- 5 main types of soft roofing

- The cost of installation of shingle roof units

- Slope Selection Criteria

- Common styling mistakes

- Types of soft roofs

- Tools and equipment for soft roofing

- Roofing nails and screws

- Ventilation device technology

- How is soft flooring installed?

- Installation of the valley cover

- Some nuances of arranging a soft roof

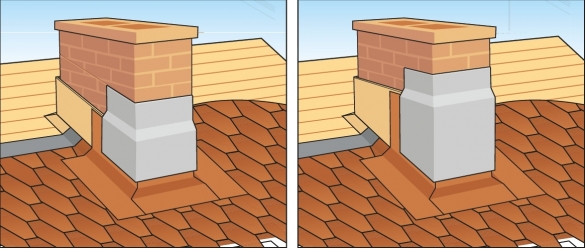

- Junction and waterproofing of chimneys on a soft roof in stone and wooden houses

- Rules for the use of soft tiles

- Inverted flat roof installation technology

- Installation of an inverted flat roof is carried out in the following sequence:

- Flexible roof device

- Works on laying a flexible roof

- crate

- Laying shingles

- Installation of the cornice row and the first sheet of tiles

- Laying subsequent rows

- Specificity of soft roof DÖCKE PIE

5 main types of soft roofing

Manufacturers offer the following classes of soft roofing materials, focused on various installation methods:

Roll coatings based on bitumen. Their predominant scope is industrial buildings and residential structures with flat and low-pitched roofs (when the slope angle does not exceed 3º).Roll materials are successfully used for waterproofing roofs, they are laid in strips, and adhesion is provided by fusing.

Installation of a soft built-up roof

polymer membranes. They are also supplied in a roll format, but they contain an additive - a polymer modifier applied over a reinforcing base. The new component improves resistance to high temperatures and maintains ductility at low temperatures. Bitumen-polymer membrane materials have good adhesion (adhesion to the surface), high mechanical strength and the ability to recover in places of minor damage. If the roofing carpet is chosen correctly, the bitumen-polymer roof will last at least 20 years.

Laying a polymer membrane

Roofing mastics and emulsions. They have a limited area for full use, as they are a polymer or bitumen-polymer mixture and correctly lie only on a horizontal surface. More recently, such materials were used only as a waterproofing or bonding layer in the roofing carpet. Today, mastic is increasingly used as a full-fledged independent coating. Depending on the type, it is applied by pouring, spraying or using a spatula (distributing over the surface). Fiberglass layers are used for reinforcement.

Roof covered with bituminous mastic

baseless materials. Relate to rolled roofing; a well-known representative of this class is polyethylene film (plain or reinforced)

Baseless materials are known for their ductility, durability and bio-permanence, making them an important part of the roofing pie (as an inner layer) for both flat and pitched roofs.

Deaf vapor barrier - polyethylene film

Bituminous tiles. At its core, these are piece products of a modified roofing material. The material has the form of flexible sheets with a curly outer edge. If rolled and mastic materials are suitable for use on the roofs of avant-garde or high-tech residential buildings, then shingles are usually chosen for buildings in the most common, classic style. It is able to elegantly imitate natural ceramics, slate tiles and wood shingles.

The cost of installation of shingle roof units

The laying of the tile itself and the installation of its nodes costs about 350 rubles per square meter (not counting the crate and preparation of the base). It is better to entrust professionals to make roof knots from soft tiles. Since these are the most vulnerable places of the roof, installation errors almost always lead to damage to the appearance and leakage.

We have been engaged in roofing for 15 years, and the production experience of our craftsmen is even longer. We will install the roof itself and / or its components quickly and with excellent quality.

At your service:

- transparent estimate, no additional costs;

- polite Russian-speaking performers;

- two year warranty.

Slope Selection Criteria

People who first encountered the construction of a roof often believe that it is possible to choose the angle of inclination of the slopes, based only on taste, aesthetic preferences.In fact, there are clearly defined criteria that help you choose the right minimum roof slope for a particular roofing material. When designing a roof, the following factors must be taken into account:

- The amount of precipitation in winter. On gentle slopes, snow masses that accumulate on the roof during snowfalls do not slide down, due to which the load on the roof frame increases significantly. The more precipitation falls in the construction region, the greater should be the angle of inclination of the slopes.

