- The choice of ventilation system depending on the material of the walls of the bath

- Choice of materials and components

- Supply and exhaust ventilation in the sauna - arrangement scheme

- Basic principles

- How to make an extract in the bath

- Hood in the bath: scheme

- DIY: how to do it right

- Useful video

- Features of the ventilation system device

- The main types and schemes of ventilation in the bath

- Airing

- Ventilation with stove

- Natural ventilation through vents

- Forced ventilation

- Features and subtleties of hood design

- Calculation of window sizes for ventilation

- The principle of placement of holes for the hood

- Ways to arrange natural ventilation

- Ventilation through the chimney

- Ventilation through vents

- Air exchange in different zones

- dressing room

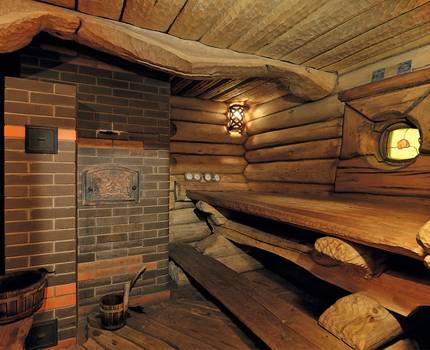

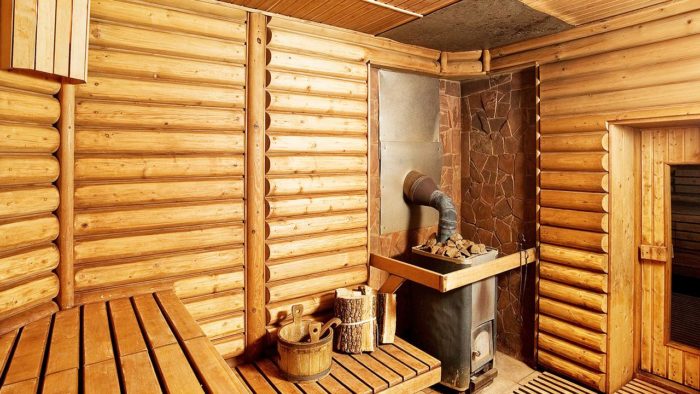

- Ventilation in the bath in the steam room

- Requirements for the arrangement of ventilation in the bath

- Algorithm for the device of a system with a fan

The choice of ventilation system depending on the material of the walls of the bath

Recommended reading: "Shelves in the bath"

Recommended reading: "Shelves in the bath"

For the construction of baths used:

- brick;

- cinder block, gas block, foam block;

- log;

- beam.

In buildings made of timber or brick, vents are made in the foundation for air inflow, a ventilation valve and an exhaust hood are installed to remove exhaust air.

In structures made of blocks, air ducts are made of stainless steel, galvanized in the form of finished pipes.Or you can make them yourself from galvanized sheets, going through the sealant at the joints. Put them on top of the wall.

To avoid drafts and high consumption of firewood, a wooden building can be insulated. Then you have to make holes in the walls for the inflow and exit of air.

Choice of materials and components

Any bath should be made of environmentally friendly materials, and also equipped with only heating appliances that comply with safety regulations.

For a traditional log house, polymer insulation, glass wool and plastic elements cannot be used.

In the bath, ventilation should be made of the following materials:

- galvanized steel or wooden boxes are used for air ducts;

- painted metal or wood is used for gratings, valves and diffusers;

- tow, moss or jute is best used to seal cracks in the walls at the exit of pipes;

- fans must be made of special plastic and have a high degree of protection against moisture penetration.

It is best not to use metal parts for the steam room, as at high temperatures they heat up and can cause burns to visitors.

Accessories for installation of ventilation in the steam room:

- ventilation valves;

- bolts;

- gratings;

- mosquito nets to protect vents from debris and insects;

- ventilation boxes;

- pipes for air supply and output;

- fan;

- special adhesive tape and sealants, clamps, a tube of mounting foam;

- fasteners and other mounting materials for windows and shutters.

Valves for ventilation come in different sizes, are made of different materials, are made in different colors. Lattices for a bath are usually made of wood, and nets are made of metal.

A ventilation duct made of wood or zinc is mounted on a wall or attached to it. The use of plastic boxes is prohibited, as they may begin to melt when the temperature in the sauna rises.

