- Do-it-yourself hood in the cellar

- Materials for manufacturing

- Fan types

- Calculation of air duct parameters

- When is a regular hood not enough?

- forced option

- The need for underground ventilation

- Step by step installation instructions

- Stage #1 - drilling holes

- Stage # 2 - installation of pipes and fan

- Pros and cons of different types of ventilation

- Which channel to close for the winter, the nuances of the hood with two pipes

- Types of ventilation

- Features of natural ventilation

- Forced exhaust systems

- Do-it-yourself ventilation installation

- Installation steps

- Cellar hood with one pipe

- Separate option - a special system

Do-it-yourself hood in the cellar

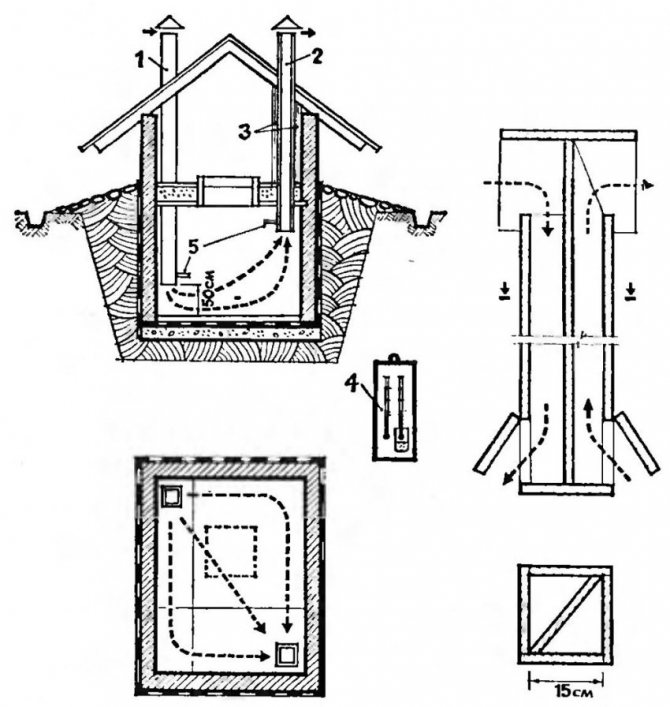

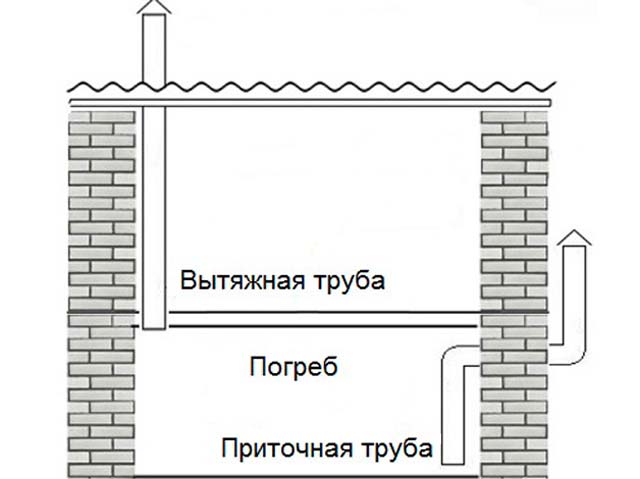

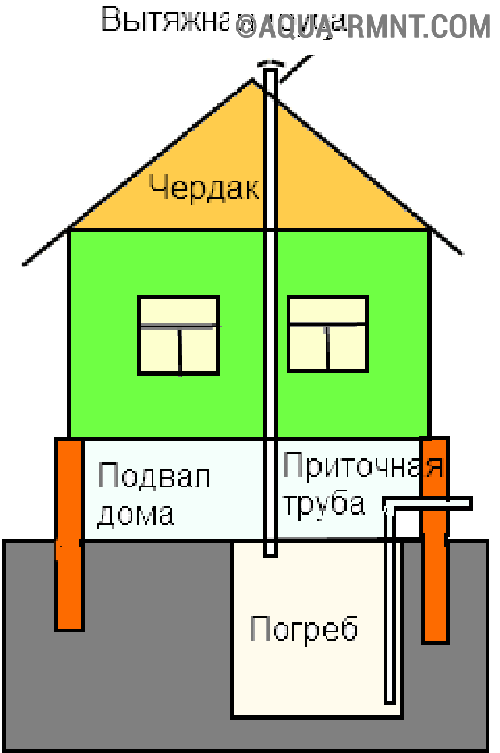

The ventilation scheme depends on the parameters of the house, the purpose of the basement and the location with climatic features. To equip a conventional system, you will need two pipes (one for supply, the second for exhaust), which will be responsible for air circulation in the storage.

Do-it-yourself ventilation system in the cellar can be made natural or forced. In forced, the main role is played by fans that will circulate air in the room

Also, when choosing special equipment for ventilation, you need to pay attention to the stability of the equipment to work in conditions with high humidity.

You will find more information about self-arrangement of ventilation in the basement in the video.

Materials for manufacturing

The existing ventilation schemes in the cellar include the use of various types of pipes in them. Among the large assortment, the most common are asbestos cement and low-pressure polyethylene.

Products based on asbestos cement look like slate, but according to their characteristics they have the following qualities: reliability, high level of strength, adhesion resistance, durability. In construction stores, they can be purchased in long lengths, which will favorably affect the integrity of the structure. Polyethylene pipes most often have to be welded together, which requires special tools and work skills.

Metal pipes are used extremely rarely for the installation of a ventilation system, since they are exposed to corrosion and quickly rot in the ground. In measures to prevent such impacts, it can be treated with anti-corrosion enamels or waterproofing materials can be used to protect against moisture.

During the use of any material, the openings for the exhaust and supply pipes must be reliably protected from moisture and debris. For such purposes, it is necessary to install a grate and a special cap on it, which can be made from any material.

Fan types

For proper air circulation in the storage, several types of fans can be used, which, according to the principle of operation and location, are divided into axial and duct (Figure 4).

Figure 4Types of fans for basements

The duct fan has an average power level and can be mounted anywhere in the ventilation pipe. The power consumption of this type of fans is negligible, which is suitable for saving money. One of the most efficient duct fans are amplitude-type devices.

Axial fans are installed in close proximity to the exhaust or supply openings. According to their principle of operation, they can produce a stronger air circulation, but at the same time they are demanding in electricity. Together with the fan, a special valve is mounted on the outlet pipe of the system, which will not let cold air in.

Calculation of air duct parameters

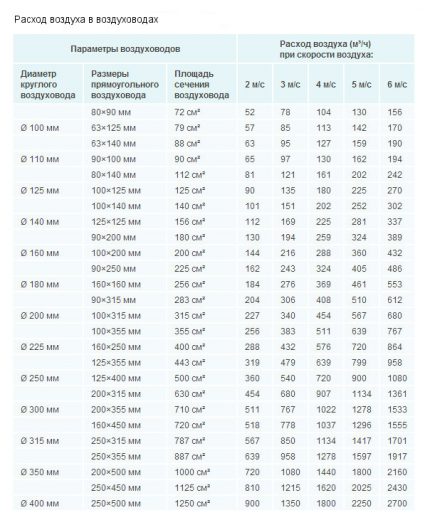

Having data on the air volume of ventilation, we proceed to the determination of the characteristics of the air ducts. Another parameter is needed - the speed of pumping air through the ventilation duct.

The faster the air flow is driven, the less volumetric ducts can be used. But the noise of the system and network resistance will also increase. It is optimal to pump air at a speed of 3-4 m / s or less.

