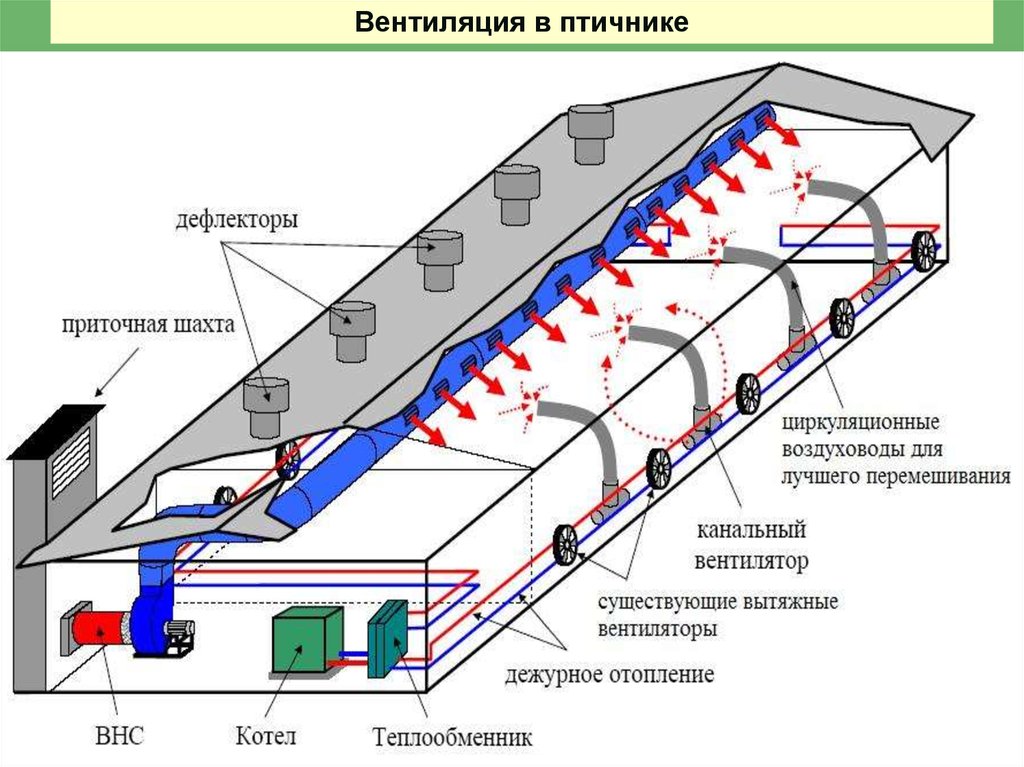

- Arrangement of natural ventilation in the barn (+ video)

- Components of gravitational air exchange

- Window inlet valve

- Wall exhaust or supply device

- Interroom transfer grates

- Barn dimensions and equipment

- barn lighting

- Implementation options for the ventilation system

- General exchange ventilation

- Supply and exhaust ventilation with recuperation

- Air handling units

- Calculation of the ventilation system

- Equipment for natural and artificial ventilation systems

- When is general ventilation needed for a welding station?

- Specifics of mechanical ventilation installation

- Examples

- Use of ventilation curtains and light-aeration skates

- Ventilation device in a pigsty: types of systems, their application

- Roof ventilation

- Other ventilation systems

- Conclusions and useful video on the topic

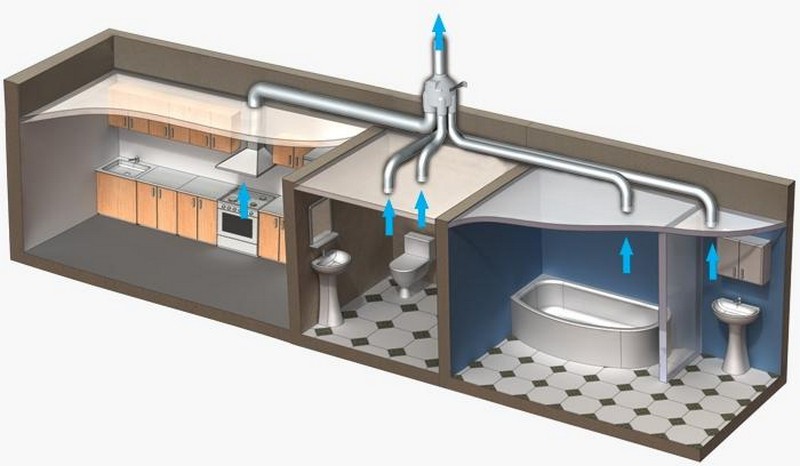

Arrangement of natural ventilation in the barn (+ video)

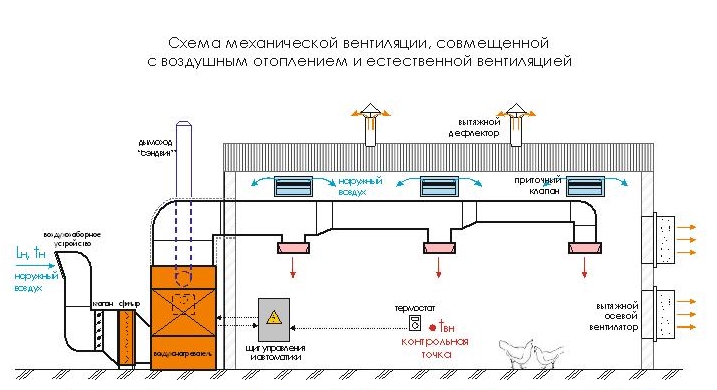

The simplest and cheapest, but also less effective option. Natural ventilation (you can read more) is bad because its work depends on weather conditions and the location of the barn.

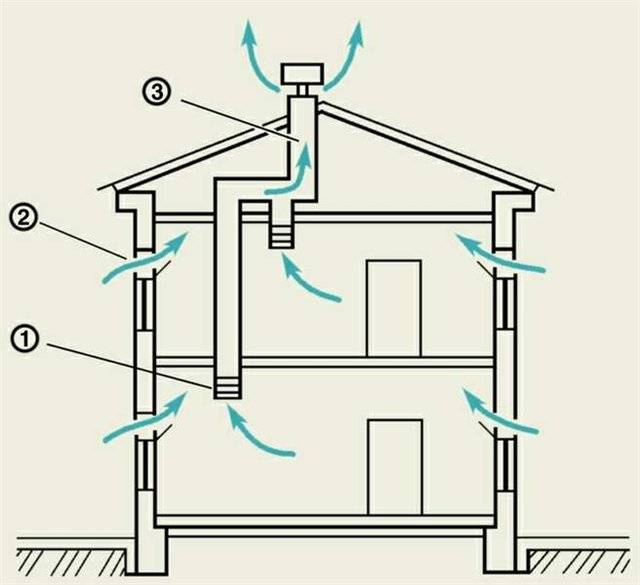

You can set it up like this:

- Inflow: done through a slot under the door, or through a window, or through an inlet valve at the bottom of the wall, or through a ventilation grill in the door.

- Exhaust: through the roof or through the wall under the ceiling, a pipe is brought out into the street. Its outer opening should be higher than the roof ridge. It is desirable to install a deflector on top of the hole to improve traction.

