- Roof ventilation

- Metal roof ventilation device

- Functional purpose

- Design methods

- Summarize

- Ventilation methods

- hip roof ventilation

- Ventilation of insulated under-roof space (attic)

- SNiP requirements for ventilation systems

- What is the principle of the structure of the ventilation passage?

- Groove ventilation

- If the attic is rebuilt into an attic

- • Ventilation of the roof covered with metal tiles

- PELTI-KTV

- Round chimney passage

- Types and arrangement of roof ventilation from metal tiles

- Where to place the ventilation outlet?

- Metal roof ventilation device

- Metal roof ventilation

- We mount the ventilation elements correctly

- 7 Step by step installation instructions

Roof ventilation

Moisture is the main threat to metal roofing. It can get into the under-roof space in several ways:

- through exits to the roof;

- slope joints;

- ventilation slots;

- vapors from heated rooms;

- leaks.

Tasks solved by metal roof ventilation:

- Prevention of condensation on the inside of the roofing material and on the thermal insulation layer.

- Regulation of the humidity regime of the under-roof space, which plays a key role in thermal insulation.

- Preservation of wooden roof elements.

- Ensuring the smooth circulation of cold (from the roof) and warm (from the premises) air flows, which allows you to keep the roof cold in winter. As a result, snow does not melt, icing and icicles do not form. In hot weather, there is no overheating of the metal tile and heat-insulating materials underneath.

The ventilation system of the roof made of metal tiles solves several important tasks.

Ventilation outlets are made in each span of rafters. If under the valley (the inner corner of the roof formed at the point of convergence of the slopes) a triangle is left without insulation, it is enough to mount one exit for every 60 sq. m. roof.

Outlets are usually mounted in the area of the ridge, so that the air, penetrating through the eaves, rises and exits, providing circulation. If the cornice is not suitable for air flow, exits (entrances) are mounted at the bottom of the slope.

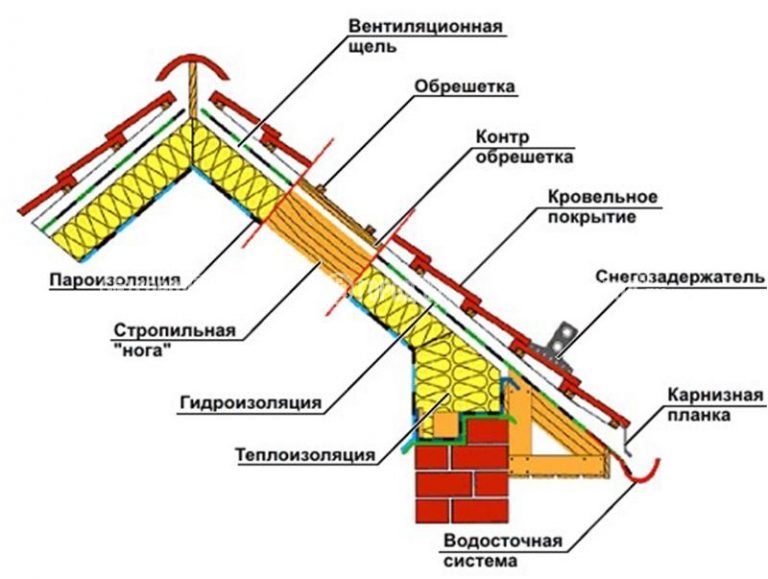

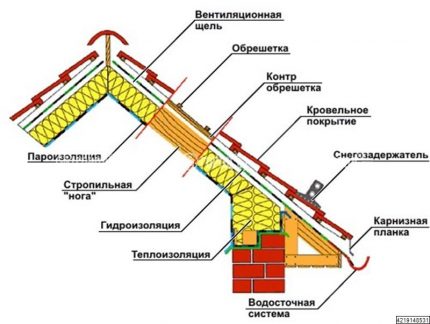

Roof ventilation is installed during the construction of the house or during the overhaul of the roof. Sequencing:

- A crate is nailed to the inside of the rafters. A beam is nailed to it from the inside. In the valley area, it should be continuous. Between the crate and the beam, you can lay a ventilation crate. It will create an additional air gap.

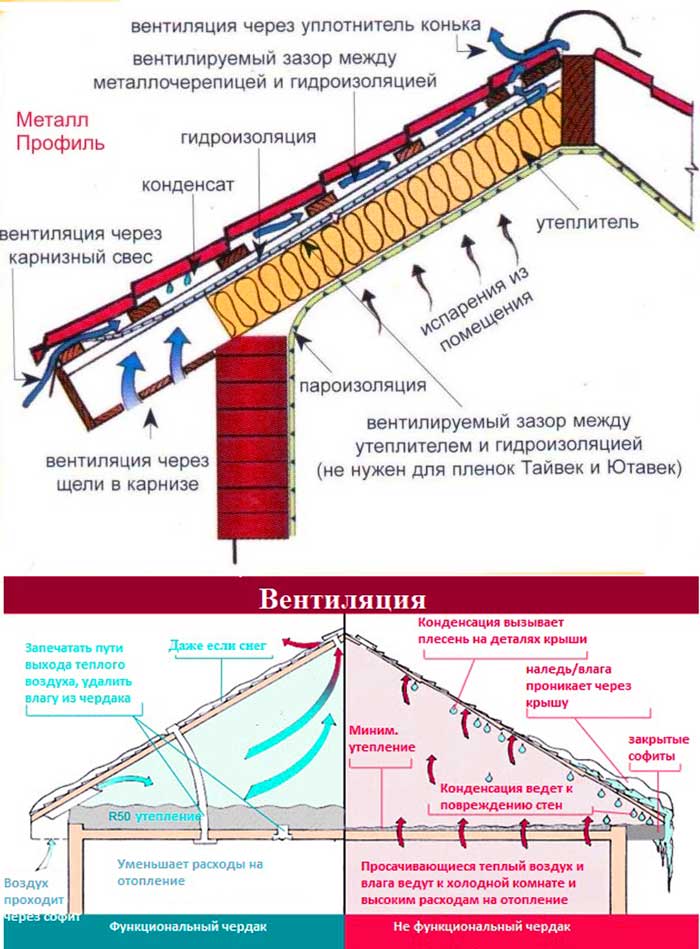

- A vapor barrier is laid on the crate. On top of it, in the intervals between the rafters, a heater is laid. The thickness of the vapor barrier must be less than the thickness of the rafters so that a ventilation cavity of at least 50 mm remains.

