- SNIP ventilation of industrial premises

- Gas supply of an apartment building

- Ventilation in rooms with gas equipment

- Exhaust ventilation device

- Supply recirculation system

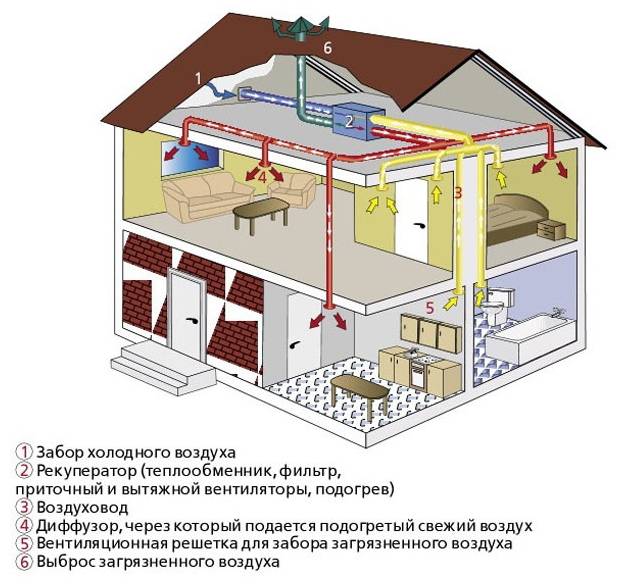

- Supply and exhaust recirculation system

- Why equip a separate boiler room at home?

- Fire hazard of industrial premises

- SNIP norms for residential premises

- Safety regulations

- What are clean rooms?

- 11.3 Notes on the calculation example

- In what cases is the organization of ventilation chambers required?

- 5.3 Ventilated ceilings

- 6 Mechanical filters

- Requirements for ventilation equipment

- Building regulations

- Air exchange requirements

- Conclusions and useful video on the topic

SNIP ventilation of industrial premises

It has the following varieties:

- The process of removing dust and gases from the working area, which are an integral factor in the operation of the equipment, is called aspiration.

- For stable and full filling of the room with air, as well as the complete removal of polluted air masses, a supply and exhaust ventilation system is used.

- The process of removing smoke emissions in case of fire or melting of equipment and / or its individual parts will help to avoid carbon monoxide poisoning of employees and specialists.This process is called smoke removal.

- Cleanliness of air masses in all used premises should be ensured.

As for technological equipment and means of forced ventilation, they are different for each working area. But the main criterion for ensuring the rules of SNIP is to prevent repeated recirculation of air masses between rooms, i.e. each room must be equipped with air inflow and outflow systems, it must not flow sequentially from one room to another, because the air mass may contain gaseous products.

They can cause fires or explosions, and can significantly increase the temperature or humidity in a room.

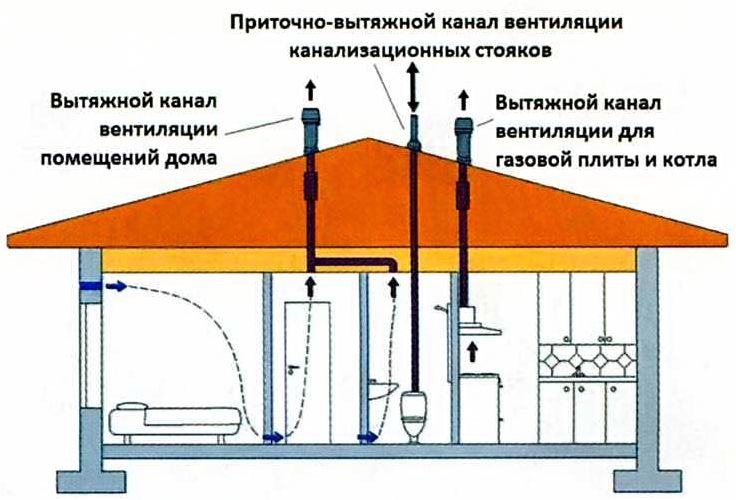

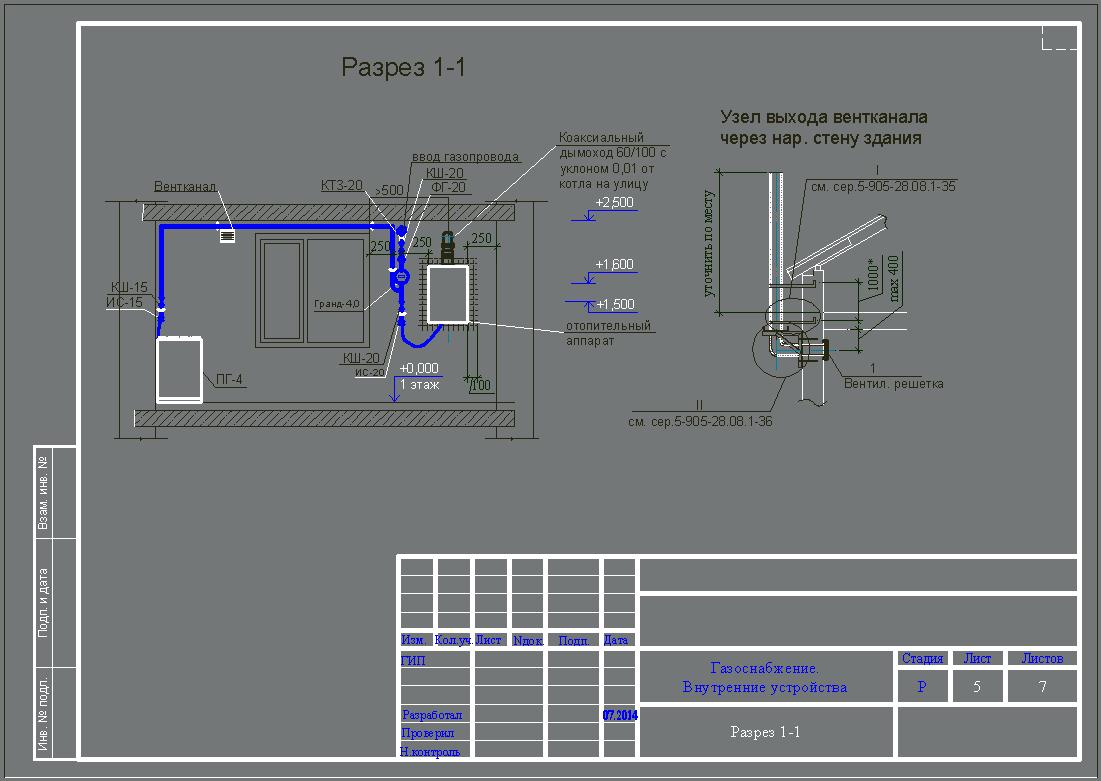

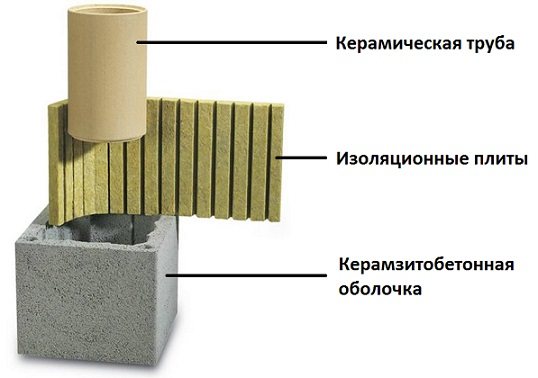

Gas supply of an apartment building

When moving it into the house, a number of safety requirements must be met. These include the following:

- the presence of independent, isolated premises;

- good ventilation with exhaust in hallways with high ceilings that are fire resistant;

- non-explosive device designed to inject natural gas.