- wind load. If the construction region is characterized by strong, gusty winds, then it is impossible to build a roof with steep slopes there, as it can be deformed due to intense wind load. Therefore, in such an area, the roof is given a minimum angle of inclination.

- material properties. Each roofing material is effective only in the range of slopes recommended by the manufacturer. Soft roofing can be mounted on roofs if the angle of inclination of the slopes exceeds 11 degrees.

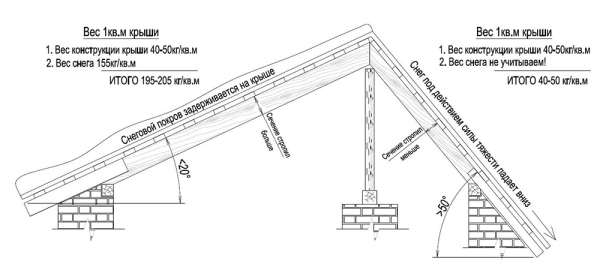

Roof load depending on slope

Roof load depending on slope

Common styling mistakes

| Problem causing leakage or damage | Description |

| Poor fixing of the flooring | If the deck flexes or deforms, the fasteners can bend and damage the tile plates, causing leaks. |

| Ignoring the vapor barrier | This leads to the ingress of moisture into the insulation and the destruction of the roof structure. |

| Incorrect laying of a soft roof in the first row | If there is a coincidence between the joints of the plates in the starting and first rows, then this will inevitably cause leakage in the area of the lower part of the ramp |

| Poor fixation of plates | With weak fastening of the plates, a gust of wind will easily lift and tear off the plate.To avoid this, it is necessary to correctly position the nails: they must be mounted through the fastener strip above the adhesive line covered by the petals |

| Roof package bend | If, during installation, a package with plates is not placed on a flat surface, it will deform, and the roof layers will separate. Packages must be placed on a flat surface. |

| The adhesive strip on the plates goes continuously | In such structures, water does not get out, falling under the plate from the side, from which it moves to the side to the joints between the roof. Usually these are places near chimneys, valleys or internal drains. |

| Ill-conceived roof design | If the roof is not designed correctly, the following problems may appear: incorrect location of valleys or gutters, dormer windows, chimneys. It is difficult to solve this problem, since it appears even during construction. But leaks need to be found. |

| Poor chimney waterproofing | Before proceeding with the correction of this problem, it is recommended to check the masonry for the presence of fallen bricks. A common mistake that causes leakage: the lack of flanging aprons when laying |

| Low quality valley coating | Most of the films offered on the market have a service life of 5-7 years, which clearly does not coincide with a roof that can stand for 50 years. Therefore, according to the installation rules, it is necessary to use a high-quality waterproof film in combination with a metal apron. |

Types of soft roofs

Soft roofing is currently used everywhere: for private buildings, public buildings, roofs of complex configuration.

Modern production has made it possible to create a relatively inexpensive coating (on average 200 - 250 rubles per square meter, the price depends on the brand of the manufacturer and the region of sale) with excellent quality and strength characteristics.

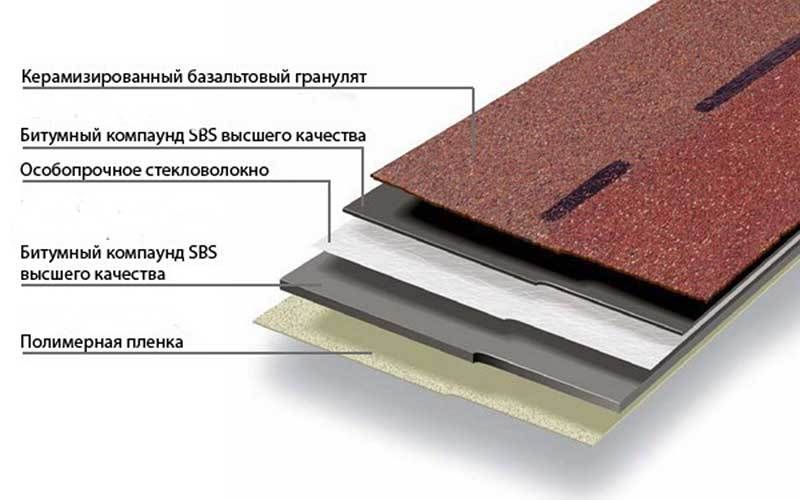

Currently, flexible roofing is produced in multilayer:

- stone granulate (colored, which makes it possible to choose the color of the coating);

- modified bitumen;

- fiberglass, which acts as a reinforcing layer;

- another layer of modified bitumen;

- self-adhesive layer;

- protective film.

