- Ventilation standards for residential premises

- Energy Saving Requirements

- Solving technical ventilation problems

- Emergency ventilation in production

- What is the feature of medical industry ventilation

- Principle of operation

- The principle of operation of natural and artificial ventilation

- Formulas for calculating ventilation

- Emergency ventilation

- Food warehouse ventilation

- What are the legal requirements for storage facilities?

- Storage requirements

- Operating pressure and duct cross section

- About air exchange

- Air curtains

- Warehouse ventilation for alcohol-containing and chemical products

- Building regulations

- What qualities should the selected system have?

- Regulatory documents and calculation of air circulation

- Production shops

- Emissions of dust and harmful substances

- Ventilation of warehouse complexes

- Calculate the heat consumption

- Excess water vapor

- What are the requirements for ventilation systems in standard warehouses?

Ventilation standards for residential premises

In order for the air in a residential building to be of high quality and in sufficient volume, must follow the rules established by law. After all, human health directly depends on air quality. For each specific residential building, a specific value is set.

When calculating air exchange in residential buildings, the method of specific norms for the circulation of air masses is used. It consists in taking into account sanitary and human loads

It also takes into account the presence of equilibrium between the supply air masses and the exhaust air masses. Air flows must move from a room with the best air circulation to buildings where air quality is lower

In order to correctly make the necessary calculations, two quantities must be taken into account - the total area of the residential building and the norms of air exchange for each person, which is in this building. To begin with, the first value is set. For this, the air circulation rate per hour is multiplied by the total volume of the room.

The first value is fixed and equal to 0.35. Then the ventilation rate of the residents is calculated. When making calculations for rooms with a total area less than 20 sq.m. per person you need to multiply the living area by a factor equal to 3.

And for residential buildings with a total area of more than 20 sq.m. per person, you need to multiply the number of residents by the standard value of air exchange per person, which is 60. After the calculations, it is necessary to produce exhaust air in additional rooms, taking into account their type (kitchen, bathroom, toilet, dressing room). Each type has its own standard. After that, the maximum result is taken into account.

The ventilation system must provide a high-quality air environment. In residential buildings, air circulation between apartments is unacceptable, between the kitchen or toilet and living rooms. Be sure to have independent ventilation. Exhaust ventilation shafts should protrude above the ridge of the roof or flat roof to a height of at least 1 m.the concentration of harmful substances in the air should not exceed the norm.

Energy Saving Requirements

The requirement for maximum energy savings is formalized in the Thermal Protection of Buildings Ordinance, developed on the basis of the current Energy Law, as well as in the well-known Federal Law on Air Emissions. With this requirement in mind, all systems of engineering equipment of buildings and warehouses should be designed and created. Against the backdrop of increased attention to the thermal insulation of buildings under construction, ventilation and air conditioning technology is becoming increasingly important, especially in newly built buildings. These systems must fully comply with the state of the art.

Whereas conventional heating installations only determine the thermal behavior of a building, air conditioning systems are able to perform broader specific tasks for indoor air quality, influencing not only its temperature, but also humidity and cleanliness. Thus, of course, a significant contribution is made to the preservation of human health and performance, and at the same time another positive effect is achieved, namely, the problem of protecting buildings from moisture accumulation in the walls of structures and on the walls themselves is solved, and the sound insulation of buildings is noticeably increased. For reasons of hygiene and taking into account a number of physical aspects from the field of construction, it is imperative to remove air from the premises that is saturated with moisture and contains harmful substances and odors.

Solving technical ventilation problems

There are many different possibilities for solving ventilation-related technical problems.At the same time, when choosing a particular installation, one has to take into account the special boundary conditions related to a given building or room, because only a solution in relation to a specific problem will give the desired result - an economical, environmentally friendly, energy-saving method of construction. Therefore, all engineering communications, building equipment systems, and air conditioning equipment in particular, must certainly be considered in close connection with the architectural and construction solutions of the facility under construction.

Emergency ventilation in production

It is an independent installation, which is necessary to ensure safe working conditions in the workplace with the likelihood of the release of harmful and hazardous substances.