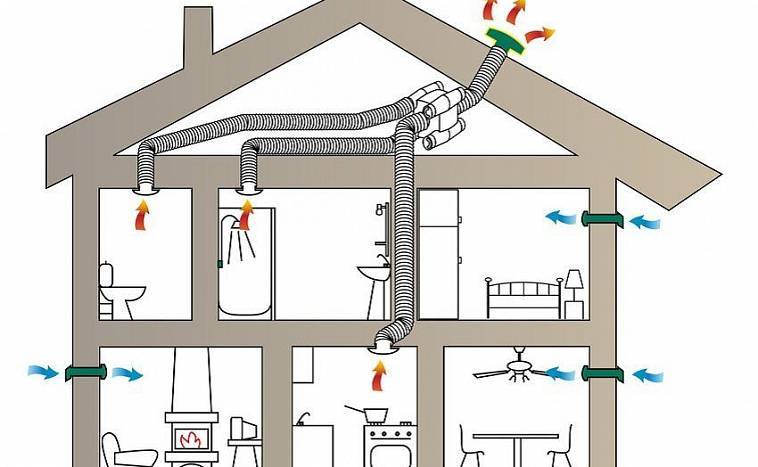

Scheme of a simple natural ventilation system

A natural ventilation scheme is not recommended if:

Components of gravitational air exchange

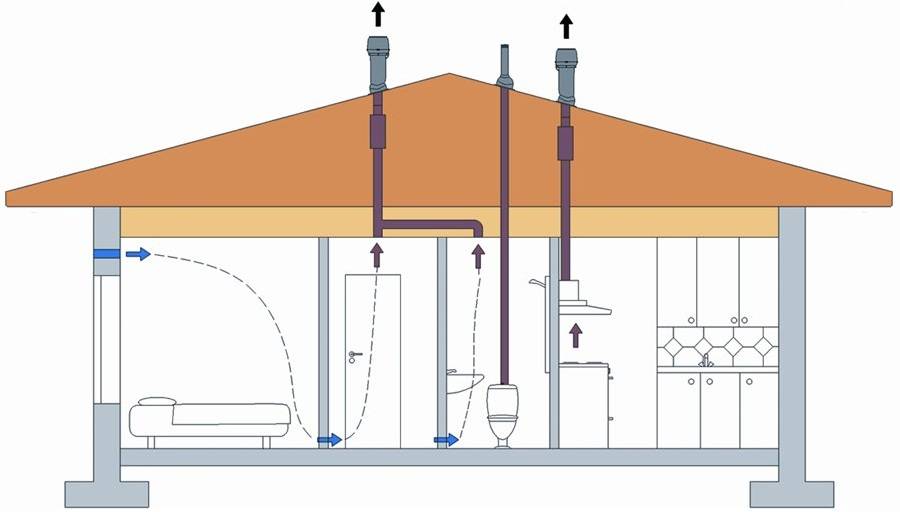

One of the common problems with natural ventilation in a private house is the lack of fresh air entering the room. Gravitational ventilation works flawlessly only when the density of the air mass outside the window is much higher than inside the premises. In the summer, when their density equalizes, the air from the street does not flow by itself.

In addition, serious obstacles are now being placed in the way of naturally moving air currents. Window and door seals, offered to the consumer today, perfectly resist heat leakage, but they also do not let air in from the outside.

In order to ensure natural inflow in houses with sealed windows, it is worth putting inlet valves into the wall, and supplying exhaust ventilation pipes with deflectors

In order to ensure natural inflow in houses with sealed windows, it is worth putting inlet valves into the wall, and supplying exhaust ventilation pipes with deflectors

The issue of fresh air entering rooms with practically hermetic windows and doors is solved by installing ventilation inlet valves. If you do not want to install valves, you will have to purchase supply devices for plastic windows or buy window packages with vents built into them initially.

Window inlet valve

This device is also called a window ventilator.Refers to the most common options for solving the problem of air exchange. The design of such a valve is mounted directly in the window profile.

The flow of incoming air through the window ventilator is directed upwards, so that the cold supply air is more efficiently mixed with the already heated indoor air and does not cause discomfort to residents

Some valves are equipped with automatic air flow control. It is worth noting that manufacturers do not equip all models of ventilators with mechanical adjustment. This can create certain problems with sudden temperature changes.

The main disadvantage of the window inlet valve is the relatively low performance. Its bandwidth is limited by the size of the profile.

Wall exhaust or supply device

To install a wall ventilator, you need to make a through hole in the wall. The performance of such a valve is usually higher than that of a window valve. As in the case of a window air inlet, the incoming volume of fresh air is controlled both manually and automatically.

Wall exhaust valves are usually located at the top of the wall, where the exhaust air naturally rises. Inlet valves to the wall are most often mounted between the window and the radiator. They do this so that the incoming cold air at the same time also heats up.

If the wall vent valve is installed directly above the radiator, the fresh air flow will spontaneously heat up before being delivered to the room.

Advantages of installing a supply valve over conventional ventilation:

- The ability to regulate the flow of fresh air;

- The ability to pass significantly less street noise;

- The presence of filters of varying degrees of air purification.

The design of the wall supply and exhaust valve does not allow moisture to penetrate into the room. Many models of these local ventilation devices often include filters to purify the air.

Interroom transfer grates

In order for fresh air to freely penetrate into all parts of the house, overflow components are needed. They allow air flows to flow freely from the inlet to the exhaust, taking with them dust suspended in the air mass, animal hair, carbon dioxide, unpleasant odors, household fumes and similar inclusions.

The flow is carried out through open doorways. However, it should not stop even if the interior doors are closed. To do this, a gap of 1.5-2.0 cm is left between the floor and the canvas of interior doors.

In order for fresh air to move freely to the hood and wash all the rooms, overflow grilles are installed in the door leafs. If they are not there, then a gap of up to 2 cm is left between the floor plane and the canvas.

Also for these purposes, overflow gratings are used, mounted in a door or wall. The design of such gratings consists of two frames with blinds. They are made from plastic, metal or wood.

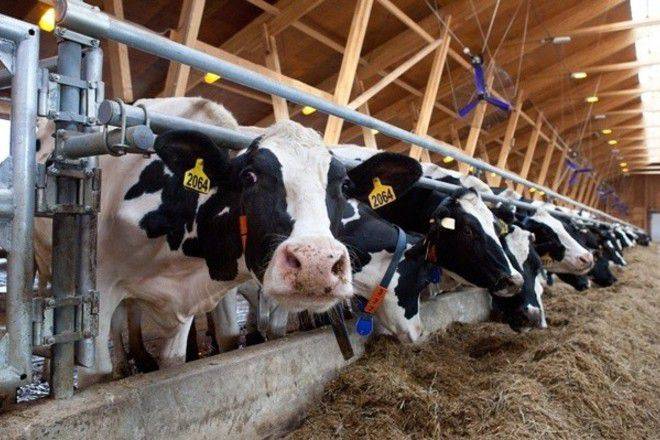

Barn dimensions and equipment

The size of the room will determine which ventilation system to choose and how to install it correctly. It will also allow you to calculate the initial costs for creating comfortable conditions for the stay of animals. Here are the basic requirements for the size of the building:

- height from 2.5 meters;

- area 6 sq. meters per individual;

- the presence of a zone for cows with calves;

- allocation of space to accommodate the material and technical base.

