- Is it necessary to ventilate the chicken coop, and why?

- One of the arrangement options + allowable errors (video)

- Microclimate norms: what should be the temperature, humidity and air exchange?

- What affects the structure of the system?

- System calculation

- Ventilation schemes in the chicken coop, calculation of fan performance

- Classical (traditional) ventilation scheme

- Tunnel ventilation scheme

- Mixed ventilation scheme

- Types of ventilation systems for the chicken coop

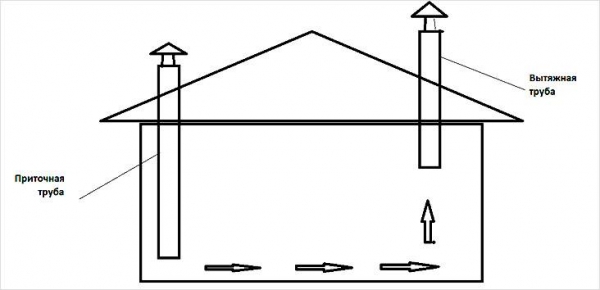

- Natural ventilation system

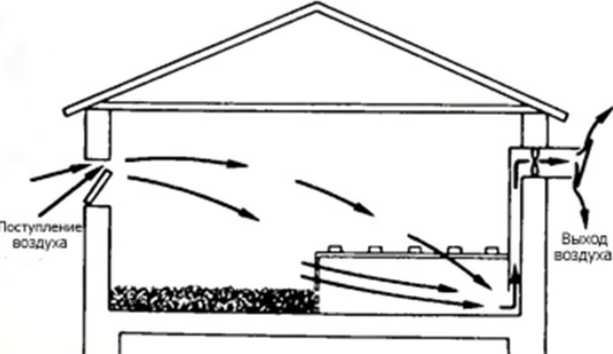

- Supply and exhaust ventilation system

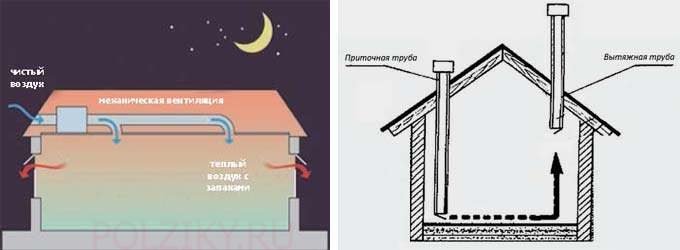

- Forced (electromechanical) ventilation system

- Ventilation installation scheme

- Option number 1. natural ventilation

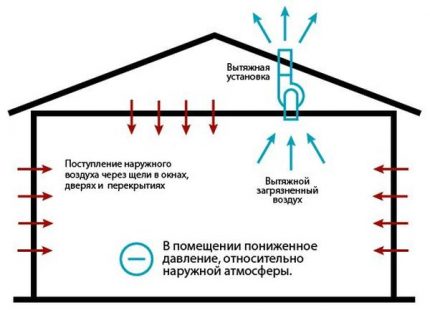

- Option number 2. Exhaust system

- Option number 3. mechanical ventilation

- A simple way to organize supply and exhaust ventilation

- Prices for ventilation units

- Diameter and shape of pipes

- Prices for deflectors

- Possible problems and their elimination

- How to make a hood in a chicken coop

- Construction rules

- Peculiarities

- How to make a hood without electricity

- How to calculate ventilation in a chicken coop

- Why is there ventilation in a chicken coop?

- 10 useful tips

Is it necessary to ventilate the chicken coop, and why?

And man, and animal, and bird - any living creature needs oxygen.Therefore, in any room - including in the poultry house - the air must be updated in sufficient volume.

In the chicken coop, ventilation is necessary for the following reasons:

- For the breath of birds. Like humans, birds take in oxygen from the air and exhale carbon dioxide.

- To remove ammonia. Chickens, especially those raised for meat, eat a lot and shit a lot. Bird droppings contain ammonia. Accumulating, this gas can harm birds: at high concentrations, they may develop keratoconjunctivitis (swelling and discharge of pus from the eyes, lacrimation), loss of appetite.

- To maintain normal humidity. Stale and too humid air is a favorable environment for the development and spread of infections. Under such conditions, morbidity and mortality of the livestock and a drop in productivity can increase. In addition, moisture quickly leads to spoilage of feed and bedding. Too dry air is also harmful - in such conditions, birds can peck at each other.

- To maintain normal temperature. In summer, increased air exchange will make it easier to endure the heat. In winter, it is difficult to ventilate through open doors and windows, because the room will cool too quickly. Both the cold and the very fact of a sharp drop are harmful to the bird (quick change of conditions = stress).

In addition to the life and health of the bird, the ventilation system is also important for extending the life of the building itself. High humidity harms building materials (especially if it is wood), which lose their strength and can collapse faster.

One of the arrangement options + allowable errors (video)

Microclimate norms: what should be the temperature, humidity and air exchange?

Here is a list of dry numbers - the norms that are recommended to be observed:

- Planting density. With floor content - up to 5 chickens per 1 m², with cage content - 4-10 chickens per 1 m².

- Temperature regime for adult birds. Optimal range: +16…+18º. Temperatures above +28º can lead to a drop in productivity, and above +35º - to heat stroke and death.

- Temperature conditions for broiler chickens (about a week old): about + 26º (when kept on the floor).

- Humidity in the room (for adult birds): 60-70%.

- Air exchange rate: 1. It means that in 1 hour the air in the chicken coop should be completely replaced.

What affects the structure of the system?

When choosing a system, consider:

- The number of chickens to be kept inside. The more birds, the more productive the system should be, and the more stable and accurate it should work. If in small poultry houses (relatively speaking - up to 50 chickens) you can get by with natural ventilation, then for a large room (conditionally from 50 heads or more) it is already worth making a forced system.

- The volume of the room. The larger the volume, the more air will need to be replaced, and the more powerful the system should be.

- Building layout. If we are talking about a building with several rooms, air exchange must be organized in each of them.

- climate in the region. If your region is characterized by severe / prolonged frosts, either the ventilation system will have to be able to heat the supply air, or there should be a heating system inside the room.

- The purpose of the building. Some owners build separate poultry houses: one for the summer, the other for the cold. Ventilation in such buildings is organized in different ways.

System calculation

It was already mentioned above that the air exchange of the house should be equal to 1 - that is, in 1 hour the air in the room should be completely updated.

Please note: for large poultry houses, it is recommended to make more powerful systems, with a margin of performance

Ventilation schemes in the chicken coop, calculation of fan performance

In the modern world, there are three types of ventilation schemes for poultry houses: the classic scheme, tunnel and mixed.