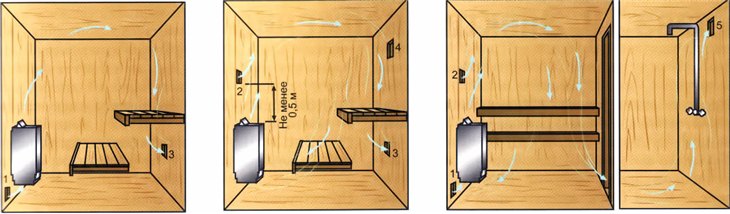

Supply and exhaust ventilation in the sauna - arrangement scheme

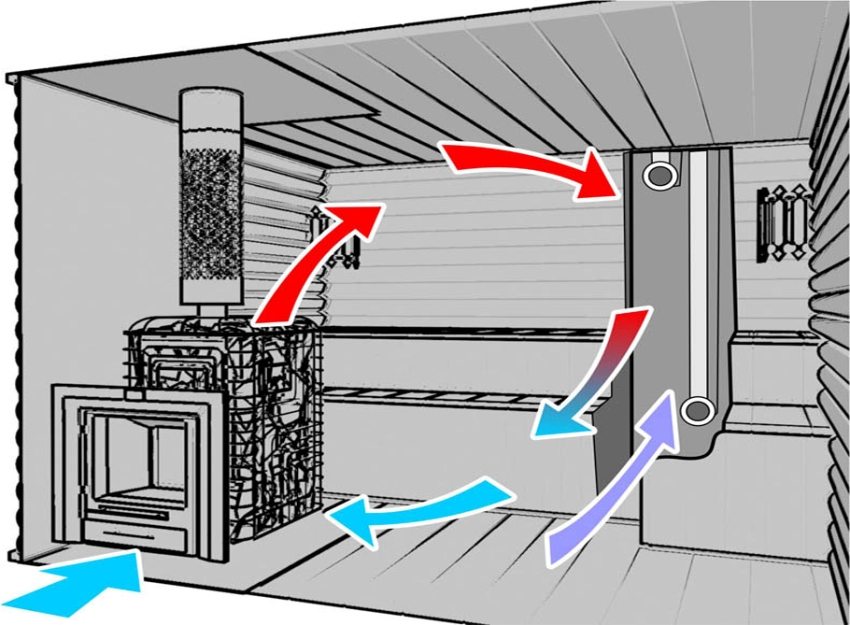

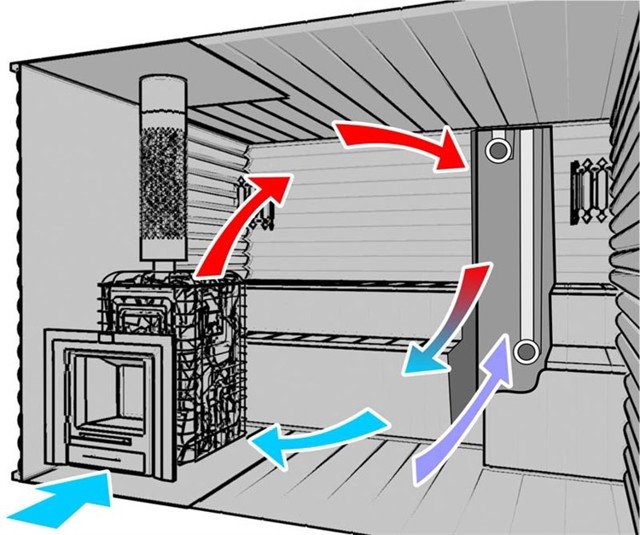

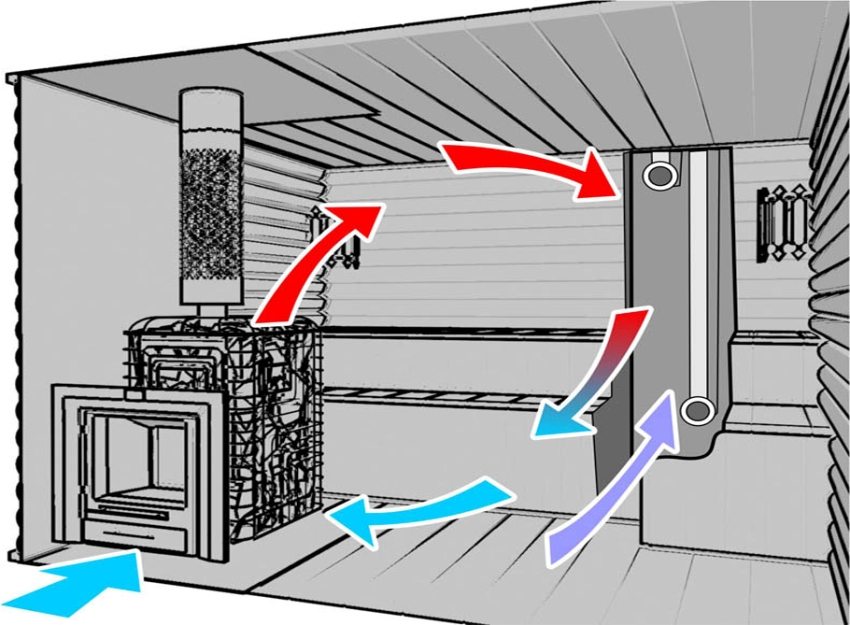

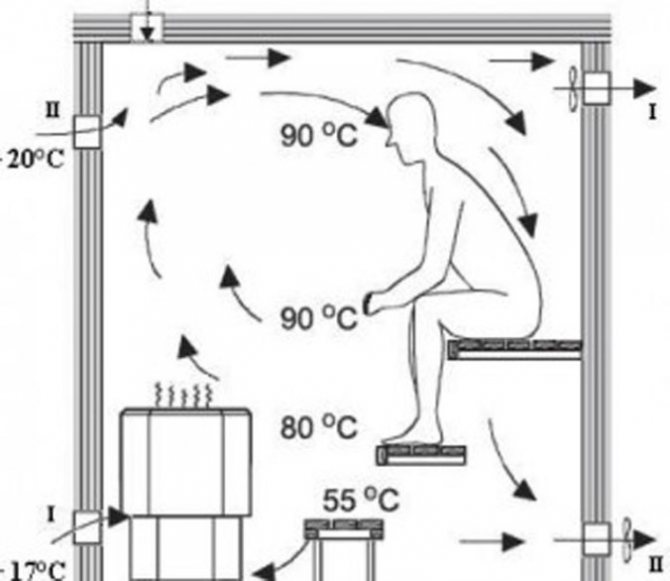

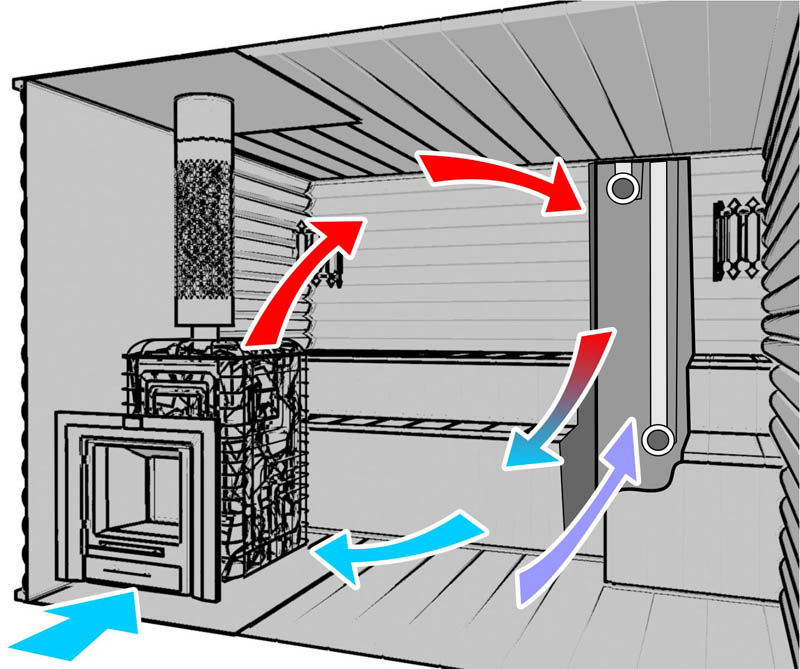

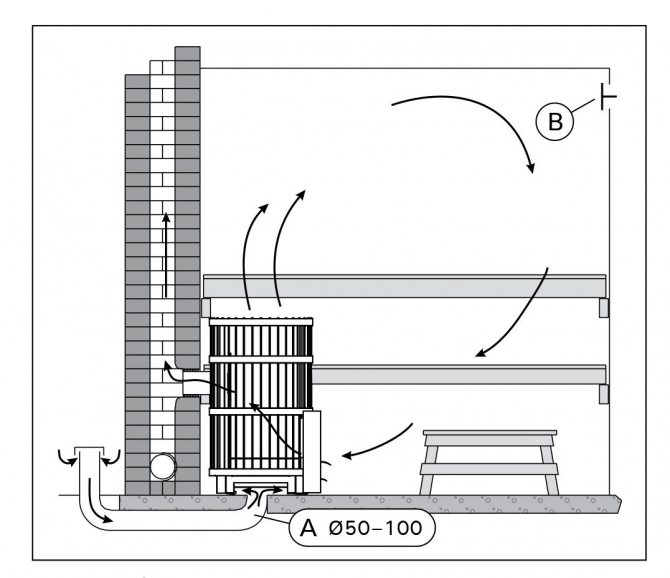

To begin with, consider the classics - natural supply and exhaust ventilation. The hood law of this type is the correct location of the inlet and outlet openings. The correct one is when the inlet is located near the stove or under it (if we are talking about the electric version), while the outlet is located on the opposite side. Also, cold fresh air will enter the steam room through a specially left 5-7 cm gap under the door.

For proper air circulation, one exhaust opening will not be enough. On the opposite side of the inflow, the first hood is located at a height of about a meter, the second is under the ceiling. Both openings must be connected by an exhaust duct, which leads either to the main ventilation system or to the chimney

If the air duct goes separately, then you need to remember that the higher the pipe rises above the roof level, the more thrust will be in the system - it is important not to overdo it!

So that you can regulate the intensity of air exchange, it is imperative to install shutters on the air outlets. How does such a system work? Let's imagine a standard steam room with a stove-heater at the far wall and a door at the near one. As expected, a gap was left under the door, and the hoods are located on opposite walls: near the stove and at the door.

Before heating the steam room, it must be properly ventilated so that there is fresh air in the room.The doors and outlets are then closed, leaving only the inlet valve open. The steam room will heat up quickly enough, since the hot air will soon have nowhere to go, which means that there will be no air discharge in the inlet.

When the sauna has warmed up, we still leave the upper channel closed, while opening the lower channel a little - thanks to this, air circulation in the steam room will begin, while the upper layers of the warmest air will not leave the room. Cold air will again begin to enter through the supply channel, but due to the proximity of the heater to the resting people, it will get already warmed up, gradually rising up and replacing the stagnant air.

Thanks to this air exchange, the room will have fresh and warm air. Vacationers may not even notice such a change, enjoying the process. Such a system provides economical handling of already heated air, which means you will save on coolant consumption. In addition, problems with mold and fungus will not affect you - thanks to such circulation, all elements will dry properly.

