- Why is ventilation needed and what does it do?

- Do-it-yourself ventilation installation

- Installation of air valves

- Installation of ventilation ducts

- Exhaust fan installation

- Do-it-yourself ventilation ducts in aerated concrete house: brickwork

- Why ventilation is needed

- System installation

- Do-it-yourself installation

- System installation

- Types of ventilation systems

- Natural passive ventilation

- Forced

- mixed type

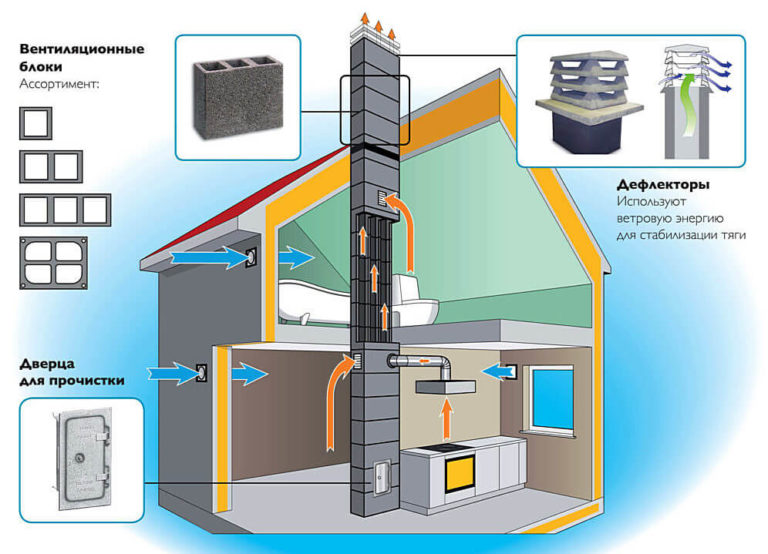

- Arrangement of natural ventilation

- Device of ventilation ducts

- Brick ventilation ducts

- Lining with plastic pipes

- Pros and cons of the two systems

- natural ventilation

- artificial ventilation

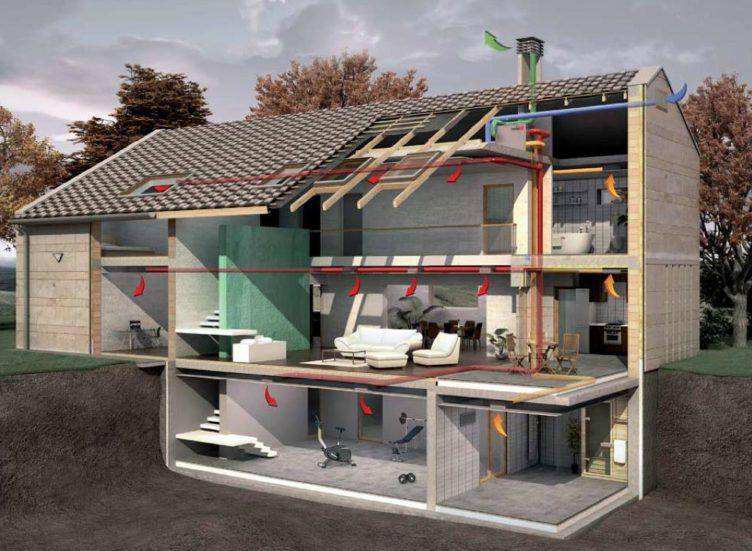

Why is ventilation needed and what does it do?

For a comfortable stay of a person in a working / residential / utility room, certain microclimate parameters must be maintained: lighting, temperature, humidity, concentration of oxygen, carbon dioxide, the permissible percentage of airborne contaminants, etc.

You have probably noticed that sometimes, even at a comfortable temperature, we become stuffy, damp and uncomfortable. Smells from the kitchen or bathrooms scatter throughout the house and do not disappear for a long time, and countless dust particles are visible in the rays of sunlight. Unfortunately, such situations are familiar to many owners of houses.

Without a properly functioning ventilation system that provides regular air exchange, it is impossible to achieve the microclimate parameters required for a comfortable and safe living

The cause of all these troubles in most cases is improper operation or lack of ventilation system. After all, it is she who is responsible for removing the spent air mass from the room and supplying a fresh and clean stream in return.

Since school, we know that in the process of breathing and life, a person consumes oxygen and releases carbon dioxide and moisture into the air around us. Also, a lot of moisture gets into the air when washing and drying clothes, cooking, wet cleaning, taking a shower.

It is better to build a ventilation system with risers located in structures during the construction process. However, if its organization was missed, then ventilation is not too late to do even after finishing work

We constantly, without thinking about it, bring home dust on clothes and things. The atmosphere within enclosed spaces is literally teeming with volatile microscopic organic and mineral pollution, animal hair.

If the house does not have a ventilation system, then all moisture, dust and CO2 accumulate in the air. At the same time, the amount of oxygen, on the contrary, decreases, making our stay in the room unbearable. If you ignore this state of affairs for a long time, then problems with well-being and health may arise.

Regular air exchange is carried out through the intake of air from the street through the supply components and the removal of the exhaust air mass through the hood

Regular air exchange is carried out through the intake of air from the street through the supply components and the removal of the exhaust air mass through the hood

Without a stable air exchange in a house with aerated concrete walls blocks, condensate will not be removed in a timely manner. As a result, a fungus will settle in building structures, destroying both building materials and the health of owners and households.

