- Ways to arrange natural ventilation

- Ventilation through the chimney

- Ventilation through vents

- How to make ventilation in each room of the bath?

- What materials may be required?

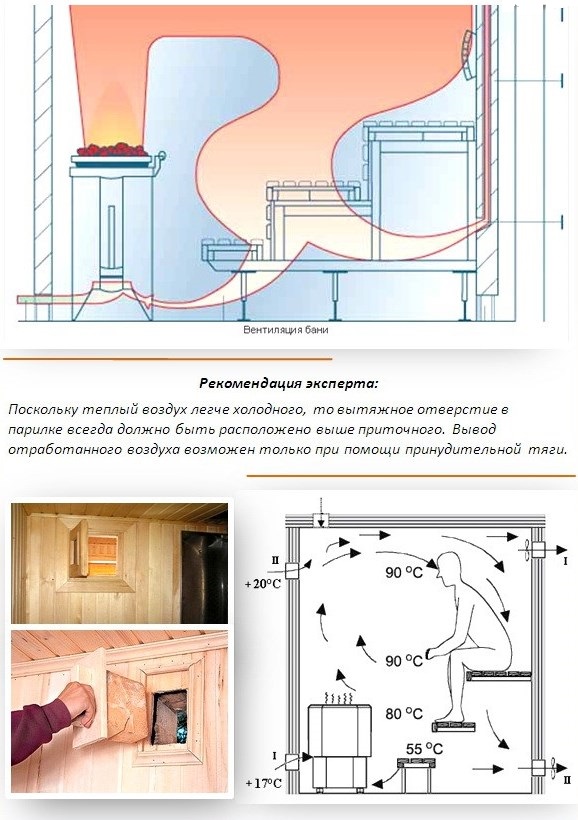

- How to equip ventilation in a steam room?

- And what about the washer?