This is the standard and most reliable option, some manufacturers produce five-layer building materials, where the second layer is modified bitumen, and the third is basalt dressing for reinforcement.

Also included in the category of soft roofs are:

- Rolled building materials, which are the latest generations of roofing material or polymer membranes. For laying roofing felt rolls, fusing technology is used, the installation of a polymer membrane consists in gluing.

- Roofing mastic for flat roofs is sprayed or applied in a thick layer, forming a durable seamless coating.

To use the technology of soft roofing from built-up materials (bitumen rolls), a special gas burner is required. As the roll unfolds, it is heated from the back side by a burner, resulting in sintering with the substrate. The polymers are heated with a building hair dryer and glued.

Mastic can be either hot (during application it requires preheating to high temperatures of 160-180 degrees), and cold, which is sprayed or applied manually (for example, with a roller).

All described types (rolls, mastic, tiles) can be both domestic and imported. Among domestic manufacturers, TechnoNIKOL, RoofShield, Ruflex are well known, imported ones are Tegola (Italy), Owens Corning and CertainTeed (USA), FinMaster and Katepal (Finland).

Flexible roofing sheets are produced in different colors and configurations: fig. 1. This allows you to choose the most attractive coating texture (in terms of overall design).

Tools and equipment for soft roofing

A set of tools required for laying a soft roof can be found in every home workshop:

|  | ||

| Roofer's hammer | Putty knife | Knife for cutting shingles | Metal shears |

|  |  | |

| Sealant gun | Building hair dryer | Construction lace for marking or a coil of ordinary nylon cord | Roulette |

Roofing nails and screws

| Fastener type | Application area | Fastener type | Length | Peculiarities |

| Type 1 | Underlayment carpets, ordinary flexible tiles, ridge and cornice tiles, valley carpet, cornice and end strips | Galvanized ruffed nails | Not less than 30 mm | Cap diameter from 8 mm |

| Galvanized screw nails | ||||

| Type 2 | Solid base - OPS-3 boards or FSF plywood | Galvanized ruffed nails | Not less than 50 mm | countersunk head |

| Galvanized screw nails | ||||

| Self-tapping screws galvanized, anodized or galvanized wood |

In addition to tools, you will need:

- flooring material;

- aerators for roof ventilation;

- lining and valley carpet Döcke PIE;

- metal eaves and pediment strips;

- rectangular ridge-cornice and decorative row tile Döcke PIE.

- bituminous mastic Döcke PIE;

- snow retainers;

Safety gear is also required for safety.