Do-it-yourself ventilation installation

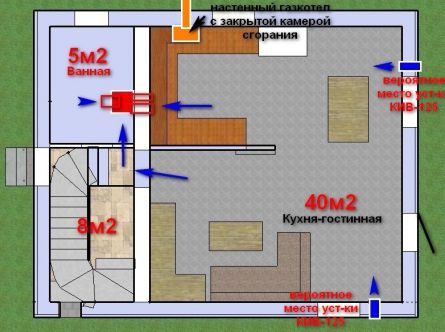

Installing a ventilation system in an aerated concrete house is not an easy process. It is required to assemble the channel together with the wall, or a modular scheme is assembled in the attic or attic with the installation of a fan. It will be necessary to create holes in the ceilings in order to pass the pipes. All this requires skills and a professional tool from the master.

Installation of air valves

This is the easiest way to create ventilation in an aerated concrete house. Aerated concrete is characterized by softness and porosity of the structure, so it is not difficult to drill holes in it. This will require a crown or a conventional drill, with which holes of small diameter are made around the circumference.

Installation of ventilation ducts

Ventilation duct assembly algorithm:

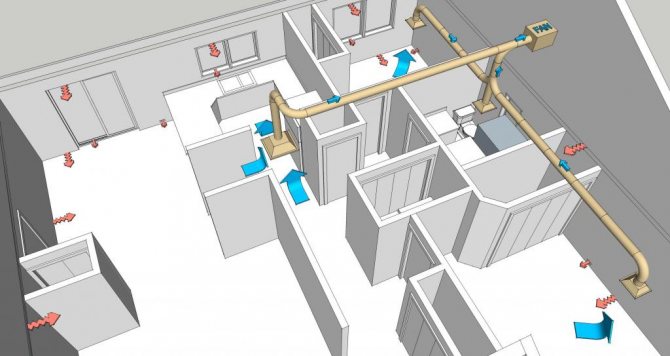

- Determination of the duct installation scheme. The main should capture all service premises with one air duct. It is carried out above the ceilings horizontally.

- Determination of the section of air ducts.

- Calculation of the number of clamps and connectors with the designation of the length of the sections.

- Purchase of materials and tools for the installation of the pipeline.

- Assembly. It is better to start the process from the most extreme room. Holes for pipes are made in each wall between rooms. Pipes are assembled on clamps (for metal pipes) or couplings (plastic pipes).

- Laying the outlet through the kitchen and the wall associated with the street.

- Create duct windows in each room. They need to be covered with a grate.

Then you can proceed to the selection of additional equipment, the calculation of its power, purchase and installation.

Exhaust fan installation

Fans are different. If you choose a channel model, you will need to install it into the wall in the hole for the hood. Wall units are mounted on the wall from the inside. This is an option for bathrooms.

Do-it-yourself ventilation ducts in aerated concrete house: brickwork

The construction of ventilation systems for a private house is best left to specialists. If you follow the building codes and follow the rules of laying and installation, it is possible to arrange the hood yourself. First of all, it is determined by which of the known methods the exhaust channel will be mounted.

When laying channels with bricks, you need to consider:

- Location - in one of the walls of the room, where moisture especially accumulates.

- The fewer channels, the better. This issue is resolved territorially - the premises of the kitchen, sanitary rooms are located in close proximity to each other (“neighboring”). By the way, this requirement applies not only to ventilation, but also to sewerage and water supply systems.

- The brick structure should not come into contact with the wooden building elements of the house - the temperature of the channel will gradually destroy the tree.

- Only solid brick is used. Laying is also allowed from facing hollow, but with careful filling of voids with mortar. Silicate, which has the ability to crumble, is not suitable for such work, it does not tolerate the temperature regime formed inside the ventilation duct.

- The channels are tied together, the separators are ½ bricks.

- The brick is laid on a single-row dressing system.When applying the solution for the next row, it is necessary to ensure that the mixture does not get inside the channel.

Important! Ventilation in the bearing wall of aerated concrete, as in other cases and in houses made of other materials, is not laid! This is not a mandatory requirement, but experts recommend due to the fact that, in general, load-bearing walls are located outside the building - condensation will form on them. The inner surface of ducts, ventilation and smoke, should be as smooth as possible

Therefore, during the laying of bricks, excess mortar is removed from the joints, and the surface is smoothed with a trowel (trowel). Also, there should be no protrusions or depressions on the inner surface - they interfere with normal air circulation.

The inner surface of ducts, ventilation and smoke, should be as smooth as possible. Therefore, during the laying of bricks, excess mortar is removed from the joints, and the surface is smoothed with a trowel (trowel). Also, there should be no protrusions or depressions on the inner surface - they interfere with normal air circulation.

Particular attention is paid to the seams, which must be filled with mortar and wiped, in order to prevent combustion products, exhaust air from entering adjacent channels or rooms of the house. Grouting is done after laying 2-3 rows of bricks

The process is carried out manually, with reciprocating and circular movements along the inner surface of the structure.

Important! A feature of brick ventilation ducts is that they are not equipped with mechanical devices

Why ventilation is needed

Before the advent of plastic windows, stretch ceilings and vapor-proof materials for wall decoration, there was practically no need for forced ventilation of rooms. Fresh air entered the house through cracks and leaks in wooden frames, and excess moisture was absorbed by wooden or brick walls and gradually vented out.

Modern materials make our life easier and more comfortable, but at the same time they cause new problems. One of them is faced by owners of aerated concrete houses in which there is no ventilation system.

Since this material has a high absorption capacity, the protection outer walls from homeowners do not forget atmospheric moisture, finishing them immediately after construction is completed. But aerated concrete easily absorbs excess moisture from the interior, which leads to deformation of the finishing layer, the appearance of mold, and the appearance of an unfavorable microclimate in the house.