Note

Served in residential liquefied gas at home with odorants has many advantages. It is cheap, burns to the end, is characterized by a high temperature during combustion, as well as a large calorific value. However, when mixed with air, it creates a mixture that can explode.

Due to the fact that the gas is twice as heavy as air, if there is a leak, it fills the basement and is able to travel considerable distances. Even a small leak in an apartment can cause death by asphyxiation or cause a fire.

Ventilation in rooms with gas equipment

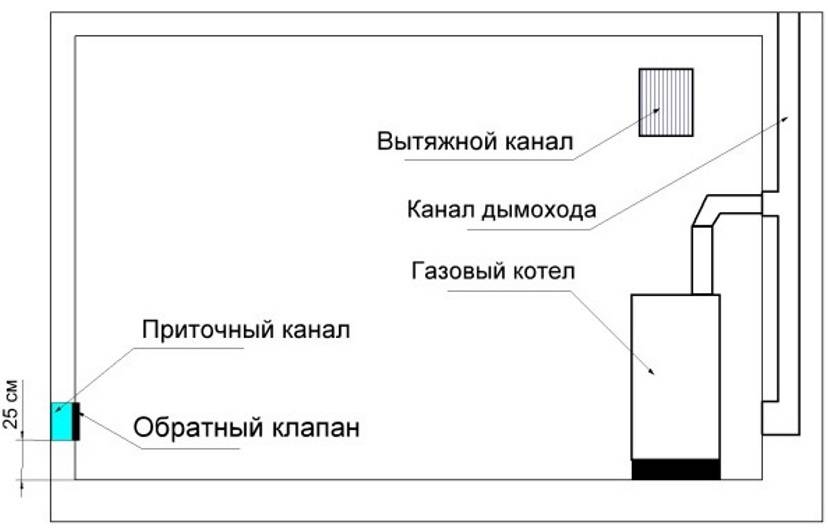

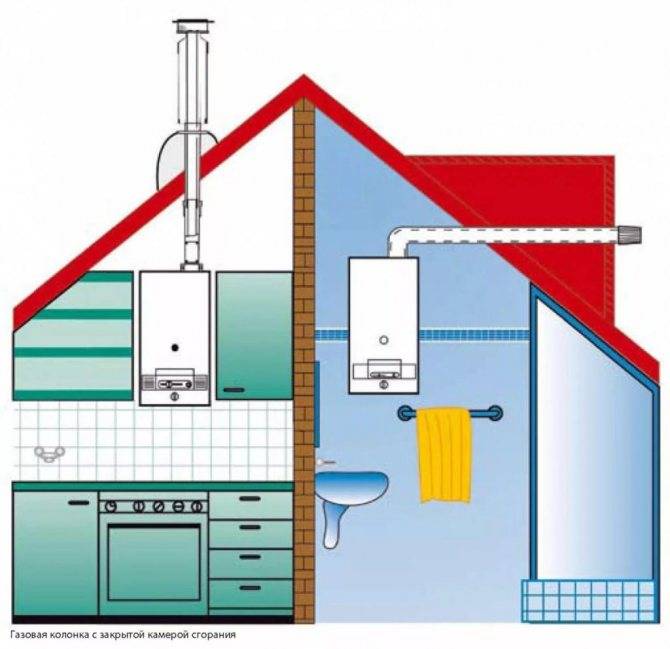

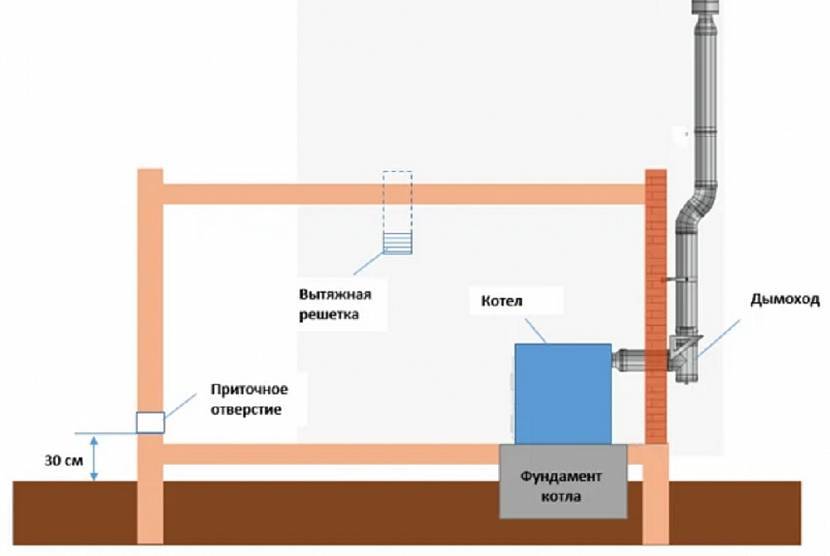

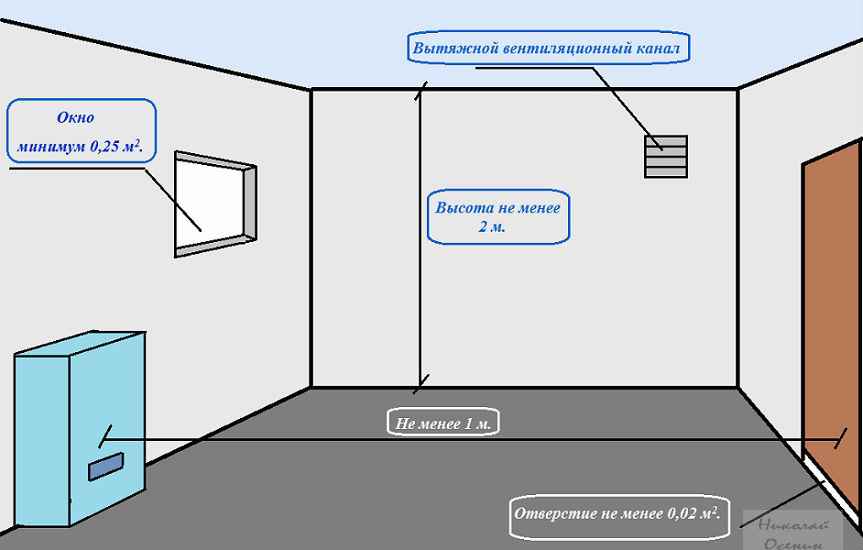

Designing a ventilation system designed for small-sized domestic premises with a boiler or gas stove will not cause difficulties. You can deal with it on your own.