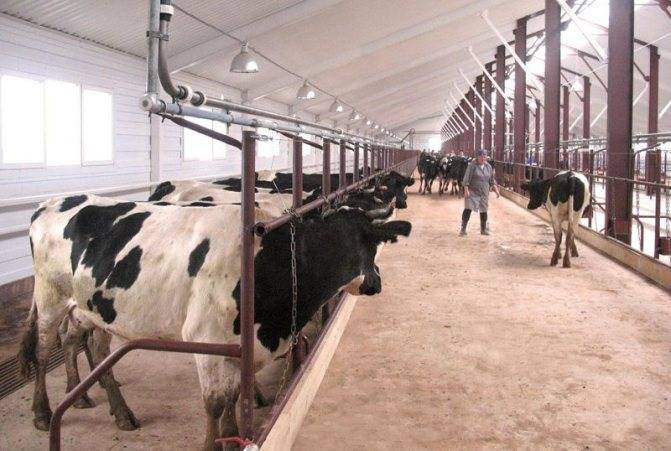

Most ventilation systems are designed for cow housing

What kind of equipment is needed depends on how the cows are kept. The stall method is most often used. In this case, the animals stand in the place allocated for them. However, sometimes they use pasture-stall. Then the cows walk in a territory specially prepared for them.

barn lighting

Milk yield depends on the length of daylight hours, so it is necessary to create artificial lighting in the barn. Animals should be active 16 hours a day. 8 hours of sleep. Cows should wake up at 4 in the morning, and their day ends at 20.00.

In addition to ventilation, the barn must be equipped with a lighting system.

Here are the basic principles of lighting installation:

- uniform arrangement of lamps;

- instant switching on the entire territory of the barn from one switch;

- lamp pulsation factor up to 1%;

- the quality of the lamp does not change during the entire period of operation.

There are many different solutions for building a lighting system.

The most important thing is to provide an even distribution of light so that there are no dark corners and overly lit areas.

Implementation options for the ventilation system

The implementation of high-quality ventilation and air conditioning systems in public spaces is a guarantee of comfort and well-being of people. There are several basic technical solutions for these engineering systems.

