- Possible problems and solutions

- Requirements for air ventilation systems

- Why ventilation and is it necessary

- Types of ventilation of the "Canadian" house

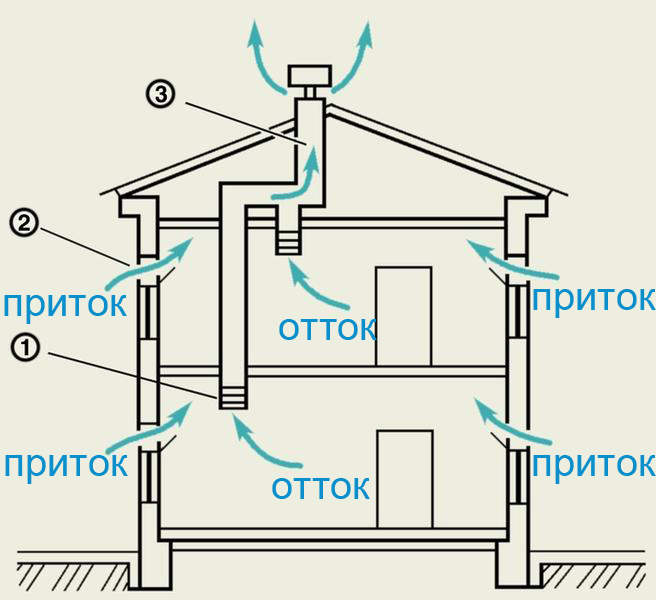

- natural ventilation

- Features of static ventilation

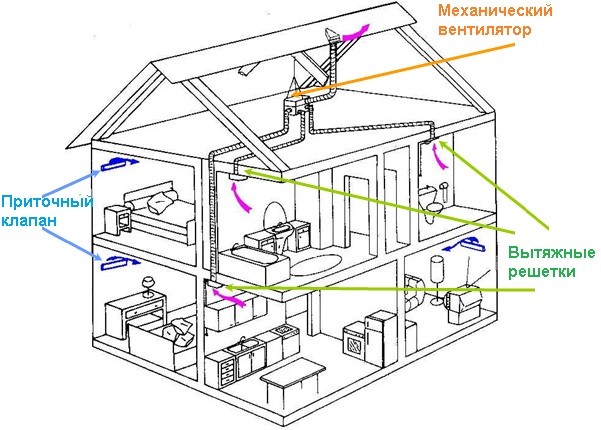

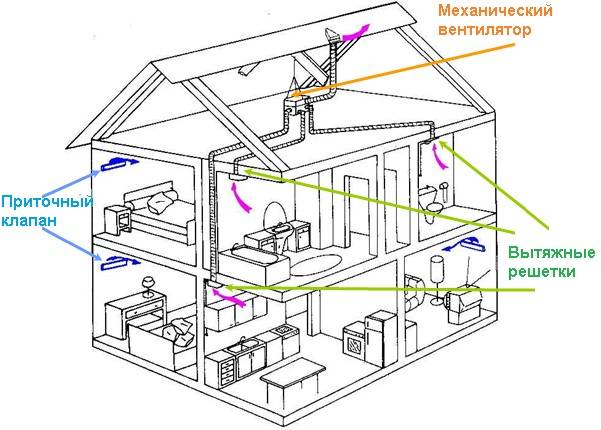

- Forced ventilation (mechanical)

- Designing a ventilation system

- Stage 1. Flow

- Stage 2. Inflow

- Stage 3. Extraction

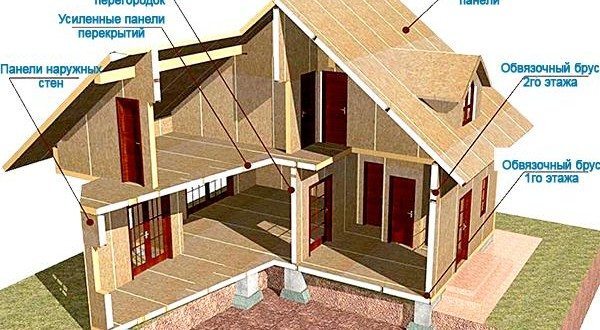

- Meet SIP panels (sandwich panels)

- Do-it-yourself artificial ventilation in a house made of SIP panels

- Possible problems and solutions

- Advantages of houses from sandwich panels:

- Varieties of ventilation in houses from SIP panels

- Ventilation design

- Video description

- Conclusion

- Laying a strapping (crown) beam

- Ventilation methods

Possible problems and solutions

You can understand that the ventilation system for air purification is possible if the following points are observed:

- in the living rooms there is stale, “heavy” air, coming in from the street, and you just want to quickly open the window;

- fungus and mold appear in the kitchen and bathroom;

- water vapor appears on the windows.

In the first case, everything is clear: ventilation is not working at full capacity. That is, either initially the power of the fan and the entire system was calculated incorrectly, or the ventilation ducts were simply clogged.