- We take care of the ventilation system in the dressing room

- Why is it needed and why is it useful

- Types of ventilation

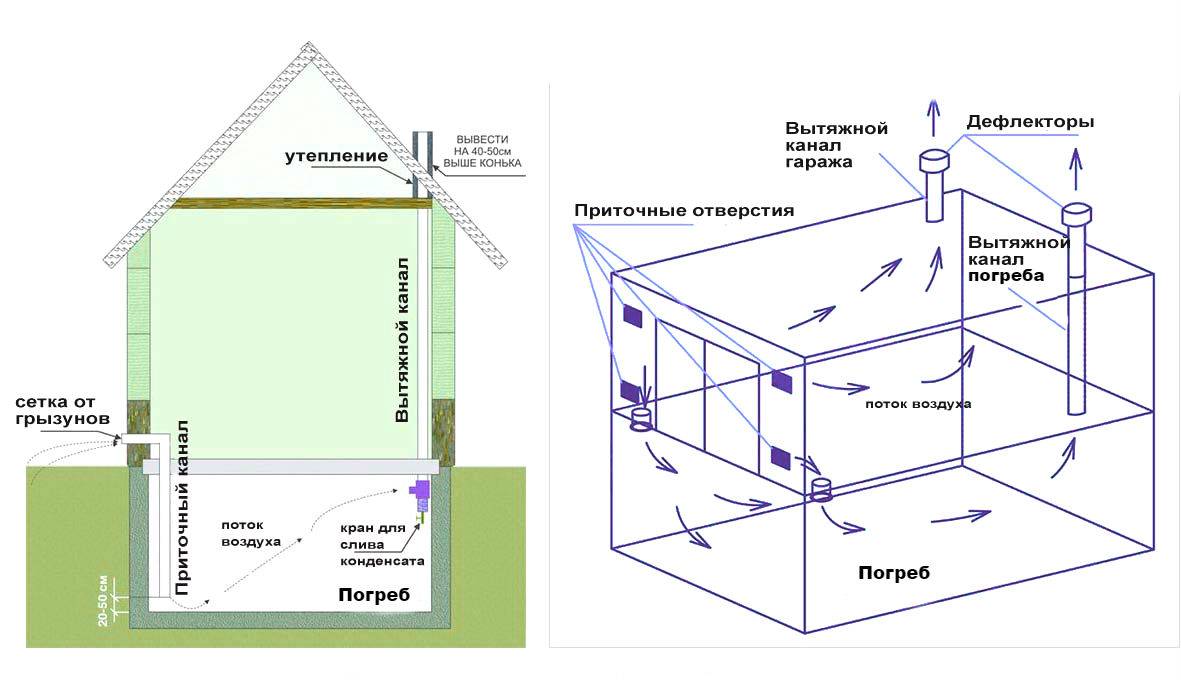

- natural ventilation

- Forced ventilation

- Organization of the duct system with a fan

- Types of ventilation systems

- Ventilation of the bath

- Instructions for self-calculation of air exchange

- Seasonal maintenance of the ventilation system with products

- Conclusions and useful video on the topic

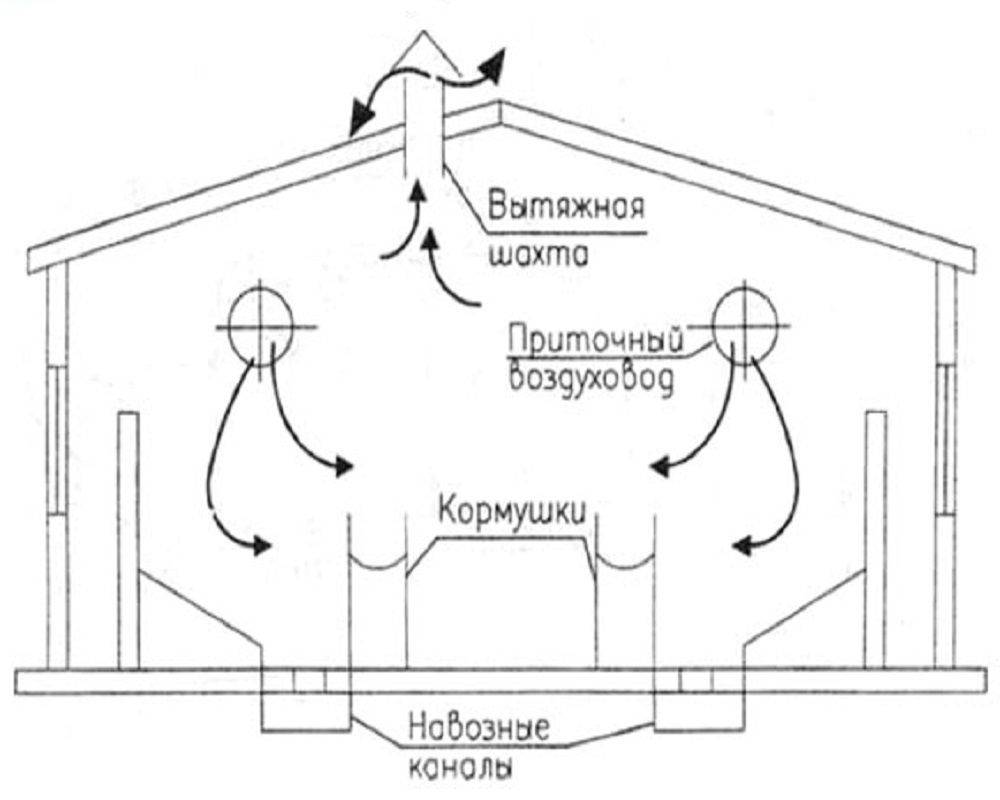

Ways to arrange natural ventilation

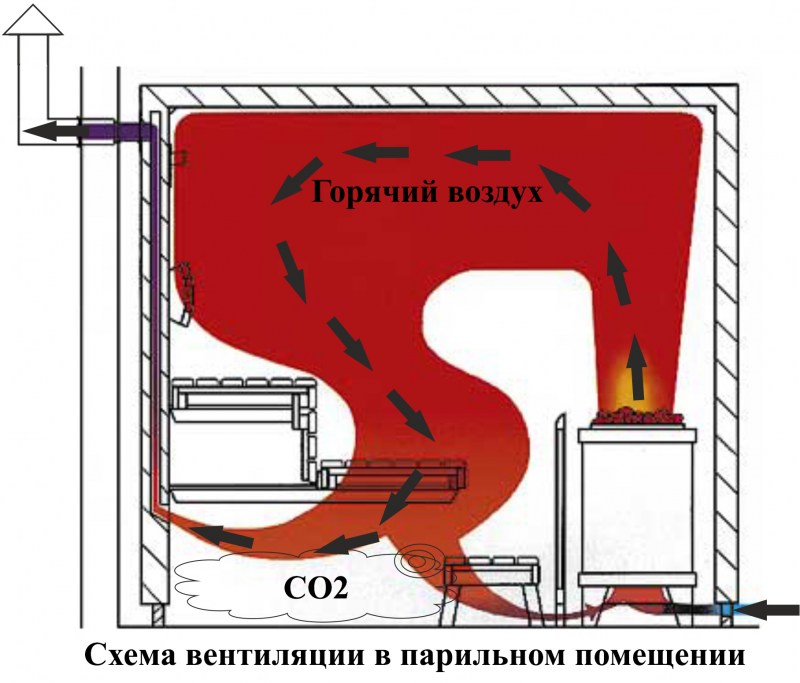

Dense and heavy cold air always goes down, and heated is displaced by it and rises up. This is how moving air flows arise in rooms with any heating device. But without an influx of fresh air, it does not renew itself, but simply moves.

If a hole is made in the lower part of the wall, air from the street will flow through it if its temperature there is lower than in the room. And through the hole at the top, it will stretch. This is natural ventilation.

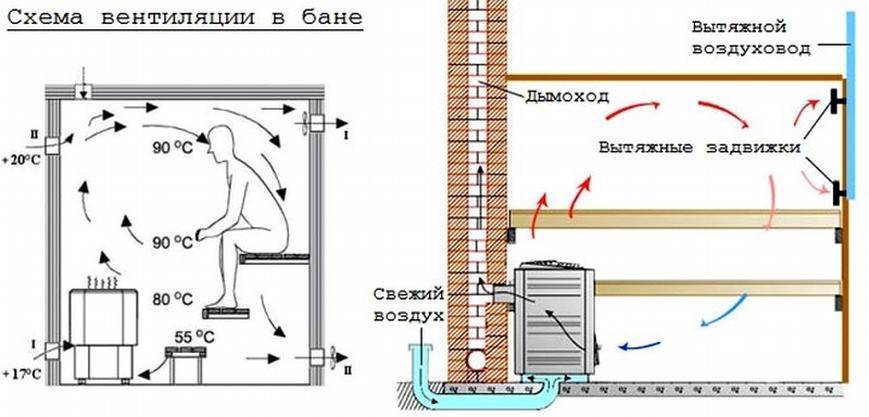

Scheme of the movement of air masses in a heated room

This elementary law of physics is used when they think about how to make ventilation in do-it-yourself bath without using any mechanism. As a rule, natural ventilation without forced air intake is enough for a small bath. Unlike living quarters, where in summer it is as hot as outside, the temperature in the bathhouse is always higher.

But it is necessary to maintain a temperature comfortable for receiving procedures in it, and so that drafts do not form, and there is no sharp difference from heat on the shelf to cold on the floor. To do this, air flows must move along a certain trajectory, which is set by placing supply and exhaust openings in specific places.

