- Types of ventilation

- natural ventilation

- Forced ventilation

- What you need to consider for the organization of the hood in the home

- Pros and cons of the two systems

- natural ventilation

- artificial ventilation

- Features of the construction of the chimney

- Where is the best place to install?

- Ventilation versions

- Boiler room ventilation requirements

- Ventilation device

- Regulatory framework of the Russian Federation

- Legislative acts and GOSTs

- Certification of ventilation equipment

- Indoor installation

- Exhaust ventilation

- Supply type ventilation

- Test and verification

- Boiler Ventilation Requirements

- Is it necessary to ventilate a boiler room in a private house, and why?

- The main rules and requirements for ventilation of the boiler room in accordance with SNiP (+ video)

- Air exchange calculation with formula and example (+ video with more detailed explanations)

Types of ventilation

There are only two main types of ventilation: forced and natural, and in some cases a combined one is used, which is sometimes distinguished into a separate category.

As can be seen from the names, the first type of ventilation uses forced air supply, for which air pumps or fans are used. In the second case, the air flow occurs due to the difference in its temperature and pressure - in the room and outside it.To ensure air exchange, it is enough to correctly position the ventilation openings. Also, part of the air can enter the room through natural openings - for example, cracks under the doors.

If there is such an opportunity, then it is most advantageous to use a combined system - while natural ventilation copes with air exchange, forced ventilation is in standby mode.

natural ventilation

If a three-fold change in the volume of air per hour is provided, then in a standard six-meter (in height) room, it is possible to manage with the organization of natural air exchange.

When lowering the ceiling for each meter, you will have to increase the air circulation by at least 25%. Plus, in any case, you should design air exchange with some margin.