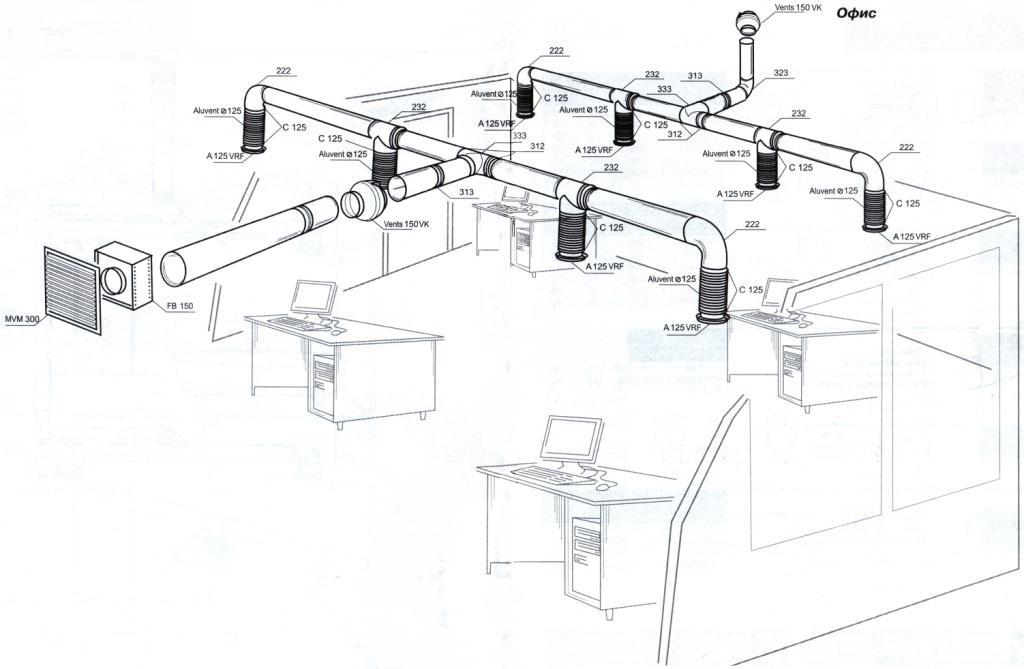

Exhaust ventilation device

Exhaust ventilation action aimed at removing polluted air from the room.

For its installation, the following components are required: a fan, an air duct, a ventilation grill.

In summer, the efficiency of the exhaust ventilation system decreases. Its productivity can be increased by means of additional gaps in the doorways and opening the vents for ventilation.

In summer, the efficiency of the exhaust ventilation system decreases. Its productivity can be increased by means of additional gaps in the doorways and opening the vents for ventilation.

When choosing a fan, it is recommended to give preference to devices with a check valve. It will secure from entering the premises air from outside.

Air ducts are a pipe made of PVC or other materials. Its diameter should match the size of the fan.

When choosing a ventilation grill, you should pay attention that now there are many models on sale that differ in size, performance, design. Therefore, it is easy to choose the option that is ideal for the style of the room.

Supply recirculation system

Supply equipment provides fresh oxygen supply to the room with gas-using devices. The main element of such a system is the supply unit.

Its function is to supply oxygen from outside. At the time of passing through it, the air is filtered, heated or cooled if the device is additionally equipped with a heat exchanger.

For domestic use, low-power installations are suitable. The main advantage of this type of ventilation is noiselessness and comfort in operation. The simplest instance is a supply fan.

The performance of the supply ventilation system directly depends on the correctness of the calculations, the technical characteristics of the equipment and the design features of the room

The performance of the supply ventilation system directly depends on the correctness of the calculations, the technical characteristics of the equipment and the design features of the room

Inflows are divided into the following categories:

- Electrical device for ventilation. Provides not only filtration of incoming oxygen, but also its heating.

- Wall inlet valve. It can work in automatic mode and have an additional option of oxygen filtration. For installation, you will need to make a through hole in the wall of the building.

- Window inlet valve. It can be either mechanical or automatic. It is installed in the sash of a plastic window. Minus - the likelihood of icing at extremely low temperatures.

All listed types of supply ventilation are easy to assemble and operate. You can install the structure yourself.

Additional requirements regarding the supply system are put forward for rooms equipped with plastic windows that close hermetically.

The required extractor power is calculated using the following formula:

M \u003d O x 10, where

O is the volume of air, which is calculated as follows:

O = H x L x S.

H is the height of the room, L is the length, S is the width.