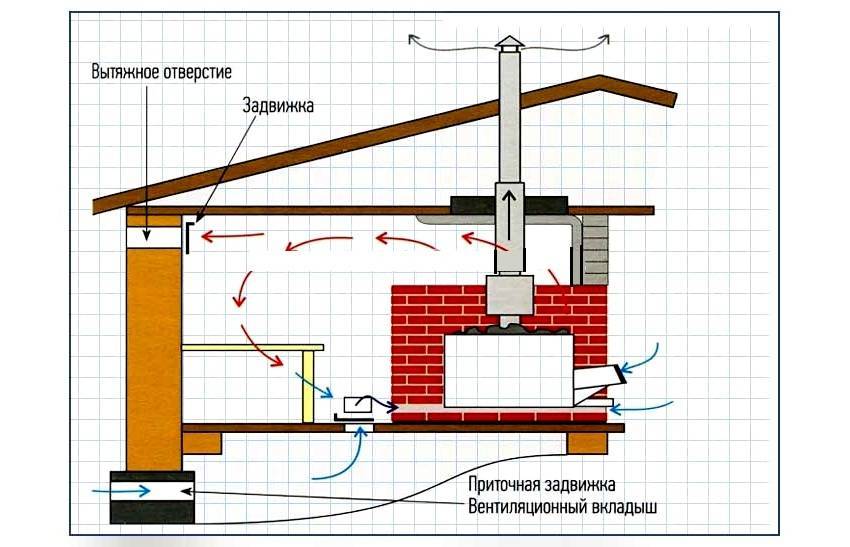

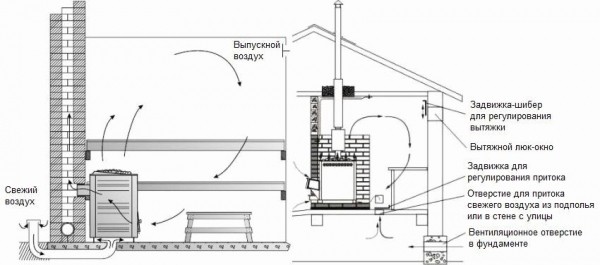

Ventilation through the chimney

The easiest way to solve the problem is how to make ventilation in the steam room if there is a furnace with a blower in it. It will serve to remove the exhaust air through the chimney, in which draft occurs during the combustion of the fuel. But this scheme will work only if there is an influx of air from the outside.

Open door to the steam room

Inflow can be provided in the following ways:

- from time to time slightly open the door to the steam room;

- make a small gap of 1 cm in the door or leave the same gap between the door and the floor;

- if the log cabin of the bath is not sheathed, such a gap can be left between the first crowns below the floor level, provided that the boards are not stacked tightly;

- make a special opening in the wall opposite the stove at a height of 20-30 cm from the floor.

In any of these cases, the cold stream penetrating into the room moves to the heat source and displaces the air already heated by it upwards.When moving, it warms up the entire room, gradually cooling down and falling down. Here it is drawn into the blower and led out through the chimney to the street.

Air movement pattern

This method of how to make ventilation in a steam room is not the most reliable and efficient, since most of the fresh air is immediately drawn into the stove. Therefore, even during the construction of the bath, it is advisable to consider other options with the installation of products in the walls.