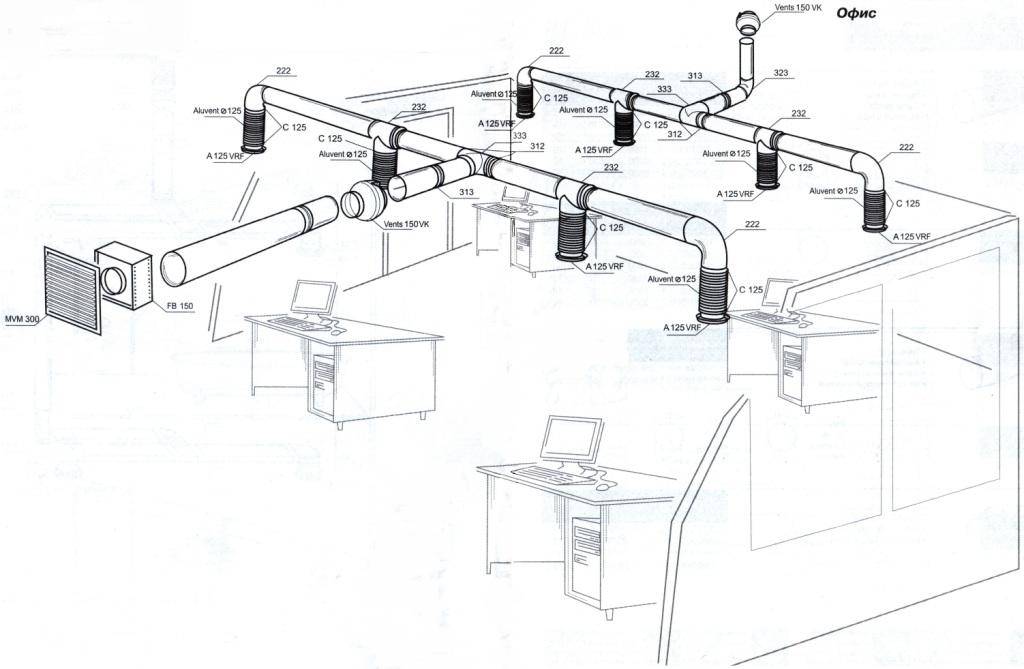

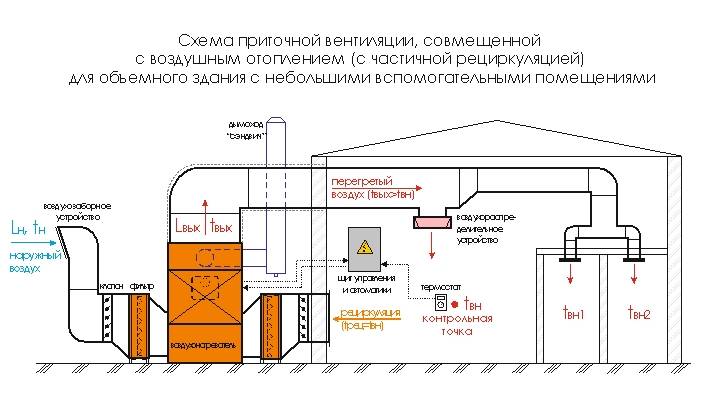

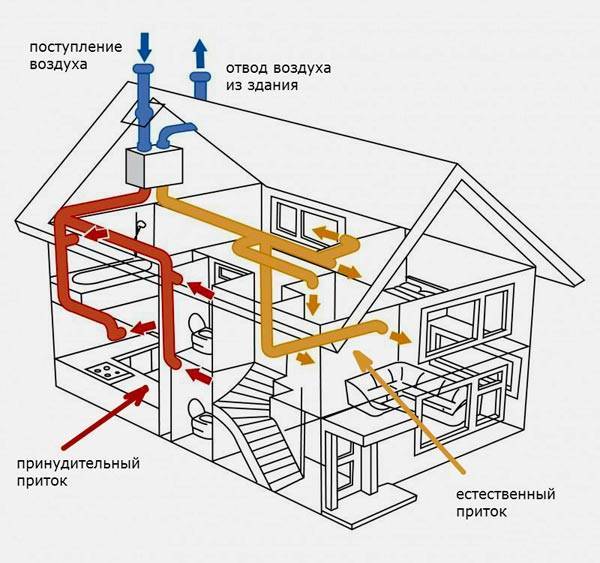

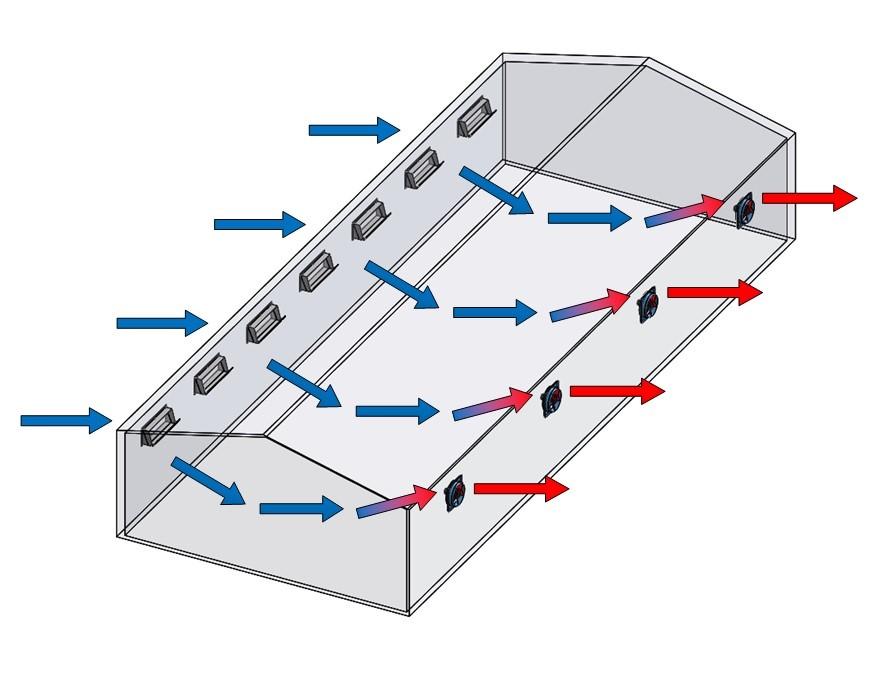

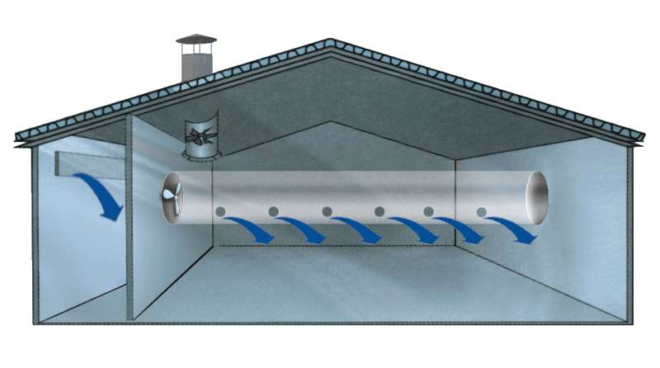

General exchange ventilation

The exhaust part of the ventilation system is needed to eliminate polluted air, excess moisture and heat from the room.

Its correct operation depends on a constant supply of air. For this, forced ventilation is needed, supplying fresh air from outside the room.

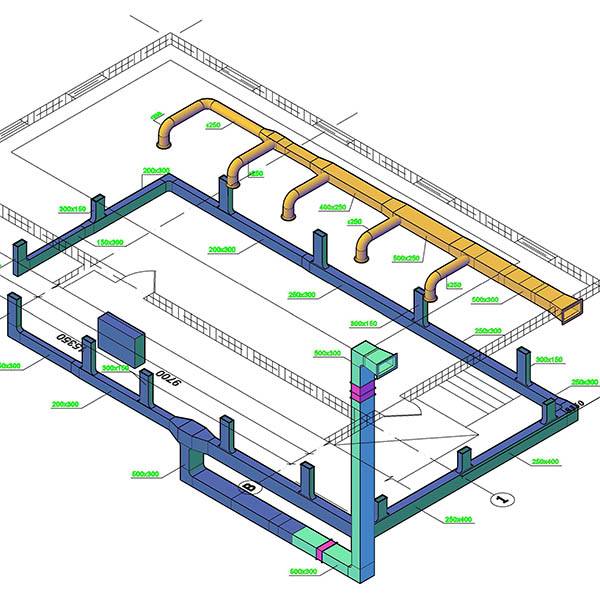

Within one floor, the air ducts are bred along the ceiling, later, when the system is fully assembled, they can be hidden behind the false ceiling

Type-setting exhaust ventilation consists of: an external grille, a fan, an automation unit, air ducts, exhaust hoods (kitchens, laboratories), an internal grille or exhaust diffusers.

The supply ventilation requires the following components: an external grille, a filter, an air heater, a silencer, humidity, temperature, frost sensors, a fan, air ducts, internal wall or ceiling grilles, supply diffusers.

This type of ventilation is used most often in public buildings. Several branches of general ventilation are mounted in the building, which do not communicate with each other.

The advantage of stacked ventilation is separate air purification in different rooms, the ability to adjust the power of the air flow in each office. But such an engineering solution also has a number of disadvantages. The main one is bulkiness. In buildings where it is not possible to hide the air ducts behind a false ceiling, there are problems with the aesthetics of this design.

In the case when the ventilation is interfloor, vertical air ducts are mounted by building up from above or building up from below.

In cases where the installation of a false ceiling is not possible, the air ducts cannot be hidden behind it. The ventilation system is laid in an open way, the air ducts are decorated in accordance with the interior of the establishment

Some bars and restaurants use air ducts as part of their decor.In this case, stainless air ducts are usually used. In general, neatly mounted ventilation fits into the interior of the establishment.

To suppress noise, the air ducts are covered with insulating material, which effectively prevents the propagation of sounds between individual rooms and practically reduces the air noise in the air ducts themselves.

Such a ventilation system is suitable for buildings with a large number of separate rooms.