Built-in ventilation helps to clean the air in the barn in a timely manner and regulate the temperature inside the building

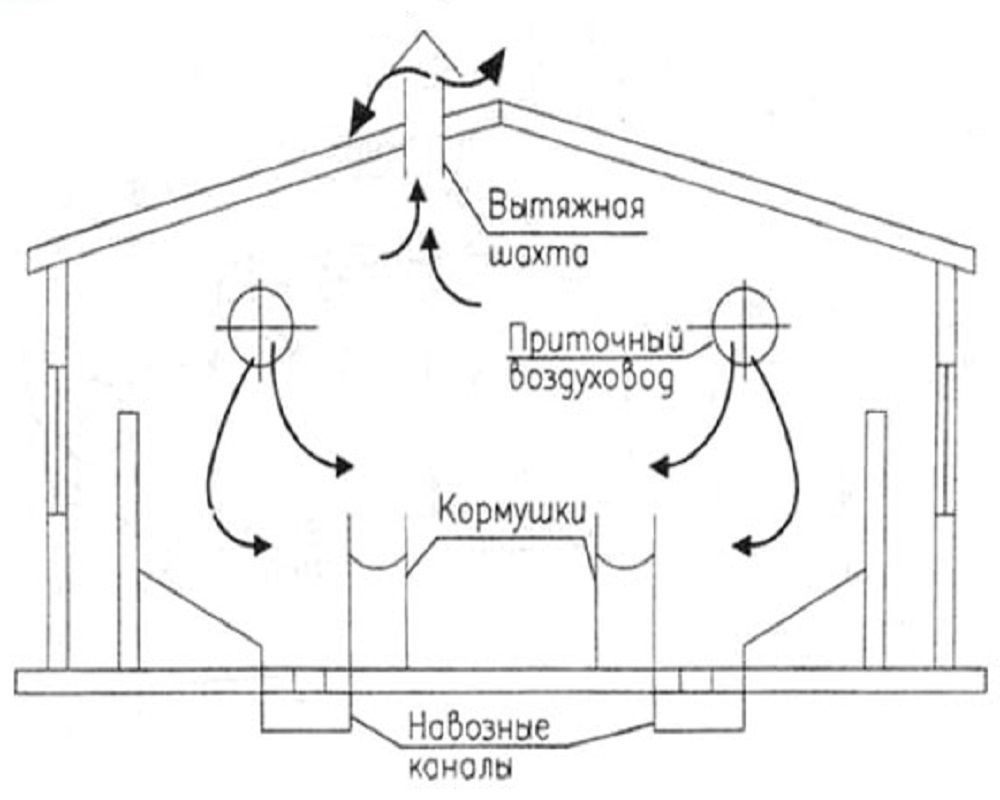

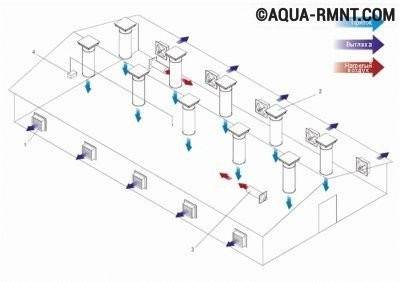

Classical (traditional) ventilation scheme

The classic ventilation scheme involves:

- axial fan VO-7.1 or 8.0;

- roof fan VKO-7.1P or supply air shaft type KPR;

- ventilation system control station.

The number of fans is taken from the calculation of the norm in the summer - 6 cubic meters per hour per 1 kg of live poultry.

classical large chicken coop ventilation scheme consists of two types of axial fans and a system control station

The working basis of such a scheme is axial window fans installed in wall openings on both sides of the building, as well as fans for the roof (or shaft) with insulation. They have a built-in cone-shaped airflow divider. The scheme works according to the type "air intake through the roof - output through the windows", allowing you to significantly reduce the cost of the heating system.

Such ventilation is used when keeping chickens on roosts and in cages. Axial fans up to 18000 m3/h are good for air supply. BUT fans suitable for exhaust productivity 8000-20000 m3/h.The fans are equipped with electric motors and gravity closing shutters.

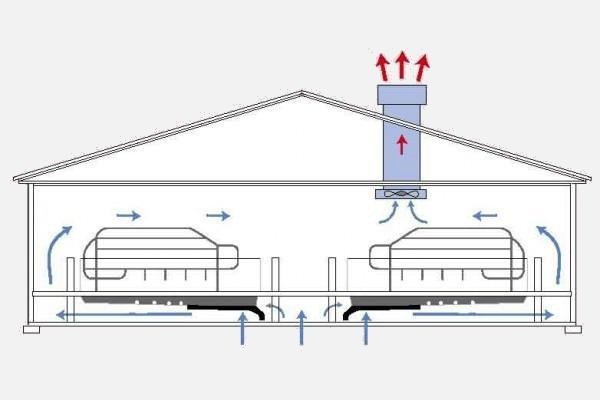

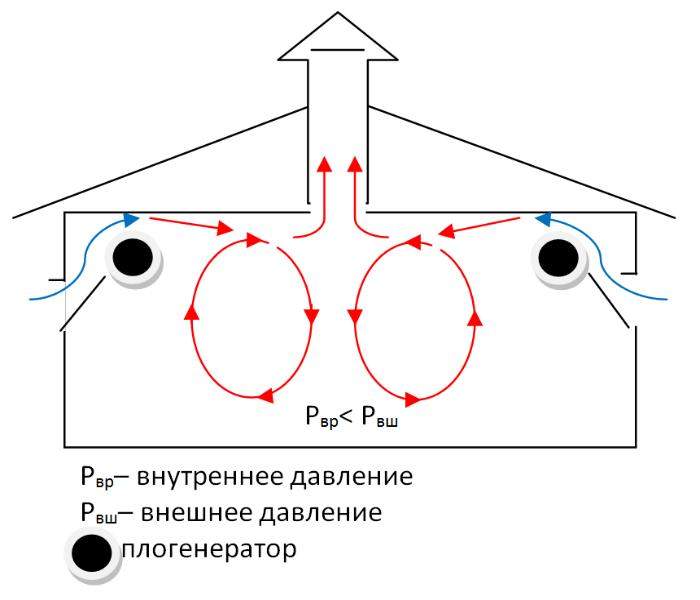

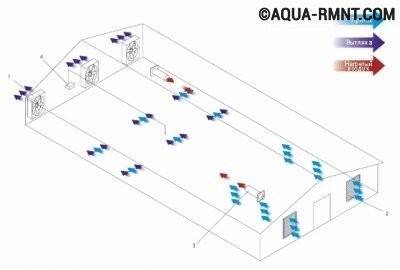

Tunnel ventilation scheme

The tunnel ventilation scheme involves:

- axial fan VO-12.0;

- supply valve type KPR-12.0;

- automated control station of the ventilation system.