- On top of the insulation and the "air" cavity, waterproofing is laid on the rafters.

- On the outer side of the rafters, a counter-lattice is nailed, on top of it is a crate.

- A metal tile is mounted on the crate.

- Ventilation exits are made in the gaps between the rafters in the tiles.

Insulation is not laid in the eaves. Holes are made in its inner walls through which air will flow. It will rise through the cavity above the insulation and exit through the holes in the area of \u200b\u200bthe ridge.

How to make a ventilation passage through a metal roof with your own hands?

To perform the work, you will need the following tool:

- Twincutter for making holes in sheets of metal. If it is not there, then you can use a drill, special scissors, etc.

- Drill.

- Screwdriver or screwdriver.

- Self-tapping screws, moisture resistant sealant.

Sequencing:

- Mark the locations of the holes.

- Make holes in the metal tile according to the marks of the desired diameter.

- Install the outlets in the holes, the edges of which are pre-treated with sealant.

- Attach the exits to the tiles with self-tapping screws.

Metal roof ventilation device

Ventilation of the under-roof space creates a favorable microclimate, affects the service life of wooden roof structures and metal tiles.

A well-arranged ventilation system provides a constant supply of air and its output, relieves the owner of the house from many problems.

The lack of air movement causes increased humidity in the attic or attic space, mold on the walls and structural elements of the roof, their decay and corrosion.

Condensation and moist vapors are always present in the under-roof space to one degree or another, which are formed due to the difference between warm air in the house and cold air outside, defects in thermal insulation, leaks in vapor barrier coatings.

Functional purpose

- removal of condensate and moisture from the under-roof space;

- ventilation of the roofing pie;

- removal of warm air when the tiles are heated.

Ventilation of the metal roofing ensures the constant removal of moisture-saturated air, keeping the elements of the truss system and insulation (if any) dry.

Ventilation of the roofing cake relieves the insulation of wet vapors, retains its thermal insulation properties. To do this, a ventilation gap is made between the layers, which ensures constant air circulation and drying of the insulation.

In the summer, the metal tile heats up quite strongly and to maintain a comfortable temperature, constant air exchange and removal of hot air from under the roof is necessary.

In winter, warm air under the roof causes the formation of ice and icicles, so its timely removal is no less important. Read how the roof pie is arranged under the metal tile

Design methods

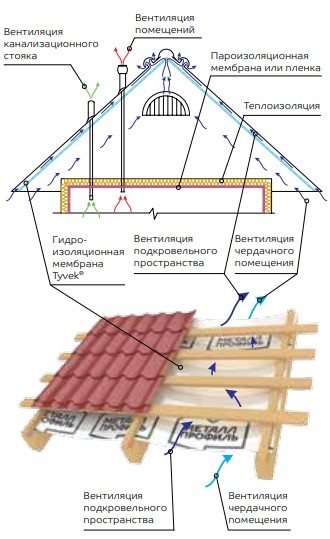

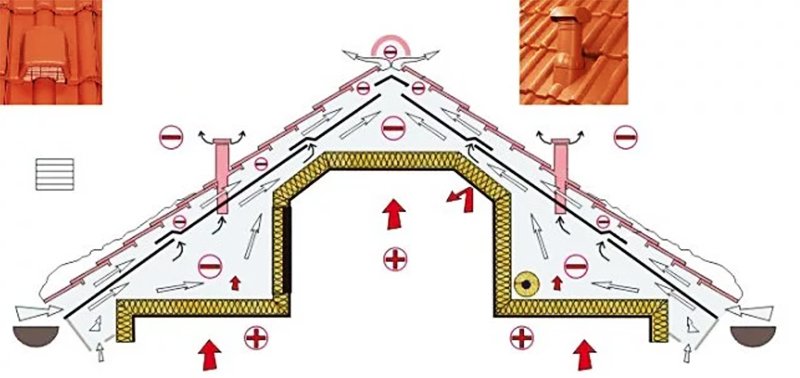

The organization of the ventilation system in the house begins at the design stage. Most often, continuous and spot ventilation is used.