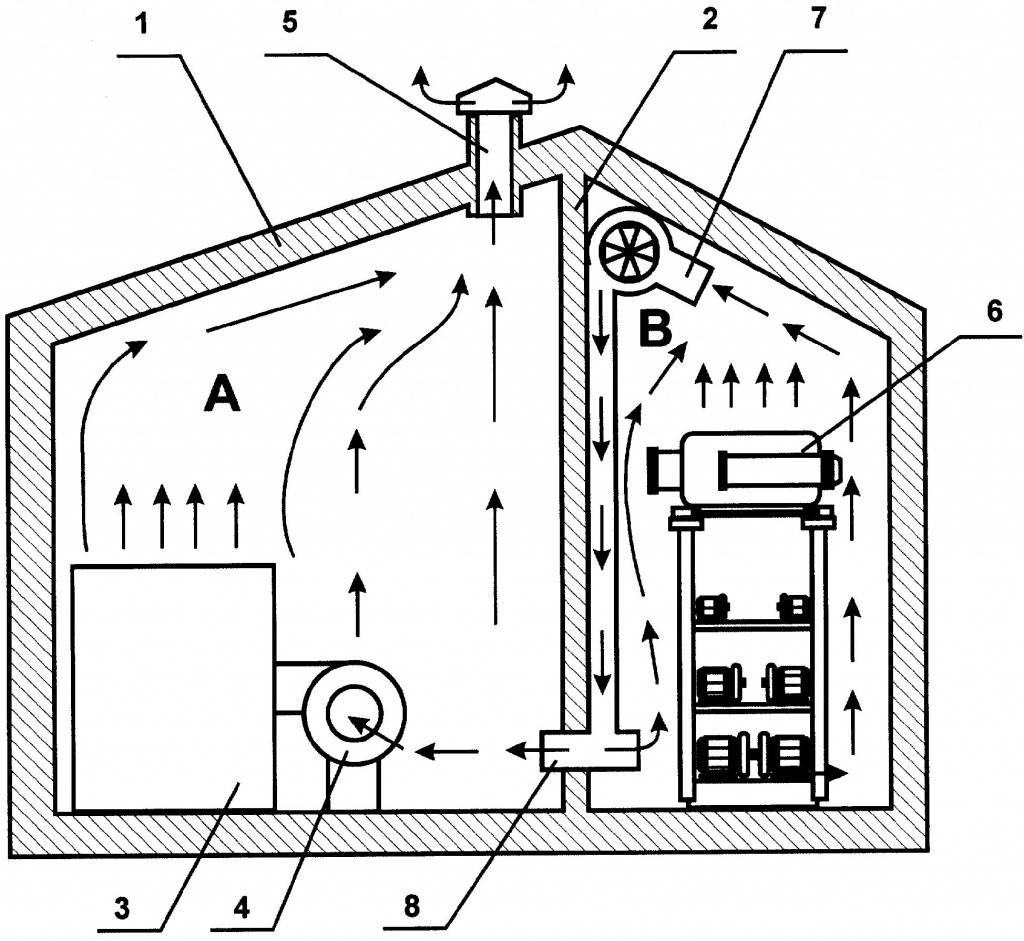

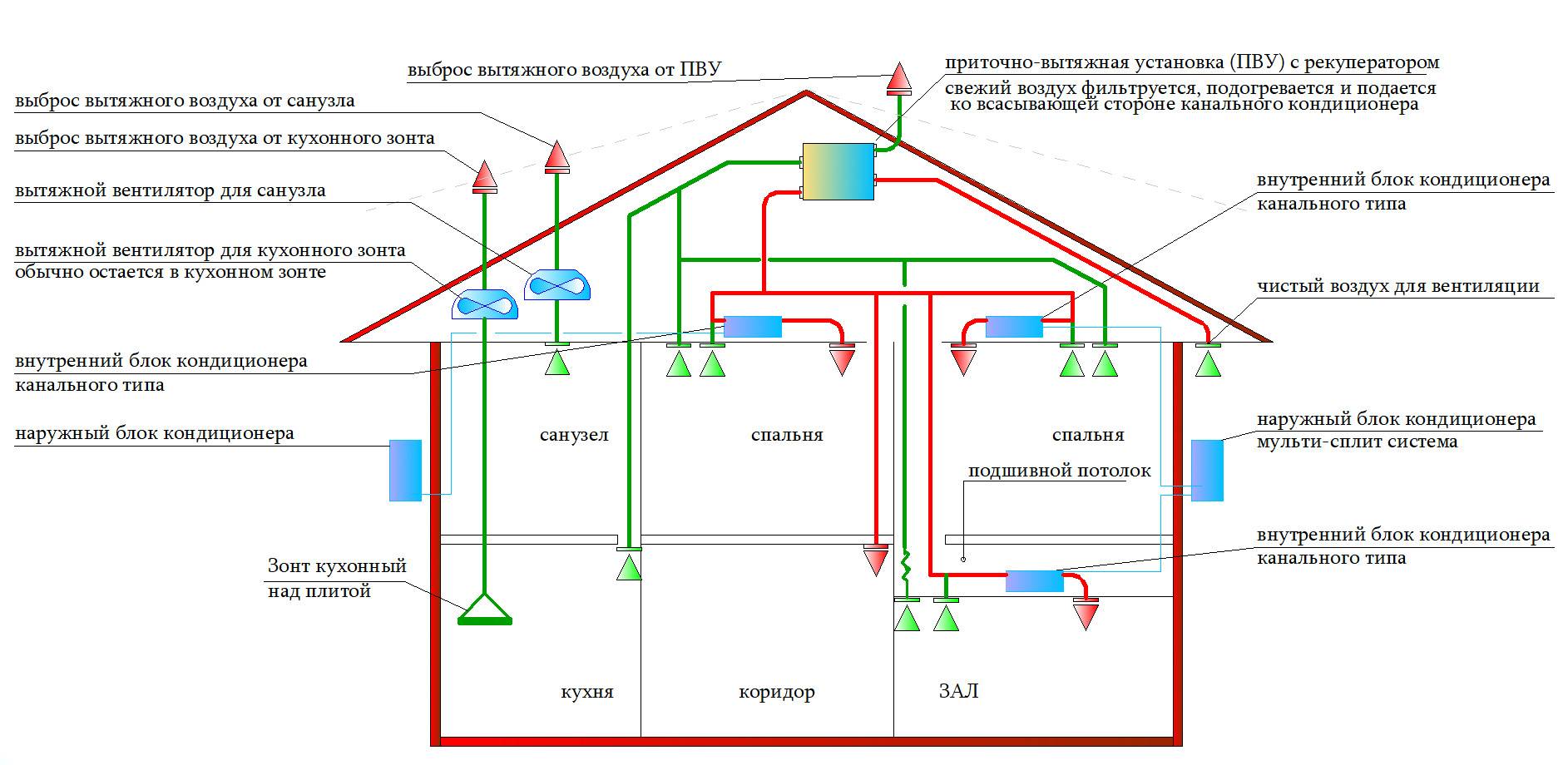

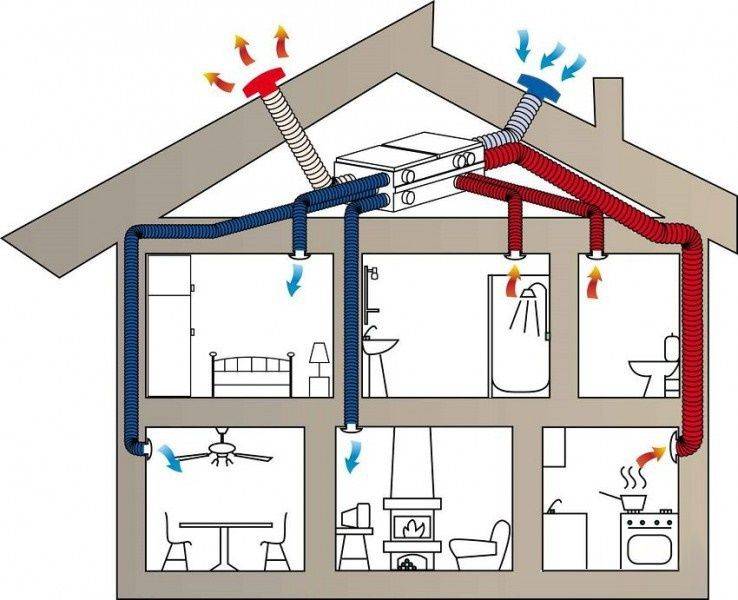

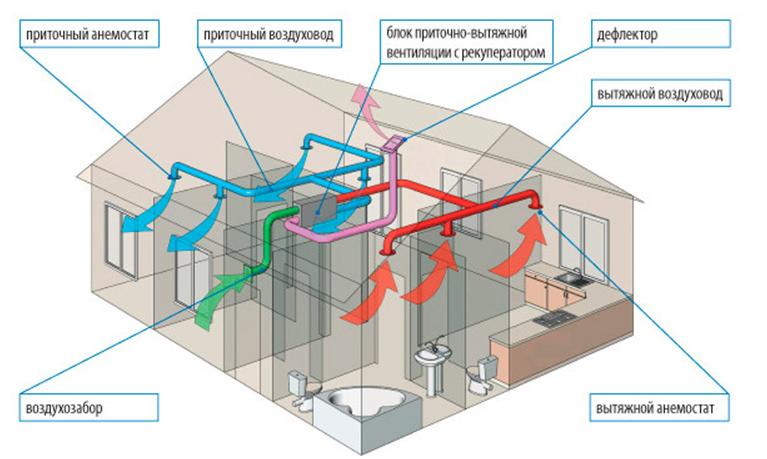

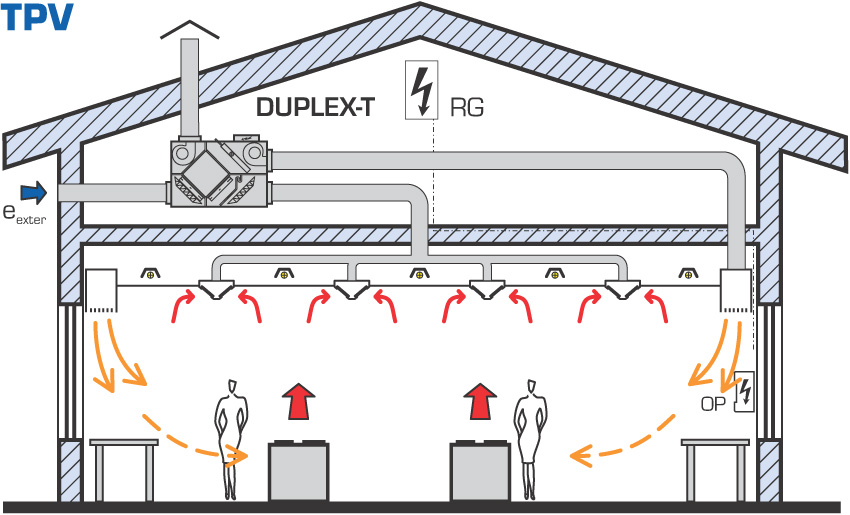

Supply and exhaust ventilation with recuperation

This ventilation system differs from the previous version by the presence of a heat exchanger - a surface-type heat exchanger. It is installed at the intersection of the supply and exhaust branches of ventilation.

The air removed from the room leaves heat on the heat exchanger plates. The air that enters through the supply system is heated by its ceramic plates.

The recuperator in the ventilation system heats fresh air to a comfortable temperature. This energy-efficient fixture allows you to save about 20-30% of heat

Non-return valves in the heat exchanger housing prevent air from escaping between the ventilation branches.

Recuperation allows you to significantly save on heating. This advantage of the heat exchanger is especially noticeable in a large room: a conference room, a cinema, an assembly hall.

Air handling units

Using the ventilation unit scares away many building owners due to the high price of the unit itself. It is an all-in-one device - the main elements are placed in the case.

Some models are equipped with an air cooler. Unfortunately, it is difficult to use it for conditioning a large number of cabinets for various purposes.This is due to the inability to set an individual temperature regime for each individual room.

The use of ventilation units will eliminate noise and unnecessary hassle with the arrangement of ventilation and guarantee a minimum of hassle with the maintenance of the ventilation system

Air handling units are the simplest way to organize a ventilation system. A fairly compact device does not take up much space in the ventilation chamber.

Due to the fact that the fans are located inside a well-insulated housing, the noise level from the air handling unit is lower. Maintenance of installations is much cheaper than stacked systems. Their disadvantage is the need to install additional ventilation equipment in bathrooms, smoking rooms, and server rooms.

Calculation of the ventilation system

For the correct functioning of the system before its installation, it is necessary to carry out a preliminary calculation. When calculating, it is necessary to take into account the temperature in the room, humidity and time of year

It is worth paying attention to heating. Thanks to these parameters, you can use the calculation system

For the calculation, the following formula is used:

This formula is an example for farmers, because many do the ventilation in the barn with their own hands. Legend:

- L - the amount of air that enters and leaves the room. It allows you to find out how much air has entered and exited within an hour. This indicator is measured in m3 / h;

- Q is the amount of evaporation that occurs as a result of the habitation of cows;

- K - moisture that is formed during the breathing of the animal at different temperatures;

- a - allowance, which is measured as a percentage and depends on evaporation;

- q1 - humidity inside the barn;

- q2 - humidity that enters the room.