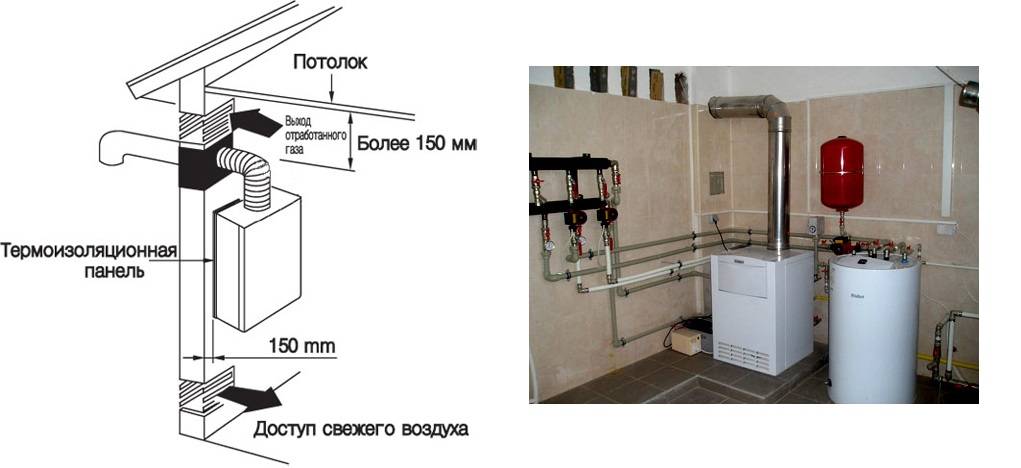

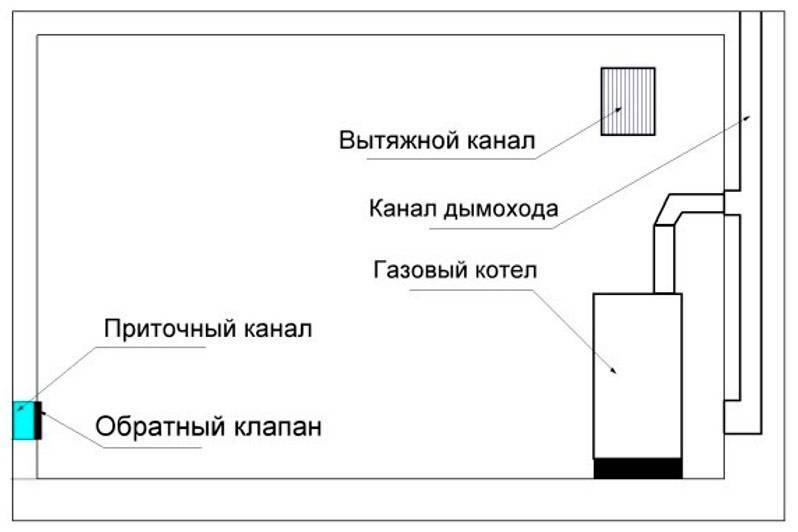

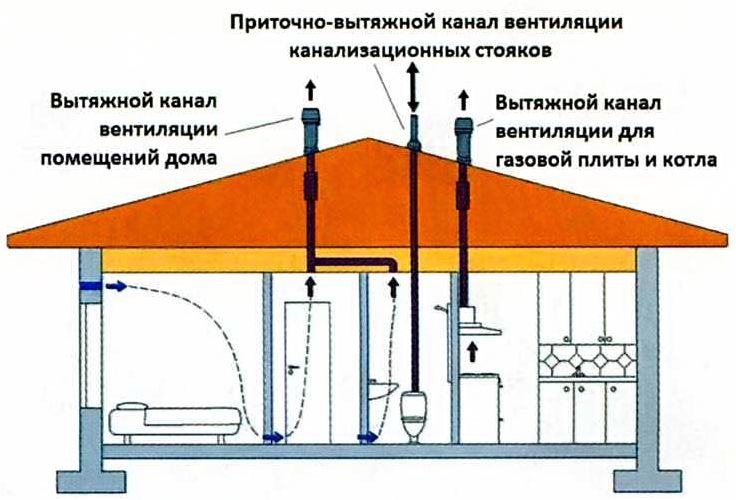

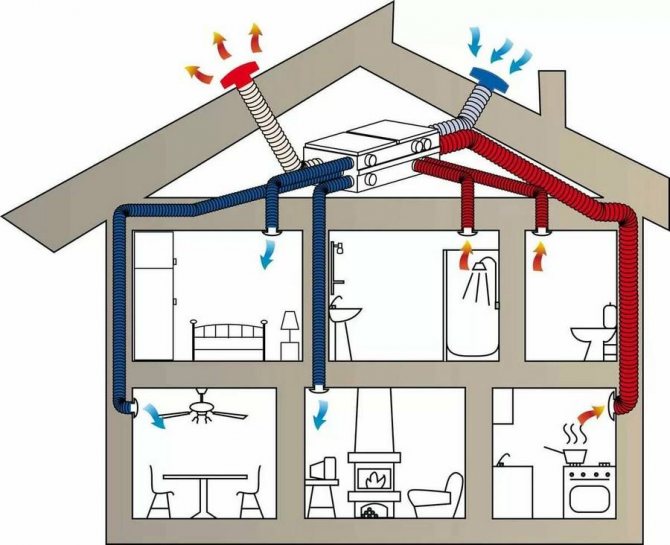

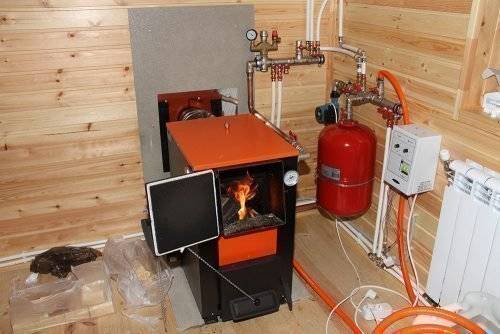

Scheme of the ventilation system in the boiler room of a private house

The scheme is extremely simple - in front of the boiler, in a door or wall, a ventilation inlet is organized (the diameter depends on the power of the boiler), which is located no higher than its working area. The second, exhaust hole is organized above the boiler, usually an air duct with a check valve is attached to it (so that the hood works only in one direction) and an “umbrella” on the outside (so that the pipe does not flood).

The distance between the "inlet" and "outlet" of the air in the room should be as large as possible to ensure the best draft.

Disadvantages of natural ventilation:

- Weather dependent. It is necessary to protect air ducts from external influences of the environment.

- Difficulty in accurately calculating conditioning. Depending on the direction and strength of the wind, different volumes of air can enter the room.

- It is very difficult to design one ventilation system for several rooms - so that one pipe passes through all the rooms. Mostly the conclusion from each room is made immediately to the street.

Forced ventilation system or, more simply, a hood for a boiler in a private house

Forced ventilation

Forced air supply is carried out by the so-called "mechanical devices", that is, fans. This type of air exchange arrangement is convenient for two features at once:

- It becomes possible to install climate equipment, with heaters and filters, which will clean and heat the incoming air;

- It also becomes possible to turn on the system only at the necessary moments, which will save electricity, turning it on, for example, only when the boiler is running.

The disadvantages of forced ventilation are as follows:

Cost - first of all, such a system will cost more than natural ventilation;

In some cases, noise - for example, when installing climate equipment with air conditioning;

Choosing equipment without proper training can be fraught with a safety hazard: in particular, for gas boilers, it is important to have fire-resistant equipment.

The heating system is a rather complex set of equipment, so it should be selected and adjusted

What you need to consider for the organization of the hood in the home

If you decide to install a hood in your home that takes the exhaust air outside, you may encounter some legal aspects of this process.

To equip the hood, it is necessary to make a hole through which air will escape, and also adjust the outlet of this air.Two questions arise: is it possible to make a through hole in the wall of an apartment building and is it allowed to remove dirty air outside the apartment?

If the diameter of the hole does not exceed 200 mm, then no permit is required for it. Such holes are allowed to be made for ventilation and air conditioning. However, it will not work to bring the hood into such a hole - according to the law, this can violate the comfort of neighbors, through whose window your exhaust air can go. Before installing the hood, it is necessary to design the exhaust duct and go through the approval procedure.

The simplest and most convenient option is a hood with an exhaust channel in the wall.

The video shows how to properly organize the exhaust channel:

Pros and cons of the two systems

natural ventilation

For the equipment of such a hood, you do not need special skills on your own, while it has a number of advantages:

- The absence of mechanisms makes such air exchange reliable and durable.

- There is no need to spend money on the purchase of devices.

- Simplicity in work.

- Quiet during operation.

At one time, such an extract fully met its requirements, but with the advent of new gas equipment, the view on this has changed.

This revealed the following significant shortcomings:

- The dependence of optimal air circulation on the season and climatic conditions.

- Impossibility of regulation of an air stream.

- Penetration of foreign particles through the system.

We recommend to read: barn ventilation

And also with a decrease in air intake, there is a likelihood of an increase in humidity in the room.

artificial ventilation

Artificial hood is the best option when installing gas boilers, because:

It is possible to independently adjust the air supply

The importance of this ventilation in enclosed spaces. Pleasant microclimate in the room

Possibility of regulation of air exchange by means of the panel. Independence from weather conditions.