Knowing the calculated cross section of the air ducts, you can choose their actual cross section and shape according to this table. And also to find out the air flow at certain speeds of its supply

Knowing the calculated cross section of the air ducts, you can choose their actual cross section and shape according to this table. And also to find out the air flow at certain speeds of its supply

If the interior of the basement allows you to use circular ducts, it is more profitable to use them. In addition, a network of ventilation ducts from round ducts is easier to assemble, because. they are flexible.

Here is a formula that allows you to calculate the area of \u200b\u200bthe duct according to its cross section:

SSt.=L•2.778/V

Wherein:

- SSt. - the estimated cross-sectional area of the ventilation duct (air duct), cm2;

- L is the air consumption during pumping through the air duct, m3/h;

- V is the speed at which air moves through the duct, m/s;

- 2.778 - the value of the coefficient that allows you to coordinate non-uniform parameters in the formula (centimeters and meters, seconds and hours).

It is more convenient to calculate the cross-sectional area of \u200b\u200bthe ventilation duct in cm2. In other units of measurement, this parameter of the ventilation system is difficult to perceive.

It is better to supply air flow to each element of the ventilation system at a certain speed. Otherwise, the resistance in the ventilation system will increase.

It is better to supply air flow to each element of the ventilation system at a certain speed. Otherwise, the resistance in the ventilation system will increase.

However, the determination of the calculated cross-sectional area of the ventilation duct will not allow you to correctly select the cross-section of the air ducts, since it does not take into account their shape.

You can calculate the required area of the duct according to its cross section using the following formulas:

For round ducts:

S=3.14•D2/400

For rectangular ducts:

S=A•B /100

In these formulas:

- S is the actual cross-sectional area of the ventilation duct, cm2;

- D is the diameter of the round air duct, mm;

- 3.14 - the value of the number π (pi);

- A and B are the height and width of the rectangular duct, mm.

If there is only one air line channel, then the actual cross-sectional area is calculated only for it. If branches are made from the main line, then this parameter is calculated for each "branch" separately.

When is a regular hood not enough?

In a number of situations, you can get by with the usual natural supply ventilation, which is so popular with suburban homeowners. It will not require serious costs for the arrangement and operation, however, one can argue about the effectiveness of its work (especially in the summer).A natural hood does not need additional fans in the cellar, so the installation costs are really minimal (you only need to buy pipes and protective caps).

Air ducts fixed on the wall of the cottage.

However, natural ventilation will not give the desired effect if:

- The basement has an area of 40 sq.m. and more. In large storage facilities, in the absence of good ventilation during the winter months, the warm air inside is saturated with moisture. In the chimney, moisture condenses and remains on its walls (this happens according to the laws of physics, due to the temperature difference). Drops of condensate quickly accumulate, and due to the negative temperature they soon turn into frost. When frosts last for several days, frost closes the exhaust pipe with a dense layer, which excludes the normal movement of air outside. This moisture can be eliminated only with the help of fans in the cellar, which are placed inside the supply and exhaust pipes. An exception is the situation when the basement is divided into several rooms and natural ventilation pipes are installed in each. Then a forced ventilation device in the basement is not required.

- Natural ventilation is indispensable in those basements where it is planned to make living rooms, or rooms in which people will stay for a long time (workshop, bathhouse, gym, etc.). Only an extractor hood based on the operation of a cellar fan will be able to supply oxygen in sufficient quantity for a comfortable stay of people.

- Also, good fans in the cellar are needed if there is a large amount of food in the storage. In the case of a vegetable cellar, the hood will fight not only with humidity, but also with unpleasant odors.

forced option

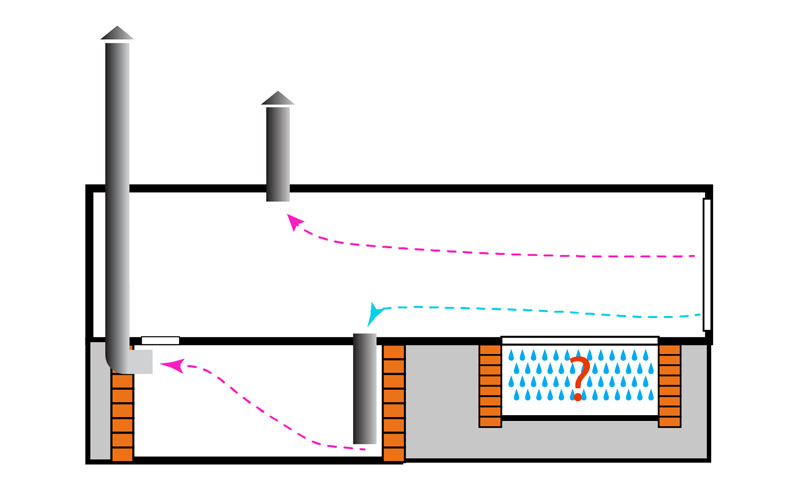

Forced ventilation of the cellar involves the use of two plastic pipes of different diameters. One works for inflow, and the second for outflow. The formula will help determine the optimal diameter. There are 26 square centimeters of section per square meter of area. There are 13 square centimeters per square centimeter of pipe diameter.

For example, the area of \u200b\u200bthe room is 8 squares. We multiply them by 26, and then the resulting value is 208, divided by 13, the total is 16 cm square, this will be the required pipe diameter. Using the calculation systems, they proceed to the construction of a schematic drawing.

