- Stages of installation work

- Installation Features

- Consequences of installation errors

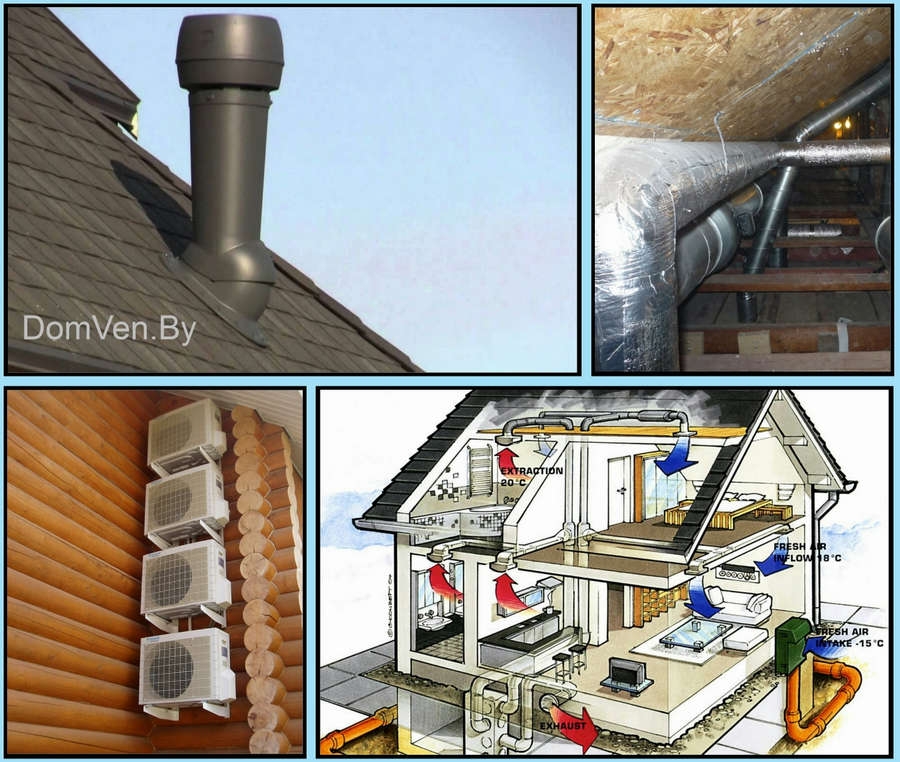

- Ventilation installation options

- Other Methods for Eliminating Condensation

- Option 1

- Example

- Option #2

- Why is an air exchange system necessary?

