- Popular brands ↑

- Peculiarities

- Appointment of aerators

- How soft roof ventilation is arranged - important features of the roof

- Device and installation

- How to install?

- How to properly prepare the base for a ridge aerator

- Ventilation design

- Eaves overhang device

- Air outflow through the ridge and aerators

- Ventilation gaps and waterproofing

- Ridge bar installation technology

- Types of ridge seal

- Ridge rail mounting rules

- Helpful Tips

- The device of the ventilation system of the soft roof

- Metal roof ventilation

Popular brands ↑

The efficiency of the aerator largely depends on its correct choice. In order not to be mistaken, it is better to choose designs from well-known manufacturers, say, Ridge Master.

Main advantages of Ridge Master Plus:

Ridge Master 2

Ridge Master 3

Ridge Master 4

Ridge Master 5

Ridge Master 6

Ridge Master 7

Ridge-Master-8

- The strips have a length of 122 cm, which allows you to minimize losses as much as possible. They can be quite easily connected to each other.

- The shape is calculated very precisely on the computer and functions perfectly even in difficult conditions. For example, the speed of a shower can reach 140 km per hour, and snow - 200 km per hour.

- A special filter protects against the entry of insects into the house.

2020

Peculiarities

Soft roof ventilation is not an independent process. On the contrary, the presence or absence of ventilation in the premises directly affects the exchange of air in the roof. For effective removal of destructive moisture from living quarters through the roof it is necessary to analyze the ventilation all elements of the house as a holistic process.

As a result of good ventilation, the air in the space under the roof should be replaced approximately 2 times per hour.

The performance of a ventilated roof depends on the slope of the slopes. The steeper they are, the more intensive the ventilation process is.

And, on the contrary, in roofs with a slope of less than 20%, the ventilation of the under-roof space is unstable and is effective only under wind pressure.

Aerators are mounted near the ridge. In a two-layer welded-on roofing, aerators are mounted on the bottom layer of the material.

The thermal characteristics of the insulation and the strength resource of roof structures directly depend on the presence of moisture in them. As a result, a ventilated roof and a room ventilation device are economically viable, even when forced air exchange is to be installed.

Appointment of aerators

How to prevent moisture from settling on roofing surfaces? Or to drain structures already saturated with moisture?

The laws of physics will come to our aid. Moisture can be removed by its evaporation, which occurs during the movement (circulation) of air flows.Since there is a significant difference between the internal (in the house) and external (on the street) pressure indicators, for air circulation it is enough to ensure the process of communicating two media.

If the attic is cold, then effective ventilation can be provided quite simply - through dormer windows, loose fit of cornice overhangs, cracks in the ridge. For warm attics and mansards, this solution is not suitable, since in the cold season unregulated ventilation will reduce the temperature in the room.

In such houses, the most acceptable is the use of roof aerators - ventilation ducts connecting the under-roof and over-roof spaces. After installing the aerator, due to the pressure difference, a forced draft is created in its pipe, which draws wet vapors from under the roof.

A very important point: in order for the process of extracting air through the aerator to become possible, it is necessary to provide for a supply of fresh cool air in the overall system. Otherwise, air masses will not circulate. To do this, ventilation products are equipped in the cornices, where fresh air is continuously supplied. Passing through the attic space, it heats up and rises up - to the roof.

Thanks to the created draft in the aerator, it passes through its pipe and is thrown out into the street. With well-equipped ventilation, in just 1 hour, the air flow passes through the roofing cake 2 times, drying and ventilating it.

Accordingly, by installing aerators for a soft roof in the right amount, you can not worry about the dryness of the coating and insulation. Therefore, it is more correct to proceed with their installation at the construction stage. But, if for some reason this did not happen, you can do it later.The main thing is not to wait for the occurrence of irreparable defects in the roof (swelling, destruction of the material). Fortunately for many developers, with the help of aerators, you can not only prevent the accumulation of moisture in the new roofing pie, but also drain the old roof already saturated with moisture.

How soft roof ventilation is arranged - important features of the roof

A reliable and durable roof is the key to the durability of a residential building as a whole. However, the quality of the roof structure directly depends on the many nuances that should be taken into account when arranging it.

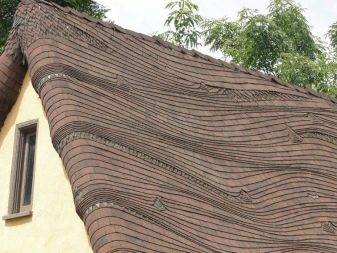

Is no exception and soft roofing, which is very popular in modern construction. Its installation requires taking into account many factors and the competent arrangement of various components, among which an effective ventilation system plays an important role. Without providing normal air exchange inside the roof structure, one can hardly count on the fact that it will serve for a long time and flawlessly.