One of the consequences of improper or absent ventilation

One of the consequences of improper or absent ventilation

This can be avoided if the air is not allowed to stagnate by arranging a high-quality ventilation system.

System installation

Many people who have just moved into a purchased house or are building it from scratch ask themselves a completely logical and reasonable question, how to make ventilation in the house?

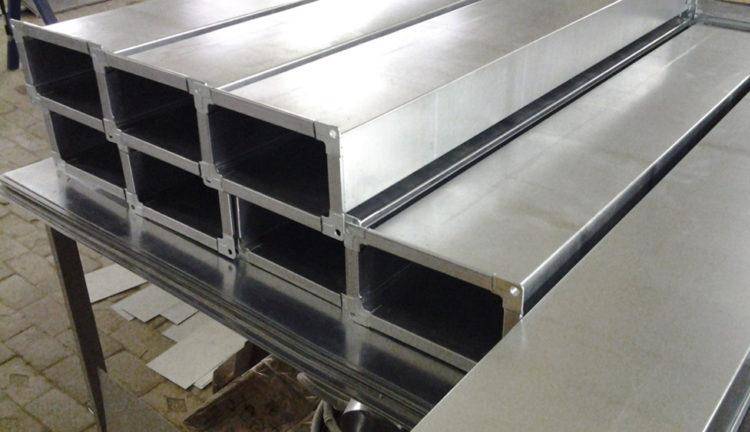

Moreover, it is very important that the ventilation system fully complies with all sanitary and technical standards. Use a specialized complex, which consists of certain systems. Air ducts are made from the following materials:

Air ducts are made from the following materials:

- zinc;

- plastic;

- asbestos cement.

They are laid in all rooms

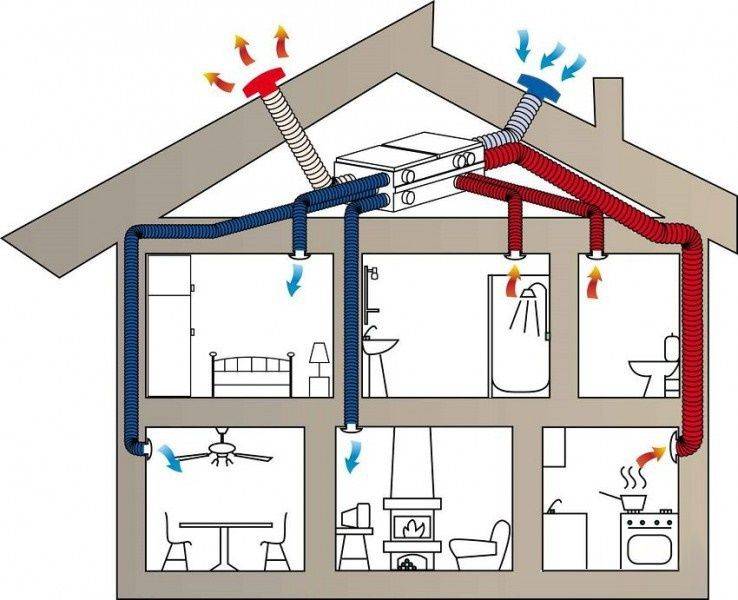

Ventilation ducts that depart from the premises are combined approximately at the level of the ceiling (attic), in such situations it is very important that they are insulated in those places where they go to the roof

For natural, pipes are taken with a slightly larger diameter, a difference of 2 centimeters. Further, a hole is made in the aerated concrete wall with a small interval of half a centimeter in each direction, and the air duct systems are fixed in them.

For successful completion, it is necessary to prepare a special solution before installation, and all holes in which pipes and fans will be mounted must be waterproofed.

Do-it-yourself installation

The installation of ventilation in a private house must be approached from the position - which system was chosen. If this is a natural model, then the main thing is to correctly lay the risers. You will have to tinker with forced ventilation, especially if it is an extensive network. The easiest option is to install wall fans, for which holes are simply made in the walls with a crown and a perforator to match the diameter of the pipe, where the equipment is inserted.

From the outside, that is, from the street, the pipe is closed with a visor and a grate. A decorative grille is installed from the inside

Here it is important to very competently connect the fan to the mains supply of electric current. To do this, wall chasing is usually carried out, where the power cable from the fan to the junction box is laid.

True, this is done at the stage of repair or decoration. If installation is carried out in a renovated room, then it is recommended to lay the wiring in special plastic boxes.

It should be noted that the supply and exhaust ducts can be equipped with fans if a complex air exhaust scheme is arranged in the house. In this case, as in the case of calculating natural ventilation, the maximum parameter is determined from two calculated ones: exhaust and inflow. It is on the basis of the calculations made that the fan is selected, or rather, its performance.

It is easy to carry out the installation of a monoblock device. The main task is the correct choice of the installation site. As practice shows, preference is given to the street near the wall of the house. Although the option in the office solves the problem of equipment freezing. This device is convenient in that it already includes all the necessary devices that are responsible not only for air exchange, but also for the purity of the supplied air flow.

In general, you can make exhaust ventilation or supply ventilation yourself, if you make preliminary calculations correctly. It is impossible to choose equipment and air ducts by eye. It may happen that their power and cross-section will be insufficient to cope with the volume of the interior.