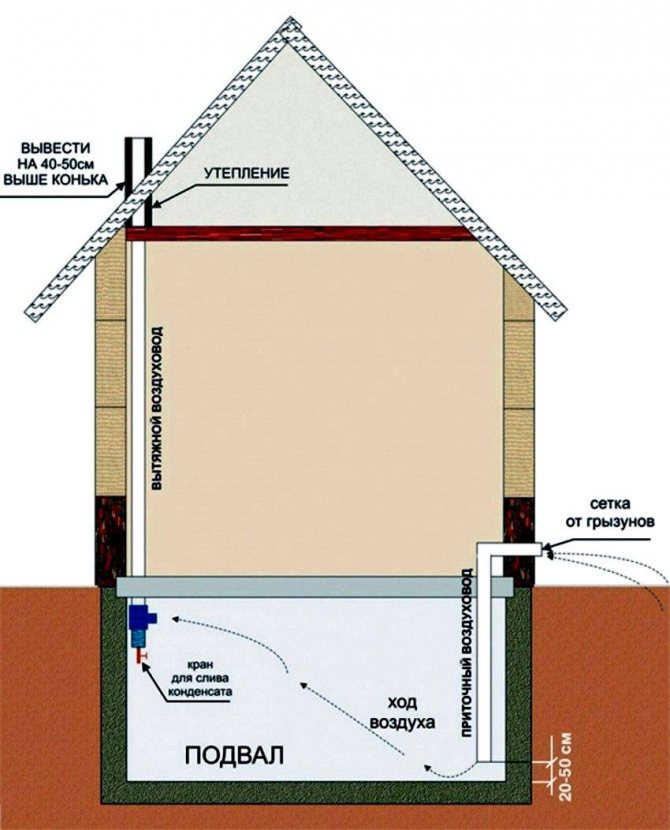

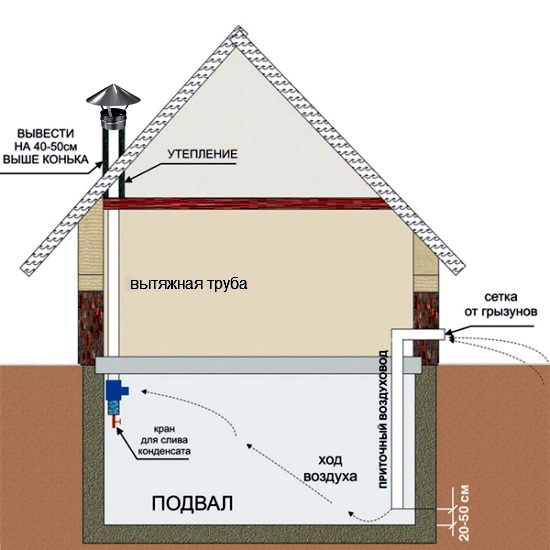

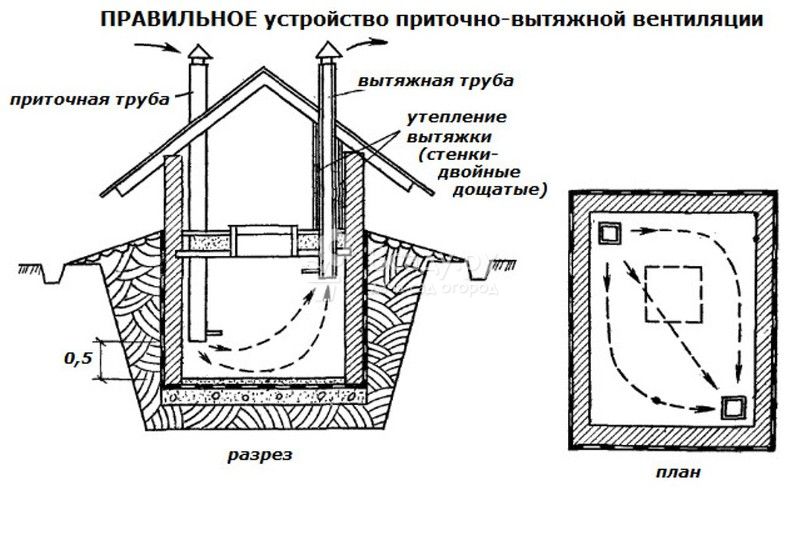

In a private house, the ventilation of the supply and exhaust type cellar is performed in accordance with certain requirements.

- The chimney exits through the roof. To increase traction, if there is a chimney, it is better to place the pipe next to it. The length must be made maximum so that the thrust is stable. The lower part of the pipe is closed with a damper for manual draft control. Special umbrellas are put on the upper opening to protect the room from precipitation.

- Installation of the supply pipe is carried out in the opposite corner of the room.

- The length of the supply pipe, on the contrary, should be smaller and be localized almost at the very ceiling, while the place of localization of the hood is almost at the very floor.

Improper arrangement of the ventilation system is determined by a simple method. A match is lit in the room: if the flame is even, then the ventilation system is designed correctly. The same method will help determine which pipe is the problem.

If there are deviations in the operation of the system, it is necessary to adjust the height of the pipeline. If the problem persists after adjustment, you can try increasing the diameter. To remove excess moisture, a lime box is often placed indoors.

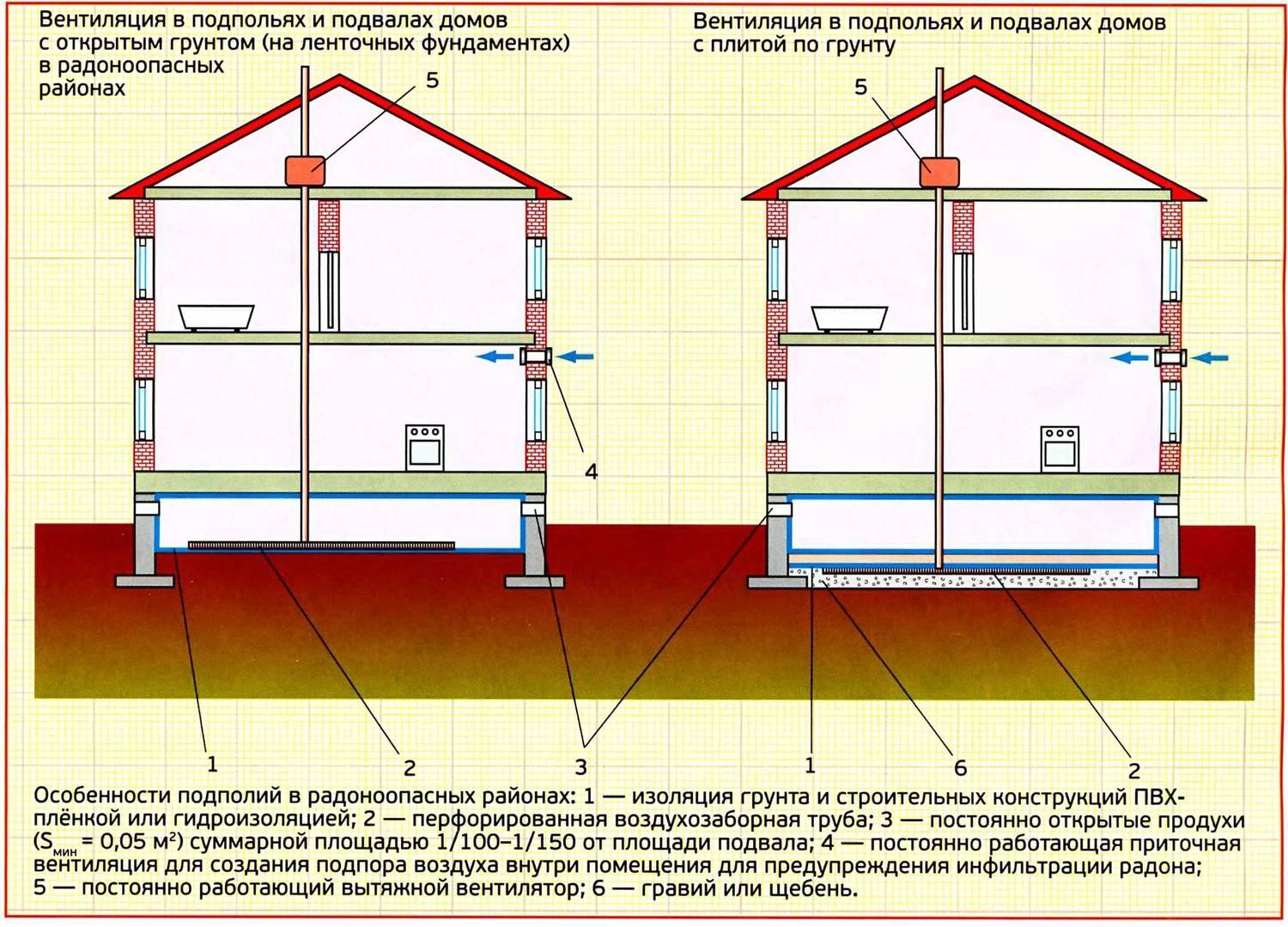

The need for underground ventilation

The organization of underground ventilation in a private building is mandatory for the following reasons:

- From the temperature difference in the street and under the floor, condensate settles on the logs with floor beams and on the base. Without the organization of ventilation, drops of water containing acid destroy concrete, brick, wood, causing corrosion of building materials.

- Humidity contributes to the appearance, resettlement and development of mold and fungus that affects wood, metal, and concrete. Mold that has already appeared, with a natural normalization of the moisture level, does not disappear anywhere, and with its subsequent increase, it will begin to develop more actively in the affected areas;

- The closed space of the subfloor accumulates carbon dioxide, especially if it stores autumn harvested crops.

The humidity of the underground increases due to contact with soils, in which there is always water in different proportions.