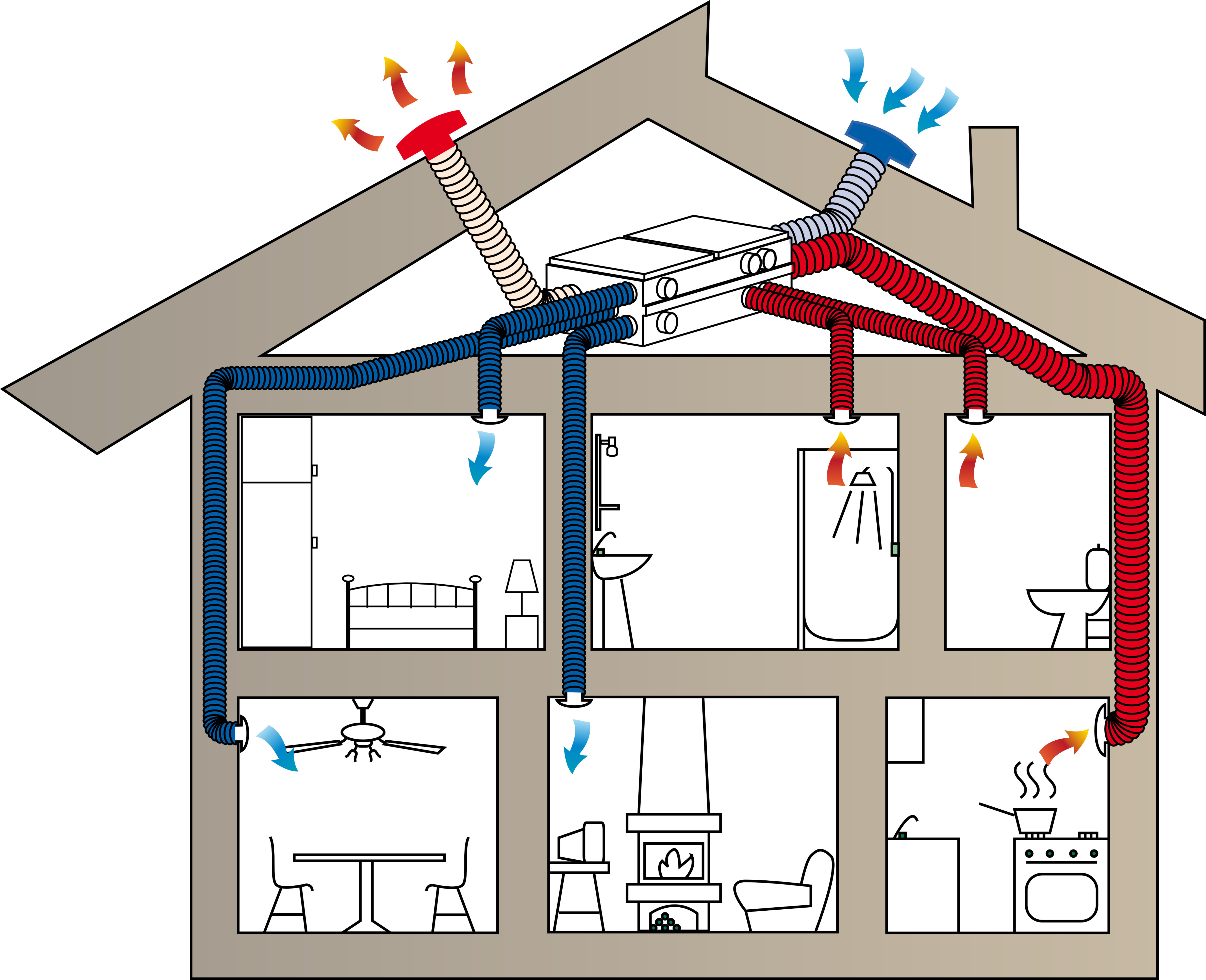

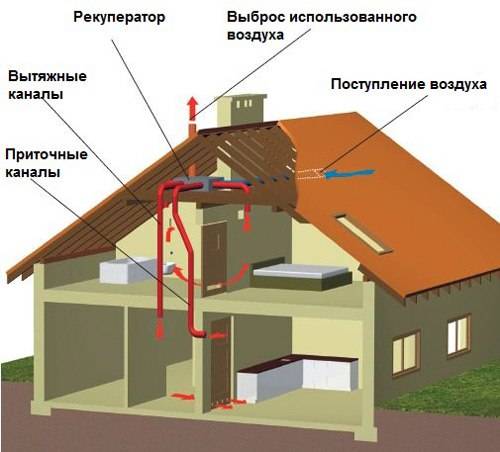

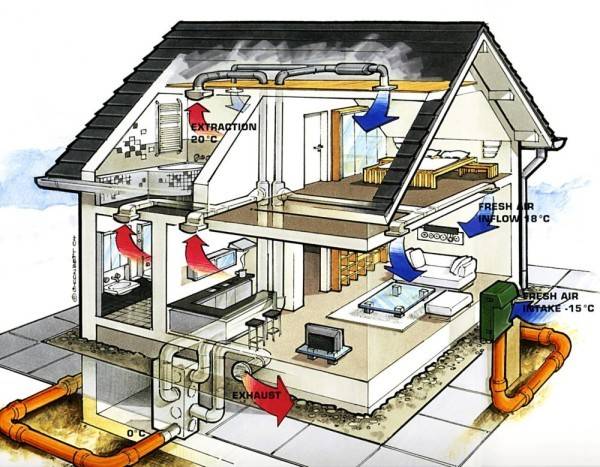

The correct arrangement of the supply and exhaust ventilation system

The correct arrangement of the supply and exhaust ventilation system

If the reason is incorrect calculations, then, alas, the entire system will have to be reinstalled, which will entail serious costs, and it will take a lot of time for such work.

As for the ventilation ducts, it is difficult to clean them with your own hands (especially in the internal ceilings of the building). Here you need special blow-off pumps.

However, the cost of such services is not so great. If fungus and mold appear, then natural ventilation does not cope with its task of cleaning the air. More precisely, here we are talking not so much about air purification, but about the fact that ventilation cannot cope with too much humidity.

Or there may be such an option: during the construction of the house, high-quality vapor barrier was not properly equipped (or the vapor barrier was generally “forgotten” for the sake of economy). If water vapor appears on the windows (the windows “cry”), then the reason is the high humidity of the rooms inside the house and poor air exchange.