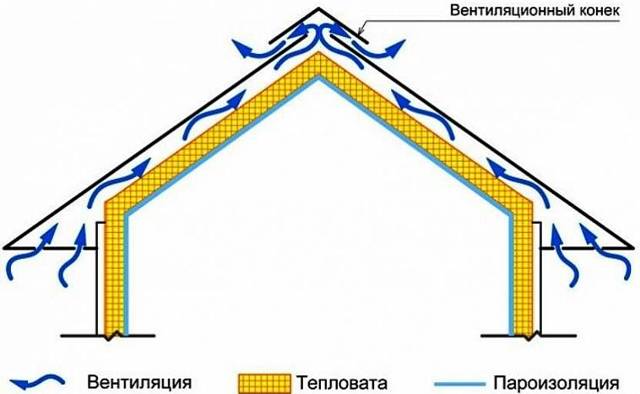

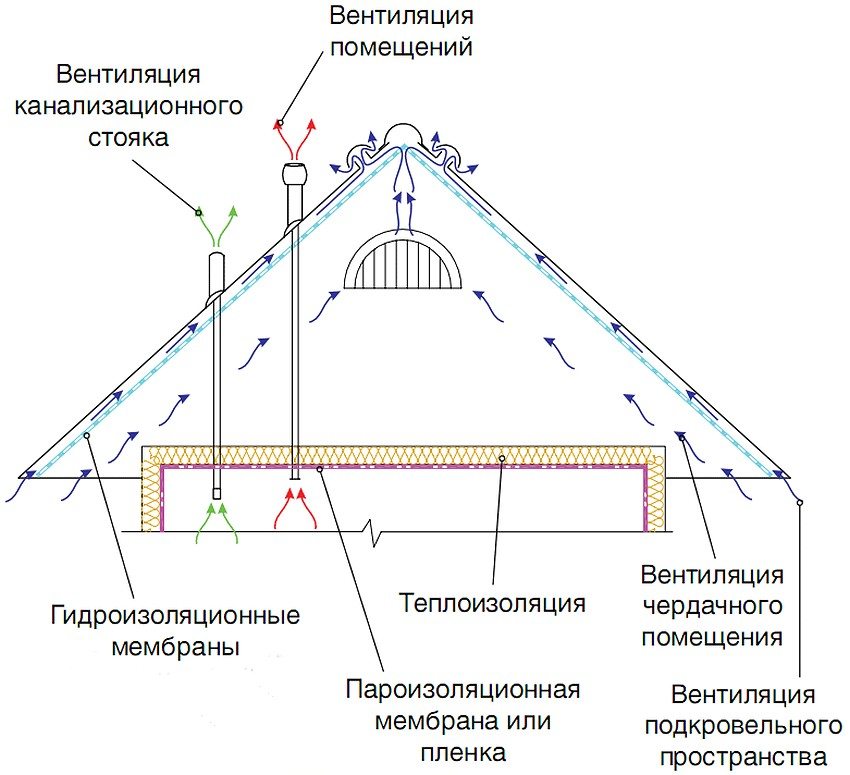

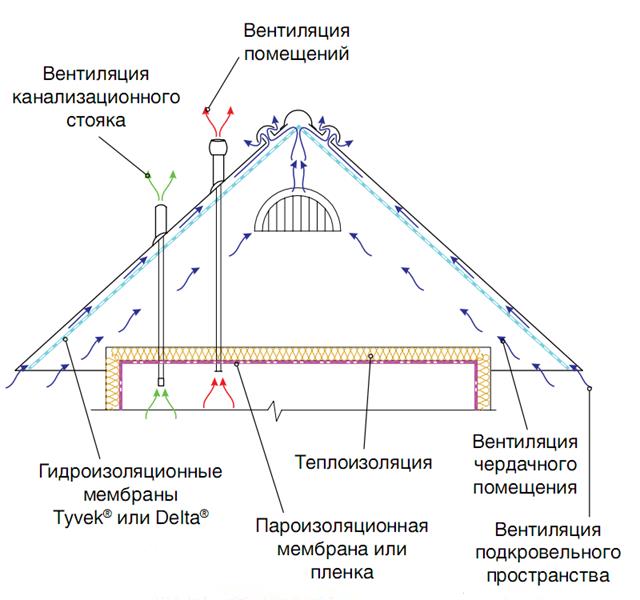

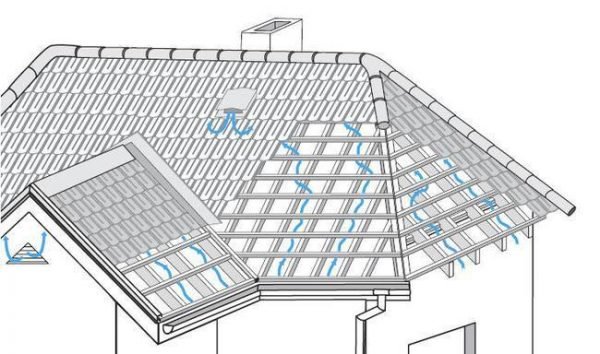

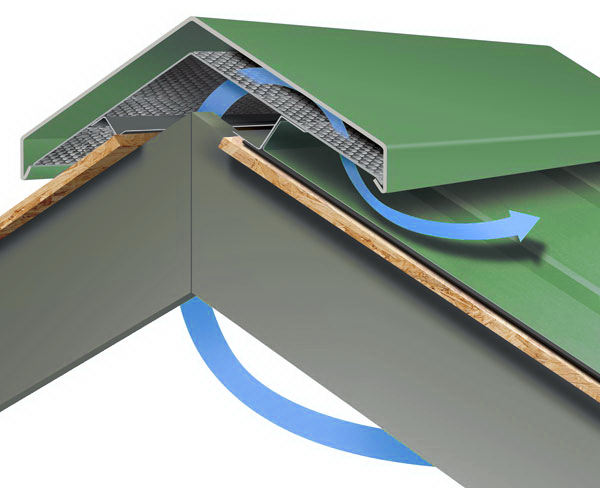

Continuous system - provides air access through the air vents located under the cornice overhang (closed with spotlights) and its output through the ridge.

This is an effective scheme for simple gable roofs, the under-roof space of which has no obstacles for air circulation.With its proper organization, a natural draft is created, like a stove. It provides a continuous natural flow of air.

It is important to ensure a balance between the volume of incoming and outgoing air. In case of malfunctions in the system, moist air remains under the roof

This leads to negative consequences: mold, fungus, rust.

Spot ventilation (aerators) - used in addition to a continuous system, on roofs of complex shape and in the presence of skylights.

Metal or plastic aerators are installed on the roof of metal tiles in the form of a pipe with a cap (from precipitation). For their installation to the metal tile, pass-through elements are used to ensure the hermetic exit of the pipe through the roofing.

The frequency of installation of aerators is calculated individually, depending on the complexity of the roof structure and the presence of skylights.

Summarize

For simple gable roofs, continuous supply and exhaust ventilation is ideal and works almost flawlessly.

If the roof has a complex shape, there are skylights - in the under-roof space for the free passage of air, many obstacles arise, “stagnant” places appear. In this case, it is recommended to combine continuous ventilation with spot ventilation by installing aerators.