The number of fans is calculated from the norm in the summer - 6 cubic meters per hour per 1 kg of live poultry.

The tunnel ventilation scheme of a large chicken coop consists of an axial fan, a supply valve and an automated control station

This installation even in the hottest summer creates a comfortable temperature microclimate in the room. In a chicken coop where birds are kept in cages, the tunnel scheme allows you to prevent the appearance of "stagnant zones", driving air flows through the entire area of \u200b\u200bthe room.

Exhaust fans are installed between the cells in the required quantity. Air enters through supply openings (windows), which are mounted at the other end of the building. They use high power supply fans with a capacity of 20,000 to 60,000 cubic meters per hour. Valves are used to vent air. The advantage of this system is a fairly low total degree of electricity consumption.

Mixed ventilation scheme

The mixed scheme includes both previous ventilation schemes: classic and tunnel. It uses:

- axial fan VO-7.1 and VO-12.0;

- supply valve type KPR-12.0;

- supply fan for the roof or shaft with a valve;

- control station for the operation of the ventilation system.

The number of fans is calculated in exactly the same way as in the previous schemes (6 cubic meters per hour per 1 kg of live poultry).

The mixed ventilation scheme is more cumbersome, because it combines the classical and tunnel ventilation schemes, but it also blows a large chicken coop much more powerfully

A mixed ventilation scheme is used in regions with a sharp temperature drop throughout the year. Such an installation copes with the ventilation of a chicken coop, fully lined with cell rows up to 5-6 tiers in height.

Air enters from both sides of the room simultaneously, into two streams - vertical and horizontal (with roof and side doors), and dirty air is removed from three sides (through three walls). Therefore, the efficiency of the mixed ventilation scheme is many times higher.

Types of ventilation systems for the chicken coop

There are three types of ventilation systems:

- natural ventilation system;

- supply and exhaust;

- forced (electromechanical).

To understand which one to choose, it is necessary to consider all aspects of the installation and operation of each of them. Ventilation in the poultry house is designed for:

- odor elimination;

- reducing the level of humidity;

- air temperature stabilization.

Properly organized ventilation will allow you to cool the chicken coop and dry it in summer, and in winter it will reduce the level of humidity due to the constant running of cold air over the entire area and temperature control.

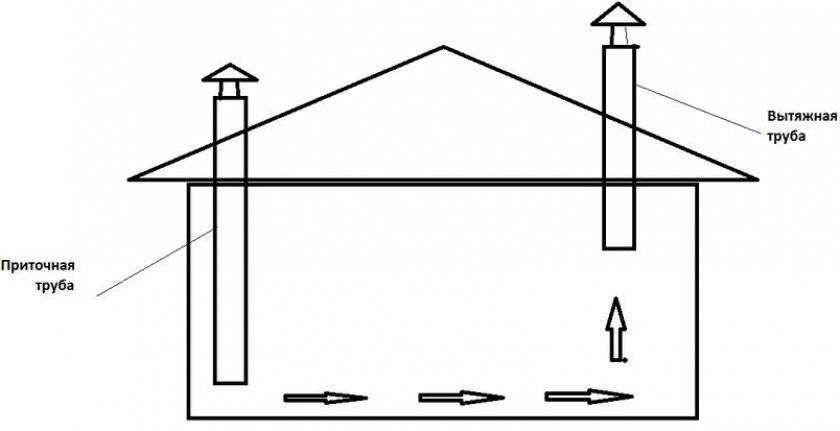

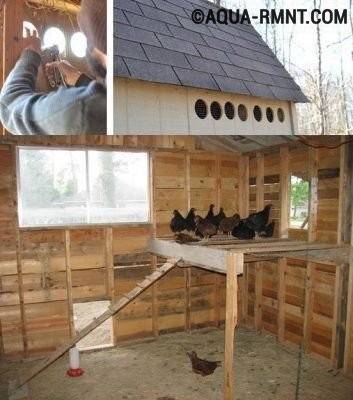

Natural ventilation system

The cheapest and most elementary way to arrange air exchange in a chicken coop is the usual cross-ventilation.

- open all windows and doors;

- install simple ventilation holes in the walls.

Door with a window for ventilation in the chicken coop: for free natural ventilation

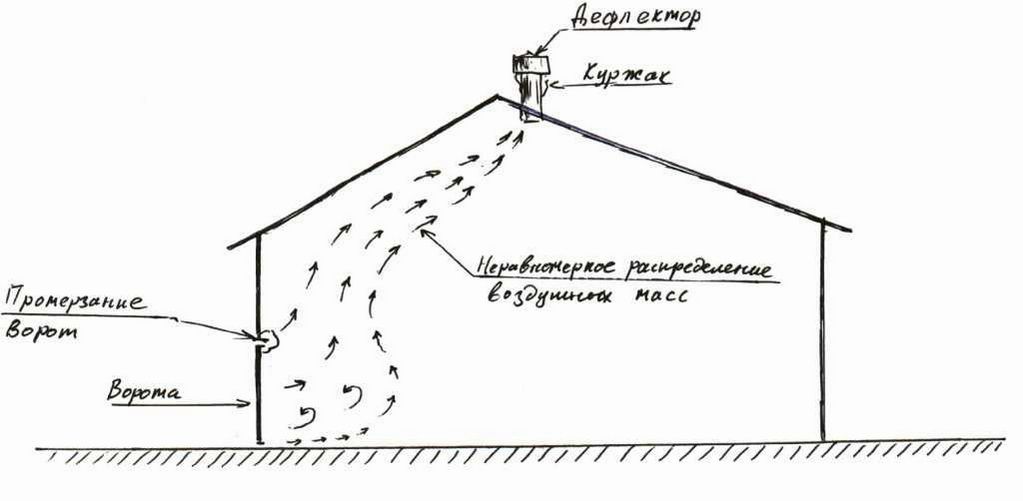

Just try to avoid strong drafts. Small vents above the door are good because they break the air flow into many small swirls, not allowing the overall draft to increase. Air vents at different levels (at the bottom and at the top of the walls) also cope with the task of gentle ventilation.

Natural ventilation, arranged with a competent approach to business, protects birds from drafts

In the cold season, such ventilation is unprofitable, as it requires additional energy to be spent on heating the chicken coop, but for the warm season it is ideal.

