- Causes of moisture

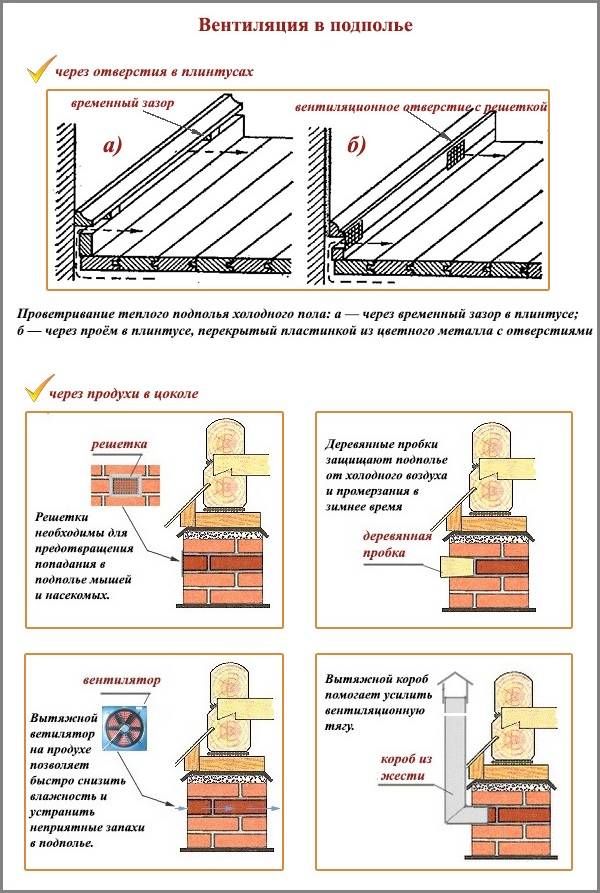

- Types of organization of air exchange of the subfloor of the house

- Features of natural air circulation

- Forced air exchange system

- Forced ventilation: basic elements and device rules

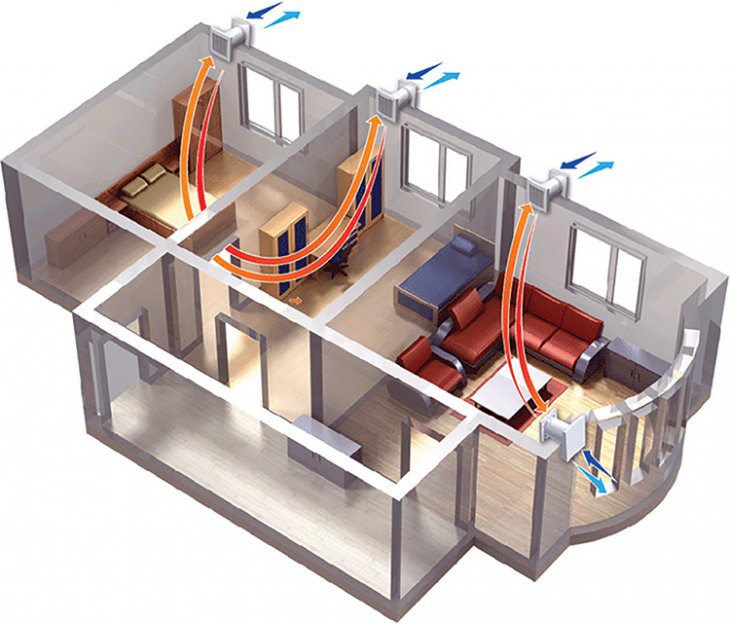

- The need for air exchange in the house

- Additional moisture reduction

- Forced ventilation in the cellar with your own hands

- Principle of operation

- Equipment

- Do-it-yourself system installation

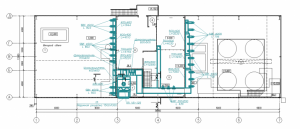

- Design features of the ventilation system

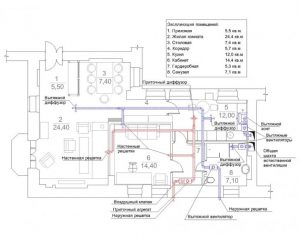

- Do-it-yourself basement ventilation device in a private house

- Types of ventilation holes in the basement

- Natural supply

- Natural exhaust

- Forced

- Supply and exhaust with heat recovery

Causes of moisture

The problem of the destruction of wooden floors has been known to builders since time immemorial. In order to understand the condition of the floorboards and the presence of moisture under the boards, two methods were used:

- An obese, heavy man with a load in his hands was asked to walk along the edges of the floorboards in the room, the furthest from the window and doors. If the deflection of the boards was not accompanied by a creak, the floors could be considered sick;

- The second sign was considered to be the presence of a heavy "earth spirit" or marsh smell, indicating high humidity and the presence of wood decay products in the air.Even internal ventilation and ventilation did not help to get rid of dampness;

- In the absence of ventilation, sections of the walls adjacent to the floor above the baseboards looked earthy, the whitewash or wallpaper changed color, often taking on a reddish tint.

Today it is known that even the absence of these signs is not a guarantee of a normal level of humidity in the subfield. The reasons why moisture accumulates under the floor boards can be very different. From improperly arranged ventilation of the waterproofing of the subfloor, the lack of vents through which air penetrates under the boards, to leaking water pipes or, even worse, sewerage outlets.

Note! Incorrect floor ventilation can also occur in apartments of multi-storey buildings, especially if these are rooms on the first or last floors of the building.