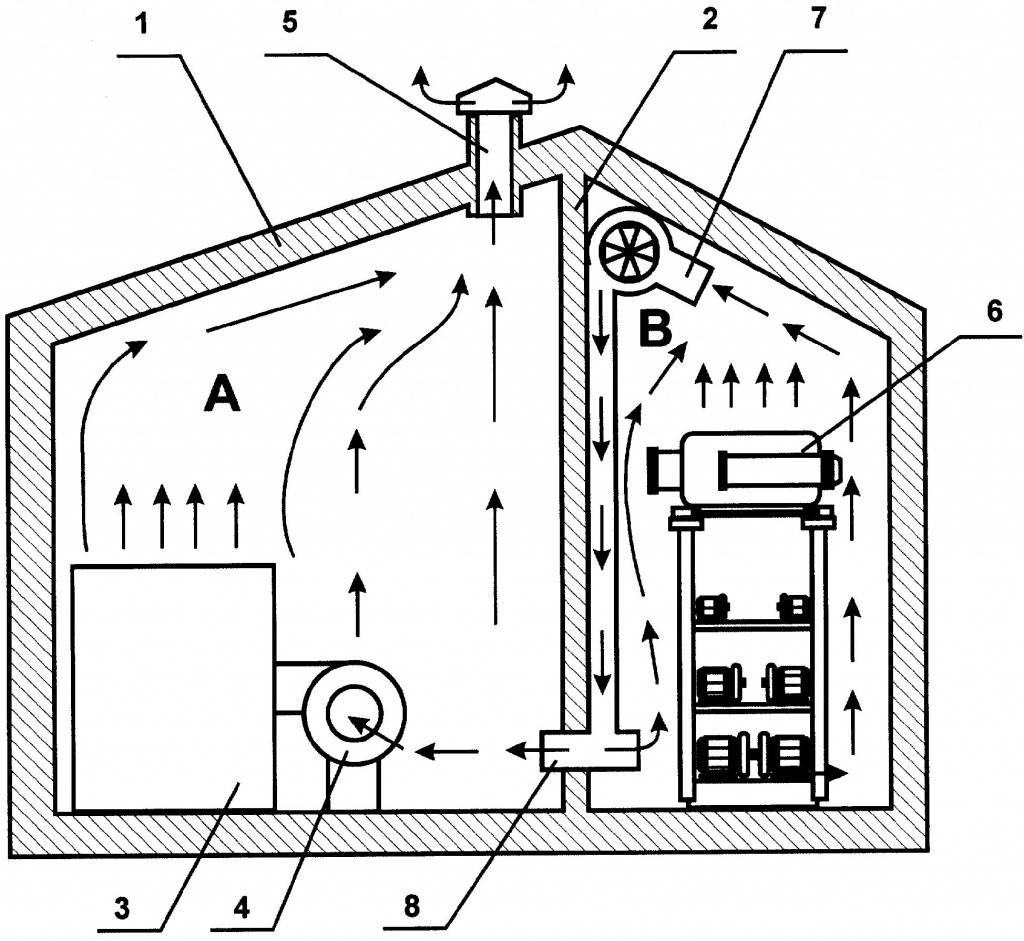

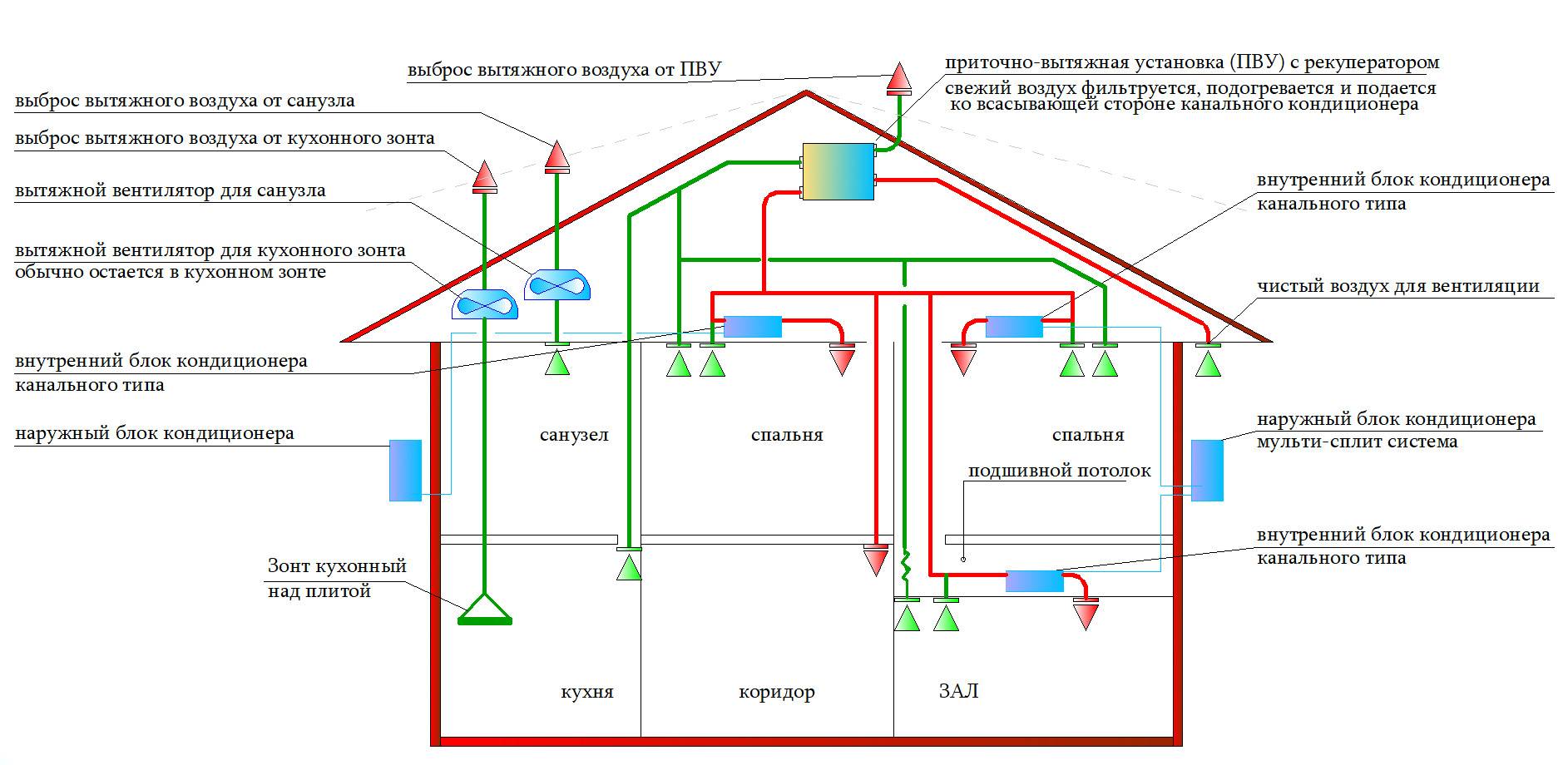

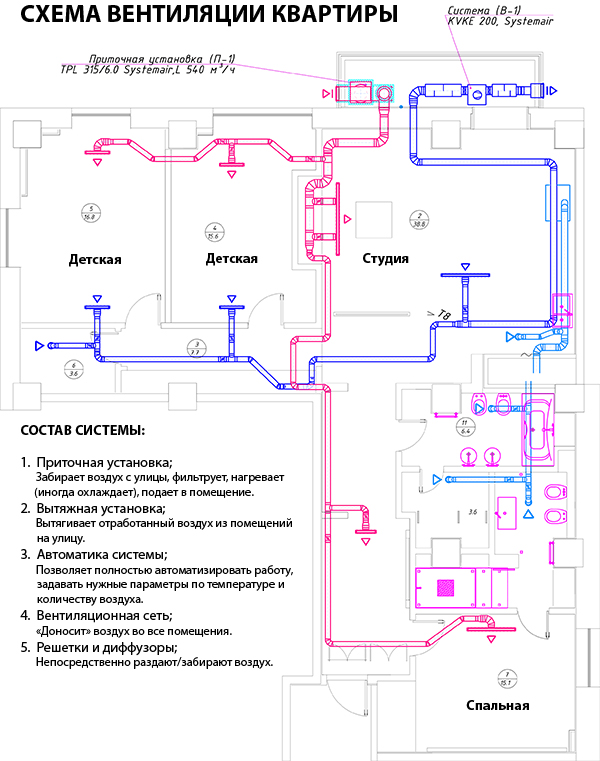

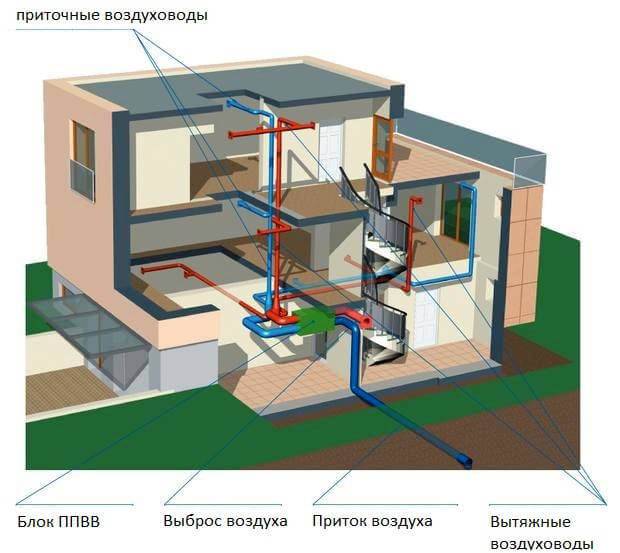

Supply and exhaust recirculation system

The mixed ventilation system ensures the simultaneous outflow of exhaust oxygen and the supply of fresh oxygen into the room. It is most often used in large-sized objects and houses, the total area of which exceeds 100 m2.

Units equipped with a recuperator will reduce fuel consumption by up to 90% due to the heating of the incoming air flow.

The supply and exhaust ventilation system is the most rational type that provides the right microclimate in the premises.Exhaust air must be removed through amenity rooms