System installation

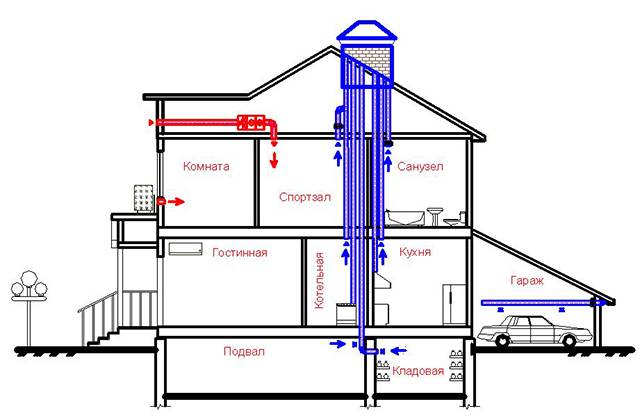

The assembly of the entire system can be carried out in different ways and depends on the chosen method of arranging ventilation. Thus, the installation of pipes and the laying of brick channels are carried out at the construction stage of the building, the installation of fans and valves can be carried out after.

It is best to make special channels at the construction stage - in all rooms or only where high humidity is noted. Brick channels or pipes in blocks are laid along the walls and lead to the attic, uniting them there and insulating them at the exit points to the roof.

Pipes are usually taken from plastic, with a diameter of 13 centimeters or more.They are laid in aerated concrete blocks, insulated with mortar.

Stages of assembling a horizontal ventilation duct system:

- Drawing up a diagram of the installation of air ducts - if the system is one, the line is created from one air duct laid horizontally under the ceiling.

- Calculation of the duct diameter based on the calculation of the volume of air that is removed.

- Calculation of the number of fittings, straight sections and their length (according to the scheme).

- Purchase of materials.

- Making holes in each wall along the cross section of the duct.

- Assembly on couplings / clamps - starts from the far room.

- The output of the outlet (usually through the kitchen) through the wall to the street.

- Execution in the duct of windows for hoods, closed with bars.

When installing the channel model, it is inserted into the hole for the hood in the wall. Wall models (often used for bathrooms) are mounted indoors to the wall exactly horizontally so that the fan works correctly.

Types of ventilation systems

Before you make ventilation, you need to study the features of installing the system in a house made of aerated concrete. In buildings made of traditional materials, channels are installed only where humidity is high (kitchen, bath, bathroom), in this case, channels are often needed in every room.

Natural passive ventilation

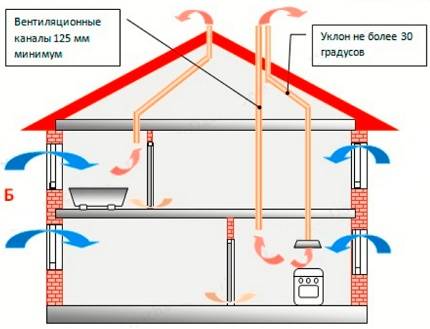

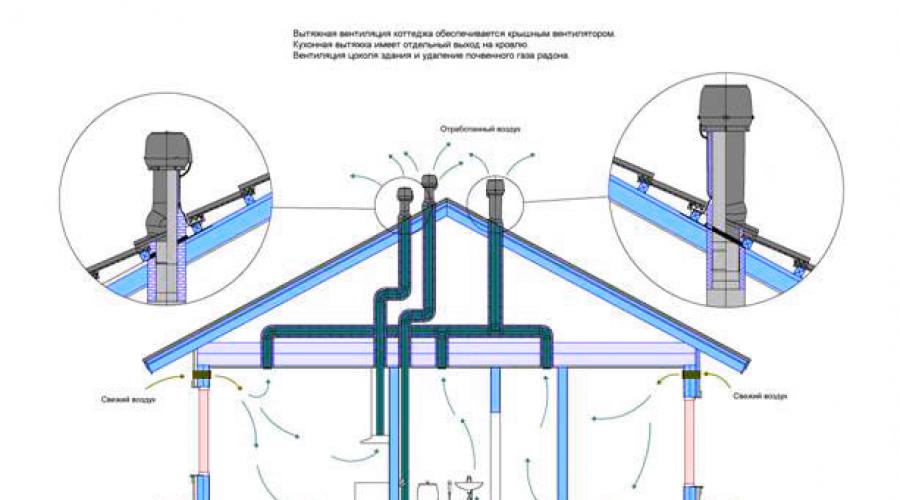

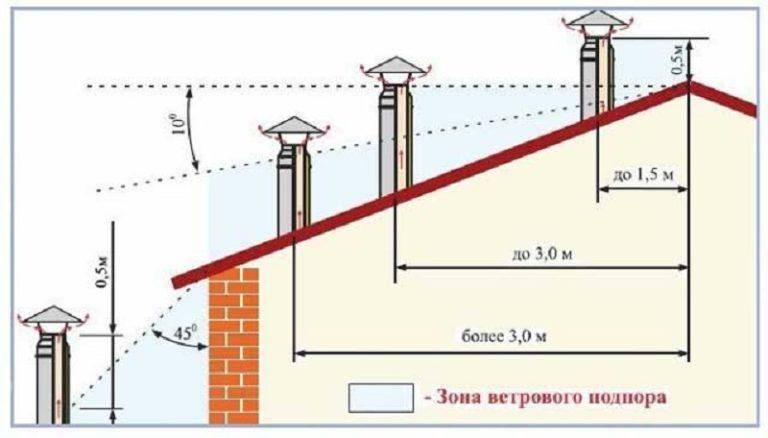

Passive ventilation works only if the installation is correct and the air supply/exhaust is normal. In order for the air to leave on its own, all ventilation ducts from the premises must go to the roof of the building to a certain height. If these nuances are not taken into account, traction will be poor and even “rollover” is possible.