A chicken coop with windows saves money on energy costs for maintaining a chicken coop in the summer: windows are used for both ventilation and lighting

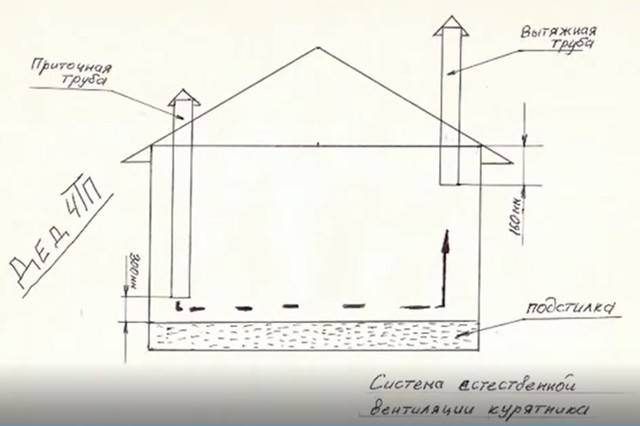

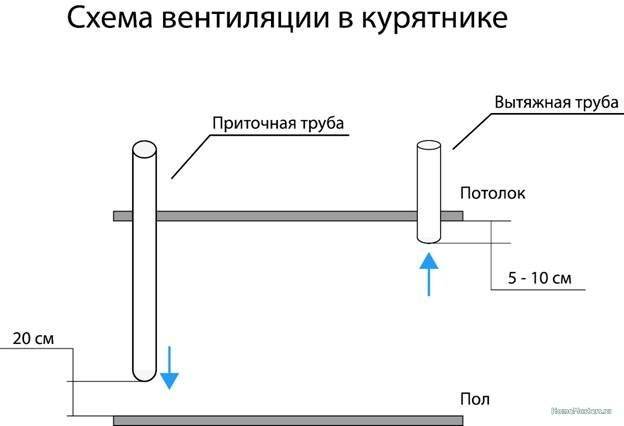

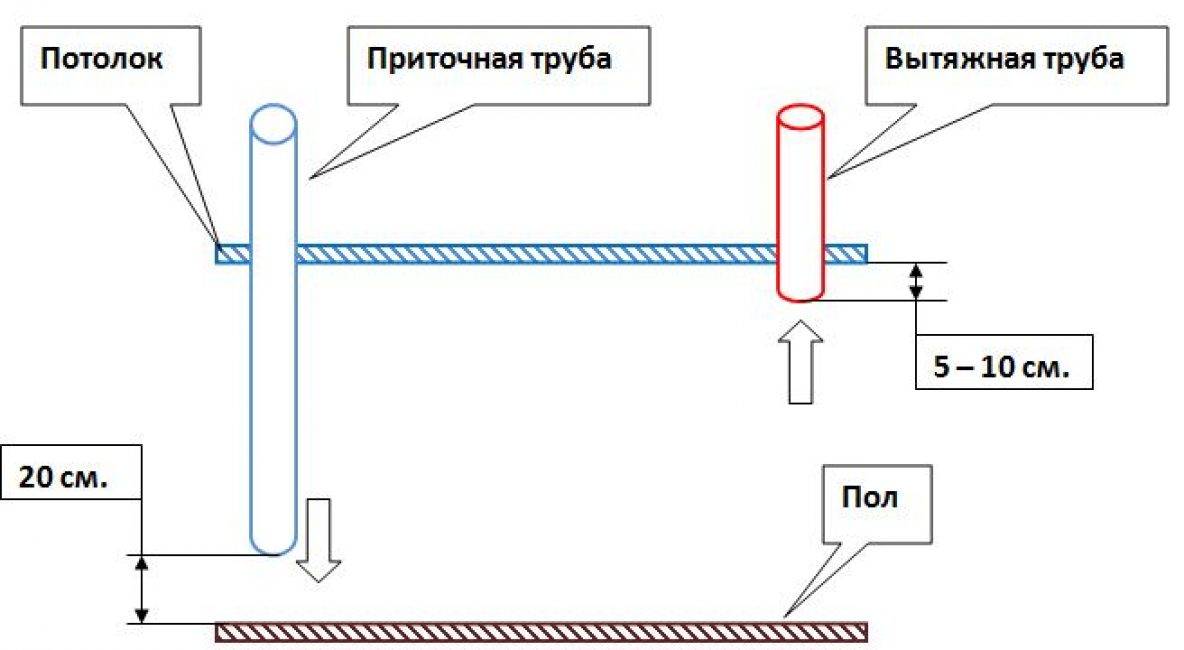

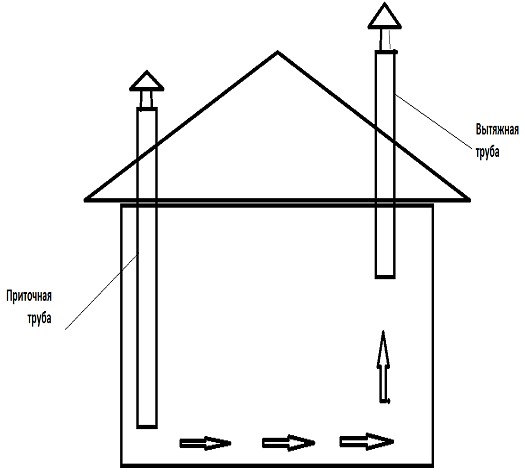

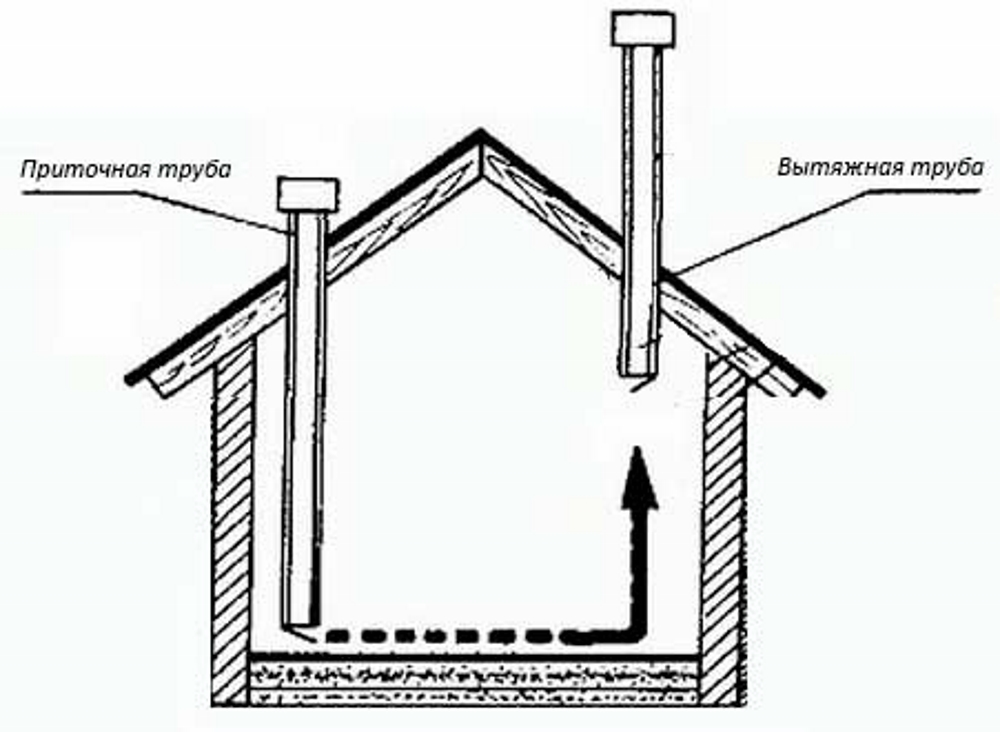

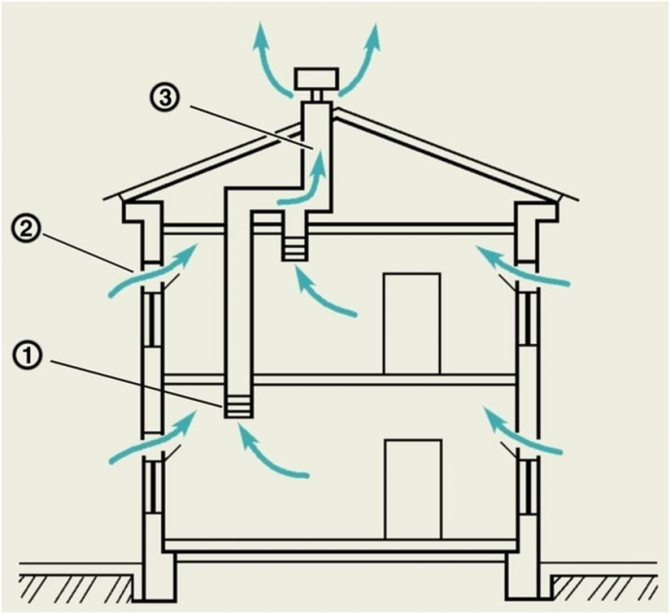

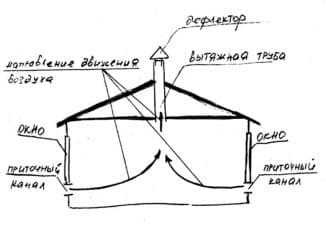

Supply and exhaust ventilation system

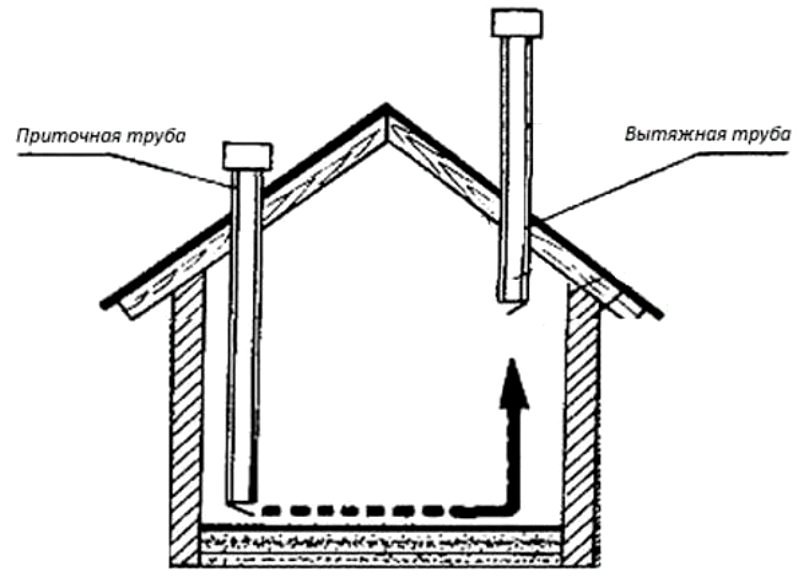

In a poultry house with an area of 9-10 m2 and with 20 chickens, such a ventilation device will be the most profitable and correct way. In large rooms, more complex ventilation systems are installed. Making a supply and exhaust system is quite simple:

-

during the installation of the roof, it is necessary to leave two round holes for pipes. The lower pipe is for air inflow into the room (draught), the upper one is for output (exhaust). The lower one is installed far from the bird perches, and the upper one is almost above them;

- we need two plastic or galvanized pipes with a diameter of 20 cm and a length of about 2 meters. Some poultry owners put wooden structures instead of pipes;

- the air intake pipe is installed 40 cm above the roof, its lower end remains hanging 30 cm above the floor;

- the upper part of the exhaust pipe rises one and a half meters above the roof, and only 20 cm is visible inside the room;