The emergency system device works only on the hood. This is necessary to avoid the entry of polluted air into different places.

Ventilation of industrial premises is a labor-intensive and energy-consuming process that requires specialized knowledge and skills. Regardless of the type and type of device ventilation in production, two main factors must be observed: correct design and functionality. Under these conditions, a correct and healthy microclimate is ensured.

What is the feature of medical industry ventilation

With the help of ventilation, clean rooms should receive air already purified from harmful impurities, therefore the main role is given to special filters, with the help of which sterility is created.

You may find it useful: How to make ventilation in the bathroom and toilet with your own hands in an apartment and in a private house.

Principle of operation

Since the system is a supply and exhaust system, their principle of operation is as follows:

- First, the fan blows air into the room;

- Then it is cleaned by three groups of filters. The first cleaner is an element that helps rid the flow of mechanical impurities. The second acts as a fine filter and antibacterial substance. The third group includes HEPA and ULPA microfilters located in the system distributors. These ventilation details make the air really clean.

Read an interesting article about the correct installation of ventilation in the bath.

In addition to the fan and filters, the design of hospital ventilation includes air distribution devices and automation to maintain temperature and humidity parameters. Developers of air purification systems make up a set of functions for them, based on their purpose and the required sterility class.

Since today the requirements for sterility and cleanliness in medical institutions and other industries are constantly tightening, this leads to the improvement of ventilation structures through the introduction of innovative technologies.

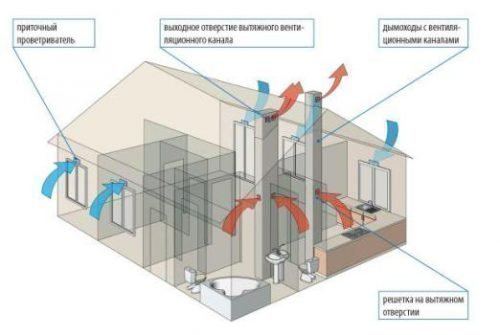

The principle of operation of natural and artificial ventilation

Warehouse Ventilation Mechanism

Natural ventilation systems provide for compliance with certain requirements. So, for example, it is necessary to maintain a distance of more than three meters in height between the location of the fence and the emission of air masses. As for the length of the horizontal section of the air outlet, it is necessary here that it be three meters or more. In addition, the calculation of warehouse ventilation should be carried out in such a way that the air speed exceeds one meter per second, at least not less. The requirements for the exhaust shaft are that it must be located one and a half meters above the roof ridge.

If we talk about the advantages of natural ventilation, then this can include the simplicity of its configuration. Maintenance is also simple, and it does not require any energy costs. However, there is also a disadvantage, which lies in the fact that the efficiency will directly depend on the wind speed, as well as on the air temperature. That is why it cannot be expected to solve complex problems that sometimes should be assigned to ventilation.

The mechanical ventilation system in the warehouse, in turn, provides for the use of electric fans. With their help, air masses move over long distances, regardless of weather conditions and in any volume. If necessary, the air can be cleaned, heated or humidified - this is one of the key advantages of forced ventilation, which, unfortunately, cannot be said about the natural counterpart.

Warehouse ventilation schematic

Forced (artificial) ventilation is also capable of solving specific problems. So, for example, it is able to quickly and quickly ventilate warehouses after decontamination and removal of rodents. Among other things, it can cope with the fastest heating of the warehouse area. It should be noted that this is a very useful advantage of mechanical ventilation, which is especially relevant for such premises. In most cases, a combination of both ventilation systems is practiced - forced and natural.

According to their design, ventilation systems are classified into ducted and non-ducted.Thus, the first ones represent a whole network of air outlets. As for the second, here there is an installation of fans in walls, ceilings, and so on. Today, the latest ventilation systems are able to be controlled by automation.

Formulas for calculating ventilation

Calculation by room area

This is the simplest calculation. For residential premises, the norms regulate the supply of 3 m3 / h of fresh air per 1 m2 of premises, regardless of the number of people.