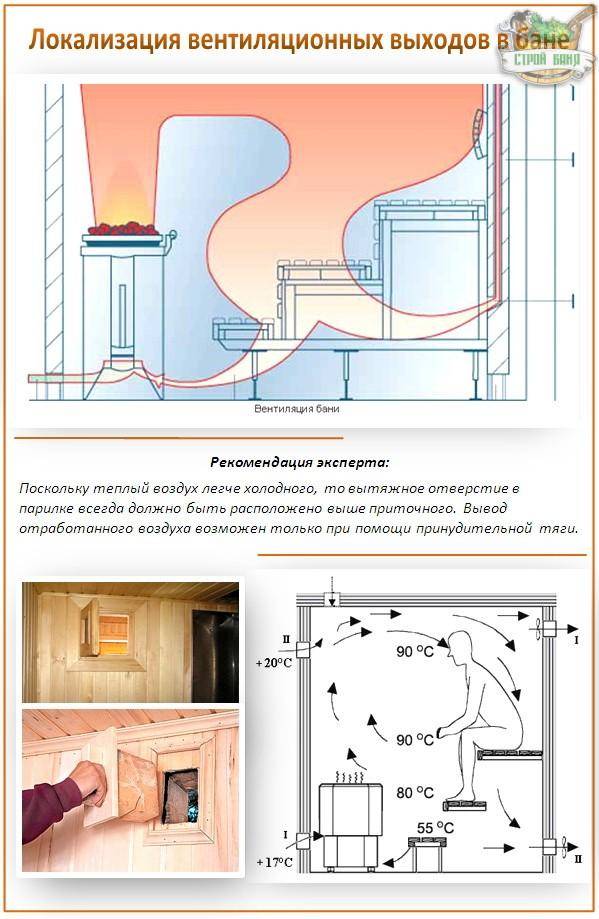

Ventilation through vents

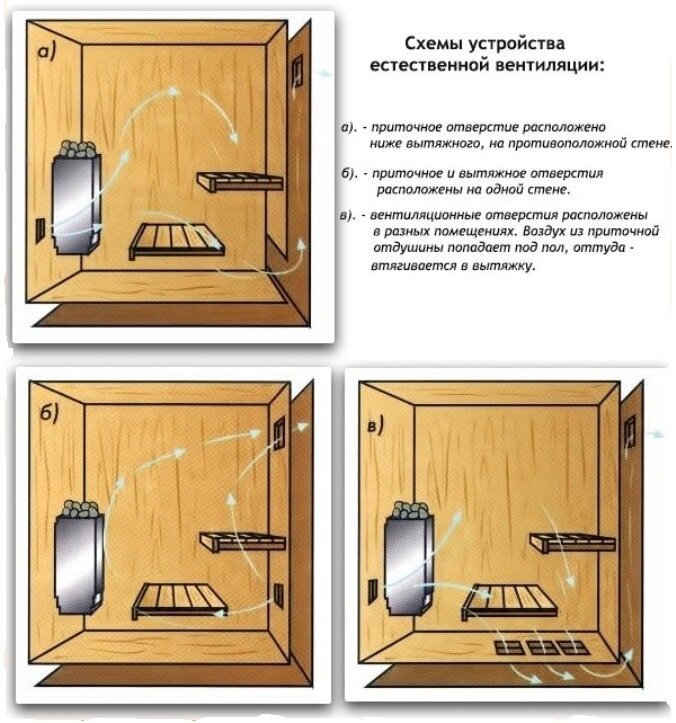

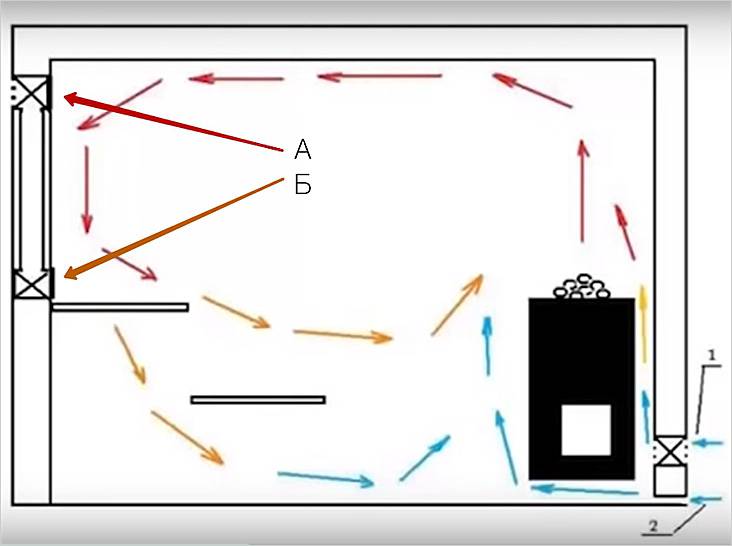

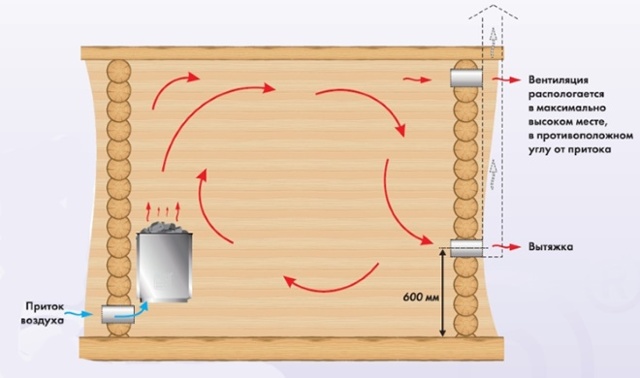

To ensure that air exchange does not depend on the operation of the furnace, special openings are arranged in the walls for the inflow and exhaust of air. It is guaranteed to work under the following conditions:

- the exhaust hole is placed under the ceiling of the bath - where heated air accumulates;

- the inlet should be located low above the floor on the opposite wall, the closer to the stove, the better so that the cold streams drawn in do not hit the legs;

- the optimal vertical distance between the products should be 150-200 cm;

- the cross section of the exhaust hole should be larger.

Cold air immediately enters the heating zone

The ideal location of the supply air is behind the furnace. Entering the room, it immediately begins to warm up, displacing the already hot air mass up and towards the hood. Therefore, cold streams and levels with noticeably different temperatures are not formed in the steam room.

If you want to know how to properly ventilate the bath and steam room, consider this scheme at the design stage and before installing the stove

It is also important to make sure to make a difference in height between the ventilation holes.If they are approximately at the same level, this will lead to a draft and a rapid passage of fresh air in a straight line, without circulation in the room.

Natural ventilation extractor

In order to be able to regulate the ventilation or restrict access to the steam room for too frosty air, it is necessary to provide covers or valves for the air.

The advantage of natural ventilation is that it works without the use of devices that require mains power and can break down. Its installation and operation do not require large expenditures.

How to make ventilation in each room of the bath?

Let's start with some design points. As noted earlier, it is desirable to draw up a ventilation system project simultaneously with the design of the bath itself. Also, certain requirements are put forward for the process of installing ventilation, which are given below.

- The system must receive enough power to function efficiently and smoothly.

- In the room where ventilation is installed, the temperature should be above zero all year round.

- Finally, take care of soundproofing as well.

What materials may be required?

In order for your ventilation to be maximally protected from various kinds of external negative factors, and also to make it look aesthetically pleasing, be sure to sew it into wooden boxes. Alas, there are no such products on the modern market yet, and therefore you must do everything yourself (or, alternatively, hire professionals for this).

In addition, at work you will need:

- carpentry/industrial tools;

- corrugated pipes (required length - 150 centimeters);

- ventilation grates;

- special sliding systems intended for exhaust ducts.

How to equip ventilation in a steam room?

We talked about the possible ways of arranging ventilation in this room, and therefore we know that two holes need to be made here - for exhaust and air flow. It is worth noting that people who think that it should always be hot in the steam room, and therefore the diameter of the ventilation ducts should be small, are mistaken - this does not comply with building codes at all. And if your holes are too large and you are sure that too much heat is escaping through them, you can simply plug them periodically using a plug made in advance for this purpose.

Even the smallest deviations from the requirements that were described in one of the previous sections of the article can lead to the most negative consequences - from constant cold to the accumulation of toxic gases in the steam room. In a word, position the ventilation holes correctly!

And what about the washer?

Rotting wood, unpleasant odors that accompany this process - all this inevitably awaits every washing room where there is no floor ventilation system. How to take care of it? Let's make a reservation right away that there are practically no special differences, if we compare everything with the same steam room.

In order to equip ventilation here, be sure to follow these steps:

- making holes between the rough / finish flooring;

- removal of the ventilation pipe to the roof;

- installation of a fan on this pipe.

thanks to the use of a ventilation system in the bath, the heating of the floor will be carried out approximately as follows: the cooled air, which we also call exhaust air, will be brought out through the pipe, and instead of it, already warm air will fall (from the upper layers located under the ceiling). Moreover, due to the sufficiently low temperature of the air flows, even a plastic box can be more fully used for this purpose.

We take care of the ventilation system in the dressing room

The air exchange features here are practically the same as in the options described above, so the ventilation in the bath in this case should be similar. First of all, what is it for? All the same, in order to bring the exhaust air outside and deliver fresh, oxygen-rich air into the room. And the circulation of air masses must be arranged in such a way as to ensure high-quality ventilation and drying not only of the room itself (that is, the dressing room), but also of all pieces of furniture and decor in it.

Experienced attendants know that the main difficulty of any dressing room is nothing more than condensate - it forms in large volumes here on the ceiling and walls of the room. Because of this, people have to face the most horrific consequences, including the appearance of mold and various kinds of fungi, which, in turn, provokes premature decay of the tree. To avoid all these unpleasant things, the dressing room needs high-quality thermal insulation, which will allow you to forget even the slightest hint of drafts.

In some cases, stoves are installed in the dressing rooms.If you have the same, then the problem of air exchange in this case disappears as such, since both the inflow of air and its outflow will be carried out precisely through it.

Why is it needed and why is it useful

A small room that opens the entrance to the bathhouse, which serves as a kind of corridor and a changing room, as well as a resting place, is called a dressing room. The floor in it is usually made of moisture-resistant wood, and the ceiling is endowed with a heat-saving function. The walls of this room are insulated with wool.