Device and installation

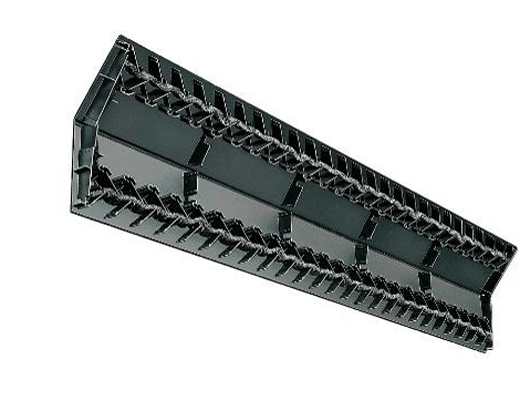

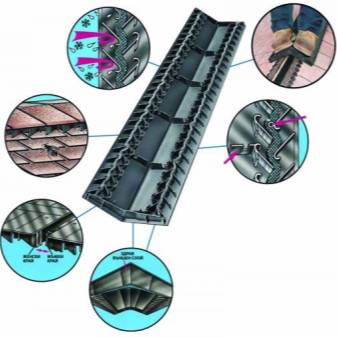

The ridge aerator, or as it is also called, the ridge valve, refers to a continuous type of ventilation devices. Production material: high pressure polypropylene. On the sides there are holes in order to ensure the exit of warm air from under the roof space. It has the form of a profile with stiffeners and a seal, which prevents various insects, debris, precipitation, etc. from getting inside.

It is installed on pitched roofs with a ridge connection, provided that snow will not accumulate on the ridge. From above it is covered with ridge tiles. Thus, it can be given a more aesthetic appearance.The installation of the ridge aerator can be carried out in one line either continuously, connecting the parts one after the other, or in separate sections.

Installation of a ridge aerator for soft roofs is carried out on roofs with a slope of 14 ° to 45 °. Also, during installation, it should be remembered that the size of the exhaust openings should be 10-15% larger than the inlets, only then a vacuum of air and its continuous circulation is created.

How to install?

Each type of aerator has a specific installation order.

Point devices are mounted on flat roofs and roofs with a slope angle of less than 12 degrees. They can also be used as an addition to ridge aerators.

Let us consider in more detail the installation technology of point aerators:

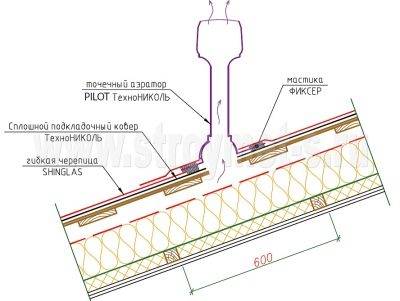

We determine the location of the aerators. We apply the aerator with the base to the installation site and outline with a pencil. On the marked mark, we make holes with an electric jigsaw.

- We install the skirt (base) of the aerator over the finished hole and fix it with self-tapping screws or nails. For a stronger fixation, you can additionally use glue. In this case, we apply bituminous mastic to the inner segment of the skirt, glue it to the base and fix it with nails.

- We coat the top of the skirt with bituminous glue.

- We cover the skirt with soft tiles, cutting the shingles at the points of contact.

- We put an aerator mesh on top of the skirt, screw it with self-tapping screws. Then we install the cap (cover), snap it on and also screw it with self-tapping screws.