Requirements for air ventilation systems

Checking the correct operation of ventilation is extremely simple. It works well if the following conditions are met:

Air from all ventilation ducts is released into the atmosphere on the roof (the end of the duct must always be above the level of the top point of the roofing - this is very important);

In a mechanical system, air is taken from the street only using special metal intake grilles, which are located about 2-3 meters from the ground;

Through the channels, the air must first pass through the children's room, living room, bedrooms, and only then go to the kitchen, bathroom, boiler room (there the air will have the most pollution, and if it goes in the reverse order, it will not be very comfortable to breathe in the rooms, and various viral diseases can appear, especially respiratory ones);

It is precisely a mechanical ventilation system that is needed for the kitchen, especially if it has not only a gas stove, but also a water heater (if a gas boiler is also installed there, then even more so, although not many people know that a standard flow geyser - the essence is the same boiler). The hood in this case is a must. In general, it is possible to build a high-quality and efficient ventilation system in the house

The main thing is the presence of a clear and well-designed engineering plan that would take into account everything, everything: from the materials from which the house is made to the regularity or irregularity of people living in the building

In general, it is possible to build a high-quality and efficient ventilation system in the house. The main thing is the presence of a clear and well-designed engineering plan that would take into account everything, everything: from the materials from which the house is made to the regularity or irregularity of people living in the building.

Ventilation in the kitchen can be built independently

The plan is drawn up only and exclusively in responsible design and engineering offices - and nowhere else! It is categorically impossible to save on the latter, because in the end we can even talk about human lives. Cases of death due to improperly functioning ventilation are common.

Why ventilation and is it necessary

The main threat to fresh air is carbon dioxide (CO2). With a slight increase in CO2 levels, a person feels stuffiness, fatigue, drowsiness, inability to concentrate, loss of attention, irritability, decreased performance. If the level of CO2 continues to rise, then breathing problems, suffocation, rapid pulse, dizziness, and someone even faints.

The concentration of co2 in the air and its impact on human well-being

The most harmful is a long-term stay in rooms with a high content of CO2, which is why it is so important to pay attention to the ventilation of the premises. A correct and energy-efficient method of air exchange control is regulation by a CO2 sensor. Whether ventilation is needed in a frame house primarily depends on the material of the frame. Standard frame-type houses are made of non-breathable materials, so the design of the system is drawn up along with the layout of the house.

And then, together with home improvement, it is carried out according to drawings and diagrams specially selected for the type of building

Standard frame-type houses are made of non-breathable materials, so the design of the system is drawn up along with the layout of the house. And then, together with home improvement, it is carried out according to drawings and diagrams specially selected for the type of building

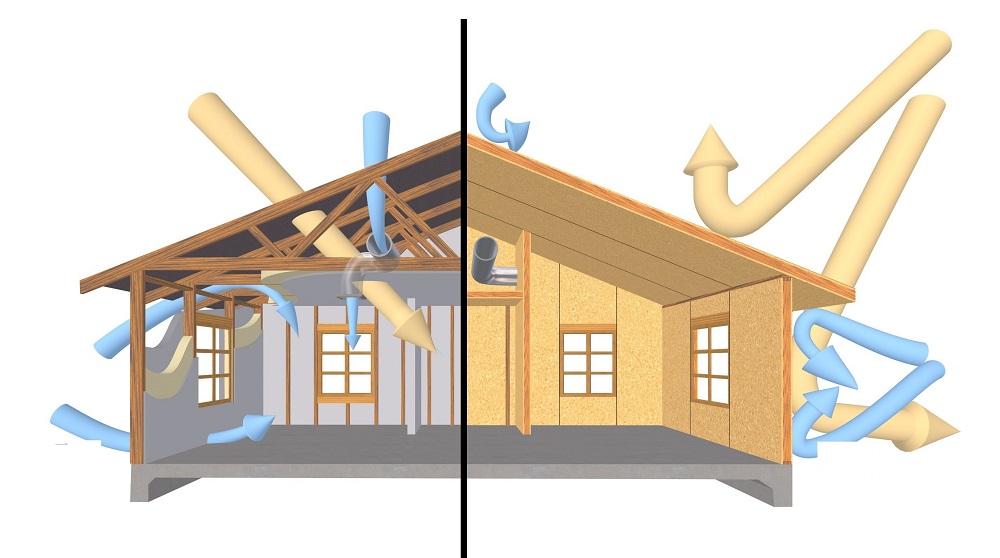

Whether ventilation is needed in a frame house primarily depends on the material of the frame. Standard frame-type houses are made of non-breathable materials, so the design of the system is drawn up along with the layout of the house. And then, together with home improvement, it is carried out according to drawings and diagrams specially selected for the type of building.

The standard frame house has an energy-saving and hermetic structure, which is complemented by plastic windows and doors. This causes the air to constantly heat up inside the room, since there is no full-fledged exchange with the air environment surrounding the house.

The most demanding rooms in the building in terms of the need for air exchange are bathrooms, toilets and kitchens. The hood in the frame house is installed in such places.

The exhaust pipe is laid under the ceiling in the process of building a house

For each type of building for use, a different type of device for air exchange is established:

- seasonal residence. Usually this is an ordinary cottage. In such cases, the system is installed naturally in all necessary premises;

- year-round country use. In several rooms, including the kitchen, an exhaust duct is installed with forced ventilation, that is, mechanical;

- permanent residence in the house. The most commonly used type of forced ventilation. A heat recuperator and a gradual air supply are used to minimize temperature fluctuations.

In addition to the options presented, there are also mixed schemes that include the features of each type of ventilation with division into rooms that require increased or reduced air exchange.