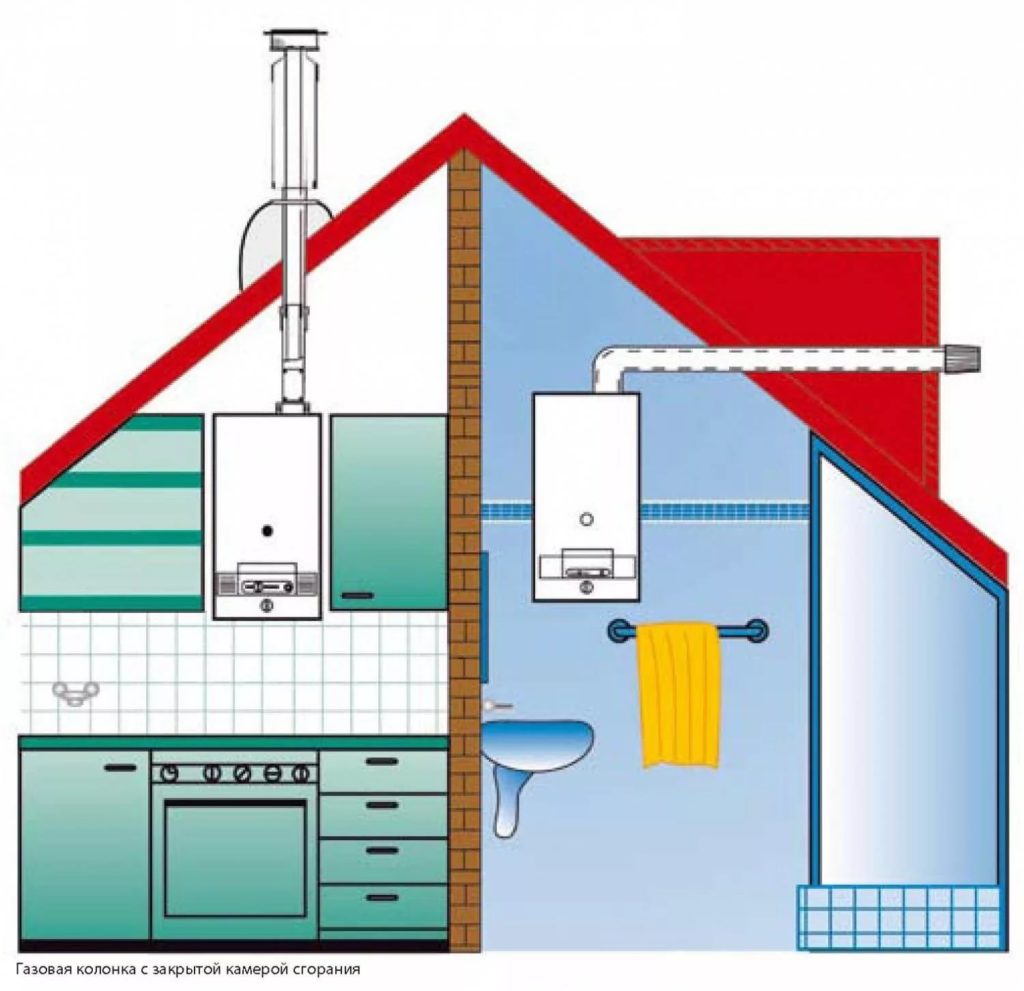

If the house has a boiler with a coaxial output, then the built-in fan in it automatically creates a favorable atmosphere for human habitation.

The only drawback of such a system is the rather high cost of this installation.

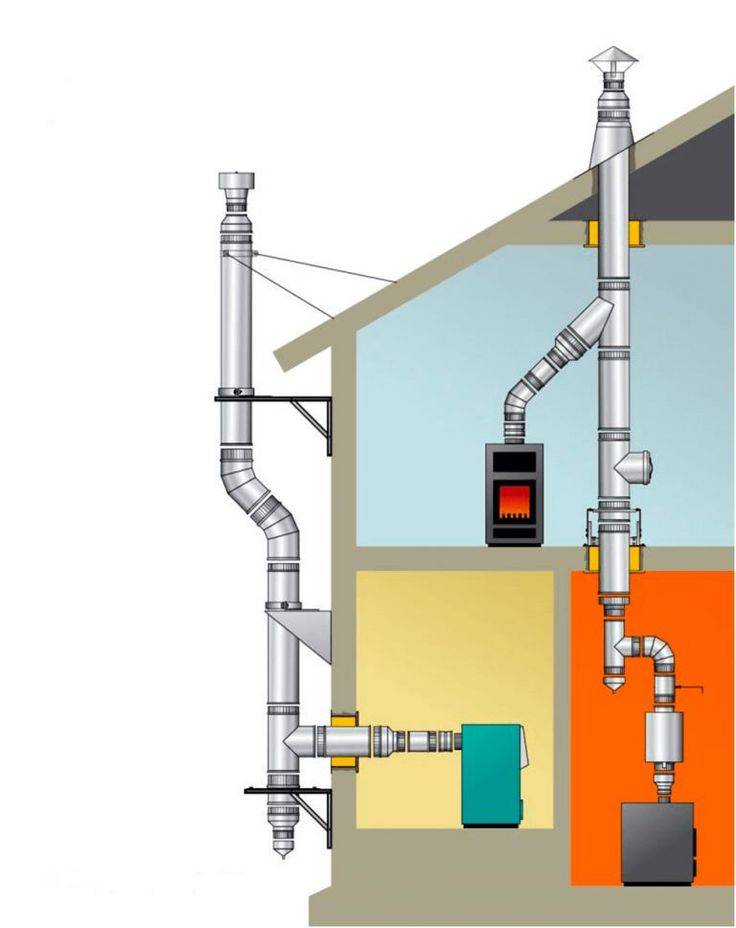

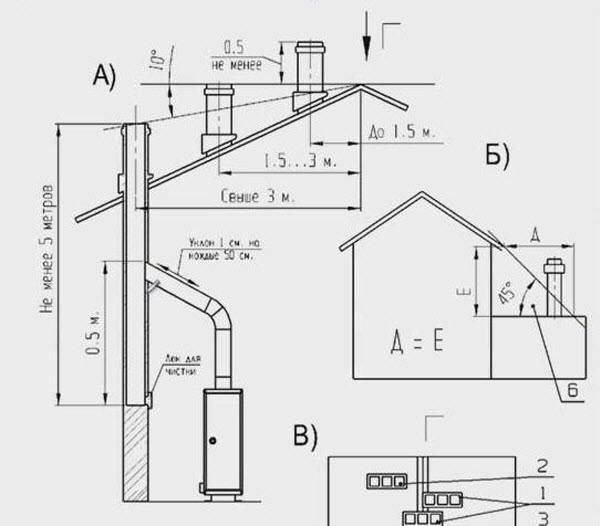

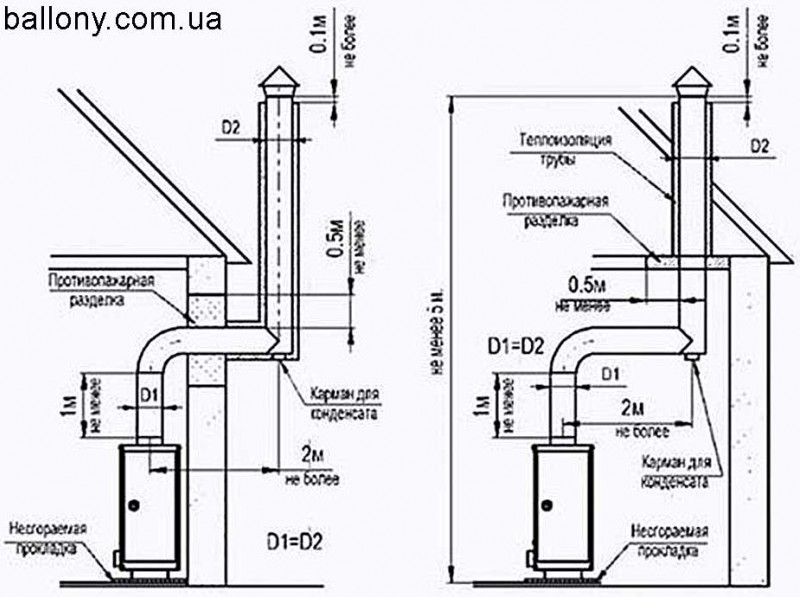

Features of the construction of the chimney

Proper arrangement of the ventilation system in a boiler room with gas equipment cannot occur without a chimney. It must meet the following requirements:

- The chimney must protect the space of the room from dust, burning and dirt. You should take care of the maximum tightness of the pipe itself. For this purpose, a two-layer chimney technology is used from a metal box and an asbestos-cement pipe.