Basic principles

Improperly equipped ventilation can lead to certain consequences.

- Even with good ventilation, the tree is subjected to enormous loads, so it often lasts no more than twenty years. Without fresh air, the service life will be reduced several times.

- If carbon dioxide is not removed from the steam room, then its use will do more harm than good. In addition to carbon dioxide, combustion products accumulate there, and fungi and mold are permanent “guests” of any room with insufficient ventilation.

- If the steam room is not ventilated, then soon it will be filled with the smell of rotten wood and stale air.

Another important function of air circulation is heat transfer. The fact is that air with high humidity does not conduct heat well and as a result, the stove will only heat the space around it.

That is why the ventilation inlet is usually located behind the stove, almost above the floor itself. This contributes to the fact that already heated air is distributed through the steam room; if the ventilation inlet is located elsewhere, it will supply cold air into the room, thereby disrupting heat transfer.

The exit must be installed on the opposite side of the entrance.

When arranging a bath, not only the correct choice of one or another ventilation scheme is important. Of great importance is the diameter of the ventilation holes. It is calculated as follows: for every 24 cm of the hole there should be one cubic meter of the room, otherwise there will be no circulation.

It should be noted that it is desirable to equip the inlets and outlets with plugs to regulate the intensity of air exchange. Mines should be laid even during the construction of the bath.

Vent valve (fungus)

How to make an extract in the bath

This has already been said more than once, and yet it is worth repeating: the cost of arranging ventilation will increase many times if it is done late, after construction is completed. At the same time, the principle of creating ventilation in the bath remains unchanged: it is necessary to create conditions for the inflow and outflow of air from the premises. So, how to make a hood in the bath with your own hands or the hands of professionals.

Hood in the bath: scheme

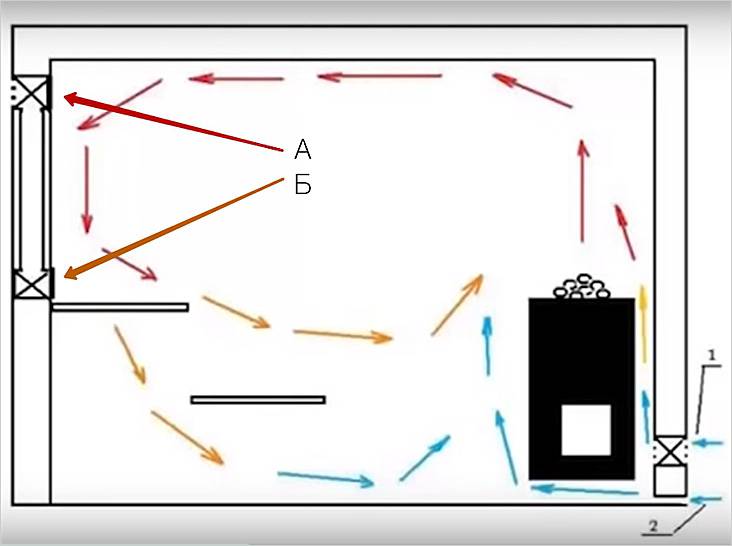

There are many schemes, but any one is suitable for understanding the principle of ventilation. Most often, ventilation schemes for the steam room are offered, but the scheme for the entire bath, with explanations, is of much greater interest.