Moisture is especially felt at the level of the soil, i.e. soil-vegetative layer up to 40 cm thick, actively absorbing rainfall and regularly irrigated during irrigation.

In the absence or insufficiently effective operation of the ventilation system, the subfield will be damp. Due to the lack of oxygen, a favorable environment will be formed for the development of anaerobic bacteria. In addition to everything, carbon dioxide will accumulate

Underfloor ventilation is necessary for almost any design solution.An exception is the construction of the floor on the ground, according to which beams or slabs are laid directly on sandy or gravel filling, and do not block the spans between the foundation walls with them.

Step by step installation instructions

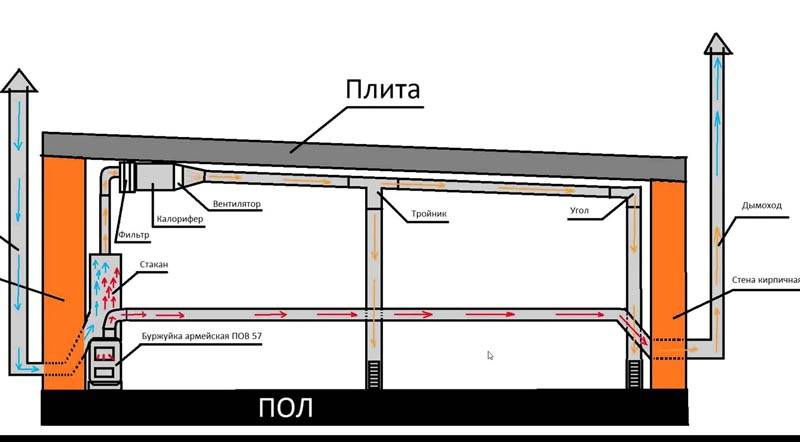

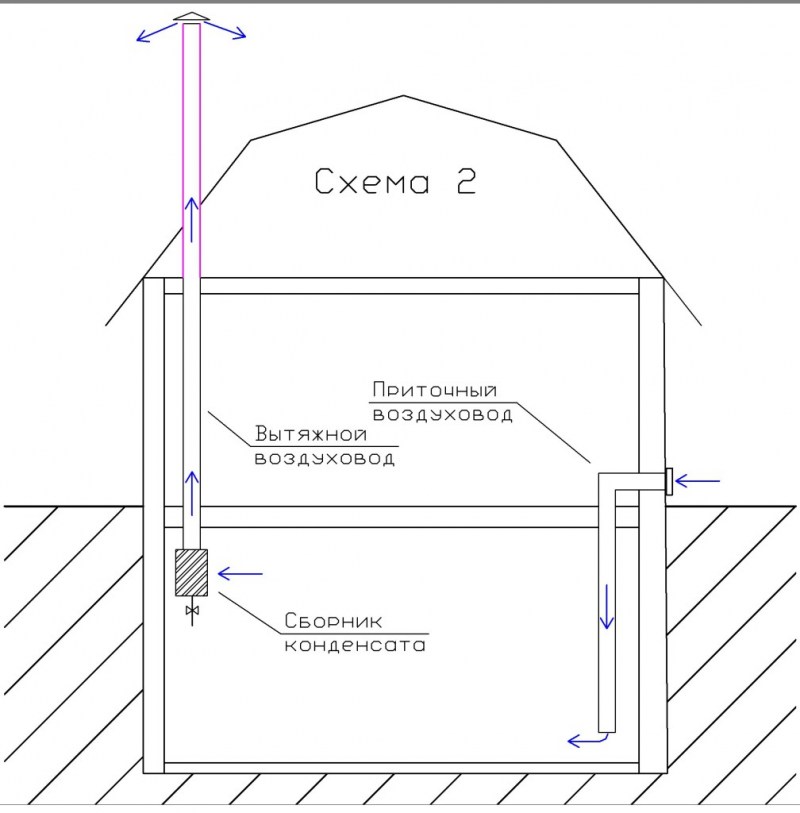

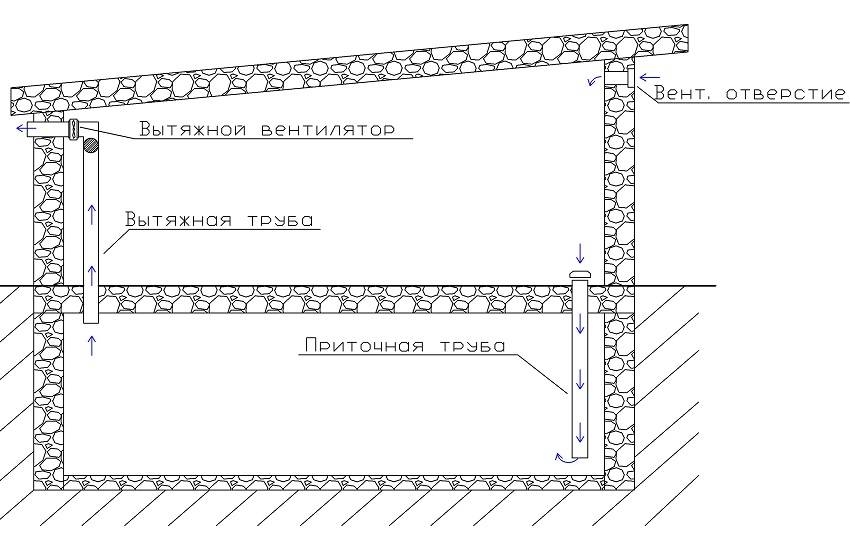

Consider, for example, the sequence of installation of a combined version of natural ventilation with an additional mechanical exhaust.

The duct fan makes it easy to turn the natural ventilation system into a forced one, and, if necessary, return it to its original form.

The duct fan makes it easy to turn the natural ventilation system into a forced one, and, if necessary, return it to its original form.

This will require pieces of plastic pipes with a diameter of 110 mm with rubber seals, a duct fan built into the air duct, 10–15 W, powered by a 220 V mains.

We select the total length of the exhaust section within 3 - 4 m, the supply - depending on the depth of the basement and the distance to the exit beyond the perimeter of the garage. You will also need two removable pieces of 30 cm. One for the fan, the other to replace it. If necessary, condensate drainage can be provided, then a tee and an elbow will be additionally required. The latter is also used when turning the pipeline.

Of the tools you will need: a puncher, a drill, a chisel, a punch, a 125 mm crown for drilling holes in concrete. With a large thickness of the ceiling, the walls will need an extension cord.

Hand punches are a good addition to your punch tool kit. They knock out fractions of crushed stone or gravel from concrete, which can occur during drilling, thereby saving expensive drills (winning or diamond-coated)

Hand punches are a good addition to your punch tool kit. They knock out fractions of crushed stone or gravel from concrete, which can occur during drilling, thereby saving expensive drills (winning or diamond-coated)

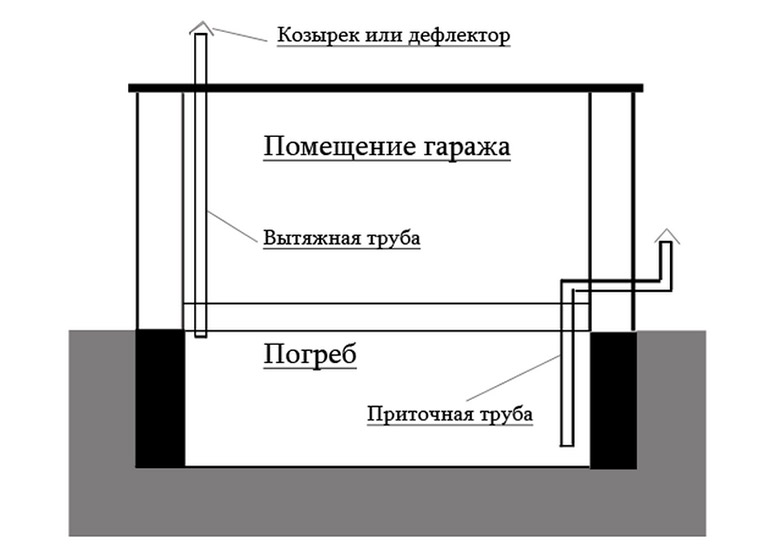

Arrangement of ventilation in the basement of the garage is carried out in two stages.