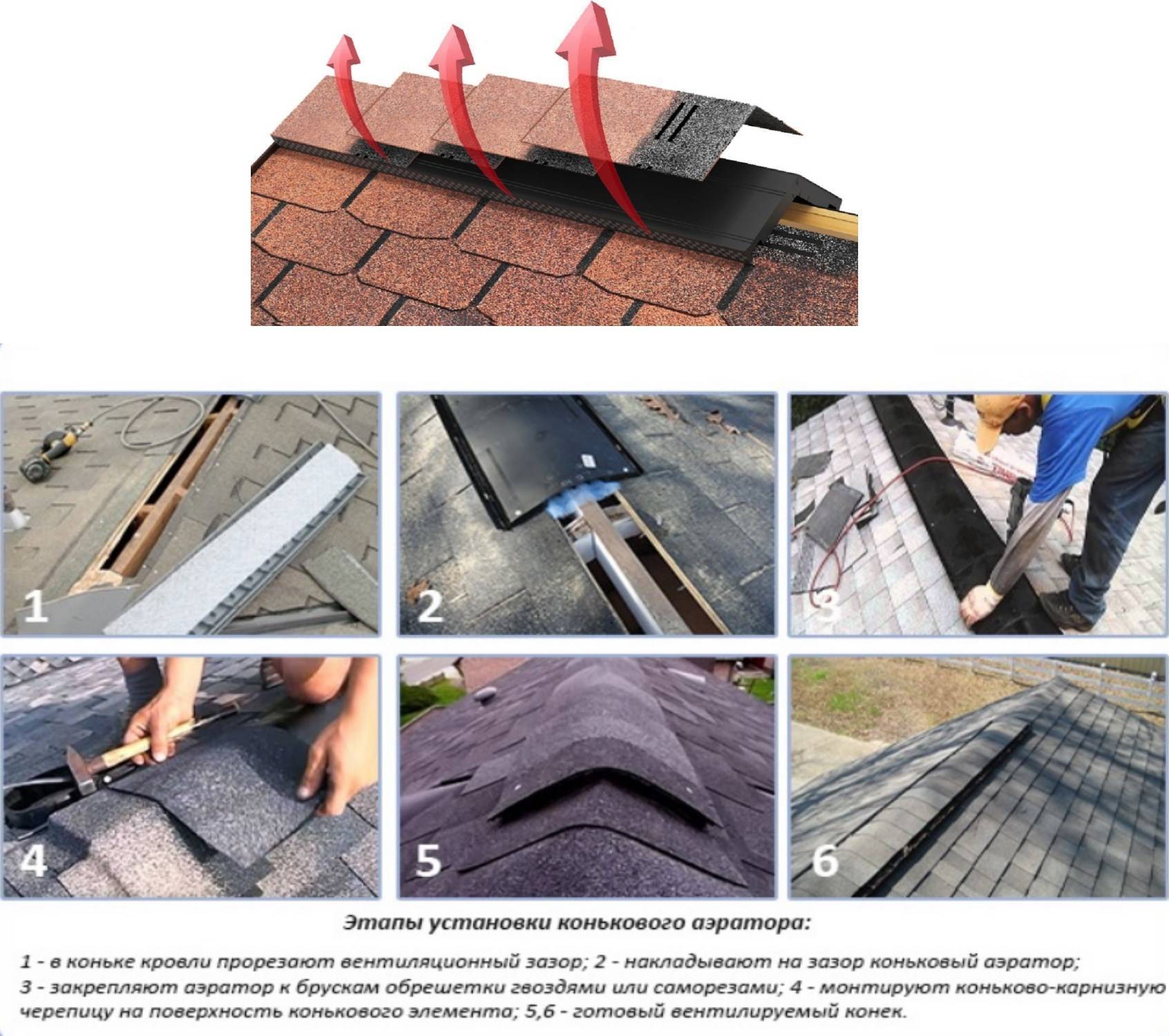

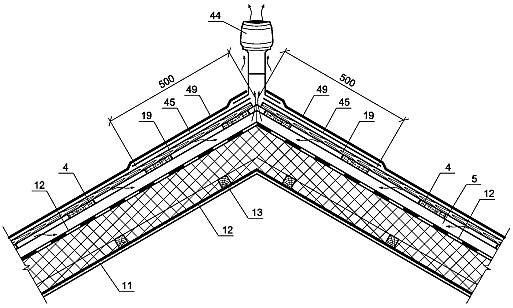

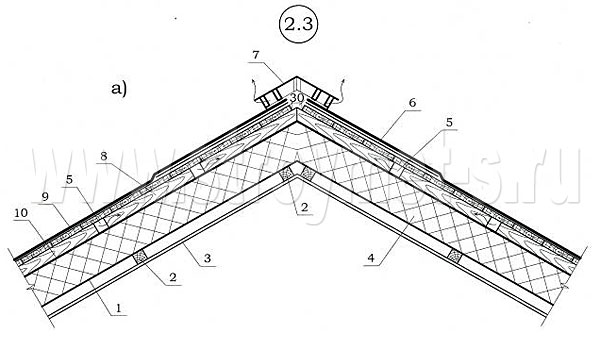

Installation of a ridge aerator is quite simple, it is installed along the entire length of a pitched ridge and its variety - a hip roof, the slope of which is from 12 to 45 degrees. There are two ways to install a ventilated soft roof ridge.

Installation technology:

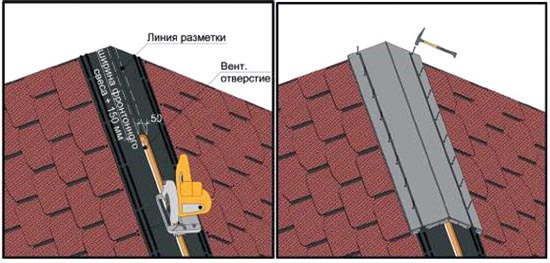

In the solid base, using a circular saw, we cut a ventilation groove. It can be single (at the highest point of the ridge) or consist of two parts (on the sides of the ridge). The total thickness of the ventilation gap should be 3-8 cm (depending on the aerator manufacturer's instructions). The ventilation groove should end 30 cm before the edge of the ridge on both sides, that is, the coating remains continuous.

- We cover the areas where the ventilation gap has not been cut with ridge tiles.

- We install an aerator. We fix each section of it with special roofing nails or screws screwed through the existing factory holes.

- We lay ridge tiles on top of the aerator profile. We overlap its petals, according to the standard mounting technology along the ribs. The only difference is the fasteners. In this case, we nail the tiles to the aerator with special roofing nails.

The second method involves fixing timber bars at the highest point of the roof slopes. It turns out a kind of crate for the ridge bar. From above, we nail plywood strips to the bars, forming a triangle. Ventilation gaps are formed between the bars, and the entire structure, as in the previous case, is covered with shingles.

Houses with tent or hip roof architecture do not have gables. But this is not a problem for the ventilation device.It is based on the same principles as for gable roofs, but at the same time, we must not forget that it is necessary to construct inlet gaps that ensure the passage of air around the entire perimeter of the roof. No matter how many slopes the hipped roof would have, each of them must be ventilated.

A great desire to forget about the device for ventilation of the space under the roof is given by a half-hip roof, since its inclined end elements have relatively small dimensions. The ventilation system here can be built according to the principle of ventilation on the main slopes of the roof.

In all the cases described, if the roofing is made of wood, then it should not be monolithic, since air must pass through its gaps into the space under the roof. But in parallel with the above installation rules, it is also necessary to make the correct calculation so that normal traction is formed under the roof. Otherwise, all this will not function.

Regardless of the method of the device, ventilation must guarantee:

- the passage of air vapor;

- protection of the space under the roof from precipitation and melting snow;

- moisture should not pass through the design of the ridge;

- ensuring the evaporation of excess liquid from the room.