Types of ventilation of the "Canadian" house

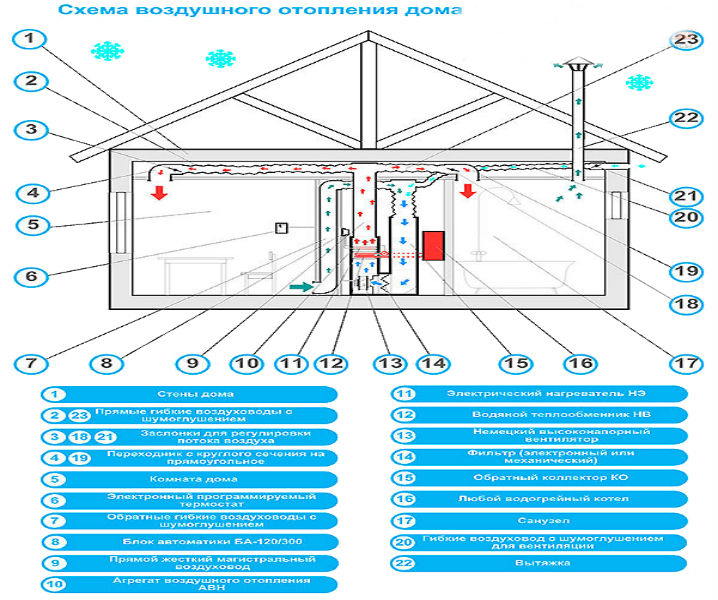

Let us consider in detail all the options for ventilation of a house from SIP panels, along with their features.

natural ventilation

In case of insufficient ventilation in a natural way, it is recommended to install an extract from the bathroom, toilet, kitchen. This will prevent unpleasant odors from traveling around the house.Vapors and unwanted odors will be immediately directed to the exhaust ducts. This type of ventilation is called static.

If you have a separate bathroom, then there are three air ducts in the house, if you have a merged one, then two. How to arrange ventilation outlets on the roof in such cases? You should not make separate holes for each channel, it is better to combine them into a common pipe just before going to the roof.

When the hood is ready, it is important to take care of the flow of fresh air into the living quarters. There are several effective ventilation system designs

Air can constantly enter the house as follows:

- by gravity, we are talking about the mode of micro-ventilation of windows;

- through supply valves (in walls, windows);

- through a separate inlet. There are options with air filtration and heating, as well as air distribution over several rooms.

Features of static ventilation

given that such houses are rarely built above two floors, it is important to take care of the mechanical exhaust of the exhaust air. Otherwise, the draft in the ventilation system will simply not be enough;

take care of the soundproofing of the exhaust fan, as the sound in houses from SIP panels spreads instantly;

do not use plastic pipes for ventilation, as they accumulate static electricity and attract dust

The best option is a galvanized steel construction;

it is impossible to lay vertical air ducts in the walls of SIP panels, so the latter are mounted in the open, and then decorated or covered with panels;

in small rooms, you need to carefully choose a place for mounting ventilation valves.Remember that cold air that enters the room from the outside needs to be mixed with warm air. Therefore, if you mount the valve in the immediate vicinity of the bed, you will feel discomfort in winter.

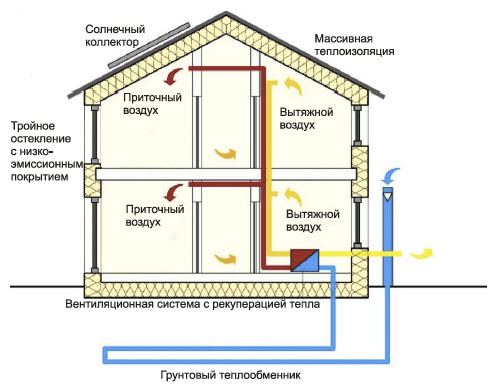

Forced ventilation (mechanical)

- supply;

- supply air with VAV function;

- supply and exhaust;

- supply and exhaust with heat recovery.

Supply ventilation with VAV function or ventilation on demand: the principle of operation of this type of system is similar to the previous one, but the residents of the house can optionally turn it off in some rooms or on the entire floor. Let's say you spend time during the day on the first floor - this means that you do not need intensive air supply on the second floor. This approach to creating a healthy microclimate in the house allows you to save a lot on electricity and gas.

Supply and exhaust ventilation is used in houses with weak draft. Fresh air is both forced in and forced out. Sometimes clean air is heated when it is supplied. This solution involves the laying of air ducts (supply and exhaust ducts). From the point of view of sanitary standards, ventilation should provide from 20 to 60 cubic meters. m. of air per person per hour. The ideal option is a complete change of the entire volume of air in the room within an hour. The air handling unit can be placed in a technical room, for example, in a boiler room, or in a bathroom.