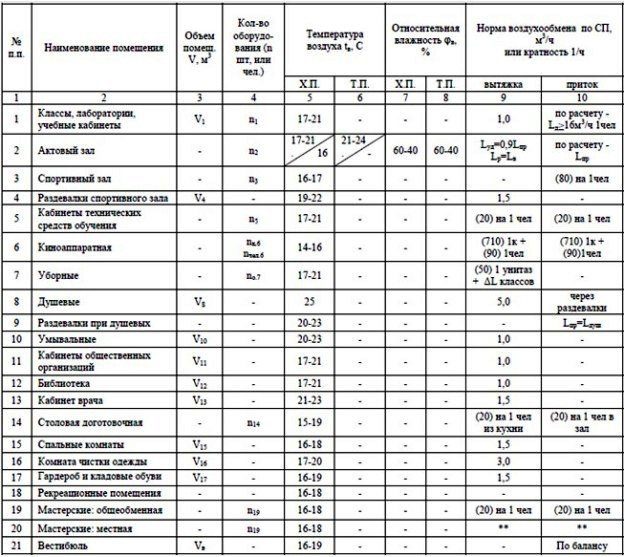

Calculation according to sanitary and hygienic standards

According to sanitary standards for public and administrative buildings

60 m3/hour of fresh air is needed for one permanently staying indoors person, and 20 m3/hour for one temporary person.

In the case of a dwelling, you can focus on how much time the tenants spend in which room. For example, for a bedroom, it is recommended to accept that the owners are there constantly (8 hours in a row), and for an office, you can accept 1 person - permanently, and 1-2 temporarily.

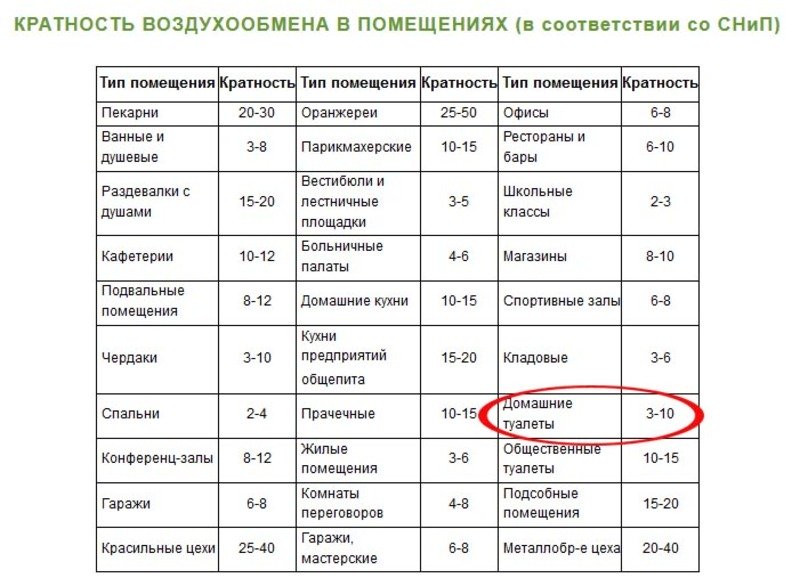

Calculation by multiplicities

The document (SNiP 2.08.01-89 * Residential buildings, Appendix 4) contains a table with air exchange rates by type of premises (Table 1):

| Premises | Estimated temperature in winter, ºС | air exchange requirements | ||

| tributary | Hood | |||

| common room, bedroom, office | 20 | 1x | — | |

| Kitchen | 18 | — | According to the air balance of the apartment, but not less than, m3/h | 90 |

| Kitchen-dining room | 20 | 1x | ||

| Bathroom | 25 | — | 25 | |

| Restroom | 20 | — | 50 | |

| Combined bathroom | 25 | — | 50 | |

| Washing machine room in the apartment | 18 | — | 0.5 times | |

| Dressing room for cleaning and ironing clothes | 18 | — | 1.5x | |

| Vestibule, common corridor, stairwell, entrance hall of the apartment | 16 | — | — | |

| Switchboard | 5 | — | 0.5 times |

Here is an abbreviated version of the table, if you did not find your type of room, refer to the original document (SNiP-u).