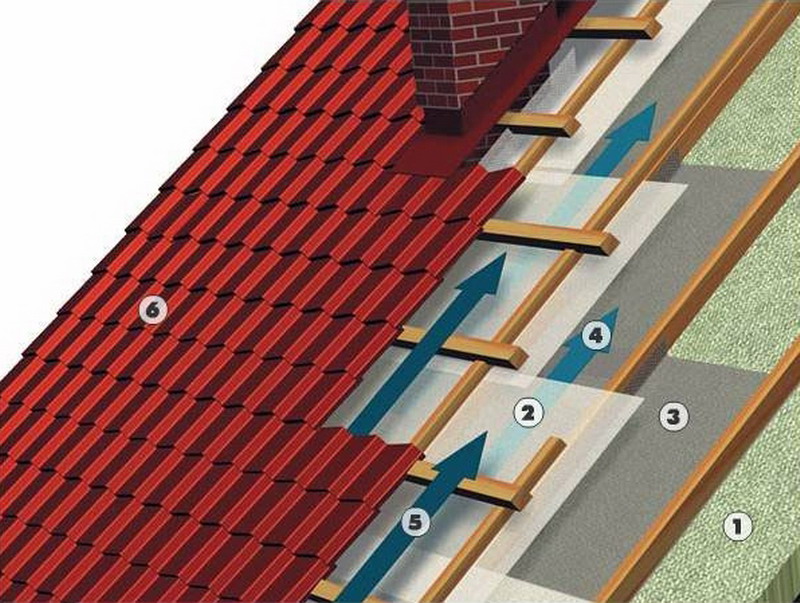

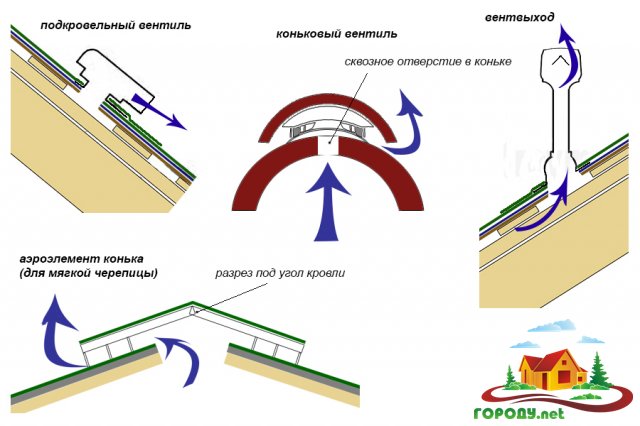

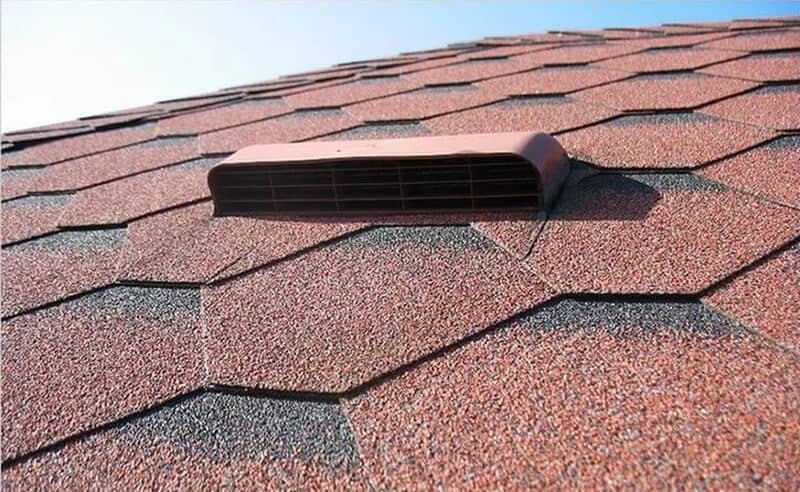

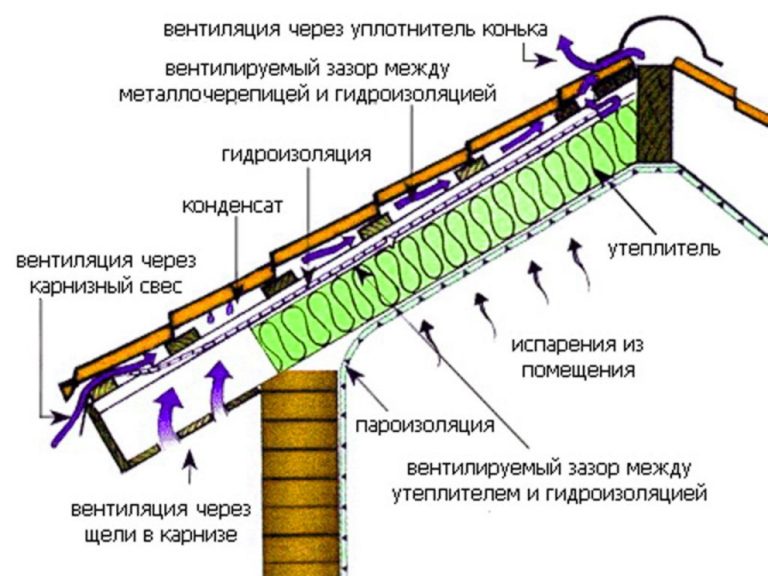

Ventilation device technology

The bituminous coating is excellent at repelling water due to the minimum number of pores that allow moisture and air to pass through. The hydrobarrier functions in two directions: precipitation does not penetrate the roof, but steam does not leave it either. If you do not provide for evaporation to the outside, condensate will begin to settle on the crate and rafters.

In order for the roof to last for a long time, roof ventilation should be provided, consisting of:

- from the air vents that serve for the entry of air in the zone of the cornices and are open channels, which are formed due to the crate and the counter-crate;

- ventilation gap between the bituminous coating and the insulation mounted on top of the vapor barrier layer;

- holes located at the top of the roofing pie. They can be the ends of the slope, not closed from above, plastic vents in the form of tubes.