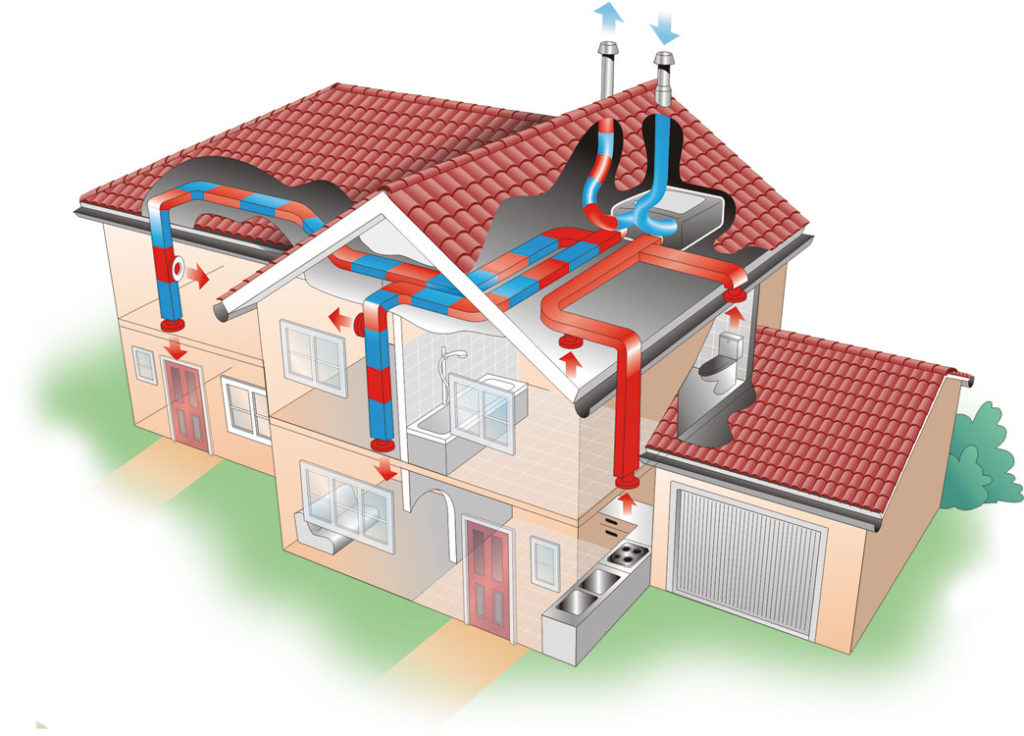

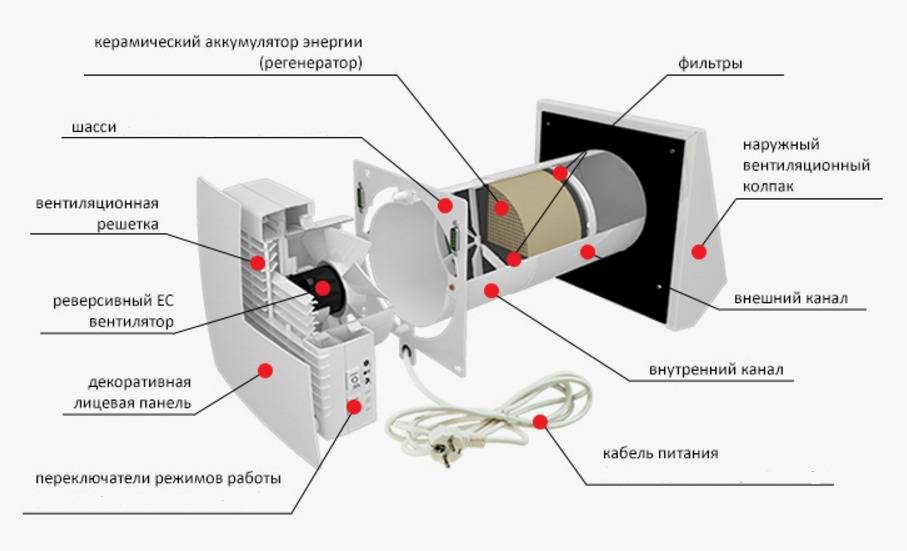

Supply and exhaust ventilation with heat recovery is chosen by the owners of houses made of SIP panels, who want to save a lot on energy. Polluted air is sucked out through the heat exchanger. This device makes it possible to heat the incoming clean air with the help of energy from the exhaust air.This type of ventilation is worth paying attention to if the house does not have enough energy to heat the air coming from outside. Supply and exhaust ventilation with heat recovery works best during the cold season, as well as during the peak of the summer heat. In winter, it reduces heat loss, and in summer it gives coolness.

Summing up, we note that additional ventilation in houses made of SIP panels is not a luxury, but a necessary solution. Otherwise, the residents of the cottage will suffer from poor air circulation and struggle with dampness, mold and unpleasant odors to no avail.

When choosing a type of ventilation system, it is important to analyze the following factors - budget, seasonality of residence, heating system and interior features. Until we meet again on the pages of the site!

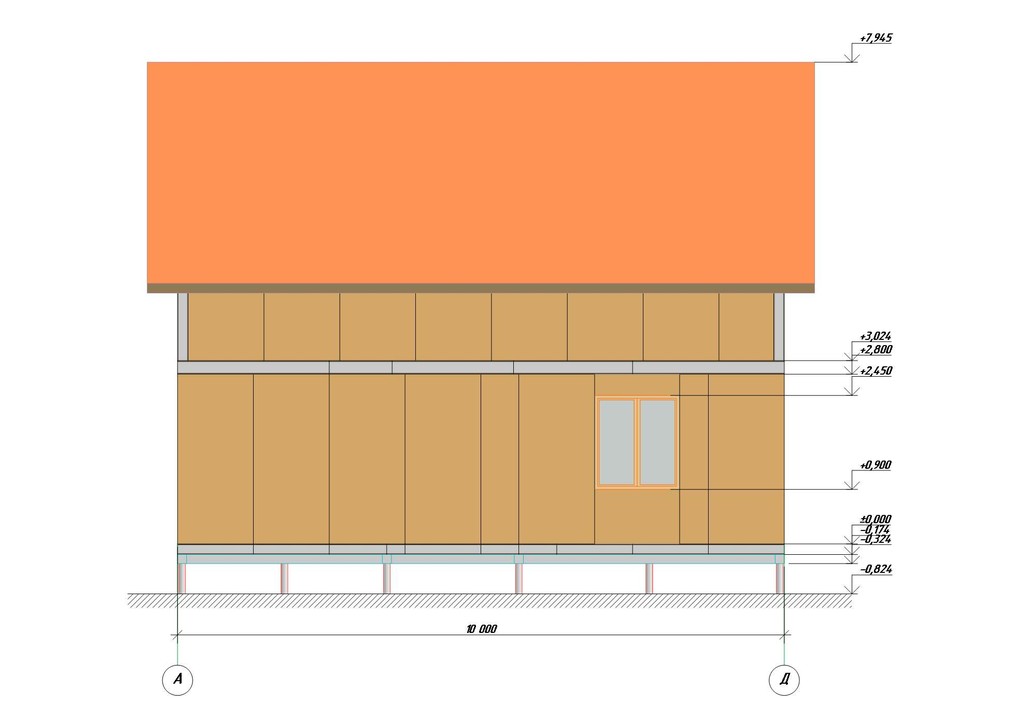

Designing a ventilation system

Stage 1. Flow

This is the initial stage of organizing the movement of air masses in a private cottage. Arrangement of air flow paths from supply channels to outgoing channels is mandatory. Ventilation in a brick house, a building made of wood or other materials will not work correctly if there are obstacles in the way of the air flow in the form of doors or impenetrable partitions.