In addition to heating, ventilation must be present in the room. It performs the function of protecting the dressing room from excessive moisture, dampness, and various fungi, thereby preventing the decay of the wood from which the building is made. The influx of fresh air replaces the remote one. Incorrectly equipped ventilation system and insufficient heating can lead to the formation of condensate in the dressing room.

Visitors to the bathhouse expect a long and comfortable pastime, and a well-installed ventilation system will help ensure it. One ventilation to maintain a sufficient temperature in the room will not be enough.

High-quality equipment will require a lot of money, but it's worth it. On cozy winter evenings, sitting in a warm sauna, you will not regret the money spent. The influx of fresh air is provided by a ventilation circulation, and this allows a person to breathe normally in the steam room.

Depending on the process regulator, ventilation in the bath is of the following types: natural, mechanical and combined. The first, according to the principle of operation, is based on the difference between internal and external pressure, the second - on the operation of special devices, and the mixed one - on the operation of fans.

Make sure the system is functioning correctly. Ventilation should not:

- incorrectly distribute air flows, directing coolness to the wrong destination;

- break the usual degree of the bath;

- eliminate the necessary air.

Failures and even life-threatening situations can result from system malfunctions. In addition, the comfort conditions and the smell in the room will leave much to be desired.

Unpleasant smells, disturbed comfort conditions and even increased risk of endangering the life of visitors are the consequences of improper ventilation.

Types of ventilation

There are two types of ventilation:

- natural;

- forced.

Which one to choose when installing a ventilation system with your own hands depends on the design of the bath and the volume of its premises.

Ventilation system with electronic control unit

natural ventilation

This type of ventilation works due to the difference in temperature and pressure inside and outside the room. The efficiency of its work depends on the location of the openings for the inflow and outlet of air. The most suitable solution is that the supply openings are located near the floor, at a height of 250-350 mm, next to the stove, and the exhaust openings are on the opposite wall, 150-200 mm below the ceiling level.

Natural ventilation systems are not suitable for ventilating a steam room or steam room, since the cold air in this room collects at the very floor, and the hot air in the upper part. Adjusting the movement of air flows is accompanied by difficulties, but with the correct arrangement of the ventilation elements in the steam room of a Russian bath, it is possible to cope with this problem with your own hands.

Natural ventilation is not suitable for a steam room, it is advisable to equip it in a rest room

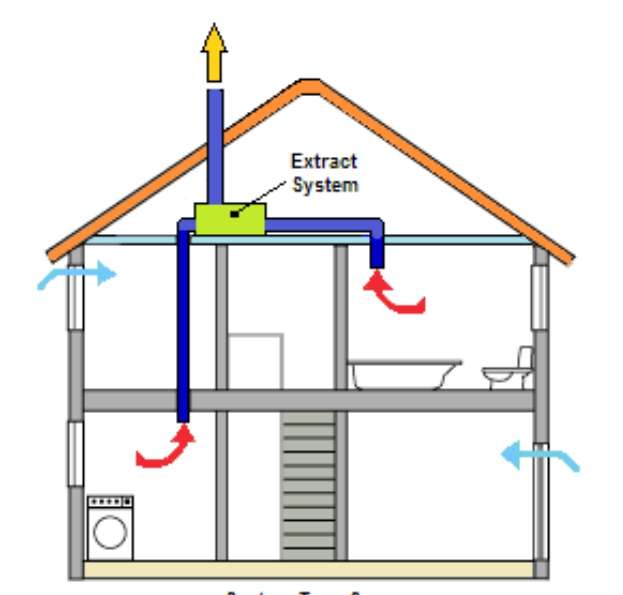

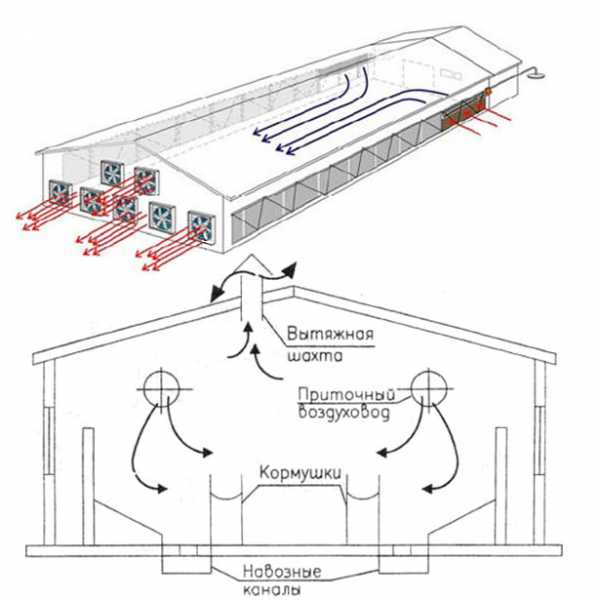

Forced ventilation

For this type of ventilation in the steam room of a Russian bath or sauna, two subspecies can be distinguished:

Ventilation with the help of special electronic systems that control the temperature and humidity of the air, regulating its flow and filtration with the help of automation. Such systems are quite expensive, and their use is often knocked out of the budget.

Combined ventilation system, when due to the use of fans, the effect of natural ventilation is obtained.