- The height of the outdoor part of the chimney must be located above the maximum point of the roof. The minimum distance from the roof ridge is 2 m.

- The diameter of the ventilation shaft at home is made larger than the size of the exhaust pipe of the boiler itself. Each type of equipment has its own calculation standards.

This is especially true for the desired diameter of the exhaust system. For gas boilers, the power of which does not exceed 30 kW, it is advisable to use a pipe up to 130 mm. If the boiler is 40 kW - 175 mm, and at 55 kW - 195 mm

If the power of the equipment exceeds 80 kW, it is important to install a pipe with a diameter of 230 mm

For the construction of ventilation with your own hands, other features are also important. When choosing a design for a chimney, sheet steel is the best option. Suitable sheets of stainless steel or galvanized.The structure itself should be simple without obstacles, its thickness should be equal in any of its sections, and an inspection window is made from the side of the boiler room.

Where is the best place to install?

The calculation of the ventilation of the boiler room begins with the part of the dwelling where the heating device is located.

Calculation of ventilation in the boiler room depends on where exactly the heating device is located

- in a separate building;

- in the attic;

- in the attached part of the house;

- in a separate room reserved for such equipment.

Boilers that operate on the combustion of liquefied gas are prohibited from being located in the basement. The specific gravity of the gas itself is much higher than ordinary air, so if a leak occurs, then its spread through the basement can lead to a fire. For private houses, modern gas heating systems require a three-fold air exchange, which will remove the processed gas from the dwelling space as quickly and efficiently as possible.

In accordance with the norms, supply ventilation in a boiler room with gas equipment is a necessity. With a power of more than 30 kW, it is forbidden to consider the need to install boilers in a residential part of the house. A boiler with a power of less than 30 kW can be located in the kitchen.

Having decided to install such a boiler, you should make sure that all the requirements are met: the area of the room must be at least 15 square meters, and the ceiling height - 2 meters. There must be windows in the kitchen or in another room, the area of \u200b\u200bwhich is at least 3 square meters. cm per 1 cu. m of space.

Ventilation of a gas boiler room is required to ensure comfort and safety

Therefore, it is important to monitor the organization of the process of high-quality inflow of clean air.When located boiler in the kitchen, the interior door is located with a gap between the floor (at least 1 cm)

And the heating equipment itself should be installed next to a wall protected from ignition. The minimum gap between the device and the wall is 1 cm.

Ventilation versions

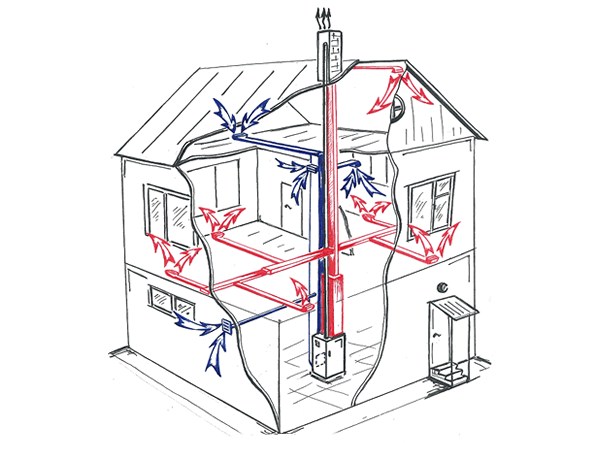

Ventilation for a gas boiler in a private house is created as follows:

- Naturally - for devices with power up to 30 kW.

- Forced - for stronger systems.

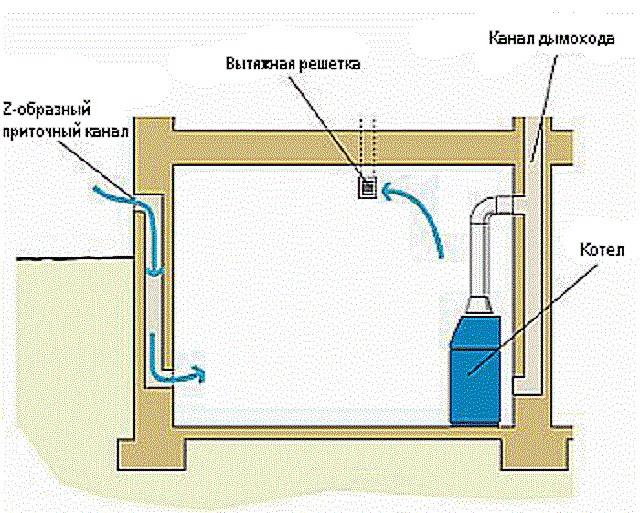

The first option is arranged in small buildings with modest heating equipment: sheds, garages, basements, attics, etc.

The ways of air penetration are windows, slots under the doors. The hood is arranged through pipes at the top of the walls, or ceilings, then it is brought out, above the roof.

What should be the hood for a gas boiler in a private house in the first scenario? This implies compliance with these points:

- Minor holes in the door closer to the floor. If she and the floor are separated by a space of 2.5 cm or more, they are not needed.

- Proper natural lighting.

- Well opened window.

- A hole in the wall with a diameter of 15-20 cm at a distance of 1-1.5 m from the boiler.

- If there is a ventilation shaft, a decorative grill is placed in the wall, and the pipe leading to the roof is protected by a cap.

- Installation of supply valves is an alternative to item 5.

- If the boiler is located in the kitchen, the hood goes into a special shaft in the standard way.

- In the absence of a shaft, the pipes run along the walls of the rooms and the attic, and overcome the roof.

- Pipes are supplemented with components such as gates, gratings, dampers, etc.

How to do it right chimney for gas boiler in a private house, shown in the proposed structure:

Two tunnels are being installed: for air and for the elimination of harmful substances.To create the first one you need:

- Pick up a piece of plastic pipe, a grid of the required parameters and a check valve. The more powerful the boiler, the larger the diameter of the pipe. With its power up to 30 kW, a parameter of 15 cm is enough.

- Punch through the outer hole near the boiler, but not above its functional spectrum. A pipe is installed in the created space, the voids are filled with a cement mixture.

- Outside, a small grate is placed on it. Inside is a check valve.

The outlet can also be a plastic pipe. Its minimum diameter is 2 cm. The shape is round. The inside surface is smooth.

For work you will need:

- special circular saw

- silicone sealant,

- thermal insulation - sprayed insulation.

It should go 50-100 cm above the roof. Then it is covered with a defensive cap.

Particular attention is paid to its diameter. It is determined by the dynamics of air exchange, the volume of the room and other factors.