Does not save a room with improper ventilation, even if the walls and ceilings in the building are made of treated wood. The floor of a wooden house in the absence of ventilation collapses in the same way as in ordinary stone or frame buildings. The protective impregnation or coating penetrates only a few millimeters deep into the wood. If cracks form on the surface of wooden logs, beams or boards, even with impregnation, the fungus easily infects the wood.

There is only one way out - to properly ventilate the floor. In this way, you can protect your home from many health problems, the origin of which we do not know anything.

Types of organization of air exchange of the subfloor of the house

From the foregoing, we can conclude: due to the described features, the air exchange in the basement of a wooden house needs to be adjusted accordingly.

In addition, floor ventilation in a private house will be useful. For this, the floor structure is usually chosen to be floating.

More expensive, but also more effective is forced ventilation. Its distinguishing feature can be considered the use of special electrical appliances to increase the speed of air flow in the basement.

Typically, a forced ventilation system works in conjunction with natural ventilation.

The choice of ventilation scheme is carried out at the design stage of a wooden house. Its installation and installation should be carried out simultaneously with its construction.

This significantly reduces labor costs, because during construction, pipes can be immediately laid for the required number of supply and exhaust channels.

Then, after the completion of the laying, drilling large diameter holes in the concrete foundation is an extremely thankless task.

Features of natural air circulation

It is desirable to think over the system of natural ventilation of the subfloor at the construction stage

After the future ventilation scheme of the subfloor of a wooden house is chosen at the design stage, you can begin to implement the design solution. In any case, it is necessary to make mortgages for natural ventilation.

They are cuts, as a rule, of plastic sewer pipes with a cross section of 120 mm or more, or they can be square. The length of these elements is equal to the thickness of the walls of the foundation.

Wooden houses are built most often:

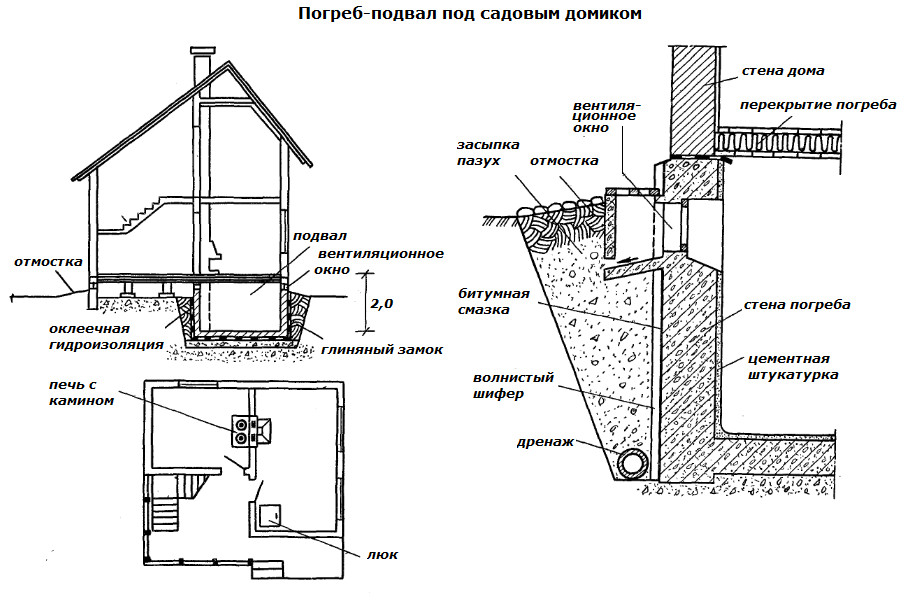

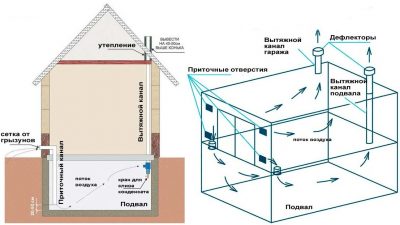

- on a strip foundation: its walls are located under all the walls of the house. During pouring, the elements mentioned above are inserted into the body of the foundation to organize air passages in the foundation;

- on a columnar foundation: piles or pillars, for example, made of brick, are interconnected along the perimeter of the house. The draft floor in the same way rests on individual pillars. At the same time, gaps are left between the draft and finishing floors and between the floor and walls, which serve for natural ventilation. In the outer basement belt, mortgages are made for supply channels;

- on a solid concrete slab: in this case, the ventilation ducts for the subfloor are arranged in the plinths of the wall structures.

Strictly speaking, the channels that serve to pass the air, and constitute the main part of the natural ventilation system of the underground space. From the material presented above, it becomes clear how to ventilate the basement.

You can do the work on your own. The easiest way to do this is at the stage of pouring the foundation and construction.