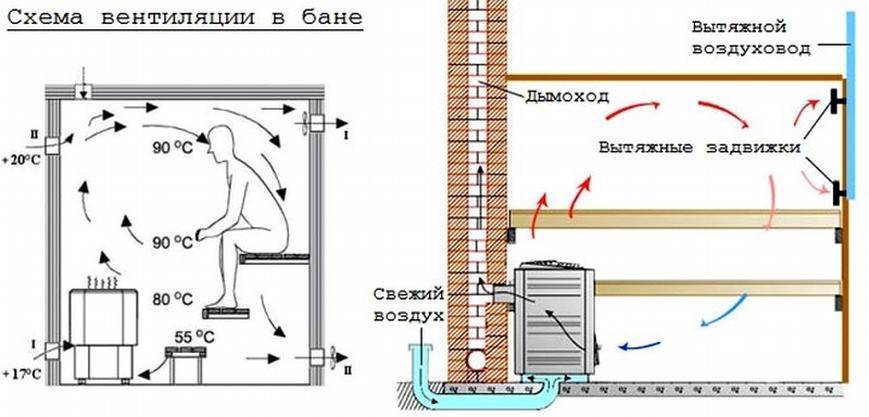

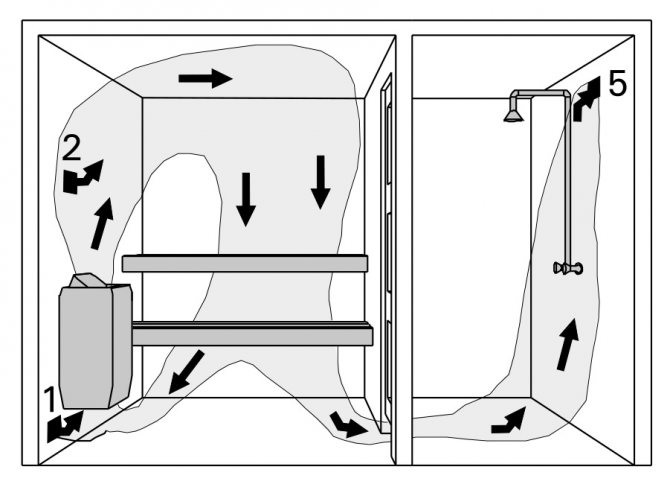

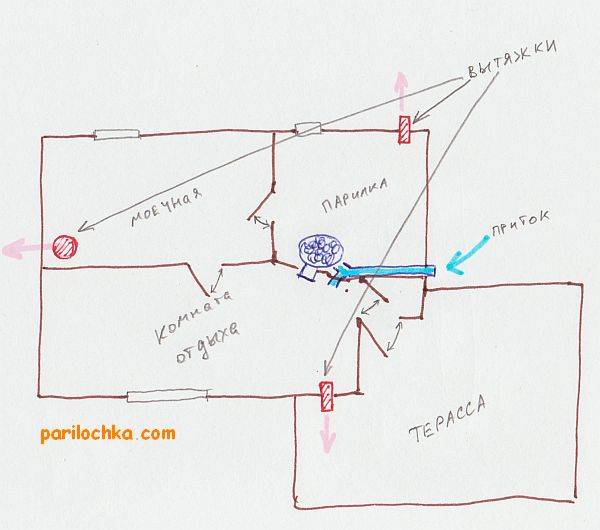

Look at the sketch. It shows that ventilation is carried out in the washing room, steam room and rest room. Moreover, the air flow is carried out from one pipe to two points, one of which is located in the steam room, and the second - in the rest room. The hood is located in the washing room, and in the steam room, and in the rest room. Let's describe all the ventilation devices in each room:

- Washing room - a window made of metal-plastic, an adjustable hood that takes air through a diffuser located on the ceiling. From there, the air escapes through a pipe to the roof.

- The steam room is an insulated window located below the shelf, an adjustable hood, which is a vertical box, the intake hole of which is 150 cm² located below the shelf, and the exit from the pipe to the street is near the ceiling. One of the channels of regulated inflow near the stove, cross-sectional area 150 cm².

- Recreation room - adjustable hood, which is a box with a cross section of 150 cm², the height of the intake hole is 30-40 cm from the floor, exit through the pipe to the street near the ceiling. Regulated inflow through the second channel with an exit near a furnace fire chamber.

DIY: how to do it right

Do-it-yourself exhaust in the bath is not something that cannot be done, but you need to approach the matter prudently and slowly. In order to independently make the hood, you need to choose a scheme and prepare materials according to it. It is also necessary to calculate the cross section of the ventilation pipes.

IMPORTANT! The inflow volume must be equal to or less than the exhaust volume.

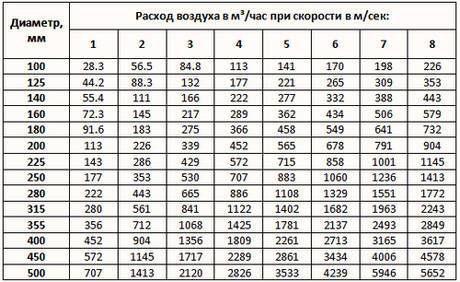

To do this, you need to know the volume of the room and the multiplicity factor (how many times the air should be updated per hour) - it is in the regulations. In the main air ducts, the speed of movement should not exceed 5 m / s, in the branches - 3 m / s, in the steam room - 2 m / s, natural ventilation - up to 1 m / s. Further in the table we find the value of the pipe section, which most closely gives the desired volume at a given speed.

Knowing the cross section, it remains to prepare a corrugation or pipes of the appropriate diameter, which at one end are mounted indoors at the desired height according to the scheme, and the other ends go outside. Self-tapping screws, metal tape and polyurethane foam are used for fastening. The openings are supplied with shutters in the room, gratings at the exit. By the way, ventilation should be cleaned once a year.

Useful video

Watch a short video showing ventilation in one bath:

+++

Well, now you know exactly how to properly draw a hood in the bath in order to save yourself, household members and guests from suffocation in the bath. It remains only to correctly apply the information received.

You may also need from the ventilation section for baths:

- how to do it yourself;

- ventilation of baths by their types;

- ventilation in the steam room.

Features of the ventilation system device

An important role in choosing the optimal ventilation scheme is played by the material of the bath, its location, whether it is freestanding or not. All this helps to make the right decision when installing a ven system.

One of the effective methods of ventilation is burst ventilation - when you need to quickly ventilate everything, all doors and windows open. Of course, this can be implemented if there are windows.