First, we make all the necessary holes in concrete floors, brick partitions inside the basement, garage and on the roof. Then we install pipes.

Stage #1 - drilling holes

We adhere to the following sequence of actions:

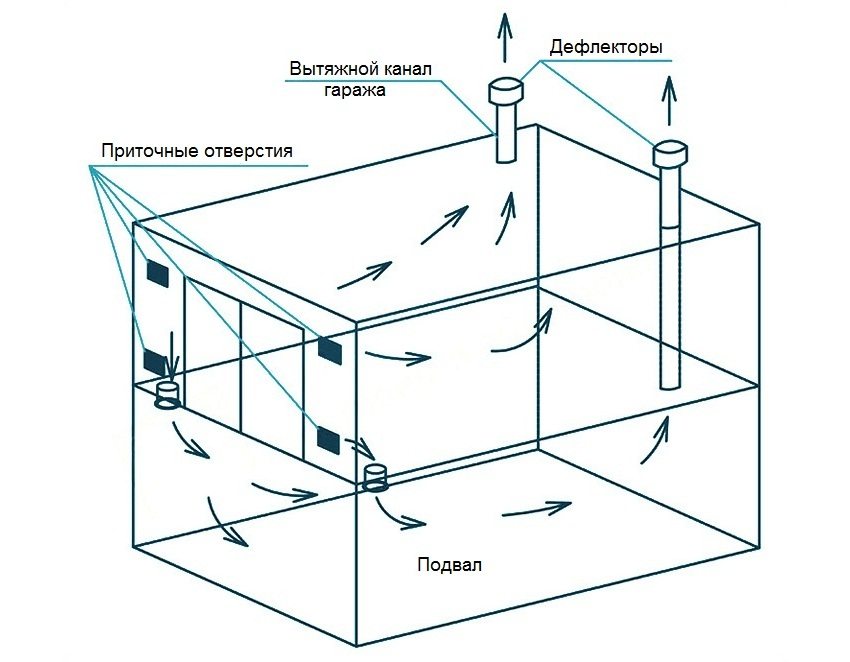

- We determine the location of the openings of the supply and exhaust pipes in the basement. They should be placed diagonally in different corners of the ceiling or top of the wall. At the same time, the supply pipe should go to the north side of the garage, and the exhaust pipe - to the roof, or to the south.

- From the basement we drill with a drill in the ceiling the center of the future hole for the hood.

- At the top, in the garage, we mark a circle of 125 mm around the drilled center. We make a few holes inside it with a drill. Then we drill with a crown. In case of contact with reinforcing rods, we free them from concrete with a chisel and cut them off with a reciprocating hacksaw for metal.

- We put the pipe vertically from the resulting hole in the floor to the ceiling, and mark the position of its center. Drill a hole with a drill.

- On the roof of the garage, repeat the operations of paragraph 3.

- Similarly, we make a hole for supplying air from the street to the basement, following steps 2 and 3.

This completes the most laborious part of the work.

It is more convenient to drill concrete floors in sequence from bottom to top. This makes it easier to ensure the accuracy of the alignment of the holes. Don't forget to wear goggles and a respirator

It is more convenient to drill concrete floors in sequence from bottom to top. This makes it easier to ensure the accuracy of the alignment of the holes. Don't forget to wear goggles and a respirator

Stage # 2 - installation of pipes and fan

The next stage - the installation of pipes and the installation of the fan - is carried out in this order:

- We fix the fan inside one of the removable pipe sections.

- We mount an exhaust section in the garage, connecting three segments. The location of the fan is chosen based on ease of access.The upper pipe should go at least a meter above the roof, the lower one should go into the cellar to the level of the ceiling. Between them we insert a piece of pipe with a fan, the rotation of which should be directed upwards to the hood.

- We install the supply pipe, lowering it into the cellar from 0.5 m to 0.2 m above the floor. We bring the entrance part to the north side of the garage, raising it 20 cm above the ground. We finish the hole with a knee or a tee with a protective metal mesh.

- We seal the joints of pipes with ceilings with mortar or mounting foam.

- We connect the fan and check the draft in the basement, leaning a piece of paper against the exhaust hole.

- We insulate the pipe section above the roof with any available material. If the garage is not heated, then you need to insulate the entire exhaust pipe.

The use of a fan may only be required during the summer months. During the rest of the year, natural air circulation will suffice. To do this, you just need to replace a pipe fragment with a fan for the same segment without it.

Pros and cons of different types of ventilation

With non-stop air circulation, the temperature and humidity regime will be stable, however, in the cold season, the room may freeze.

1. The channel is necessary to remove moisture, odor and toxic compounds.

2. The supply pipe provides fresh air to the interior of the cellar.

3. The single-pipe system is the simplest method, which has its pros and cons:

- the positive side is the low cost of the hood and the relative ease of installation;

- the disadvantage is that full-fledged air exchange is problematic due to weak inflow.

If the cellar is small, then it is recommended to install this option. The air duct must be divided into separate ventilation openings.

4. Installation of a two-pipe type is preferable because of the ability to ensure greater safety of provisions and things that are underground, but it requires large financial costs.

The correct design approximately 2 times per hour completely changes the air in the room. The circuit diagram with natural circulation is laid down in the project at the initial stage of its creation.

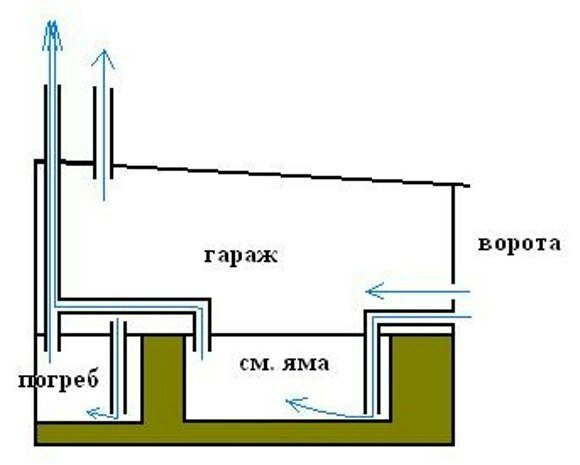

In what cases can you get by with one pipe and determine the diameter

In a separate cellar with a small area, as well as in a garage or a shed, installation of a one-pipe system. Its top should go out at a distance of at least 80-100 mm from the roof ridge.

- In a structure with a perimeter of 2x3 or 3x3 m, it is necessary to erect a structure with a cross section of at least 150x150 mm, with a wind catcher at the end.

- The hood is necessarily divided in half by a vertically located partition that runs along the entire length.

- In one compartment, air enters the room, in the second it leaves it outside, so for each part a separate damper is made, which closes.

- Before completing the installation, it is necessary to check the circulation. To do this, you can smoke the underground and monitor the pace of cleaning.

In order for the system to function correctly, it is necessary to accurately calculate the diameter of the ventilation ducts.

- The underground area should be proportional to the cross section of the pipe and be 1m2 / 26 cm2.

