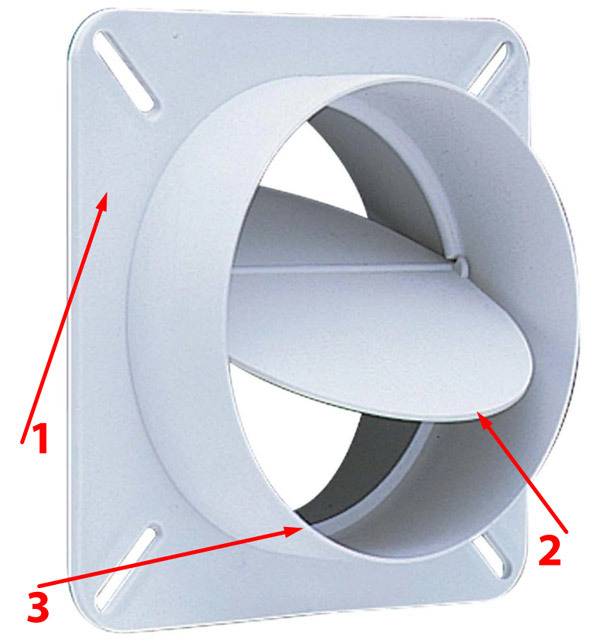

Valves of the second type consist of a body and petals that completely block the channel section when the air flow moves not in the design direction. They are conditionally divided into two groups - single-petal and two-petal ("butterfly" type).

Check valves single-petal and "butterfly".

In check valves of the first type, the petal, which blocks the movement of air, is freely fixed on the axis in the section of the product. The position of the petal depends on the angle of inclination of the valve and the air pressure. In a disconnected system, they can be in both open and closed positions, and when air moves in the right direction, the flow area increases in proportion to pressure.