The location of the ventilation ducts inside the walls of the bath

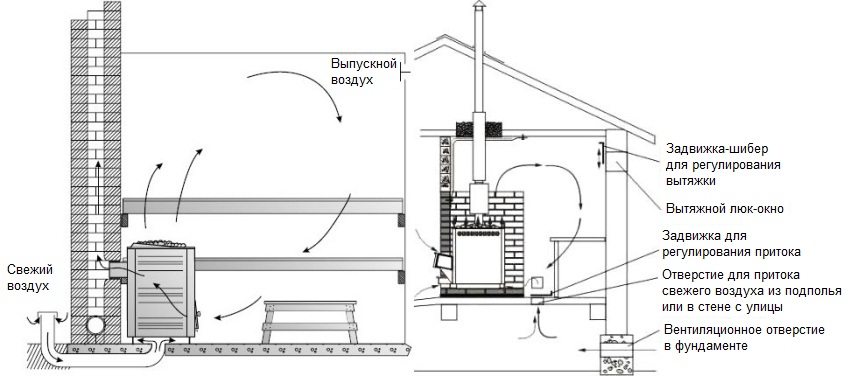

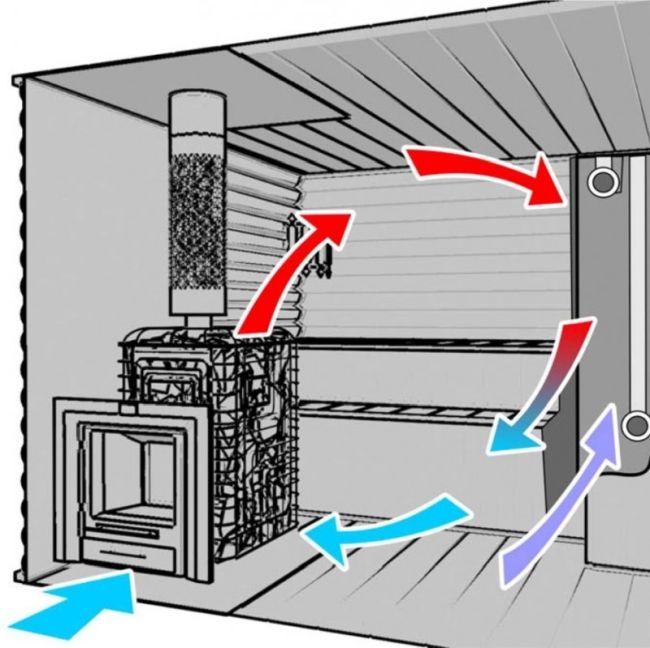

Organization of the duct system with a fan

The combined system is the most popular and effective for a bath, since it involves the use of a powerful blade fan for additional air supply.

- Preparation of working material and tools is underway: hacksaws, drills, three-wire electrical wiring, dampers, a suitable fan model.

- Using a drill, holes are made in the log house next to the funnel.

- The connecting elements between them are sharpened with a hacksaw to combine the holes into a single entrance (for the inlet air duct).

- Similarly, a hole for the outlet channel is prepared.

- Checking the direction of movement of air masses. After preliminary clogging of the holes, the first furnace fire is carried out. When the air heating temperature reaches 60 degrees, the air channels open, and a second check is performed.

- In the corrugation of heat-resistant material, electrical wiring for the fan is laid.

- In the central part of the ventilation hole, a fan is mounted with fixation on self-tapping screws.

- Dampers are inserted into the provided grooves, which reduce heat losses in the room.

- If the building is located separately from a residential building, protective gates are also installed from the outside.

Proper organization of ventilation is a responsible and time-consuming process. However, even a novice master can mount a ventilation system with his own hands, if you follow our instructions and follow the rules.

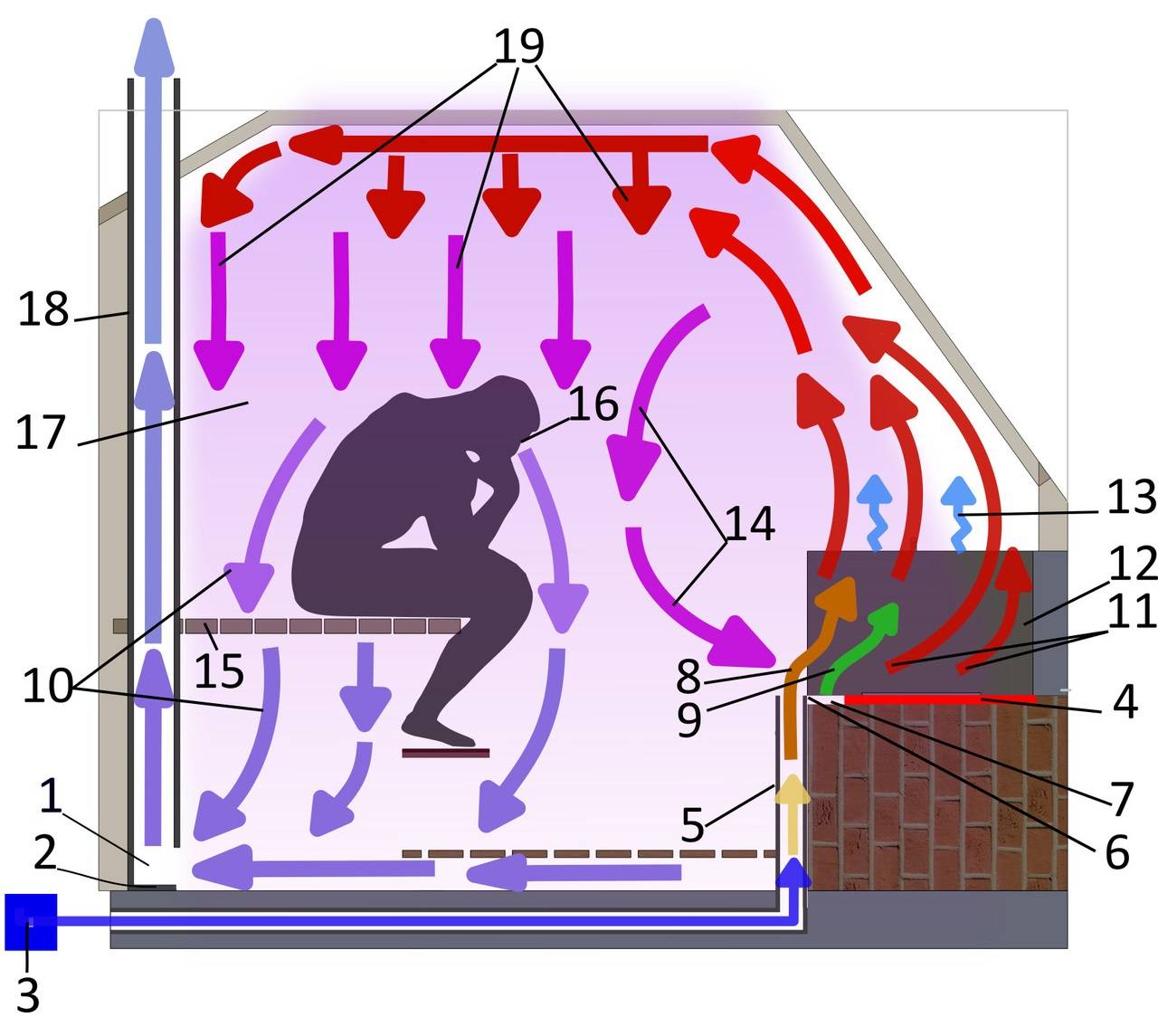

Types of ventilation systems

The ventilation device in the bath varies according to the design of the room and its total volume. Natural ventilation is based on the difference in temperature and pressure inside and outside. In order for it to work efficiently, the air inlet is organized near the stove, at a level of 25-35 cm from the floor. The outlet is made on opposite walls about 15-25 cm below the ceiling

But it is important to consider that such a scheme is not good enough for steam rooms, since it is relatively cold down there, and always hot upstairs.