Forced air exchange system

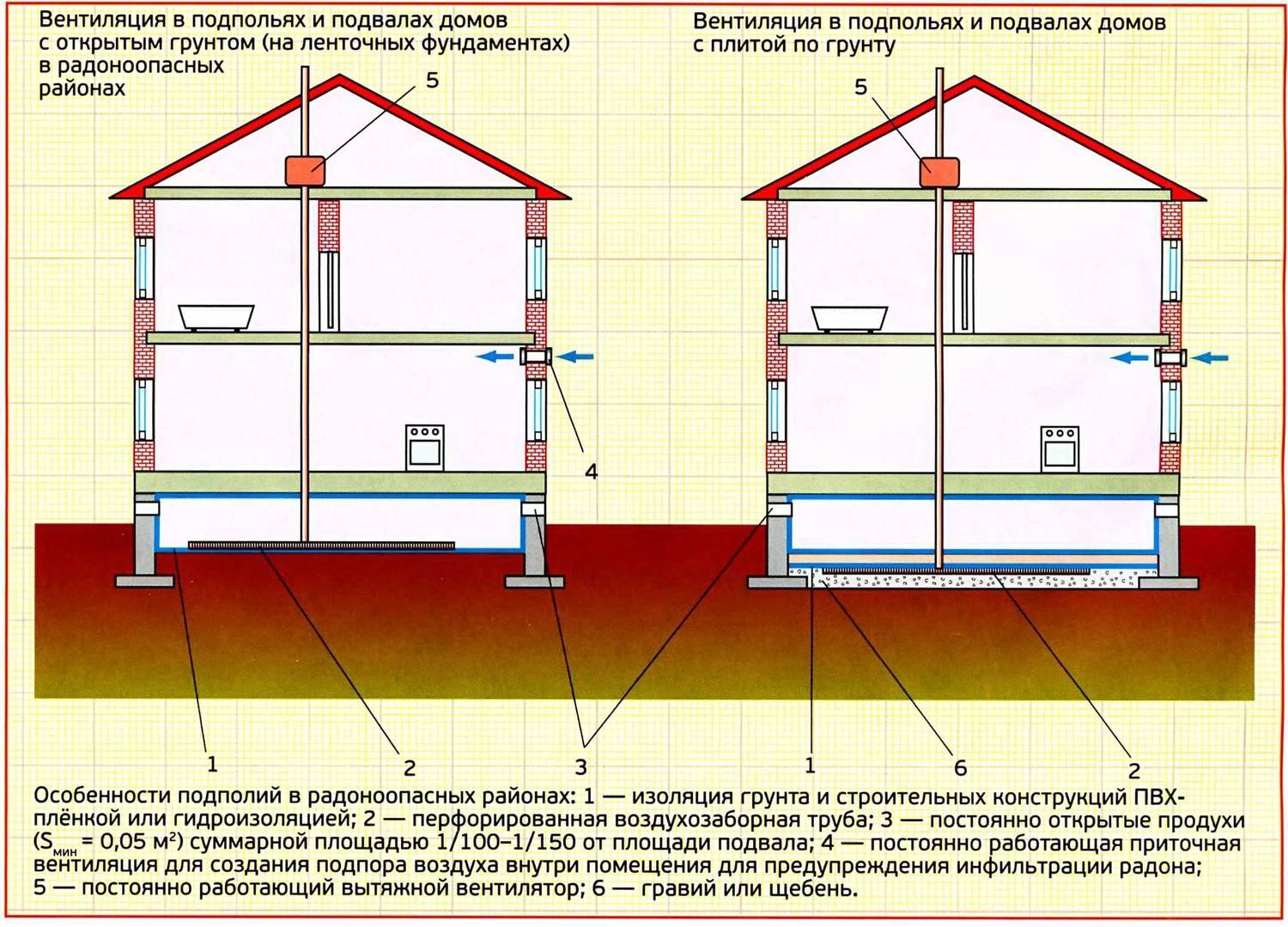

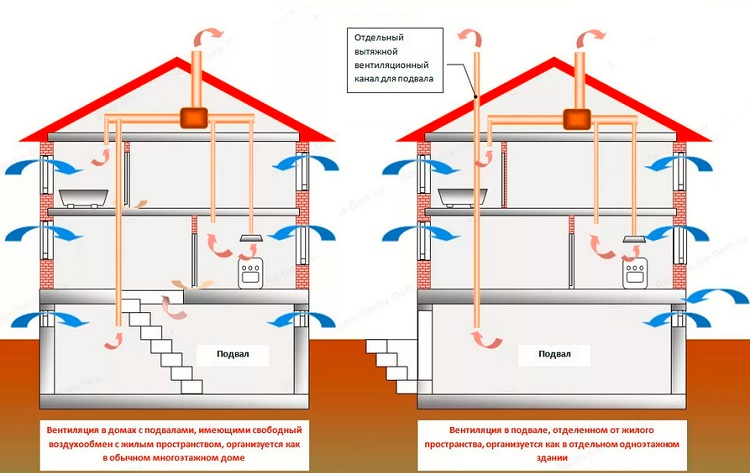

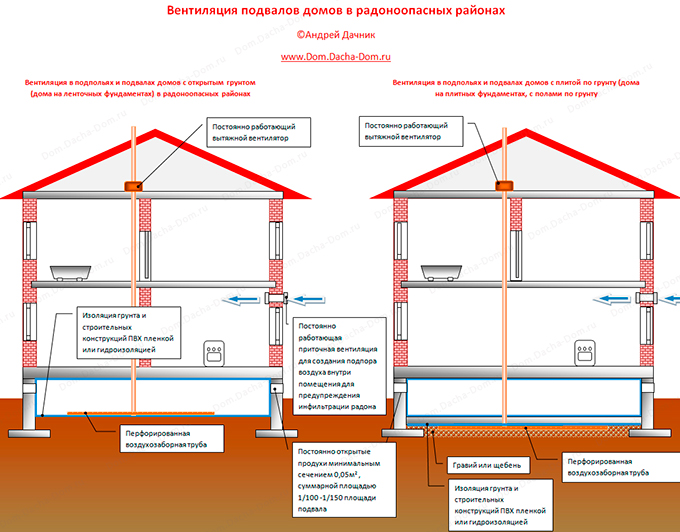

It happens that the power of natural ventilation is not enough to qualitatively remove excess moisture from the underground. This is most often characteristic of houses that have large basements.