How to properly prepare the base for a ridge aerator

The ridge aerator must cover the entire length of the ridge

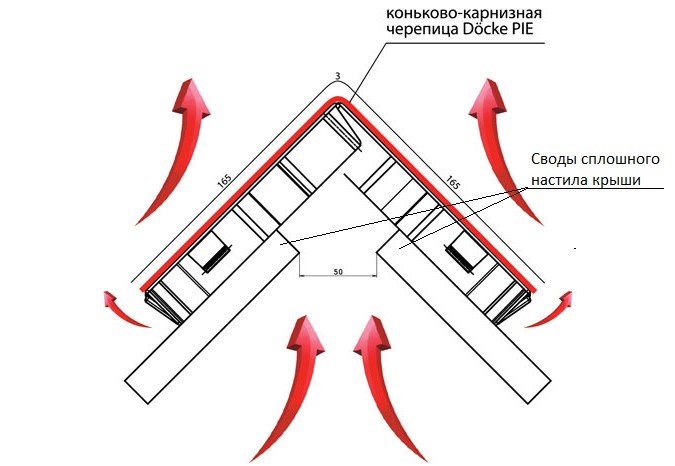

At the same time, it is extremely important to correctly arrange the junction of two slopes .. Almost along the entire length between them there should be a free strip 5 cm wide. To do this, the desired hole is either provided in advance when arranging a solid flooring, or drilled

Almost the entire length between them should remain a free strip 5 cm wide.To do this, the desired hole is either provided in advance when arranging a solid flooring, or drilled.

- Dense docking of slopes is carried out only on two sides of the gable, while the width of this section should be at least:

- the sum of the width of the frontal overhang and the width of the wall that accounts for this section;

- 30 cm at the point of joining with the valley gutter or junction with the wall.

- Despite the presence of a continuous section, the installation of the ridge duct is carried out without indentation, directly from the edge of the gable cornice.