The natural movement of air in such a situation is too difficult to organize, you will have to very carefully and accurately arrange the components of the ventilation system. A forced circuit does not always require the use of electronic control systems, with complex panels and so on. There are simpler options when ventilation windows, placed in a special way, are complemented by an exhaust fan. The combination of such components is especially effective when the bath is located inside the house, the windows are not placed inside the outer wall, but are connected to the exits by a long ventilation box. Duct fans must be selected very carefully, because the conditions for their operation in baths differ from the usual parameters.

The peculiarity of such devices lies in the increased waterproofing of electrical circuits and main mechanical parts, in adaptation to work at high temperatures without consequences for technology. The state of supply ventilation and its arrangement in each room is adapted to individual characteristics and to the type of bath. It follows that the time spent on calculations and thinking through the project is not wasted - it will save a lot of money and time, get the best result sooner.

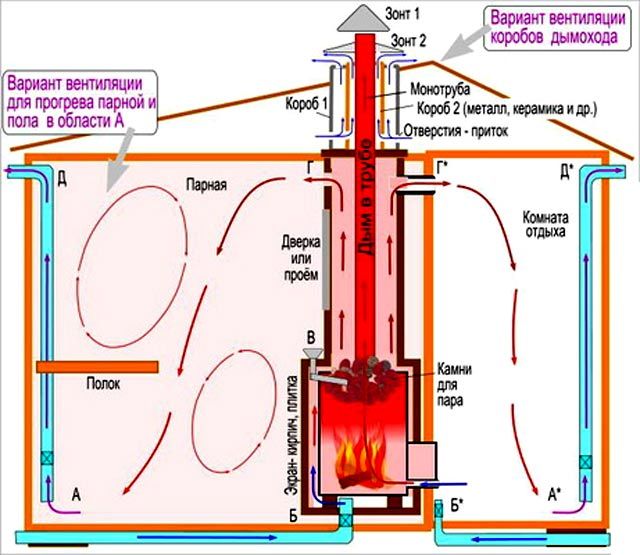

As already known, the bulk of the projects involve the location of the introductory windows near the furnaces, 0.25-0.35 m from the floor. With this design, the stove transfers heat to the air coming from outside, and a flow occurs that moves in the direction of the hood. Having overcome the entire distance, hot and street flows eventually cover the entire volume of the steam room, and the area where the upper shelf is located is heated the most.

In the second option, by installing an exhaust fan, it is possible to mount the inlet and outlet openings on the same wall. The air flow is directed first in the direction of the heating device. Having received a thermal impulse, it begins to rise towards the ceiling and moves in a wide arc that covers the entire room. This approach will be effective if the bath is built into the house and has only one outer wall, while there is no need to arrange a ventilation duct.

If a bath with a leaking floor is created, the introductory window is placed in the same place as in the first case, directly next to the stove. When the heated air gives off heat in the upper lobe of the steam room, it cools and descends to the floor, leaving through the holes in the flooring.This technique improves the evaporation of water accumulating below and allows you to delay the failure of the wooden floor. The hood is placed either in the next room, or in isolated channels that do not allow air to return to the steam room. The complexity of the flow path makes the use of a fan mandatory. This option is used very rarely, since it is not easy to calculate everything exactly, it is not easy to foresee the details properly.

Another type provides for a continuously operating furnace, the blower hole of which replaces the hood. For the inflow, a window is made under the shelf opposite the furnace itself and at the same level. Cold air displaces the heated mass upwards, and when the heat-releasing parts of the flow descend, they go into the blower channel. There are even more complex systems when a pair of supply and a pair of outlet ventilation windows are placed (always with a forced circulation type). It is rather difficult to adjust complicated complexes, but their effectiveness is higher than in the simplest cases.

The Bastu system is the placement of supply openings (with adjustable valves) behind or below the furnace. The organization of vents under the stove is not required, although it is highly desirable. Through these openings, air from the underground part of the bath enters the room, which is connected to the external atmosphere by the foundation vents. When a bath is made in a previously finished room, you need to choose a room with a pair of external walls; when preparing the basement, choose an angle that meets the same requirements. The dimensions of the inlet and outlet are calculated according to the general rules.

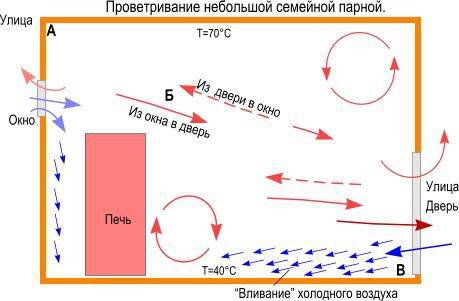

Ventilation of the bath

The simplest, but also the least effective way of ventilation.

Ventilation of the bath

In the steam room, the door opens or the door and the window open at the same time - ventilation occurs quickly, but not in the way we would like. Why?

Steam is removed from the bath, and this has negative consequences.

- Firstly, if you open the door, then the steam does not go out into the street, but into other rooms. Humidity rises sharply in them, heated steam immediately condenses on all surfaces. What can happen next - no need to explain.

Condensation collects on the ceiling in the bath

- Secondly. Lowering the temperature in the steam room is only a subjective phenomenon. There are two concepts of temperature - actual and perceived. The actual temperature is a physical indicator, the perceived temperature is subjective. We feel the same actual temperature in different ways depending on environmental factors. Increased humidity "increases" the temperature we feel, strong wind lowers it. So, due to simple ventilation, only excess steam can be removed, and the actual air temperature returns to its previous values within a few minutes.