- Primary requirements

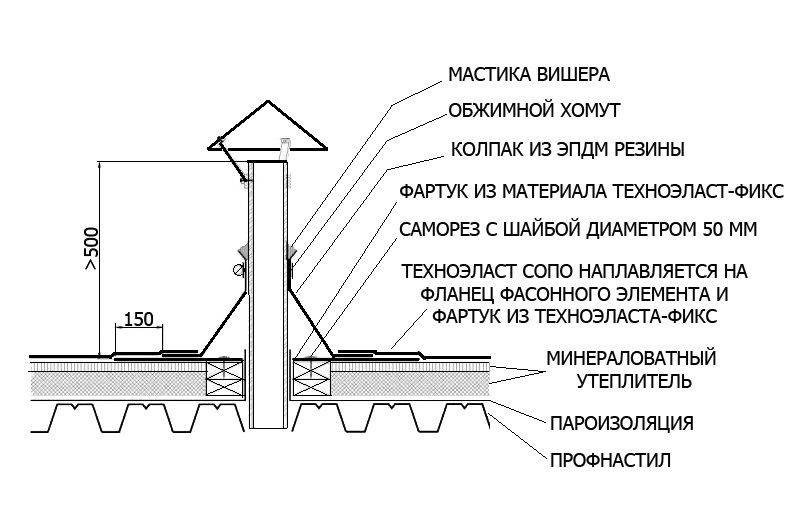

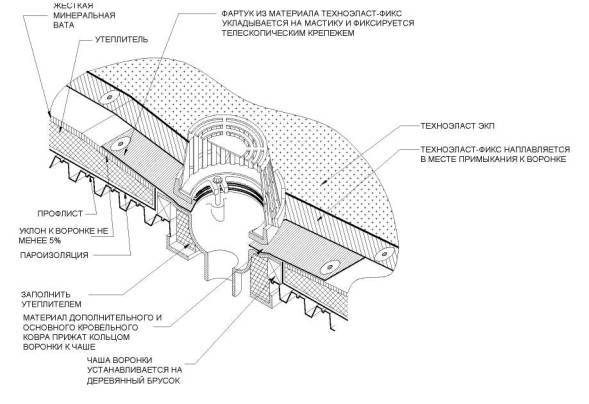

- Precipitation and ventilation pipe: ways to protect

- Importance of ventilation and indoor air circulation

- Types of UE

Stages of installation work

The ventilation pipe is brought to the roof and securely fixed after the internal system is equipped with wiring. A set of tools is selected depending on the type of roof. The standard kit for installing the ventilation pipe includes the following materials and tools:

- insulation;

- electric drill, chisel, electric jigsaw and a set of screwdrivers;

- fixing hardware;

- sealant;

- Bulgarian;

- passage node;

- rags and protective equipment.

To facilitate installation work, use the passage assembly, which is pre-assembled. Mounting process:

- In the area of \u200b\u200bthe roof where the ventilation shaft will exit, markings are made. To do this, use a marker. Marks are made according to a standard template, depending on the size of the outlet pipe and its cross section.

- Using a grinder, a hole is cut in the roof for a pipe. In this case, the top layer of the roof is removed.

- Holes are drilled to secure the outlet section of the ventilation shaft.

- In the place where the passage node will be installed, markup is made.

- According to the finished markings, grooves are cut out. They are designed for self-tapping screws.

- Then install the passage assembly and fix it with self-tapping screws.

- The pipe is mounted on top and securely fixed with hardware.

At the end of the work, insulation is carried out. If there are gaps and holes, they are isolated.

Installation Features

All calculations for design and installation it is better to entrust the ventilation system to specialists, since the scheme must comply with the technical situation. Installation Features:

- The efficiency of ventilation increases in winter, and decreases in summer. This is due to the temperature difference that occurs at the inlet and outlet of the ventilation duct. Different temperatures inside and outside the structure increase the draft inside the channel.

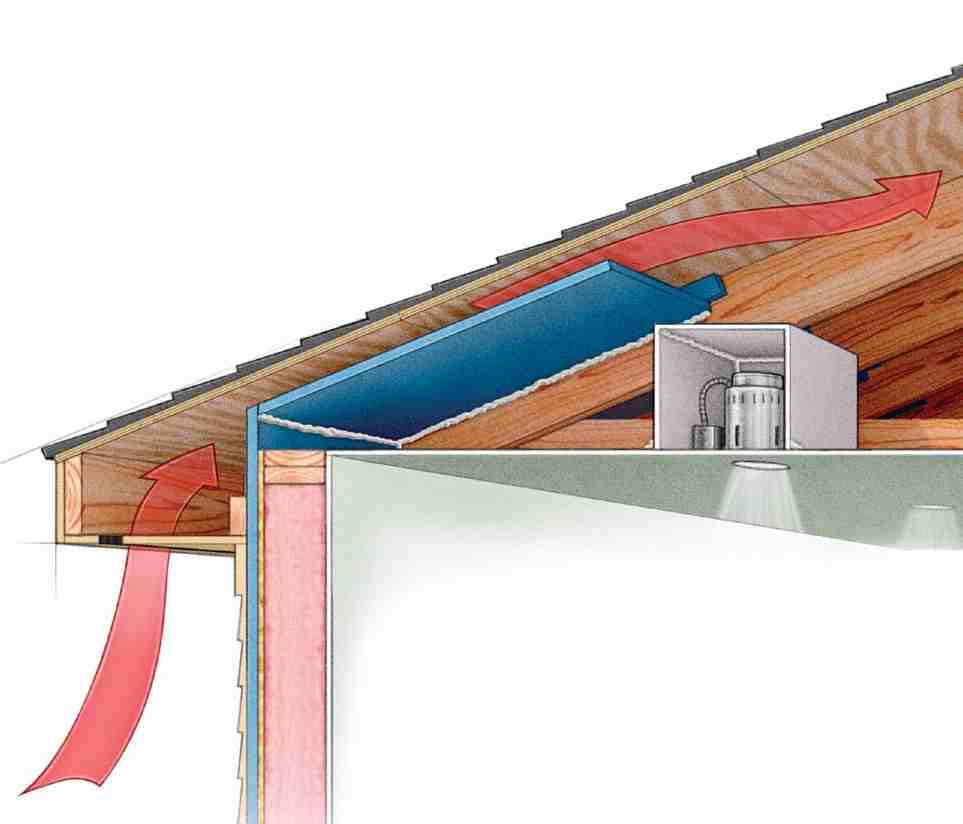

- So that later the air draft does not become smaller, the channels located under the roof elements must be thermally insulated. This point is taken into account during design. Thermal insulation will protect the channels from the accumulation of moisture.