Air flow organization scheme

When arranging the flow, the following nuances must be taken into account:

- the exhaust opening should be located in the most “dirty” room - the kitchen or sanitary block;

- so that air can freely pass through the doors, the distance between their lower edge and the floor covering should not be less than 2 cm;

- if interior doors are equipped with a threshold, an overflow grill must be installed in the lower part of the door;

Stage 2. Inflow

For effective organization of air exchange, a constant supply of fresh air from the street into the room is necessary. Previously, the inflow was provided due to infiltration, that is, the penetration of air masses through the pores and cracks in the walls, windows, vents, and so on.

But now, as a rule, this is not enough. Therefore, even if ventilation is designed in aerated concrete house, passing air, it is necessary to provide for the installation of additional inlet air valves.

There are two types of air supply organization:

- natural;

- forced.

Consider in more detail the existing methods:

- Ventilation through windows.

A very common method of organizing ventilation, which has many significant disadvantages:

- large heat losses in the cold season;

- during ventilation, window blocks and adjacent structures cool down, which leads to the formation of condensation on the glass after the windows are closed;

- for complete air exchange, it is necessary to keep the windows open for at least half an hour.

Ventilation by opening windows is not the most effective way

- Ventilation by fully opening windows and doors. The result is the fastest possible air exchange. It takes about 4 minutes to completely replace the air masses in the room. However, in the process, a very dangerous draft arises, which cools the room in a matter of minutes.

In addition, sanitary standards require that the air in living rooms be completely replaced within an hour. That is, you need to repeat the described procedure every 60 minutes, which, you see, is quite inconvenient.

- Ventilation with inlet window valves. This is the most modern and best way.By purchasing and installing a device, the price of which, by the way, is not very high, you ensure constant efficient air exchange.

Supply valve - a source of constant air supply to the house

By the way, there are models of window blocks already equipped with ventilation valves.

- Ventilation with inlet valves equipped with fans. The latter can be turned on and off manually, as well as electronically controlled, taking into account the humidity and temperature in the room.

Varieties of supply valves with a fan

Stage 3. Extraction

Whatever method of ventilation (natural or mechanical) you choose, you cannot do without making an exhaust duct. If the construction of the dwelling is carried out independently, the project should provide for the arrangement of ventilation shafts in the inner walls of the kitchen and sanitary blocks in advance (as a rule, this has already been done by engineers and architects developing the project).

The exhaust duct must be part of the building structure

Otherwise, the design of air ducts is necessary. Most often, wiring channels are made in the attic, and the suction holes are placed in the ceiling.

There are two types of exhaust systems:

- Natural. Suitable when the area of ventilated premises is small and the design of the house allows you to make a shaft of the desired section in the wall. In this case, the inlet opening is formed by a decorative grille, protected by a mesh from the possible penetration of insects.

- Mechanical. It is used when the section of the exhaust ventilation shaft does not allow pumping the required amount of air due to natural draft.Then electric fans are installed on the outlet openings, which enhance the air exchange. They are very effective in the bathroom, as they quickly reduce the humidity in the room.

Extractor hood in the bathroom equipped with a fan

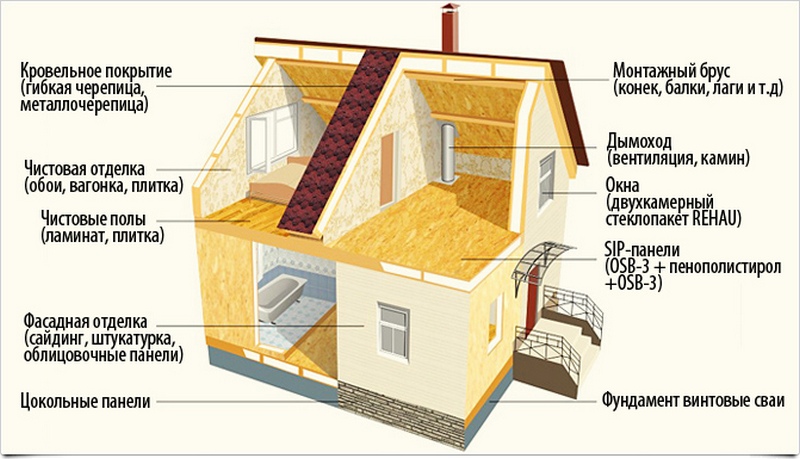

Meet SIP panels (sandwich panels)

SIP (Structural insulated panel) or sandwich panels are a material consisting of three layers.

Durable sheet material is used as the outer layers: OSB (oriented strand board), magnesite board, fiberboard (hardboard), wooden boards. The thickness of the plates is 9 mm or 12 mm. Most often, in SIP panels for the construction of houses, OSB-3 (OSB-3) slabs with a thickness of 12 mm are used, intended for use in load-bearing structures at high humidity.

The core of the sandwich panel is a heater: expanded polystyrene, polyurethane foam or mineral wool. The thickness of the material varies according to the needs of the customer and can be from 50 mm to 250 mm. Most often, expanded polystyrene PSB-25 or PSB-S-25 with a density of 25 kg / m³ is used.

The outer layers are bonded to the core under high pressure. The result is a new durable composite material.

In the CIS, SIP panels of various sizes are used:

- 12+100+12=124 mm;

- 12+150+12=174 mm;

- 12+200+12=224 mm.