- A pipe diameter of 1 cm is equal to 13 cm2 of section, hence: (Sroom x 26 cm2) ÷ 13. If S of the basement is 9 m2, then it will turn out (9x26) ÷ 13 \u003d 18, which means that the size of the cross section must be at least 18 cm.

- ventilation pipes are taken 1-2 cm more than the value obtained. For S = 9 m2, it is necessary to take a material with a cross section of 19-20 cm.

From the side of the street, the channel is located in places accessible to blowing by strong winds, otherwise it will be inactive.

Which channel to close for the winter, the nuances of the hood with two pipes

The use of a two-pipe design to form a full-fledged supply and exhaust system requires the most accurate calculation, therefore, it is desirable to first create a circuit.

- For uniform air exchange, channels with an equal cross section are installed. If it is necessary to drain the cellar or get rid of a musty smell, then the outlet should have a large diameter.

- The fewer twists and turns, the better the ventilation will be.

- Optimum temperature conditions and circulation are achieved due to the maximum removal of the hoods from each other. It is preferable to place them at different ends of the room.

| View | Installation | Nuances |

| exhaust | The lower end is 150 cm from the floor, as close to the ceiling as possible. The output channel to enhance traction is closed with a mesh or a deflector is attached to it. | 1. The ventilation openings of the pipes must have a height difference of at least 100 cm. 2. The supply channel of the underground on the street is below the exhaust. 3. Air masses form condensate: when winter comes, it cools down and turns into frost. The street end requires mandatory insulation. 4. To remove condensate, a drain cock is mounted in the lower part of the exhaust pipe. |

| Supply | The hood should be at a height of about 30-50 cm from the floor. The outer end rises above the roof by a maximum of 25 cm. If the channel is arranged in the ceiling of the basement, then a grill is attached to it from the outside, which protects against the penetration of rodents. |

In order to regulate the intensity of air movement, it is necessary to open and close dampers installed on the ends of the hoods located inside the room.