For ease of installation, combined systems can have a vertical, horizontal or universal orientation. Installation is carried out after the completion of the plastering and puttying of the walls, but before the installation of the ceiling, since the entire infrastructure will be hidden under it.

As a rule, in supply and exhaust system includes the following components: air intake damper, cleaning air filter, heater, heat exchanger, cooling unit, external grille.

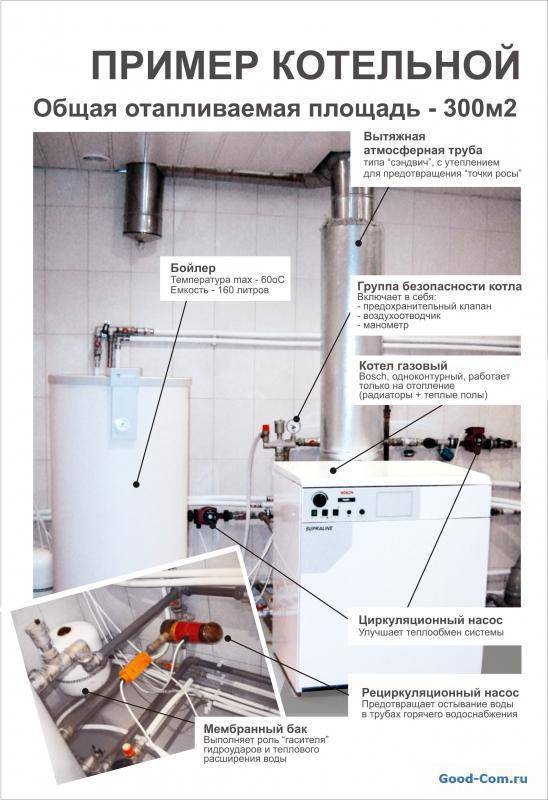

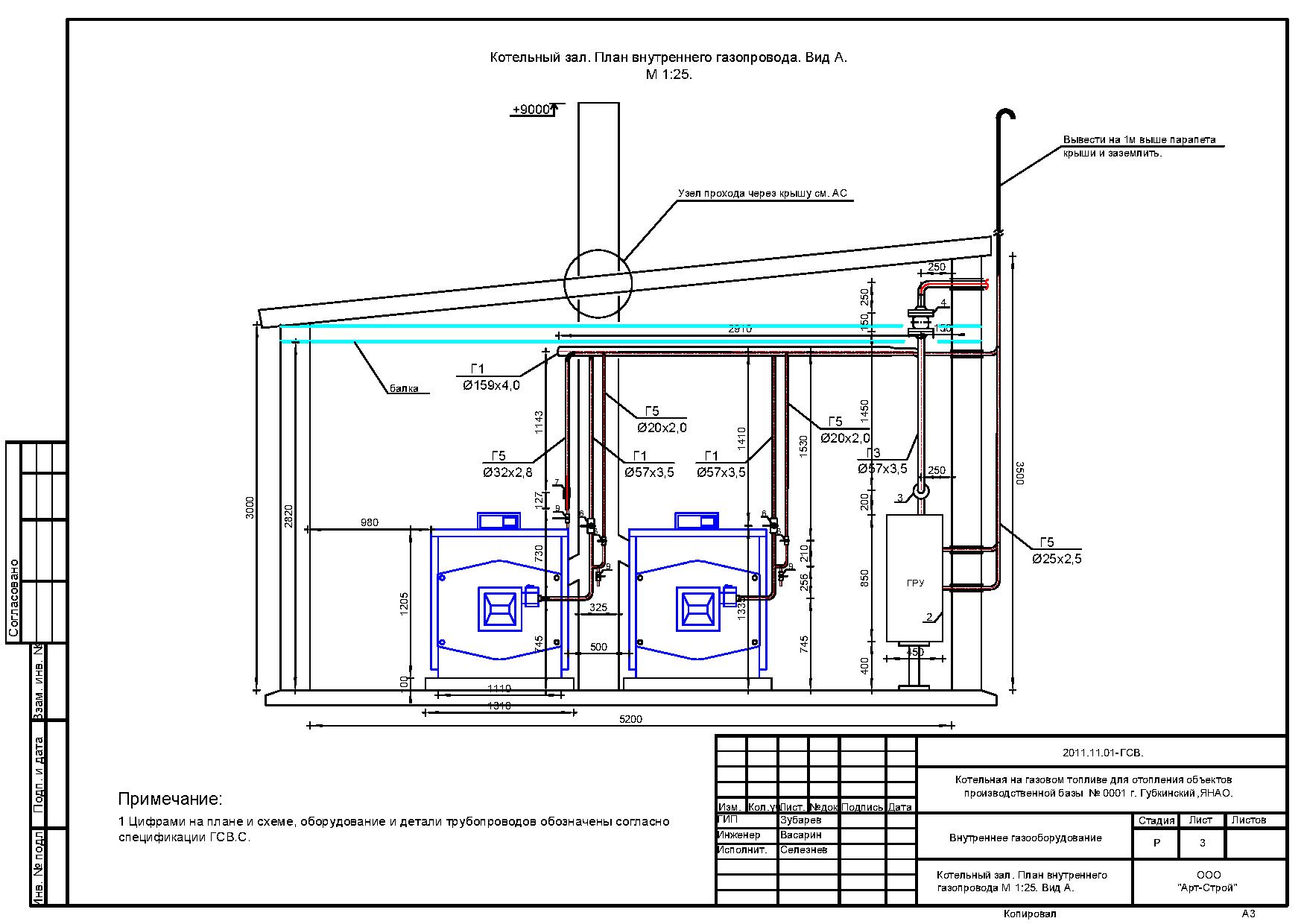

Why equip a separate boiler room at home?