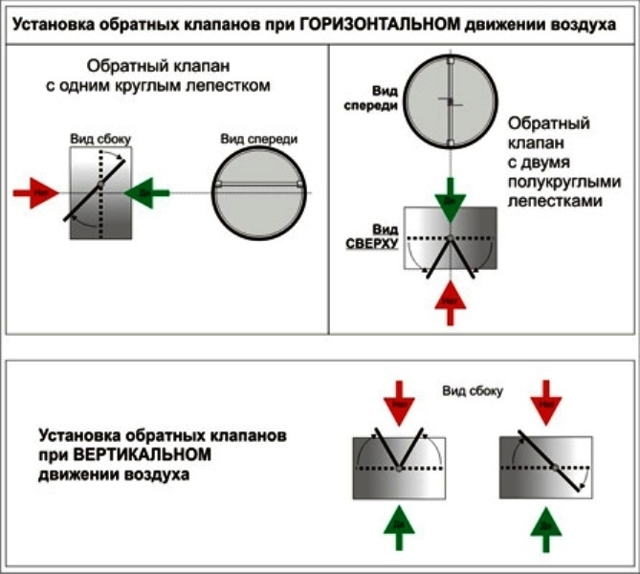

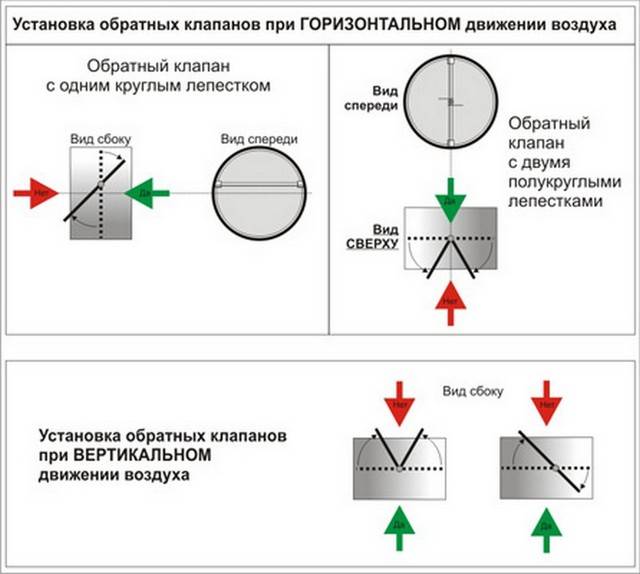

Products with two petals are equipped with a spring retainer or counterweight. In the absence of air movement, the device is completely blocked. They are used in a vertical and horizontal position, unlike single-lobe, which, with the calculated movement of air from top to bottom, cannot be installed in the closed position when the system is stopped. All types of valves are produced for both rectangular and round ducts. The maximum speed of movement in the section of the check valve is 12 m/s.

The operation of valves with petals.

Due to technical and structural features, double-leaf valves with a spring are not applicable in natural ventilation systems, since the pressure in them is not enough to open.Single-lobe devices work effectively as check valves in the natural ventilation system. Consider the application scheme.

Valve types

By design, valves can be:

- Single leaf. An effective but less common option. During the movement of the air flow, pressure is exerted on the valve flap, which causes it to open and release excess odors. When there is no movement, the sash closes under the influence of the reverse thrust. This prevents unwanted odors from entering the room. If a person uses natural ventilation, this option is most preferable.

- Butterfly type valve (two-leaf). The most common model, which is equipped with two curtains. They open due to the strong influence of the air and close when there is no movement. Everything works automatically without user intervention.

- Blinds. The principle of operation of this device is the same as that of the first option. The only difference is the dimensions. Therefore, it is installed in large manufacturing enterprises or in large houses.

- Membrane type construction. The principle of operation of the device is based on a change in the position of the plate due to the influence of the air flow. The equipment has been widely used in places with natural ventilation, since there is no need to exert a strong influence on the main element.

These are not the only differences, there are also models:

With manual control, the device is installed in large enterprises where there is high air movement. Automatic products work without user intervention, this option is more suitable for home installation.

They differ in the way of installation.There are horizontal and vertical options.

Available in round and rectangular

To choose the right option, it is important to understand that the shape depends entirely on the size of the air channel section.

Throughput is also taken into account. It all depends on the volume of air that passes through the valve.

The last difference is the material of manufacture

Plastic ones are suitable for installation in houses and apartments, as they make less noise during operation. For office buildings and industrial enterprises, it is recommended to install metal products. They are larger and have higher throughput.

Types of check valves

The purpose of the check valve is to reduce or increase the cross section of the ventilation duct. Depending on the task assigned to the check valve, there is a greater or lesser influx of fresh air or an outflow of polluted air masses. But the main task, nevertheless, is to prevent the influx of foreign odors into the living quarters, which can penetrate for various reasons - clogging of ventilation ducts, their poor tightness.

Today, the consumer has the opportunity to choose among a variety of similar devices a non-return valve for natural ventilation:

- according to the material of manufacture;

- in form;

- according to the way of functioning;

- at the place of installation;

- by the ability to pass a certain amount of air.

According to the material of manufacture, they are made of metal and plastic, the shape of the check valve can be round or rectangular and depends on the design features of the ventilation system itself, the shape of its section.

Plastic and metal are materials of different qualities, so valves made from them are used in various ventilation systems, depending on the conditions and design features of the latter.

According to the method of controlling the ventilation device - automatic and manual. Automatic devices can be controlled, almost without human intervention, using microcircuits. Manual control is used in simple ventilation systems where the amount of air flow and time is controlled by simply opening or closing dampers.

The check valve can be installed vertically or horizontally, depending on the design of the ventilation system. If the air ducts are located vertically, this implies that the air masses move vertically, so the installation of the check valve on the ventilation is done horizontally so that the blades of the device can pass the air flow with great effect. With a horizontal arrangement of ventilation ducts, the check valve is mounted vertically.

Throughput is a parameter that determines the amount of air that can pass through the ventilation device in a certain time. Different types of check valves have different flow rates.