It is important to design and install ventilation systems correctly - the service life of the roof and the comfort of living in the task depend on their proper operation.

Ventilation methods

To create conditions for the unhindered circulation of air masses in the attic space, there are two ways: point and continuous.They differ in the different distribution of the outgoing air flow, which carries away all the evaporation with it.

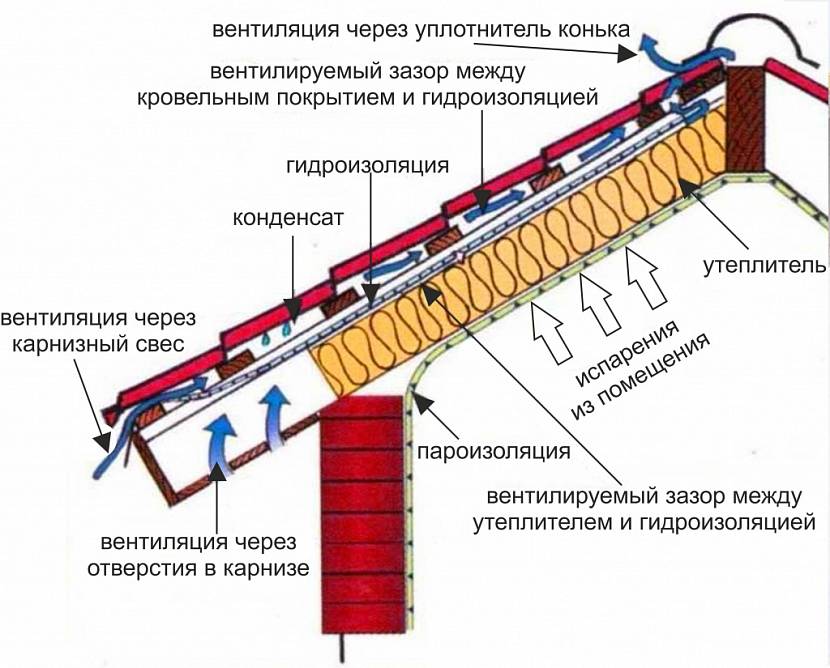

Ventilation by a continuous method is laid even during the design of the roof or before the installation of metal tiles. Its essence lies in the equality of outgoing and incoming flows, achieved due to the same ventilation gaps-air vents. They start at the eaves and end at the ridge, i.e. roof tops.

Proper installation assumes that both between the roofing and the waterproofing layer, and between the protective membranes and thermal insulation, gaps will be laid

Proper installation assumes that both between the roofing and the waterproofing layer, and between the protective membranes and thermal insulation, gaps will be laid

To exclude the possibility of clogging the holes, they are covered with overlays or gratings with small cells. An important nuance is that the total area of the gaps should be at least 1% of the total roof area.

In order to ensure this condition, it is necessary to decide in advance with the height of the timber for the installation of the lathing and the counter-lattice on top of the steam, heat and hydro insulation.

This method works effectively on simple gable roofs, the air in the under-roof space of which can circulate unhindered. If the scheme is executed correctly, there is a natural, like stove draft. It provides a constant supply of air.

Failures in the functioning of the system lead to stagnation of moist air under the roof and, as a result, the appearance of fungus and rust. The point method, as an addition to the continuous method, is used on complex roofs and in the presence of an attic.

For a roof area of up to 60 m², one aerator is enough. If the house is large and the roof area is significant, it is necessary to install several point exits

"Dirty" air flows are removed through a metal or plastic aerator, a device made in the form of a short pipe with a deflector or a flat tile with a grate. Aerators are installed in places that require active removal of moisture to the finished roof, taking into account the wind rose of the area.

In order not to damage the structure, more than one aerator cannot be installed on one floor sheet. On a roof with complex geometry and with several ridges, ventilation outlets for metal tiles are made near each of the ridges with a distance of no more than 0.6 m from them. A point outlet is recommended for a small roof slope (up to 1/3).

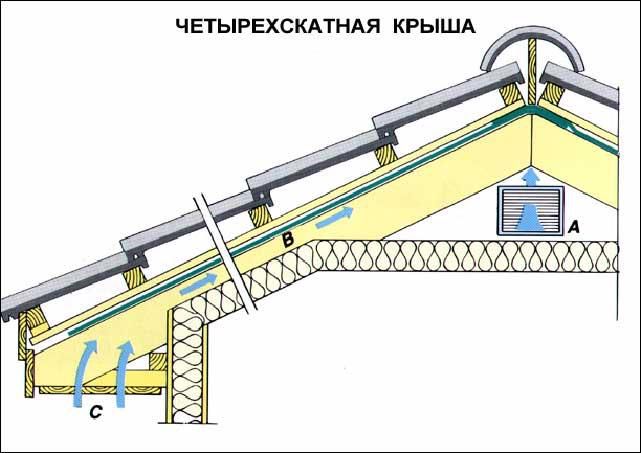

hip roof ventilation

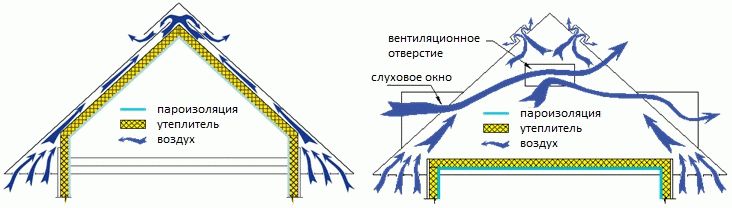

Ventilation of hip roofs can conditionally be divided into two groups - ventilation of a cold attic and an insulated attic.

Arrangement of ventilation of a cold attic space will not present difficulties. Due to the large volume of the attic, there are practically no barriers to the normal circulation of air flows. Air exchange occurs through the cornice overhang, ridge and ridge. Dormer windows, barred and located on opposite sides of the roof, provide a draft.