And there is no way to do without the installation of forced ventilation.

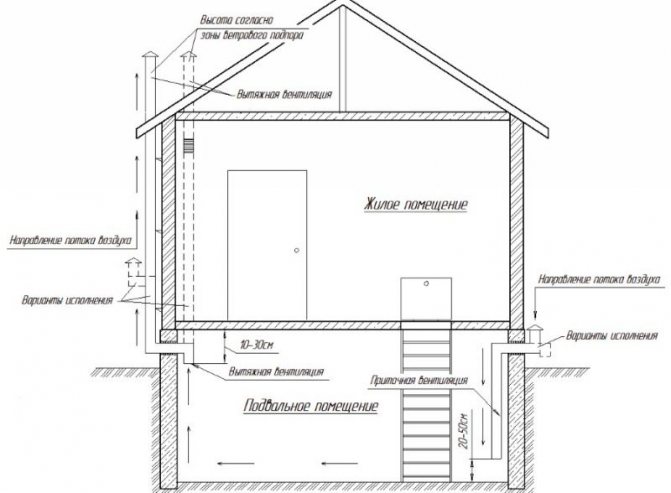

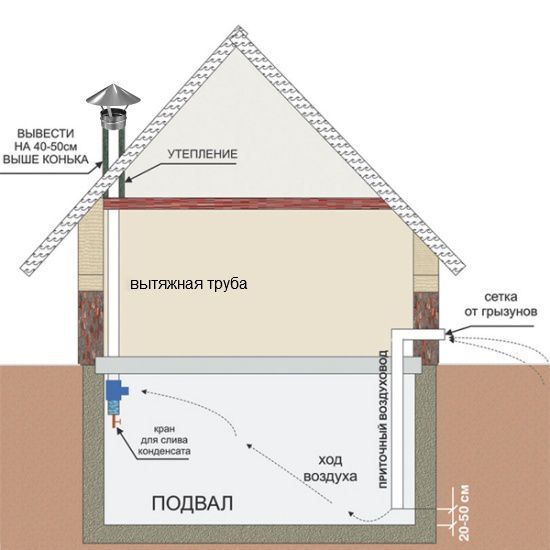

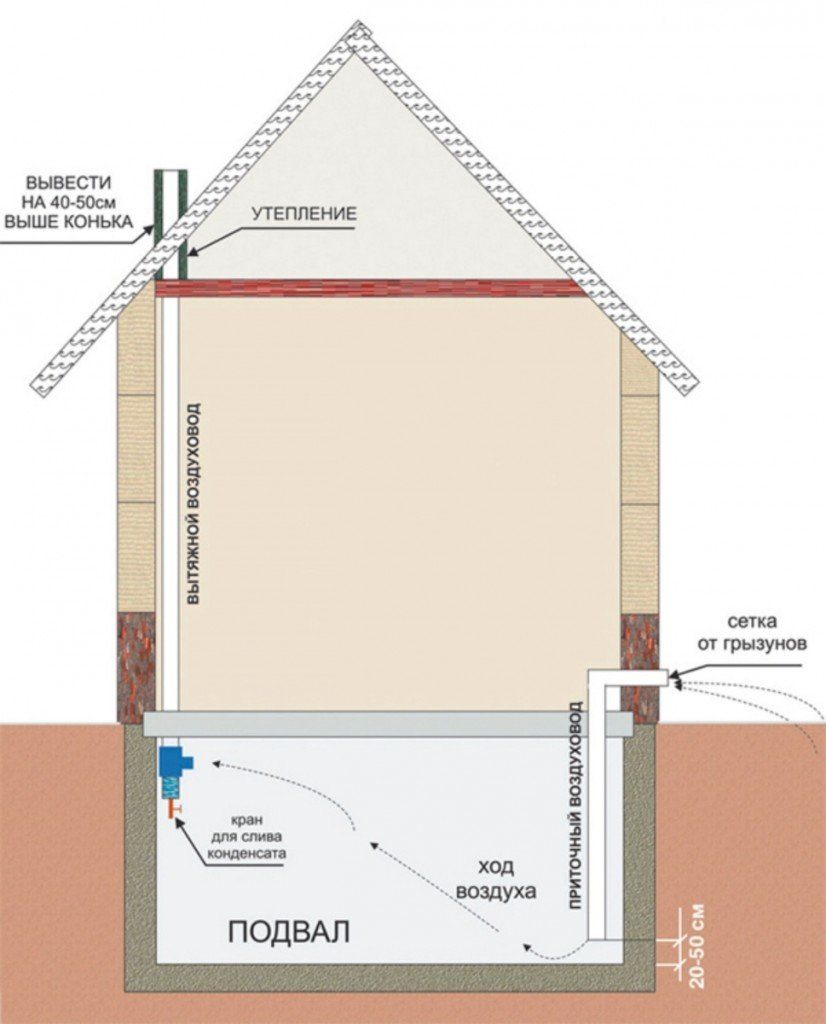

For its proper operation, it is necessary to have supply ventilation ducts, which are located in the body of the foundation or basement. In addition, vertical exhaust ducts must be installed to remove air from the subfloor.

They are also made of plastic pipes or boxes and must exit through the roof. Such a system of channels will enhance the natural flow of air due to the temperature difference in the street and in the basement.Extraction of exhaust air will occur continuously.