Height of ventilation ducts:

- Subject to location from the ridge at a distance of 150 centimeters - 50 centimeters above the ridge

- If the distance is up to 3 meters - the head of the channel is performed at the level of the ridge

- Provided that the distance is more than 3 meters - the top of the channel should not be lower than the border of the line conventionally drawn from the ridge at an even angle of 10 degrees to the horizon

To ensure the flow of fresh air, you need:

- Windows with air valves - these can be either slotted systems, or simply the presence of a design in the form of a handle for opening the sash (they have a minimum opening area, so they are not suitable for large rooms and can be an auxiliary option).

- In-wall air vents are the most efficient choice, installed on the walls and providing a normal supply of fresh air.

The ventilation ducts must be kept clean, as debris will interfere with the operation of the system. That is why intra-wall shafts and structures in the format of boxes extending as a vertical pipe beyond the boundaries of the roof are gradually abandoned - they eventually cease to fulfill their functions.

Useful tips: if you put the valves under the windows, in winter the air will warm up with heat from the radiators. When bringing the exhaust pipe to the roof, you need to mount an umbrella / fungus on top to protect against precipitation or a deflector.

Forced

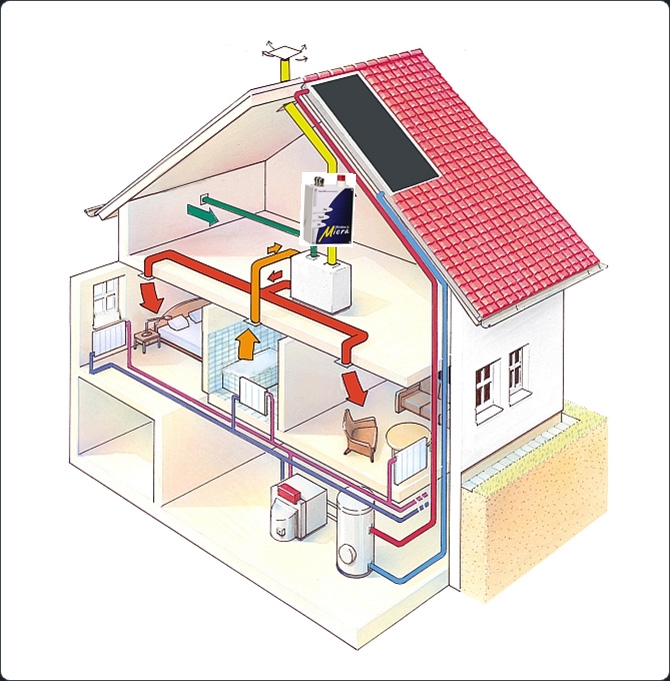

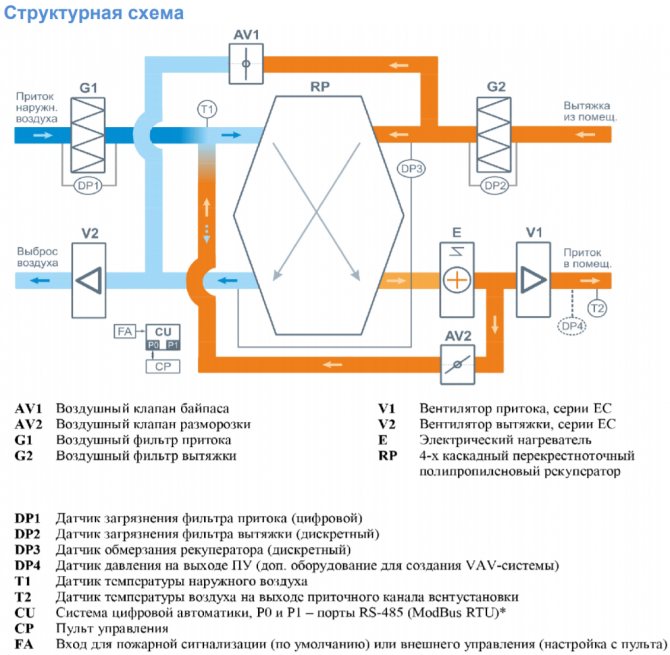

This type of ventilation system involves high installation and operation costs, since it includes special devices and uses electricity for operation. But the efficiency of such systems is much higher.

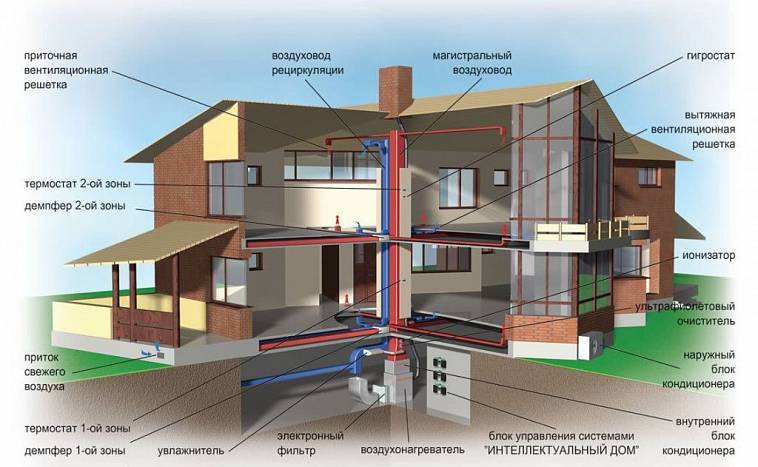

Features of the forced ventilation system:

- Air ducts are mounted with exhaust fans, fresh air is supplied through its network of channels.