Excess steam escapes through the open door

- Thirdly, ventilation will never be able to establish stable indicators of the microclimate in the room. As soon as the doors are closed, the temperature and humidity rise sharply; as soon as the doors are opened, the humidity and temperature also drop sharply.

Airing does not allow creating an ideal microclimate in the steam room

Bottom line - ventilation is not the method of ventilation that should be used all the time. This is an extreme method, it is recommended to resort to it only in case of urgent need.

Airing the steam room

Instructions for self-calculation of air exchange

For the calculation, an elementary formula is used:

That is, first you must calculate the volume of each room and find for it the required indicator of the volume of clean air (in calculations it is customary to denote Wpr, i.e. inflow) and a similar indicator of exhaust air (indicated as Wvt, outflow). In this case, multiplicity factors must be taken into account. The calculated values are rounded up - the last digit in the number must be 0 or 5.

Next, the summation of all Wpr is performed. A similar action is carried out for the found Wvt. The amounts received are compared. If the total value of Wpr exceeds the total indicator Wpr, it is necessary to increase the exhaust volume for rooms with a minimum air exchange value, if vice versa, increase the inflow by the missing value. That is, at the output, the sum of all Wpr should be equal to the total value of the found Wvt.

Table. Example of calculation of bath ventilation

Table. Example of calculation of bath ventilation

In the given example, the total value of Wpr is less than the sum of all found Wvt by an indicator equal to 110 m3. In order for the balance to be maintained as a result, it is necessary to ensure the flow of clean air in the missing amount. This can only be done in the waiting room. Thus, the value of 55 m3 for the dressing room, given in the table, must be replaced with an indicator of 165 m3. Then the balance will be struck.

Proceed to the calculation of the installed air ducts and drawing up the structure of the equipped ventilation system.

The ventilation system is designed in such a way that the air moves through the installed air ducts with the following speed indicators:

- ≤ 5 m/s in main channels and ≤3 m/s in existing branches - for mechanical ventilation systems;

- ≤ 1 m/s - for air exchanges operating according to the natural principle;

- 2 m/s - for natural air exchange directly in the steam room.

Ventilation valve behind the heater

When choosing a section of air ducts, consider the above indicators. As for the profile of the box / pipe, this moment is determined by the design features of the air exchange and the bath itself. For example, air ducts with a circular cross section are easier to install than their rectangular counterparts, and it is much easier to select the required connecting fittings for round air ducts.

The relationship between the diameter of the air ducts and other significant indicators is shown in the following tables.

Table. Parameters of circular ducts

Table. Rectangular air ducts

For example, we will work with round ducts. We select the necessary sections according to the corresponding table, focusing, at the same time, on the indicators of the table An example of calculating ventilation.

Estimated air consumption is 165 m3/hour. The air flow at this flow rate should not move faster than 5 m/s. In accordance with the table above for round ducts, we select the section according to the specified data. The tabular value closest to ours is 221 m3/h. Air duct cross section - 125 mm.

In the same order, we determine the optimal sections for all branches of the system in the serviced premises, remembering that in them the air flow should move at a speed not exceeding 3 m / s (in vestibules and closets - 1 m / s, in the steam room - 2 m / s). sec):

- steam room: calculated Ww is 60 m3 / h, which requires the installation of an air duct with a cross section of 125 mm;

- shower room - Ww is 50 m3 / h, air moves at a speed of 3 m / s, a 100 mm air duct is suitable;

- toilet - the indicators are similar to the shower room;

- pantry, vestibule, etc. - indicators (except for the speed of air movement) are similar to the shower and toilet.

For greater convenience, enter all the information received in the table. As an example, you can use the template below.

Table. Results of calculation and design of ventilation

Norms and rules

The cross-sectional area of the ventilation window is determined in accordance with the volume of the served room: 24 cm2 for every 1 m3.

It remains to figure out only the optimal height of the ventilation holes:

- for the influx of fresh air - an average of 25-30 cm above the floor (in the steam room - near the stove);

- for the outflow of exhaust air - about 15-20 cm below the ceiling, as a rule, on the wall opposite to the supply air.

Seasonal maintenance of the ventilation system with products

The main controversy in the care of the ventilation system raises the question of whether to close the vents for the winter or not.

There are 2 points of view here:

- With open vents. Through them, moisture will be removed, which falls in the form of condensate in heated, overly insulated rooms. The floor directly communicating with the ground will always be cold in them, which means that the formation of “dew” will increase during the heating season. However, if you invest in floor insulation, this can be avoided.

- With closed for the winter products. Warm moist air of the living space will fall on the cold surfaces of the subfloor (basement walls). The condensate will drain into the ground.In spring / summer, it will evaporate, increasing humidity, so drying the subfloor with heaters will be required.

The vents will have to be closed if the house is wooden, and the flooring is made using floating technology, i.e. there are gaps near the walls, and ventilation holes with gratings are also selected in the floor. Otherwise, the floor will be very cold.

It is not recommended to close the ducts for the winter, ventilation of the underground should be carried out in all weather conditions. It makes sense to reduce the airflow by the method shown in the photo

In other cases, both options can be considered. In addition, in winter it is necessary to regularly clear the plinth of snow so that the ventilation openings do not completely fill up. After all, even when closed, they will contribute to ventilation, even if in a reduced state.

In other seasons, the care of the ventilation system is simple:

- in the spring - open the vents and dry the underground;

- in summer - make sure that the ventilation holes are not filled up with debris and they are not obscured by grown plants;

It is necessary to install ventilation grilles on all types of vents (preferably metal ones) so that rodents and raccoons do not climb inside, and regularly clean them of debris so that the air flow is not reduced.

Conclusions and useful video on the topic

Bastu ventilation drawing with the transition from a vertical exhaust duct to a horizontal one:

How best to do bastu ventilation, examples of errors, and what they lead to:

Now you know what basta ventilation is and how you can improve circulation in the bath, make it more comfortable. We told how the ventilation system works, how it works, and also went through the main options for installing it.Even if you didn’t understand the design of the bath before, you now know the main thing about its ventilation and you can assemble a new bastu system or improve the old one.

Write comments if you collected ventilation for a bath or thought to do it. Tell us about your steam room. Perhaps you are just planning to build a bathhouse and do not know where to start arranging ventilation? Ask your questions in the form below the article.