Based on these indicators, you can calculate which ventilation system is needed for a particular room. This will allow you to determine the type of system, because different types of air exchange are used for different barn sizes.

When making calculations and choosing the right system, you can achieve optimal conditions for keeping livestock. You need to know the requirements that any ventilation system must meet, for each type they are different.

Equipment for natural and artificial ventilation systems

The table below outlines the ingredients that you will need to create a comfortable environment for cows.

Table 1. Equipment for the ventilation system in the barn

| artificial system | natural system |

|---|---|

| Wall and ceiling fans | light horse |

| ventilation shafts | Ventilation curtains |

| Supply and exhaust devices | Supports for doors and windows so that they do not shackle |

| Uninterrupted power supply unit |

Accordingly, for a mixed type system, a full range of the above equipment is required.

It is important to understand exactly what conditions should be created for cows to obtain maximum milk yield.

When is general ventilation needed for a welding station?

In accordance with SNiP2-33-75, the ventilation system of the welding shop must be of a mechanical type, that is, equipped with special fans.The fresh air supply must be provided by air terminals installed at a distance of 6 m from the floor when the flow is downward in a vertical position, or at a distance of 4 m when the flow is in a horizontal position. You should also take into account the speed of the flow of air masses, which cannot be less than 0.1 m / s.

When equipping ventilation with parallel flows, the conditions for performing work and purifying the air are the most optimal, since the exhaust air masses containing harmful gases and aerosols move in the same direction as the supplied air. The mass of supplied flows should be less than the amount of polluted air removed. This principle can significantly improve the efficiency of the system.

Specifics of mechanical ventilation installation

With the installation of a ventilation unit of a supply type, a home master, no doubt, could have coped without the involvement of workers.

However, it is worth remembering that the work is carried out at a height dangerous for an inexperienced performer. Therefore, it is better to involve those who have experience, tools and safety devices to perform the following steps:

Upon completion of the at all difficult manipulations for the installation of the direct supply unit, it remains only to connect it to the communications.

Let's take a closer look at this process with the help of the following photo selection.

Information about the sequence of installation of forced ventilation installations will help to avoid many of the grossest mistakes made by inexperienced installers.

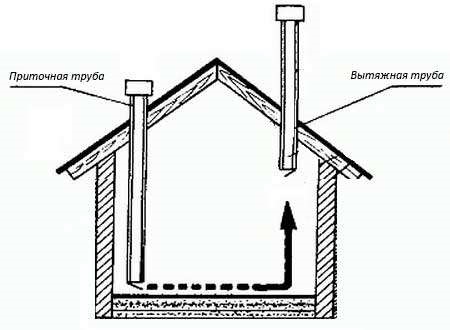

Examples

Schematic diagram for installation in country houses and in the country - ventilation with natural air circulation. It is suitable for brick and wooden buildings, as well as structures made of expanded clay concrete.As a rule, the design of just such a scheme prevails in the construction of apartment buildings. If you have purchased an apartment in Khrushchev, then be guided by the fact that there will be natural ventilation.