When arranging the heating system, the owner of the house faces a choice where the gas-using equipment will be located.

The decision may be due to aesthetic and design considerations, the issue of security (in the presence of disabled persons at home, as well as children). But in addition, this may be dictated by the current standards for equipment power.

The decision may be due to aesthetic and design considerations, the issue of security (in the presence of disabled persons at home, as well as children). But in addition, this may be dictated by the current standards for equipment power.

Consider the types of location of boiler rooms.

Boilers can be located:

- inside the house - usually provided for even at the stage of building a house, since in the built one there may not be a free room that is suitable in terms of parameters;

- on a separate foundation as an extension, along a blank wall and observing a distance from the nearest door and window of 1 meter without a major connection to a residential building;

- detached - located at some distance from the main house.

The regulations determine that if the power of gas-using equipment does not exceed 60 kW, it can be placed in the kitchen (except for the kitchen niche), in the kitchen-dining room, and in other non-residential premises, except for bathrooms and bathrooms.

The minimum volume of furnace for 30 kW of power is at least 7.5 cubic meters. m. From 60 to 150 kW require the arrangement of a separate room. The minimum volume of the room is 13.5 cubic meters. m. From 150 to 350 kW. Minimum room volume - from 15 cubic meters. m.

A freestanding gas boiler room must be designed before construction or installation. Follow all the rules for its arrangement, otherwise, the location of gas-using equipment in it will not be approved

A freestanding gas boiler room must be designed before construction or installation. Follow all the rules for its arrangement, otherwise, the location of gas-using equipment in it will not be approved

We are talking about individual boiler houses, that is, with equipment power from 60 to 350 kW.

Fire hazard of industrial premises

We sorted out the premises of single-family and multi-apartment buildings. Now let's talk about heat generators for industrial and storage purposes. According to Federal Law No. 123 TR on fire safety requirements.

The designation helps to determine what and in what cases is necessary to ensure the safety of people and their property in buildings in the event of an emergency. For example, equipping a building with a fire alarm, fire extinguishing system, degree of fire resistance of finishing materials, type of emergency evacuation, and so on.

The designation helps to determine what and in what cases is necessary to ensure the safety of people and their property in buildings in the event of an emergency. For example, equipping a building with a fire alarm, fire extinguishing system, degree of fire resistance of finishing materials, type of emergency evacuation, and so on.

To determine the degree of explosion / fire hazard of an object, use the division into classes and categories.

According to PP No. 390, a gas boiler house is classified as a hazardous production facility and belongs to category F5. According to the regulations, premises of this type are normalized to the category of fire hazard from the most dangerous under the letter A, to the least, denoted by the letter D:

- Increased fire/explosion hazard is A.

- Explosion and fire hazard B.

- Fire hazard belongs to category B - from B1 to B4.

- Moderate fire hazard - under the letter G.

- For a reduced fire hazard, to which it is difficult to attribute such a gas installation, the symbol is D.

As a rule, it is difficult to coordinate the arrangement of a gas facility with the D-subclass, so we will consider boiler houses from A to D.

It is not so easy to take and define a specific subclass. To do this, it is necessary to carry out the necessary studies and calculations with the help of specialists with experience in designing gas-using heat generators.

It is not so easy to take and define a specific subclass. To do this, it is necessary to carry out the necessary studies and calculations with the help of specialists with experience in designing gas-using heat generators.

The subclass should be calculated based on:

- The type of fuel used.

- According to the degree of fire resistance (I, II, III, IV and V).

- The equipment that is installed in the room.

- Design features of the boiler house itself (hazard class according to the design of the gas boiler house C0, C1, C2 and C3). Defined by Article 87 of the Federal Law No. 123.

- Characteristics of ongoing processes.

The subclass is also conditionally determined on the basis of SP 12.13130.2009, NPB 105-03, SP 89.13330.2011, Federal Law No. 123. In principle, it is not necessary to determine which hazard class a particular gas boiler room belongs to, if the task is simply to determine whether it is a hazardous production facility.

The boiler room, in any case, is a gas consumption network. OPO is determined by the following features:

- The presence of boilers under excess pressure or temperature indicators of the working environment over 115 degrees.

- If the gas boiler house contains gas pipelines with a pressure of 0.005 MPa or more.

- The boiler house is a centralized system or installation serving socially significant segments of the population.

The class of fire hazard according to all signs is determined by specialists-designers.

SNIP norms for residential premises

In the process of carrying out the life of people in residential areas, an increase in the volume of carbon dioxide is observed, the air temperature rises and humidity increases. Unpleasant odors are also often felt, which are caused by dust settling on various elements of the living quarters.

In this case, it is necessary that the entire air volume, which contains harmful substances, be fully removed from the room and replaced with fresh air. So the requirement for ventilation for residential premises involves the following parameters:

- The percentage of carbon dioxide in the room air should be between 0.07 and 0.1%.

- In a dwelling, 30-40 cubic meters of fresh air per hour should be supplied per adult, and from 12 to 30 cubic meters per child.

- Temperature jumps are not allowed in the room, so the deviation from the normal value should not be more than 3-5%.

- Humidity also needs to be within normal limits. However, its values differ for all rooms in a residential building.

Safety regulations

In any construction, it is necessary to follow the established standards. It is thanks to compliance with these standards that people gain confidence in the safety of their home or their stay at industrial facilities. For example, the gas supply rules give instructions on where to lay the pipeline to the houses, its distance from the ground or underground.

The rules must be followed when installing gas equipment, as well as operating the facility. Gas supply will be laid in residential buildings only when building standards are met during their construction.

All components must meet certain requirements.For example, steel pipes installed indoors must be different from those installed outside the home. Rubber or rubber-fabric hoses may be used if they are sufficiently resistant to the passing gas. The pipes are connected by welding. A threaded connection can also be used, but then a shut-off valve is mounted.

To ensure the safety of gas supply, special rules have been developed for the design, construction and operation of supply systems, as well as the production and use of equipment. According to them, the requirements are set:

What are clean rooms?

The definition of a clean room implies a room of a certain area in which, with the help of special equipment, the concentration of aerosol particles (dust, chemical vapors, microorganisms) in the air is maintained within specified limits.

In such a room, the amount of polluting particles on the surface of the walls, ceiling and in the air should be kept to a minimum.