Often, ready-made tables with calculations are used, for example, this one:

You can also see how the natural system works in practice in this video:

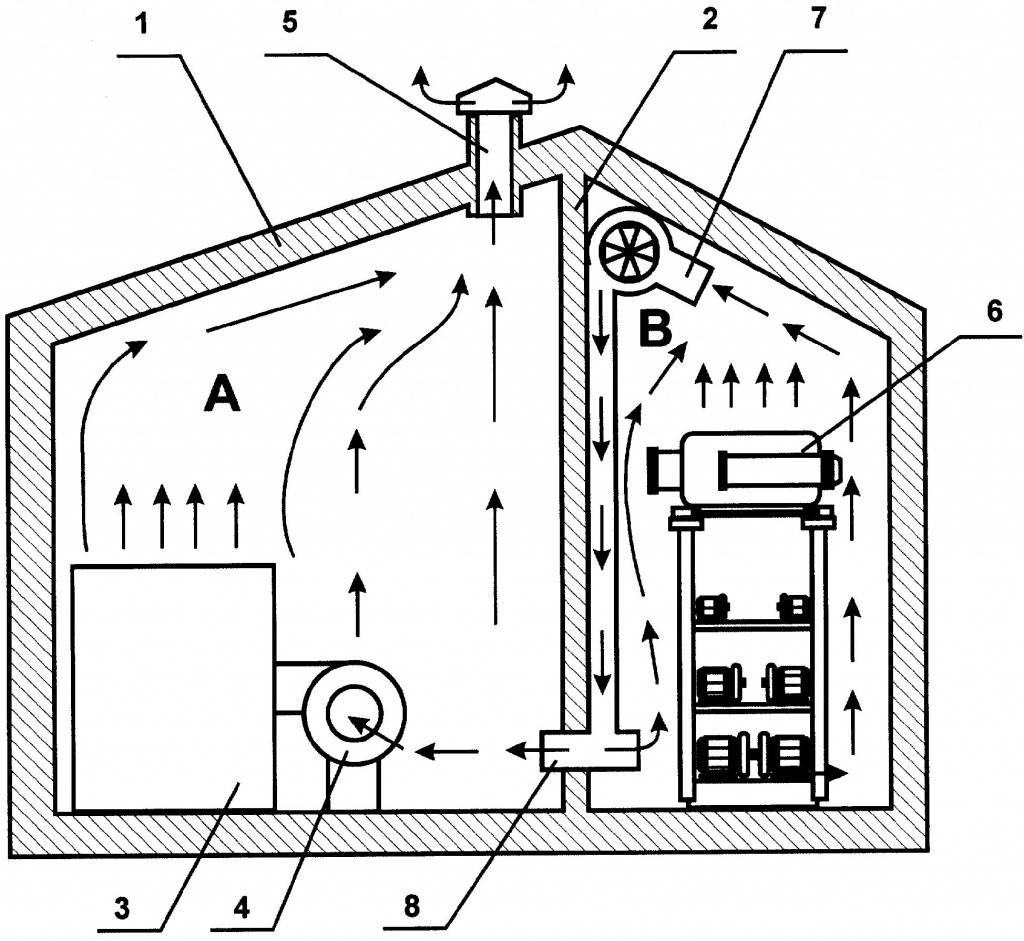

If it does not cope with the tasks, then forced ventilation is arranged. For this, a special fan is placed in the channels. Experts recommend creating a combination in which the air is directed to the combustion chamber, and the combustion products will come out with optimal dynamics for air exchange.

How to make a hood for a gas boiler in a private house in a similar combination? First, a natural structure is installed, then fans, their power cables, sensors, filters, sound insulation, and the boiler itself is configured.

For the right choice fan, its efficiency is taken into account. With a boiler room volume of 10 cubic meters.and the condition of three air updates per hour, it turns out a multiplication of 10 x 3. The result is the minimum efficiency of the fan.

For reliability, choose products with cases made of plastic and metal. They are resistant to wear, deformation and heat.

Boiler room ventilation requirements

Due to the fact that, as a rule, small rooms or extensions are allocated for boiler rooms, high-quality ventilation of a boiler room in a private house is an important condition, the fulfillment of which requires compliance with established norms and requirements. The following provisions are defined in SNiP (II-35-76, 2.04-05) and are applicable to both gas and solid fuel boilers:

The following provisions are defined in SNiP (II-35-76, 2.04-05) and are applicable to both gas and solid fuel boilers:

- The ventilation system of the boiler room must have a separate air outlet route;

- Be sure to arrange an air channel in the ceiling;

- The presence of two chimney channels in the wall: one for the chimney and one for its maintenance (located under the first one and has a diameter of at least 25 centimeters);

- The intake of clean air can be carried out from the street or through a special grill in the boiler room door;

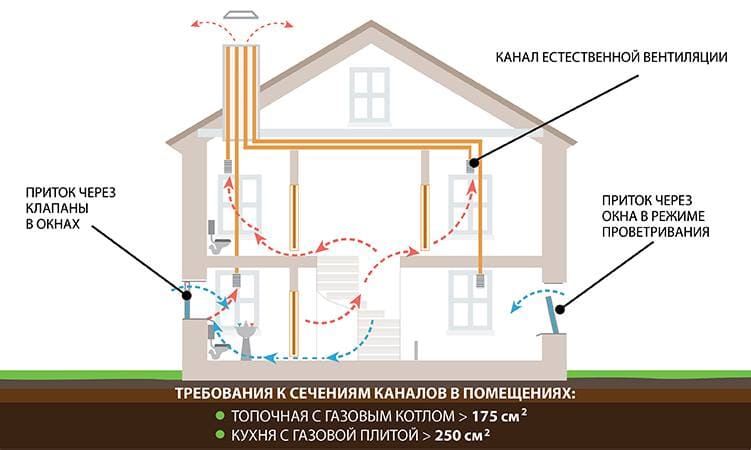

- Openings for air inflow from the street are calculated based on 8 cm2 per 1 kW of heating unit power or 30 cm2 per 1 kW if air is supplied from the inside;

- For any gas equipment, it is required to provide three air exchanges during one hour of operation of the boiler, without taking into account the air sucked into the furnaces of the boilers for combustion;

- Finishing of a floor covering and walls from nonflammable and fire-resistant materials.The wall adjacent to the adjacent room is also finished with fireproof floor slabs, with a fire resistance limit of at least 0.75 hours.

In accordance with current laws and regulations, the height of the room for the boiler room must be at least 6 meters. If compliance with this parameter is impossible due to the peculiarities of the building, the rule applies for such cases: the lower the height of the boiler room, the greater the air exchange should be. With a room height of less than 6 m, the air exchange rate should be increased at the rate of 25% for each meter of height reduction.