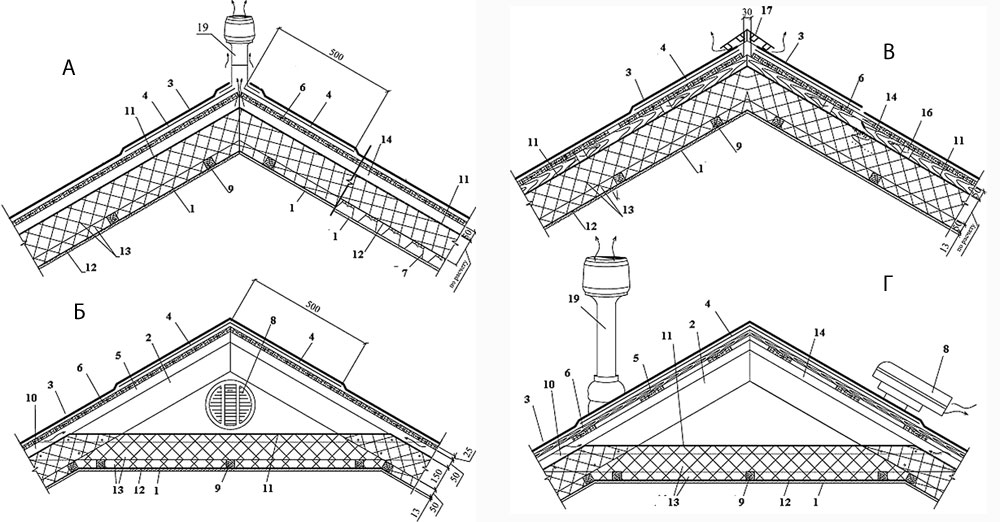

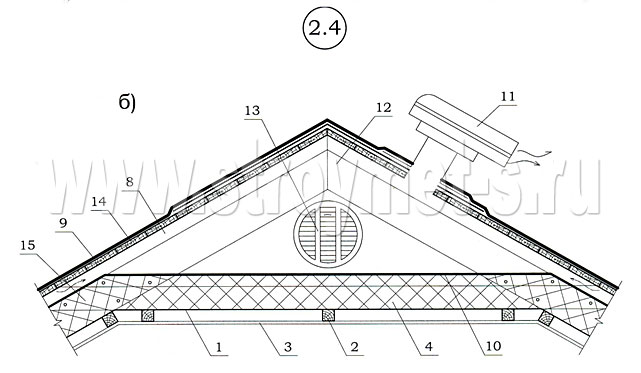

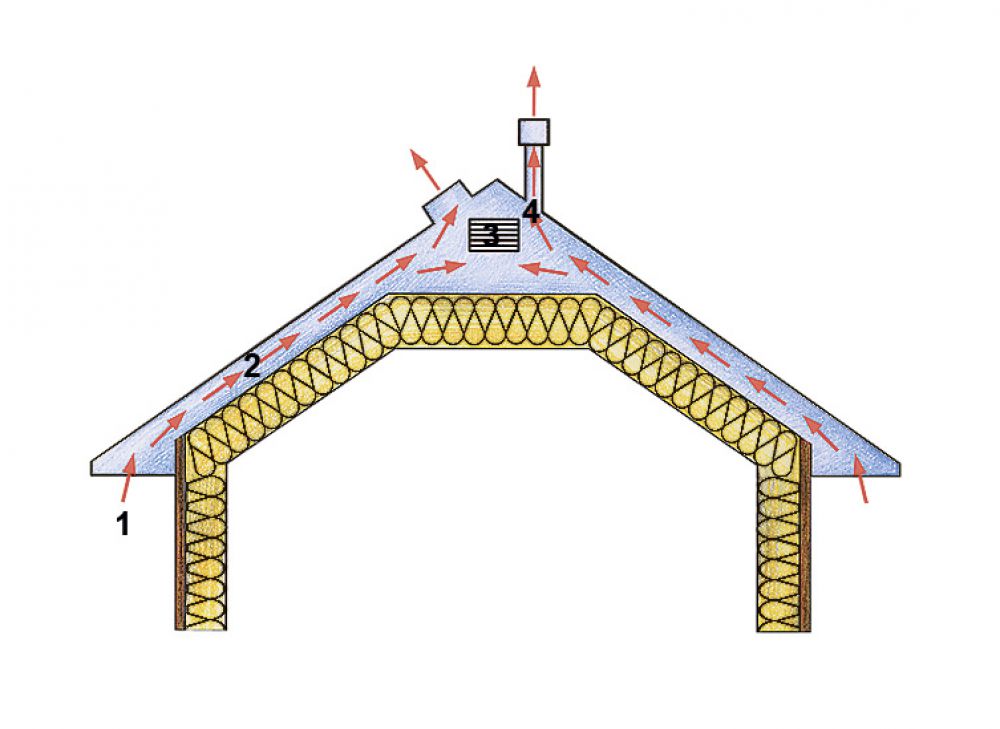

Ventilation design

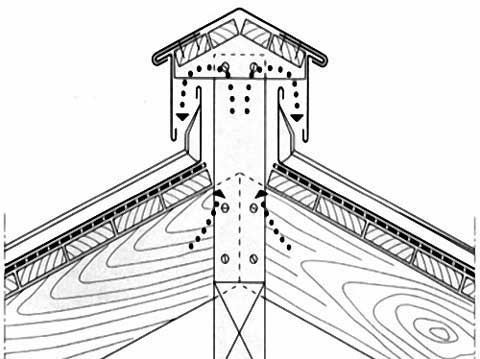

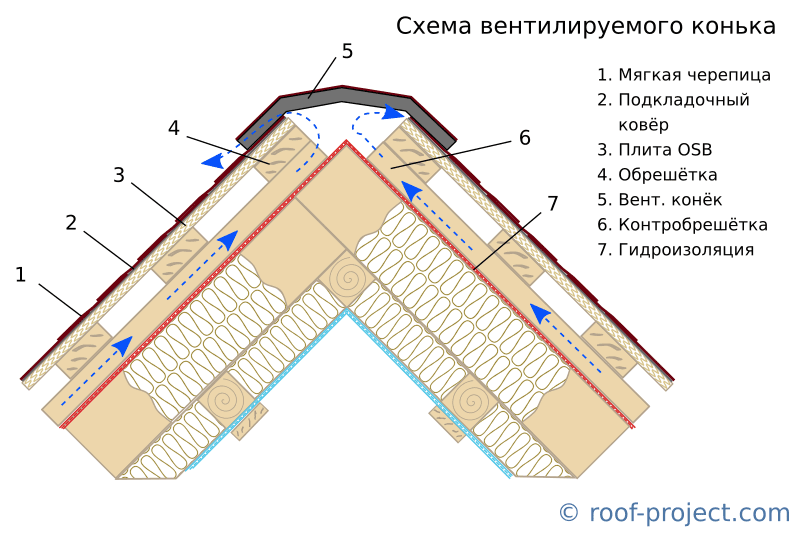

The operation of the ventilation system is based on natural convection, the air rises when heated.

The classic scheme - cold air enters the under-roof space through the holes in the cornice overhang and exits through the holes in the ridge or aerators.

Eaves overhang device

When designing a ventilation system, for air access to the under-roof space, spotlights or a passage under the drip, which is closed with a plastic mesh, are used.

Soffits are special panels that are used for filing the cornice overhang. There are two types: solid and perforated. Material: plastic, metal or aluminium. The perforated surface allows air to pass freely, while protecting the roof from debris, insects and small birds.

When installing spotlights, the waterproofing film is not brought to the edge of the cornice overhang, but cut closer to the wall of the house so as not to block air access.

The disadvantage of this method is the dripping of condensate through the perforation holes, and in winter, the formation of icicles is possible.

The method of ventilation through the passage under the drip also has its drawbacks.The accumulation of snow on the gutters blocks the access of air and the ventilation stops working.

Air outflow through the ridge and aerators

The exit of air flows can be carried out through: a ventilated ridge, point aerators, inertial wind turbines.

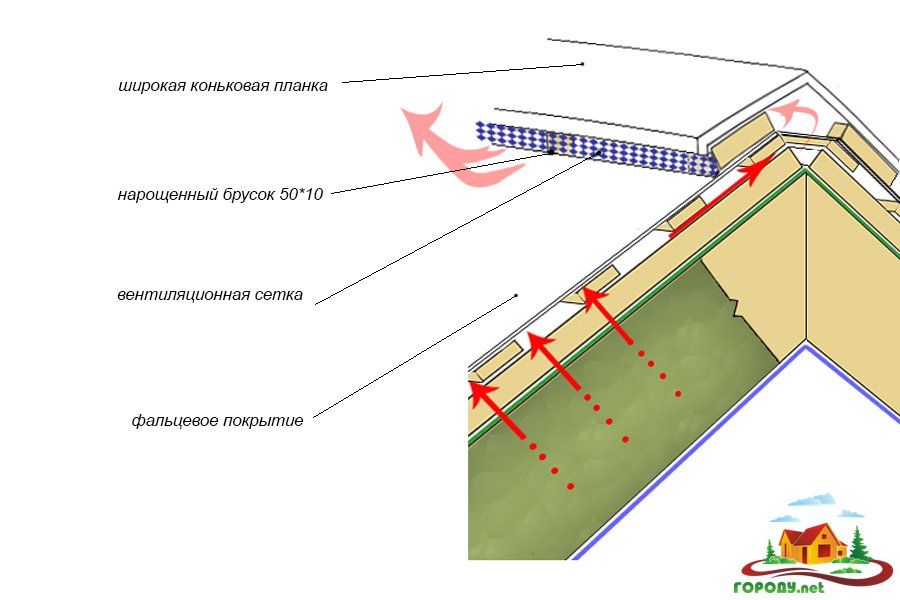

Ventilated ridge - for its device, a passage is formed between the roof slopes, which is closed by a ridge aerator. Some builders make it themselves, others use ready-made solutions in the form of a plastic element or tape with holes for air to escape.