Ventilation is arranged so that air sacs cannot form in the under-roof space.

How is soft flooring installed?

Soft tiles are great for building a roof from scratch, as well as for repairing old structures. The second option involves the use of the material as an additional layer to the existing coating, which will become the lining carpet. In this case, the installation of a roof for a soft roof involves the preparation of old material - it must be well fixed and cleaned.

Any wooden elements of the roof base are treated with a special refractory and antifungal compound. The allowable gap between the boards installed to the rafters is no more than 2 mm.Additional waterproofing is carried out using a lining layer - the method of its fastening is shown in the photo.

At the next stage, the installation of metal aprons is carried out, which reliably protect the ends and cornice overhangs.

The correct location of the roof - from the eaves to the ridge. You can fix the tiles on nails, on top of the caps of which the next layer of coating should be laid, that is, the device of a soft roof is carried out with a slight overlap of each of its elements (read: “Elements of a soft roof - installation”). The peculiarity of the installation is the gradual horizontal shifting of each subsequent row so that the tongues located on the tiles are connected to the cutouts in the coating below the laid row.

Installation of the valley cover

It is the zone of internal fractures of roofs (valleys) that is subjected to the greatest load during rain and snowmelt. Döcke PIE valley carpet is used to waterproof these areas.

Rules for laying the valley web:

- Installation is carried out over the lining carpet so as to avoid overlapping seams. To do this, a slight offset (2-3 cm) is made relative to the axis.

- Along the perimeter on the reverse side, the edges of the valley coating are smeared with bituminous composition. To remove air, the carpet should be pressed tightly against the base, especially at the junction of two slopes.

- For additional fixation, stepping back from the edge of the canvas 3 cm, a row of nails is stuffed in increments of up to 10 cm.

- In the center of the recess formed by the slopes, markings are applied to the laid valley sheet with a cord, indicating the edges of the gutter, the total width of which should be in the range of 10-15 cm.

- If possible, the valley carpet is laid in a single panel.If docking cannot be avoided, then the joint should be located as high as possible, performing an overlap of 20 cm or more with mandatory lubrication with bituminous mastic.

Some nuances of arranging a soft roof

The composition of the roofing cake is important for the long-term trouble-free operation of the roof. If you use inappropriate materials or change (reduce) the number of layers of the roofing cake, the consequences will not be long in coming. The roof structure will become unusable; you will get leaks, condensate, damp insulation and rotten elements of the roofing system requiring replacement.

In order for the roof to serve its time perfectly, during installation it is necessary to use additional recommendations, which include the following tips:

Soft roof urgently needs ventilation. The waterproofing of the roofing pie not only reliably protects the structure from raindrops, but also prevents steam from escaping. Failure to ventilate will cause condensation to accumulate inside the cake and cause it to leak.

Arrangement of ventilation (ridge air

- Types of ventilation. The roof ventilation system can be passive when ventilation gaps (open channels) are formed between the layers. When arranging the forced option, the roof structure is equipped with a factory-made ventilation system. Such a system is able not only to effectively ventilate the under-roof space, but also to start forced air circulation in the attic and in the attic.

- Chimney bypass.An important technological subtlety is a soft roof, all types of which serve as a high-quality replacement for traditional tiles, unlike the latter, should not adjoin the chimney. During installation, the chimney is carefully insulated around the entire perimeter; the conditions for ensuring the fire safety of a roofing pie are regulated by SNiP standards.

- Mixing shingle. During installation, it is recommended to mix bituminous elements from several packages. Shades from different packs (even in the same batch) may vary slightly. Mixing will allow you to evenly distribute the tones over the surface of the roof, avoiding sharp transitions from tone to tone (which is always striking). This will be useful in the future, if you need to pick up material for repairs.

Arrangement of abutment to the pipe

A shingle roof surpasses many roofing materials in terms of strength (easily tolerates hail), resistance (to wind gusts) and solidity. To keep these wonderful properties as long as possible, it is necessary to carefully care for the roof during operation. To clean the roof from snow, a wooden shovel is chosen (it will not damage the protective basalt dressing on the shingle). It is convenient to remove summer dust and dirt with a water jet from a hose.