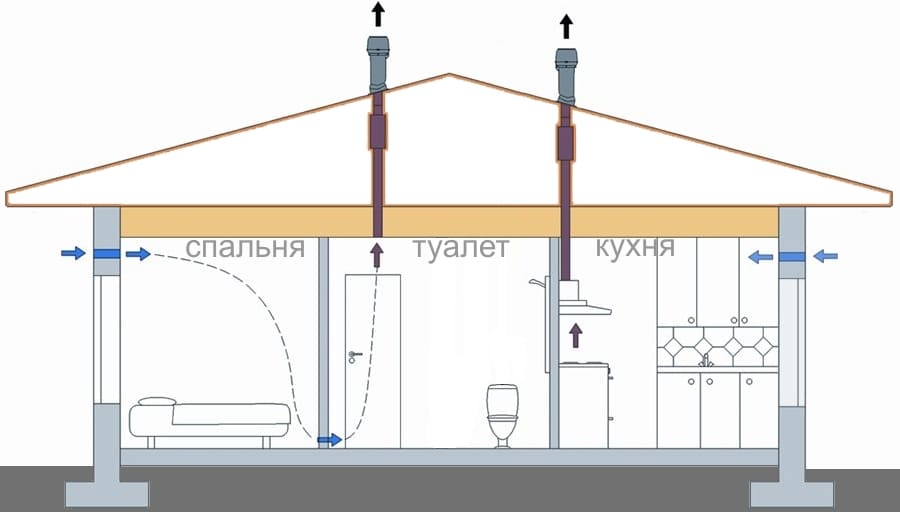

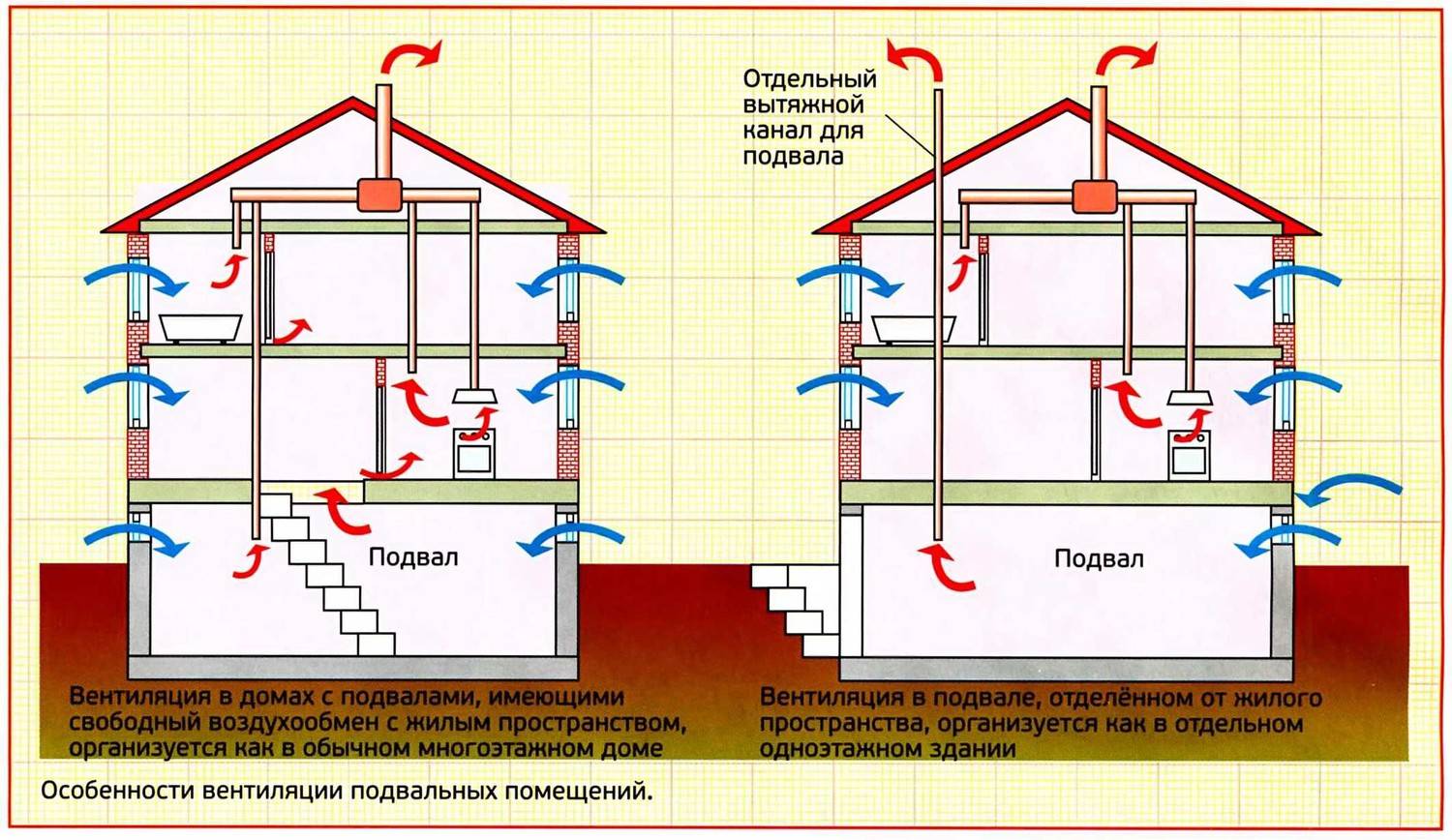

Types of ventilation

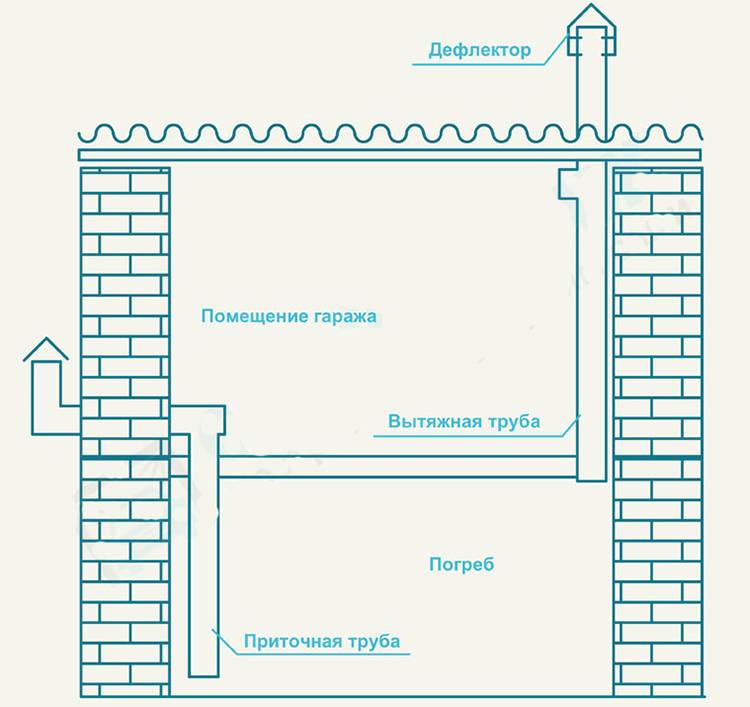

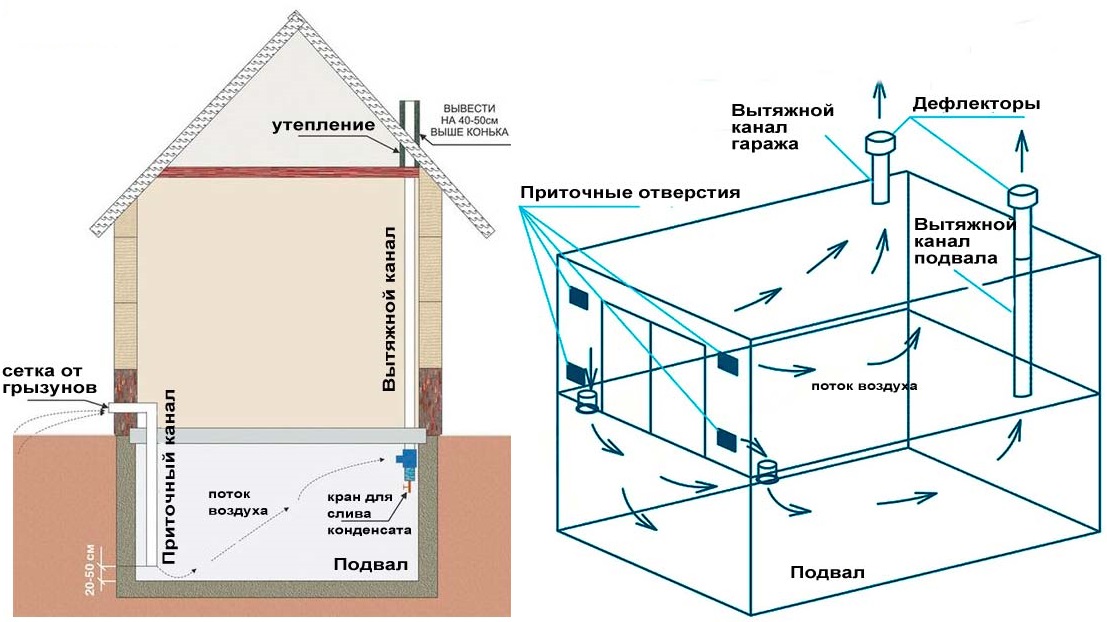

A separate hood for the cellar, like all known ventilation systems, is organized in two ways: natural or forced. Their arrangement differs significantly in the design schemes used and in the funds invested in them. Natural ventilation in the cellar is done in accordance with a standard project, according to which air enters it due to the temperature difference between inside and outside. When using the second scheme, a pressure injection element is introduced into its composition, which is usually a fan.

Features of natural ventilation

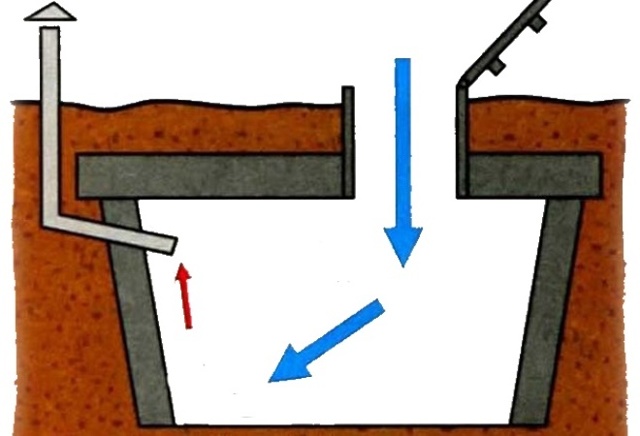

Due to the always existing difference in the temperatures of the external and internal environment, a pressure gradient appears on their border, causing the movement of air masses. Due to this, fresh air from the street through the intake hole enters the basement and displaces its settled and musty masses through the outlet channel. The main elements of a natural exhaust include a supply pipe line, an exhaust duct that removes air from the basement and the so-called “vents”.

The inlet is equipped with a fine mesh, which protects against dirt, foreign objects and rodents from entering the pipes, and the outlet is closed with a protective visor.To obtain the required draft, the basement ventilation is equipped in compliance with the following rules:

- First of all, the problem of creating a maximum difference in height between the inlet and outlet openings is solved.

- You should also try to place them along the longitudinal diagonal of the basement (at opposite ends).

- The supply hole is made at the bottom of one of the walls, and the hood is made in the upper part of the wall opposite the first one.

For laying pipes and ducts of the exhaust system, unified blanks of a suitable size are used.

Forced exhaust systems

Forced exhaust in the cellar functions by moving air masses driven by an external device, the function of which is usually performed by a fan. Its main components:

- air ducts through which air masses move;

- a pressure unit, through which air exchange of the desired intensity is achieved;

- intake devices designed to maintain air circulation;

- mating structures that combine air lines with different sizes of pipes and ducts.

Typical examples of the latter are tees used when it is necessary to combine or separate air flows. They also include extension cords and diffusers of various configurations. The forced ventilation system is additionally equipped with the following elements:

- special filters that purify the air pumped in from outside;

- a heating unit designed to heat it;

- temperature control unit, set depending on the design features of the basement and customer requirements.

Forced exhaust equipment is prepared according to a pre-drawn scheme. Even at the design stage, the system is calculated, the results of which determine the required intensity of air exchange and select its operating modes.

Due to the extended functionality, forced ventilation has a number of advantages:

- independence from weather conditions;

- the presence of automation that allows you to effectively distribute air flows and choose the optimal temperature regime;

- the possibility of operation in the basement of a large area.

Do-it-yourself ventilation installation

Independent performance of work on the installation of air circulation equipment in the basement requires a detailed acquaintance with the features of the equipment and the principles of ventilation.

Depending on the size of the basement, install a specific air circulation system:

- Install natural ventilation when the basement area is less than 50 square meters.

- Installation of forced ventilation is carried out with an increased area of \u200b\u200bthe basement.