- To maintain the optimal temperature regime in the room, the system is equipped with units for heating the air coming from the street.

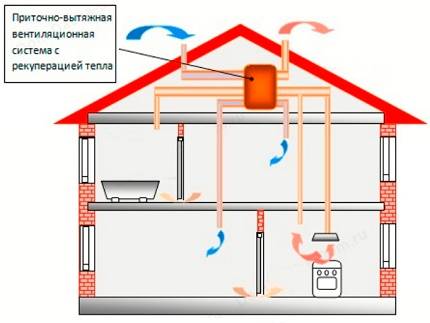

- The most economical option is to use a heat recuperator instead of an electric heater. Such a heat exchanger is equipped with two fans (exhaust / supply), in which fresh air is heated by the heat of gases that are removed from the house.

Forced ventilation is assembled according to a scheme similar to natural, it is simply mounted additionally with a fan.

Three types of ventilation:

Supply type - the fan is mounted on the supply duct: the device works with injection, so the air movement is slow

In this regard, it is important to correctly determine the installation point of the fan and do it in such a way that the air flows along the walls, and not perpendicularly. Usually caps with slots along the walls are attached to the valves.

Exhaust type - the most popular, the fan works on the hood

Mounted on the plane of the wall with a through hole or in it. It is important to correctly determine the performance of the device: for example, 25 m / h is enough for a bathroom, 60 m / h for kitchens, and 30 m / h for living rooms.