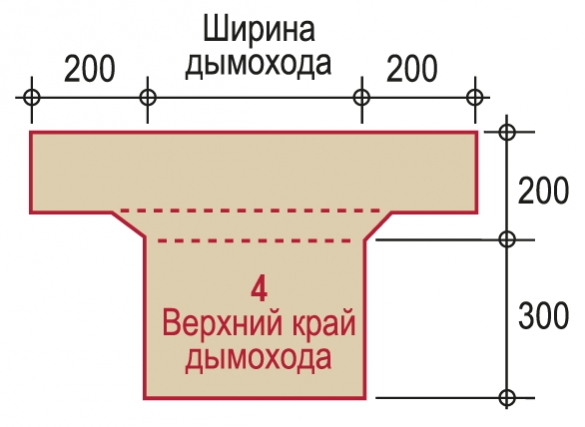

Junction and waterproofing of chimneys on a soft roof in stone and wooden houses

If we summarize the most frequent questions of developers on the junction of flexible tiles to chimneys, then they sound like this:

- How to make the correct connection of chimneys and air ducts on a soft roof?

- How to get around the chimney pipe with a soft roof if the house is wooden and subject to shrinkage?

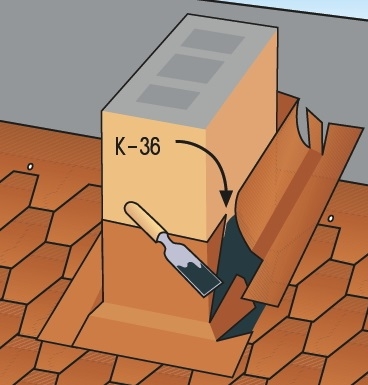

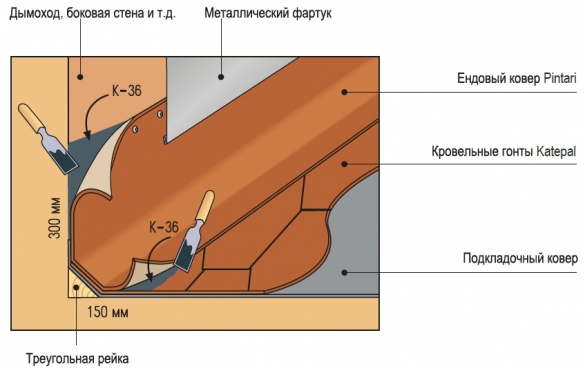

First, we will tell you how to mount the junction of the soft roofing of chimneys in ordinary houses.

One of the most modern and aesthetic solutions is to bypass the pipe with a valley carpet or a metal apron. When using a metal apron, the installation of flexible tiles is carried out as usual, but the edge of the shingles is brought to the side of the apron. It is also necessary to retreat about 80 mm from the bend. The resulting gutter provides an unobstructed flow of water around the pipe.

Let us dwell in more detail on sealing the junction with a valley carpet. The difference between a valley carpet and an ordinary lining carpet is that it is based on high-strength polyester. It provides unsurpassed strength compared to fiberglass, which is the basis of the underlayment.

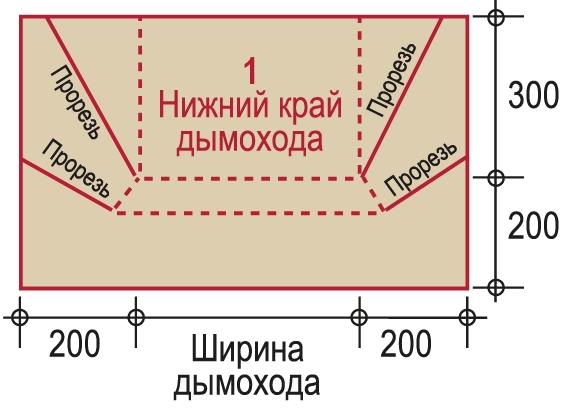

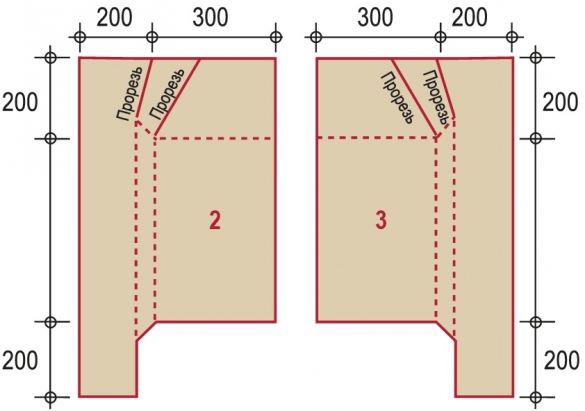

Chimney sealing procedure:

- From the valley carpet, according to the pattern, the chimney sealing elements are cut out.