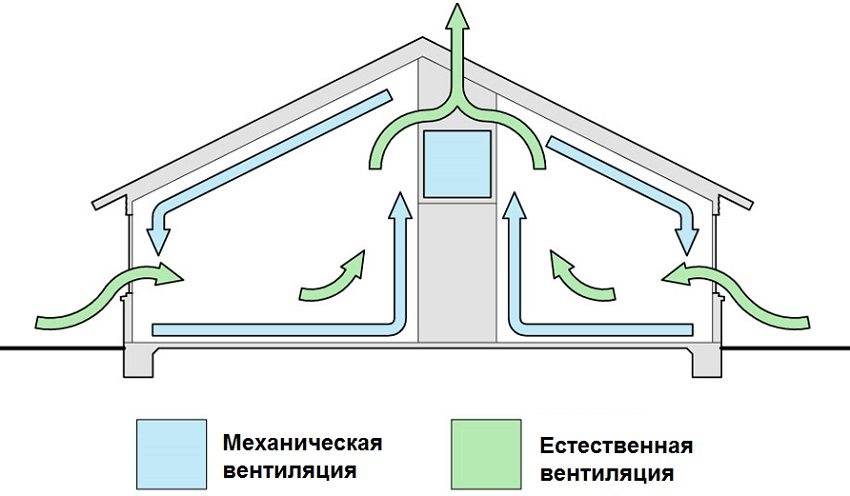

Natural air exchange is based on the difference phenomenon air column pressure. The ventilation system is easy to install and operate, does not depend on the availability of electricity, does not require the installation of expensive equipment. However, the system is affected by weather conditions, in particular wind, and temperature, since natural circulation requires that the temperature inside the room is higher than outside. Otherwise, air movement stops.

In the age of developing technology, many use forced ventilation. It can be partially automated, when the equipment is used only to force air into the building, or, conversely, to remove fumes to the outside, or fully mechanized, which involves the use of fans at both stages.

Since the ventilation shaft in the kitchen usually has a larger diameter, all flows rush to it. In windy weather, this powerful channel can “overturn” the smaller one in the bathroom, forming a reverse draft, that is, a cold wind will begin to blow from the toilet. In this case, a competent installation of forced ventilation is necessary.

A ventilation system is also required on a glazed balcony or landscaped loggia. There are several options for its arrangement. First of all, it is natural due to the opening of windows, but during the cold period it is not always convenient.Some window manufacturing companies build ventilation holes in them, with the help of which micro-ventilation is carried out. More often, the owners install a hood, which ensures the removal of condensate.

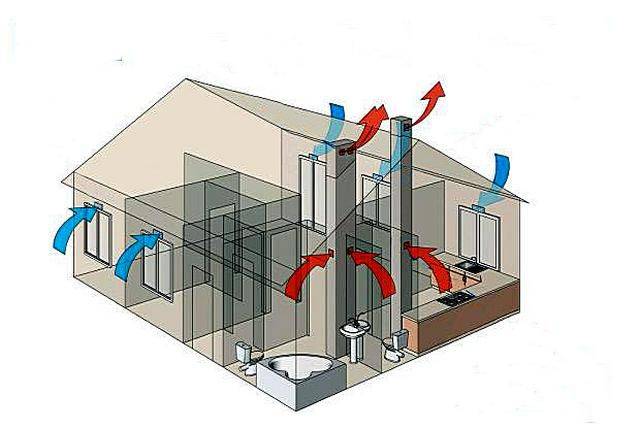

The supply and exhaust circuit is necessary for ventilation in a room without windows, for example, a pantry. In particular, for security reasons, many technical premises require to be equipped with a forced system (garages, boiler rooms, boiler rooms, warehouses).

The ventilation complex in the case of a mixed scheme is a system of pipes, some of which draw in air from the outside, others take the exhaust air outside the building. The inflow is provided by a convector, which additionally heats, filters and disinfects the flow from the street with ultraviolet light. In order to prevent the forced air from expelling heat from the room during the cold period, a special heat exchanger was developed - a heat exchanger, which is designed to use the temperature of the outgoing stream to heat the incoming one.

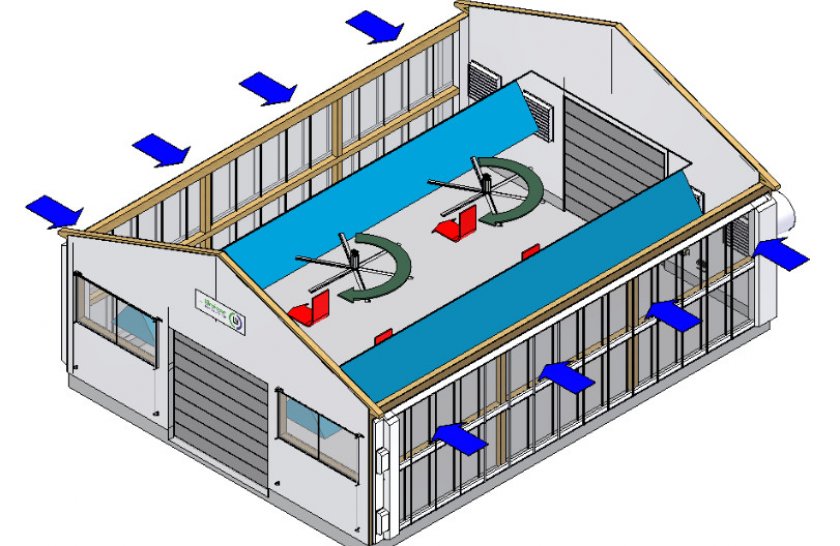

Use of ventilation curtains and light-aeration skates

The equipment of such air exchange systems is used in large livestock farms, requires serious financial investments, as well as the involvement of professional designers and builders.

Installing adjustable curtains on wall sections allows them to be opened in the warm season, providing animals with free access to fresh air.

Such curtains can be vertical or horizontal, opening automatically or manually.Their material must be resistant to temperature changes, moisture and ammonia, and also be easily cleaned from various contaminants.

The light-aeration ridges installed on the roof of the barn are strips of special roofing material that let in sunlight and provide natural light to a modern livestock farm. In the hot season, special shutters open, through which the exhaust air is removed with the help of cross-ventilation.

In each individual case, livestock breeders and farmers have the opportunity to independently choose which of the methods of barn ventilation is most preferable for them.

Like the article if it was interesting and useful for you.