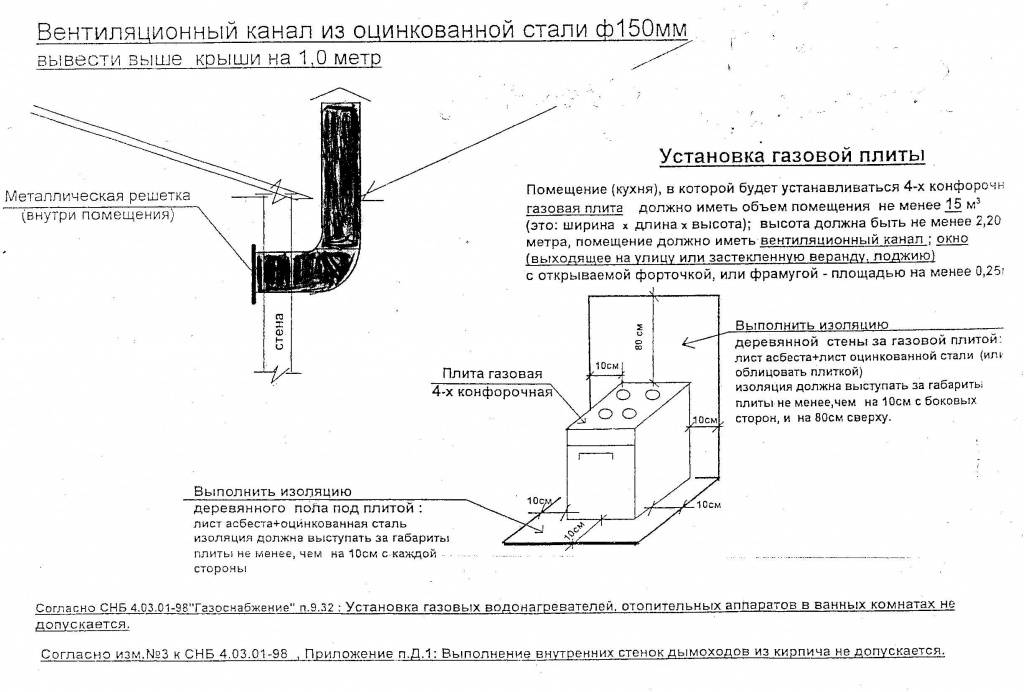

If it is impossible to provide the necessary air exchange due to natural ventilation, mechanically driven ventilation should be designed.

If a gas boiler of low power (up to 30 kW) is enough to heat a private house, a separate room is not required. The requirements for such equipment are as simple as possible: the area of the room should be from 15 m2, the ceiling height should be from 2.20 m, fresh air is supplied through the window (based on the glazing area of at least 0.3 m2 per 1 m3 of the room) or a window. Installation of equipment is carried out at a distance of at least 10 cm from the wall from non-combustible materials.

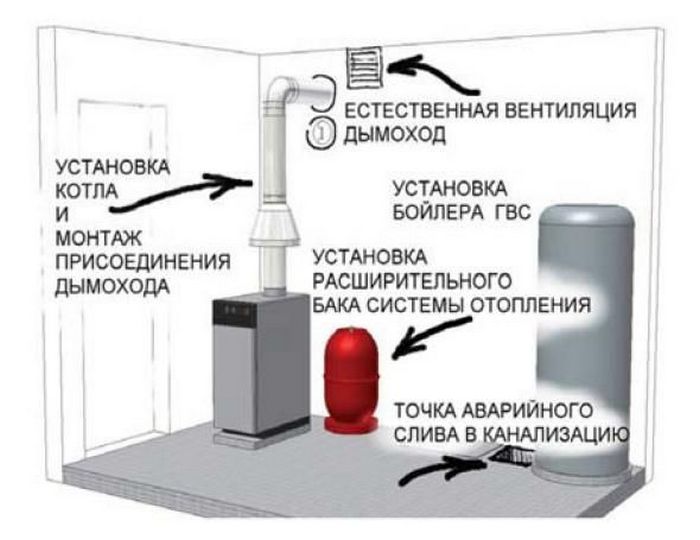

Ventilation device

Let's ask ourselves, what elements does ventilation for a gas-fired heating boiler consist of? The installation of a ventilation system for a boiler is labor-intensive and complex work and requires strict adherence to the technology of the selected scheme. Only a properly calculated and mounted circuit will function effectively.

Here are the main requirements installation of ventilation for . It is carried out in this order:

- First of all, all elements of the ventilation system are assembled.

- In places where pipes pass through the building structure, special access elements are equipped to avoid damage.

- Installed thermal insulation. Its presence is mandatory at the joints of chimneys with combustible material of house structures.

Ventilation for a gas boiler in a private house consists of a fairly large number of elements. We list the main ones:

- An adapter connecting the chimney pipe to the outlet pipe of the heating boiler;

- Revision tee fitting to help remove condensate;

- Mounting clamp for walls;

- Pass pipe;

- Channel pipes (telescopic);

- Bends installed near the beginning of the chimney in order to prevent a decrease in draft;

- A conical tip used in a gas boiler chimney.

Heating gas equipment of any brand and design cannot be used without sufficient air exchange. Therefore, ventilation for a gas boiler in a private house is extremely important. There is no place for negligence, Russian “maybe”! It is about human health and life. Failure to comply with the correct selection of the ventilation scheme, its installation, may lead to the penetration of both gas fuel and carbon monoxide into residential premises. The gas is colorless and odorless, although it is deadly to all living organisms.

Moreover, its excess can lead to fire and explosion! The gas boiler room constantly needs special attention and care

The most suitable and safest option is a turbocharged boiler with a double-circuit coaxial output to the outside in any design (floor, wall, etc.).In such air is taken in from the outside and additionally warmed up along the outer radius, since at the same time exhaust is emitted from the boiler along the inner radius.

Experts recommend combining natural and forced ventilation, which, in the event of a power outage, will make it possible to partially replace the operation of the forced system. Also, power supply will not be required if the fans are switched to the energy generated by the windmill on the roof.

Comments:

- The main types of ventilation in a private house and their features

- How to check the ventilation of a gas boiler in a private house?

- Choosing a ventilation system for a private house

- Arrangement of supply ventilation in a private house with a gas boiler

Currently, a lot of homeowners use gas boilers for heating. This allows not only to create a comfortable and cozy atmosphere in the house, but also helps to save money. However, it must be remembered that when using this method of heating, it is necessary ventilation in a private house for gas boiler.