The top structure is covered with shingles of soft tiles and does not spoil the appearance of the roof.

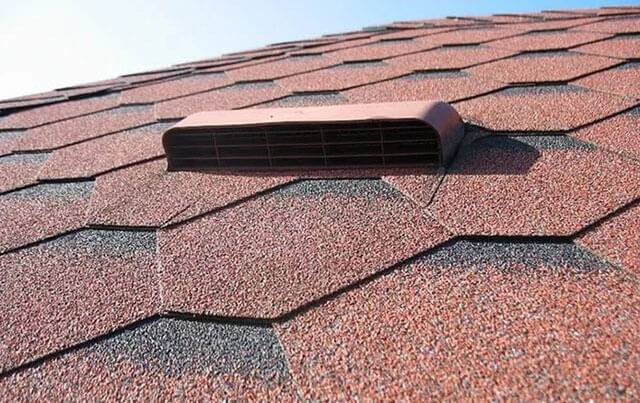

The roof aerator is a round pipe with a diameter of 6 to 12 cm, it has an umbrella on top to protect it from precipitation and debris. It is mounted on a wooden base, in which a passage is first made. The lower part of the aerator (skirt) is smeared with mastic and screwed on with self-tapping screws.

Spot aerators are installed on roofs of complex shape, above skylights, on long slopes where air movement is difficult. Small devices are mounted on every 60 sq.m of the roof surface, large ones are placed on every 100 sq.m.

Wind turbines installed on the roof surface begin to rotate with any breath of wind. At the same time, they effectively draw out the air that has stagnated under the roof.

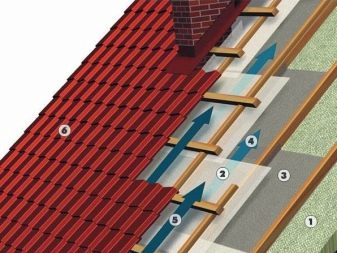

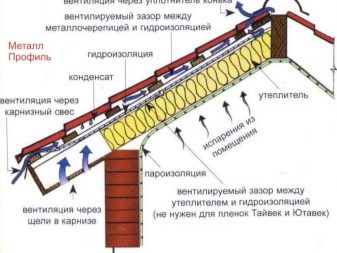

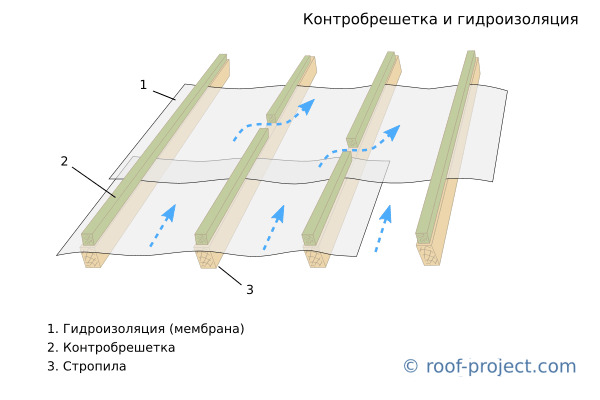

Ventilation gaps and waterproofing

In order for the ventilation system to work correctly, it is necessary to ensure the unhindered passage of air flow under the roof. To do this, ventilation gaps are formed in the roofing pie with the help of a counter-lattice.