It is possible to strengthen the removal of exhaust air from the underground with the help of fans that are installed in the supply ducts or in the exhaust manifolds. The use of such devices makes the ventilation system forced.

It remains to add that there are many varieties of forced ventilation. But these systems are rarely used in small private homes because of the high cost. Most often, in this case, a couple of fans in the basement do the job quite well.

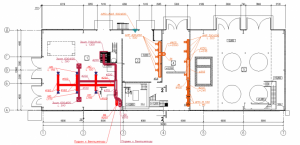

Forced ventilation: basic elements and device rules

Unlike natural ventilation, where air moves due to pressure differences, electrical appliances create forced gas movement. These are fans of various types, among which there are very technological ones. They maintain a predetermined temperature and humidity regime, purify the incoming air, and also carry out recuperation - the transfer of heat from heated air masses to cold ones.

In home basements, all these complex devices are not necessary. As a rule, the simplest devices with manual control are used. More advanced installations with control sensors are relevant for large vegetable stores, wine cellars and other facilities where it is necessary to maintain certain conditions. For a private cellar, the main thing is efficiency and safety.

Forced ventilation can be organized in various ways:

- install a fan in the exhaust duct;

- install 2 fans at once in two pipes;

- use a rotary diffuser-weather vane, which is attached to the top of the exhaust pipe and is powered by wind pressure;

- place an incandescent lamp inside the hood, when heated, the air will rise faster, thus stimulating the evacuation of polluted gases from the cellar.

Since the basement is a room with high humidity, when installing and operating electrical appliances, you must carefully monitor the implementation of electrical safety rules. It is forbidden to use 220 V sockets. A step-down transformer must be installed so that the supply voltage does not exceed 12 or 36 V. Accordingly, electrical equipment must be designed for these loads.

The need for air exchange in the house

A well-thought-out and correctly implemented ventilation scheme in the house acts as a guarantor and basis for the formation of comfortable living conditions.

Ventilation of premises, provided by various systems and additional devices or devices, is a mandatory process due to such factors:

- the ability to regulate the temperature regime and create comfortable conditions;

- adjustment of humidity parameters necessary for normal life;

- saturation of all rooms with oxygen and removal of the polluted gas-air mixture;

- removal of unpleasant and specific odors or steam from the target premises;

- preventing the deposition of condensate, which provokes the development of fungus and mold.

A high-quality and well-organized air exchange process in a residential building plays a big role and requires careful planning.

Additional moisture reduction

So that the ventilation system does not have to be strengthened by increasing the total cross section or installing fans, the following work must be carried out:

- The device of an effective drainage system is the diversion of water from the foundation.

- Waterproofing the base of the house and basement. There are many types of waterproofing: it can be rolled, welded, coated, etc.

- Implementation of insulation. The best material in terms of economy and efficiency is XPS. It is a good thermal insulator that does not let water through. It does not interest rodents and does not rot. EPPS can also be insulated with a blind area.

The listed measures do not cancel, but only supplement ventilation. Only in a complex it is possible to achieve ideal drainage of space in the basement compartments.

If the house is built on a soil base that does not drain water well, in addition to the ventilation system, drainage and storm water are required. The drainage system will collect water from the soil and the upper layers of the soil, the storm drain will collect and remove precipitation

When a system is arranged according to a forced scheme, the costs for installation, maintenance and service will be greater than when organizing a natural type. It should be borne in mind that in winter, condensation can form on the walls of the ventilation pipes themselves, and in cold weather, the cross section can completely clog the jacket.

To avoid this, the pipes can be thermally insulated with penofol. At the lower turn of the pipe, you can come up with a condensate trap - for example, drill a hole or put a tee instead of a corner.