The value of ventilation systems cannot be overestimated. In the absence of adequate ventilation in homes that use natural gas for heating and cooking, occupants may suffer from health and well-being problems.

This is due to the fact that during the combustion of gas, combustion products and water vapor enter the air, and insufficient removal of combustion products leads to insufficient removal of moisture. Increased humidity levels lead to the appearance of mold, which also negatively affects the microclimate of the house and the health of residents. Mold and gas combustion products are especially dangerous for the elderly and people who suffer from lung diseases.Poor ventilation negatively affects the condition of the skin, causing a state of increased fatigue, drowsiness and headaches.

To determine the sanitary and hygienic norm, the capacity of the house, the number of people living and the type of their activity are taken into account. With insufficient air exchange, the air becomes heavy and there is a desire to open windows for ventilation. Because of this, the air temperature inside the house begins to fall and the requirements for heat consumption, which is necessary for heating, increase. From this it should be concluded that air exchange affects not only the sanitary and hygienic condition of the house, but also energy costs. In old houses, the ratio of the amount of heat that is needed for ventilation to the total cost of heating is about 15%. In new homes, this ratio is much higher.

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (p. 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If, during the commissioning tests, defects in the ventilation system and technical inconsistencies with the design documentation are revealed, the commissioning of the heating system will be refused.

The tasks of the gas service inspector include visual inspection of the equipment, checking the safety functions, control and making control measurements of carbon monoxide. If necessary, the owner of the premises may require the inspector to provide certificates of permission to work with an anemometer or SRO

The tasks of the gas service inspector include visual inspection of the equipment, checking the safety functions, control and making control measurements of carbon monoxide. If necessary, the owner of the premises may require the inspector to provide certificates of permission to work with an anemometer or SRO

Ventilation provides a constant intensive supply of fresh air.The functioning of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These NPAs include:

- Federal Law No. 384;

- Government Decree No. 1521 on mandatory enforcement of 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on security measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, therefore, when installing ventilation equipment for arranging a gas boiler house, one should follow their latest revisions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified at the gas service of your locality

All standards and regulations that will be applied when checking ventilation equipment can be clarified at the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SPs:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on the microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Based on these regulations, design documentation should be drawn up. So that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the stage of project development.

Certification of ventilation equipment

When buying extractor and fresh air supply devices, check their documents. For ventilation equipment sold on the territory of the Russian Federation, a declaration of conformity is mandatory.

This document confirms that the devices comply with all current requirements of the Customs Union, as set out in the following technical regulations:

- TR TS 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on the electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of products and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler house. It contains all technical specifications of the product.

But voluntary certification requires additional investment, so it is often saved on it. In line with Federal Law No. 313 and Government Decrees No. 982 and No. 148 mandatory certification of ventilation equipment has been abolished.

Indoor installation

Gas ventilation in the boiler room can be either exhaust or supply type. Consider the installation process of each type.

Exhaust ventilation

For a device of this type of ventilation, the following sequence of actions must be observed:

- mark the outlet of the air duct. It is carried out according to the size of the pipe diameter with a margin of about 1 cm. When choosing a place for laying a pipe for an exhaust, it should be noted that its outlet should be no closer than one meter to the gas boiler so that cold air does not affect the operation of the device;

- drill a hole;

- install the exhaust pipe in a drilled opening with a slight slope from the gas boiler towards the street;

- use mounting foam to fill the gaps and only when it hardens remove the excess;

- install a damper with which the size of the through hole is regulated;

- install an exhaust fan;

- attach a ventilation grill at the outlet. It will protect the housing from the penetration of insects and street dust, and also give the system a finished look.

Supply type ventilation

Installation of supply ventilation is carried out in a similar way, with only one difference: instead of an exhaust fan, a supply-type device is installed. It receives the air flow, cools it or warms it, and then redirects it into the room. For the boiler room of a private house, you can use a simple model of such an installation - a supply fan. Watch the installation video:

Test and verification

Checking the efficiency of the gas boiler exhaust is carried out with the front door closed and the window in the boiler room open. An ordinary paper napkin is applied to the inlet of the ventilation duct. During the normal functioning of the ventilation, it will be attracted to the hole, in case of clogging of the channel or incorrect installation, the napkin will fall to the floor.

Boiler Ventilation Requirements

Gas ventilation must meet the following requirements:

- permissible slope angle of individual elements of the chimney - no more than 30º;

- maximum branch length - 1 m;

- the maximum allowable number of knees in the chimney - 3 pcs.;

- there should be no ledges and narrowing of the transverse profile in the system;

- the design should include devices for revision and a drip;

- turning points are equipped with a cleaning hatch;

- for arranging ventilation, only products that are perfectly smooth from the inside are used;

- the distance between the air ducts and the surface of the ceiling and walls made of flammable materials must be at least 0.25 m. It is allowed to reduce this distance to 5 cm for structural elements made of non-combustible materials;

- the minimum size of the ventilation inlet for air supply from the street is 8 cm² per 1 kW of the rated power of the gas unit; for air flow from the inside - 30 cm² per 1 kW.

Is it necessary to ventilate a boiler room in a private house, and why?

Yes, in the boiler rooms of private houses it is imperative to organize ventilation that meets the standards of SNiP.

In this room, the ventilation system will perform the following functions:

- Provide oxygen supply for normal combustion. If there is not enough oxygen, any fuel will not burn completely. As a result, less heat is released, more fuel is spent to maintain the desired temperature in residential premises, the wear of the boiler is accelerated, and ashes accumulate inside the chimney.

- Remove carbon monoxide. Not all combustion products can be removed through the chimney - in a small amount they can enter the room.If ventilation does not provide sufficient air exchange, the concentration of carbon monoxide can rise to critical levels and penetrate into other rooms.

- Remove gas if possible. Over time, the gas line to the boiler may lose its tightness, and gas may accumulate in the room. If this is not noticed, an explosion or poisoning is possible.

That is, properly equipped furnace ventilation gives the following effect:

- reduces the risk of fire or explosion;

- reduces the likelihood of natural or carbon monoxide poisoning;

- the boiler works with full efficiency, without exceeding loads (which means it can last longer without repair);

- the temperature in the house is maintained without excessive load on the boiler and without exceeding the fuel consumption.

The main rules and requirements for ventilation of the boiler room in accordance with SNiP (+ video)

Do you need a ventilation system - found out. Now about the main rules and requirements for its arrangement.