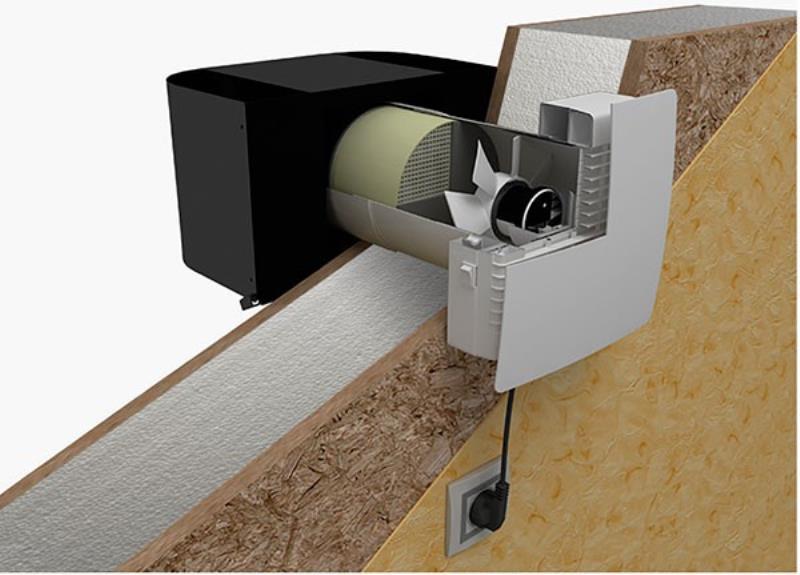

Do-it-yourself artificial ventilation in a house made of SIP panels

When natural ventilation is not enough, mechanical ventilation is used, the design of which includes fans, heaters, and various filters. The system is climate-independent and enriches the rooms with a healthy microclimate. The work consists in the fact that air is removed from the room, which is mixed with clean air from the street, and then returned back.This option is designed so that with such an exchange the temperature does not change at all, and the external air flow becomes the same as the internal one.

When natural ventilation is not enough, mechanical ventilation is used, the design of which includes fans, heaters, and various filters. The system is climate-independent and enriches the rooms with a healthy microclimate. The work consists in the fact that air is removed from the room, which is mixed with clean air from the street, and then returned back.This option is designed so that with such an exchange the temperature does not change at all, and the external air flow becomes the same as the internal one.

Houses made of SIP panels really need high-quality air exchange, since in its absence you can feel dampness, the windows will fog up inside, especially in winter. After all, one of the drawbacks of this building finishing material is poor air tightness. We can say that the building is like a drum, so it is necessary to use devices that have a soundproof housing.

There is more than one type of artificial ventilation. The most accessible and simplest is forced ventilation, the work of which is to remove air from rooms through individual channels by forcing a fresh stream. Such supply can be selective: if possible or necessary, certain zones can be turned off. More expensive is airing performed using heat recovery. This is an energy saving technology. The air entering inside is heated by the outgoing flow. The disadvantage of this duct is the high cost of installation and operation. Houses from SIP are warm in themselves, so this type is redundant and economically unjustified.

Possible problems and solutions

Serious mistakes made during installation lead to the need to replace all ventilation in a private house with a frame sheathed with SIP panels. This results in a considerable cost of material resources and time.

The most common problem is clogged ventilation ducts. To solve it, powerful equipment is used that blows pipes.

A malfunction in the ventilation system causes an increase in humidity in the room.Dampness leads to mold, fungus forms on the ceiling and walls.

Such phenomena are accompanied by insufficient system performance or excessive channel contamination.

Accurate calculations and further correct installation of ventilation equipment of the required power allow to ensure optimal air humidity in the frame structure.

Advantages of houses from sandwich panels:

- Very quickly built. The box at home is easily mounted within a week or two.

- Can be built at any time of the year. There are no limits on building temperature.

- Thin walls, due to which the usable area inside the building increases.

- Excellent thermal insulation. They warm up quickly and perfectly retain heat, since the lion's share of the thickness of the walls is made up of insulation.

- They do not shrink or deform. You can start interior and exterior decoration immediately after the construction of the building, and then immediately call in and live.

- The material of the sandwich panels perfectly soundproofs.

- The walls are strictly vertical and even. It is very easy to install the panels in a vertical position.

- You can save on heating.

- No reinforced foundation required.

- Durable. Withstand hurricanes.

- Sandwich panels are easy to transport and assemble as a constructor.

- Cheap. The price for a house made of sandwich panels is the lowest - and this is the most significant plus of this technology.

Which house do you like best?

Timber house 17.28%

Brick house 8.78%

Log house 7.03%

House from aerated concrete blocks 20.5%

Frame house 30.16%

Foam block house 16.25%

Voted: 683

As you can see, the list is rather big, but there are also disadvantages:

- fragility. The service life of sandwich panels is not as durable as wood, brick or concrete.The maximum is 25-30 years. Although the stated period is 50 years, let's face it and take into account our climatic conditions.

- The strength of such a house is very relative. Maybe he can withstand hurricanes, but cutting a hole in the wall with an ax will not be difficult and does not take much time.

- Absolute non-environmental. Sheathing sandwich panels made of OSB (Oriented Strand Board), which uses a resin binder and other additives. And the inner filling is a heater, for example, polystyrene foam is an absolutely synthetic product. Like it or not, but all this during operation emits not the most “pleasant” substances. On the other hand, there are people who build houses from fixed formwork from the same polystyrene foam or simply insulate their houses with foam plastic, so this is everyone's choice. I like to live in a thermos, no one can forbid it.

- Absolute tightness. To create normal living conditions, the arrangement of forced supply and exhaust ventilation is required. Otherwise, the movement and renewal of air simply will not occur. And these are additional costs that offset the cheapness of construction.

- The sandwich panels are on fire. All statements that the material has a flammability class G1, we will leave on the conscience of the manufacturers. Not only do they burn, but in addition, during combustion, polystyrene foam turns into a liquid state and simply drips or pours “rain from fiery lava” from above. We will keep silent about the fact that in the process of burning OSB boards and polystyrene foam any poisonous muck is released.

- They require a special type of heating system - air.You can, of course, install the familiar to us - radiators under the window, but it will not be practical due to the complete tightness of the structure.

- Due to improper operation and lack of proper ventilation, mold and fungus can form in the panels.