Air exchange rate - this is a value that means how many times during an hour the air in the room

completely replaced with a new one. It directly depends on the volume of the room. That is, a single air exchange is when

within an hour, a volume of air equal to the volume of the room was supplied and removed into the room; 0.5 faucet air exchange -

half the volume of the room, etc. In this table, the last two columns

the multiplicity and requirements for air exchange in the premises according to the inflow and

air extraction respectively.

Formula for calculating ventilation,

including the right amount of air looks like this:

L=n*V (m3/h) , where

n – normalized air exchange rate, hour-1;

V - the volume of the room, m3.

When we consider air exchange for a group of rooms within one

building (for example, residential apartment) or for the building as a whole (cottage), their

should be considered as a single volume of air. This volume should

meet the condition ∑ Letc = ∑ Lyou are t That is, how much air we supply, the same must be removed.

In this way, the sequence of calculation of ventilation by multiplicity next:

- We consider the volume of each room in the house (volume \u003d height * length * width).

- We calculate the required air exchange for each room using the formula L=n*V.

To do this, select from table 1 the norm by multiplicity

air exchange. For most rooms

only inflow or only exhaust is normalized. For some (eg.

kitchen-dining room) and both. A dash means that no norms have been established for this room.

For those rooms for which instead of the multiplicity

the minimum air exchange is indicated (for example, 90 m3 / h for the kitchen), we consider the required air exchange to be equal to this recommended one. At the very end of the calculation, if the balance equation (∑ Letc and ∑Lyou are t) does not converge, then we will increase the air exchange values for these rooms to the required value.

If there is no room in the table, then the air exchange rate for

we consider it, considering that for residential premises, the norms regulate

supply 3 m3/hour of fresh air per 1 m2 of the area of the room. Those. we consider the air exchange for such rooms according to the formula: L \u003d Spremises*3.

- We summarize separately L those rooms for which the inflow is normalized

air, and separately L for those rooms for which the hood is standardized.

We get 2 digits: ∑ Letc and ∑Lyou are t - We compose the balance equation ∑ Letc = ∑ Lyou are t.

If ∑Letc > ∑Lyou are t , then to increase ∑ Lyou are t up to ∑ Letc

increase the air exchange values for those rooms for which we in 2

point, the air exchange was taken equal to the minimum allowable value.

Emergency ventilation

Emergency ventilation systems must be installed in rooms with industries of category B4, as well as in those where a significant amount of harmful or explosive gases or vapors can suddenly enter the air.

The operation of emergency ventilation systems for warehouse buildings of categories A, B, C1, C2, C3 and C4 should be carried out using two or more ventilation units. If emergency ventilation is integrated with the main ventilation system, it is required to ensure its operation in forced mode with maximum flow in order to quickly eliminate the consequences of fire or pollution.

Food warehouse ventilation

Grocery warehouses can be conditionally divided into several subtypes:

- dry bulk products;

- fruits and vegetables;

- canned food (groceries).

The main parameters for food storage are temperature and humidity. It should not be higher than plus 15 ° C, or maintained at the level required by storage conditions. This means that the project for heating and ventilation of these warehouses is carried out in accordance with the terms of reference.

If bulk products are stored in the warehouse, then, in order to reduce its temperature and equalize humidity, then the conditions are regulated by the Order of the city of N 185 on the approval of instructions for storing grain, seeds, flour, cereals; storage conditions are also regulated by other standards, in accordance with which project documentation will be executed.

For example, if the humidity of rice reaches 13%, and the relative humidity of the outside air is 55%, then further drying of the cereal is prohibited. If you continue drying, the output will be rice with cracks.

Fruits and vegetables should be stored at 1-2°C. In large quantities, they release a lot of moisture. Therefore, when designing a ventilation system, these conditions must be provided for (for a vegetable store), as well as all the conditions for storing vegetables, are prescribed in the Terms of Reference for the design.