Natural air circulation occurs through the ventilation gap in the roof and dormer windows

When it is necessary to increase ventilation, aerators are installed along the passage of the valleys. But they make sense if the slope angle is more than 45 °. Otherwise, in difficult areas in winter, due to the accumulation of snow, the work of aerators will be inefficient.

With small slopes, it is better to make forced ventilation using roof fans, inertial turbines or nozzles of sufficient height so that they are not covered with snow.

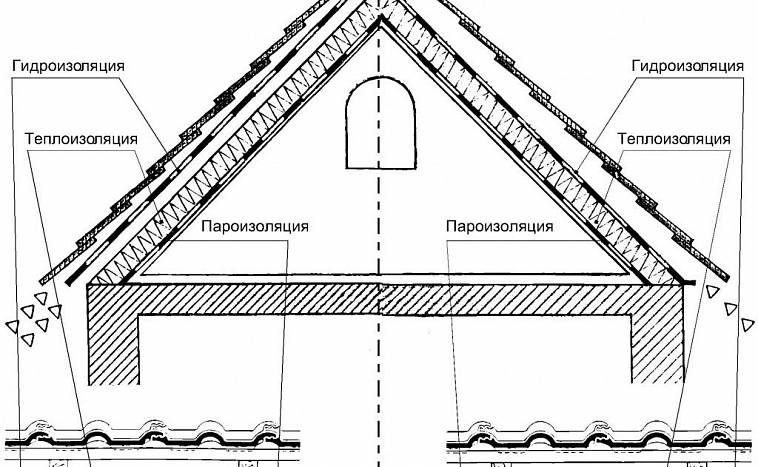

Ventilation of insulated under-roof space (attic)

It is advisable to plan attic ventilation during construction, since its arrangement is more laborious than ventilation equipment for a cold attic. There is no free air circulation here, therefore the space for air exchange is created due to the crate mounted between the insulation and the flooring.

Air circulation in the insulated room occurs due to the ventilation gap in the roofing pie

In addition, a gap of at least 2–3 cm is required between hydro and thermal insulation. If the depth of the rafters does not allow you to make the desired gap, then they are built up with the help of boards.

But such a method of air exchange is quite difficult to do on roofs of complex shapes with many kinks and junctions. Therefore, roofers are advised to mount diffusion membranes (vapor-permeable) directly on the insulation, which allow moisture to pass in only one direction.

SNiP requirements for ventilation systems

The requirements of SNiP can be considered redundant, but they still need to be fulfilled. They clearly prescribe not only the minimum required air exchange for each of the premises, but also regulate the characteristics of each of the elements of the system - air ducts, connecting elements, valves.

The required air exchange is:

- for the basement - 5 cubic meters per hour;

- for living rooms - 40 cubic meters per hour;

- for a bathroom - 60 cubic meters per hour (plus a separate air duct);

- for a kitchen with an electric stove - 60 cubic meters per hour (plus a separate air duct);

- for a kitchen with a gas stove - 80 cubic meters per hour with one working burner (plus a separate air duct).

It is logical to equip the bathroom and kitchen with a forced ventilation system, even if it is natural enough for the rest of the house. The extraction of air from the basement, in order to avoid the concentration of carbon dioxide heavier than air, is also often provided by a separate duct.

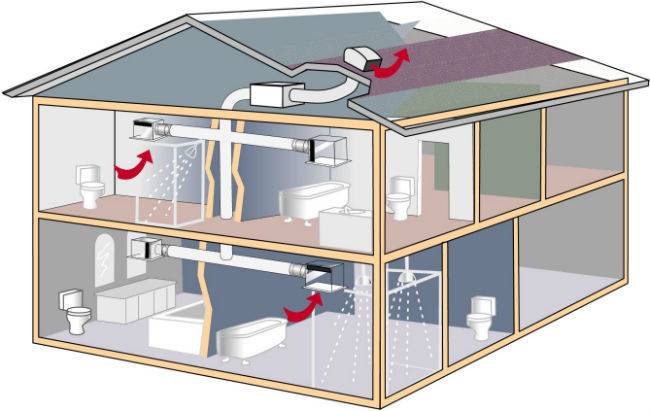

The scheme of air circulation in the house, made in the style of infographics, gives an idea of the flow of air flows

It is very important to check the functionality of the system after installing the duct system. Homeowners who are not ready to turn the roof of the house into a palisade of air ducts often think about how best to equip ventilation communications within the attic.

After all, I would like the design to be not too cumbersome

Homeowners who are not ready to turn the roof of the house into a palisade of air ducts often think about how best to equip ventilation communications within the attic. After all, I would like the design to be not too cumbersome.

But is it possible to remove the exhaust air through the roof structure and its supporting frame - the truss system? And if this solution is acceptable, how best to implement it? What equipment will be required for the arrangement?

What is the principle of the structure of the ventilation passage?

The design features of the ventilation passage, in addition to the removal of dirty air, make it possible to ensure a strong sealing of the roof and protect against the penetration of atmospheric precipitation into the attic. Each node consists of an adapter of a certain diameter, which is inserted into a branch pipe fixed to a concrete sleeve.

Node systems are fixed with anchors, which are included in any standard kit.On a metal base, fastening is also carried out, however, instead of a concrete glass, a similar metal one is built in.

The support ring, which is part of the assembly structure, guarantees a perfect connection between the structure and the roof surface. Clutch flanges provide reliable fastening - the lower one is connected to the air duct, the upper one is the support of the ventilation umbrella, which protects the pipe from precipitation. A ring is placed inside the pipe, which guarantees the removal of condensate.

Groove ventilation

aerators along the valley

From the point of view of erection, subsequent use and ventilation, the valley or groove can be considered the most difficult element of the roof. It is strongly not recommended to make two ventilation gaps if the roof structure is complex, with a long groove and small cornice overhangs. In this case, it is very difficult to create air exchange in the insulation and the rafter system near the valley. Holes in the rafters do not work at all, which also reduce the strength of the structure.