- When selling such a house, its cost will be much lower than that of a brick one.

Now the choice is for everyone, to build or not to build. Of course, the low cost of a house made of sandwich panels is a significant argument, therefore, such houses are often built in dachas for temporary residence. If you decide that you need just such a house, let's understand further.

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

sip.domik

Varieties of ventilation in houses from SIP panels

Ventilation in a frame-type residential building is a necessity. Consideration should be given to its arrangement at the stage of construction of the building. In a house that is not ventilated, there is a high probability of the appearance of bacteria and fungi and the decay of structural parts and wiring.

Air in a room without or with improperly equipped ventilation is polluted by the following sources:

- pets;

- carbon monoxide from stoves and other appliances;

- powders and detergents;

- human waste products (carbon dioxide, skin particles, hair, etc.);

- mold and fungus.

All of the above factors can lead to illness in the household or to the destruction of the wooden parts of the building.

Ventilation design

Ventilation unit project - what must be taken into account without fail?

The location of the air ducts should be logical and cannot block light sources, violate the stability of the house structure and disfigure the interior. All air ducts should be planned as short as possible, and near the central fan, make a connection to the sewer to drain the condensate that forms in the heat exchanger. Ventilation ducts must be sealed and insulated with mineral wool. The duct diameter should be chosen so as to achieve a sufficient air flow rate. The use of hoses with smaller diameters than justified by the designer will lead to an increase in the resistance of the installation, and this will cause a violation of its operation and an increase in noise level.

Video description

For the basics of ventilation design, see the video:

Any future ventilation project is carried out with the obligatory consideration of air exchange rates for each individual room and in general for the entire building. In accordance with the norms and requirements, air exchange must comply with the following indicators:

- room 3 m3/h for each 1 m2 of residential premises;

- bathroom, lavatory, shower room 25 m3/h;

- combined room 50 m3/h, 25.

The parameters are indicated for the temperature in the cold season, indoor temperature is 16-25 °C.

The proper functioning of ventilation is given special attention when designing smart home systems.

After creating the project, installation of ventilation can be carried out, on which only specialists should also work. The process itself takes place in several stages - the preparation of the scheme and the project of the house. In this case, all other communications and systems must be taken into account. Installation and design of ventilation in country houses is a rather complicated procedure and mistakes cannot be made here.Otherwise, they will not be able to achieve their goals. For example, the ventilation system requires preparatory actions:

- determination of the capacity of power grids, their laying and possible reduction in energy consumption;

- the possibility of installing special equipment, as well as the arrangement of air ducts;

- selection of equipment taking into account the characteristics of the premises and operating conditions;

- installation of all selected equipment.

Conclusion

Professional ventilation will make your stay in the cottage safe and comfortable. The system will constantly function for the benefit of man.

When using modern equipment, you can control the flow of fresh air or set the system to operate automatically.

Such systems allow you to make your stay as comfortable as possible at any time of the year and in a variety of weather conditions. In addition, a high-quality ventilation system of the premises allows you to purify the air from pathogenic microbes and microorganisms. This is a very important indicator, especially if there is a small child in the house. The correct calculation of ventilation is a rather difficult task, the solution of which should be dealt with by professionals.

Laying a strapping (crown) beam

We take a beam with a section of 250x150 mm and lay it in the middle of the foundation. We carefully measure the horizontal position of its location.

We connect the beam in the corners with the help of a cut “in half a tree” or “in a paw”. Then we fix the connection with a wooden dowel. To do this, we drill a hole in the bars with a diameter of 20 mm and a length of 100 - 150 mm. We drive in a dowel with a length slightly less than the hole. We finish it with a mallet.

We fix the beam to the foundation with the help of anchors.There are two anchors in the corners and at a distance of 1.5 - 2 m from each other. The length of the anchor should be 350 mm, diameter 10 - 12 mm. We embed the heads of the anchor bolts into the strapping beam.

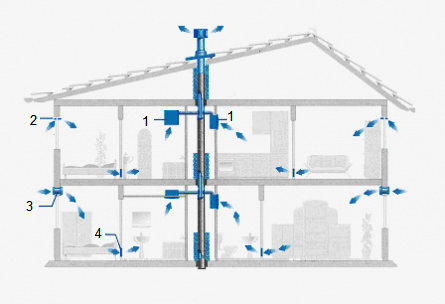

Ventilation methods

The design of the panels is aimed at ensuring the maximum level of thermal insulation with a minimum weight of the structure. The panels have a sandwich structure: outer layer, thermal insulation material, inner layer. Often use additional external and internal cladding of the building. As a result, 5 layers are formed, which reliably isolate the interior of the house from the penetration of cold air. This is a great bonus for saving heating costs. But residents are faced with the problem that there is nothing to breathe in the house. Now it's time to install high-quality ventilation.

And its installation requires certain skills and a professional approach.

Ventilation shafts. This method of supplying the house with clean air is the most rational. Its essence lies in the fact that window frames and walls are supplied with special channels through which air is exchanged. Taking care of their design is at the stage of erecting walls, as well as installing window frames.

And yet, air ducts alone may not be enough. In this case, the air will move only in one direction - inside the house. Therefore, it is recommended to install ventilation shafts to remove carbon dioxide from the room. To speed up the process, special fans are installed that help remove carbon dioxide and dirty oxygen. Installation of shafts in living rooms is not recommended, as extraneous sounds will interfere with sleep. Install mine stands in the hallway, in the kitchen, in the bathroom.

To ensure high-quality ventilation in a room of about 100 m², it will be enough to install 3-4 shafts. If it is not possible to install so many shafts, then the number can be compensated for by the power of the fans. The downside is that heat comes out with the air, which is extremely unprofitable.

Air recovery is used to combat heat loss. Its essence lies in forced fan heaters that remove dirty air, retaining all the heat, after which all the thermal energy is returned back to the house, providing the optimum temperature, microclimate in the house, and saving on heating.