With volley airing, in a matter of minutes, the main moisture leaves, preventing the wooden trim of the bathhouse from getting wet

In the ventilation of the bath take part:

- window;

- vents in the foundation;

- special holes in the wall/ceiling;

- doors and the gap under them.

The decision to install a window in the steam room is very good, but it is another matter that it is not always possible to implement it. It is in such cases that it is necessary to choose another option for organizing the ventilation of the room.

Air in the foundation is also not often able to be used. Especially if the owner decided to allocate one of the rooms of the house for the steam room, the foundation of which is not equipped with special holes. Here, forced ventilation with a carefully selected layout of supply and exhaust openings will come to the rescue.

No matter how much you want to protect the room from steam leakage, diligently covering it with vapor-tight materials and tightly fitting the doors, you should not do this. Under the door to the steam room, be sure to leave a gap of 2-3 cm and nothing else.

The gap under the door of the steam room will provide a more uniform flow of air, which will favorably affect the steaming people

For air flow, it is desirable to make holes in the lower part of the room that communicate with the street. After all, the room needs clean and fresh air, especially if the bathhouse is located outside the city, next to a coniferous or deciduous forest.

Holes designed to remove exhaust air are located in the upper part of the walls opposite the walls with supply valves. Moreover, their height depends on the chosen ventilation scheme and starts from 80 cm from floor level and more.It is also possible to install an exhaust valve in the ceiling with a ventilation duct outlet to the roof.

The supply openings are closed with valves, latches, so that it is convenient to control them in the process of taking bath procedures

The main types and schemes of ventilation in the bath

As in any other room, the bath can be forced or natural ventilation. Natural air exchange is provided by the natural physical property of air to rise when heated and fall when cooled. The inflow and exit of the medium is carried out through specially made holes or slots.

Forced - a network with built-in superchargers of a mechanical or automatic type. The formation of forced ventilation is difficult due to the high level of humidity - water can lead to breakdown of the units.

Consider the optimal options for the formation of air exchange in the bath.

Airing

A simple and effective option when opening doors and windows in a room.

Air exchange is fast, but has negative consequences:

- Hot steam comes out of the steam room. It settles on the planes of the dressing room, other rooms.

- A simple ventilation removes excess steam, the actual temperature (heat) will return to its original value within a few minutes.

- The impossibility of forming stable parameters. When the doors are opened, the humidity and heat decrease rapidly, and when the doors are closed, they rise again.

The main disadvantage of ventilation is the instant cold air settling in the lower part of the room. This can lead to damage to the heating equipment.

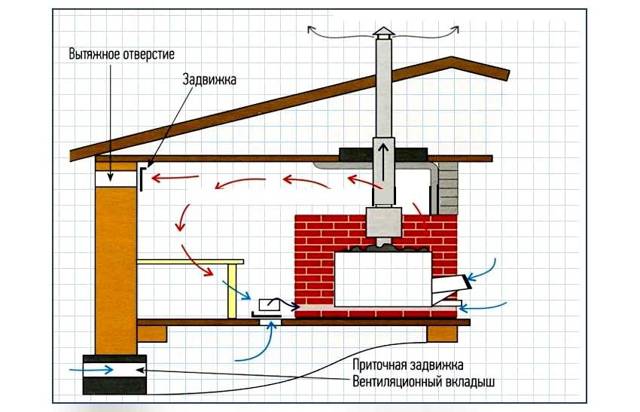

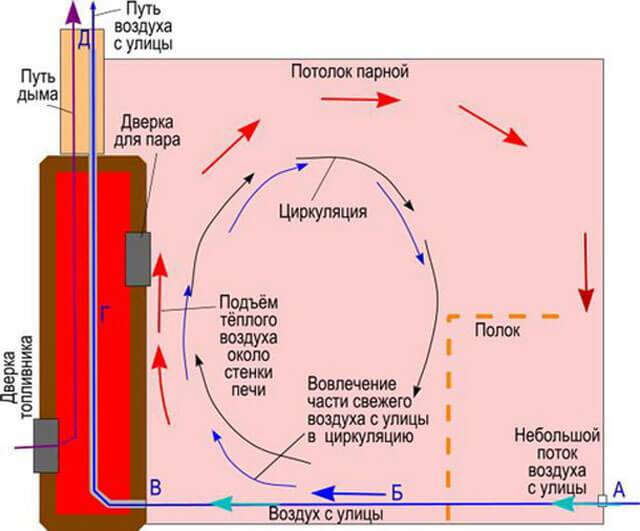

Ventilation with stove

Optimum ventilation in the steam room of the Russian bath, if the firebox is located in the steam room.In this case, warm streams are eliminated through the furnace into the chimney, and a fresh stream enters through the window, cracks in the floor or under the door.

Advantages of the method:

- ease of formation;

- the ability to control the supply of fresh air;

- universality of application in a bath from any materials.

The disadvantages include low productivity and inadequate ventilation. However, the last drawback can be leveled if gaps are left along the entire plane of the floor. The ventilation option is suitable for any objects, it is inexpensive and is formed both at the construction stage and after it. For example, you can shorten the door leaf by placing a perforated grill in the lower part. Having slightly opened the window at the top, the user will ensure good air exchange in the steam room.

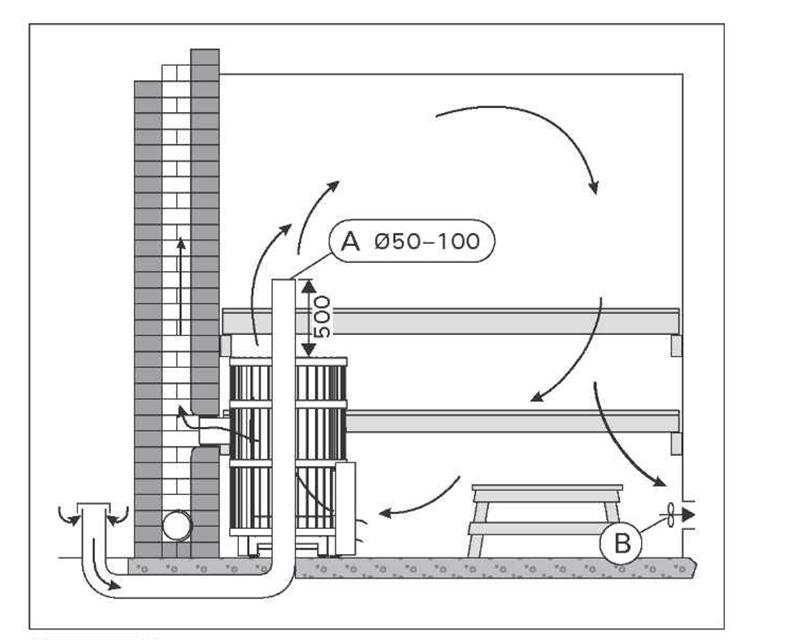

The bastu ventilation option in the bath is a kind of natural air exchange. It is understood that the upper part of the bath is a closed air space, the lower part is supplemented with a supply and exhaust system. The configuration maintains constant heating at the top of the room and fresh air from below. For the network to work, a pipe is needed to take air from the street and supply it to the room. The bastu system is complemented by dampers to regulate air exchange and reduce heat loss.