- Also, the pipe must be heated if its installation site is near the chimney. The draft in this design works differently, therefore, if the calculation is incorrect, the ventilation performance is impaired.

Ventilation of the room will be effective with the proper arrangement of the ventilation duct. If you study the features of the installation, then all the work can be done independently. For tiled roofs, it is recommended to install the ventilation outlet closer to the ridge.

Consequences of installation errors

In order for the whole system to work efficiently and without disturbances, it is necessary to make the correct installation of the ventilation pipe. If you do not follow all the installation rules, the following problems may occur:

- all the unpleasant smell will begin to accumulate inside the room;

- fresh air will no longer enter the room;

- condensation will accumulate inside the ventilation system;

- traction will decrease;

- improper installation may cause mold and fungus;

- kitchen cabinets are covered with soot and grease;

- family members begin to get sick more often;

- some structural elements located on the structure begin to freeze slightly.

A comfortable state in the house is created due to high-quality air exchange

Therefore, it is important to properly install the ventilation system.

Ventilation installation options

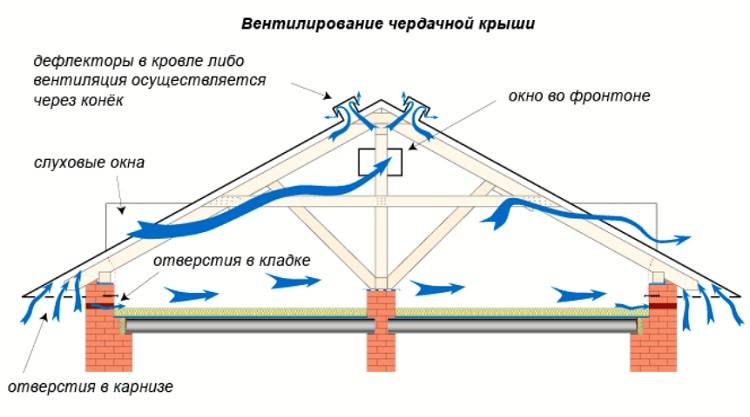

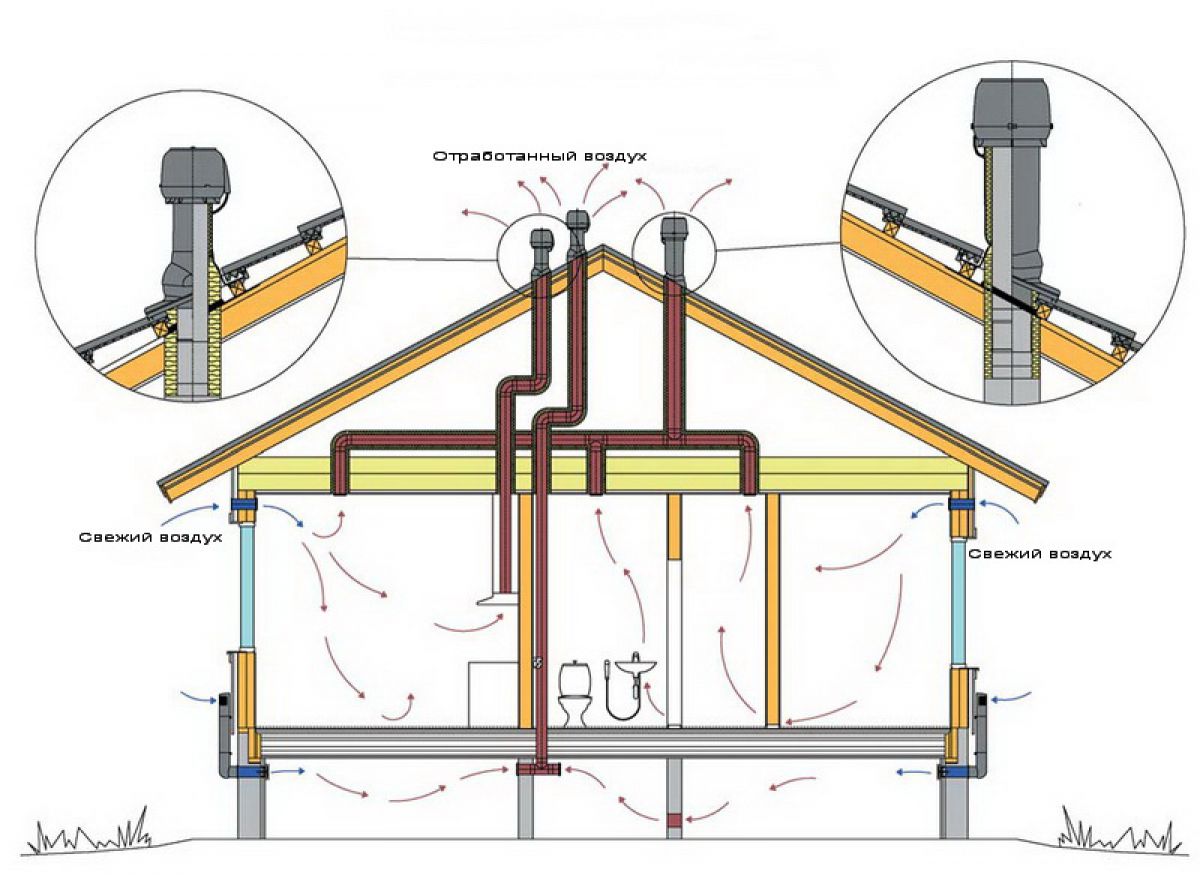

To this end, it is possible to provide exhaust outlets on the ridge or near it. Such outlets are called roof aerators. They can be placed pointwise or made into a continuous gutter. The greatest efficiency will be ensured if they are located along the entire edge of the roof. Roof aerators can be combined with the general ventilation system of the house.

Roof aerators will not spoil the appearance of the house, as the main coating is laid on them. When constructing this type of ventilation, it is impossible to seal using mounting foam or special tapes. This will block the access of air, due to which the natural ventilation of the roof will become impossible. To make a roof with 2 gaps, you will need to cut holes in the film, as it will also block the access of air from the outside.

Practically for any roofing there are functional elements with which you can make ventilation. These elements include:

- plates with air channels;

- air elements;

- ventilation rolls.