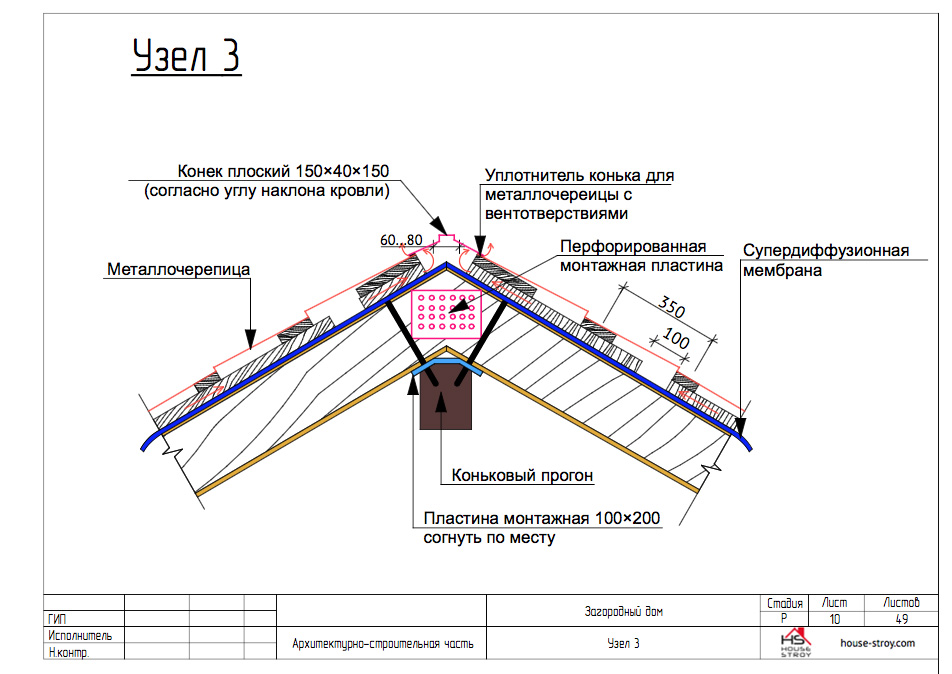

When using a waterproofing film, two ventilation gaps are made: one between the insulation and the film, the second between the film and the wooden base on which soft tiles will be laid. This is necessary to dry the insulation and remove saturated vapors from it.

When using a superdiffusion membrane, one ventilation gap is sufficient. The membrane passes air well and fits directly on the insulation and allows it to "breathe".

You can read about films and membranes here.

The counter-lattice is made from a bar 50 x 50 mm. Experts recommend mounting the timber at a small distance from each other so that air flows can move freely in the plane of the roof.

When installing a soft roof, you should take care of its ventilation. That is, about the elements that start the circulation of air masses and continuous ventilation of all components of the roof, including insulation and rafters.

If the roof is pitched, then a ventilated ridge for a soft roof can solve the ventilation problem. It is equipped from ready-made ridge elements (aerators) or they are made with their own hands from improvised building materials.

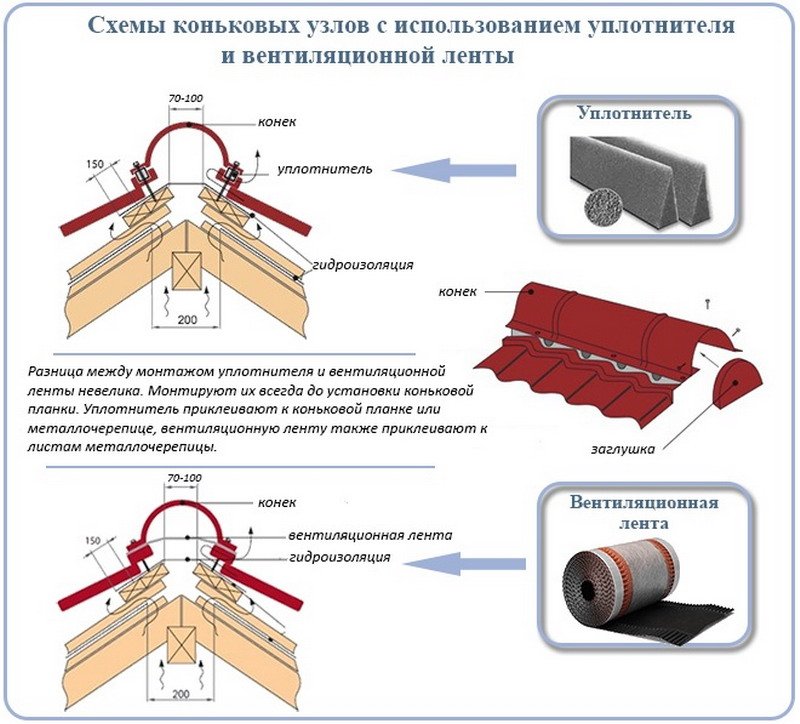

Ridge bar installation technology

Let's start with the fact that corrugated board is profiled material. That is, its shape is rounded or trapezoidal waves. The ridge mounted on them provides one hundred percent ventilation. It adjoins the mounting shelves to the upper waves of the roofing material, and is attached to them, and through the space formed by the planes of the lower waves and the ridge shelf, air escapes from under the roofing.

But this free space is a place where dust, insects, small birds, debris and other troubles fly under the roof. Today, this problem is solved by installing a special sealing material between the ridge strip and the corrugated board. In fact, this is a tape made of porous material, which, when compressed, forms a dense protective barrier.

Installation of ridge slats on the roof

Types of ridge seal

Manufacturers today offer several varieties of skate seals made from different materials.

Polyurethane foam seal. It is a versatile open porosity material with a long service life. In the presented model line there is a self-adhesive option, which increases the convenience of installing the tape on profiled sheets.

polyethylene. This is a figured type sealant, exactly repeating the shape of the profiles. The material is dense and rigid with closed pores. It has holes for ventilation. But they can be kept closed if aerators are installed on the roof: pitched or ridge.

Tape PSUL. This is a self-expanding sealant made from acrylic and polyurethane. It goes on sale in compressed form. After installing the ridge, it expands, completely filling the space between the roofing material and the ridge. By the way, the material expands 5 times from its original state.

Please note that almost all sealants completely close the gap between the ridge strip and the roofing material. Therefore, in most cases, ventilation of the roof ridge under the corrugated board is organized through the side holes, which are closed with perforated plugs.

Often, even plugs are not installed.

Ridge rail mounting rules

Installation of a corrugated roof ridge begins with the choice of the type of ridge strip. Then you need to decide on the number of purchased items. Everything is simple here. It is required to know the length of the ridge run, which is divided by the length of the bar. Be sure to take into account the fact that the elements are mounted between themselves with an overlap of 15-20 cm. That is, the number of joints will increase the length of the span. Therefore, they do it simply, they buy one more element to the calculated amount.