In the roofing film, holes are made in each span or ready-made elements of the lower protective film are installed. It is also possible to equip a continuous air channel along the groove.

Aerators or special ventilated tiles along the valley are placed on the roof.

Therefore, roof fans or nozzles are installed to prevent the penetration of snow.

Such a roof will cost much more. Many customers stop at finely perforated films and subsequently suffer losses due to condensation on the roof.

If the attic is rebuilt into an attic

A simple attic in order to expand the living space can be converted into an attic.In this case, the roof is usually rebuilt. Insulating and roofing materials are replaced with better ones. More efficient ventilation of the roofing pie is being arranged. However if initially the roof is very good installed, you can improve it a little without disassembling it.

In any roof there is at least a very small gap in the crate. It needs to be turned into a ventilation duct. This is achieved by installing special pipes in the plane of the roof through which steam will be vented. Closer to the roof ridge, holes are made with the calculation of 1 pipe per 50 sq. meters of roof. Each such element must be protected from precipitation. As a result of installing a pipe ventilation system, ventilation on the roof will become more intensive.

• Ventilation of the roof covered with metal tiles

Our company offers a range of Vilpe roofing elements for ventilation of the under-roof space for a roof covered with metal tiles.

PELTI-KTV

Roof valve Pelti-KTV is designed for ventilation of insulated (mansards) and non-insulated (attics) roof structures made of metal tiles. The maximum wave height of a metal tile is 38 mm. Pelti-KTV can be supplied with or without an adapter. The valve with an adapter is used for ventilation of attic spaces. In this case, the adapter is connected to a pipe that leads to the attic. Pelti-KTV with adapter can also be used to ventilate sewer risers for countries with warm climates.

Size of the Pelti passage element: 355x460 mm Installation method: installed during installation and on the finished roof

Round chimney passage

If the choice was made in favor of a pipe with a circular cross section, then usually special cuts with a circular cross section made at enterprises are used to ensure a tight fit to the roof and eliminate the risk of leakage and heat loss. In appearance, they resemble corrugated cuffs equipped with wide brim. They are made of rubber, but special - heat-resistant, synthetic. Aluminum cutouts are also on sale. The convenience of their use lies in the fact that they easily repeat the wavy profile of the metal tile and can be fixed both with the help of fasteners and with adhesives.

Chimney seal

A hole is cut in the synthetic rubber penetration, 20% smaller than the diameter of the pipe itself. Then it is pulled onto the pipe itself (to facilitate the process, you can use a soapy solution applied to the pipe). After that, the rubber product is pressed against the roof and fixed on it with a sealant and roofing screws in increments of about 3.5 cm.

The transition from a brick channel to a metal one may be necessary both when installing a new chimney and when repairing an old one.

Types and arrangement of roof ventilation from metal tiles

The ventilation outlet implies the use of a metal or plastic pipe. Its diameter should vary between 30 - 100 mm.

The length often does not exceed 50 cm. The distance from the ridge should not exceed 60 cm. This will allow the internal heated air to freely go outside.

Below are several ways to ventilate the under-roof space of a metal tile:

The first method: to normalize the temperature inside the ventilation gap, a roof type of air exchange is used. With its help, the risks of excess moisture formation, which negatively affects all wooden elements inside the structure, are minimized.

It should be noted that due to overheating of the inner surface of the ceiling, there is the possibility of ice formation, blocking the free circulation of air. This fact determines the low popularity of this method. Roof ventilation involves the installation of pipes equipped with a deflector and elastic penetration. Their length should reach the level of the rafters.

The second method is to arrange ventilation through the roof of the metal tile. In this case, the ventilation outlets will be through, reaching the attic. According to the principle of operation, they are similar to coaxial pipes.

Their design assumes the presence of two independent circuits that contribute to the constant removal of excess moisture and air exchange. The disadvantage of this method is its high cost.

However, this significantly increases efficiency, which in the future will avoid the cost of premature repair of the roofing.

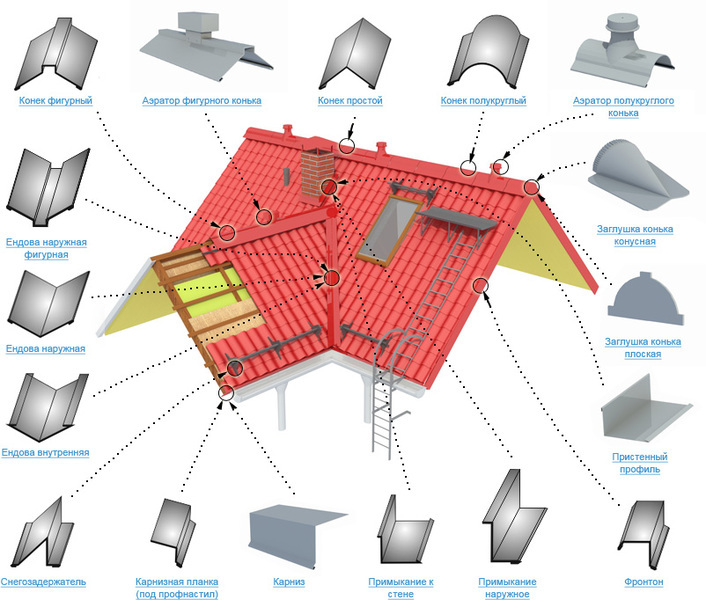

Depending on the design of ventilation, there are several varieties of it.

The eaves air is a kind of entrance for air currents.

One of the options for the eaves

Can be of two types:

- point vents are small holes, the diameter of which does not exceed 1 - 2.5 cm. The size depends on the slope of the roof - the stronger it is, the smaller the holes are needed. They are often located under the grooves for draining water.This prevents them from freezing and forming an ice crust. The outer part is protected by special soffits that prevent clogging with foliage and other debris;

- slotted vents are horizontal or vertical slots, the width of which should not exceed 2.5 cm. Thanks to them, constant air circulation is maintained in the space under the ceiling. The outer part is closed with a woven mesh to prevent clogging.