With the help of these roofing elements, ventilation of the roof of the house can be ensured. The ventilated ridge system created using these elements, rather than installing them separately, gives the greatest efficiency.

The arrangement of a ventilated cornice is an opportunity to provide an area for air penetration sufficient for effective ventilation of the roof. Cornice ventilation can be of several types:

- soffit, which is the gap between the wall of the building and the cornice board;

- in the form of ventilation grilles embedded in spotlights;

- using a special material in which air vents are provided, laid slightly above the level of the cornice overhang.

In order not to block access to air, it is necessary to abandon the laying of heat-insulating material in the eaves or placing plantings on it. It is possible to provide effective protection of ventilation ducts located on the cornice overhang:

- special grilles and air elements;

- location under the roofing of the elements of the drainage system;

- installation of snow guards.

Attic ventilation scheme through dormer windows.

Roof valley or gutter is a more complex option for ventilation output. If the cornice overhang is too short and there are 2 ventilation gaps (or long grooves) on the roof, then certain difficulties may arise with the withdrawal of ventilation.

It is possible to ensure ventilation of the roof if ventilation openings are made in the film in each span of the truss system. Instead of an opening, you can make a solid channel for ventilation along the gutter.

In such difficult cases, aerator elements can be placed along the valley. This is very useful on roofs with a slope of 45°. If the roof is flat, then such ventilation will not be effective. In this case, the best option is roof fans powered by electricity, high ventilation nozzles, inertial turbines, etc. However, the cost of such ventilation is much higher than with the arrangement of ventilation in a natural way.

The most common way to create ventilation is to make a dormer window. This element carries not only a functional, but also a decorative load. The roof with a dormer window looks very attractive. You can make a hole for a dormer window of various shapes.

A single pitched dormer can be installed on any roof. The base of the gable should be a roof made of metal or soft coating. But if you wish, you can equip windows with a more complex design.