Natural ventilation through vents

Another easy way to ensure normal air exchange with your own hands in the steam room and dressing room. Efficiency reaches 100% with minimal heat loss.

There are more benefits:

- It becomes possible to quickly ventilate the premises. A constant flow of air is created - this ensures that the set mode is maintained for a long time.

- Autonomy.The system is not inferior in efficiency to forced, but works without the use of electrical appliances.

- Versatility. Air vents cut through buildings made of any material and regardless of the service life.

Natural ventilation in a sauna or bath works in all climatic zones. If necessary, a fan is installed in the duct, which allows you to instantly provide the desired microclimate inside the building.

Forced ventilation

The arrangement of the electrical network in a room with high humidity has its own risks. Experts recommend choosing devices in protective casings. Forced ventilation in the bath is formed in different ways, for example, installing an inlet valve in the upper part of the bath, an exhaust fan at the bottom. Or embedding the unit in the window, the hood is equipped through the door leaf, flooring.

The advantages of the system are in its functionality regardless of weather conditions. Minus in the thoroughness of calculations, increased cost.

Features and subtleties of hood design

When starting to design a ventilation system in the dressing room and other rooms of the bath, you should consider all the subtleties and features of the placement of its individual elements.

Therefore, it is necessary to decide how to make a hood in the dressing room, steam room and rest room at the planning stage of building a bath.

The passages themselves, through which air flows from the street will enter the steam room, dressing room, shower room and rest room, and the exhaust air and accumulations of carbon monoxide and steam will go outside, will need to be completed during the construction of the bath frame.But additional elements in the form of grilles, valves to control the intensity of the air supply, as well as fans and other mechanisms, are installed already in the process of final finishing the bath from the inside.

The following parameters affect how efficiently the ventilation system in the bath will work:

the principle of placement of air duct windows;

the dimensions of the supply and exhaust openings, which are calculated based on the volume of the room in which they are located, and it does not matter whether it is a shower room, a rest room, a dressing room or a steam room.

Calculation of window sizes for ventilation

It is necessary to calculate the size of windows for blowing and blowing air, based on the size of a particular bath room, that is, for a steam room, a rest room, a washing room or a dressing room, these indicators will be different

At the same time, it is equally important to provide for the possibility of adjusting the size of such a window and, accordingly, the power of air flows, by installing special grilles and valves. Note that if the ventilation ducts are made too large, it will be quite difficult to maintain the temperature in the room at an optimal level, which in parallel entails unnecessary costs of electricity or fuel

Yes, and adjusting the gap in the duct, which you need to open the valve, will be quite difficult.

Note that if the ventilation ducts are made too large, it will be quite difficult to maintain the temperature in the room at an optimal level, which in parallel entails unnecessary costs of electricity or fuel. Yes, and adjusting the gap in the duct, which you need to open the valve, will be quite difficult.

When constructing ventilation in the dressing room of the bath with your own hands, you should start from the estimated value of the blowing window of 24 cm2 per 1 cubic meter of the room. But the blow hole should be made larger to ensure good traction.

The principle of placement of holes for the hood

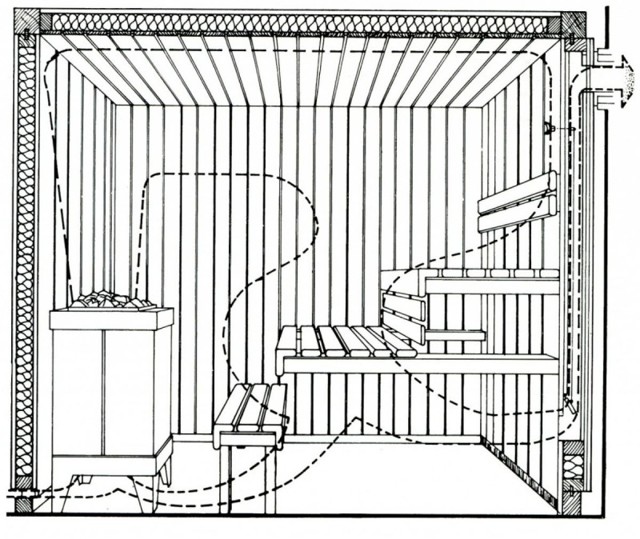

The replacement of air in the room occurs due to the gradual rise of the heated air masses up to the ceiling in the direction of the exhaust opening, bringing them outside and the supply of a similar volume of cold fresh heavy air from the street through the supply window.

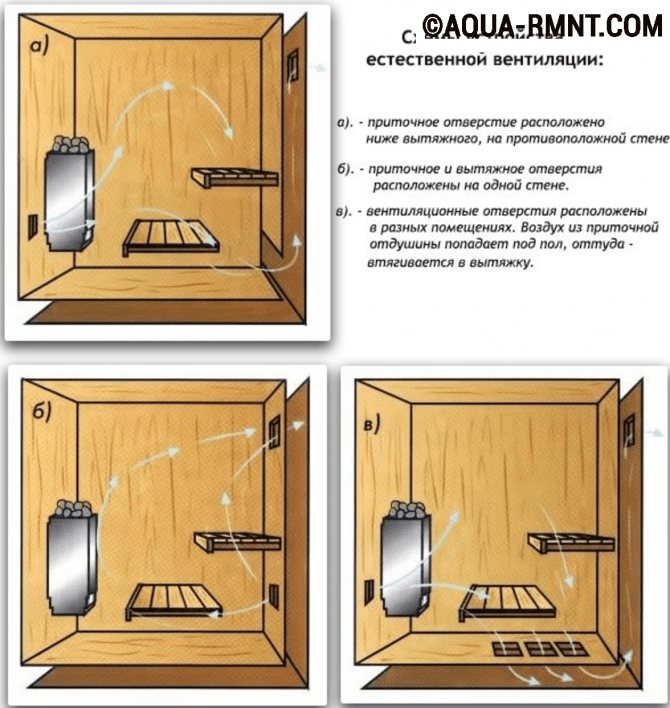

Ways to arrange natural ventilation

Dense and heavy cold air always goes down, and heated is displaced by it and rises up. This is how moving air flows arise in rooms with any heating device. But without an influx of fresh air, it does not renew itself, but simply moves.