The ventilated ridge is a ventilation outlet.

Scheme of operation of a ventilated skate

It is the highest point of the system and contributes to the release of vapors and moisture. It happens slit and point.

The roof aerator enhances the circulation of air flows in the required direction. Outwardly, it looks like a pipe up to 50 cm long.

The inner part is a passage that provides tightness. A deflector (cap) is placed on top to prevent debris and foliage from entering.

Roof aerator

The advantage of this type is that the installation can be carried out both at the initial stage of the installation of the roof, and after commissioning. Aerators are suitable for all types of floors - both for soft bituminous and metal ones.

Firms that produce roofing materials also produce aerators. The range includes more than 50 products of various shapes and sizes.

Grooves (valley) are suitable for roofs with a complex structure and are installed in the event of the formation of depressions at the junction of slopes.

With its help, a channel is formed for the constant circulation of air flows. Depending on the specifics, the grooves are divided into open and closed.

A universal way to arrange ventilation involves the use of a pipe whose diameter should not exceed 50 cm. In addition, it must be equipped with a protective deflector located on the head.

To date, a wide range of plastic aerators is presented. This allows you to choose the right option, taking into account the characteristics of the roof, weather conditions, climate, landscape.

Modern aerators are made of high quality materials that are resistant to constant solar radiation and precipitation, acid damage. Some manufacturers promise to maintain the performance of systems at temperatures from -50 to +90 degrees Celsius.

The cost of metal aerators is much higher. The scope of their application is large industrial and production facilities.

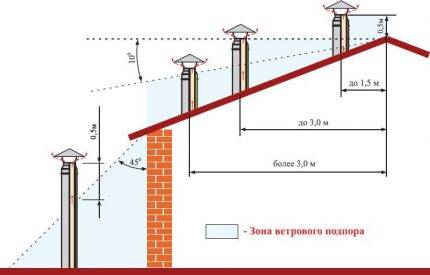

Where to place the ventilation outlet?

When arranging an exhaust outlet through the roof, it is important not only to ensure the tightness of the passage through the roofing pie, but also to choose the right location. You also need to correctly determine the height of the exit, because the draft in the ventilation duct directly depends on it

Firstly, it is better to make the ventilation outlet through the roof as close to the ridge as possible.

Even a ventilation outlet with an electric fan is better to bring closer to the ridge. In this case, during a power outage, natural traction through it will remain.

Even a ventilation outlet with an electric fan is better to bring closer to the ridge. In this case, during a power outage, natural traction through it will remain.

This arrangement has several advantages:

- Most of the ventilation duct will pass through the attic, where there is no wind, and the temperature is always slightly higher than outside. Thanks to this, the layer of insulation on the pipe can be made thinner;

- The ventilation outlet, located at the ridge, has a minimum height above the roof surface, therefore it is resistant to gusts of wind and does not require additional fasteners;

- You can use a factory-made ventilation outlet, which will give the roof additional aesthetics.

Don't worry. It is better to think carefully about how to make a tight exit of the ventilation pipe on the roof if it is not possible to install it close to the ridge. In this case, the passage simply needs to be additionally isolated and secured.

Secondly, in order not to get into the wind backwater zone with the pipe, which every house with a pitched roof has, the height of the ventilation pipe deflector should be:

- 0.5 m above the roof ridge, if the exit is located no further than 1.5 m from the ridge;

- not lower than the roof ridge, if the exit is at a distance of 1.5 m to 3 m from the ridge;

- not lower than a line drawn at an angle of 10o from the ridge to the horizon, if the ventilation outlet is located more than 3 m from the ridge;

- if the ventilation pipe is removed from the annex to the house, then its deflector should be located 0.5 m above the line drawn from the roof eaves of the main building at an angle of 45o to the horizon.

Providing the specified height above the roof is extremely important for any ventilation, and for natural ventilation it is vital. Do not allow the end of the natural ventilation pipe below the dotted lines indicated in the diagram

If this rule is not observed, there will be no normal draft in the ventilation duct.

Do not allow the end of the natural ventilation pipe below the dotted lines indicated in the diagram. If this rule is not observed, there will be no normal draft in the ventilation duct.

Do not allow the end of the natural ventilation pipe below the dotted lines indicated in the diagram. If this rule is not observed, there will be no normal draft in the ventilation duct.

If this rule is neglected, then the hood deflector will fall into the zone of wind backwater and in windy weather, at best, there will be no draft, and at worst, reverse draft will appear and air from the street will go into the house.

Metal roof ventilation device

The roof ventilation system consists of the following structural elements:

- cornice products;

- ventilated skate;

- roof aerators;

- groove.

Let's consider each of the devices in more detail.

- Cornice air. Another name is a ventilation inlet, since air is drawn in through the slots and holes in the plank under the cornice, which then enters the under-roof space. Distinguish:

-

point blowers. Holes with a diameter of 10 to 25 mm in the lower part of the eaves. The smaller the slope of the roof, the more air is made. As a rule, the holes are located under the gutters to avoid icing, and lined with soffits on the outside to protect against clogging by leaves or debris;

-

slotted vents. Holes in the form of a vertical or horizontal slot up to 2.5 cm in size. Provide round-the-clock access of fresh air to the under-roof space. In order to prevent leaves and small debris from clogging the cracks, an additional ventilation mesh, consisting of a fine-meshed braid, is mounted on top of the vent.

-

-

Ventilated ridge (or ridge vents). Another common name is a ventilation outlet. Since the ridge is the highest point of the pitched roof, this is where the air comes out. It is produced in two ready-made versions: with slit-shaped vents (up to 50 mm) or with pin holes along the entire length of the ridge.