Design differences

The check valve device is not a complex engineering mechanism and looks like blades or horizontal blinds freely attached to the axis.Also in the design there is a counterweight, the task of which is to stop the operation of the check valve at a time when the supply fan is not functioning.

Such devices are used in ventilation systems that use air ducts of various large sections, in shape - square, rectangular or round. Mounted on holes specially made for this purpose. If used in industrial systems where there is an increased explosion hazard, then the check valve can have dimensions from 125 mm to 1000 mm.

The butterfly check valve for ventilation is made of zinc-coated steel, has two blades fixed on an axis, which is installed in the center of the ventilation duct opening. The damper operates only when the supply fan is on; when it is turned off, the blades close. This principle of operation is relevant for almost all such devices.

There are models of this type of check valve that are equipped with rubber seals, which makes it possible to reduce the noise level emitted by the movement of the blades. Products with section sizes from 100 mm to 315 mm are produced.

There is also a flap type check valve, also called "blinds". It is a lattice with horizontally narrow blades that allow air masses to pass in only one direction. They are often used in everyday life when it is necessary to improve the operation of the exhaust ventilation system.

Instead of several blades, the air check valve for ventilation may have a design consisting of square or round plates that perform full or partial blocking of the ventilation channel.

Such devices cannot always be used, because at negative outside temperatures, the plate, in contact with the walls of the ventilation shaft, can become covered with ice, which has to be removed with a building or household hair dryer. To do this, it is necessary to make easy and convenient access to the check valve.

Device advantages

The check valve grill is a simple and easy-to-use device, characterized by a number of advantages:

- Prevents the penetration of cold or hot air from the outside.

- Serves as a reliable barrier against dust and insects.

- Protects the room from the penetration of extraneous noise and unwanted odors.

- It is easy to install and maintain.

- Has an attractive design. A wide range of such devices will allow you to easily choose the grate that best suits the interior of the room.

At negative temperatures, the valve may freeze, which is easily solved by adding a heater to the system.

Types of devices by design

Check valve devices are available in rectangular and round design, which allows you to choose the right model for each type of air box. By design, valves are divided into four groups:

- A single-leaf valve device (the so-called "Petal") has a single locking leaf. The axis on which the sash sits is offset from the center of the air duct. Therefore, the bottom of the screen is heavier than the top. Direct air flow lifts the lightweight plastic shutter, and in its absence, gravity returns the shutter to its place. The disadvantage of the system is that installation is possible only in horizontal sections of the air duct.

- Multi-leaf devices ("Grid" type) are similar, but have not one locking element, but several. They are made in the form of blinds covering the ventilation grill on one side. As a rule, gratings are placed at the outlet of the ventilation well from the house.

-

Bicuspid valves ("Butterfly" type) have a pair of flaps fixed on the same axis. Outwardly, the wings resemble the wings of a butterfly, hence the name. A spring fixed between the shutter petals returns to the closed position of the sash. "Butterflies" are great for ventilation systems equipped with exhaust fans. But the force of the natural air flow may not be enough to move the sash.

When choosing a butterfly valve for ventilation, make sure that the spring power is not excessive, and that the petals are equipped with a damper gasket. Otherwise, the valve will knock when closing, which can irritate the nerves.

- Valves based on a flexible membrane are the simplest in design. They have a thin polymer film acting as a damper. Direct airflow deflects it to the side. And the reverse flow (even the weakest one) tightly presses the light plastic to the body, blocking the lumen of the box. The main advantage is simplicity and low cost. The main drawback of the design is low durability.

Expensive valve models are equipped with adjustment mechanisms that allow you to adjust the sensitivity of the device. On cheaper varieties, such opportunities are not available.

Types of ventilation

What is ventilation - if we look superficially, this is the process of replacing the air that was used indoors with clean - outdoor. With ventilation, perhaps change the physical parameters of the environment, that is:

- heat

- cool

- condition

- filter

- drain

- ionize etc.