-

from above, the pipes are hidden under an umbrella from rain and snow;

-

pipes are installed in opposite parts of the room so that it is ventilated along the entire length.

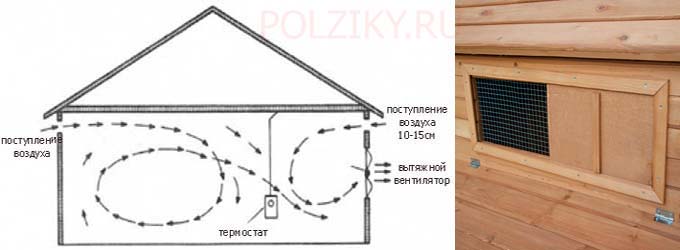

Forced (electromechanical) ventilation system

Forced ventilation is used in large rooms where the number of chickens is more than 500 pieces. But in domestic chicken coops, you can use such a system. The main thing is to choose a fan for your needs. When choosing a fan, study its technical characteristics. In winter, experts recommend arranging air circulation at the rate of 4–6 cubic meters per 1 kg of bird live weight. At the same time, the temperature in the room should be maintained within + 18-20 ° C, and the humidity should not exceed 60-70 percent.

The electric fan in the chicken coop itself monitors the process of air purification, freeing you from unnecessary worries, and shows the results of its work on the scoreboard

Fans crash into the window. A small inexpensive fan is manually started, which is convenient for taking emergency measures to ventilate the chicken coop.

Some exhaust fans make a lot of noise and keep the chickens entertained.

There are also expensive fans - modern models with remote control. Also in specialized stores are offered sensors built into the ceiling or walls, which automatically monitor the level of humidity and turn on ventilation when the norm is exceeded.