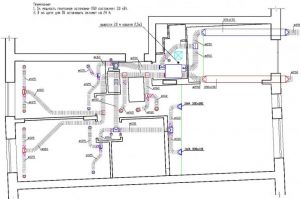

Forced ventilation in the cellar with your own hands

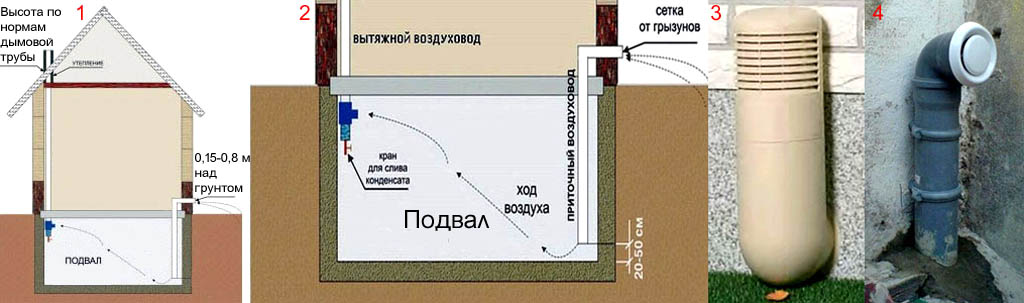

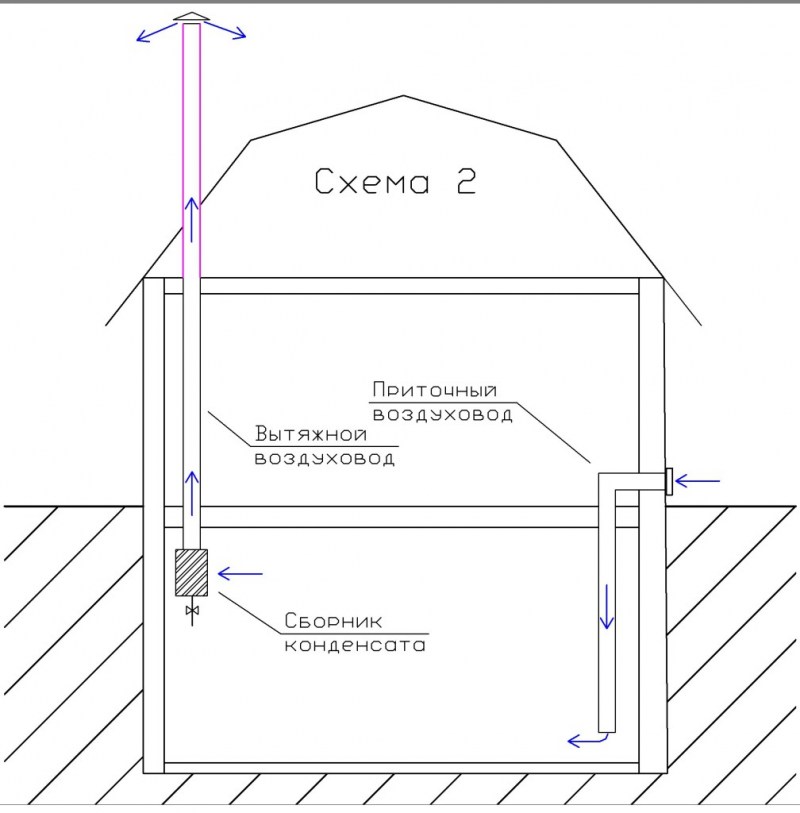

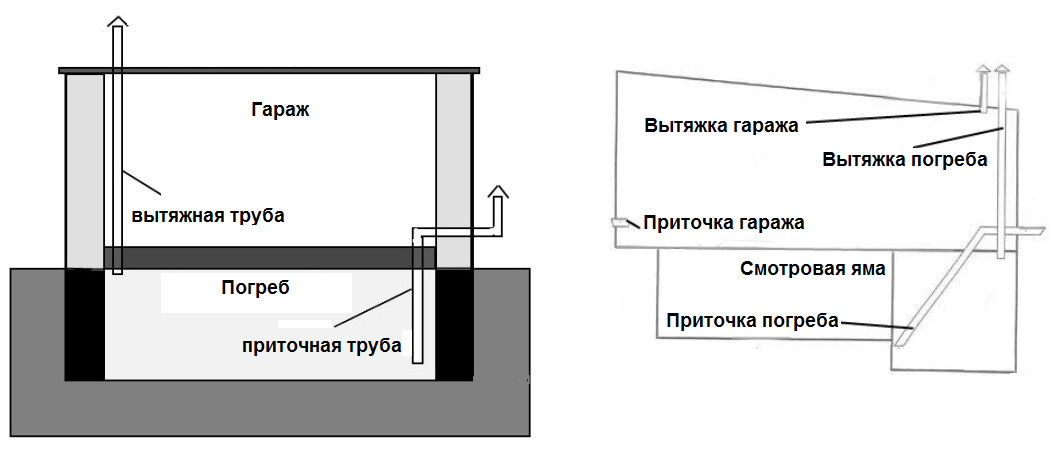

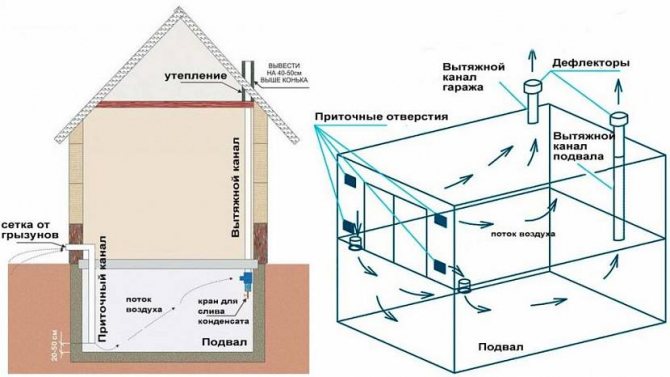

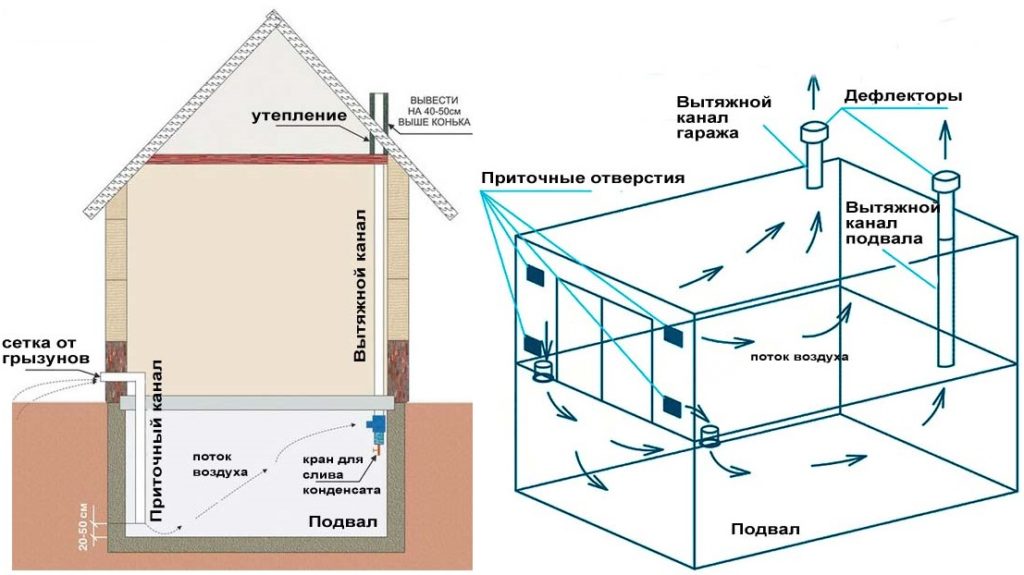

In fact, forced ventilation differs from natural only in that fans are installed inside the pipes (ventilation ducts), which provide a more intensive air supply and exhaust (Figure 4).