Thus, roof ventilation is an indispensable element that serves to remove warm and humid air from the house. With the help of a ventilation system, rotting and mold can be prevented on floor beams and roof supports. There are several ways to arrange ventilation on the roof. One method or another may be more or less effective depending on the design of the roof.In some cases, it may be necessary to include special devices in the ventilation system that operate from the mains. This will make ventilation more efficient, but will increase energy consumption. It is recommended to resort to this method of arranging ventilation only in cases where the roof structure prevents natural ventilation.

Other Methods for Eliminating Condensation

Option 1

Perhaps the option with warming will not work for someone, so you can do it differently. The ventilation pipe that runs through the attic is disconnected. A tee with a conical plug is inserted at the separation point. It is in the place of the cone that the condensate will drain. The disconnected part of the ventilation pipe that goes outside should be installed in a tee. This method is called the removal of condensate from the exhaust ventilation ducts. It is not expensive and does not require much effort, the main thing is to correctly install the tee in the duct. Next, you need to insulate this structure, and instead of draining the condensate, you can mount a tube through which the condensate will flow out.

Example

The private house has 2 bathrooms, each of them equipped with exhaust fans in the ventilation ducts. For ventilation, metal pipes with a cross section of 125 mm were chosen. Ventilation pipes in a horizontal position pass through an unheated attic (the length of one pipe is 7.5 meters, the length of the other pipe is 9 meters), then they go outside. The pipes are insulated with mineral wool. In winter there is condensation, what should I do? Moreover, its quantity is very large, water flows out even through fans.

There are several options for solving the problem, the insulation of the pipe must be carried out completely, up to the last section facing the street. It is possible to mount the ventilation pipe outlet directly on the roof without horizontal sections, equipping it not with a duct fan, but with a turbo deflector. The last best option is to install a drain in a place where ventilation in a private house drips condensate, through which water will quietly drip, for example, into a sewer drain.