Different types of rooms use different sanitary standards. Technological premises where complex chemical processes take place, and calculation during the construction of civil buildings. They have completely different sanitary and hygienic standards of air and air.

How to make a check valve for ventilation systems

The question of how to make a check valve to equip the ventilation system is no less relevant than the manufacture of such a device for water supply or sewerage. By installing a check valve in the ventilation system, you will reliably protect your home from polluted and cold air entering such a system from the outside.

The simplest vent check valve is a piece of flexible material placed on the grate, but this design will not work with natural exhaust

It should be noted that the check valve of the proposed design, when compared with serial models, is no less efficient and can successfully serve you for two to three years.

A more advanced design consists of two movable flaps attached to the sides of the ventilation grille.

So, the manufacture of a home-made check valve for equipping the ventilation system is performed in the following sequence.

- First of all, it is necessary to make the main element of the check valve - a plate on which the flaps will be fixed.To create such a plate, which is cut strictly according to the shape and size of the ventilation duct, you can use sheet textolite or other durable plastic with a thickness of 3–5 mm.

- Along the edges of the sawn plate, it is necessary to drill holes with which it will be connected to the fan and fixed in the exhaust duct. In addition, holes must be drilled in the central part of the plate. This is necessary so that air can freely pass through it. The throughput of your ventilation system will depend on how many holes you drill in such a plate.

- The plate, using a sealant and a gasket, should be fixed in the chimney. Under the places where the plate will be fixed with screws, it is also necessary to place rubber gaskets. This will reduce noise and vibration levels in your ventilation system.

- According to the shape and dimensions of the plate, a piece of dense film is cut, the thickness of which should be at least 0.1 mm. From the film, which is glued to the plate along its edge, the shutters of a self-made check valve will be formed in the future.

- The exhaust pipe, in which a plate with a film glued to it, is already installed, must be installed in the ventilation duct using dowels or self-tapping screws for this purpose. After installing a check valve in the ventilation duct, it is necessary to securely seal the gaps between the walls of the duct and the exhaust pipe.

final stage of installation of a homemade check valve in the ventilation system is cutting the film pasted on the plate into two identical halves.When performing such a procedure, for which it is best to use a sharp mounting knife, it is necessary to ensure that the cut is perfectly even.

The principle by which the check valve of the design proposed above works is quite simple and is as follows.

- Nothing interferes with the flow of air that passes through such a valve in the direction from the room: the flaps open and let it through freely.

- When a back draft occurs in the ventilation system, the flaps of the check valve close securely, preventing outside air from entering the room.

In all systems where water is used, its flow is implied in a certain direction.

Backflow can be caused by various reasons, which we will discuss later, and is considered an abnormal situation.

A check valve will help prevent a failure in the systems. With your own hands, this mechanism can also be made. Consider how to make a check valve for a pump, a sewer with your own hands, where the device is used and how it works.

Ventilation grills

The ventilation grille, despite its simplicity, is a reliable constructive solution. Rigidity of a product is provided with a strong frame. It can be combined with the air duct or fixed to the wall surface. In large lattices, there is a division of the structure into several smaller sectors, and this is done using a frame. Due to this, the strength characteristics of the product are increased. A removable plastic or metal panel covers the working area of the grate. It should be noted that the distributors are:

- adjustable - the direction of the air masses can be changed;

- non-directional action - oxygen freely penetrates into the room, often perform a decorative role.

- with check valves. At enterprises, warehouse and industrial complexes, gratings of this type are installed. They eliminate the effect of reverse thrust, prevent the penetration of dust, small insects. This design ensures the movement of polluted air exclusively to the outside. It can also be installed in the apartment in order to exclude the receipt of an unpleasant smell from the neighbors.

- Inertial shutters are similar in operation to non-return damper solutions. Horizontal lamellas move and block the air flow. To ensure quick adjustment, light and reliable materials (PVC, aluminum) are used.