If a hole is made in the lower part of the wall, air from the street will flow through it if its temperature there is lower than in the room. And through the hole at the top, it will stretch. This is natural ventilation.

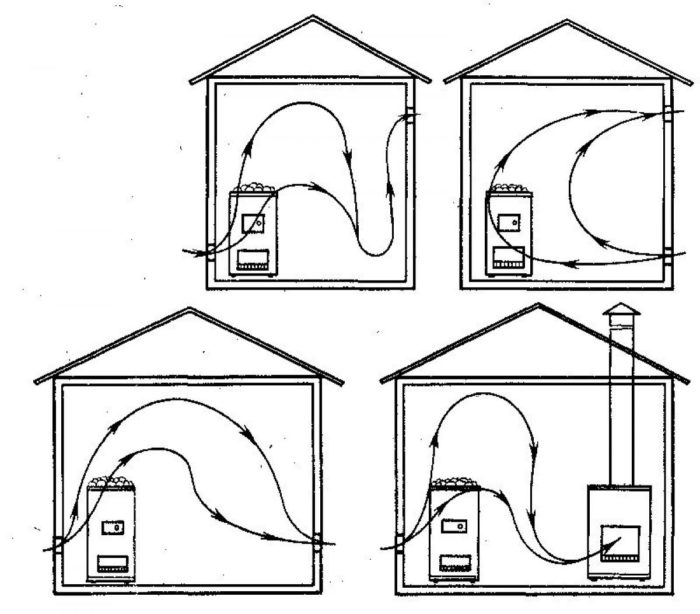

Scheme of the movement of air masses in a heated room

This elementary law of physics is used when they think about how to make ventilation in the bath with their own hands without using any mechanisms. As a rule, natural ventilation without forced air intake is enough for a small bath. Unlike living quarters, where in summer it is as hot as outside, the temperature in the bathhouse is always higher.

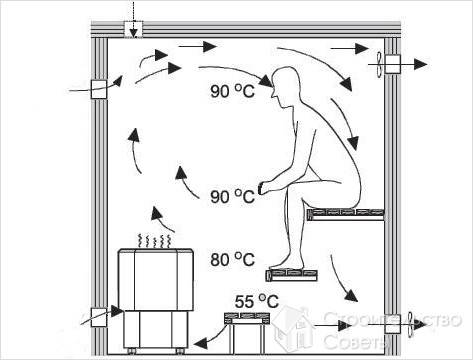

But it is necessary to maintain a temperature comfortable for receiving procedures in it, and so that drafts do not form, and there is no sharp difference from heat on the shelf to cold on the floor. To do this, air flows must move along a certain trajectory, which is set by placing supply and exhaust openings in specific places.

Ventilation through the chimney

The easiest way to solve the problem is how to make ventilation in the steam room if there is a furnace with a blower in it. It will serve to remove the exhaust air through the chimney, in which draft occurs during the combustion of the fuel. But this scheme will work only if there is an influx of air from the outside.

Open door to the steam room

Inflow can be provided in the following ways:

- from time to time slightly open the door to the steam room;

- make a small gap of 1 cm in the door or leave the same gap between the door and the floor;

- if the log cabin of the bath is not sheathed, such a gap can be left between the first crowns below the floor level, provided that the boards are not stacked tightly;

- make a special opening in the wall opposite the stove at a height of 20-30 cm from the floor.

In any of these cases, the cold stream penetrating into the room moves to the heat source and displaces the air already heated by it upwards. When moving, it warms up the entire room, gradually cooling down and falling down. Here it is drawn into the blower and led out through the chimney to the street.

Air movement pattern

This method of how to make ventilation in a steam room is not the most reliable and efficient, since most of the fresh air is immediately drawn into the stove.Therefore, even during the construction of the bath, it is advisable to consider other options with the installation of products in the walls.

Ventilation through vents

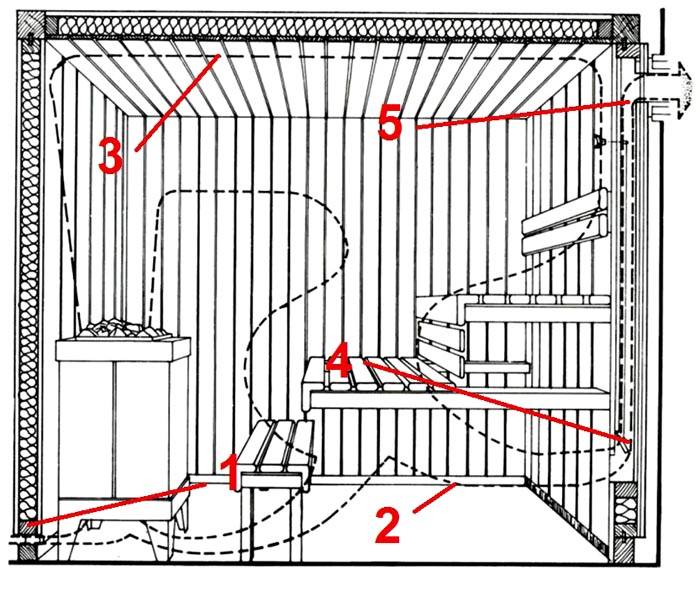

To ensure that air exchange does not depend on the operation of the furnace, special openings are arranged in the walls for the inflow and exhaust of air. It is guaranteed to work under the following conditions:

- the exhaust hole is placed under the ceiling of the bath - where heated air accumulates;

- the inlet should be located low above the floor on the opposite wall, the closer to the stove, the better so that the cold streams drawn in do not hit the legs;

- the optimal vertical distance between the products should be 150-200 cm;

- the cross section of the exhaust hole should be larger.