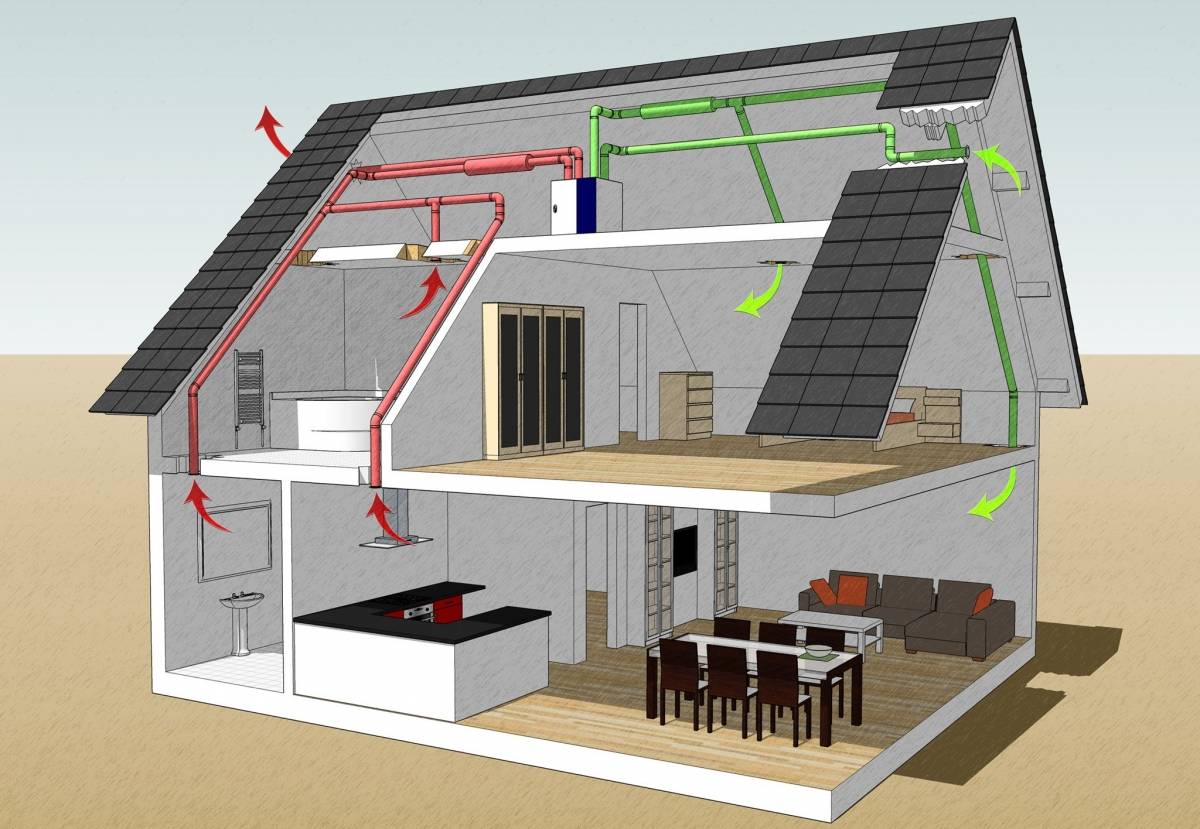

Option #2

A plug is made on the old ventilation and a new forced-type ventilation system is mounted. An exhaust fan is installed in the room where the most evaporation occurs. Often a mechanical device is mounted in a window pane. The supply of fresh air can be provided by a supply valve, which is installed near the battery or behind the gas boiler. Installing air inlets near heating equipment will warm the winter air and heat loss in the house will be minimal. Such an expensive option allows you to permanently remove condensate from the ventilation.

The correct approach to the insulation of ventilation pipes solves such problems - increasing the operation of ventilation ducts. Noise isolation during the passage of air masses. Reducing heat loss in winter. Condensate does not drip from the ventilation in a private house. Prevents the spread of fire when ignited.

To date, heaters in stores are presented in the form of cylinders, cords, half-cylinders. The diameter must also be selected individually. The thickness of the insulation is also different.It is advisable to approach the issue of warming ventilation ducts even at the stage of building a house.

Why is an air exchange system necessary?

Air exchange is not only a matter of comfort, but also of health. The air in rooms where people are present may contain substances that have a negative effect on the body. One of them is carbon dioxide, which is produced during inhalation/exhalation.

This volatile chemical formation is dangerous in high concentrations. Carbon dioxide also comes from stoves, fireplaces, boilers and other heating systems. If the room is not supplied with fresh air in the right amount, then as a result of combustion in these devices, extremely toxic carbon monoxide can be formed.

Another unpleasant substance is the steam we produce when we breathe, cook, iron or dry clothes. Its excess leads to constant humidification of the atmosphere in the house, enclosing structures, finishing materials, which affects the development of mold fungus. In addition, damp surfaces are a breeding ground for dust mites.

Option roofing installation selected based on performance. Depending on the required performance, it is equipped with a fan, a deflector or a conventional protective grill

Ventilation on the roof of a private house should provide conditions for air replacement at least:

- kitchen with gas stove - 65 m³ / hour;

- kitchen with electric stove - 55 m³ / hour;

- separate toilet - 25 m³ / hour;

- utility rooms - 14 m³ / hour;

- separate rooms - 25 m³ / hour.

Fresh air must be supplied to other interiors (bedroom, living room, etc.). In a typical private house, this gives about 200 m³ / h.

The rules allow to reduce the intensity of ventilation at night, but not more than 40%. It is also recommended to install additional devices in kitchens that allow periodically increasing the flow of exhaust air to at least 120 m³ / hour.

Primary requirements

A number of requirements are imposed on the ventilation system, which have not bypassed the duct itself. You can check them out in the list below.

- The minimum cross-sectional diameter that the ventilation duct has is fifteen centimeters. A galvanized air duct with such parameters shows good work efficiency.

- In the process of arranging the supply and exhaust ventilation system, it is necessary to make sure that the pipeline has an increased annular rigidity in the design of the outlet part. The reason is as follows - in the area that rises above the roof, the pipe is constantly faced with a significant wind load. Therefore, the design must effectively cope with it.

- The ventilation pipe must have an increased margin of safety while simultaneously having a minimum wall thickness. The smaller the thickness index, the higher the overall throughput will be.

- Metal ventilation ducts should not become covered with a layer of rust over time. In the room there are moisture vapors that settle inside the pipeline. They should not cause the development of corrosion processes.

- The chimney itself must not emit harmful gases during operation and must not become a source of fire spread.

- The design must have a minimum weight.

It should be noted that brick and galvanized ventilation ducts fully comply with almost all the qualities indicated above.The brick pipeline has a weight that meets regulatory requirements. A metal pipe during operation is able to attract dust to itself, as static electricity accumulates on the walls.