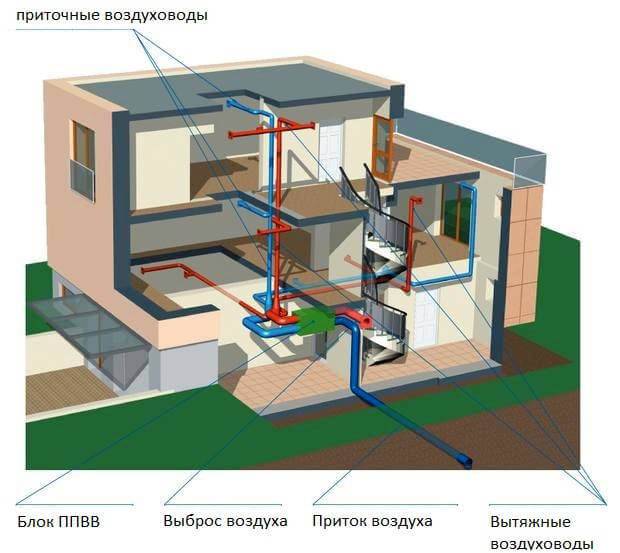

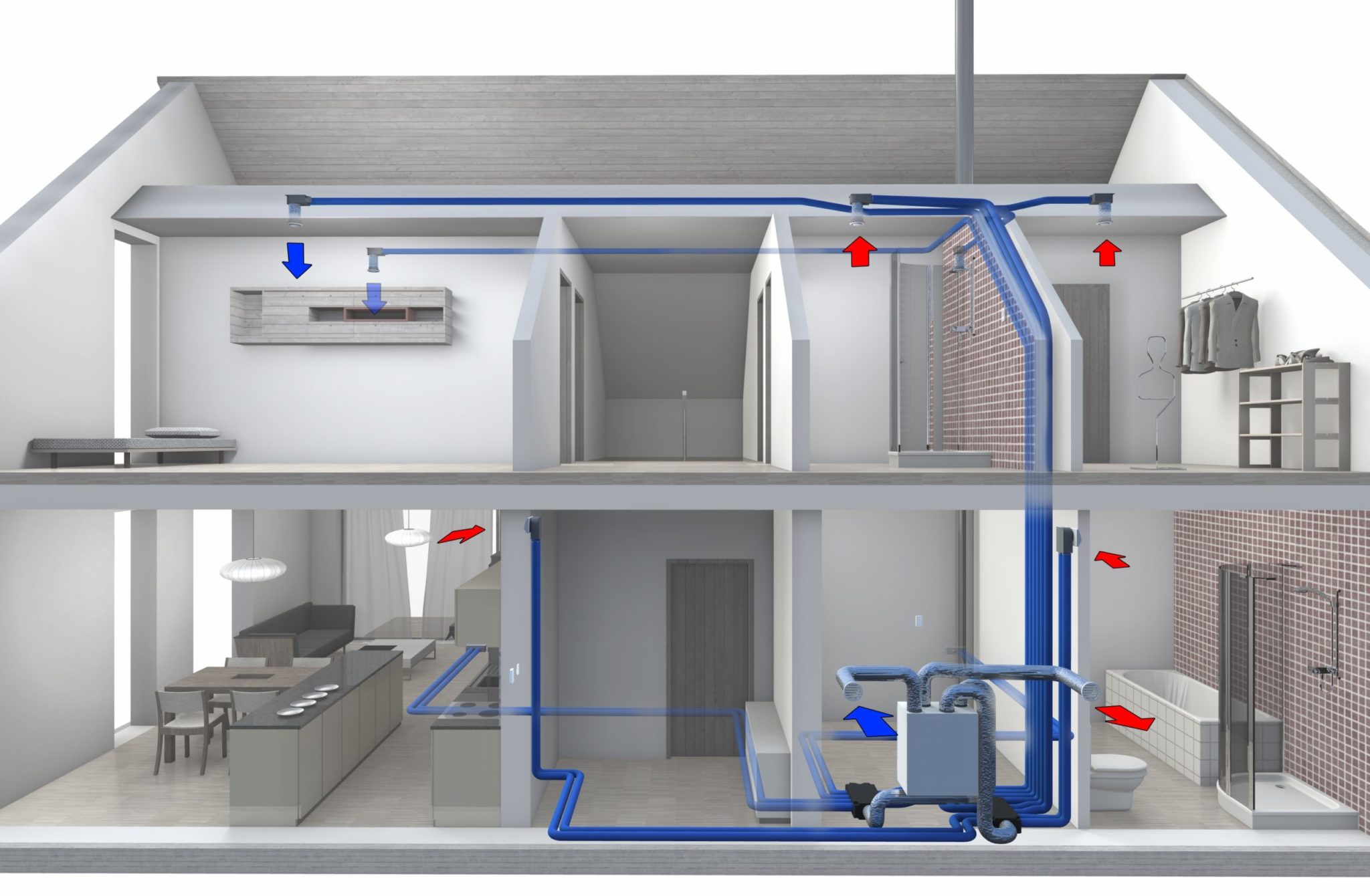

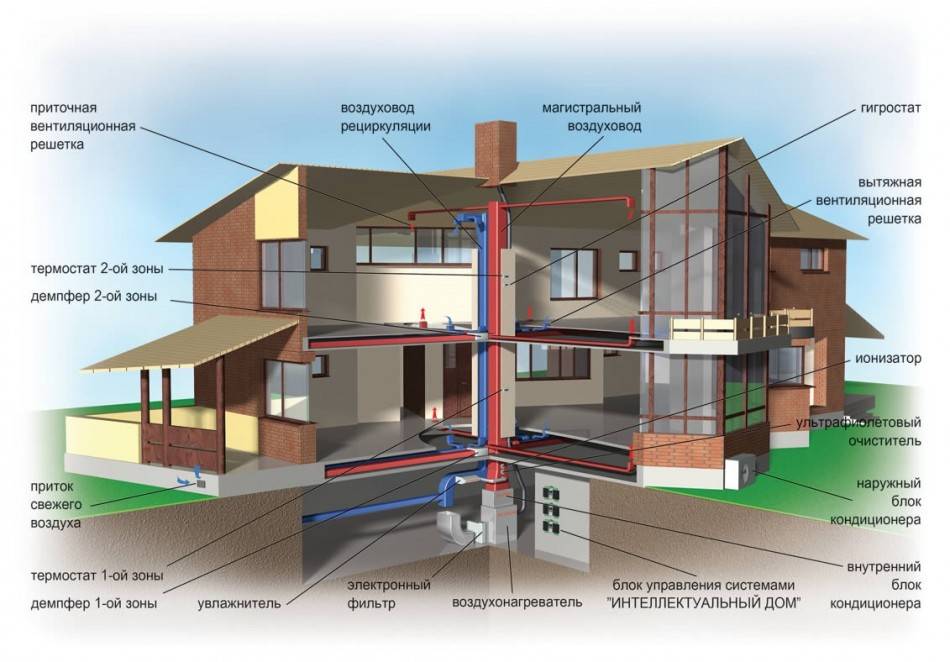

Supply and exhaust type - fans are installed both on the extract and on the inflow. There are ready-made blocks of equipment that are mounted in the attic in the format of ducting through the rooms that go through the ceiling. Blocks are necessarily completed with heaters, recuperators, filters.

mixed type

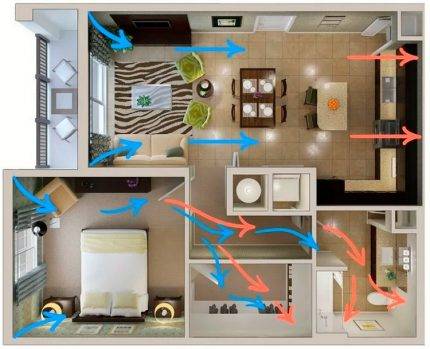

In a system of this type, fresh air comes in naturally, and the exhaust is carried out by exhaust fans - one powerful one (installed in the attic with ducting) or separate devices built into the walls and windows of the premises.

As for the kitchen hood, in an aerated concrete house it is better to choose models with exhaust air exhausted through a window / wall directly to the street. It is desirable that this be a separate unit.

Arrangement of natural ventilation

For the device of natural ventilation in a private house with your own hands, it is necessary, first of all, to calculate the ventilation system, made on the basis of such data as the volume of air in the room and the number of people living in it. Before installing a ventilation system, it is also worth considering devices that burn oxygen and emit harmful substances.

Installation of both natural and mechanical ventilation is carried out in seven stages:

- Calculation of the volume of air exchange (determination of the required amount of incoming air masses that meet sanitary requirements).

- Determining the dimensions of the ducts.

- Choice of ventilation system (natural or mechanical). The decision is made after a thorough analysis of the parameters of the premises and the environment.

- Drawing up a scheme of ventilation ducts.

- Determining the location of ventilation equipment.

- The choice of places for the intake and output of air masses.

- Installation of the ventilation system.

To build natural ventilation in a cottage with your own hands, it is not necessary to have professional skills. You just need to study some points of installation. One of them is laying in the bearing wall of an exhaust duct with a diameter of 14 cm, with a masonry thickness of one and a half bricks. This condition is necessary to prevent the effect of reverse thrust.Further, from the central channel, a horizontal wiring is laid through the rooms, the diameter of which is 10 cm. To ensure sufficient traction, the exhaust pipe is made higher than the ridge.