Principle of operation

The principle of operation of forced ventilation is quite simple.In the simplest version, the fan is installed only on the exhaust pipe. This creates a more active movement of air through the supply opening.

In large rooms, it makes sense to install fans for both exhaust and supply. In this case, it will be difficult to cope with it yourself and it is better to contact a specialist who will help determine the appropriate pipe diameter and fan power.

Equipment

Since forced ventilation is considered more reliable and modern, additional equipment will be required to equip it. Of course, first of all, you need to prepare the required number of channels of a suitable diameter. After that, you should buy fans of a suitable size and power.

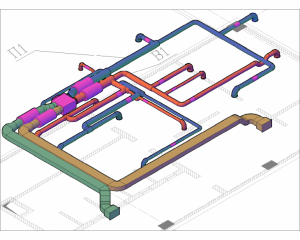

Figure 4. Main elements of forced ventilation

It is also necessary to provide waterproofing of devices from moisture, which can enter the room from the outside or seep through the walls.

Do-it-yourself system installation

Forced ventilation is a little more difficult to install than natural. To help you install it yourself, we recommend using our step-by-step instructions.

Forced exhaust in the cellar is set as follows:

- Holes are drilled in the walls or ceiling for ducting, or voids are used that were previously left for this purpose during the construction phase.

- Pipes are laid in the holes. You can use metal, plastic or cement products.

- The supply and exhaust pipes are installed in opposite corners of the room and at different levels, as in the case of natural ventilation.

- A fan is mounted inside each pipe and dampers are installed so that the intensity of ventilation can be adjusted if necessary.

The upper parts of the pipes protruding to the surface must be covered with visors. In the case of natural ventilation, this requirement is more of a recommendation, while for the forced type it must be observed, as rainwater can damage the fans and the entire system will be disturbed.

The video shows how best to equip natural ventilation in the basement.

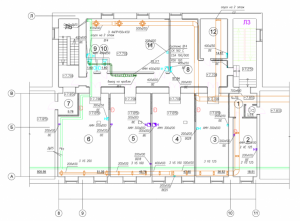

Design features of the ventilation system

To understand how to make ventilation in a house, it is necessary to carefully study typical projects and be sure to take into account a set of important factors:

- the internal volume of the entire premises, and the number of people living in the house;

- the need to equip the ventilation of the underground, attic and other rooms;

- free flow of air exchange processes in all rooms of housing;

- the use of filters to clean the fresh air coming from the street;

- the use of equipment for additional heating or cooling;

- installation of a check valve to prevent the return of the waste mass.

Additional devices for optimizing air exchange are used quite often and can improve the efficiency of the ventilation device in a private house.

Do-it-yourself basement ventilation device in a private house

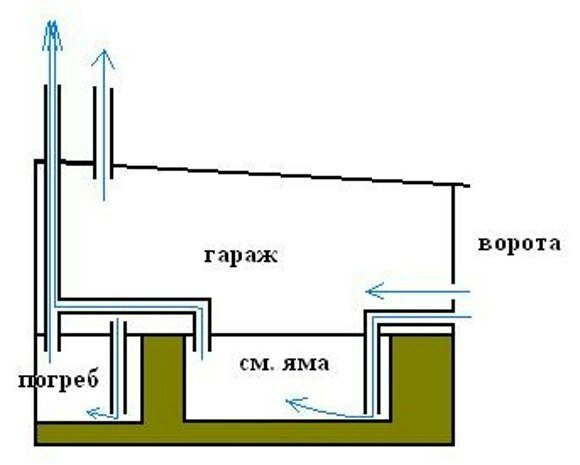

The basement in a private house is often used for household needs. To avoid dampness and condensation on the walls, it is necessary to have ventilation in the basement of a private house. With your own hands, you can arrange simple ventilation by punching holes on opposite sides of the plinth.Cover them with bars so that rodents cannot get into the basement.

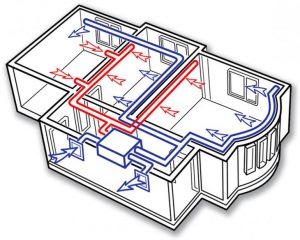

The device and principle of operation of the supply and exhaust ventilation unit.

The device and principle of operation of the supply and exhaust ventilation unit.