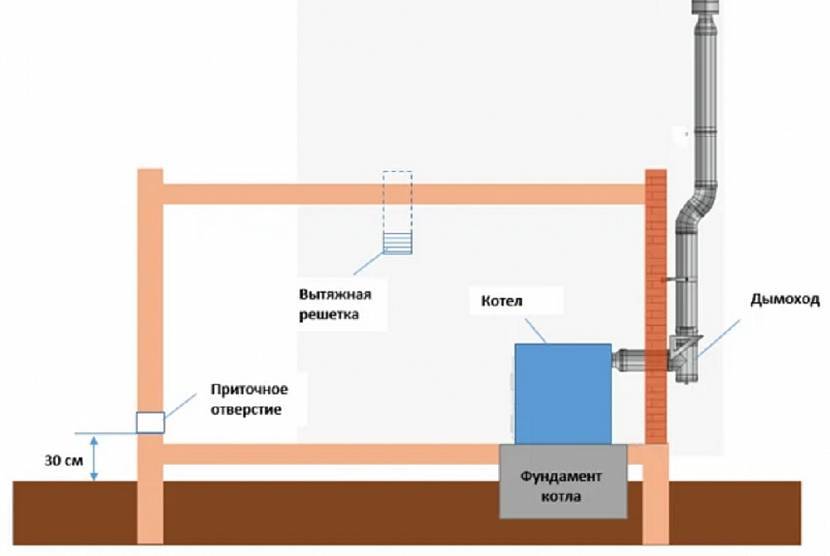

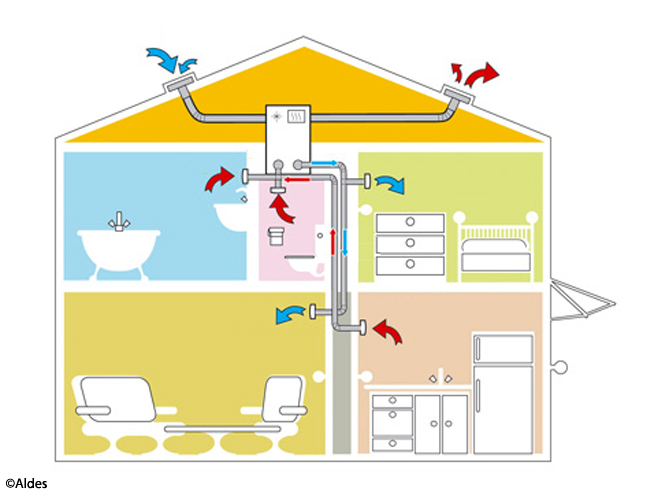

Simplified boiler room ventilation scheme

The boiler room can be equipped in such premises:

- Freestanding building or block module.

- Annex.

- Room inside the house.

- Kitchen (permissible if the boiler power does not exceed 30 kW).

- Attic.

During the construction of private houses, furnaces are usually equipped in a separate room on the ground floor, next to a garage or other room.

Requirements and standards for the arrangement of boiler rooms in private homes are regulated in SNiP 42-02-2002.

From the main requirements:

- Requirements for the room, if the boiler is placed in a separate room: volume - from 7.5 m³, area - from 6 m², ceiling height - from 2.5 m.

- Boilers with a capacity of 30+ kW - should be installed only in a separate room. Boilers with less power - can be placed in the kitchen.

- When installing the boiler in the kitchen, its area must be more than 15 m²

- The boiler room must have a separate door to the street.

- The cross-sectional area of the openings for inflow: from the street - from 8 cm² for every 1 kW of boiler power, from an adjacent room (for example - from the kitchen, through the wall) - from 30 cm² for every 1 kW of power.

Air exchange calculation with formula and example (+ video with more detailed explanations)

It is necessary to choose the sections of the ventilation ducts and the power of the exhaust fan based on the desired air exchange.

To calculate the right amount of air, you need to know:

The rate of air exchange. According to SNiP - for boiler rooms it is 3 (that is, in 1 hour in the boiler room, the air must be completely updated 3 times).

The volume of the room. To measure, you need to multiply the height by the width and multiply by the length (all values \u200b\u200bare taken in meters).

How much air does the boiler need for combustion

For gas boilers (it doesn't matter - with open or closed chamber combustion) in private homes, high accuracy is not required, so you can take 10 "cubes" of air per 1 "cube" of gas for calculations. For diesel fuel - 12.

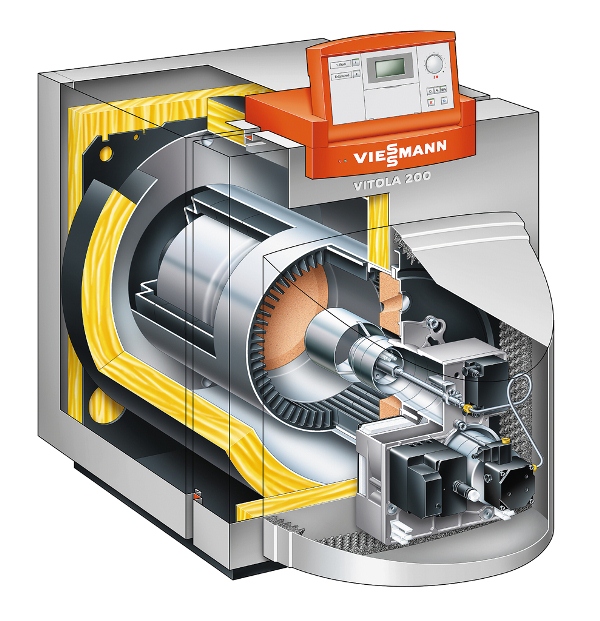

Let's give an example - let's calculate the ventilation system for a boiler room in a separate room attached to the house:

- We calculate the volume of the room. For example, let's take the dimensions 2.5 x 3.5 x 2.5 = 21.875 m³. For a more accurate calculation, you can subtract the volume (size) of the boiler itself from the “total” volume.

- We look in the characteristics of our boiler how much gas it can burn maximum in 1 hour. For example, we have a model Viessmann Vitodens 100 (35 kW), with a maximum consumption of 3.5 "cubes". This means that for normal combustion at maximum load, the boiler needs 3.5 x 10 = 35 m³ / h of air.This characteristic is not covered by the rule about three times, so we simply add it to the result.

Now we perform the calculation using all indicators:

21.875 x 3 (three air changes) + 35 = 100 m³/h

Just in case, you need to make a reserve - on average up to + 20-30% of the resulting value:

100 + 30% = 130 m³/h (rounded up) must be supplied and removed by the ventilation system in the boiler room at maximum load on the boiler. For example, we took the maximum margin (30%), in fact, you can limit yourself to 15-20%.