What are the legal requirements for storage facilities?

For all areas used for the reception, placement and release of raw materials and goods, special rules apply. The requirements for storage facilities ensure the safety of objects, and are also aimed at protecting the health and life of the enterprise's personnel and their property.First of all, the areas under consideration are subject to norms, the implementation of which prevents the occurrence of fire. Fire safety requirements for warehouses provide for special measures, in accordance with which instructions are developed for each object. Each employee, when enrolled in the state or when transferring from one unit to another, must familiarize himself with them against signature.

Storage requirements

The warehouse must be solid, dry, clean, well ventilated, free of foreign odors. Relative humidity in the room should be 60% ±10%, optimum temperature: +18ºС ±5ºС, minimum temperature: +8ºС. In warehouses in an accessible place, properly functioning and kept clean psychrometers (psychrometric hygrometers) must be installed. Instrument readings should be recorded daily in appropriate temperature and relative humidity logs.

Sharp fluctuations in the relative humidity of the air in the room are not allowed. Maintaining the required temperature and humidity in the warehouse is ensured by changing the intensity of air exchange by the ventilation system or airing, regulating the operation of heating devices.

The safety and shelf life of goods and products stored in a warehouse is largely ensured by selecting the right temperature, air mobility and relative humidity.

Requirements for cargo storage conditions are divided into 4

- Protection of products and materials from atmospheric precipitation and low or high temperatures: precision instruments, electrical materials, certain steel grades, rolled non-ferrous metals. As well as protection against a sharp temperature drop, storage in cooled and insulated heated warehouses.

- Protection of goods from low temperatures and atmospheric precipitation: tin, paints and varnishes, measuring instruments, cable products, tools. And their storage in heated insulated warehouses.

- Protection of materials from high temperatures and precipitation: rubber, roofing felts, roofing material, leather. And storage under refrigerated conditions in insulated warehouses.

- Protection from precipitation. Storage under a canopy in uninsulated warehouses.

To create the necessary climatic conditions, heating, air conditioning and ventilation systems are used. And in unheated warehouses - a ventilation system. Warehouse ventilation is a set of systems and devices that serve for organizing air exchange. The purpose of ventilation is to provide the necessary climatic conditions and clean air in a room that meets sanitary, hygienic and technological standards.

Operating pressure and duct cross section

Schematic diagram of the operation of the air heater.

Calculation of ventilation involves the mandatory determination of such parameters as operating pressure and cross-section of air ducts. An efficient and complete system includes air distributors, air ducts and fittings. When determining the working pressure, the following indicators must be taken into account:

- The shape of the ventilation pipes and their cross section.

- Fan settings.

- The number of transitions.

The calculation of a suitable diameter can be performed using the following ratios:

- For a residential building, a pipe with a cross-sectional area of 5.4 cm² will be enough for 1 m of space.

- For private garages - a pipe with a cross section of 17.6 cm² per 1 m² of area.

Such a parameter as the speed of the air flow is directly related to the cross section of the pipe: in most cases, the speed is selected in the range of 2.4-4.2 m / s.

Thus, when calculating ventilation, whether it is an exhaust, supply or supply and exhaust system, a number of important parameters must be taken into account. The efficiency of the entire system depends on the correctness of this stage, so be careful and patient. If desired, you can additionally determine the power consumption for the operation of the system being arranged.

About air exchange

Air exchange is the process of replacing exhausted (polluted, heated) air with clean air to create an optimal microclimate in a warehouse. Distinguish natural and artificial air exchange.

Natural air exchange is carried out due to the pressure difference inside and outside the air - without the use of special equipment. It is carried out by natural ventilation (through windows, vents) - aeration, as well as due to the movement of air flows through cracks and pores in walls, windows, doors and roofs - infiltration.

Artificial air exchange is carried out under the influence of special equipment combined into ventilation and air conditioning systems.

The air exchange rate is an indicator that determines how many times per hour it is necessary to completely replace all the air in the room in order to achieve acceptable parameters of sanitary and hygienic standards in terms of air pollution (MAC).