Powerful forced ventilation keeps your birds healthy

It will not be difficult for a person who is familiar with electricity to independently assemble and establish the operation of such ventilation.

The forced ventilation hole on the facade of the chicken coop is covered with a grate: it protects the mechanism from accidental small objects and makes the appearance

The disadvantage of such a system is a serious consumption of electricity, but even it can be learned to regulate.

Ventilation installation scheme

Among poultry breeders, there are three popular ways to ensure proper air circulation inside the chicken coop. We will review them all. Perhaps this information will be useful to you when arranging a room for domestic chickens.

Option number 1. natural ventilation

This is the easiest, most practical and cheapest way to provide chickens with comfortable conditions. You do not need to do anything with your own hands.

The essence of natural ventilation is the simple ventilation of the room. This is best done by opening doors and windows. Despite the simplicity of the method, it has some nuances.

For example, in order to avoid drafts, it is recommended to make the exhaust window small. It should be located directly above the front door or in the ceiling of the house. It is best to make such a window like a window so that you can control the draft.

Natural ventilation in the coop It works like this: fresh air enters through the door, and exhaust air exits through the window.

There are many drawbacks to such a simple scheme. For example, along with the air, heat will also come out. Accordingly, a lot of resources will be spent on heating the poultry house. In general, a very unprofitable ventilation system, but for the first time it can come in handy.

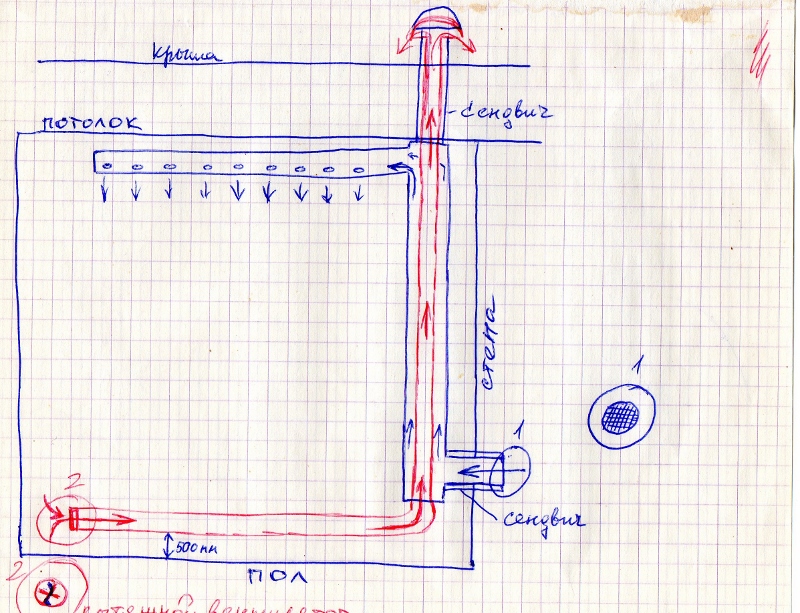

Option number 2. Exhaust system

A more convenient and reliable way to circulate indoor air. If your household contains more than 20 chickens, then this ventilation method will be optimal. Such a system is very easy to install with your own hands. It looks like this:

- When installing the roof, it is necessary to provide two holes for pipes. In this case, the pipe for the influx of fresh air should be located away from nests and perches.

- The diameter of the ventilation pipes should be about 200 millimeters. Length - 2 meters. Instead of pipes, you can make wooden boxes, but they will need to be puttied and painted.

- The pipe through which fresh air will flow is installed in such a way that it rises above the roof by about 30-40 centimeters. It should not reach 20-30 centimeters to the floor of the chicken coop.

- The exhaust pipe should be located in close proximity to perches. Its lower part should be about 20 centimeters from the ceiling, the upper one should protrude one and a half meters above the roof.

- To protect against precipitation, the upper ends of the pipes must be equipped with small sharp umbrellas.

Option number 3. mechanical ventilation

This method is widely used in large farms, but it can also be used in private households. Air circulation is carried out by a conventional fan.

For greater system efficiency, the fan can be mounted in the window. With minimal knowledge and skills, it is easy to do it yourself.

Such ventilation is turned on manually, but you can install sensors in the chicken coop that will monitor the humidity in the room. If you are familiar with electrics, this will not be difficult to do. Of the minuses of such ventilation in the chicken coop, one can note the additional consumption of electricity.

We hope that this article was as informative as possible, and the question of how to make ventilation with your own hands will no longer bother you.It is possible that you use one of the above options in your household.

A simple way to organize supply and exhaust ventilation

Prices for ventilation units

Ventilation units

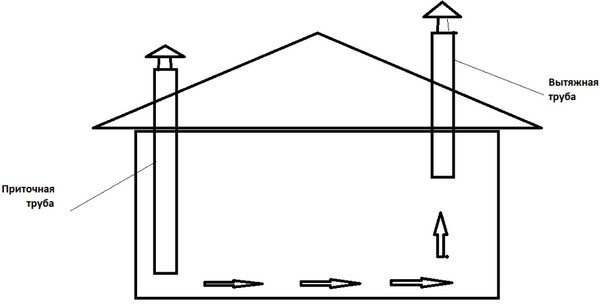

This system is suitable for poultry houses, the area of \u200b\u200bwhich does not exceed 9 square meters. For its construction, you will need two pieces of a metal or plastic pipe with a diameter of not more than 100 mm (the required length should be calculated independently, taking into account the height of the roof).

The first pipe (exhaust) is placed above the perch, flush with the ceiling or lowered 10-15 cm below its level. A hole of the desired size is cut in the ceiling. The resulting extra spaces are sealed with improvised means - for example, polyurethane foam. A piece of pipe is brought to the roof, above which it should rise one meter.

Easy-to-use supply and exhaust ventilation option

In the opposite side of the room, a second section of the pipe (supply) is cut. It is installed away from the perch. This will help avoid drafts. The inlet of the second pipe is placed at least half a meter lower than the first. In this case, it is necessary to observe the distance to the floor covering - 25 cm. This pipe is also brought out to the roof, leaving about 30 cm outside.

Dampers (valves) are installed on top of the pipes. The element is necessary to block the pipes in severe frosts, but in the summer they are completely opened. In the absence of dampers at very low temperatures, the pipes are closed with rags. Ready-made valves are on sale. But they are produced for pipes with a diameter of more than 25 cm.Adjustment can be carried out manually, using an electric or pneumatic drive. Valves come in round and square sections.

Finished store shutter

When there is no money to purchase a ready-made valve, it is cut out independently from a plywood sheet or cardboard, focusing on the diameter of the pipe.