Ventilation device in a pigsty: types of systems, their application

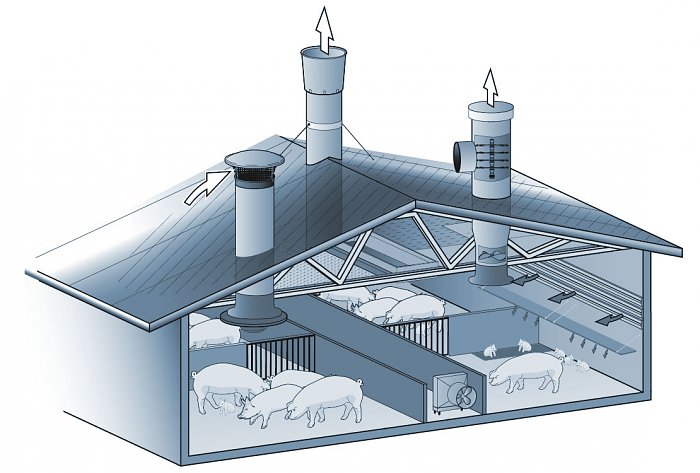

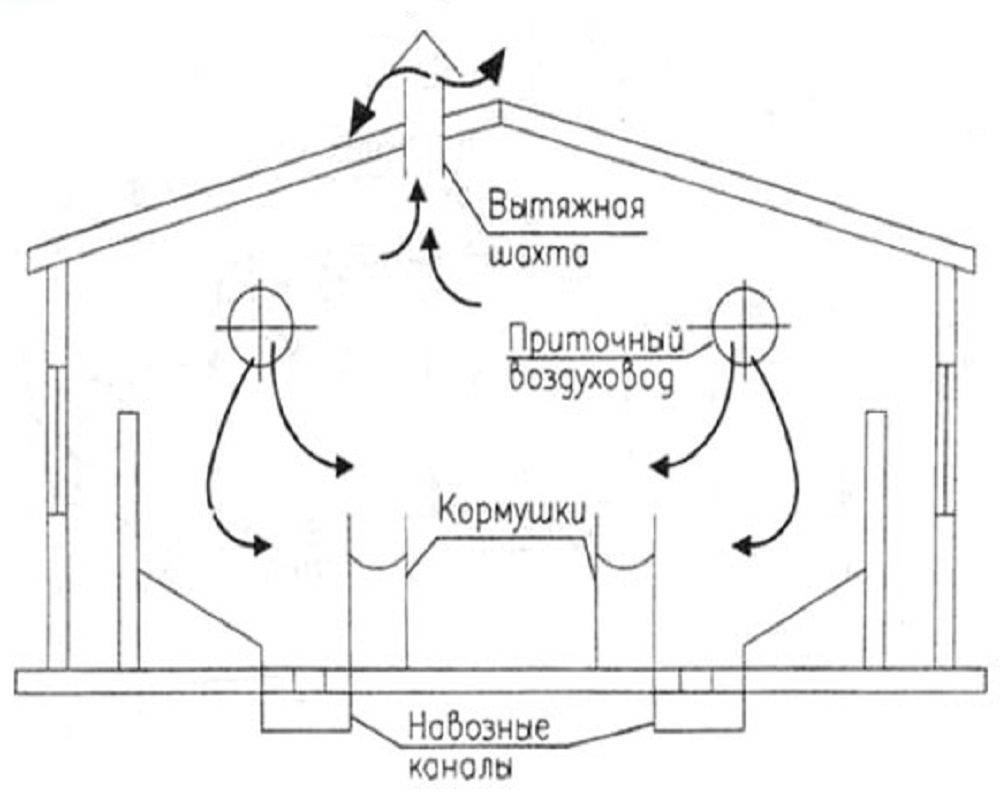

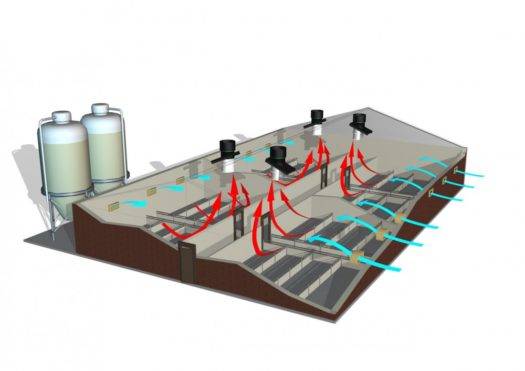

There are some of the most common methods for arranging air exchange in pig rooms. The easiest way to ventilate a pigsty with your own hands is by roof ventilation.

Roof ventilation

The method is based on the use of three valves for air circulation. A pair of inflow valves are placed on the side walls, and the third valve, used for exhaust, is mounted on the roof ridge. The efficiency of such air exchange is determined by the strength of the wind. It is recommended for rooms in areas with windy weather.

When the system is operating, the side supply valves let in cool outside air, which displaces the warm, polluted air through the upper exhaust valve to the outside. Adjustment of intensity of work is made by opening/closing of valves.

The key advantages of the method are simplicity, economy, no need for electricity, ease of installation. And the disadvantage is the dependence on weather conditions.

The diffuse type roof system is quite effective in calm weather. It belongs to the combined type and includes side windows with adjustable shutters and outlet shafts to the roof with fans connected to them.

In case of insufficient natural ventilation, the intensity of air exchange is maintained by connecting fans. Both roof ventilation systems are usually used for pigsties located in small areas.

Other ventilation systems

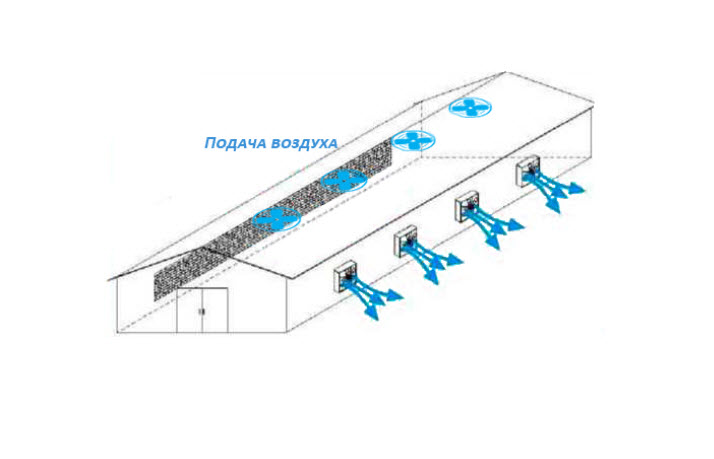

For large areas, systems of transverse, longitudinal or tunnel types are used.

Crosswise effective ventilation of the pigsty is based on the flow of air through valves located along the wall. The hood is carried out by a number of fans placed on the opposite wall. Typically, such a system provides for adjusting the speed of the fans, which allows you to adjust the ventilation.

The operation of the longitudinal system is similar to the transverse type air exchange, but the inlet valves and exhaust fans are located on opposite end walls. For better performance of the circuit, reversible powerful fans are used.

The tunnel type system also provides for circulation along the room using exhaust fans in the end wall. Blinds are mounted on the opposite wall to the fans. Active air exchange units are efficient, do not depend on external conditions, and allow precise control of climate conditions over large areas.But their disadvantage is the cost, complexity, the need for electricity consumption.

Among the manufacturers of ventilation equipment for pigsties, the following stand out:

- Valco Holland, equipping louvered tunnel systems with efficient adjustment servomotors, offering a wide range of different fans and meshed air inlets for cross units;

- Danish equipment Skov - includes improved supply valves and exhaust shafts, climate control systems;

- German systems Weda - provide for the installation of stretch ceilings, improved exhaust pipes, the use of climate controllers.

Conclusions and useful video on the topic

You can see how the equipment is placed in the barn for supply and exhaust ventilation in the video below:

On the video you can also see an example of ventilation of a small barn (up to 100 heads):

In the article, we talked about comfortable conditions for keeping animals, air exchange standards, and also examined the existing types of ventilation equipment. We analyzed the features of creating an exhaust system in a barn with our own hands.

Thus, the productivity of cows directly depends on the conditions of detention: ambient temperature, humidity and the presence of fresh air in the room. The ventilation system allows you to create an optimal microclimate. For small barns, the natural type is suitable. It is advisable to equip farms with a livestock of 20 or more individuals with ceiling or booster fans.

Would you like to supplement the above information with useful information? Or would you like to talk about your personal experience in arranging ventilation in a barn? Write your additions, share information, participate in discussions - the feedback form is located below.