I would like to draw attention to two points regarding the formation of the ridge run:

Edges of profiled sheets should not close the ridge run. The distance from the edge of the stacked sheets to the top of the roof is 5-10 cm.

Under the upper edges of the roofing material must be laid continuous crate from two boards lying next to each other. The bottom line is that the fastening of the ridge on the roof of corrugated board is carried out not in the roofing material, but in the crate.

And one more important point. The line of intersection of the slopes should be even. The error is allowed, but not more than 2% of the width of the mounting shelf. For example, if it is planned to install a ridge strip 2 m long with a mounting shelf width of 20 cm, then the deviation from the line of intersection of the slopes should not exceed:

Sheets of corrugated board should be joined in a straight line

If this parameter does not meet the required standards, then the likelihood that the roof will leak exactly at the installation site of the ridge bar will be quite high. This problem is solved in two ways:

The most difficult - Lay out the roofing material.

Simplest - choose a ridge strip with a larger width of the mounting shelves.

Installation of strips starts from any edge of the roof. First lay the sealant. Two methods are used here:

glue the sealant on back surfaces mounting shelves;

stick to the roofing material.

The first option is simpler and more convenient to implement.

Lay the first plank. It is attached to the crate through the upper corrugations of the corrugated board with roofing screws. Fasteners are screwed in every 30-40 cm with an indent from the edges of the shelves within 2-3 cm. Then the second one is mounted with overlapping edges. The mount is exactly the same. And so are all the other elements.

Pay attention to the correct selection of the length of the fastener, because screwing is done in the upper wave. Usually this parameter consists of the wave height of the profiled sheet and the thickness of the crate

Helpful Tips

When ventilating the under-roof space with your own hands, a number of important points should be taken into account.

- If you intend to get a stronger effect from the movement of air flows, then you need to use steam and hydro barriers located under the crate. They are specialized meshes that allow air to pass through without difficulty, but prevent the passage of moisture and steam.

- To provide ventilation under the roof of an ordinary pitched roof, a small number of vents placed in the lower and upper parts in equal numbers will suffice. If necessary, you can supplement the ventilation system with a fan for forced exhaust.

If you install a fan in a building that is located in an area with above-normal humidity, then the fan must also be equipped with a higher motor power. The fans must be installed parallel to the roof structure. Inserting a device into a finished roof is more difficult and will cost significantly more.

On the roof, the combination works perfectly - full ventilation of the ridge and auxiliary elements to enhance air flow. If, for example, one of them is damaged in winter, the rest will remain in working order.

The under-roof space will be one hundred percent protected from the accumulation of condensate.

It is also necessary to pay attention to the total component of all precipitation falling during the year. In areas with heavy snowfalls, it is necessary to raise the air ducts to a higher level, otherwise the snow drifts will block the low-mounted aerators.

And lastly, the desire to save money when installing roof ventilation can end badly, being a source of problems both with the roof covering and with structural elements. Proper organization of effective air exchange is a guarantee that the roof will last for decades without the need for repair, providing thorough protection for the entire structure and comfortable living conditions.

Arranging ventilation under the roof with your own hands for a roof of any kind is not so difficult, and such a design has a considerable amount of positive effects.

Roof ventilation in shingles is shown in the following video.

The device of the ventilation system of the soft roof

In the past, during the construction of houses, the ventilation function of the under-roof space was assigned mainly to dormer windows equipped for this. However, their effectiveness is usually insufficient, and in any case there are areas with poor ventilation. Therefore, more modern ventilation structures are currently used for this purpose. In particular, one of the most effective options is the arrangement of a ventilated ridge for a soft roof.

The functioning of ridge ventilation occurs due to the process of convection, as a result of which warm air masses rise from the cornice upwards, and cold air, on the contrary, is pulled down. At the same time, the ventilation system has its own entry and exit zones. Air enters the under-roof space from below, through roof overhangs, and the ridge structure at the top serves as an exit point.

Installation of a ventilation ridge for a soft roof is carried out in one of two ways:

- In the ridge structure of the roof, a gap is arranged along its entire length, on which a ridge element (usually triangular) with perforations or gaps on the sides is mounted on top.

- A special ridge aerator is mounted along the upper edge of the roof. It is an element with a solid upper part and perforations on the sides, inside of which there is a filter that prevents precipitation, insects, leaves and dust from entering the ventilation space. Roof aerators usually have a length of 50-122 centimeters, so for laying along the entire length of the ridge, several of them are fastened together. From above, the ridge aerator is covered with shingles of a soft roof, which makes it invisible against the background of the roofing.

The material for the manufacture of modern ridge aerators is most often durable plastic, resistant to ultraviolet rays and temperature extremes. Less commonly, they are made of low-density polyethylene or polypropylene.

Metal roof ventilation

The metal roof is beautiful, modern, durable and reliable, but it has one big drawback - limited air exchange, that is, it does not pass air well. To ensure normal circulation, ventilation is established according to the following algorithm:

- Holes are made in the cover sheet for the exit of ventilation ducts, adhering to the norms - one hole per 60 m² and placing them at least 0.6 m from the ridge. On a roof with a complex structure, the number of exits is increased.

- The front metal part near the hole is treated with an antiseptic to prevent corrosion.

- The rubber seal is coated with silicone and reinforced with screws.

- After the sealant dries, install the penetration and fix it with special screws included in the delivery.

- From the inside, they provide a reliable connection with vapor and water insulators (films).

-

To prevent moisture from penetrating into the insulation, a sealant is additionally applied at the junction of the insulation.