Cold air immediately enters the heating zone

The ideal location of the supply air is behind the furnace. Entering the room, it immediately begins to warm up, displacing the already hot air mass up and towards the hood. Therefore, cold streams and levels with noticeably different temperatures are not formed in the steam room.

If you want to know how to properly ventilate the bath and steam room, consider this scheme at the design stage and before installing the stove

It is also important to make sure to make a difference in height between the ventilation holes. If they are approximately at the same level, this will lead to a draft and a rapid passage of fresh air in a straight line, without circulation in the room.

Natural ventilation extractor

In order to be able to regulate the ventilation or restrict access to the steam room for too frosty air, it is necessary to provide covers or valves for the air.

The advantage of natural ventilation is that it works without the use of devices that require mains power and can break down. Its installation and operation do not require large expenditures.

Air exchange in different zones

dressing room

Ventilation in the dressing room when installing a stove in it is the simplest and most effective type of air exchange. Air circulates through the furnace. But the proximity of the room to the steam room leads to the deposition of condensate on surfaces: walls, ceiling. In order to preserve the wooden cladding, to prevent its decay, the dressing room is well insulated. Drafts are excluded. It is necessary to maintain the dimensions established by the norms: for 1 washable at least 1.3 sq.m. area. The simplest bathroom ventilation plan for this room is reduced to the withdrawal of exhaust air masses through a bathroom or washing area. But it is best to provide a forced type of air exchange in the dressing room.

Exhaust channel in the steam room

Exhaust channel in the steam room

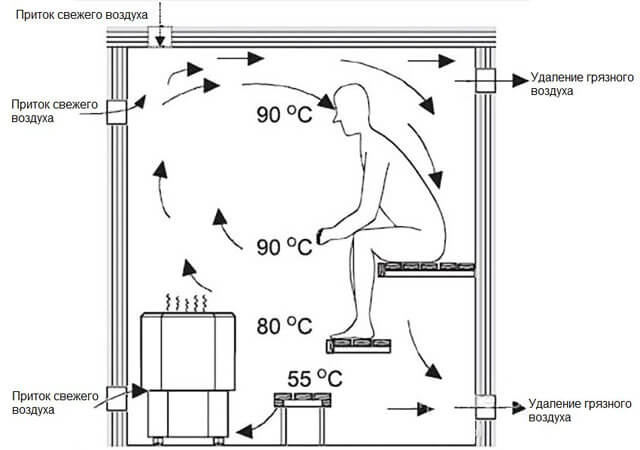

Ventilation in the bath in the steam room

Complete replacement of air in the steam room should occur 3 times per hour (at least). This is due to oxygen deficiency during bathing procedures and its constant replenishment by ventilating the room. Air is sucked in from below at a height of 1.5 m from the floor directly from the street, and not from the interior. If a stove is located in the steam room, dampers that specifically regulate the flow of air, a valve for ventilation in the steam room, etc., then these are natural ways to regulate air exchange. Air exchange can also be controlled by adjusting the duct section. The movement of air streams of different temperatures depends on the places where the ventilation holes are arranged.The layout in the steam room is on the same wall, but at different heights or on opposing wall surfaces with different levels of location.

The air duct can be made from a conventional corrugated pipe

The air duct can be made from a conventional corrugated pipe

In the best case, the arrangement of air vents is carried out as low as possible: this way heat is better retained. But for the intensity of the exchange of air masses in the steam room, it is necessary to equip forced ventilation (deflector, fan).

Requirements for the arrangement of ventilation in the bath

Complex solution for the ventilation system: steam room + washing room

Complex solution for the ventilation system: steam room + washing room

Properly designed ventilation in the steam room with your own hands ensures a long service life of building materials, as well as the safety and comfort of such a room. The steam room must meet the following requirements:

- The processes of air inflow and outflow are interconnected. If one of them is present, the other must also be provided. A necessary condition is the ratio of the volumes of air inflow and outflow. In addition, the ventilation scheme must be designed in such a way that it is possible to adjust and predict the direction of air flows.

- The ventilation system must be provided in such a way that the air moves in a strictly specified direction: from living quarters to technical rooms. For example, from the steam room, through the dressing room, to the bathroom or vestibule.

- According to the general rules, mechanical ventilation assumes the presence of an inlet at a height of at least 2 meters from the floor level, which must be equipped with a ventilation grill.In the steam room, another rule is relevant: the air inlet is located at a height of no more than 1.5 meters, which will allow you to warm up the fresh air as much as possible before it leaves the room through the hood.

- The air outlet hole must be placed in the upper part of the opposite wall relative to the "inflow".

- Forced ventilation becomes most effective if burst ventilation is provided in the steam room (normal ventilation of the room). The combined ventilation system allows you to best cope with dampness and unpleasant odors.

- The size of the supply and exhaust openings must comply with the standards so that at least 3 complete air replacement cycles are carried out in 1 hour.

With salvo ventilation, you will have to manually manage the air exchange process.

With salvo ventilation, you will have to manually manage the air exchange process.

Algorithm for the device of a system with a fan

Exhaust fan

Exhaust fan

A step-by-step installation guide for the combined version provides for increased fresh air injection with a special wide-blade fan.

- To work, you will need tools: a hacksaw, a drill, three-wire wiring, etc.

- A fan of rated power and performance is purchased.

- In a wooden frame, a drill with a special funnel makes adjacent holes.

- With the help of a hacksaw, the membranes between them are cut down, the holes are combined into one hole.

- In the same way, the channel for the inlet (outlet) of air is made.

- The vector of motion of the air flow is experimentally checked. For this, the holes are all clogged, the stove is heated. When the temperature in the bath exceeds +50°C, the holes open. Air flows are being studied.

- Rigid wiring is laid in a waterproof corrugated sheath to power the fan using an RCD.

- A fan is installed in the center of the vent. Attaches with screws.

- Dampers are manufactured or purchased to prevent heat loss, reduce the heating time of the stove. Inserted into fixed skids or mounted on hinges. If the bath is located autonomously, the shutters are also hung from the side of the street.

So, do you need ventilation in the bath - yes, you need it. Is it possible to arrange it yourself without the use of complex equipment - yes, quite. But, with the obligatory study of theoretical foundations, the development project and drawing up a diagram production of works.