The supply of fresh air can be carried out through the inlet window valve installed in the metal-plastic windows by the manufacturer. The valve is an adjustable slot at the top of the window. This method is considered if it is necessary to replace old or install new metal-plastic window blocks.

If the windows are already installed, natural ventilation in a private house can be provided by an inlet wall valve. A through hole is made in the wall and a round pipe is inserted, equipped with gratings on both sides. From the inside, the valve opens and closes with an adjustable grate. In order not to spoil the interior of the room, the valve installed near the window is covered with a curtain. To warm up the air coming from the street in winter, the supply valve can be installed directly behind the heating radiator.

At the request of the homeowner, supply valves are equipped with sensors and filtration systems. They are installed, as a rule, in the hall, bedrooms, offices. Exhaust channels are made in household rooms. Thus, the correct direction of movement of air masses is observed. If a sufficient supply of fresh air requires the installation of a large number of supply valves, it would be more appropriate to opt for mechanical ventilation.

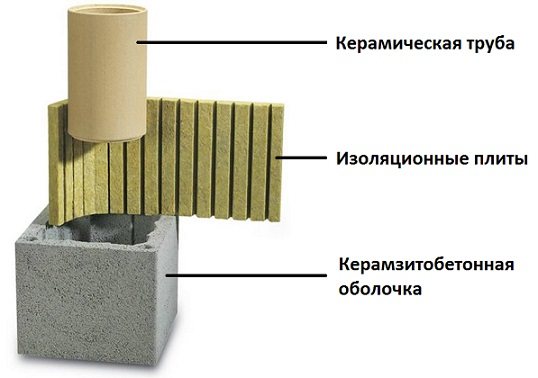

Device of ventilation ducts

When planning to make a ventilation system in a house made of aerated concrete with your own hands, you need to carefully study everything

Particular attention is always paid to the installation of ventilation ducts, remembering that aerated concrete is a fragile material, it is afraid of sudden changes in temperature, moisture

Masters do not advise mounting the system in external walls, as condensation will appear, it is better to equip everything in separate ventilation shafts or partitions.

Methods for arranging ventilation ducts in an aerated concrete house:

- Lining with pipes made of plastic, asbestos

- Laying out of brick

- Installation of a box made of zinc-coated steel with laying in small-sized blocks of aerated concrete

Brick ventilation ducts

Laying brick ventilation ducts involves a certain sequence of actions, as well as the availability of the necessary materials and tools.

How to lay out ventilation ducts from bricks:

- It is desirable that there are few such channels in the building; it is better to build them in the walls of adjacent rooms where high humidity is noted.

- Masonry is performed only from solid bricks, if hollow - then with the subsequent filling of voids with cement mortar.

- The solution must be applied carefully so that the mixture does not get inside the channel. The seams are completely filled, overwritten every 2-3 rows of stone, so as not to allow the exhaust air to end up in adjacent rooms and rooms.

- Inside the walls of the channels, it is desirable to create smooth, so that the air circulates unhindered. The excess mixture from the joints is immediately removed, the surface is smoothed with a trowel. Also, then you can sleeve the channel with an air duct made of metal.

Silicate brick is not used in such masonry, as it is afraid of high temperatures and crumbles. Mechanical devices cannot be installed in brick channels.

Lining with plastic pipes

The most effective way to install forced ventilation.In the installation, plastic pipes with a cross section of 13 centimeters or a rectangular shape with a cross section of 150 cm2 are used.

For natural ventilation, it is better to take more pipes. For an accurate calculation of air ducts, the following data are needed: the number of people in housing, the volume of exhaust air, climate features, etc. Calculations should be carried out by a specialist. Ventilation is arranged simultaneously with the construction of the house.

How to mount ventilation from plastic pipes:

- Fastening the outlet in a block located at the level of the ventilation hole, connecting it to the pipe.

- Cutting holes a couple of millimeters more pipes in blocks for air ducts (during masonry). Usually a hacksaw is used for this.

- Filling with mortar the space between the air ducts and the sawn walls of the blocks. Docking of pipes (building up) in the process of laying walls.

- Insulation of pipes in the areas of their passage through the attic, roof.

- Separate air ducts at the attic level are connected into a single channel, which is brought out into the street through the roof or connected to a heat exchanger, a duct fan. All openings are carefully sealed and sealed.

Pros and cons of the two systems

natural ventilation

For the equipment of such a hood, you do not need special skills on your own, while it has a number of advantages:

- The absence of mechanisms makes such air exchange reliable and durable.

- There is no need to spend money on the purchase of devices.

- Simplicity in work.

- Quiet during operation.

At one time, such an extract fully met its requirements, but with the advent of new gas equipment, the view on this has changed.

This revealed the following significant shortcomings:

- The dependence of optimal air circulation on the season and climatic conditions.

- Impossibility of regulation of an air stream.

- Penetration of foreign particles through the system.

We recommend that you read: Types of built-in hoods 90 cm in the kitchen

And also with a decrease in air intake, there is a likelihood of an increase in humidity in the room.

artificial ventilation

Artificial hood is the best option when installing gas boilers, because:

It is possible to independently adjust the air supply.

The importance of this ventilation in enclosed spaces.

Pleasant microclimate in the room.

Possibility of regulation of air exchange by means of the panel.

Independence from weather conditions.

If the house has a boiler with a coaxial output, then the built-in fan in it automatically creates a favorable atmosphere for human habitation.

The only drawback of such a system is the rather high cost of this installation.