-

Roof aerators.They are additional components of the general roof ventilation system. With the help of aerators, they increase the movement of air masses, give it the right direction. The design is a pipe of short length (up to 50 cm), inside which there is a passage that ensures the tightness of the connection with the roof, and a deflector - a cap to protect against water and dirt. The installation is carried out both during the initial assembly of the roof and on the roof that is already in operation. The versatility of aerators lies in the fact that they are used for all types of roofs and coatings, from metal to soft bituminous roofing. Each company engaged in the production of roofing material produces aerators for its own products. The range includes up to 50 items of various shapes and sizes.

-

Grooves are a ventilation element that serves the roof of a complex configuration. If a depression (valley) forms at the junction of the slopes, then before laying the metal tile, it is necessary to install a groove that will create a ventilation channel for air movement. There are two types of grooves: internal and external.

We have considered passive ways to remove moisture. Most of the time, they do a great job. But if such ventilation is not enough, forced air circulation systems are used. Their main difference lies in the presence of an electric fan, which is located inside the pipe and accelerates the passage of air.

Air speed adjustment can be carried out automatically or manually from a special operator panel

In addition, there is a group of so-called turbine-type aerators. Many experts consider them to be the most efficient roof ventilation devices. The upper part of the device, which interacts with the external environment, is equipped with a deflector with a turbine, which rotates under the influence of the wind. At the same time, the natural thrust increases many times (by 5–7 times, depending on the strength of the wind). A necessary condition for the use of such equipment is an adequate increase in the size of eaves and spotlights.

The turbine built into the pipe increases the efficiency of the aerator several times

picking up ventilation kit roofs made of metal, you need to pay attention to such points:

- you should purchase an aerator with a base profile that matches the relief of the tiles;

- the following elements must be included in the package - a list of technical characteristics of the device, an installation and operation manual, a mounting template, gaskets, a pass-through element, a set of fasteners;

- it is desirable to match the color of the aerator to the color of the metal tile;

- the larger the size of the serviced area, the larger the diameter of the aerator (small areas can be equipped with pipes with a small diameter);

- the material of the product must comply with the conditions in which the device is operated (the quality of plastic or metal must be documented).

Metal roof ventilation

The metal roof is beautiful, modern, durable and reliable, but it has one big drawback - limited air exchange, that is, it does not pass air well. To ensure normal circulation, ventilation is established according to the following algorithm:

- Holes are made in the cover sheet for the exit of ventilation ducts, adhering to the norms - one hole per 60 m² and placing them at least 0.6 m from the ridge. On a roof with a complex structure, the number of exits is increased.

- The front metal part near the hole is treated with an antiseptic to prevent corrosion.

- The rubber seal is coated with silicone and reinforced with screws.

- After the sealant dries, install the penetration and fix it with special screws included in the delivery.

- From the inside, they provide a reliable connection with vapor and water insulators (films).

-

To prevent moisture from penetrating into the insulation, a sealant is additionally applied at the junction of the insulation.

We mount the ventilation elements correctly

It is important to install penetrations through the roof correctly. To do this, follow a simple step-by-step algorithm:

Mark a hole in the metal tile for the pipe. Then carefully cut it out.

Fix the passage element in the tile. Use self-tapping screws for fastening. Do not forget to apply sealant before fixing it.

Insert the outlet carefully into the lead-through element. The output can be sewer, ventilation, etc.

It is important that the outlet is absolutely vertical. Use a level to check

When you are sure that the outlet is installed correctly, secure it with self-tapping screws.

Connect the outlet of the hood to the air duct, which is located directly inside the house. To do this, you need to use a corrugated pipe. It will be stretched through layers of vapor and waterproofing, as well as through insulation. Be sure to provide good waterproofing in places where it passes. To do this, use adhesive tape, as well as a sealant, sealant.

You must understand that the penetration must withstand a certain load, including vibration, atmospheric pressure, and temperature changes. Different materials are used for the manufacture of penetrations. It is most often silicone, rubber. The advantage of these materials is that they are not afraid of corrosion, the scorching sun. They will fit snugly on the roof. Remember that this is one of the main barriers that will protect the rafter system. If you do not provide good protection, the tree will quickly rot.

When installing ventilation, it is important to properly arrange the passage of the shaft through the roof. Here you will need to install the passage node

There are several types of it. They have differences in installation. Each type has its own characteristics of the installation.

When choosing a node, consider the type of ventilation.

Air ducts are most often installed on reinforced concrete glasses. They are fixed with anchor bolts or nuts. Such nodes will carry air if the humidity is not higher than 60%.

7 Step by step installation instructions

The procedure for installing a ventilation duct on a roof structure is not too complicated. It can be easily performed by anyone, but for this you need to be guided by the following instructions:

- 1. First of all, you should deal with the installation location of the pass-through unit on the roof.

- 2. On the upper wave of the metal tile, it is necessary to draw the contours of the future hole, applying the template that comes with the element itself.

- 3. After that, cut a hole on top with a chisel and scissors for metal, and also make several holes in the lower layers of the roofing cake.

- 4. Following the template, you need to drill several holes for the screws.

- 5.Then it remains to clean the roof surface from moisture and dust residues.

- 6. Apply a layer of sealant to the bottom of the gasket.

- 7. Then it is necessary to lay the gasket in the right place and fix the passage element in it. After making sure of the reliability and correct location of the structure, you can proceed to fixing. For this, screws are used.

- 8. At the end, it is necessary to ensure the tightness of the ventilation outlet to the roof from the attic.

Based on the foregoing, there are practically no difficulties in installing a ventilation duct on the roof. If you draw up the right project in advance, make calculations and study the installation instructions, the future ventilation system will work in the best possible way. At the same time, the operational life of the roof, which has gone through a lot of changes due to the appearance of a new node, will not be reduced in any way. But for this you need to responsibly treat the upcoming work and follow the basic installation rules.