Cleanrooms are used in microelectronics, space technology, thin-film manufacturing, printed circuit production - wherever the elimination of contaminants is necessary.

Cleanrooms are used in microelectronics, space technology, thin-film manufacturing, printed circuit production - wherever the elimination of contaminants is necessary.

These special rooms are equipped with the following components:

- antistatic floor;

- transfer window openings;

- transitional gateways;

- blind construction with wall panels;

- ceilings with recessed lighting.

The extremely clean atmosphere in such rooms can be achieved in one way - the displacement of existing air masses and the influx of fresh filtered conditioned air.

Clean rooms are necessary for such areas of human activity as medicine, pharmaceuticals, the manufacture of various electronic devices and food production.

11.3 Notes on the calculation example

11.3.1 If there is a common umbrella

above the line of kitchen equipment, kitchen emissions and air flow through

the umbrella should be determined separately for each unit according to the formula (4), then

summarize.

11.3.2 At a given volume

air flow from the hall to the hot shop, check the speed in the dispensing

opening, which should be about 0.2-0.3 m / s.

11.3.3 When choosing a calculated

air temperature in summer tn should be taken into account that in a dense city

building, the air temperature at the air intake of the supply ventilation

installation can be 5 °С-10 °С above tn

In what cases is the organization of ventilation chambers required?

Central ventilation equipment is known to emit noise and vibration during operation, and therefore it should not be installed in rooms intended for permanent human stay (more than 2 hours in a row). It is behind the false ceiling of technical rooms or in separate rooms specially designed for this purpose (ventilation chambers).

Moreover, the standards determine the value of the maximum performance of ventilation equipment that can be placed behind a false ceiling - 5000 cubic meters per hour (clause 7.9.3 of SP 60.13330.2012). For more powerful installations, ventilation chambers should be provided. The requirements and arrangement of these premises will be discussed below.

5.3 Ventilated ceilings

5.3.1 Ventilated ceiling

performs a role similar to local suction, occupying all or a significant

part of the ceiling surface of the hot shop.

As well as local sucks,

ventilated ceilings serve to contain and remove kitchen secretions. AT

ventilated ceilings can be placed devices for supplying air

air.

5.3.2 By design

ventilated ceilings are divided into two types: open and closed (Figure 3).

Figure 3 - Ventilated ceilings:

a) open

ventilated ceiling with removable filters;

b) open

ventilated ceiling with removable filters and condensate drains;

c) closed

ventilated ceiling with insulated supply and exhaust air ducts;

d) closed ventilated ceiling with exhaust ducts and open

supply air

in ventilated ceilings

closed type exhaust air ducts are connected directly to the airtight

metal exhaust duct with filters.

in ventilated ceilings

open type exhaust duct and ventilated ceiling are not connected

metal box. The walls and ceiling of the hot shop room form

closed volume above a ventilated ceiling. Exhaust duct connected

directly to this volume.

5.3.3 Ventilated ceilings

made of stainless steel or a combination of stainless steel and

aluminum with an oxide or enamel protective coating. directly above

gas kitchen equipment, it is allowed to install ventilated panels

ceilings made only of stainless steel.

5.3.4 Filters installed in

ventilated ceilings, should be easy to clean or be of a removable design for

subsequent cleaning.

5.3.5 Ventilated ceilings

closed type should be installed in all cases if kitchen discharges

contain combustion products of solid fuel or vapors and fat particles. In all

in other cases, it is allowed to install ventilated ceilings as closed,

and open type.

6 Mechanical filters

6.1 Air, removed by local

suckers and ventilated ceilings, must be cleaned of grease particles to

entry into exhaust ducts.

6.2 Design of mechanical

filters must satisfy the conditions set out in 6.2.1 to 6.2.5.

6.2.1 Filters should be

installed at an angle to the horizon from 45° to 90°, so that the kitchen

the secretions accumulated in the filters freely entered the chute to collect fat.

Note - In ventilated ceilings, installation is allowed

filters at an angle to the horizon of less than 45°, if the design of the filter provides

effective removal of fat in the collectors mounted under filters.

6.2.2 Fat construction

filter should prevent the spread of fire from kitchen equipment to

exhaust duct.

6.2.3. The filter must be

easily removable for periodic cleaning or replacement.

Note

— Non-removable filters may be used in ventilated ceilings if they are

the design provides a constant outflow of the collected fat and accumulated in

extraction filter do not change the air resistance of the filter by more than 20

Pa at the calculated air flow.

6.2.4 Dimensions of removable

filters should not exceed 500×500 mm so that they can be washed in

dishwashers.

6.2.5 Installation not allowed

homemade grease filters. Grease filter manufacturers must supply

filters with a passport containing:

- name and address

manufacturer;

- Permits received

documents (certificates) of supervisory authorities operating on the territory of the Russian Federation

Federations;

— overall dimensions and weight of the filter;

- the name of the material from which

filter is made

— air flow range

(minimum, maximum), m3/s;

— aerodynamic resistance of the filter at

minimum and maximum air flow, Pa;

is the filter efficiency

particle retention at minimum and maximum air flow.

Presented in the form of a graph or table - filter efficiency in

depending on the particle size at a given air flow and resistance

air;

- Grease filter efficiency

in the particle size range from 5 to 7 microns should be at least 40% at

calculated air flow.

Requirements for ventilation equipment

Service requirements for ventilation chambers are mainly formed by the requirements for maintenance of ventilation equipment, which, in turn, are declared by the manufacturer of this equipment.

Complete ventilation systems consist of various sections - filtration, heating, cooling and others - each of which must be accessed from the service side. Usually this is one of the sides of the ventilation unit. By the way, when ordering a ventilation unit, you should indicate from which side (left or right in the direction of air movement) it will be serviced.

The service area on the side of the ventilation unit is usually equal to the width of this unit plus 200-300 millimeters.The fact is that many sections should be able to be removed from the ventilation unit, and their width almost coincides with the width of the ventilation unit. Therefore, for comfortable extraction of sections, the service area must have a width not less than the width of the ventilation unit. An additional 200-300 millimeters will provide convenience when transferring or turning these sections.

For narrow spaces, some manufacturers of ventilation units offer units with top service. In this case, the free space above the installation should allow one or another section to be pulled up and taken out of the ventilation chamber.

In general, all requirements for the geometry of ventilation chambers can be easily clarified by mentally moving in and out of all sections of ventilation units. This procedure allows you to quickly determine the width and height of the doorway, the width of the passage inside the ventilation chamber, the width and height of other doors and access routes.