Ventilation grilles are often equipped with horizontal blades, thanks to which you can adjust the intensity and direction of the supplied air.

The cleaning process is reduced to the removal of the decorative patch. After that, the product can be treated with detergent and washed under running water.

Removing the decorative part for cleaning

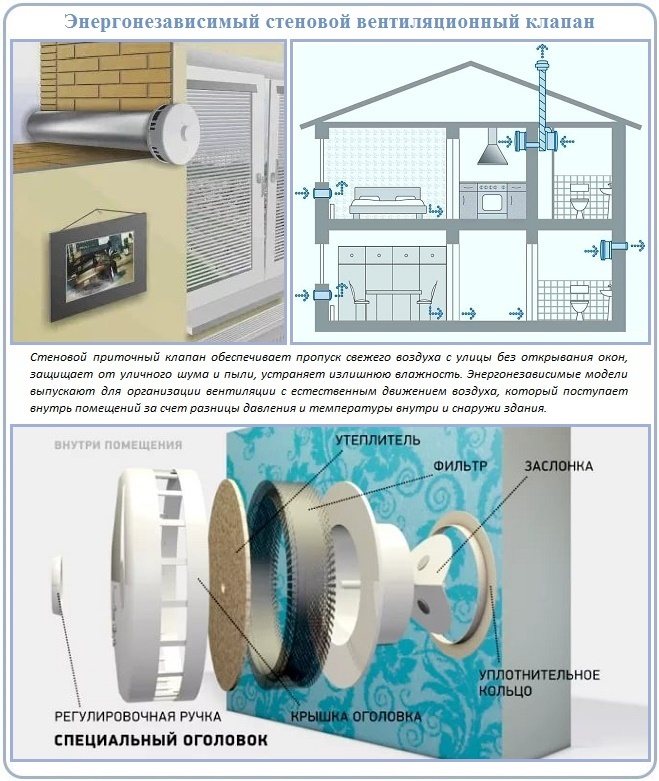

Advantages and disadvantages

The main advantage of the valve is that it can be used to easily increase the efficiency of the ventilation system. At the same time, minimal finances are invested. The device itself is inexpensive, and its installation is just drilling a hole in the wall where the device is installed.

And other benefits:

- If we compare the wall-mounted ventilation valve with window valves, then it is many times more efficient and powerful. Its productivity varies within 60-70 m³/h. This is a serious indicator.

- There is no need to open windows.That is, the service life of the fittings of the latter, and hence the window structures themselves, increases.

- The air from the street, passing through the filter, becomes cleaner. Dust will not pass through the valve, which means that the rooms will be much cleaner than if the rooms were ventilated through windows.

- It is always possible to regulate the incoming air flow. That is, you can adjust according to the size of the room and the whole house, as well as taking into account the season.

- Air exchange through the valve is not accompanied by heat losses in comparison with window ventilation.

- The device works offline. He doesn't need any energy.

The air flow is controlled by a damper

As for the shortcomings, they primarily relate to improper installation. And although manufacturers describe this process in detail in the instructions, home craftsmen manage to do something wrong. That's why:

- A hole in the wall reduces the strength of the supporting structure. The risk of loss of integrity is negligible.

- If the installation is not carried out correctly, then it is likely that the wall will freeze at the place where the valve is installed.

- In severe frosts, cold air can seep through the device.

- Installed inside the wall, the cylinder becomes clogged with dust over time. It will have to be removed periodically.

It is believed that the supply type valve is a source of cold air entering the rooms from the outside, which reduces the temperature inside the house. If it is installed in the wrong place, this can happen. Therefore, most often the device is mounted in the wall between the window sill and the heating radiator. That is, cold air entering the house is immediately heated by the heat of the radiator of the heating system.Of course, no one forbids installing the valve in some other place, but under the window is an ideal area.

Installation is best carried out above the heating radiator