The air exchange rate N is determined by the formula: N \u003d V / W times per 1 hour, where:

- V (m3 / h) - the required amount of clean air entering the room for 1 hour;

- W (m3) - the volume of the room.

Air curtains

When calculating the curtain for a warehouse building, it is necessary to take into account the type of gate, the intensity of their operation, the presence of vehicles in the openings and other factors. Air curtains are installed indoors, on the side of each side of the opening to be opened

The air temperature from the air curtains should not exceed +70°C.

The air outlet velocity of air and thermal air curtains must be checked geometrically for opening occlusion or jet range, but must not exceed 25 m/s. If the dimensions of the vehicles are of different sizes, it is required to use fan trays with guiding devices. Such a device of the system will allow you to quickly turn on the required number of air-thermal curtains located at the height of the gate, depending on the height of the car.

Warehouse ventilation for alcohol-containing and chemical products

Ventilation of a warehouse of alcoholic beverages and chemicals has a number of features. Mandatory conditions:

- the presence of a supply and exhaust system of a mechanical type;

- maintaining a specific temperature level at a constant level in accordance with the requirements for a particular type of alcohol.

Detailed parameters for the storage regimes of alcoholic products are established by the relevant regulatory authorities - the Federal Service for Regulation of the Alcohol Market of the Russian Federation.

The ventilation project of a warehouse for the storage of alcohol-containing products must necessarily take into account the indicators of the air exchange rate. The following requirements for multiplicity (unit of time - 60 minutes) apply to warehouses for storing various substances:

- Gasoline, kerosene, oils: multiplicity 1.5-2 (temporary stay of people) / 3-5 (permanent stay of people).

- Liquefied gas in cylinders: 0.5.

- Solvents: 4-5/10.

- Alcohols, esters: 1.5-2 / 3-5.

- Poisonous substances: 5.

Warehouse ventilation scheme

Building regulations

- Code of rules SP 60.13330.2016 "SNiP 41-01-2003. Heating, ventilation and air conditioning” - this set of rules establishes design standards and applies to systems of internal heat supply, heating, ventilation and air conditioning in the premises of buildings and structures.

- Code of Rules SP 113.13330 SNiP 21-02-99 "Car Parking" - this set of rules applies to the design of buildings, structures, sites and premises intended for parking (storage) of cars, minibuses and other motor vehicles.

- VSN 01-89 "Departmental construction standards for car maintenance enterprises" - designed to develop projects for the construction of new, reconstruction, expansion and technical re-equipment of existing enterprises. (lost power)

- Code of rules SP 56.13330.2011 "SNiP 31-03-2001. Industrial buildings” – this set of rules must be observed at all stages of the creation and operation of industrial and laboratory buildings, workshops, warehouse buildings and premises.

- Code of rules SP 54.13330.2016 "SNiP 31-01-2003.Residential multi-apartment buildings" - this set of rules applies to the design and construction of newly built and reconstructed multi-apartment residential buildings.

- Code of rules SP 118.13330.2012 "SNiP 31-06-2009. Public buildings and structures” - this set of rules applies to the design of new, reconstructed and overhauled public buildings.

- Code of rules SP 131.13330.2012 “SNiP 23-01-99. Building climatology" - this set of rules establishes the climatic parameters that are used in the design of buildings and structures, heating, ventilation, air conditioning systems.

- "SNiP 2-04-05-91. Heating, ventilation and air conditioning" - these building codes should be observed when designing heating, ventilation and air conditioning in the premises of buildings and structures.

- SN 512-78 "Instructions for the use of buildings and premises for electronic computers" - the requirements of this instruction must be met when designing new and reconstructed buildings and premises for the placement of electronic computers.

- ONTP 01-91 "All-Union norms for the technological design of road transport enterprises" - should be observed when developing technological solutions for projects for the construction of new, reconstruction, expansion and technical re-equipment of existing enterprises, buildings and structures intended for organizing inter-shift storage, maintenance (TO) and current repair (TR) of the rolling stock.