Two side pieces.

- Patterns are smeared with bituminous mastic.

- Then, in numerical order, the valley carpet is glued to the pipe and to the roof slope covering.

Important. Before laying the pattern strips, on the pipe, from below, a fillet (triangular rail) is mounted to form a smooth interface at the transition point of the roofing to the pipe

Also, according to the markup, a strobe is made on the pipe, at a distance of 30 cm from the base. The strobe, after gluing the valley carpet, is closed with a metal junction bar (apron), planted on a sealant and mechanically fixed.

4. Reconciliation of the valley carpet is laid with tiles indented from the pipe by about 8 cm.

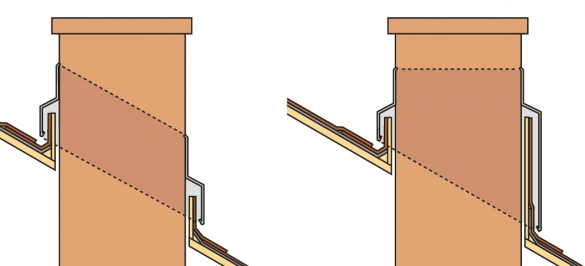

Sealing of chimneys and air ducts in wooden houses subject to shrinkage is carried out in such a way as to untie the junction of the roofing to the pipe. Those. the roof must drop freely relative to the chimney.

The junction bar is installed on the chimney, blocking the rise by at least 20 cm. The junction bar itself is not fixed on the roof surface or roofing. Consequently, during the settlement of the building, the structures move independently of each other, but, at the same time, the junction bar hermetically closes the gap between the upper edge of the junction and the chimney.

Important. To prevent water and snow from accumulating behind the chimney, it is recommended to make a slope at the top, on the roof deck.

Before laying a soft roof, we advise you to study the installation instructions for flexible tiles, which describes in detail the stages of work.

Rules for the use of soft tiles

When choosing a roof covering with a soft roof, you should have an idea about the features of a flexible tile. When conditions change (non-compliance with installation rules), these features can turn into minuses, and the same material under different conditions will last for different times. The main differences between soft tiles and other roofing materials include the following facts:

-

Soft tiles not suitable for use, if the slope of the roof does not reach 12° (on a flat surface, the risk of water retention and seepage increases).

-

Impossible to objectively determine the quality coatings and bases of bituminous shingles. The material should be purchased from a trusted manufacturer, when buying, studying the certificate, markings and warranties. Soft tiles offered at a suspiciously low (below average market) price are always suspicious.

-

Laying soft roof is carried out only on a solid moisture-resistant base. To do this, you will have to purchase plywood sheets, grooved or edged boards, or OSB sheets, which will increase the final cost of the roofing carpet.

Laying shingles

-

Installation looks simple, the main thing is in the process of laying prevent deformation of soft tiles (which, in the absence of experience, is not so difficult to do).

-

Installation in the cold is difficult, So how in such conditions the adhesive layer does not provide proper adhesion. In order for the roof to still turn out to be airtight, the packages with the material are preliminarily kept in a warm room (at least a day), and during installation, 5-6 packages are taken out into the air.

-

Soft roof repair may be much more difficult to install. After laying the shingles, under the influence of sunlight, stick together, forming a single cover. If over time one of the tiles is damaged, due to adhesion of the material, a replacement of the roof section will be required, and one cannot do without the involvement of a specialist.

Inverted flat roof installation technology

An inverted roof is more reliable and durable than a traditional roof, it does not leak for several decades.

When constructing this type of structure, the order of the layers is changed, thereby improving the quality of the roof. Unlike the first method, such a structure can be operated.

- For minimum loads, porous-insulating, heat-insulating, and waterproofing materials are used. As a final coating, roll-type materials are used.

- For medium loads, it is necessary to use stronger and denser thermal insulation.As a final coating, paving slabs or other types of similar material are used.

- For significant loads, reinforced material is installed between the main layers of insulation. And as a final coating, a reinforced concrete slab is used.