The outer ends of both segments are formed with a knee in the shape of the letter G or protected with umbrellas so that snow, rain and dust do not get inside the room.

Diameter and shape of pipes

When installing a ventilation system, it is important to correctly calculate the diameter of the pipes. Too wide air ducts provoke the appearance of drafts

With an insufficient diameter of the pipes, ventilation will not cope with its functions in full, which will affect the condition of the bird flock.

For a small chicken coop (less than 12 m²), a pipe with a diameter of 100 mm is considered optimal. For large rooms order or develop their own special project. It is believed that preference should be given to air ducts made of round pipes, since air masses circulate in them most efficiently.

Round pipes are considered the most efficient

Prices for deflectors

Deflector

Instead of umbrellas, deflectors are often installed on top of the pipes. This is a device that accelerates air flow and enhances traction. You can make this element yourself. For a chicken coop, it is recommended to use the Volpert-Grigorovich model.

Step-by-step instructions for making a deflector:

Step 1. Make calculations for pattern parts. All formulas are tied to the diameter of the ventilation pipe, and are shown in the figure

Step 2. Cut out the parts, leaving allowances for fasteners of 10 mm

Step 3Give the details the necessary shape, fasten at the seams

Step 4. Assemble the device, cut out and attach the legs

Step 5. Install the device on the pipe

Parts must be connected with reliable fasteners, especially in areas with strong winds.

Possible problems and their elimination

When properly done ventilation from sewers pipes, air moves from the room to the outside. But for a number of reasons, situations arise that disrupt the operation of the hood. Consider frequently occurring cases and methods for troubleshooting.

- Air enters through the exhaust air outlet, the effect of overturning the thrust is triggered. The method of combating this phenomenon without losing heat is to install a non-return ventilation valve. Existing varieties - mechanical, triggered by air movement, manual, opening with a lever. Pluses - they block the reverse movement of air. Cons - they slam when closed, periodic cleaning is necessary.

check valve

- No draft in the hood. The solution is to install a deflector on a section of pipe that rises above the roof. The principle of operation of the device is to cut the air jet, as a result of which the pressure in the pipe decreases and the thrust increases.

- The appearance of condensate in winter is solved by additional insulation of pipes.

- An increase in humidity and ammonia vapors in winter can be solved by installing an electric fan in the chimney.

- A couple of times a year, the air ducts must be cleaned against accumulated dust, dirt and cobwebs.

I wish that your chickens are always healthy and productive!

Anyone who first encountered ventilation work cannot avoid mistakes. But the solution to problems can be found during operation and eliminated in a timely manner.The main thing is to follow the rules of competent installation in order to provide the bird with comfortable conditions.

How to make a hood in a chicken coop

Chickens are very sensitive to the microclimate of the room in which they are kept.

Therefore, it is important to ensure not only a stable temperature, but also a constant supply of oxygen.

The temperature regime should be paid attention to for several reasons:

- If it is lowered, the birds use the food they eat not for the formation of eggs, but for increasing body weight, and egg production decreases;

- At an elevated level, the weight of chickens decreases, their egg productivity decreases and the quality of the shell deteriorates.

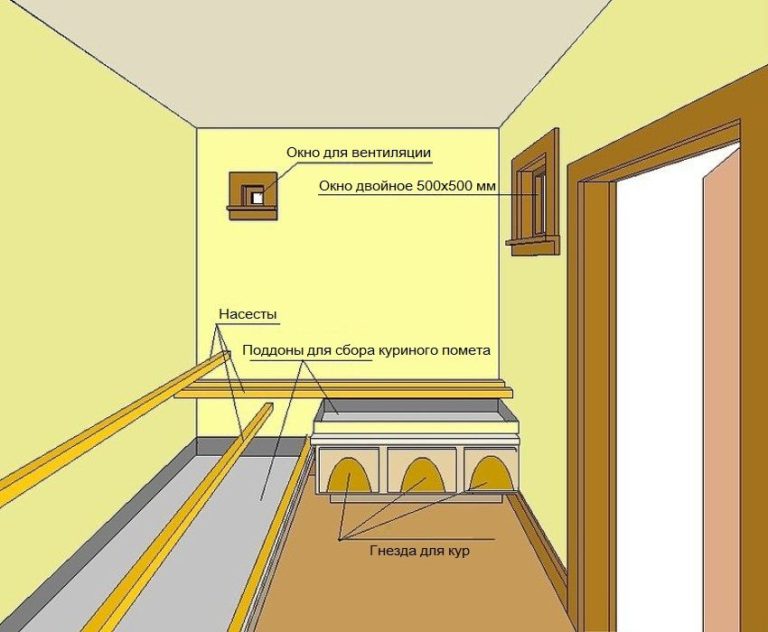

Providing an optimal microclimate plays an important role. To do this, it is necessary to conveniently place perches and nests. Examples of poultry house interior equipment are shown in Figure 1.

The behavior of birds will help determine the optimal temperature regime:

- If it is normal, the hens are mobile, evenly placed in the house, eat and drink well;

- With a reduced indicator, chickens begin to crowd and spread their feathers, as a result of which weak individuals may die;

- If the room is hot, the birds refuse to feed, drink a lot, open their beaks, fluff their feathers and mostly lie down.

The easiest way to ensure the flow of fresh air is through conventional vents. However, it should be borne in mind that in winter, cold can penetrate through them, so the windows must be additionally insulated.

Construction rules

If you want to ensure a constant supply of oxygen to your house during the winter, you need to know what requirements the system must meet.

Figure 1. Ensuring the optimal microclimate of the poultry house: equipping perches, nests and feeders

In general, the ventilation of the room is carried out according to the following rules:

- Sufficient supply of fresh air: the more birds are kept in the house, the more powerful the system should be.

- Maintaining heat indoors also plays an important role, especially during the cold season. Therefore, it is recommended to install grilles on exhaust pipes that will let oxygen through, but prevent heat loss.

The finished system must be positioned so that birds cannot contaminate the pipes with food residues or droppings, and the pipes themselves must be freely accessible to humans for periodic cleaning and disinfection.

Peculiarities

A more practical option for ventilation is the installation of supply and exhaust pipes. Any material is suitable for their manufacture, but it is better to use wood. In addition, it is necessary to install several plugs on each pipe, with the help of which it will be possible to regulate the flow of oxygen in the future (Figure 2).