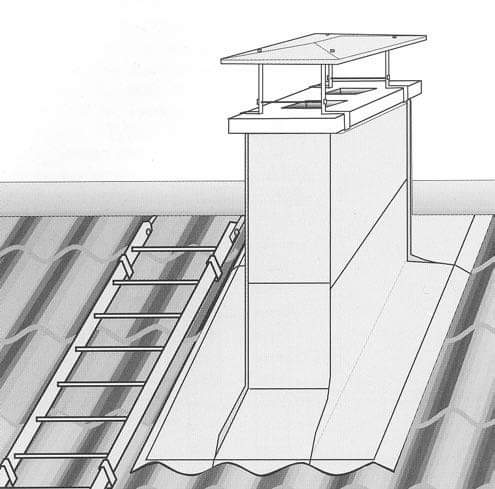

Ventilation outlet to the roof

Precipitation and ventilation pipe: ways to protect

To protect ventilation ducts from seasonal precipitation, you can use a fungus for ventilation. It is mounted on top of the ventilation pipe. Vertical racks are placed under the cone-shaped cap. The protective device is most often made of stainless steel or polypropylene. The main requirement is the resistance of the material to corrosion. Since it is installed at the highest point on the building, no additional care is provided for it.

A ventilation fungus on the roof should be installed not only to protect against precipitation - it prevents wind from blowing into the duct. Also, the fungus can serve as a decoration of the building - manufacturers produce it in different colors.

The fungus is easier to mount on ventilation ducts with a round cross section. In order to fit the protective structure to a ventilation pipe with a certain diameter, manufacturers make the rim of the protective umbrella open. The fungus on the roof for ventilation is attached with self-tapping screws or screws to the ventilation pipe. Protecting ventilation from birds, you can additionally install a grid on it.

Protecting the ventilation system from adverse factors, do not forget about preventive care. It should be done at regular intervals. Pipes become dirty and clogged during operation.Prevention is a simple task, so you can do everything yourself, while saving money on calling specialists.

Importance of ventilation and indoor air circulation

A house or apartment is a hermetically sealed space. In the process of life, a person inhales oxygen and exhales carbon dioxide. Cooking and other processes also fill rooms with odors and exhaust air. Since the room is sealed, fresh air can be provided by opening windows and doors. But, this is the most primitive option, which has a lot of drawbacks. While the ventilation system allows you to regularly fill the house with fresh air.

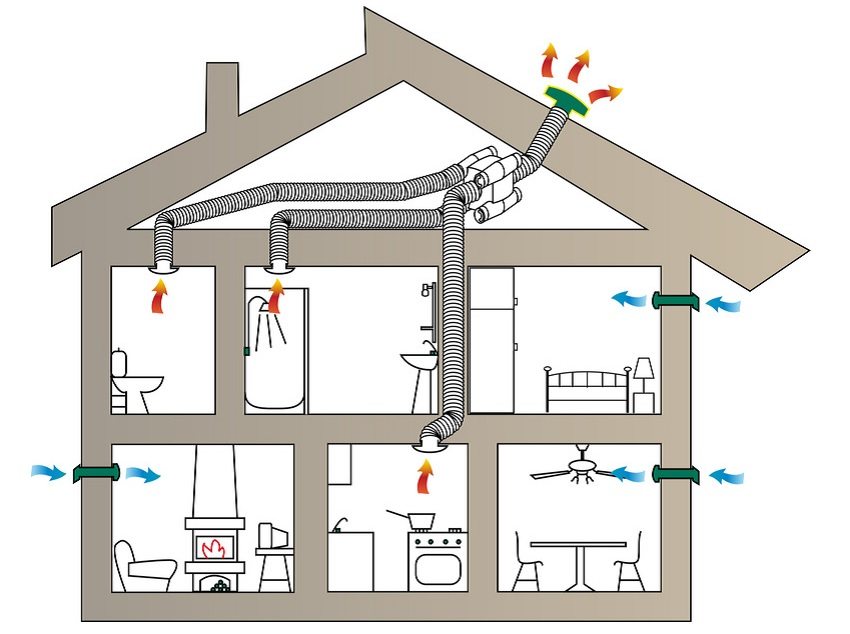

There are such types of ventilation:

- residential ventilation;

- under-roof space ventilation;

- ventilation through a vent pipe from the sewer.