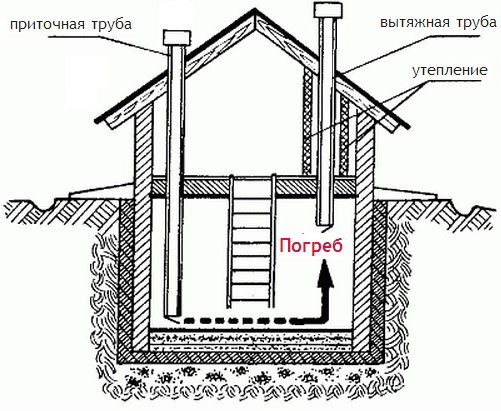

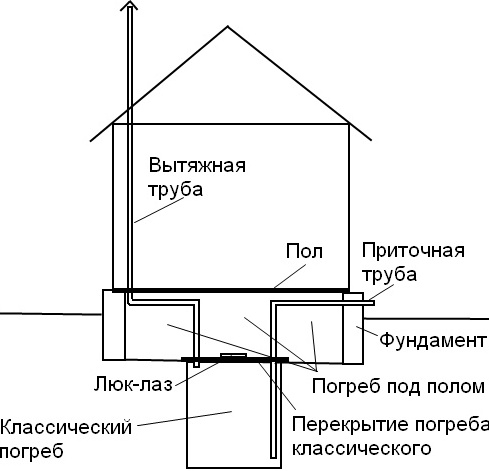

More effective basement ventilation can be done using pipes. For installation, you will need two pipes (diameter 8-15 cm), gratings, visors that protect against precipitation, thermal insulation. One end of the supply pipe is installed in the wall hole at a distance of 25-35 cm from the basement floor. The upper end of the pipe is brought out through the base and placed along the wall. The length of the outer part of the pipe should be 50-60 cm. For a more aesthetic appearance, the pipe can be made invisible.

The supply pipe must be installed in a hole under the basement ceiling. If the basement is used for food storage, then it is recommended to place the pipe in close proximity to them. The pipe from the basement is led out through all the ceilings and ends at a height of 40-60 cm from the roof. It should be noted that in private houses, condensate in the ventilation, which forms in the exhaust pipe, will drain into the basement. Therefore, a container is placed in the basement into which condensate is collected. Pipes for ventilation can be used plastic or asbestos-cement.

Ventilation scheme in a private house, which you can create yourself.

Ventilation scheme in a private house, which you can create yourself.

On the Internet you can find various ventilation schemes in a private house. It is much easier to do the installation according to the scheme with your own hands. The video will tell about the options for installing ventilation systems in the basement of a private house.

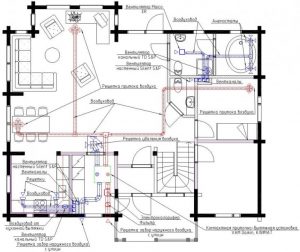

Types of ventilation holes in the basement

The classification of ventilation by type depends on the purpose, method of arrangement.The principle of their operation is based on the law of physics, according to which the flow of warm air tends to rise, and cold air falls down.

Natural supply

Created during the construction of the house, it is a small opening in the upper part of the basement. Refers to the simplest way to ensure air exchange in the cellar.

To make an exhaust hood in a basement below ground level, the openings in the wall are equipped with asbestos-cement or plastic pipes with a cross section of 10–15 cm. They are brought out above the ground on the leeward side, at a distance of 30 cm from the surface. The products are covered from the outside with bars to protect the room from rodents and foreign objects.

Attention

The natural supply system is used for ventilation of non-residential basements, garages or for additional air exchange.

Natural exhaust

The correct operation of natural exhaust ventilation occurs due to the installation of two pipes:

- The first serves to remove warm air, is located in the upper part of the basement. To avoid exposure to adverse environmental conditions (precipitation, frost, etc.), the outer part of the pipe is insulated, a visor is installed.

- The second pipe is designed to deliver fresh air to the cellar. It is placed at a distance of 30-40 cm from the floor, bringing the other end of the pipe to the street, covering it with a grate. For the most efficient operation of natural ventilation, two or more supply pipes are equipped (depending on the area of \u200b\u200bthe cellar) on opposite sides of the room. Due to the temperature difference in the basement and outside, air movement is ensured.

here

We offer a video on how to make natural ventilation in the basement:

Forced

This is a system of supply and exhaust fans and ducts that work synchronously and pump air, providing convection. Used in the following cases:

- the basement area consists of several rooms isolated from each other;

- basement occupies more than 40 sq. m area;

- high humidity in the basement, when the exhaust duct freezes in winter, disrupting the movement of air masses;

- the impossibility of installing high ventilation pipes;

- in the basement it is planned to place a cafe, a steam room, a workshop, a garage, a gym;

- natural ventilation cannot be used.

separate publication

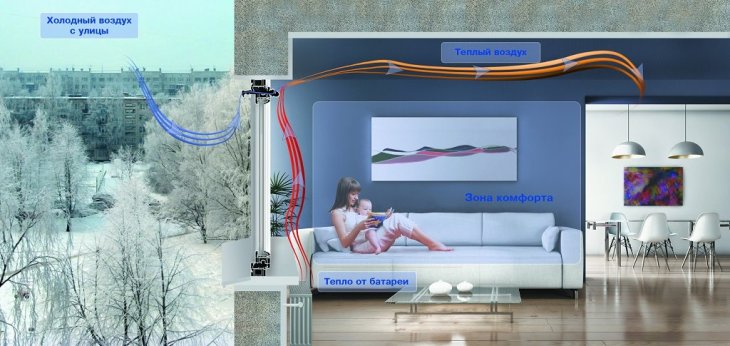

Supply and exhaust with heat recovery

It is installed in the basement floors for permanent residence, where heat and waterproofing are carried out, floors and walls are insulated. Under such conditions, the forced ventilation system is not enough, therefore, supply and exhaust ventilation with heat recovery is installed.

The device is an exhaust pipe that performs the intake and supply of already heated air, passed through a ceramic heat exchanger. Additionally, humidity, temperature, dust filters are installed. Installation is complicated, so it is done by professionals.