- "SNiP 31-04-2001.Warehouse buildings" - must be observed at all stages of the creation and operation of warehouse buildings and premises intended for the storage of substances, materials, products and raw materials.

- Code of Practice SP 7.13130.2013 “Heating, ventilation and air conditioning. Fire safety requirements. - used in the design and installation of heating, ventilation and air conditioning systems, smoke ventilation.

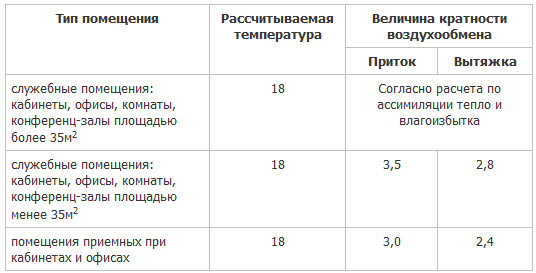

- "SNiP 31-05-2003. Public Buildings for Administrative Purposes” contains norms and rules for a group of buildings and premises that have a number of common functional and space-planning features and are intended primarily for mental work and non-productive areas of activity.

- Code of rules SP 252.1325800.2016 “Buildings of preschool educational organizations. Design Rules" - this set of rules applies to the design of newly built and reconstructed buildings of preschool educational organizations.

- Code of rules SP 51.13330.2011 "SNiP 23-03-2003. Noise protection” - this set of rules establishes the norms of permissible noise in the territories and premises of buildings for various purposes.

What qualities should the selected system have?

When designing an installation, several important issues need to be addressed, in particular, protection from precipitation, ease of assembly and ease of further operation.

It is very important to carry out the calculation of ventilation sequentially, that is, first determine the volume of incoming air mass required for the operation of the warehouse

It is from these values that you need to build on when choosing the throughput of the installation.During the calculation, it is necessary to test the warehouse for the level of air humidity, temperature and saturation with harmful gases.

Sometimes it is not possible to achieve a balance between inflow and air intake, and then it is necessary to make a choice in favor of inflow - air intake should always remain a priority. Additional tools, such as fans, will help restore this balance.

Regulatory documents and calculation of air circulation

The frequency of air exchange in the building is regulated by STO, SNiPs and safety rules applicable to a particular enterprise. Requirements for hygiene and sanitation in production premises are regulated by SanPiN 2.2.4.548-96.

Guidelines for the calculation of air circulation.

Air mass exchange is calculated as follows:

where L is the volume of incoming air m³/h;

n is a number indicating the multiplicity of air exchange;

S is the area of the object, m²;

H is the height of the object, m.

Natural ventilation conditions increase the quantitative number of the multiplicity index up to 3-4 times per hour. In order to increase this parameter, mechanical ventilation is used.

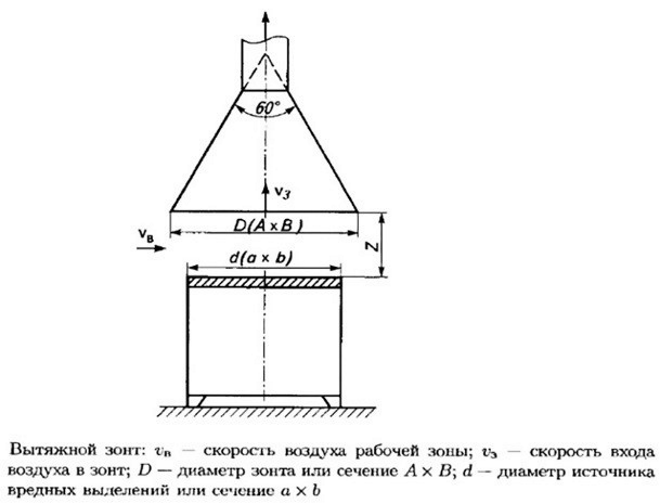

Design parameters of exhaust ventilation of production premises are determined by the following formula:

A=a+0.8z, B=b+0.8z

In case of round slopes D=d+0.8z

where a×b are the dimensions of the release source, d is the diameter.

Ʋv - the speed of air movement where it is released;

Ʋz - suction speed in the umbrella area;

z is the installation height.