Yuri Khomutsky, technical editor of the Climate World magazine

Building regulations

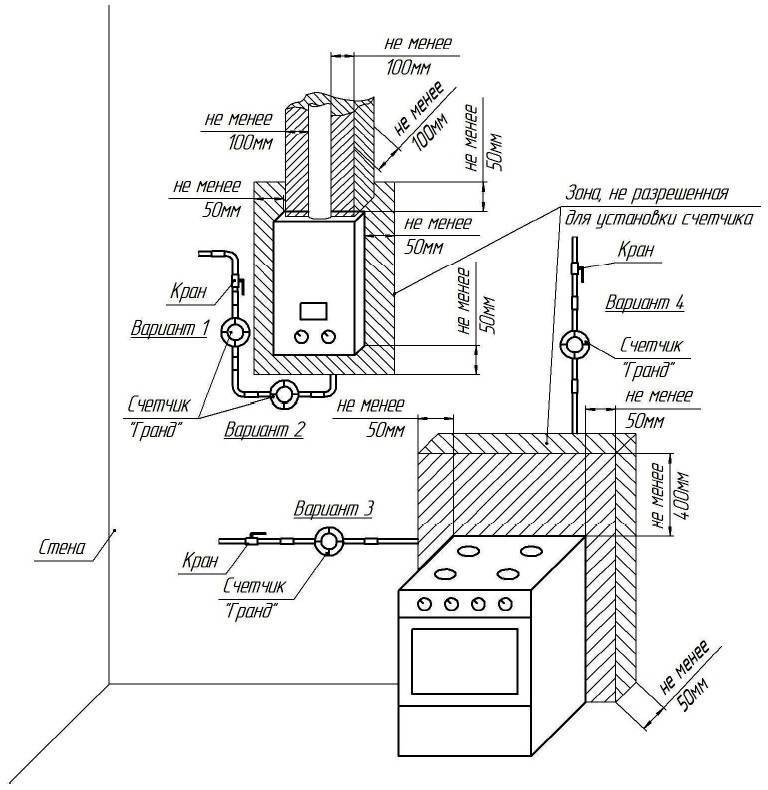

The gas supply must be secure. This is ensured by complying with the established building codes and gas supply rules (in short, SNiP). So, there is a separate document for single-family houses. The requirements are as follows:

- When consuming gas for cooking, it is allowed to use 0.5 cubic meters per day; for hot water, which is produced by a gas heater - the same standard; for heating - from 7 to 12 cubic meters per day.

- The pressure must be applied within 0.003 MPa.

- Gas pipelines located above the ground are allowed to be laid in places where vehicles and people cannot pass. At the same time, the height above ground level is not less than 0.35 meters.

- Inside the house, the pipe is equipped with a device that turns off the gas.

- The distance between the pipes to the gas line must be sufficient to carry out repairs if necessary.

- Storages should be located in the ground at a depth of 60 cm from the surface in places of freezing in winter, and 20 cm - in the absence of freezing.

- Inside the house, the pipes must be open or located near special ventilation, and be covered with shields.

- At the intersections of structures, the gas pipe is placed in a case, and the pipes should not come into contact with it (the gap is 5 cm, it is closed with a special material).

- Devices that turn off the gas are located in front of the meters.

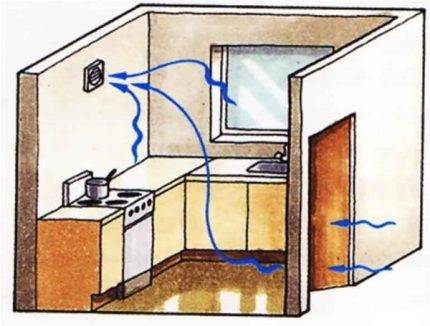

Air exchange requirements

When designing ventilation in kitchens with gas stoves, it is necessary to comply with the requirements of both sanitary and fire safety standards (GOSTs, SNiPs, SanPiNs and SPs). Gas supply to apartments and cottages is an undoubted boon, as it can significantly reduce utility costs. But there are a number of points.

Both delivery options: main gas transported through pipes and LPG from a gas tank or cylinder are a source of danger. It is impossible to neglect the regulations and forget about the safety rules.

The design and installation of kitchens with gas stoves are regulated by several documents at once. Plus, there are all sorts of recommendations based on the given standards.

The design and installation of kitchens with gas stoves are regulated by several documents at once. Plus, there are all sorts of recommendations based on the given standards.

If the exhaust and air supply in a gasified kitchen room is not organized correctly, then the room can become a source of serious problems associated with open fire and a possible explosion of "blue fuel".

Gas stoves are allowed to be installed both in private houses and in apartment buildings.The height of the building can be no more than 10 floors. At the same time, the premises for them should have a window and be well lit by natural sunlight.

If the air exhaust in the kitchen with a gas stove is insufficient, then when the burner attenuates or the pipe breaks, the gas will accumulate in the room and sooner or later will explode

If the air exhaust in the kitchen with a gas stove is insufficient, then when the burner attenuates or the pipe breaks, the gas will accumulate in the room and sooner or later will explode

A kitchen for installing a gas stove must:

- be with ceilings from 2.2 m and above;

- have ventilation with natural air supply / removal;

- have a window that has an opening sash either at the top of a transom or a vent.

The cubic capacity of a room with a household stove on gas should be at a minimum (and preferably more):

- 8 m3 - with two burners;

- 12 m3 - with three burners;

- 15 m3 - with four burners.

In some cases, it is permissible to deviate slightly from these norms, but only if such deviations are agreed with the inspectors from the Ministry of Emergency Situations and other regulatory bodies.

In order to avoid problems with the stove, the air in the kitchen should be enough to burn the gas, and it should also be constantly replaced by a new street

In order to avoid problems with the stove, the air in the kitchen should be enough to burn the gas, and it should also be constantly replaced by a new street

When organizing air exchange in the kitchen, it is important to ensure that new air comes exclusively from the street. This will prevent air masses with excess odors and moisture, as well as low oxygen content from entering the kitchen room.

Only methane or propane-butane gas stoves are not enough to work.

Air exchange rate for kitchens with gas stove - 100 m3/hour. At the same time, in most apartment buildings, ventilation ducts with a width of 130–150 mm of the general ventilation system are designed for a flow rate of up to 180 m3/hour.

It is only necessary to provide the required air flow from the outside. In a private house, everything depends on the project.Here it is necessary to look at a specific example, what the existing ventilation system is designed for.

Conclusions and useful video on the topic

Gross violation of ventilation chamber fire safety standards. An underground office is located in an isolated type room and, in addition, they smoke here:

The organization of the design and installation of ventilation chambers should be carried out by professional engineers. The project must be developed, approved and executed with all regulatory requirements, in accordance with the category assigned to the object. At the same time, accurate calculations are carried out and a list of mandatory and recommended protective measures is compiled.

Remember that a well-designed, fire-safe ventilation chamber will not only help you avoid problems with inspections from the relevant authorities, but also save you and your employees the life.

Have you ever designed ventilation chambers at your facility? What difficulties did you encounter in the arrangement of their fire-fighting system? Share your experience in the comments and ask questions about the topic of the article.