Installation of an inverted flat roof is carried out in the following sequence:

- First, the base is prepared, a reinforced concrete slab is laid, then it is coated with a primer to ensure that the waterproofing is well attached.

- Laying waterproofing material is somewhat different from the traditional method. First, a waterproof material is laid, it can be PVC or rolls, which include bitumen.

- Then proceed to laying the insulation material.

- Then the geotextile is spread, which should be located between the insulating materials of the internal composition, and the final coating.

- At the end, the final coating is laid; for roofs with a minimum load, roll-type materials or gravel are used, which is applied to the entire surface. For a roof with an average load, you can lay paving slabs or use other durable materials. For significant loads, a reinforced concrete slab of a monolithic type is used.

Flexible roof device

In order for a flexible roof to perform well during operation, it must be properly equipped. The construction of a roof made of soft tiles can be compared to a Napoleon pie. If, for example, consider what it consists of, it becomes clear why:

1. The tile is soft;

2. Lining;

3.Crate;

4.Space for air circulation;

5. Diffusion membrane;

6. Heat-insulating layer;

7. Vapor barrier.

Works on laying a flexible roof

Everything is done in 7 steps:

1. The base is being prepared;

2.A gap for ventilation is arranged;

3. A gasket made of bituminous material spreads like a continuous carpet if the slope is less than 18 degrees, and if more, then in places - where leaks are possible;

4. Now you need to fix the metal strips at the ends of the roof and on its eaves. Lay flexible tiles on top of them: eaves:

5. Next, you should start laying the valley carpet using nails;

6. The queue for laying shinglas, that is, an ordinary tile, has come;

7. Ridge tiles are laid along the slope.

crate

The shingle roof sheathing is attached to the counter lathing, which also creates space for ventilation. The crate bears all the layers of the roof.

The following materials are needed:

- edged board, preferably from coniferous trees;

- plywood, but not any, but special moisture-resistant or OSB-boards, shunted board. The larger the pitch of the rafters, the thicker the material;

- galvanized nails.

Cladding requirements:

-solid - no steps and irregularities;

- joints fit perfectly;

- if it is not planned to arrange some kind of room under the roof, then the crate is needed only in order to fix the flooring;

- between the elements to carry out a clearance of 1-3 millimeters;

-treat the crate with a composition that prevents the appearance of mold;

Do you want an attic? Ventilation gaps are required.

Laying shingles

Before starting work, the material is prepared in advance by simultaneously opening several packages of soft tiles.This is done in order to exclude sharp color transitions in the event of a possible discrepancy between the shades of the coating from different packs: during installation, the shingles are taken mixed from several packs.

Installation of the cornice row and the first sheet of tiles

A self-adhesive cornice strip is placed along the overhang, retreating 2 cm from the edge. Subsequent strips are placed butt-to-butt and fixed with nails. During further installation, the attachment points are closed with ordinary tiles.

The order of laying the first row of tiles is as follows: work begins from the center of the eaves, sequentially go towards the ends. The shingles of the first row are laid in such a way that the protrusions-petals cover the joints of the sheets of the cornice strip and the heads of the nails.

Before installing soft tiles, remove the protective film from the underside of the shingle.

The shingles are nailed around the edges and over the cutouts - four roofing nails are enough for one piece. Roof slopes greater than 45° will require two more nails per shingle for a total of 6 (for additional fastening at the top corners).

Laying subsequent rows

Each subsequent row of shingles is fixed in a checkerboard pattern: so that the middle of the petals falls on the middle line of the cutout of the previous row. Petals-protrusions of the shingles must necessarily cover the fasteners and joints. At the ends of the slopes, the soft roof is cut with a knife, and it is glued to the end plank with a thin layer of bituminous mastic.

Specificity of soft roof DÖCKE PIE

Bituminous tiles Deke PIE are supplied in shingles cut into small tiles, coated on both sides with polymeric or oxidized bitumen. On the front side of the tile, there are several adhesive strips that make it easier to fix the shingles.The elements glued in series are additionally fixed with special roofing nails.

Exposure to the sun leads to heating of the bituminous coating, its softening and sintering of the laid shingles among themselves. Thus, the roofing becomes monolithic, providing high moisture resistance. Basalt dressing applied over bitumen provides additional protection against destructive climatic and physical effects.