Production shops

Workplaces in workshops are often exposed to thermal energy and harmful substances. Air exchange rates for production shops are determined by SNiP 41-01-2003.

Design values of shop ventilation are calculated as follows:

where L- air consumption, m³;

V is the speed of the air flow in the device, m/s;

S- area determined by the opening of the installed hood, m².

The values of air circulation in production rooms depend on:

- area and shape of the workshop;

- the number of personnel;

- intensity of physical activity of people;

- production technologies;

- heat losses of equipment;

- high humidity in the workshop.

Emissions of dust and harmful substances

Depending on the direction of work carried out by production shops, harmful emissions are in the form of chemical vapors, mechanical dust, and thermal emissions.

Exhaust devices can have different power and operation scheme. In the event of an accident and a sudden release of an increased amount of poisonous vapors and gases, additional ventilation with an exhaust must be installed in the production premises, providing an exchange that exceeds the general ventilation by ten times.

The activation of ventilation equipment installed in case of an accident should be carried out both outside and inside the building, and in a short period of time reduce the concentration of toxic gases and remove hazardous waste in the form of steam at work sites.

Ventilation of warehouse complexes

Ventilation provision of warehouses ensures the safety of products stored there from the effects of harmful factors. In the premises of warehouse complexes there are emissions of dust and heat. If hazardous substances are stored there, harmful gas emissions may be present.

Ventilation rates for premises where warehouses are located are regulated by SP 60.13330.2012 “SNiP 41-01-2003. Heating, ventilation and air conditioning.

Exhaust structures are mounted in the dirtiest places in warehouse buildings.

The air exchange rate is determined as follows:

where A (m³ / h) is the air volume released in the warehouse for one hour;

V(m³) - storage space volume

Calculate the heat consumption

Excess heat (kJ/h) removed from the warehouse is calculated using the following formula:

where Q_n is the thermal energy released into the room from the equipment and working people, kJ / h;

Qsp. – release of heat into the environment, kJ/h.

Given the available heat surpluses, the calculation of the quantitative parameter of air (in m³ / h) required for removal in 1 hour is calculated by the formula:

where C is the heat capacity of air masses, C=1, kJ/kg;

ΔT is the difference between the temperature values of the incoming and outgoing air, K;

γpr – supply air density, γpr=1.29 kg/m³.

In the presence of hazardous gases or dust, the calculation of L is made separately for each case.

The calculated value of the multiplicity for heat releases is calculated as follows:

Excess water vapor

Air masses containing a high concentration of water vapor adversely affect the human condition. The relative humidity index, which ensures a comfortable stay of a person in the room, is 40-60%.

Excess water vapor is removed by installing additional slotted suction. They are able to remove air saturated with water vapor in a volume of 300-500 m³ / h.

What are the requirements for ventilation systems in standard warehouses?

Most of all groups of goods can be stored under approximately the same conditions.Such conditions include dryness and cleanliness of the room, a good exhaust hood, the absence of extraneous odors, moderate humidity (50-70%) and storage temperature (from + 5C to + 18C).

For the appropriate humidity level and temperature are monitored by responsible employees from the technical control department (OTC). Thermometers and hygrometers are installed in each room, the readings of which are read and entered into the appropriate databases every day. This allows you to timely identify temperature anomalies and unacceptable fluctuations and stabilize them, thereby avoiding possible accidental consequences.

In addition to providing the necessary storage conditions for goods, the ventilation system must use energy economically, which is officially confirmed by the “Decree on Thermal Protection of Buildings”. According to this requirement, all air exchange systems in warehouses are designed - first of all, this applies only to buildings under construction, as well as buildings with increased dust and humidity.

This is due to the functional purpose of the air conditioning system - ensuring the purity of the air in the working room, cleaning it from dust suspensions and excess moisture, which can adversely affect both the operation of working equipment and the health of personnel. Also, air conditioning will help to significantly increase the life of the building itself, as it will prevent the accumulation of moisture in its walls, which means possible corrosion and deformation.