Figure 2. Arrangement options for natural and supply and exhaust ventilation

The supply and exhaust system also provides optimal room humidity (at the level of 60-70 percent)

However, it is important that this system does not create drafts that adversely affect the health of the hens. Recommendations for the manufacture of supply and exhaust hoods are given in the video

How to make a hood without electricity

The supply and exhaust principle of the installation is taken as the basis here, it can be used all year round, and the wintering of the bird will pass without complications. To equip the structure, plastic pipes in the amount of 2 pieces will be required: a fresh stream will flow through one, and the exhaust air will leave through the second.Clean air in the chicken coop is important, otherwise there may be a problem with feathering, but here is how the fight against feathering occurs in chickens.

Instruction:

- The exhaust pipe is located near the ceiling at a distance of about 20 cm.

- The flow structure should be located near the floor about 2-20 cm from it.

Pipes are installed in opposite corners of the room - so the ventilation will be more efficient.

Street exits should be protected from moisture and debris: install a protective device, and then the chickens will only receive clean flow of fresh air, and already exhausted gases go out into the street.

You may also be interested in information about what should be the composition of feed for laying hens.

On the video - natural ventilation in the chicken coop:

But how to properly breed Welsumer chickens and how to properly create conditions for breeding is indicated here.

There are several positive factors of such ventilation:

- Low cost of installation and operation.

- It can work equally well at any time of the year.

- The presence of a person is not needed to control the ventilation process.

But if there are more than 50 different birds on the farm at the same time, then such ventilation cannot cope with the task, and it is necessary to design a mechanical type of forced ventilation system.

It will also be useful for you to learn about what to do if the chickens fall on their feet and how to properly keep them in a dry place.

- Better air exchange throughout the room.

- Will be able to refresh more space than in a simple way.

- Can be used throughout the year.

But the arrangement of this type of ventilation will cost much more than the usual type with exhaust pipes, you will have to pay extra for electricity consumption.

You may also be interested in information on how trout are bred at home.

But! It is not advisable to use cheap asbestos-cement pipes where the bird is located: chickens will definitely taste them, that is, peck at material that is dangerous to their health. It will be deposited in the lungs and this can lead to dangerous diseases. It is best to use special pipes made of food-grade plastic, which are used to equip the water supply at home, they can be found in abundance in the construction markets of different diameters and sizes.

How to calculate ventilation in a chicken coop

In order to choose the optimal ventilation option, the following factors should be analyzed:

• the volume of the premises and the number of individuals per unit area;

• method of keeping (in cages or free);

• cleaning frequency.

The larger the volume of the house and the higher the number of birds per square meter, the more intensive air exchange must be provided. If up to 20 individuals live in a chicken coop, an ordinary hood is enough. If the number of livestock is 20-50 individuals, it is necessary to make supply and exhaust ventilation. If the number of individuals exceeds 50 pieces, natural ventilation will not be enough, in this case, forced ventilation in the chicken coop is necessary.

Selection of the recommended scheme depending on the number of chickens

Selection of the recommended scheme depending on the number of chickens

With a free content, the birds spend most of the day on the street and enter the chicken coop only at night.When kept in cages, it is necessary to provide more intensive air exchange.

For poultry houses with an area up to 12 m², it is recommended to use pipes with a diameter of about 22 cm and a length of up to 2 meters.

Calculation of the required performance of the exhaust (supply) fan: 4 m³ / hour * number of chickens.

With frequent cleaning, litter does not accumulate in the building, respectively, there are less gaseous products of its decay. If it is often not possible to clean, it is necessary to increase the air flow.

Why is there ventilation in a chicken coop?

There are several reasons why good air exchange is necessary in a chicken room:

- As a result of air exchange, oxygen enters the room, which is vital for the functioning of every organism.

- In the air of the poultry house there are gaseous waste products of birds, which should be disposed of in time. First of all, it is carbon dioxide emitted by all living organisms in the process of respiration. Secondly, ammonia and hydrogen sulfide are substances formed during the decomposition of chicken manure. With an increase in the concentration of these gases in the air, the poultry loses its appetite, its health deteriorates and, accordingly, growth and egg production decrease. In addition, it is these substances that are responsible for the presence of a characteristic smell in the room.

- With intensive air exchange inside the building, the level of humidity decreases. For the normal development of chickens, humidity should be in the range of 60-80 degrees. If these indicators are exceeded, pathogenic microflora begins to develop intensively, infectious diseases develop in poultry, which can provoke a mass death. In addition, in winter, increased dampness can lead to hypothermia and colds.

- In the hot season, the entry of fresh air into the room helps to reduce the temperature in the chicken coop.

For example, at high humidity, the solubility of ammonia in the air of the chicken coop increases and its toxic effect increases. As a result, protein metabolism is disturbed in birds, hemoglobin decreases, anemia occurs, which leads to the death of the farmstead.

This is interesting: Do-it-yourself supply ventilation in a private house

10 useful tips

If a chicken breeder does not have a specialized education and is installing a ventilation structure for the first time, he can make a number of irreparable mistakes. In this case, there are two options - entrust the installation to a professional (but this will create additional costs) or carefully study the information and use the recommendations of experienced professionals

What to look for:

- When using pipes, choose a round section, as it creates better air exchange.

- If you install plastic or metal structures for the winter period, be sure to insulate them with special materials. The fact is that a large temperature difference contributes to the formation of condensate. For insulation, you can use polystyrene foam, mineral wool and even improvised materials (straw, woolen rags, old coats and fur coats). Wrap the pipes and fix the material.

- For the density of fastening of pipe structures, they are located in close proximity to the rafters. For secure fixation, it is better to use staples.

- If you do not have the opportunity to buy plastic / metal pipes, but wooden boards are available, feel free to use them. To do this, make long structures by connecting the boards together with special devices.To close the cracks, use construction foam. Remember that the square section of the channel does not give the same efficiency as the round one.

- If the roof of the chicken coop is 2-pitched, then the draw structure should be installed on the visor.

- If the roof is flat, but has a slight slope, then the upper part of the supply pipe drops to a distance of up to 30 cm in relation to standard norms (about one and a half meters).

- Both pipes should be on opposite sides of each other. This is the only way to create a normal level of air exchange.

- To avoid condensation in the elbow, which is located on the street side, it is recommended to make a small hole (4-5 mm).

- The exhaust system must be cleaned twice a year, as debris, cobwebs, dirt, dust, dry leaves, etc. accumulate in it. If there is no damper or visor in the design, it is advisable to do this 3-4 times a year.

There are several factors to consider when installing electrical equipment. Noise volume should not exceed 60-70 decibels.

Stopping the choice on one or another ventilation system is a personal matter for every poultry farmer. But without ventilation it is impossible to do. Not everyone understands this immediately and install structures after the appearance of negative consequences. Do not save on equipment, take care of your birds in a timely manner.