Installation of ventilation equipment in the constructed building can be done on your own. You will need a puncher, a grinder and a drill to make holes and form channels in the base of the building, walls, basement and ceiling. Let us dwell in detail on the stages of the implementation of measures for the installation of ventilation communications.

Installation steps

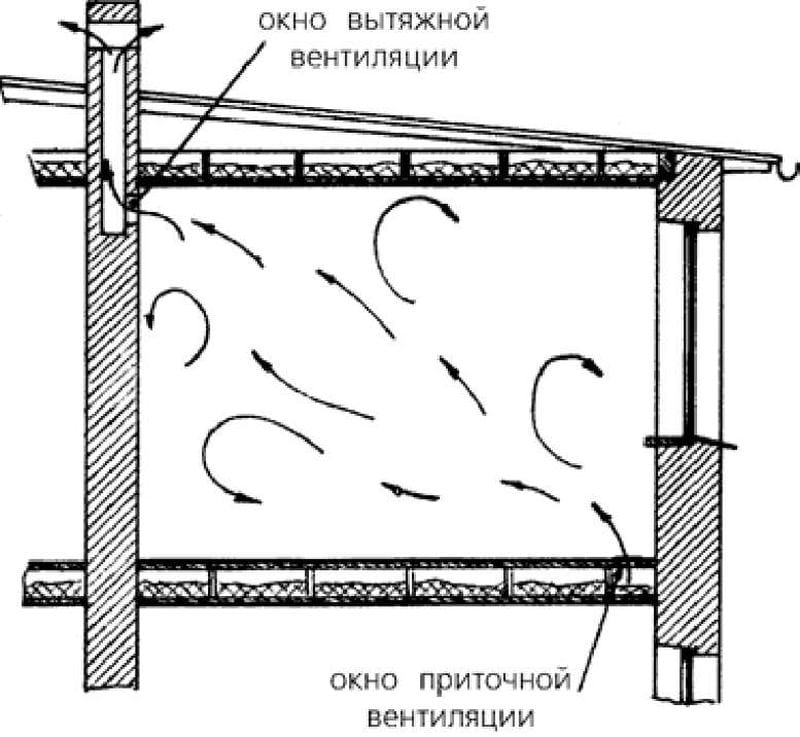

With a small area of \u200b\u200bthe basement, to ensure air exchange, make small channels (air vents) located on opposite walls in the basement of buildings.

Ventilation of small basements is carried out through channels in the base of the building

Install gratings to prevent rodents from entering the basement.

Installing a grate will reliably protect the basement from rats and mice

Mount dampers inside the basement on the holes designed to adjust the volume of incoming air.

Air ducts do not always provide the desired air exchange efficiency. In this case, we recommend installing ventilation of the supply and exhaust type.

Supply and exhaust ventilation consists of two air lines

Proceed as follows:

- Prepare metal or plastic pipes for the supply line and exhaust duct with a diameter of 10–15 cm. Using standard elements will speed up installation

- Mark the opposite sections of the basement in which it is necessary to make holes for the supply of air ducts.

- Drill holes in the basement and ceiling of the basement, corresponding to the dimensions of the air lines. Using a special tool facilitates the work

- Install the supply pipe, ensuring that the outer part is located at a distance of 1 meter from the zero mark, and the inner part is at a level of 0.2–0.5 m from the floor. The supply duct provides air flow

- Insert an exhaust pipe into the ceiling hole, which should exit through the hole in the roof of the building.

- Fix the exhaust line, providing a distance above the ridge of the building of more than 50 cm, necessary to ensure traction.

- Insulate the surfaces of the exhaust pipe extending outside the building and located in the attic. By insulating the pipes, you can reduce the likelihood of condensation

- Eliminate the gaps between the pipes in the basement and ceiling using sealant.

- Install a condensate collector equipped with a tap to remove liquid in the basement on the exhaust duct.

- Fix a cap in the upper part of the exhaust line, which protects the pipe from precipitation and enhances traction. Installing the cap will protect the line from precipitation

- Install protective grilles on the supply channels.

Use clamps to fasten pipes, securely fasten system elements during installation.

The effective operation of the supply and exhaust system is guaranteed with a basement area of 20-40 square meters. m. For enlarged rooms, installation of a forced air exchange unit will be required. We recommend entrusting the installation of complex ventilation systems equipped with air conditioning and temperature control devices to professionals.

Cellar hood with one pipe

In order for the basement to be ventilated, dry, even one pipe is enough. Any gaps will play a positive role.

Hood with fan

The only thing worth paying attention to is that the diameter of the duct tube must be no more than fifteen centimeters. If it is not possible to establish air circulation, it is recommended to organize the process using a mechanical awakening

Everything is extremely simple: install a fan in the exhaust pipe.

The main component of the excellent microclimate in the cellar is the air humidity, which can be regulated with a fan

It is important to note that too high a humidity level worsens the quality of ventilation. This is the case if groundwater penetrates into the basement, which happens in the spring when snow melts.

During this period, the cellar becomes damp, and the ventilation system is not able to cope with such serious loads.

See also: how to make ventilation in the garage with your own hands.

You can solve the issue as follows: take a tin, it should be one and a half millimeters larger than the pipe hole.  Drill a sidewall at the bottom, carefully cut a hole, and attach a screw below so that the nut and thread remain outside. It turns out a self-made balancing system that can upholster an even position for the windcatcher. In the side of the can, namely opposite the hole, a trapezoidal tail should be mounted so that it performs the function of a weather vane, namely, it turns the device towards the wind and catches air currents.

Drill a sidewall at the bottom, carefully cut a hole, and attach a screw below so that the nut and thread remain outside. It turns out a self-made balancing system that can upholster an even position for the windcatcher. In the side of the can, namely opposite the hole, a trapezoidal tail should be mounted so that it performs the function of a weather vane, namely, it turns the device towards the wind and catches air currents.

Install the wind trapping system on the tube: put the threaded axle, fix it with a bracket. Drill the bottom in the center, pull the bolt from the inside and screw on the threaded axle. Complete the installation process by balancing. With the help of such a device, ventilation can be significantly improved. The principle of operation of a cunning device is incredibly simple. The system is rotated by a weather vane so that the side opening is directed against the air flow. Thanks to this scheme, clean air can easily enter the pipe and enter the basement.

We recommend a useful article for summer residents and gardeners: How to make a machine for ventilating a greenhouse with your own hands.

Summing up, it can be noted that well-equipped ventilation shows its own priorities for several weeks. The air in the cellar will be cleaned, slightly moistened, and the products will not freeze and dry. As for the temperature indicators, they can easily stabilize.

Loading …

Separate option - a special system

For ventilation of cellars, the supply and exhaust version of the natural air exchange regulation system is the most reliable and budget option. The disadvantage of this method is the direct connection between the operation of the system and the temperature difference in the street and the strength of the wind.

For large rooms, a forced system is used. The use of such a scheme is especially important if in the future the cellar will be used as a living room, or it is planned to convert it into a gym or a billiard room. The natural ventilation system in the cellar cannot provide sufficient air exchange in hot calm weather.

If you plan to convert the basement into a gym, you should equip a forced ventilation system

When using this method, it should be remembered that the basement rooms are quite damp, therefore, to store food in the cellar in the country, you need to connect appliances with a minimum power, otherwise you may encounter the problem of current leakage through the appliance case.

There are two methods for forced ventilation of a wine cellar. The second involves the use of deflectors, instead of electric fans. The deflector is mounted on the inlet of the hood, which is located above the roof level.

This device redirects the force of the wind and rarefies the air inside the pipeline. Instead of a deflector, mini turbines are used. When installing a forced system, a natural one must also be provided.