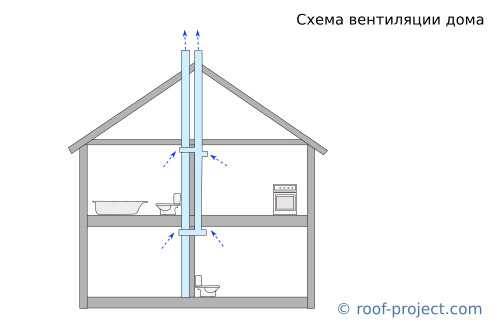

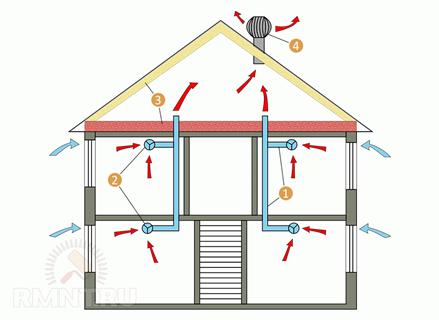

No ventilation system will work if there is no draft in it. By means of thrust, the movement of air masses is performed. Thrust can be created mechanically, by means of fans, or natural. In order for everything to work naturally, the ventilation pipe is led through the roof. Below is a diagram of how the ventilation system in the house works.

If the rules for installing ventilation channels and shafts are violated, the following consequences are expected:

- Traction will be weak or absent altogether.

- From the bathroom, an unpleasant smell will penetrate into other living rooms.

- Walls and ceilings will become wet due to increased humidity in the rooms.

- As a result, the formation of fungus and mold, affecting health.

- Lack of oxygen and stuffiness.

- Ventilation structures will begin to freeze.

- The kitchen will be filled with smoke and soot in the process of cooking.

Advice! Troubleshooting a ventilation system is much more difficult than spending time on accurate calculations and creating ventilation during the construction of a building.

That is why the ventilation pipe to the roof must be chosen correctly and removed in compliance with all the nuances.

This is interesting: Plan of a summer cottage 10 acres: we explain in detail

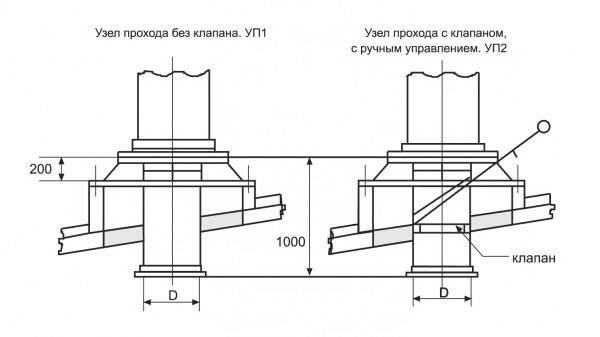

Types of UE

On sale there are a large number of varieties of passage nodes. They differ in their design and other parameters.

Round pass knot

Table. Types of passage nodes.

| Design features | short information |

|---|---|

|

valveless and with valves | Models without valves are cheaper, but they do not provide the ability to adjust the emission of air and shut off its flow. Often installed in private homes. Valve units are equipped with a damper, which, if necessary, can close the air flow, they are optimal for installing ventilation systems in administrative or industrial buildings - where constant ventilation is not needed. |

|

With insulation or without additional insulation | Insulated UEs can be equipped with a basalt or glass wool thermal insulation layer. Convenient for use in cases where the ventilation pipe is mostly outdoors or located far from the ridge. Insulation helps to get rid of a large amount of condensate that will form due to the difference between the temperatures outside and the flue gases. Non-insulated UEs are used if the building is located in a region with a mild climate or the ventilation pipe is located next to the roof ridge. |

|

Mechanical and automated | The mechanical model has a special cable that allows you to manually adjust the circulation of air flows. Suitable for arranging permanently operating ventilation systems. In automatic UE, a controller is provided that controls the system independently. |

Installation of passage nodes ventilation through the roof

All UEs have a special marking, which allows you to better understand the range of equipment. It looks like an alphabetic and digital designation - for example, UP1-01. The last two digits after the letter designation show the dimensions of the structure. They can vary from 01 to 10. As for the first digit, it shows the design features of the product. For example, a unit reports that the system is not equipped with a valve and a condensate ring. The deuce reports that there is also no condensate ring, but there is a mechanical valve. The three after the letters says that the design has both a ring and a mechanical valve. But in products of this type, the subsequent numbers will vary from 11 to 22, also reporting the dimensions of the structure.

Today, the industry produces eleven types of ventilators, including those for ventilation of seam roofing and corrugated board. For original designs of ventilation systems and aerators, non-standard versions of UE are manufactured

Square and rectangular knots on the roof